An Experimental Study on the Expansion Rate of Blasting Cracks in Prefabricated Grooved Concrete Under Vertical Stresses

Abstract

1. Introduction

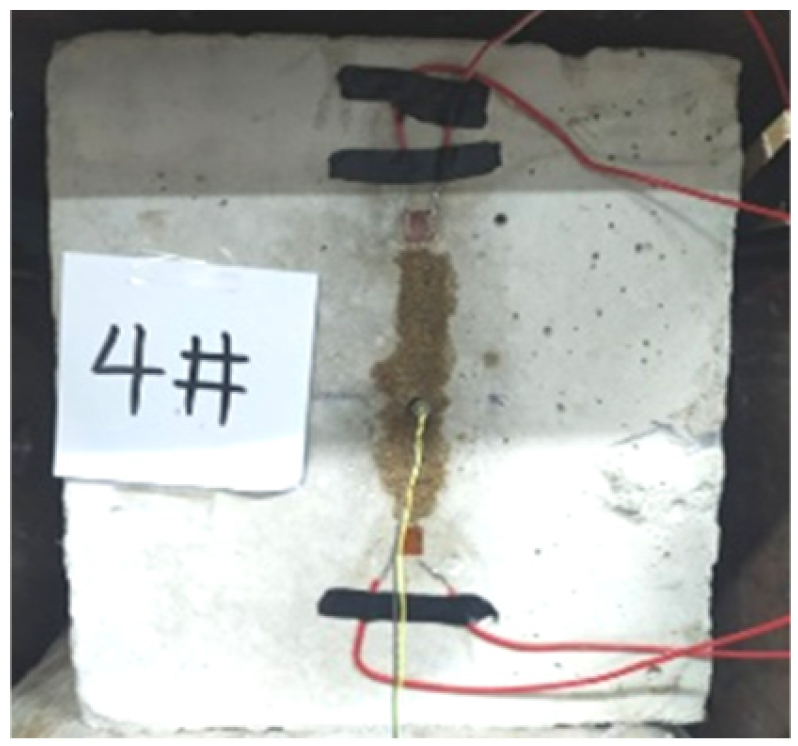

2. Model Blasting Test

2.1. Test Plan

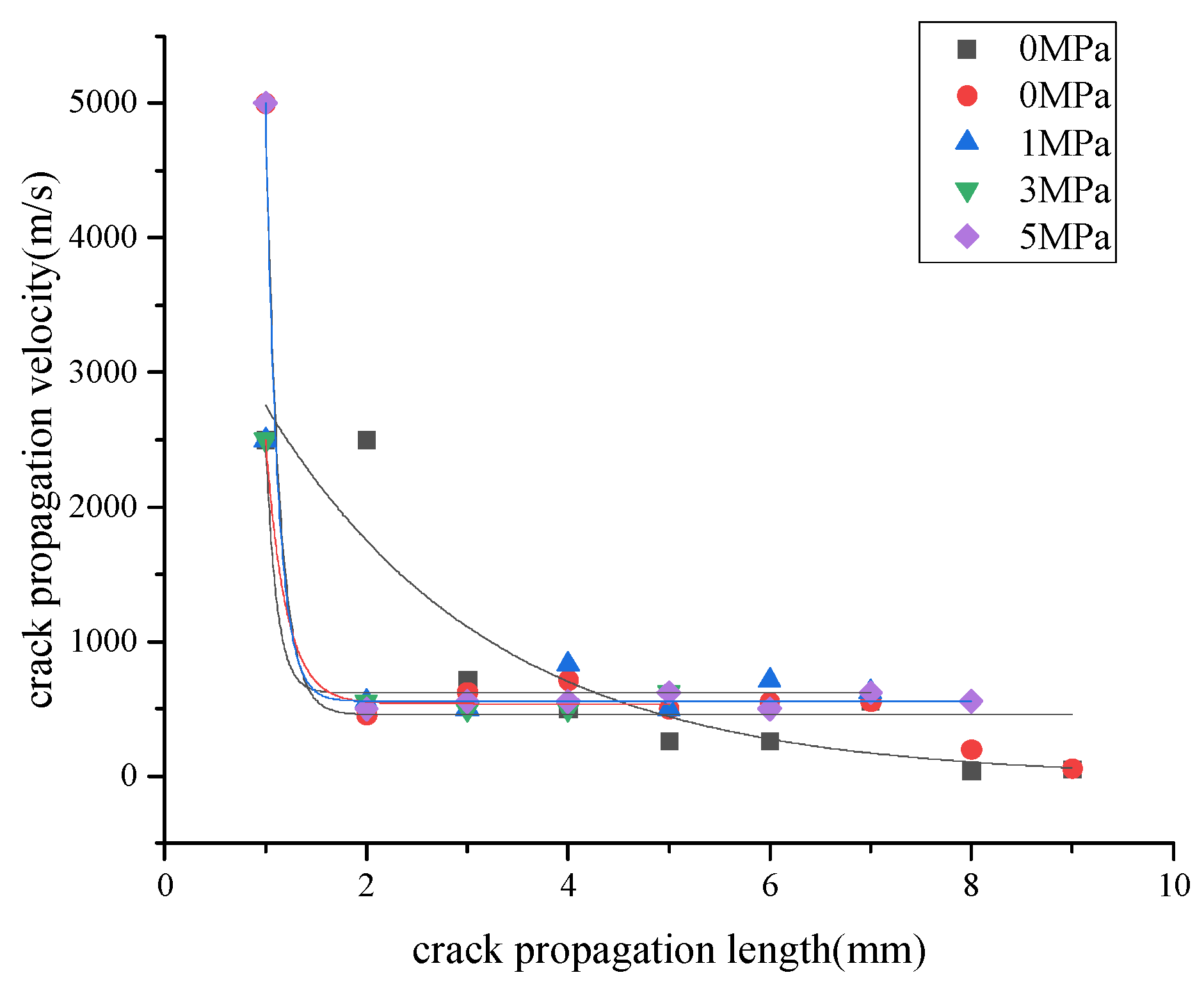

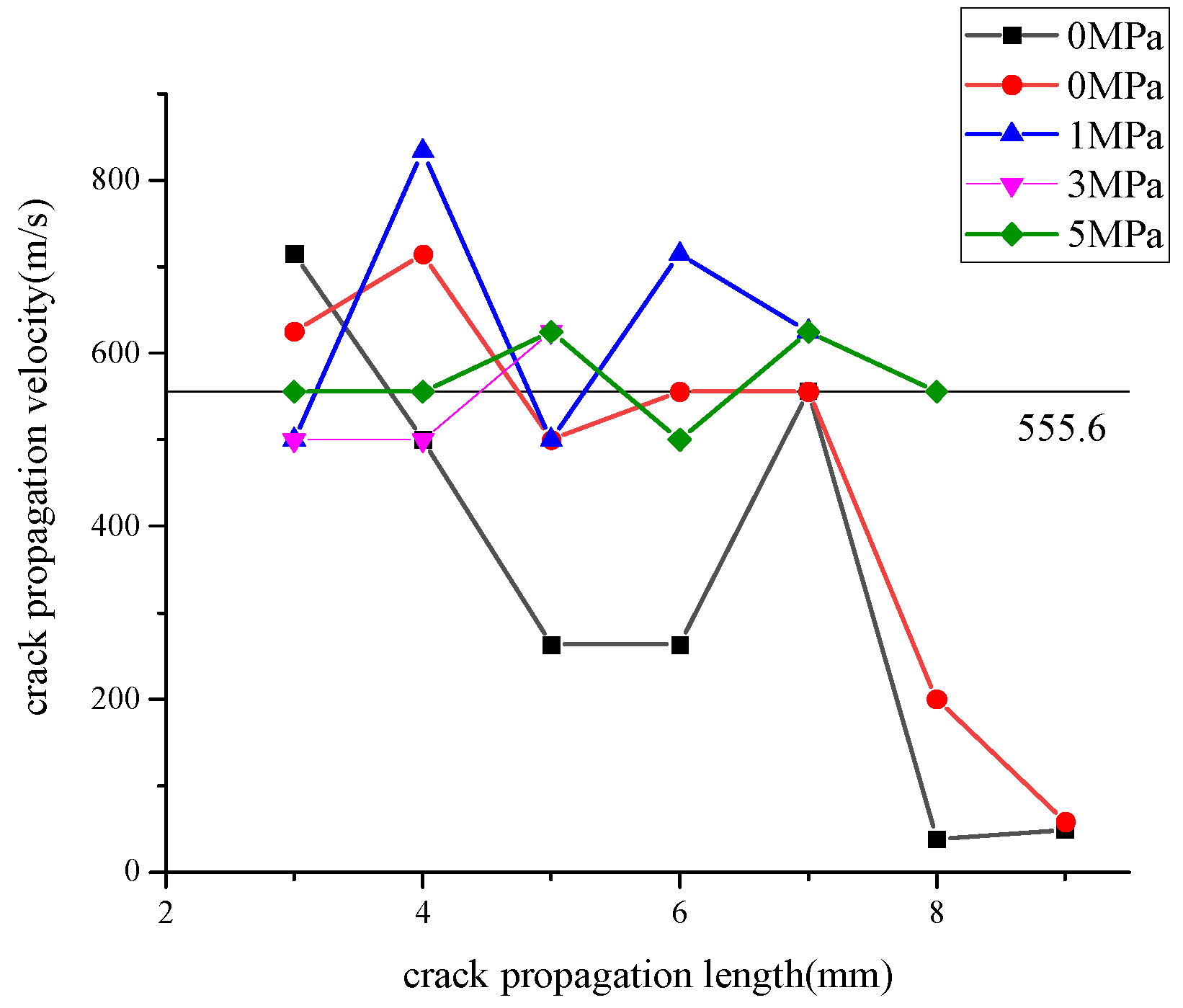

2.2. Experimental Results

3. Numerical Simulation

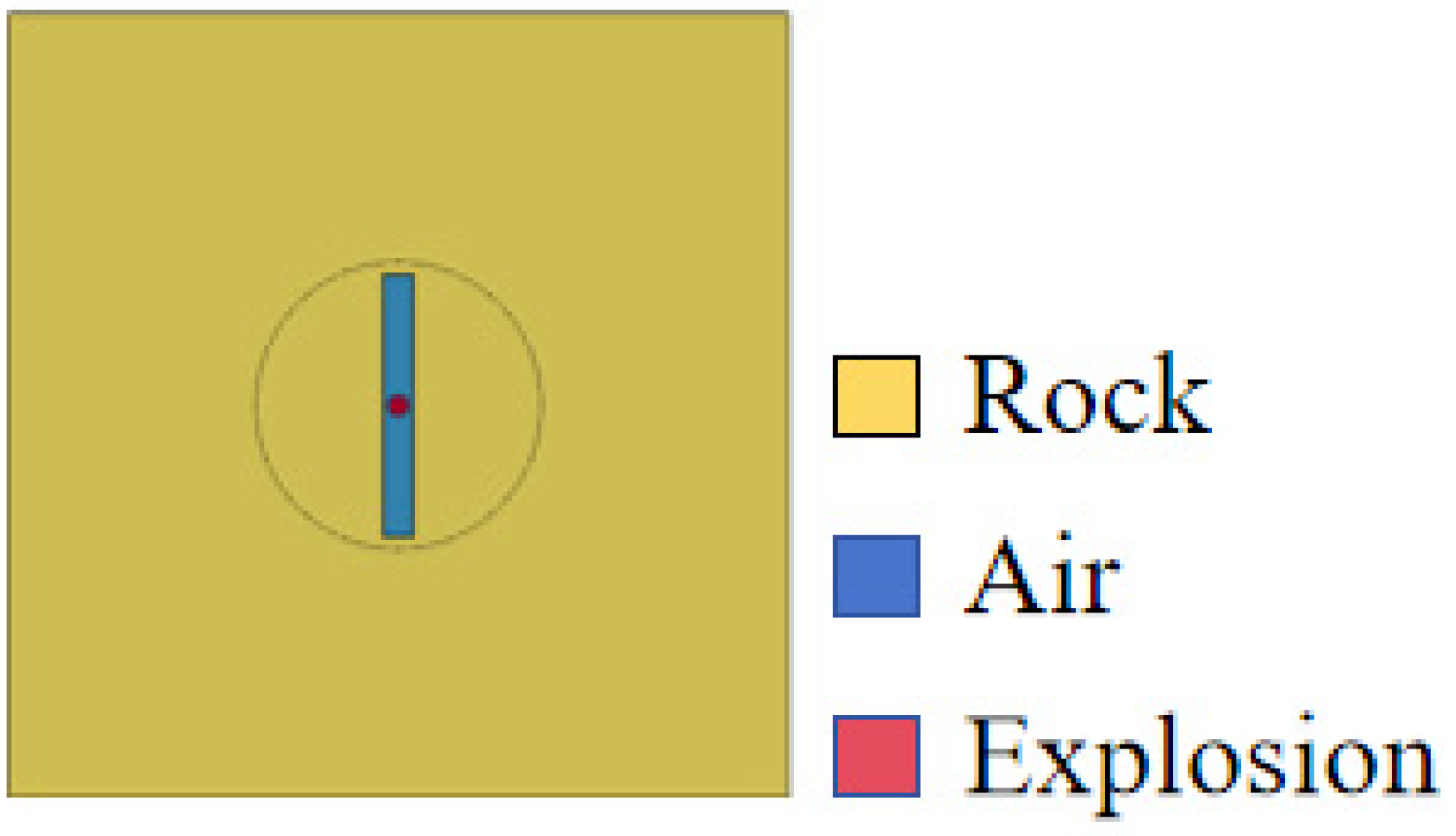

3.1. Model Establishment

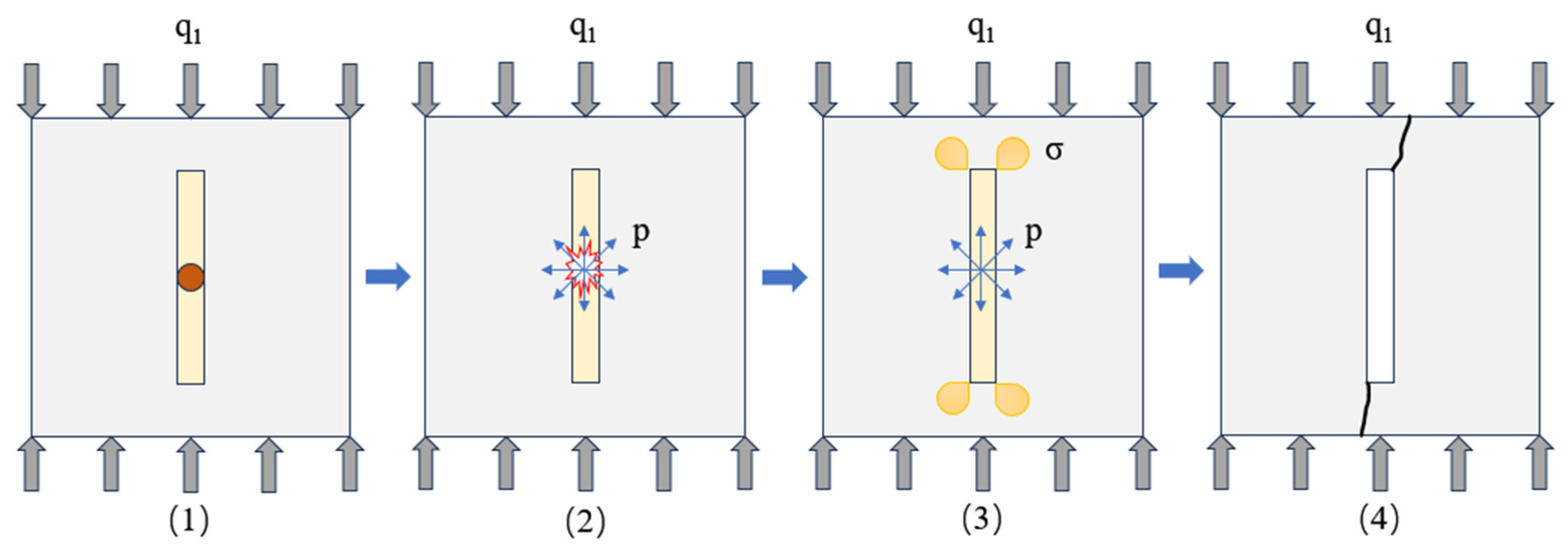

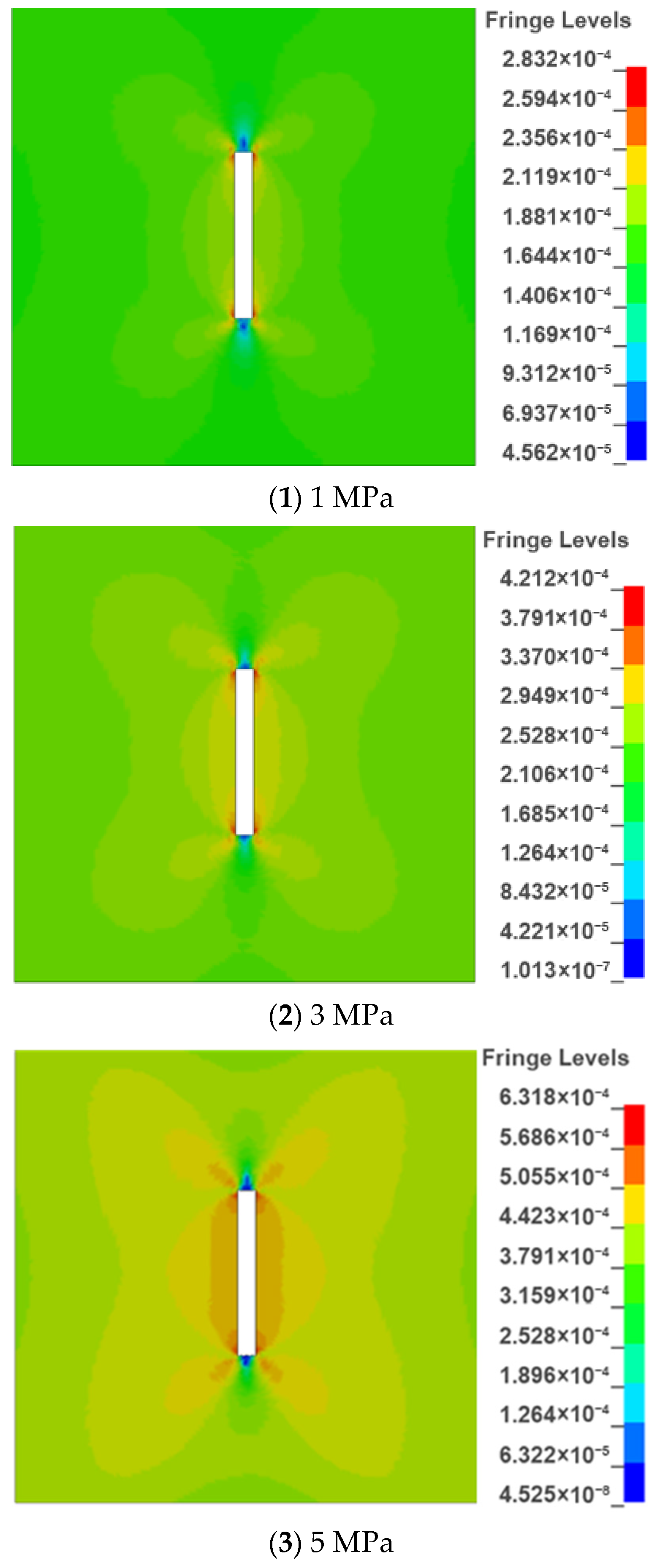

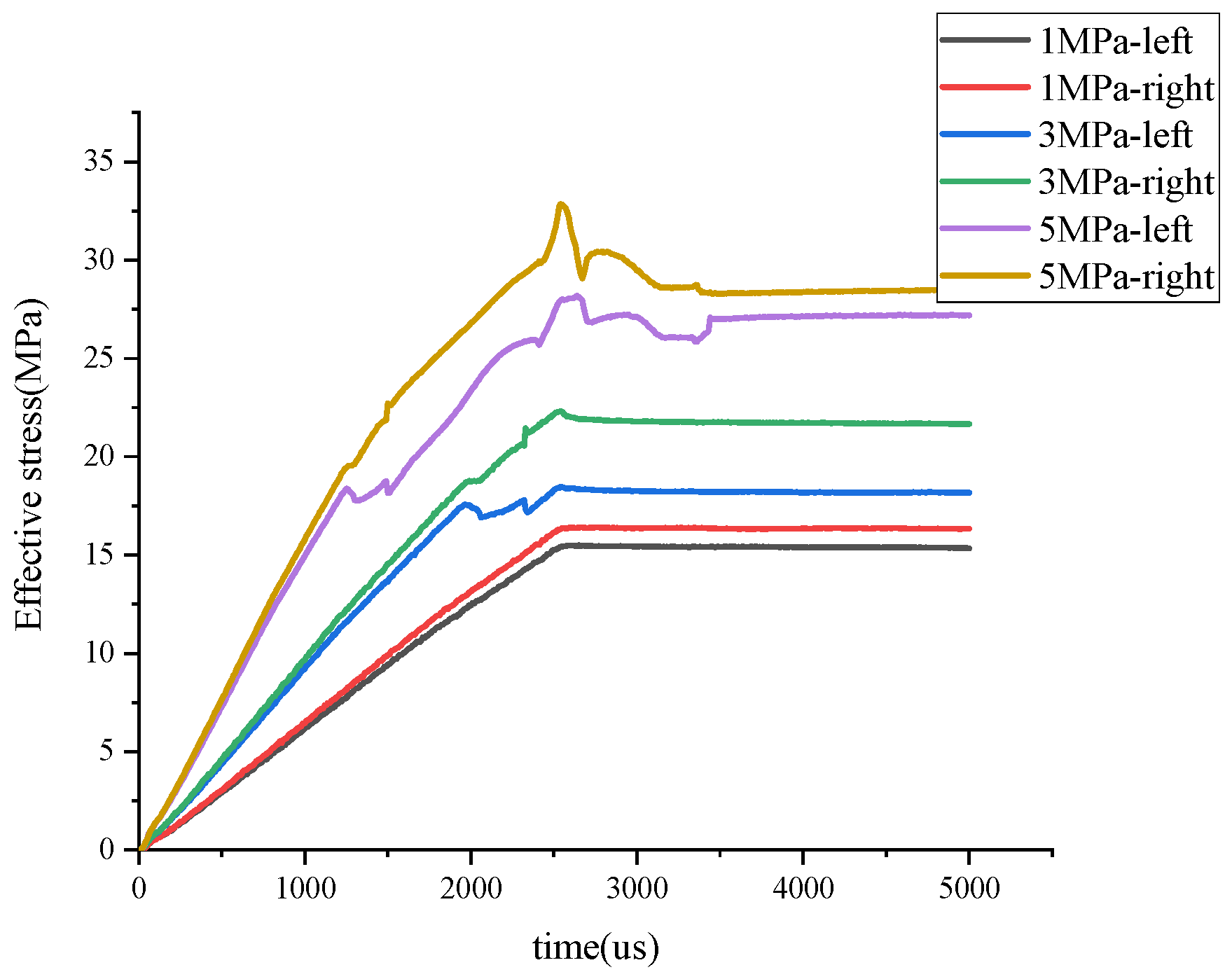

3.2. Stress Analysis of Precast Slotted Concrete

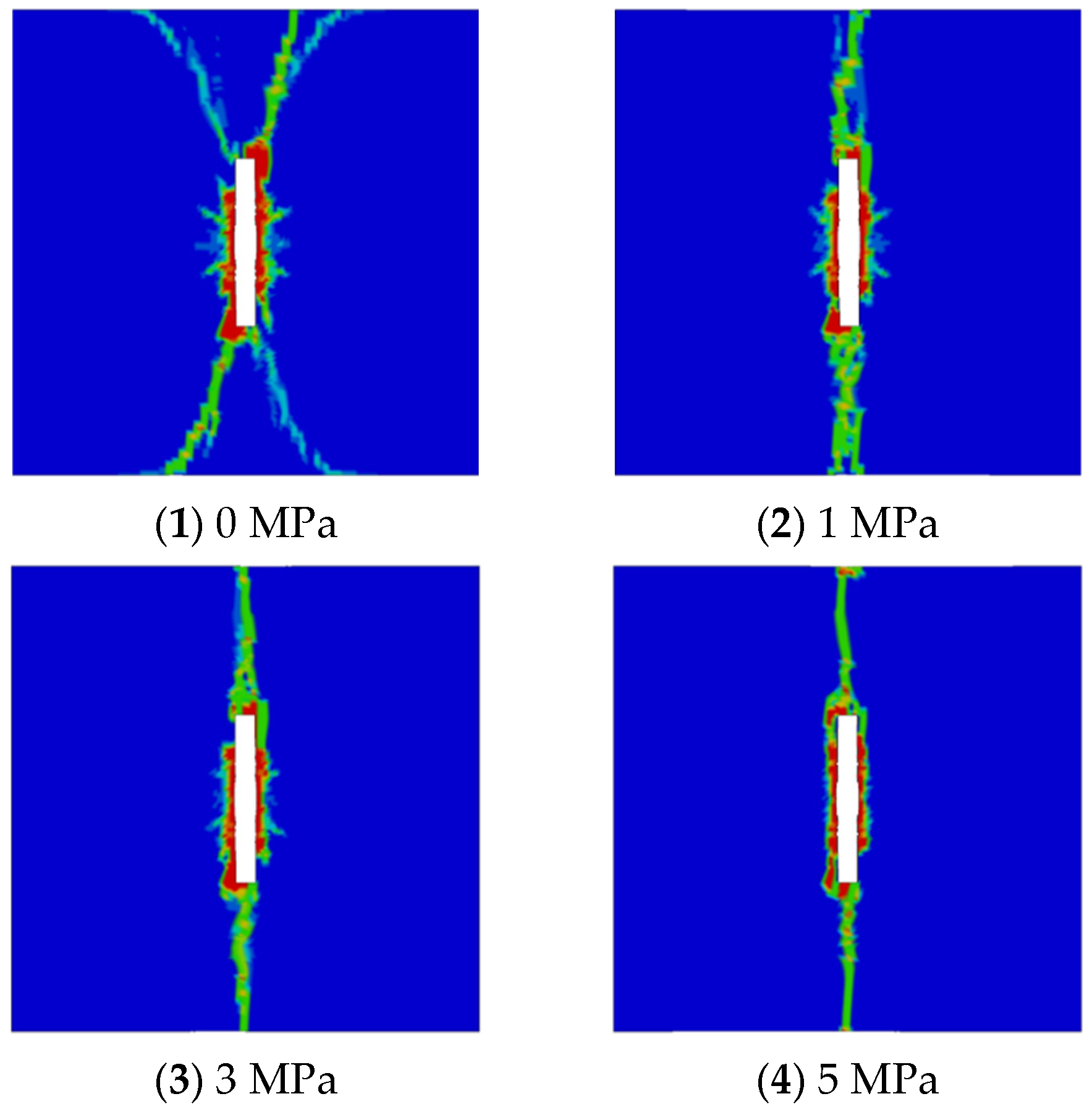

3.3. Crack Propagation Simulation Results

4. Conclusions

4.1. Practical Significance

4.2. Limitations

4.3. Future Research Directions

5. Discussion

5.1. Correspondence Between Experimental Data and Numerical Simulation Results

5.1.1. Crack Propagation Direction

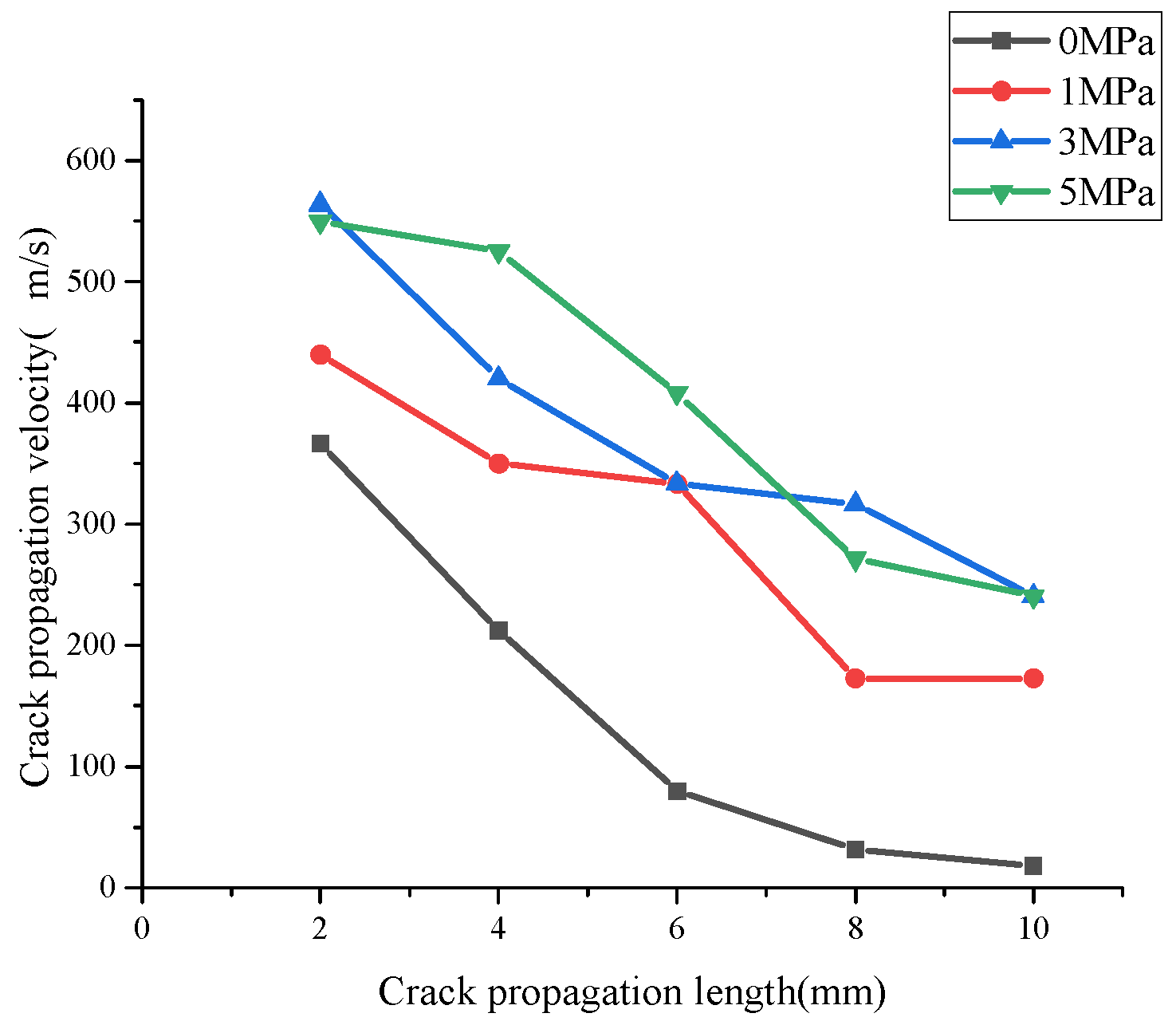

5.1.2. Crack Expansion Velocity

5.1.3. Stress Distribution Law

5.2. Key Characteristics of Aggregates in Experimental Concrete

Mechanisms of Aggregate Effects on Crack Expansion Rate

5.3. Practical Significance of the Obtained Results

5.3.1. Guiding the Optimization of Directional Blasting Parameters in Deep Engineering

5.3.2. Promoting the Application of Water Jet Grooving Technology in Deep Blasting

5.3.3. Providing a Reference for the Prediction and Prevention of Deep Rock Engineering Disasters

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pan, J.; Ma, W.; Liu, S.; Gao, J.M. A prevention technology of rock burst based on directional presplitting of water jet prefabricated slot in hard roof. Chin. J. Rock Mech. Eng. 2021, 40, 1591–1602. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, S. Theoretical model of annular slotting depth for high pressure water jet and its application. J. China Coal Soc. 2019, 44 (Suppl. S1), 126–132. [Google Scholar] [CrossRef]

- Wang, G.; Fan, J.Y.; Wang, W.R.; Xu, H. Slot spacing model of directional fracturing coal assitd by hydraulic slotting. J. Min. Saf. Eng. 2020, 37, 622–631. [Google Scholar] [CrossRef]

- Zhang, Z. On the initiating, Glowing branching and sloping of crack in rock blasting. Blasting 1999, 16, 21–24. [Google Scholar]

- Chen, J. Monitoring analysis for the velocity of crack propagation. Chin. J. Rock Mech. Eng. 1998, 17, 77–80. [Google Scholar]

- Zhang, Z. An Experimental Study of Crack Expansion Speed in Rock Blasting. Explos. Mater. 2000, 29, 1–8. [Google Scholar]

- Li, Q.; Gao, Z.H.; Xu, W.L.; Wang, K.; Liu, S.; Ran, G.F.; Hu, Y. Experimental research on the dynamic propagation process of mode I cracks in the rock under directional fracture blasting using the strain gauge method. Eng. Fract. Mech. 2020, 235, 107113. [Google Scholar] [CrossRef]

- Liu, R.F.; Zhu, Z.M.; Li, Y.X.; Liu, B.; Wan, D.; Li, M. Study of rock dynamic fracture toughness and crack propaga tion parameters of four brittle materials under blasting. Eng. Fract. Mech. 2020, 225, 106460. [Google Scholar] [CrossRef]

- Zou, X.-W.; Zhou, T.; Li, G.; Hu, Y.; Deng, B.; Yang, T. Intelligent Inversion Analysis of Surrounding Rock Parameters and Deformation Characteristics of a Water Diversion Surge Shaft. Designs 2024, 8, 116. [Google Scholar] [CrossRef]

- Liu, R.; Zhu, Z.; Du, Y.; Li, M.; Liu, B.; Wan, D. Study on dynamic propagation law of cracks with different lengths under blasting. Chin. J. Rock Mech. Eng. 2022, 41 (Suppl. S2), 3114–3123. [Google Scholar]

- Xie, H. Research review of the state key research development program of China: Deep rock mechanics and mining theory. J. China Coal Soc. 2019, 44, 1283–1305. [Google Scholar]

- Xiao, S.Y.; Jiang, Y.J.; Liu, Z.X.; Su, L.J. Hard rock blasting energy distribution and frag mentation characteristics under high earth stress. J. Vib. Shock 2018, 37, 143–149. [Google Scholar]

- Yang, J.; Wu, Z.; Yao, C.; Jiang, S.; Jiang, Q. Influences of in-situ stress on blast-induced rock fracture and seismic waves. J. Vib. Shock 2020, 39, 64–70+90. [Google Scholar]

- Li, X.D.; Liu, K.W.; Sha, Y.Y.; Yang, J.; Ma, S.; Hong, Z. Investigation on radial fracturing around borehole under combined static stress and blasting. Theor. Appl. Fract. Mech. 2023, 127, 104038. [Google Scholar] [CrossRef]

- Tao, J.; Yang, X.G.; Li, H.T.; Zhou, J.W.; Fan, G.; Lu, G.D. Effects of in-situ stresses on dynamic rock responses under blast loading. Mech. Mater. 2020, 145, 103374. [Google Scholar] [CrossRef]

- Ma, W.-B.; Zou, W.-H.; Zhang, J.-L.; Li, G. Prediction of Shear Strength in Anisotropic Structural Planes Considering Size Effects. Designs 2025, 9, 17. [Google Scholar] [CrossRef]

- Yang, R.; Su, H. Experimental study on crack propagation with pre-crack under explosion load. J. China Coal Soc. 2019, 44, 482–489. [Google Scholar]

- Ge, J.; Xu, Y.; Cheng, L. Relationship between in-situ stress and propagation direction of main cracks induced by blasting. J. Vib. Shock 2023, 42, 54–64. [Google Scholar]

- Yue, Z.; Tian, S.; Zhang, S. Experimental study of crack propagation under blasting load in notched boreholes. J. Vib. Shock 2019, 38, 186–195. [Google Scholar]

- Yang, L.; Wang, Q.; Ding, C. Experimental analysis on the mechanism of slotting blasting in deep rock mass. J. Vib. Shock 2020, 39, 40–46. [Google Scholar]

- Yang, R.; Ding, C.; Li, Y.; Yang, L.; Zhao, Y. Crack propagation behavior in slit charge blasting under high static stress conditions. Int. J. Rock Mech. Min. Sci. 2019, 119, 117–123. [Google Scholar] [CrossRef]

- Yang, L.; Huang, C.; Bao, S.; Zhang, L. Model experimental study on controlled blasting of slit charge in deep rock mass. Soil Dyn. Earthq. Eng. 2020, 138, 106318. [Google Scholar] [CrossRef]

| Specimen | 1 | 2 | 3 | 5 | 7 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Extended Length | Time/us | Velocity/(m/s) | Time/us | Velocity/(m/s) | Time/us | Velocity/(m/s) | Time/us | Velocity/(m/s) | Time/us | Velocity/(m/s) | |

| 1 mm | 0.4 | 2500 | 0.2 | 5000 | 0.4 | 2500 | 0.4 | 2500 | 0.2 | 5000 | |

| 2 mm | 0.4 | 2500 | 2.2 | 454.5 | 1.8 | 555.6 | 1.8 | 555.6 | 2.0 | 500.0 | |

| 3 mm | 1.4 | 714.3 | 1.6 | 625.0 | 2 | 500.0 | 2.0 | 500.0 | 1.8 | 555.6 | |

| 4 mm | 2 | 500.0 | 1.4 | 714.3 | 1.2 | 833.3 | 2.0 | 500.0 | 1.8 | 555.6 | |

| 5 mm | 3.8 | 263.2 | 2.0 | 500.0 | 2 | 500.0 | 1.6 | 625.0 | 1.6 | 625.0 | |

| 6 mm | 3.8 | 263.2 | 1.8 | 555.6 | 1.4 | 714.3 | / | / | 2.0 | 500.0 | |

| 7 mm | 1.8 | 555.6 | 1.8 | 555.6 | 1.6 | 625.0 | / | / | 1.6 | 625.0 | |

| 8 mm | 26 | 38.50 | 5.0 | 200.0 | / | / | / | / | 1.8 | 555.6 | |

| 9 mm | 20.8 | 48.08 | 17.2 | 58.14 | / | / | / | / | / | ||

| Average speed | 820.32 | 962.57 | 889.74 | 936.12 | 1114.6 | ||||||

| ρ (g/cm3) | E/GPa | /MPa | ||

|---|---|---|---|---|

| 1.97 | 10 | 17.8 | 0.38 | 0.1 |

| ρ (g/cm3) | D (cm/μs) | Pcj/GPa | a | b | r1 | r2 |

|---|---|---|---|---|---|---|

| 1.50 | 0.35 | 95.3 | 2.762 | 0.0844 | 5.2 | 2.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Dong, Q. An Experimental Study on the Expansion Rate of Blasting Cracks in Prefabricated Grooved Concrete Under Vertical Stresses. Appl. Sci. 2025, 15, 9747. https://doi.org/10.3390/app15179747

Wang M, Dong Q. An Experimental Study on the Expansion Rate of Blasting Cracks in Prefabricated Grooved Concrete Under Vertical Stresses. Applied Sciences. 2025; 15(17):9747. https://doi.org/10.3390/app15179747

Chicago/Turabian StyleWang, Mengxiang, and Qian Dong. 2025. "An Experimental Study on the Expansion Rate of Blasting Cracks in Prefabricated Grooved Concrete Under Vertical Stresses" Applied Sciences 15, no. 17: 9747. https://doi.org/10.3390/app15179747

APA StyleWang, M., & Dong, Q. (2025). An Experimental Study on the Expansion Rate of Blasting Cracks in Prefabricated Grooved Concrete Under Vertical Stresses. Applied Sciences, 15(17), 9747. https://doi.org/10.3390/app15179747