Hydraulic Fracturing Pressure-Relief Technology for Controlling the Surrounding Rock in Deep Dynamic Pressure Roadways

Abstract

1. Introduction

1.1. Research Background and Significance

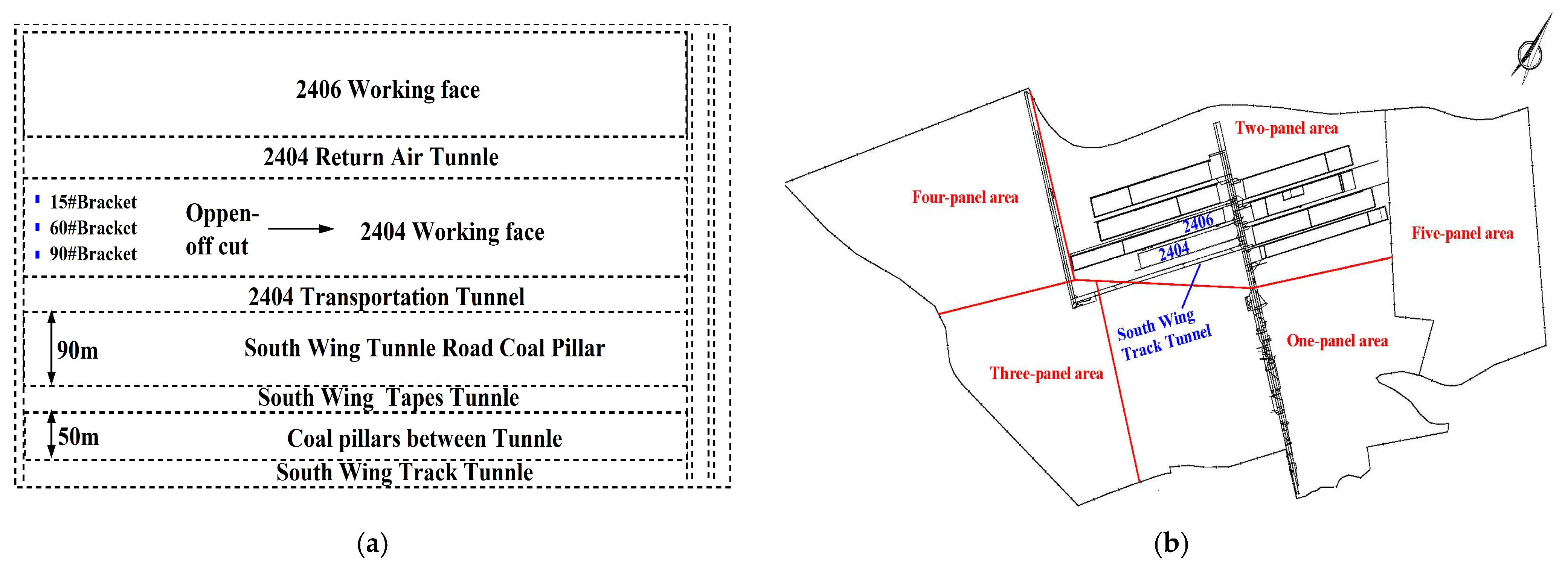

1.2. Regional Overview and Overlying Rock Characteristicss

1.3. Current Major Issues

2. Materials and Methods

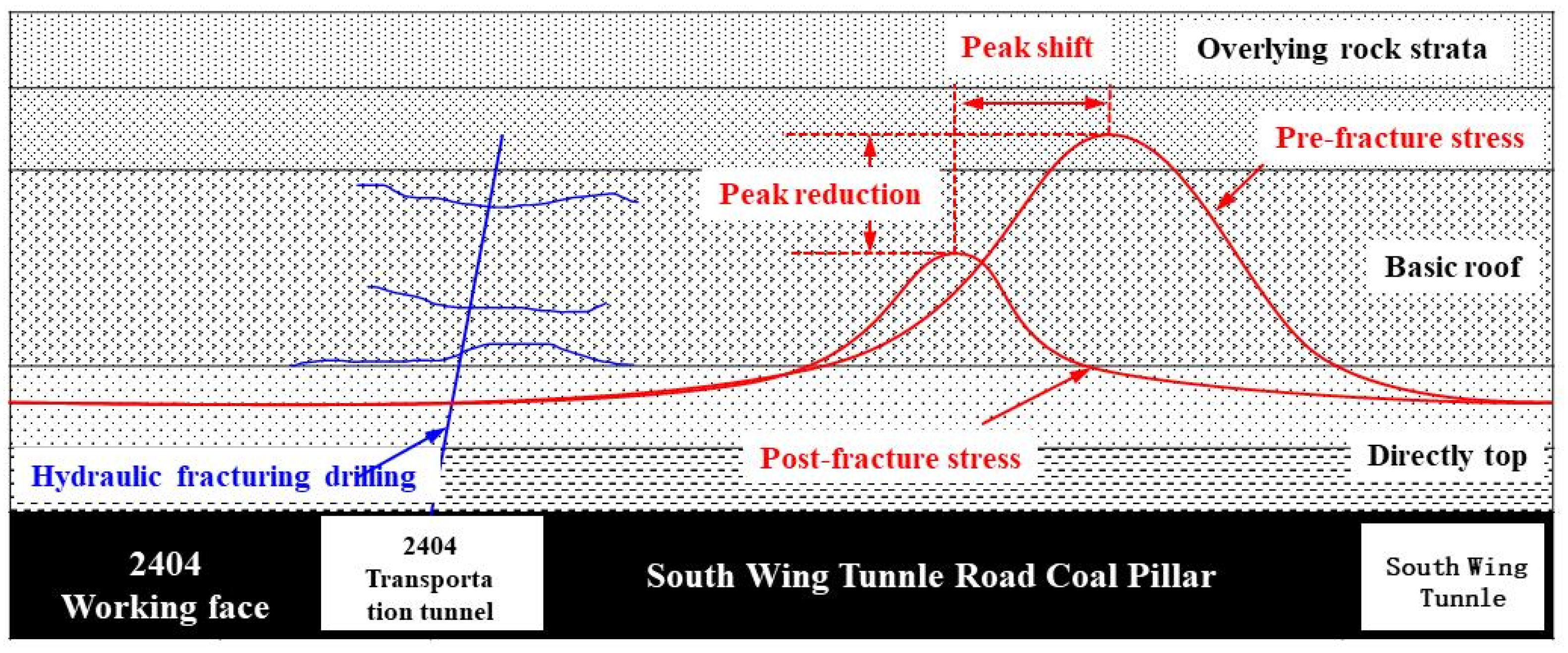

2.1. Basic Principles of Hydraulic Fracturing Pressure Relief

2.2. Hydraulic Fracturing Scheme Design

2.2.1. Key Stratum Analysis of Roof Stability

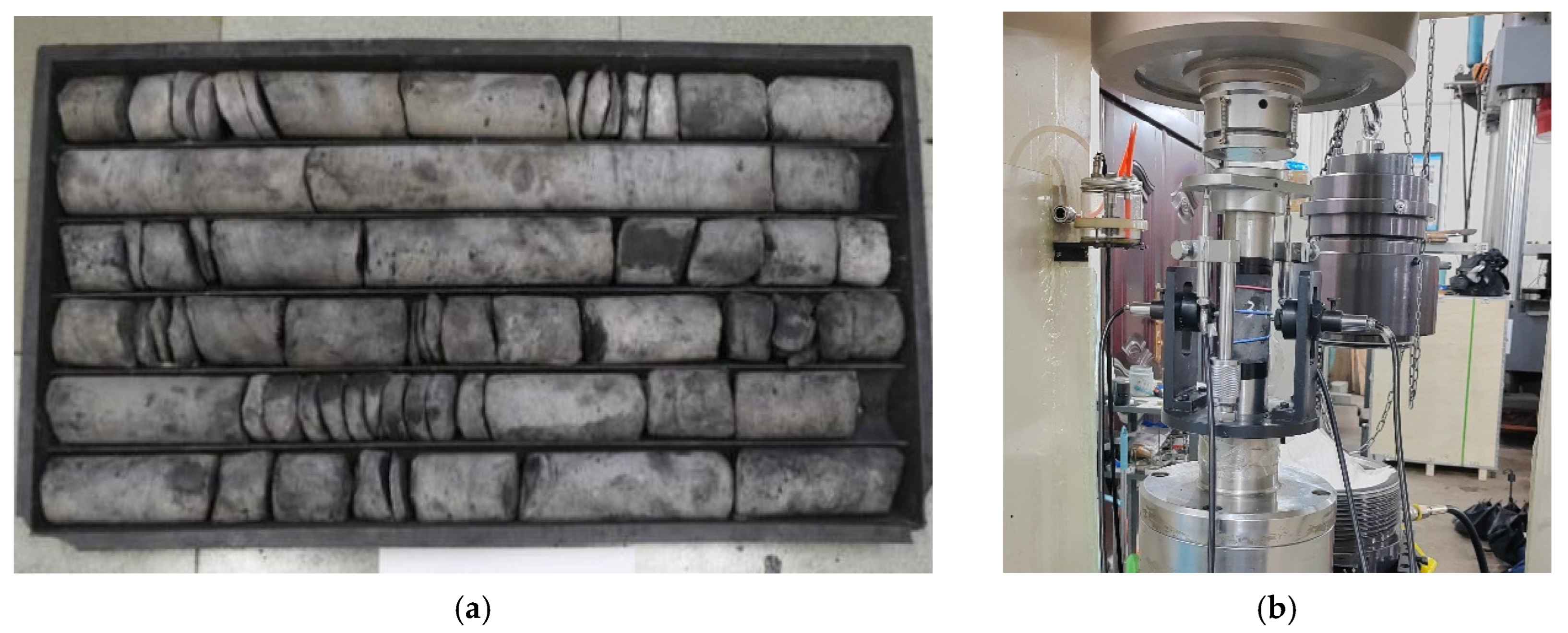

2.2.2. Geological Parameters

2.3. Scheme Design

2.3.1. Drilling Parameter Design

2.3.2. Segmented Hydraulic Fracturing Process

2.3.3. Construction Period and Safety Preparations

2.4. On-Site Construction Process

3. Fracturing Effect Analysis

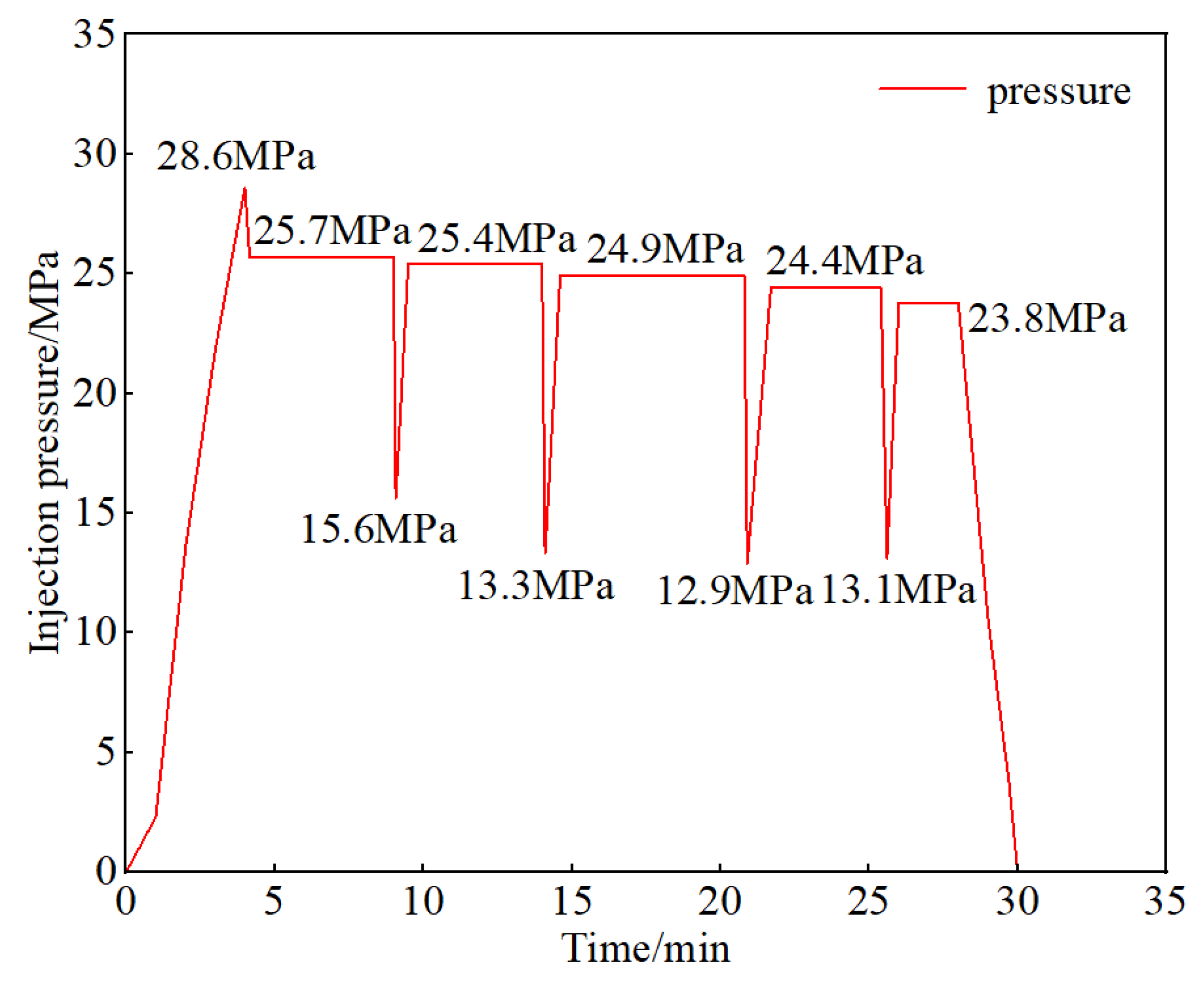

3.1. Pressure Curve Analysis

3.2. Analysis of Support Resistance in the Working Face

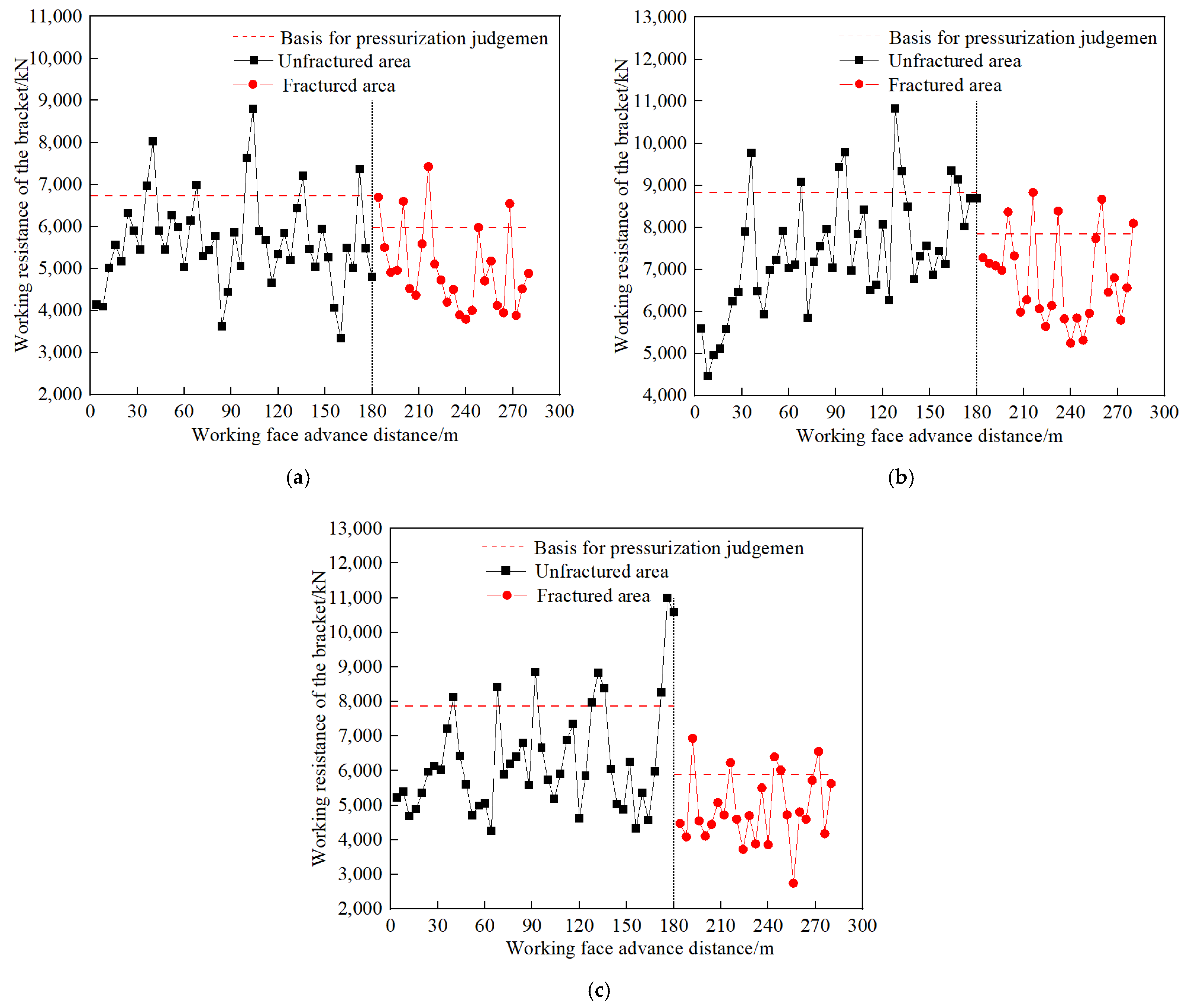

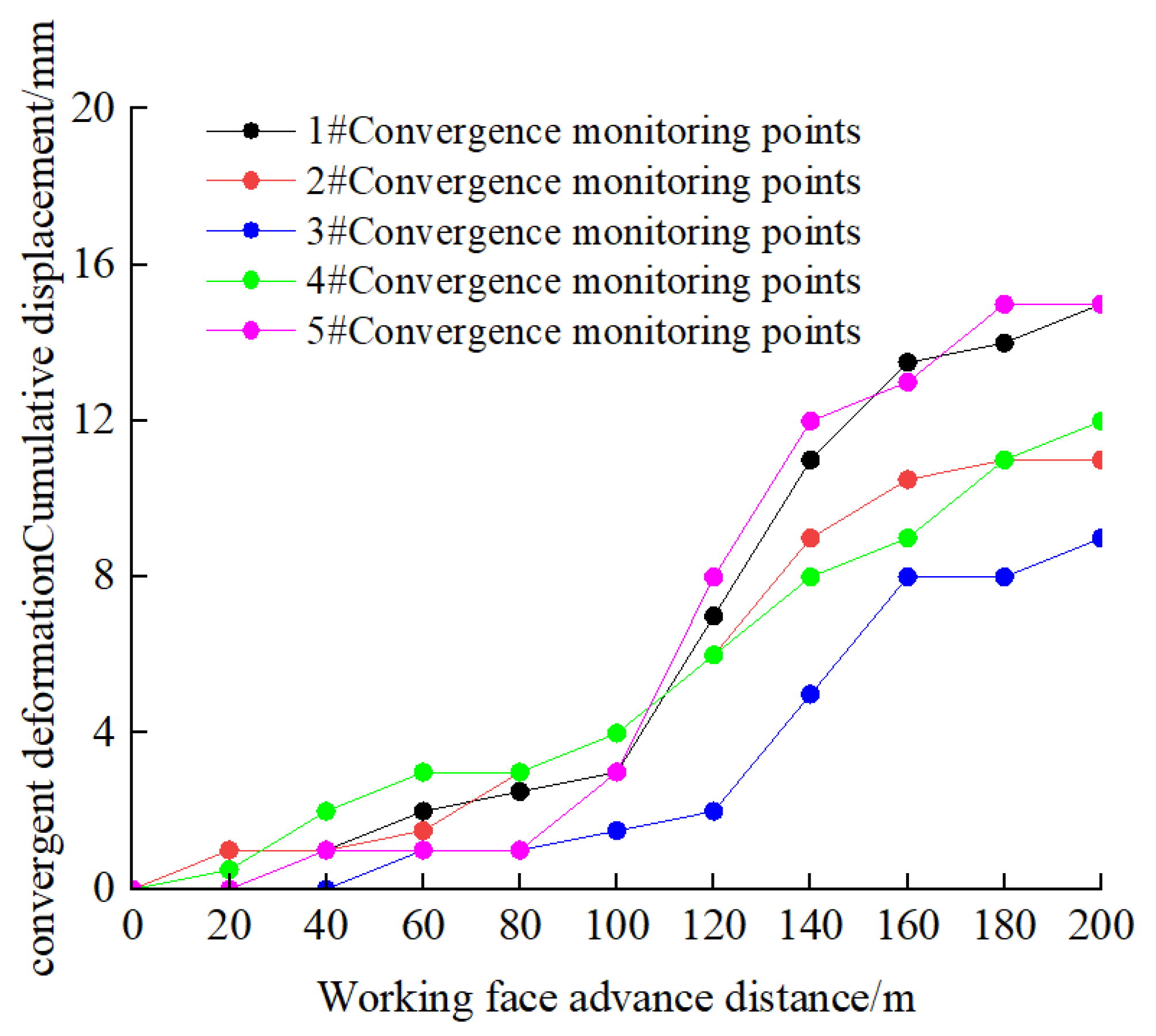

3.3. Coal Pillar Stress Monitoring Analysis

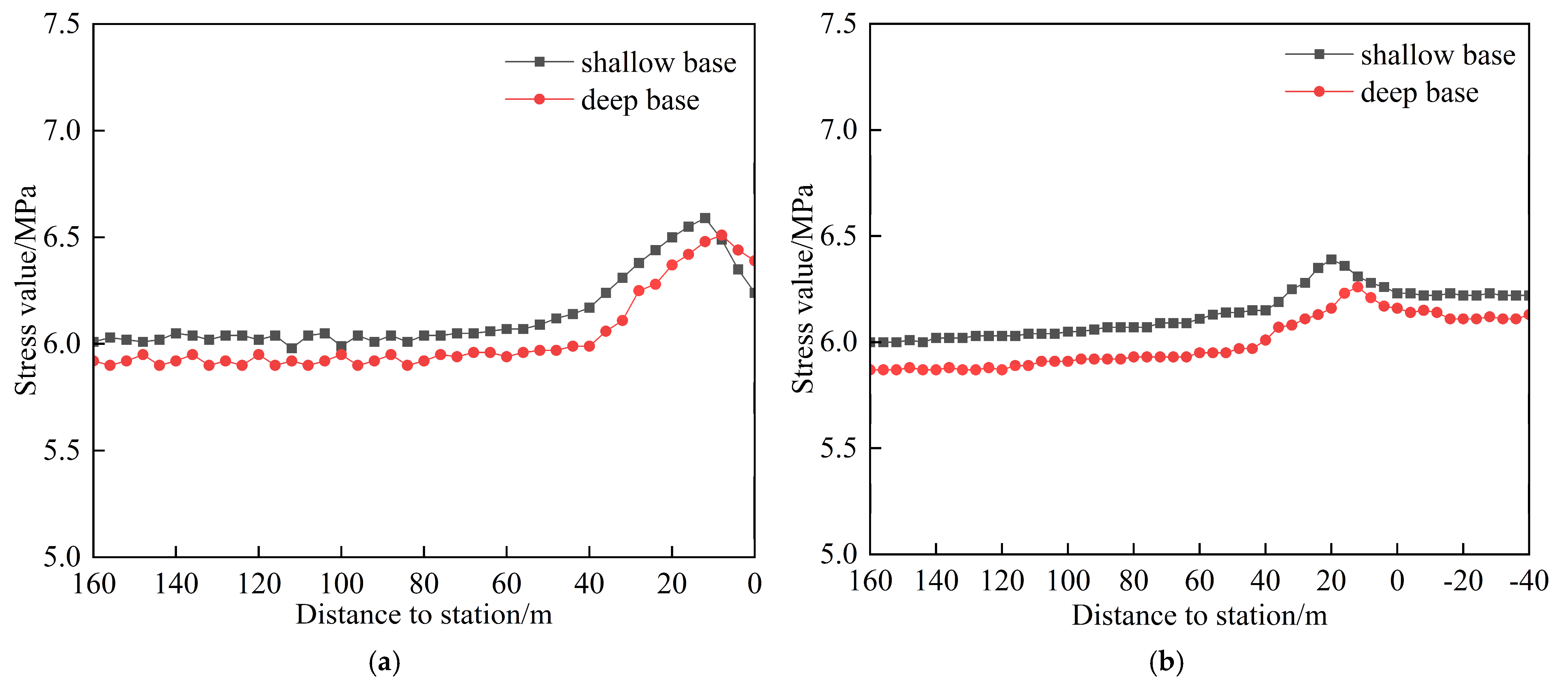

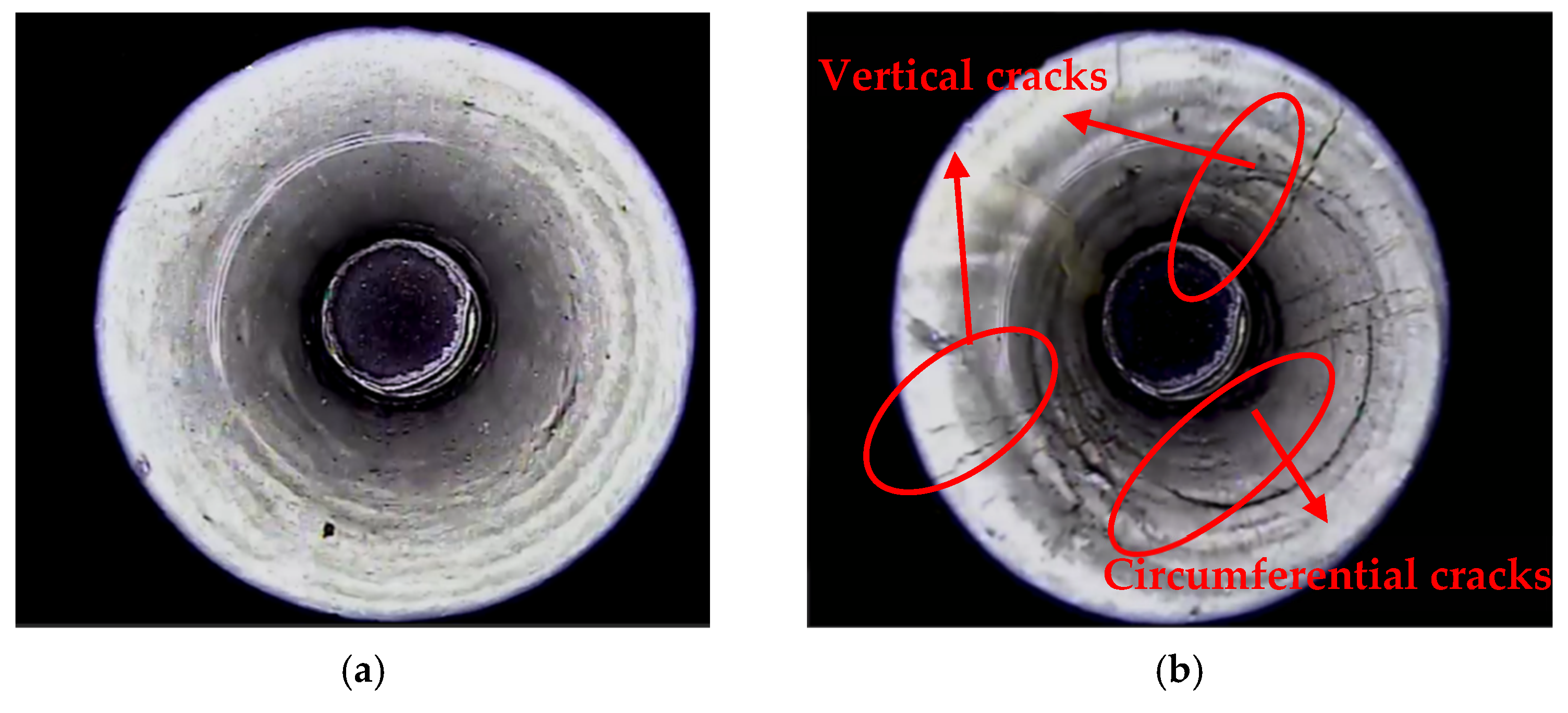

3.4. Analysis of Drillhole Inspection Results

3.5. Analysis of Water Flow from Adjacent Drill Holes

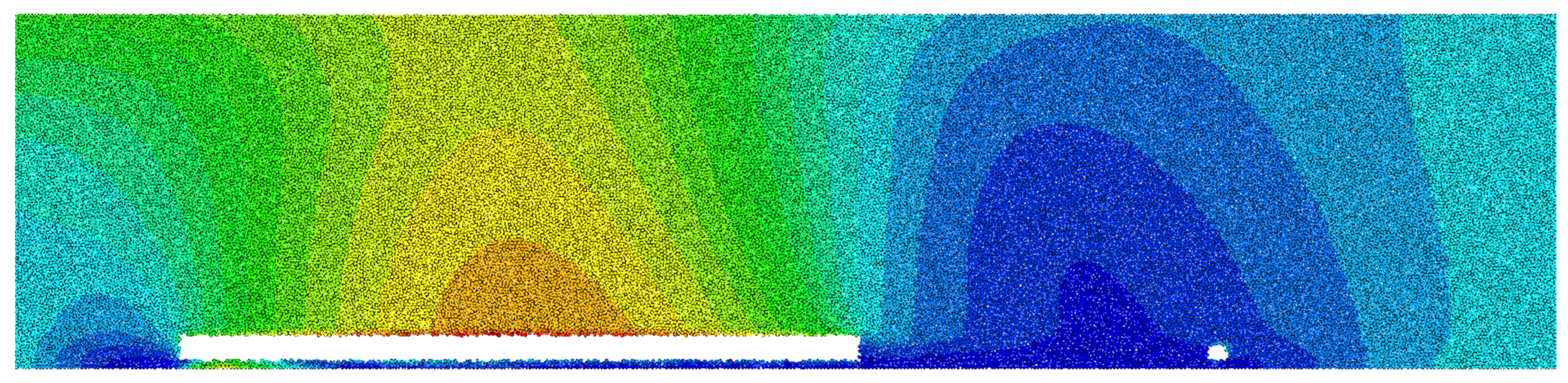

3.6. Hydraulic Fracturing PFC Numerical Simulation Analysis

- (1)

- Modeling and Parameter Selection

- (2)

- Analysis of results

4. Fatigue Deformation Constitutive Model of Double-Fractured Sandstone After Freeze–Thaw Cycles

4.1. The Establishment of Constitutive Models

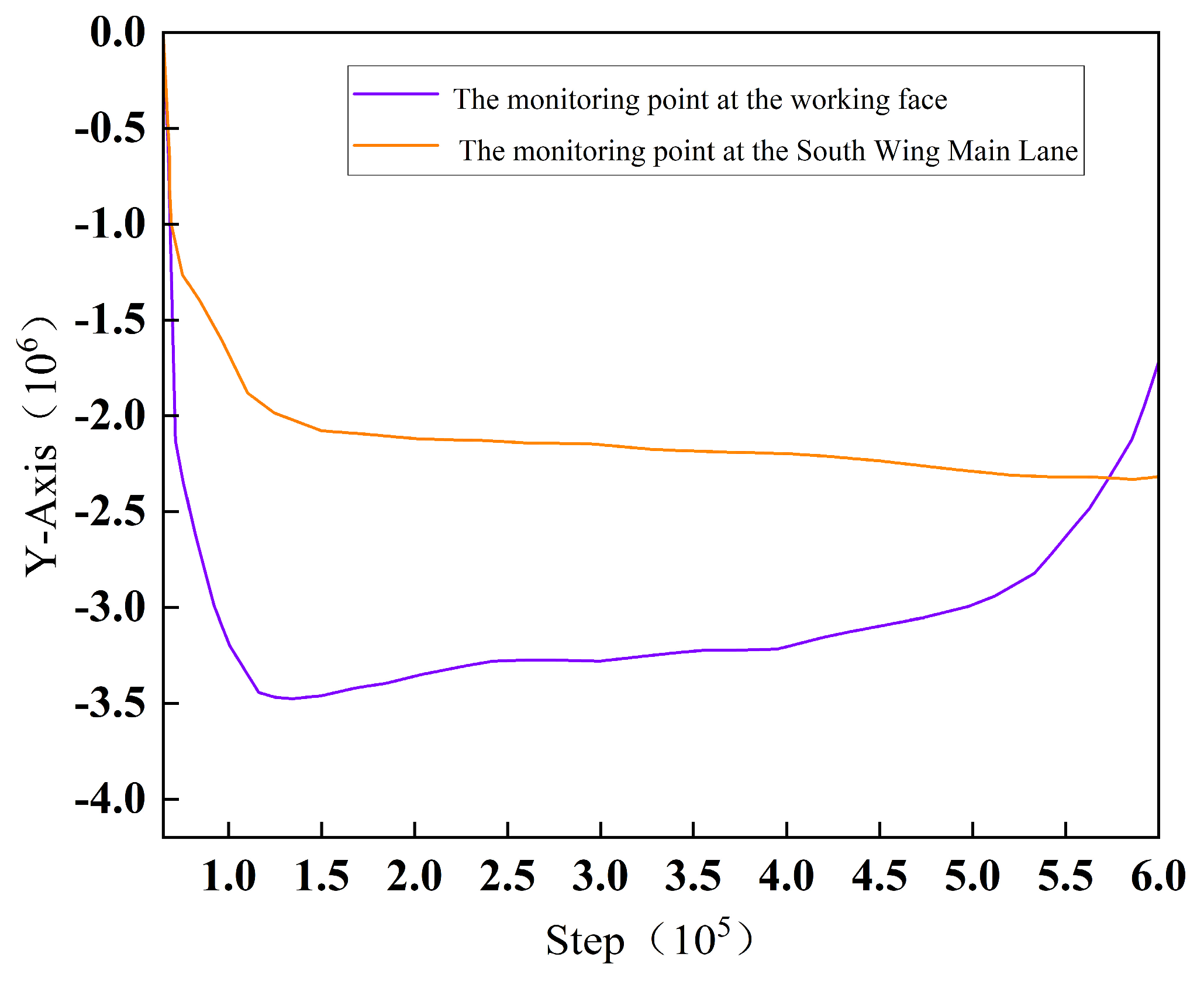

4.2. Analysis of Roof Separation Monitoring Results

4.3. Analysis of the Current Status of the South Wing Main Tunnel

5. Conclusions

- (1)

- The south wing main tunnel of a certain mine in the Jiaoping Mining Area is a deeply buried tunnel that has been significantly affected by the intense mining activities of the 2404 working face. The roof of the 2404 working face consists of thick, hard rock layers that are difficult to fracture, making it prone to forming a hanging roof. This increases the stress and deformation of the coal pillar, affecting the stability of the surrounding rock and the support structure of the south wing main drift. The method of cutting through the hard roof of the 2404 working face’s transportation drift to relieve pressure was adopted to reduce the impact of the mining pressure from the 2404 working face on the deformation of the surrounding rock in the south wing main drift, providing technical support for the safe construction of the south wing main drift.

- (2)

- The critical roof strata elevation for the 2404 working face hydraulic fracturing top-cutting operation, determined through theoretical analysis, is 50.13 m. Physical and mechanical properties of each strata elevation were determined through on-site core sampling tests. The roof caving stress relief plan for the 2404 transportation roadway was completed. The design drill hole length is 60 m, with an inclination angle of 80°, an angle of 90° along the roadway direction, a fracturing vertical height of 59 m, a drill hole spacing of 5 m, and a segmented hydraulic fracturing stress relief mode.

- (3)

- Using a multi-disciplinary approach to analyze the effectiveness of hydraulic fracturing, the results of borehole inspections and pressure curve analysis revealed significant longitudinal fractures within the borehole walls. During fracturing, the maximum pressure reached 28.6 MPa, with five distinct pressure drops indicating fracturing. Additionally, during the fracturing process, both adjacent boreholes and anchor cables exhibited noticeable water outflow, indicating the formation of interconnected fractures between boreholes. Following fracturing, the pressure step distance decreased by 34%, and the support working resistance decreased by 18%. The pressure step distance, pressure range, and support working resistance during the cycle all decreased significantly. During coal extraction, the stress changes in the coal pillar were relatively small, the support structure of the south wing main tunnel remained intact, and mine pressure was not significantly evident. It is explained that hydraulic fracturing weakened the hard roof, significantly reducing its strength and integrity, and severed the stress transfer path of the key rock layer, effectively ensuring the long-term safe use of the south wing main tunnel.

- (4)

- The pressure-relief effect shows that the cumulative displacement of the surrounding rock and the change in the roof separation in the pressure-relief area of the south wing main tunnel are relatively small. The surrounding rock of the main tunnel shows no significant deformation, and the support structure remains intact. The surrounding rock of the south wing main tunnel is basically in a stable state, indicating that the hydraulic fracturing and roof cutting pressure-relief effect is good, thereby reducing the impact of mining dynamic pressure disturbances on the deformation of the south wing main tunnel.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, J.; Liang, Y.; Cheng, K.; Wang, M.; Gao, M.; Liu, Z. Research on the construction of coal mine safety production technology management system. Coal Mine Saf. 2021, 52, 256–260. [Google Scholar] [CrossRef]

- Wang, G.; Pan, Y.; Zhao, S.; Pang, Y.; He, Y.; Wei, W. How to realize safe-efficient-intelligent mining of rock burst coal seam. Coal Sci. Technol. 2024, 52, 1–14. [Google Scholar] [CrossRef]

- Yuan, L. Theory and technology considerations on high-quality development of coal main energy security in China. Bull. Chin. Acad. Sci. 2023, 38, 11–22. [Google Scholar] [CrossRef]

- Zhang, W. Research on dynamic pressure behavior and control technology of goaf roadway in extra-thick coal seam. China Min. Mag. 2023, 32, 126–131. [Google Scholar] [CrossRef]

- Liu, G.; Mu, Z.; Chen, J.; Yang, J.; Cao, J. Rock burst risk in an island longwall coal face by stress field. Geosci. J. 2018, 22, 609–622. [Google Scholar] [CrossRef]

- He, Z.-L.; Lu, C.-P.; Zhang, X.-F.; Guo, Y.; Meng, Z.-H.; Xia, L. Numerical and field investigations of rockburst mechanisms triggered by thick-hard roof fracturing. Rock Mech. Rock Eng. 2022, 55, 6863–6886. [Google Scholar] [CrossRef]

- Kang, J.; Jian, K.; Fu, X.; Shen, J.; Wang, Y. Study on hydraulic fracturing fracture propagation in steeply inclined coal reservoirs. Coal Mine Saf. 2024, 55, 49–60. [Google Scholar] [CrossRef]

- Kang, H.; Jiang, P.; Feng, Y.; Zhao, K. Destressing technology for rock around coal mine roadways and its applications. Coal Sci. Technol. 2022, 50, 1–15. [Google Scholar] [CrossRef]

- Hou, C.; Wang, X.; Bai, J.; Meng, N.; Wu, W. Basic theory and technology study of stability control for surrounding rock in deep roadway. J. China Univ. Min. Technol. 2021, 50, 1–12. [Google Scholar]

- Yao, A.; Wu, Z.; Yang, D.; Shao, H. Prevention and control technology of roadway bottom drum based on roof cutting pressure relief method. Coal Mine Saf. 2017, 48, 92–94+98. [Google Scholar]

- Tian, Z.; Hu, Z.; Zhang, C.; Zhang, X.; Zhong, L.; Zhang, K.; Sun, N. Study on failure mechanism and control technology of extra-thick coal seam roadway under dynamic load disturbance. Coal Technol. 2024, 43, 26–31. [Google Scholar]

- Li, J.; Wu, Z.; Zhang, W.; Ma, N.; Guo, S. Study on Shape Characteristics of Plastic Zone in Heterogeneous Roadway-Surrounding Rock. Sustainability 2022, 14, 9480. [Google Scholar] [CrossRef]

- Xi, P.; Zhu, D.; Huo, Y.; Xin, C. Numerical investigation of the failure mechanism and countermeasures of the roadway surrounding rockmass within deep soft rock. Int. J. Multiscale Comput. Eng. 2022, 18, 1–11. [Google Scholar] [CrossRef]

- Meng, Q.; Han, L.; Xiao, Y.; Li, H.; Wen, S.; Zhang, J. Numerical simulation study of the failure evolution process and failure mode of surrounding rock in deep soft rock roadways. Int. J. Min. Sci. Technol. 2016, 26, 209–221. [Google Scholar] [CrossRef]

- Tian, M.; Han, L.; Meng, Q.; Ma, C.; Zong, Y.; Mao, P. Physical model experiment of surrounding rock failure mechanism for the roadway under deviatoric pressure form mining disturbance. KSCE J. Civ. Eng. 2020, 24, 1103–1115. [Google Scholar] [CrossRef]

- Yin, S.; Zheng, X.; Wang, E.; Kang, Q.; Zhang, X. Non-uniform failure and differential pressure relief technology of roadway under irregular goafs in deep close-distance coal seams. Sci. Rep. 2023, 13, 18527. [Google Scholar] [CrossRef]

- Liang, Y.; Jin, J.; Zha, W.; Xu, T.; Cheng, W. Study on the evolution law of the ‘Butterfly-type’ plastic zone in the surrounding rock of deep dynamic pressure roadway. Sci. Rep. 2025, 15, 2731. [Google Scholar] [CrossRef]

- Du, X. Research progress and prospect of borehole pressure relief technology to prevent rock burst. Coal Mine Saf. 2024, 55, 28–40. [Google Scholar]

- Sun, S.; Li, W.; Zhang, J.; Chen, D.; Zhao, J.; Zheng, K.; Long, W.; Wang, C.; Jia, B.; Du, T.; et al. Research progress and development trend of staged hydraulic fracturing technology in long-borehole underground coal mine. Coal Geol. Explor. 2022, 50, 1–15. [Google Scholar] [CrossRef]

- Niu, T. Study on surrounding rock control technology for weakened hard roof of stope by staged hydraulic fracturing. Coal Sci. Technol. 2022, 50, 50–59. [Google Scholar]

- Cheng, L.; Zhang, Z.; Jiang, P. Research and application of stress field response mechanism based on roof hydraulic fracturing pressure relief. J. Min. Saf. Eng. 2023, 40, 722–729. [Google Scholar]

- Gao, F. Influence of hydraulic fracturing of strong roof on mining-induced stress-insight from numerical simulation. J. Min. Strat. Control Eng. 2021, 3, 5–13. [Google Scholar]

- Chen, S.; Liu, J.; Li, Y.; Lyu, H. Stress transfer control technology for fracturing weak structural bodies in subgrade dynamic pressure roadways. Coal Sci. Technol. 2024, 52, 106–116. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, B.; Su, Z.; Li, S.; Shi, Y.; Sang, X.; Liu, A.; Han, W. Technology and application of long directional drilling hydraulic fracturing for preventing rock burst in thick and hard roof. Saf. Coal Mines 2024, 55, 10–21. [Google Scholar] [CrossRef]

- Hu, Q.; Liu, J.; Li, Q.; Zhang, Y.; Song, M.; Sun, W.; Song, J. Study on stress and fracture evolution of sectional hydraulic fracturing of coal seam roof. J. China Univ. Min. Technol. 2023, 52, 1084–1095+1202. [Google Scholar]

- Wu, Y.; Kang, H. Pressure relief mechanism and experiment of directional hydraulic fracturing in reused coal pillar roadway. J. China Coal Soc. 2017, 42, 1130–1137. [Google Scholar]

- Kang, H.; Feng, Y. Hydraulic fracturing technology and its applications in strata control in underground coal mines. Coal Sci. Technol. 2017, 45, 1–9. [Google Scholar]

- Kang, H.; Feng, Y.; Zhang, Z.; Zhao, K.; Wang, P. Hydraulic fracturing technology with directional boreholes for strata control in underground coal mines and its application. Coal Sci. Technol. 2023, 51, 31–44. [Google Scholar] [CrossRef]

- Qian, Y.; Li, Q.; Jiang, Z.; Hu, Q.; Wu, W.; Liu, Y.; Li, L.; Zhang, Z.; Yu, C.; Li, W. Microseismic activity characteristics and range evaluation of hydraulic fracturing in coal seam. Gas Sci. Eng. 2024, 122, 205222. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, F.; Jiang, L.; Mo, P.; Xiao, J.; Song, Q.; Luo, Y. Coupled THMC model-based prediction of hydraulic fracture geometry and size under self-propping phase-transition fracturing. Int. J. Coal Sci. Technol. 2024, 11, 78. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Ji, R.; Cheng, X.; Liu, X.; Zhang, Y.; Sho, M. Research and application of comprehensive surrounding rock control technology for strong dynamic pressure roadway in longwall top-coal caving face. Coal Eng. 2023, 55, 51–57. [Google Scholar]

- Wang, C.; Zheng, K.; Wang, H.; Li, Y.; Wang, L.; Yang, D.; Ji, Q.; Cheng, Z. Comprehensive treatment technology of hydraulic fracturing in initial mining of the first mining face under hard roof. Coal Eng. 2023, 55, 63–69. [Google Scholar]

| Survey Area | Initial Pressure Step Distance/m | First Time Cycle Pressure Step Distance/m | Second Time Cycle Pressure Step Distance/m | Third Time Cycle Pressure Step Distance/m | Fourth Time Cycle Pressure Step Distance/m |

|---|---|---|---|---|---|

| Upper | 32 | 24 | 28 | 28 | 32 |

| Middle | 32 | 28 | 20 | 28 | 28 |

| Lower | 36 | 24 | 20 | 32 | 32 |

| Average | 33.3 | 25.3 | 22.7 | 29.3 | 30.7 |

| Rock Type | Uniaxial Compressive Strength /MPa | Average/MPa | Rock Type | Uniaxial Compressive Strength /MPa | Average/MPa |

|---|---|---|---|---|---|

| Medium-fine Sandstone | 23.85 | 26.30 | Medium-coarse Sandstone | 40.85 | 41.92 |

| 25.60 | 41.77 | ||||

| 27.77 | 43.29 | ||||

| 24.86 | 39.10 | ||||

| 29.41 | 44.59 |

| Serial Number | Rock Type | Average Thickness/m | Key Layer Height/m | Remarks |

|---|---|---|---|---|

| 1 | Medium-coarse sandstone | 38.05 | 55.65 | Main key layer |

| 2 | Medium-fine sandstone | 16.30 | 17.60 | Sub-key layer |

| 3 | Carbonaceous mudstone | 1.30 | ||

| 4 | 4-2 coal | 7.50 |

| Drill Hole Depth/m | Inclination Angle/(°) | Tunnel Angle/(°) | Drill Hole Spacing/m | Number of Fracturing Segments Per Hole | Hole Diameter/mm |

|---|---|---|---|---|---|

| 60 | 80 | 90 | 5 | 15 | 56 |

| Support Number | Unfractured Zone Pressure Step Distance/m | Fractured Zone Pressure Step Distance/m | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Initial Pressure | First Cycle Pressure | Second Cycle Pressure | Third Cycle Pressure | Fourth Cycle Pressure | First Cycle Pressure | Second Cycle Pressure | Third Cycle Pressure | Fourth Cycle Pressure | |

| 15# | 32 | 24 | 28 | 28 | 32 | 12 | 12 | 28 | 16 |

| 65# | 32 | 28 | 20 | 28 | 28 | 12 | 12 | 24 | 16 |

| 90# | 36 | 24 | 20 | 32 | 32 | 20 | 24 | 20 | — |

| Average | 33.3 | 25.3 | 22.7 | 29.3 | 30.7 | 14.7 | 16 | 24 | 16 |

| Zone | Pressure Step Distance/m | Pressure Cycle | Support Working Resistance During Pressure Application/kN | Zone | Pressure Step Distance/m | Pressure Cycle | Support Working Resistance During Pressure Application/kN |

|---|---|---|---|---|---|---|---|

| Unfractured zone | 25.3 | 1 | 8160.84 | Fractured zone | 14.7 | 1 | 7219.90 |

| 22.7 | 2 | 9142.39 | 16.0 | 2 | 7404.30 | ||

| 29.3 | 3 | 8955.00 | 24.0 | 3 | 7068.06 | ||

| 30.7 | 4 | 9236.05 | 16.0 | 4 | 7320.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, J.; Su, K.; Sun, C. Hydraulic Fracturing Pressure-Relief Technology for Controlling the Surrounding Rock in Deep Dynamic Pressure Roadways. Appl. Sci. 2025, 15, 9779. https://doi.org/10.3390/app15179779

Ren J, Su K, Sun C. Hydraulic Fracturing Pressure-Relief Technology for Controlling the Surrounding Rock in Deep Dynamic Pressure Roadways. Applied Sciences. 2025; 15(17):9779. https://doi.org/10.3390/app15179779

Chicago/Turabian StyleRen, Jianxi, Kai Su, and Chengwei Sun. 2025. "Hydraulic Fracturing Pressure-Relief Technology for Controlling the Surrounding Rock in Deep Dynamic Pressure Roadways" Applied Sciences 15, no. 17: 9779. https://doi.org/10.3390/app15179779

APA StyleRen, J., Su, K., & Sun, C. (2025). Hydraulic Fracturing Pressure-Relief Technology for Controlling the Surrounding Rock in Deep Dynamic Pressure Roadways. Applied Sciences, 15(17), 9779. https://doi.org/10.3390/app15179779