Dynamic Mode I Fracture Toughness and Damage Mechanism of Dry and Saturated Sandstone Subject to Microwave Radiation

Abstract

1. Introduction

2. Materials and Methods

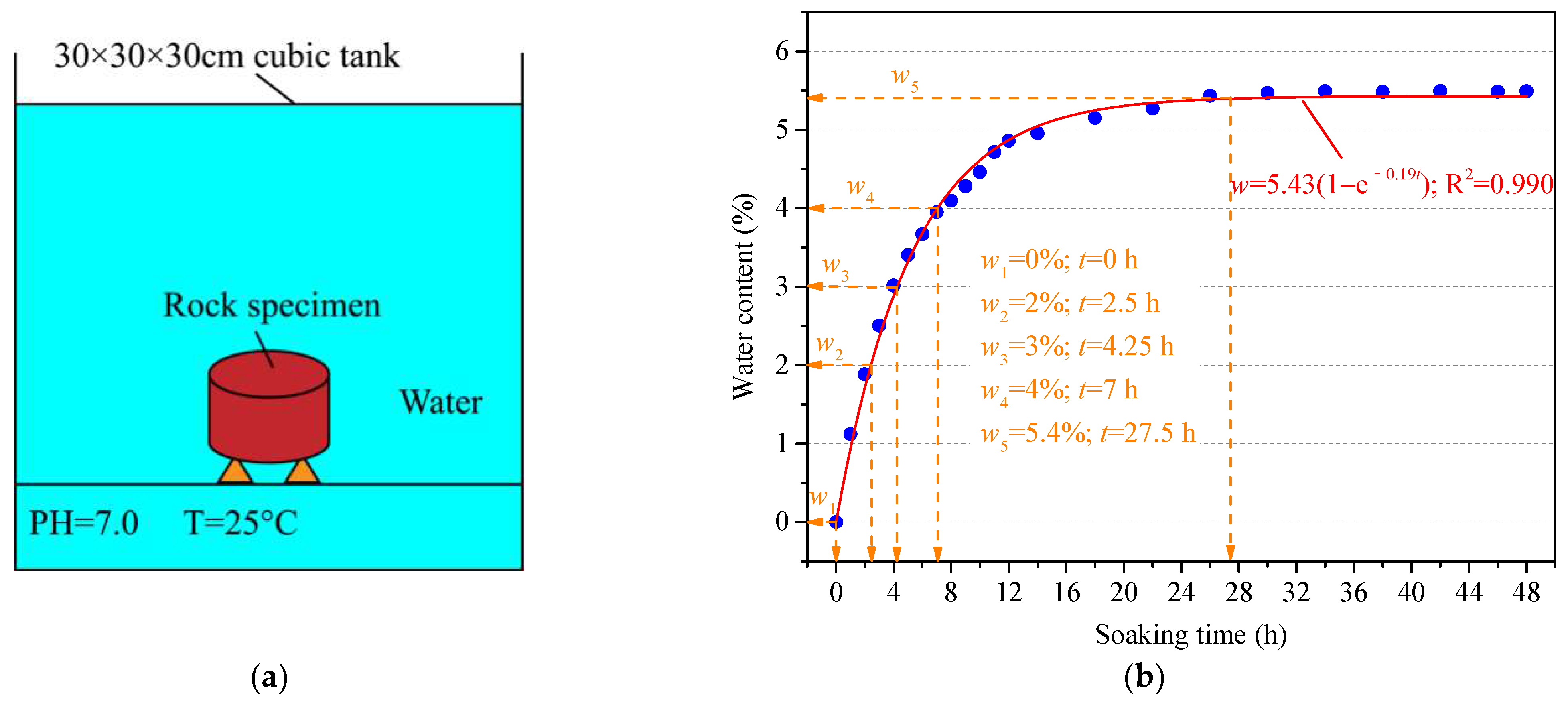

2.1. Sample Preparation

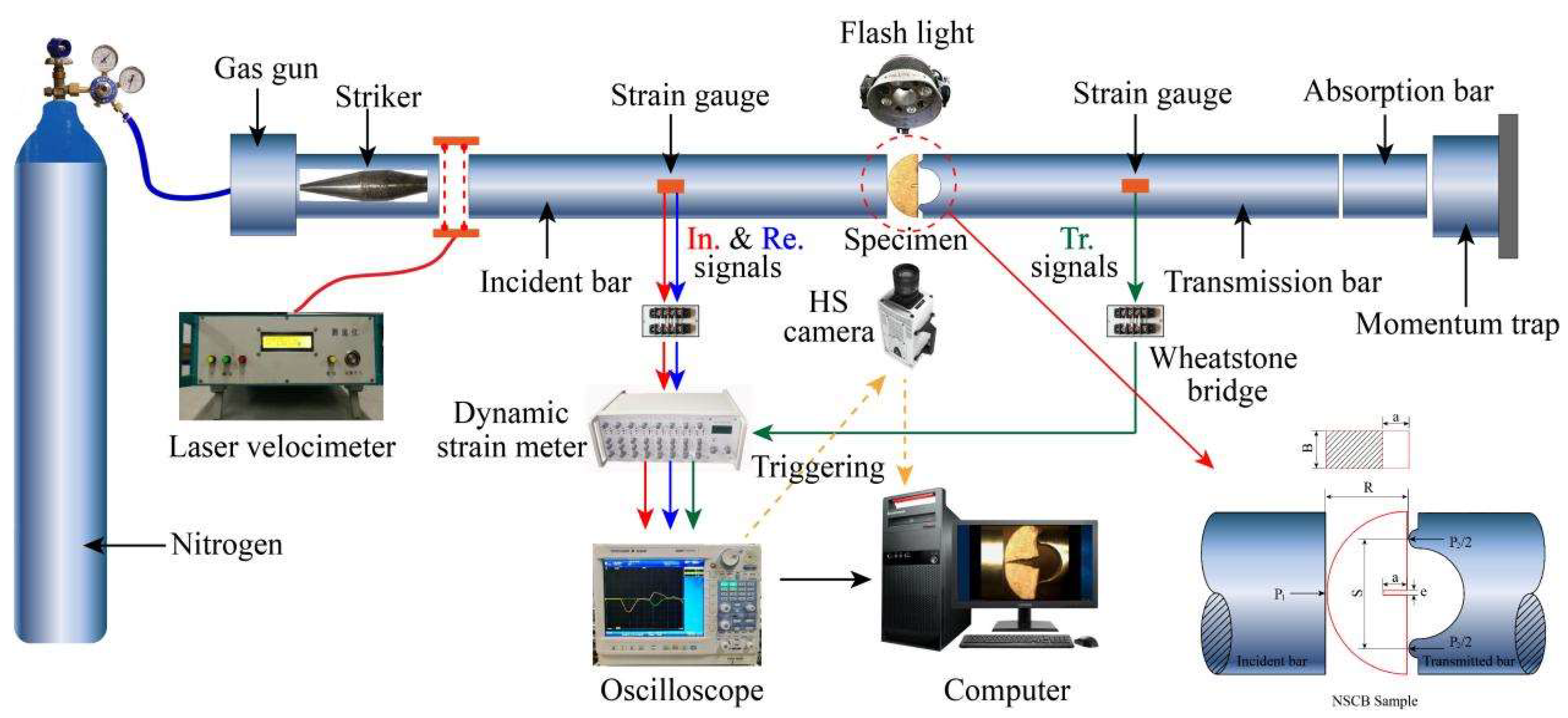

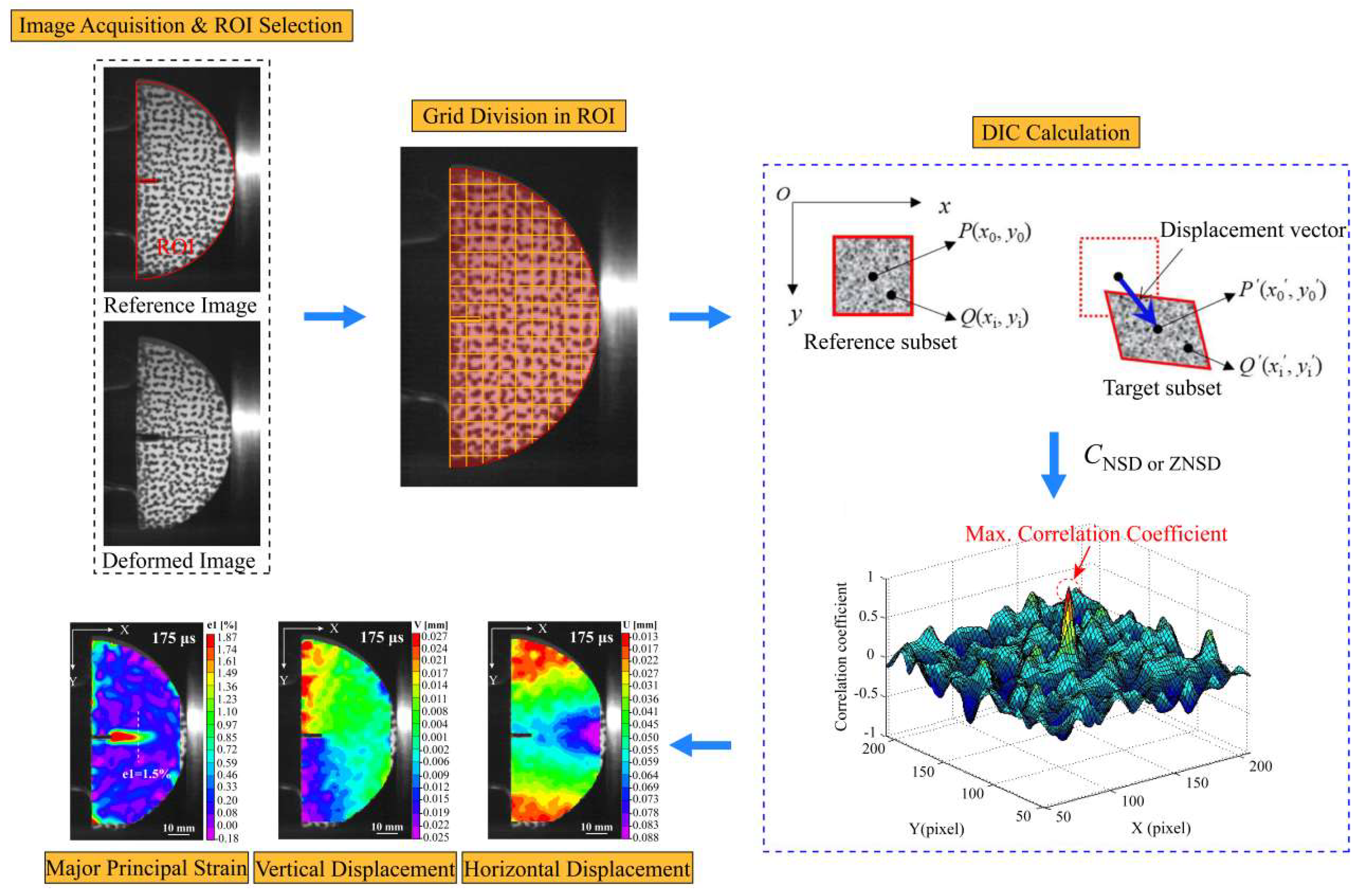

2.2. Experimental Devices and Techniques

2.2.1. Microwave Heating System

2.2.2. Split Hopkinson Pressure Bar System

2.2.3. Verify the Stress Balance

2.2.4. Digital Image Correlation Technology

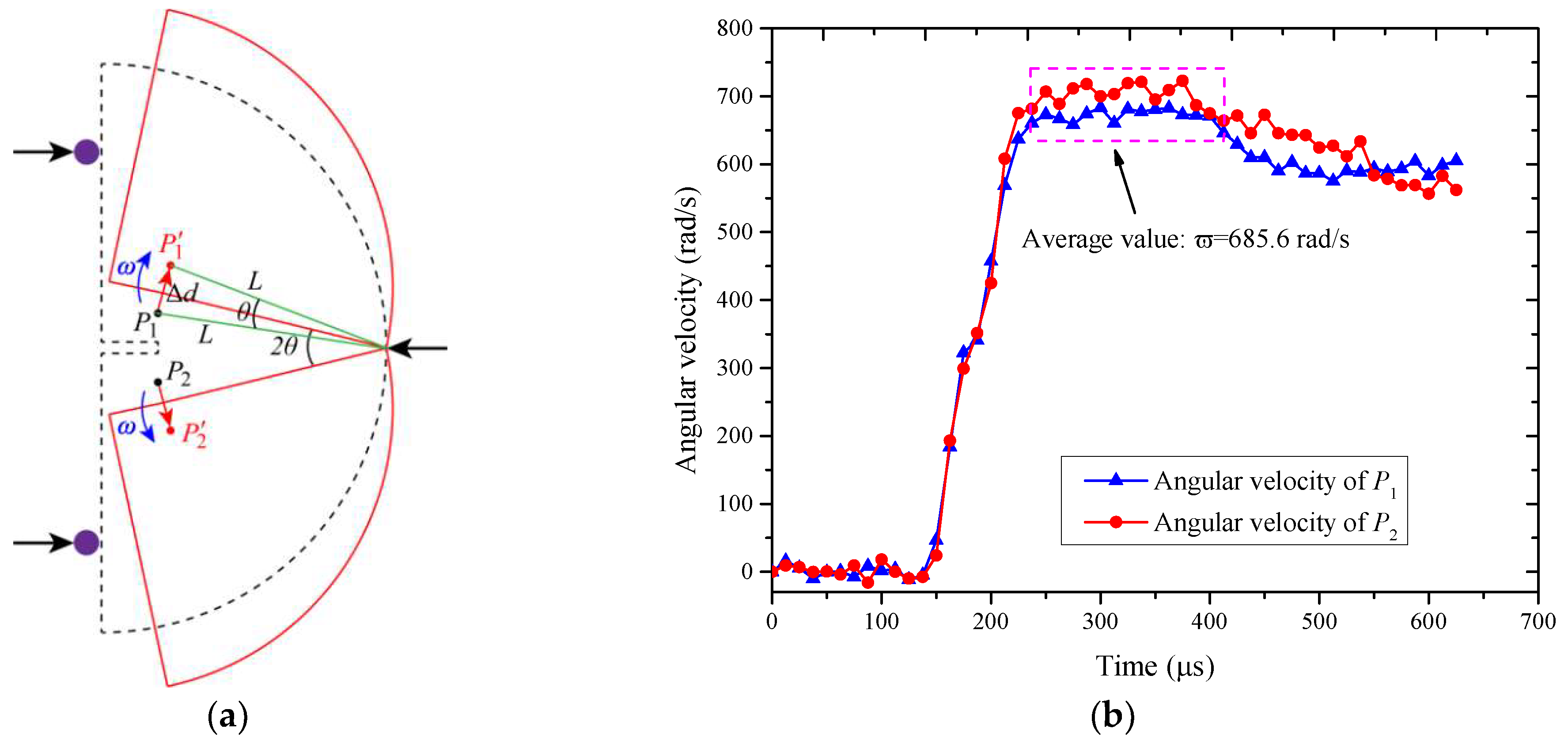

3. Results

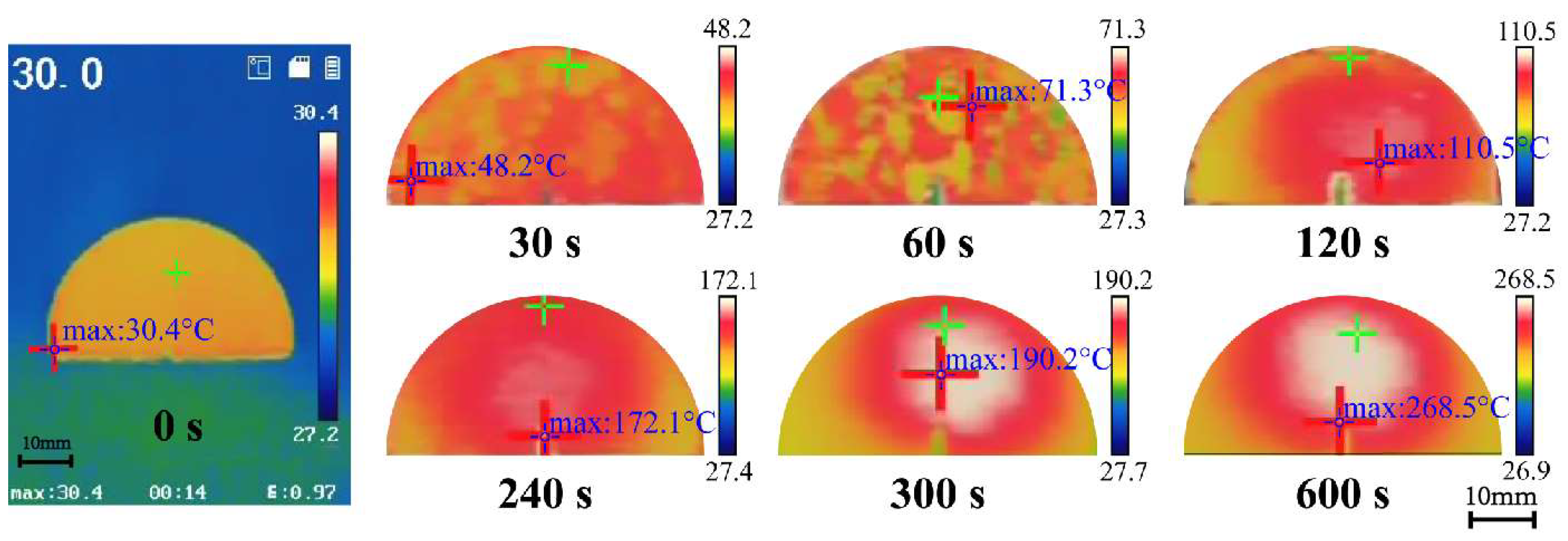

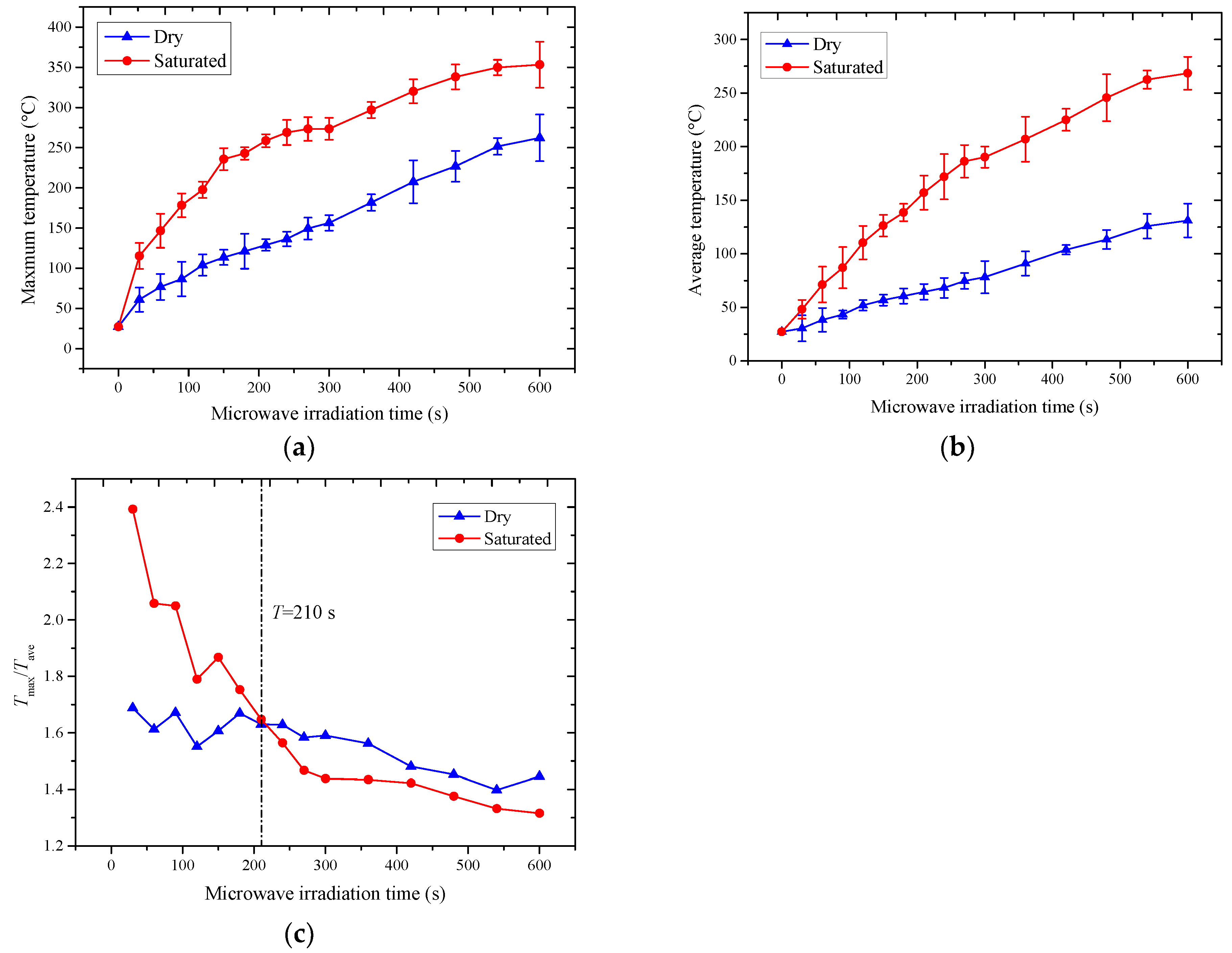

3.1. Temperature Distribution Characteristics

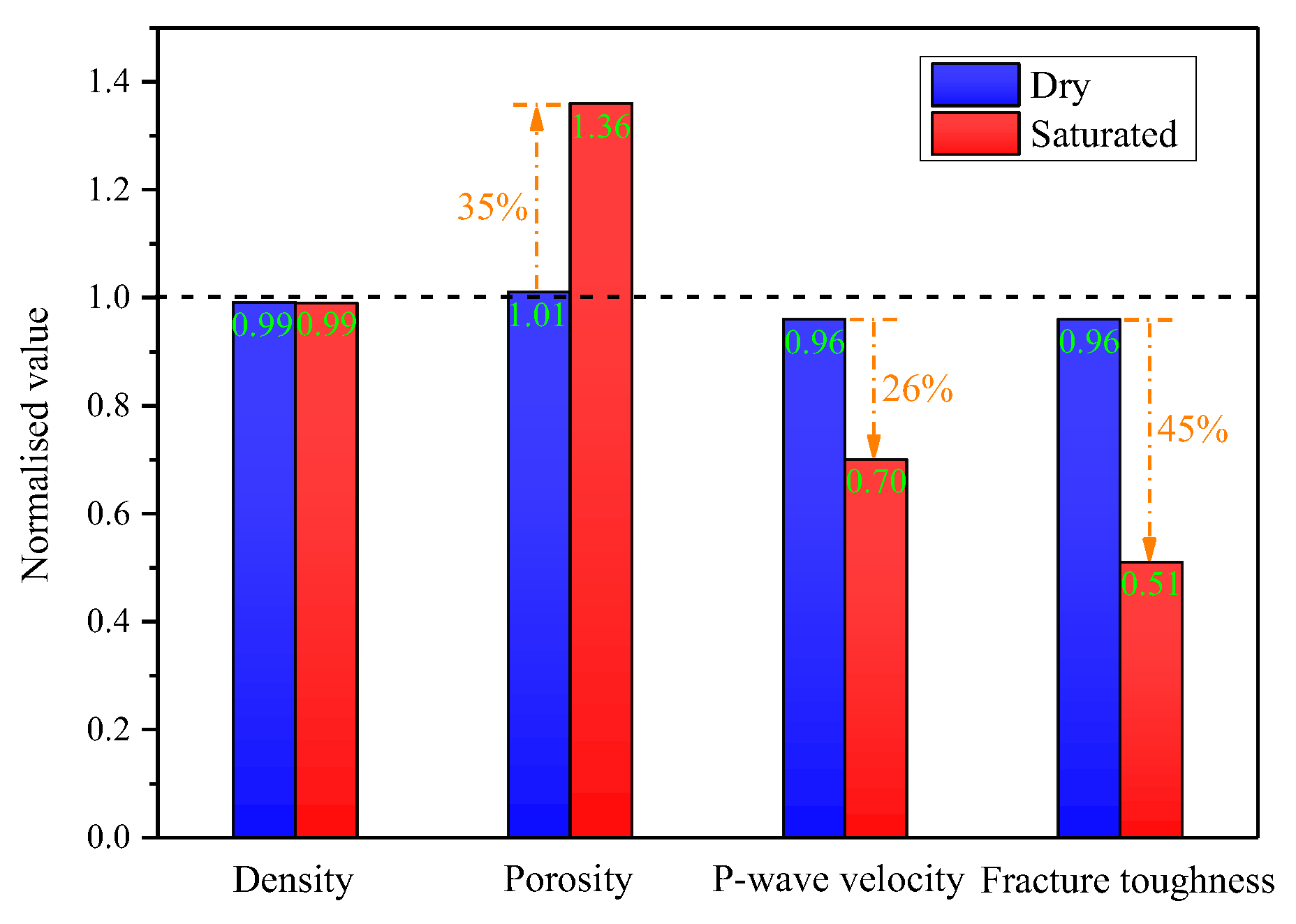

3.2. Static Physico-Mechanical Property Changes

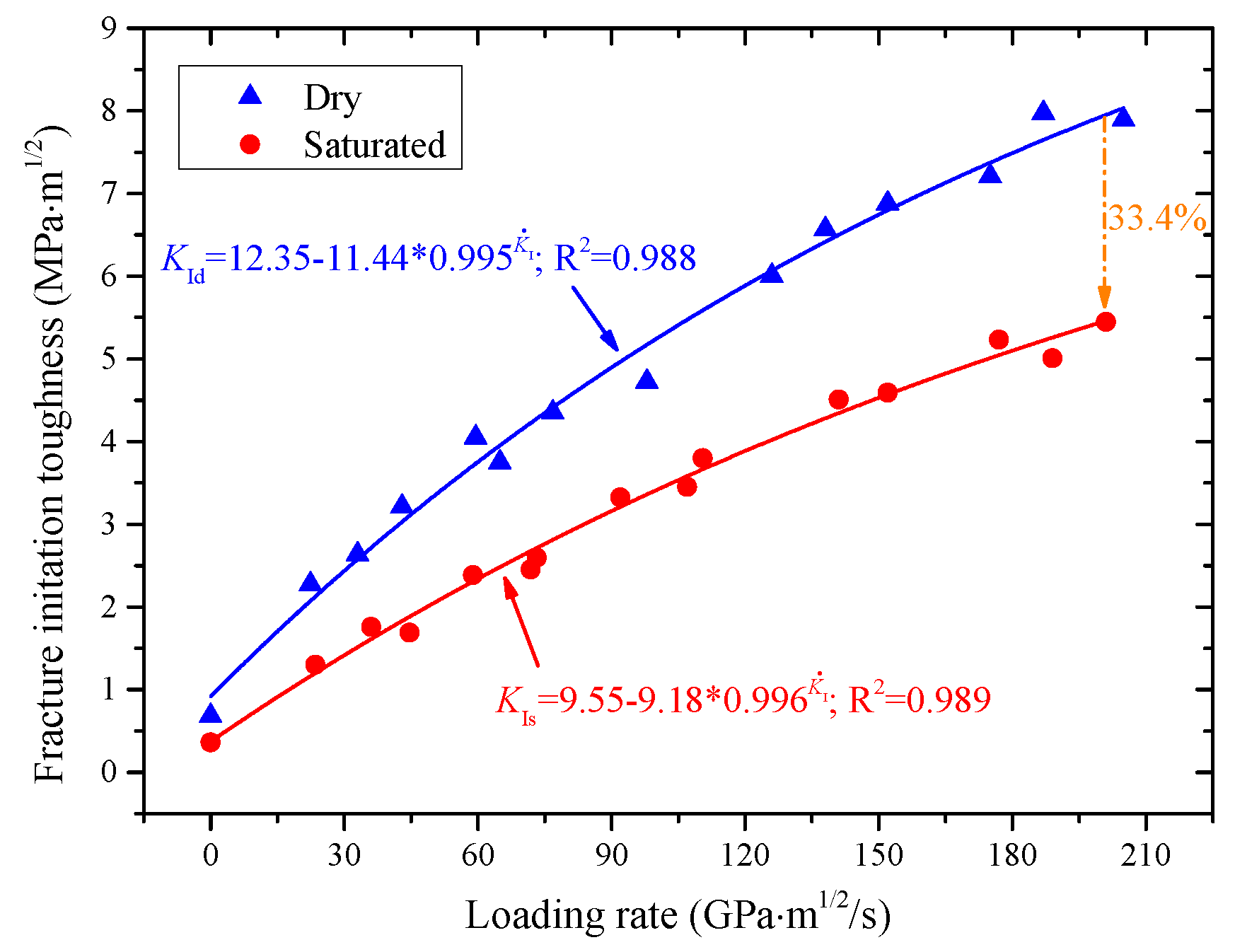

3.3. Correlation of Dynamic Cracking Toughness Rate

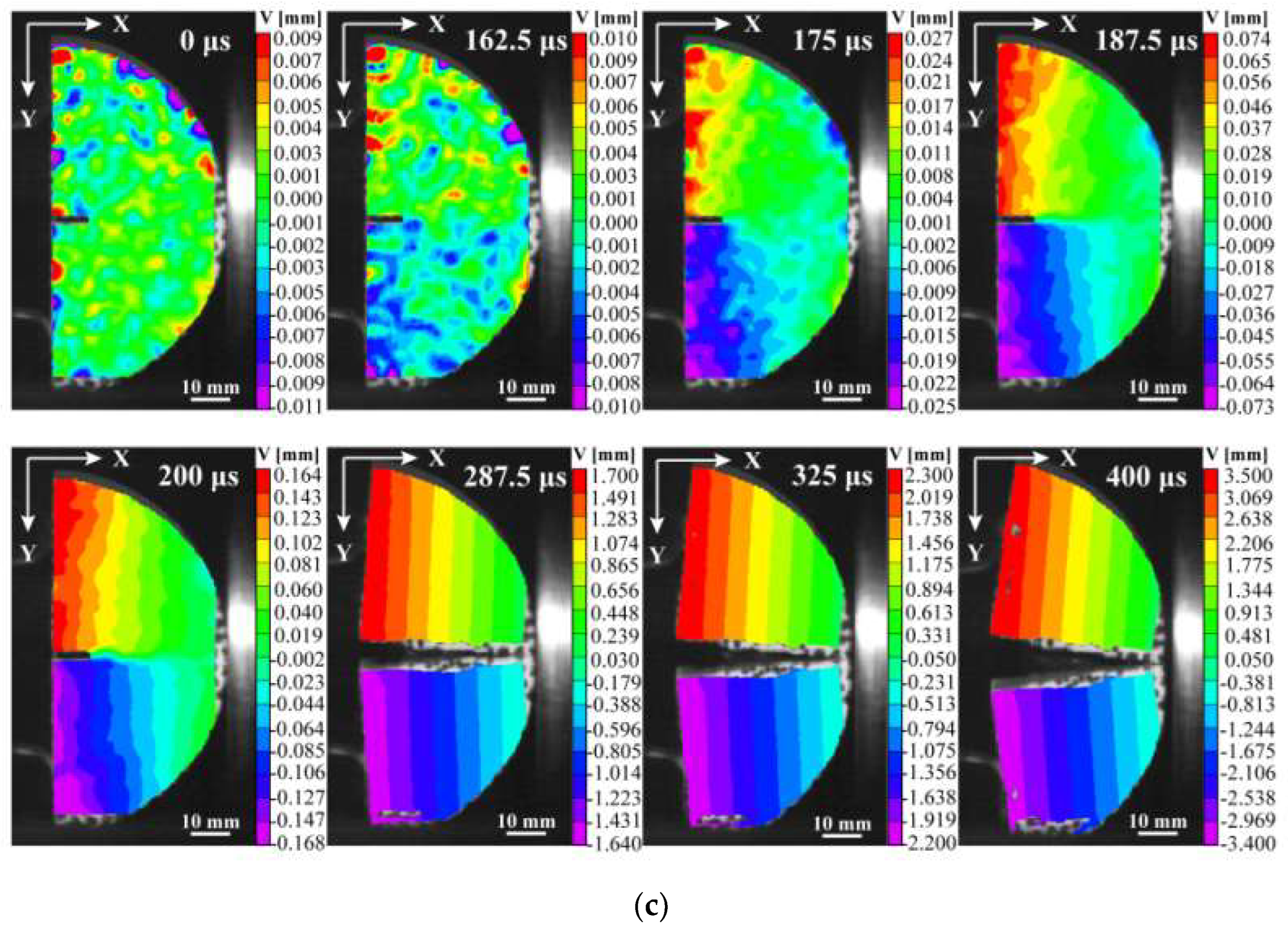

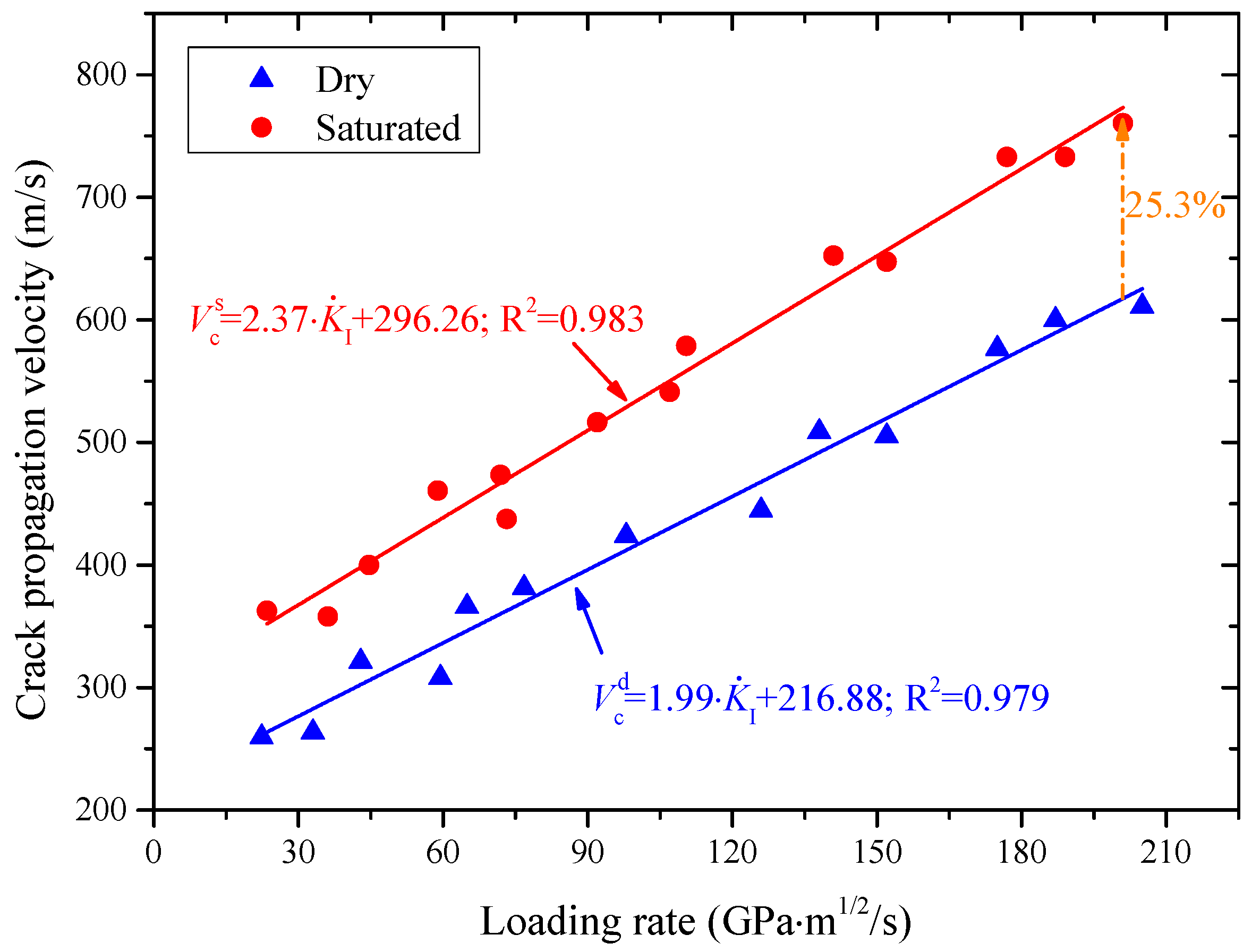

3.4. Quantification of Crack Growth Rate Based on DIC

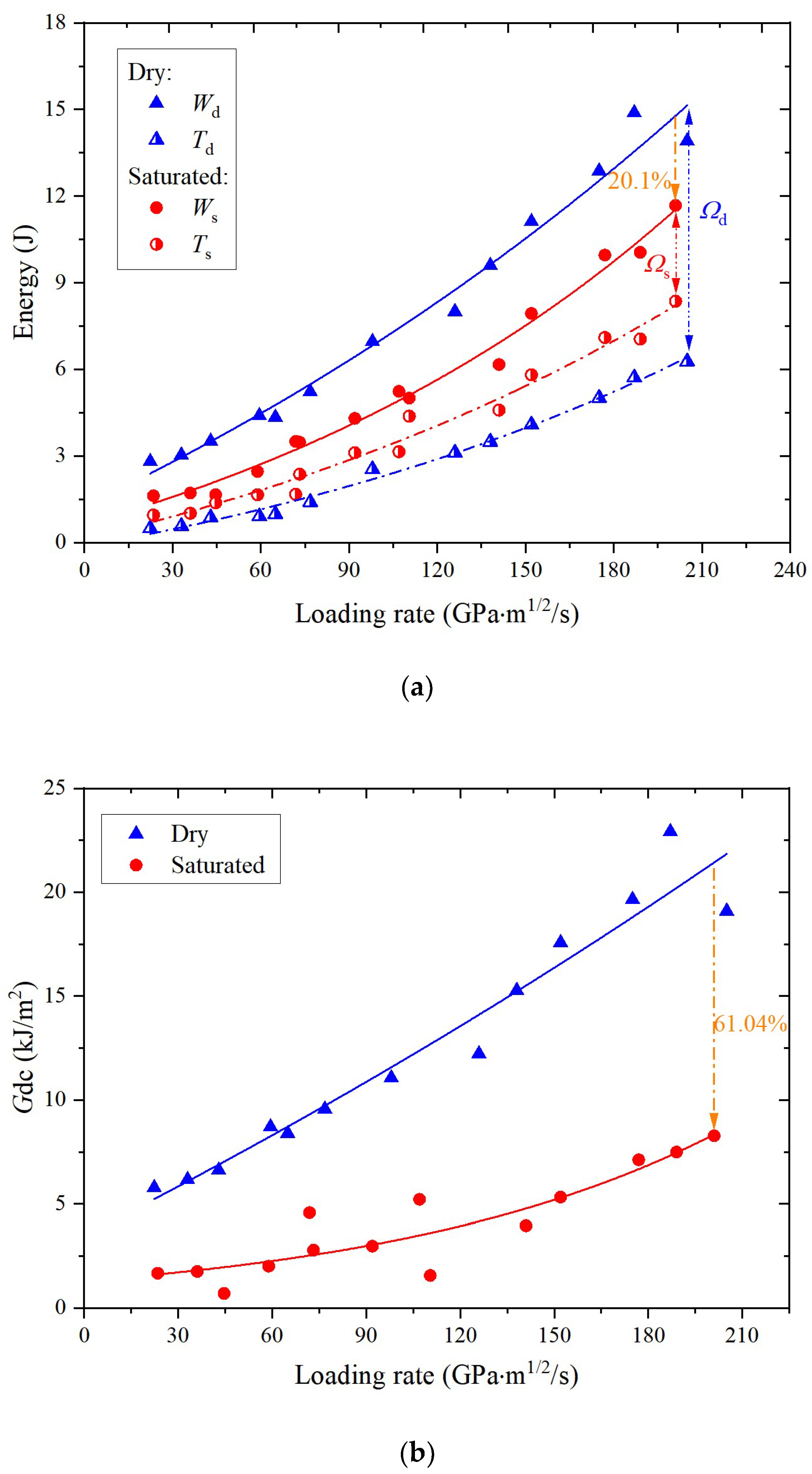

3.5. Energy Dissipation Characteristics of Dynamic Fracture

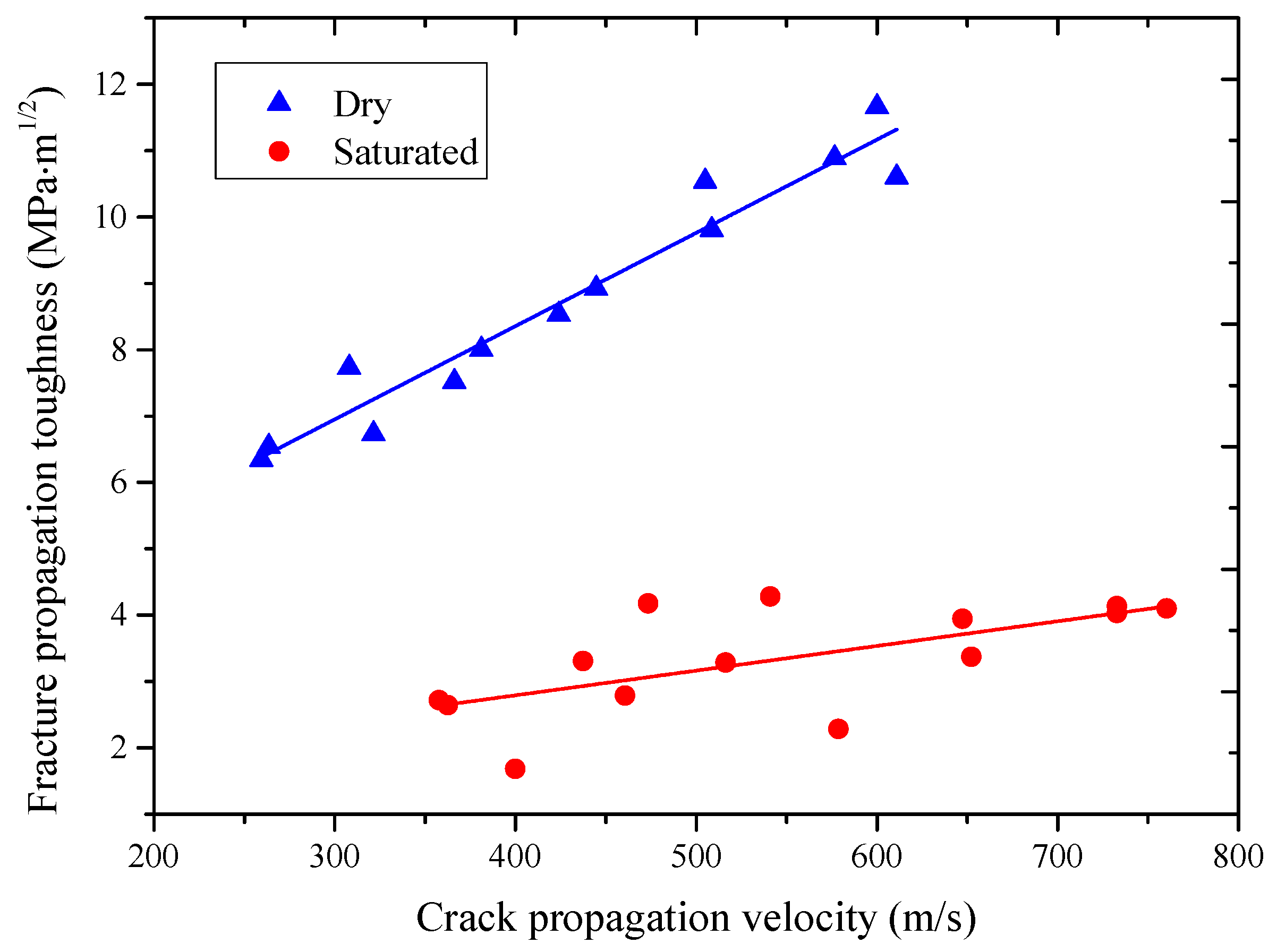

3.6. Dynamic Fracture Propagation Toughness

4. Discussion

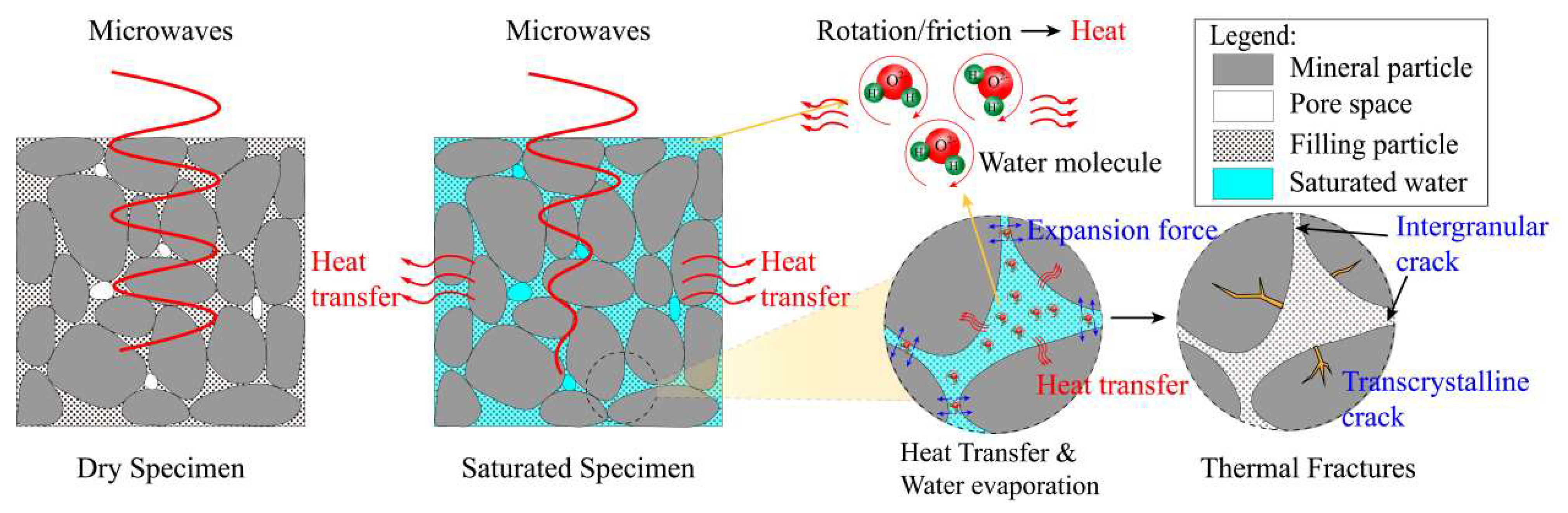

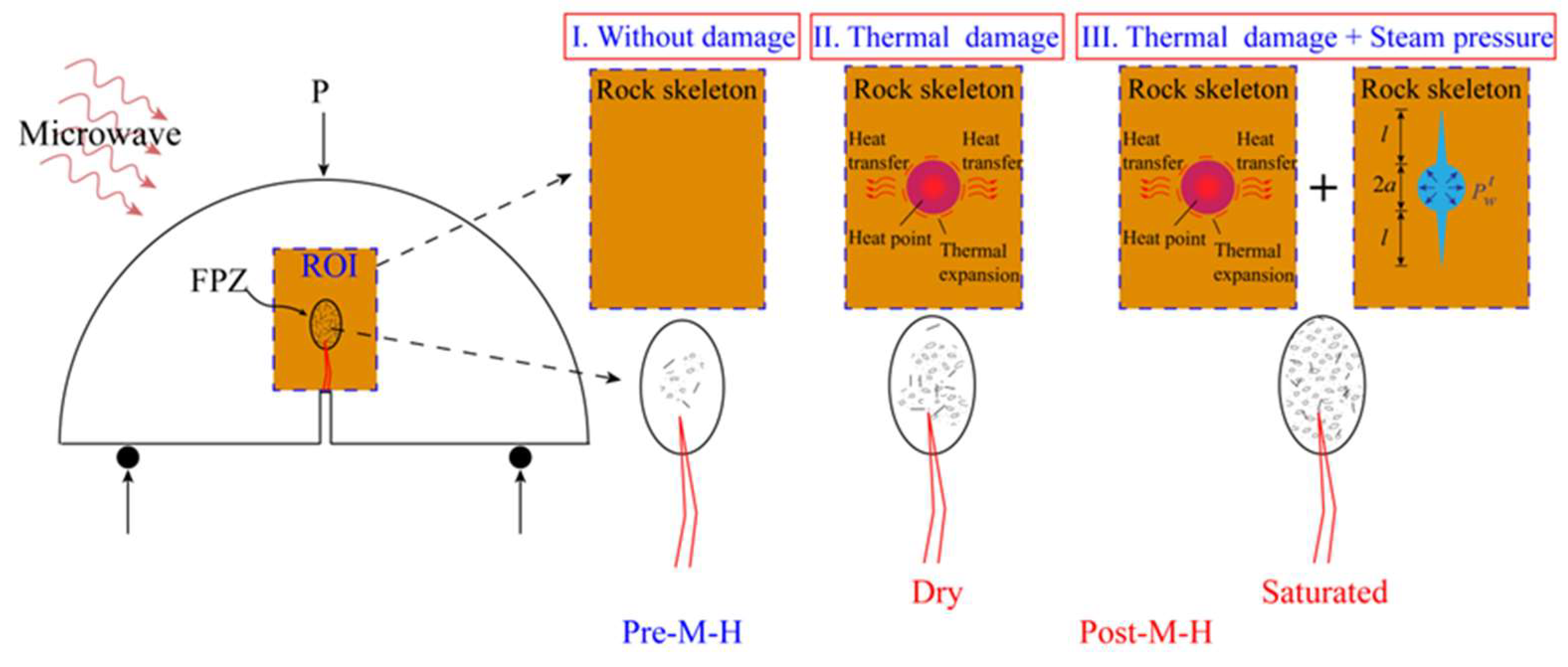

4.1. Water-Weakening Mechanisms in Microwave-Assisted Rock Breaking

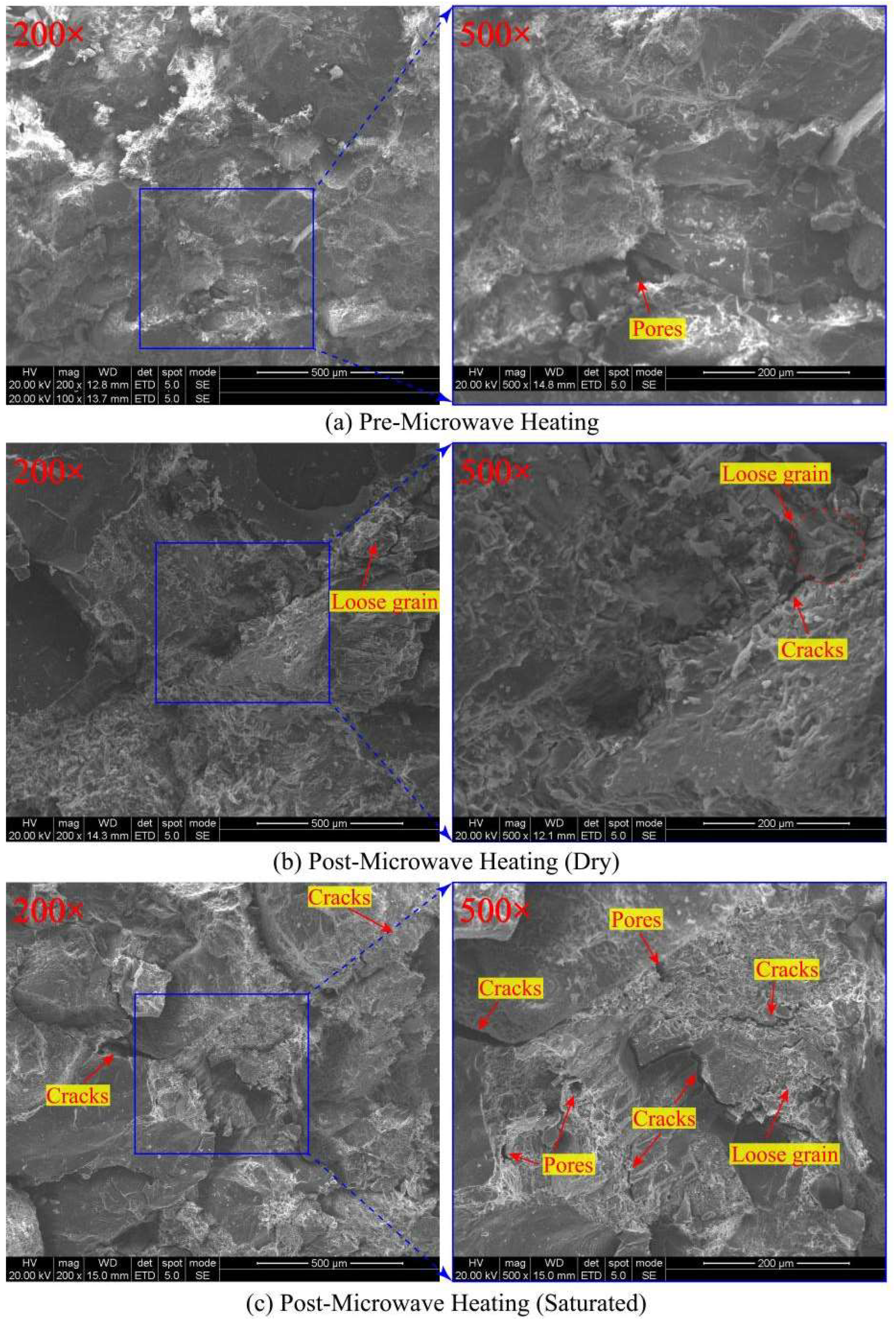

4.2. Microcrack Extension in Sandstone Microwave Damage

- (1)

- The presence of pore water within sandstone enhances the rock’s dielectric properties, resulting in a higher heating rate under microwave radiation. Moreover, under the same microwave radiation conditions, sandstone can reach higher temperatures. The combination of high temperature and thermal shock leads to significant thermal damage within the sandstone.

- (2)

- Under microwave rapid heating conditions, pore water undergoes a phase transition and quickly transforms into steam, forming a binary gas mixture consisting of water vapor and air within the pores. Due to the constraint imposed by the pore size on the volumetric expansion of water molecules, expansion pressure is generated and exerted on the inner surfaces of the pores. This pressure leads to the development of additional pores within the rock structure and causes existing microcracks to expand and coalesce. Since the size of the FPZ in rocks is proportional to the density of microcracks, microwave irradiation results in a significant increase in FPZ size in saturated sandstone. This increase is more pronounced compared to that observed in dry sandstone samples. Consequently, the dynamic fracture toughness of saturated sandstone after microwave treatment is considerably lower than that of its dry counterpart.

4.3. Limitations and Future Research Perspectives

- (1)

- The NSCB semi-circular sandstone specimens used in the experiment were small in size, which facilitated laboratory control and observation. However, their thermal conductivity and crack propagation behavior differed in scale from those of large rock masses in the field. Therefore, caution should be exercised when extrapolating the conclusions to the engineering scale.

- (2)

- Most of the studies on the response of rocks to microwave radiation have been carried out using multimode cavity microwave ovens. Compared with single-mode-cavity microwave ovens, multimode-cavity microwave ovens have the advantages of uniform heating, high energy utilization, and no risk of microwave leakage, but they have relatively low power densities and are only suitable for laboratory studies. Therefore, after fully understanding the destructive behavior of microwave irradiation on small-sized rock samples, it is necessary to use high-power single-mode-cavity microwave equipment to conduct surface radiation tests on large-sized rock bodies, thus shifting the laboratory research to field tests.

- (3)

- In engineering practice, it is sometimes necessary to simultaneously employ mechanical cutting and microwave irradiation to achieve continuous excavation in underground engineering and tunneling operations. Consequently, further research on the dynamic mechanical properties of rocks under real-time microwave heating conditions remains essential. Additionally, addressing the issue of preventing microwave leakage during shock loading is a critical problem that must be resolved first.

- (4)

- Microwave radiation is a multi-field coupled heating process influenced by electromagnetic, temperature, stress, and mass transfer fields. It is necessary to analyze the mechanical behavior of rocks under microwave radiation by the finite element or discrete element method to determine the relationship between the microwave-induced temperature distribution, thermal stress, and fracture density.

5. Conclusions

- (1)

- The heating rate of saturated sandstone samples under microwave radiation is significantly higher than that of dry sandstone. And, with the passage of microwave radiation time, the heating process of dry sandstone samples increases approximately linearly, while the heating rate of saturated sandstone samples slows down after 300 s of irradiation time.

- (2)

- The initiation toughness of sandstone exhibits significant loading rate dependence. The fracture toughness of saturated sandstone after microwave radiation is significantly lower than that of dry samples. This indicates that pore water plays a positive role in microwave weakening of rock fracture toughness.

- (3)

- The crack propagation speed of the saturated samples was significantly higher than that of the dry samples under the same loading rate condition, and the loading rate sensitivity of the crack propagation speed of the saturated samples was also higher. When the loading rate was 200 GPa·m1/2/s, the crack extension rate of microwave-irradiated saturated sandstone samples increased by 25.3% relative to that of dry samples.

- (4)

- The dynamic fracture extension toughness and fracture energy of the saturated sandstone specimens were smaller than those of the dry specimens after microwave radiation, which indicated that the saturated sandstone’s ability to resist crack extension was reduced after microwave radiation, and the rock was more susceptible to low stress fracture and rapid failure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| NSCB | notched semi-circular bend |

| SHPB | split Hopkinson pressure bar |

| TBM | tunnel boring machine |

| FPZ | fracture process zone |

| DIC | digital image correlation |

| ROI | region of interest |

| COD | crack opening displacement |

| SEM | scanning electron microscope |

References

- Gu, D.S.; Li, X.B. Modern Science and Technology for Metal Deposit Mining; Metallurgical Industry Press: Beijing, China, 2006. [Google Scholar]

- Wang, Y.M. Opportunities and challenges to metal mine mining industry and the technical countermeasures. Mod. Min. 2011, 27, 1–14. (In Chinese) [Google Scholar] [CrossRef]

- Li, X.B.; Cao, Z.W.; Zhou, J.; Huang, L.Q.; Wang, S.F.; Yao, J.R.; He, Z.G.; Ma, C.D.; Dong, L.J.; Zhao, G.Y. Innovation of hard rock mining methods and construction of intelligent green mines: A case study of kai yang phosphate mine. Chin. J. Nonferrous Met. 2019, 29, 2364–2380. (In Chinese) [Google Scholar] [CrossRef]

- Li, X.B.; Huang, L.Q.; Zhou, J.; Wang, S.F.; Ma, C.D.; Chen, J.Z.; Liu, Z.X.; Li, Q.Y.; Zhao, G.Y. Review and prospect of mining technology in hard rock mines. Chin. J. Nonferrous Met. 2019, 29, 1828–1847. (In Chinese) [Google Scholar] [CrossRef]

- Li, X.B.; Yao, J.R.; Du, K. Innovation of mining models and construction of intelligent green mine in hard rock mine: In Kai yang Phosphate Mine as an example. Chin. J. Rock Mech. En. 2013, 32, 1101–1111. (In Chinese) [Google Scholar] [CrossRef]

- Xie, H.P.; Gao, F.; Ju, Y. Research and development of rock mechanics in deep ground engineering. Chin. J. Rock Mech. En. 2015, 34, 2161–2178. (In Chinese) [Google Scholar] [CrossRef]

- He, M.C.; Xie, H.P.; Peng, S.P.; Jiang, Y.D. Research on deep mining rock mechanics and engineering disaster control. Coal Mine Support 2007, 3, 1–14. (In Chinese) [Google Scholar]

- Yao, J.R.; Li, X.B.; Sun, L.C.; Wang, M.; Yao, H.; Wang, Q.P.; Li, W.P.; Wang, S.F. Non-explosive mechanized mining of deep hard ore by using high-frequency crushing hammer. Met. Mine 2021, 50, 27–33. (In Chinese) [Google Scholar] [CrossRef]

- Xia, Y.M.; Zhang, K.; Liu, J.S. Design optimization of TBM disc cutters for different geological conditions. World J. Text Eng. Technol. 2015, 3, 218–231. [Google Scholar] [CrossRef]

- Rostami, J. Performance prediction of hard rock Tunnel Boring Machines (TBMs) in difficult ground. Tunn. Undergr. Sp. Tech. 2016, 57, 173–182. [Google Scholar] [CrossRef]

- Ciccu, R.; Grosso, B. Improvement of disc cutter performance by water jet assistance. Rock Mech. Rock Eng. 2014, 47, 733–744. [Google Scholar] [CrossRef]

- Kocis, I.; Kristofic, T.; Gajdos, M.; Horvath, G.; Jankovic, S. Utilization of electrical plasma for hard rock drilling and casing milling. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, London, UK, 17–19 March 2015. [Google Scholar] [CrossRef]

- Shi, X.M.; Duan, Y.L.; Han, B.; Zhao, J. Enhanced rock breakage by pulsed laser induced cavitation bubbles: Preliminary experimental observations and conclusion. Geomech. Geophys. Geo Energ. Geo Res. 2020, 6, 25. [Google Scholar] [CrossRef]

- Kahraman, S.; Canpolat, A.N.; Fener, M. The influence of microwave treatment on the compressive and tensile strength of igneous rocks. Int. J. Rock Mec. Min. Sci. 2020, 129, 104303. [Google Scholar] [CrossRef]

- Zheng, Y.L.; Zhang, Q.B.; Zhao, J. Challenges and opportunities of using tunnel boring machines in mining. Tunn. Undergr. Sp. Tech. 2016, 57, 287–299. [Google Scholar] [CrossRef]

- Aydin, G.; Karakurt, I.; Aydiner, K. Wear performance of saw blades in processing of granitic rocks and development of models for wear estimation. Rock Mech. Rock Eng. 2013, 46, 1559–1575. [Google Scholar] [CrossRef]

- Lu, G.M.; Zhou, J.J.; Li, Y.H.; Zhang, X.W.; Gao, W.Y. The influence of minerals on the mechanism of microwave-induced fracturing of rocks. J. Appl. Geophys. 2020, 180, 104123. [Google Scholar] [CrossRef]

- Zhao, Q.H.; Zhao, X.B.; Zheng, Y.L.; Li, J.C.; He, J.L.; Zou, C.J. Heating characteristics of igneous rock-forming minerals under microwave irradiation. Int. J. Rock Mech. Min. 2020, 135, 104519. [Google Scholar] [CrossRef]

- Hu, J.J.; Xie, H.P.; Sun, Q.; Li, C.B.; Liu, G.K. Changes in the thermodynamic properties of alkaline granite after cyclic quenching following high temperature action. Int. J. Min. Sci. Technol. 2021, 31, 843–852. [Google Scholar] [CrossRef]

- Hu, J.J.; Xie, H.P.; Gao, M.Z.; Li, C.B.; Sun, Q. Damage mechanism and heat transfer characteristics of limestone after thermal shock cycle treatments based on geothermal development. Int. J. Rock Mech. Min. Sci. 2022, 160, 105269. [Google Scholar] [CrossRef]

- Hartlieb, P.; Leindl, M.; Kuchar, F.; Antretter, T.; Moser, P. Damage of basalt induced by microwave irradiation. Miner. Eng. 2012, 31, 82–89. [Google Scholar] [CrossRef]

- Ge, Z.L.; Sun, Q.; Hu, J.J.; Guan, Y.H.; Liu, W.; Wang, S.F.; Geng, J.S. Fracture characteristics and thermal damage mechanism of shale under microwave radiation. J. Therm. Anal. Calorim. 2024, 149, 13147–13160. [Google Scholar] [CrossRef]

- Ge, Z.L.; Sun, Q.; Xue, L.; Yang, T. The influence of microwave treatment on the mode I fracture toughness of granite. Eng. Fract. Mech. 2021, 249, 107768. [Google Scholar] [CrossRef]

- Bai, G.G.; Sun, Q.; Jia, H.L.; Ge, Z.L.; Li, P.F. Variations in fracture toughness of SCB granite influenced by microwave heating. Eng. Fract. Mech. 2021, 258, 108048. [Google Scholar] [CrossRef]

- Hassani, F.; Nekoovaght, P.M.; Gharib, N. The influence of microwave irradiation on rocks for microwave-assisted underground excavation. J. Rock Mech. Geotech. Eng. 2016, 8, 1–15. [Google Scholar] [CrossRef]

- Zhou, Z.L.; Cai, X.; Ma, D.; Cao, W.Z.; Chen, L.; Zhou, J. Effects of water content on fracture and mechanical behavior of sandstone with a low clay mineral content. Eng. Fract. Mech. 2018, 193, 47–65. [Google Scholar] [CrossRef]

- Lu, G.M.; Feng, X.T.; Li, Y.H.; Hassani, F.; Zhang, X.W. Experimental investigation on the effects of microwave treatment on basalt heating, mechanical strength, and fragmentation. Rock Mech. Rock Eng. 2019, 52, 2535–2549. [Google Scholar] [CrossRef]

- Dai, J.; Du, W.P.; Wu, T. Experimental study of rock fracture after microwave irradiation and impact load. J. Henan Polytech. Univ. Nat. Sci. 2016, 35, 420–423. (In Chinese) [Google Scholar] [CrossRef]

- Dai, J.; Pan, Y.B.; Meng, Z. Experimental study on influential factors of rock strength weakening under microwave irradiation. J. Xi’an Univ. Sci. Technol. 2016, 36, 364–368. (In Chinese) [Google Scholar] [CrossRef]

- Hartlieb, P.; Toifl, M.; Kuchar, F.; Meisels, R.; Antretter, T. Thermo-physical properties of selected hard rocks and their relation to microwave-assisted comminution. Miner. Eng. 2015, 91, 34–41. [Google Scholar] [CrossRef]

- Qin, L.; Dai, J.; Teng, P. Study on the effect of microwave irradiation on rock strength. J. Eng. Sci. Technol. Rev. 2015, 8, 91–96. [Google Scholar] [CrossRef]

- Xia, K.W.; Wang, Z.; Wu, B.B.; Xu, Y.; Yue, T.L. Research progress on dynamic response of deep rocks under coupled hydraulic-mechanical loading. J. China Coal Soc. 2024, 49, 454–478. (In Chinese) [Google Scholar] [CrossRef]

- Satish, H.; Ouellet, J.; Raghavan, V.; Radziszewski, P. Investigating microwave assisted rock breakage for possible space mining applications. Min. Technol. 2006, 115, 34–40. [Google Scholar] [CrossRef]

- Li, X.; Wang, S.; Xu, Y.; Yao, W.; Xia, K.W.; Lu, G.M. Effect of microwave irradiation on dynamic mode-I fracture parameters of Barre granite. Eng. Fract. Mech. 2020, 224, 106748. [Google Scholar] [CrossRef]

- Jia, H.L.; Wang, T.; Xiang, W.; Tan, L.; Shen, Y.J.; Yang, G.S. Influence of water content on the physical and mechanical behaviour of argillac-eous siltstone and some microscopic explanations. Chin. J. Rock Mech. En. 2018, 37, 1618–1628. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, E.F.; Yang, G.S.; Tang, L.Y.; Yang, Q.; Xie, Z.W. Study on influence of water content to damage and degradation laws of argillaceous siltstone. Coal Sci. Technol. 2019, 47, 14–20. (In Chinese) [Google Scholar] [CrossRef]

- Zhao, K.; Ran, S.H.; Zeng, P.; Yang, D.X.; Teng, T.Y. Effect of moisture content on characteristic stress and acoustic emission characteristics of red sandstone. Rock Soil Mech. 2021, 42, 899–908. (In Chinese) [Google Scholar] [CrossRef]

- Dai, J.; Wang, Y.L.; Huang, B.B.; Wang, Y.P.; Li, H. Experimental study on the effect of water on the degradation of hard rock under microwave irradiation. Chin. J. Undergr. Sp. Eng. 2020, 16, 691–696. (In Chinese) [Google Scholar]

- Peinsitt, T.; Kuchar, F.; Hartlieb, P.; Moser, P.; Kargl, H.; Restner, U.; Sifferlinger, N. Microwave heating of dry and water saturated basalt, granite and sandstone. Int. J. Min. Miner. Eng. 2010, 2, 18–29. [Google Scholar] [CrossRef]

- Deng, H.F.; Li, J.L.; Wang, K.W.; Liu, J.; Zhu, M.; Lu, T. Research on secondary porosity changing law of sandstone under saturation-air dry cycles. Rock Soil Mech. 2012, 33, 483–488. (In Chinese) [Google Scholar] [CrossRef]

- Li, H.G.; Li, H.M.; Xu, G.S. Influence of water content on mechanical characteristics of weakly cemented sandstone. J. Min. Strata Control Eng. J. 2021, 3, 043029. (In Chinese) [Google Scholar] [CrossRef]

- Wang, L. Fundamentals of Stress Wave; National Defense Industry Press: Beijing, China, 2005. (In Chinese) [Google Scholar]

- Zhang, Q.B.; Zhao, J. Quasi-static and dynamic fracture behaviour of rock materials: Phenomena and mechanisms. Int. J. Fract. 2014, 189, 1–32. [Google Scholar] [CrossRef]

- Zhou, Z.L.; Cai, X.; Ma, D.; Du, X.M.; Chen, L.; Wang, H.Q.; Zang, H.Z. Water saturation effects on dynamic fracture behavior of sandstone. Int. J. Rock Mech. Min. Sci. 2019, 114, 46–61. [Google Scholar] [CrossRef]

- Chen, R.; Xia, K.; Dai, F.; Lu, F.; Luo, S.N. Determination of dynamic fracture parameters using a semi-circular bend technique in split Hopkinson pressure bar testing. Eng. Fract. Mech. 2009, 76, 1268–1276. [Google Scholar] [CrossRef]

- Kuruppu, M.D.; Obara, Y.; Ayatollahi, M.R.; Chong, K.P.; Funatsu, T. ISRM-suggested method for determining the mode I static fracture toughness using semi-circular bend specimen. Rock Mech. Rock Eng. 2014, 47, 267–274. [Google Scholar] [CrossRef]

- Zhu, Q.Q.; Ma, C.; Li, X.B.; Li, D.Y. Effect of filling on failure characteristics of diorite with double rectangular holes under coupled static-dynamic loads. Rock Mech. Rock Eng. 2021, 54, 2741–2761. [Google Scholar] [CrossRef]

- Sutton, M.A.; Orteu, J.; Schreier, H. Image Correlation for Shape, Motion and Deformation Measurements; Springer: New York, NY, USA, 2009. [Google Scholar] [CrossRef]

- Ping, Q.; Luo, X.; Ma, Q.Y.; Yuan, P. Broken energy dissipation characteristics of sandstone specimens under impact loads. Chin. J. Rock Mech. Eng. 2015, 34 (Suppl. S2), 4197. (In Chinese) [Google Scholar] [CrossRef]

- Wen, S.; Zhao, X.W.; Chang, Y.L.; Li, B. Energy dissipation of dynamic failure of mixed rock specimens subject to SHPB compression. J. Basic Sci. Eng. 2021, 29, 483–492. (In Chinese) [Google Scholar] [CrossRef]

- Chen, P.Y.; Zhao, F.J.; Chen, B.; Tian, X.Y. Energy dissipation characteristics of prefabricated fractured rock under impact load. Miner. Eng. Res. 2021, 36, 17–23. (In Chinese) [Google Scholar] [CrossRef]

- Hu, J.; Gong, F.Q.; Jia, H.Y. Research on mechanical and energy dissipation characteristics of red sandstone in SHPB compression test. Gold Sci. Technol. 2020, 28, 411–420. (In Chinese) [Google Scholar] [CrossRef]

- Wang, M.X.; Wang, H.B.; Zong, Q. Experimental study on energy dissipation of mudstone in coal mine under impact loading. J. China Coal Soc. 2019, 44, 1716–1725. (In Chinese) [Google Scholar] [CrossRef]

- Gao, F.; Yang, G.; Xiong, X.; Zhou, K.P.; Cong, L.; Li, J.L. Experimental study on the dynamic mechanical characteristics of slope rock under low-temperature conditions. Chin. J. Eng. 2023, 45, 171–181. (In Chinese) [Google Scholar] [CrossRef]

- Ping, Q.; Ma, Q.Y.; Yuan, P. Energy dissipation analysis of stone specimens in SHPB tensile test. J. Min. Saf. Eng. 2013, 30, 401–407. (In Chinese) [Google Scholar]

- Sun, Y.J.; Qi, C.Z.; Zhu, H.T.; Guo, Y.P.; Wang, Y.Q. Energy analysis on rock dynamic fracture process. Chin. J. Undergr. Sp. Eng. 2020, 16, 43–49. (In Chinese) [Google Scholar]

- Ravi-Chandar, K. Dynamic Fracture; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar] [CrossRef]

| ρ (kg·m−3) | P (%) | CP (m·s−1) | CS (m·s−1) | KIC (MPa·m1/2) | E (GPa) | v | |

|---|---|---|---|---|---|---|---|

| Mean values | 2336.2 | 13.3 | 2521.3 | 1362.9 | 0.71 | 6.47 | 0.28 |

| Standard deviation | ±2.17 | ±0.25 | ±37.5 | ±13.36 | ±0.06 | ±0.19 | ±0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Lin, Y.; Chen, D.; Yin, T. Dynamic Mode I Fracture Toughness and Damage Mechanism of Dry and Saturated Sandstone Subject to Microwave Radiation. Appl. Sci. 2025, 15, 9500. https://doi.org/10.3390/app15179500

Wang P, Lin Y, Chen D, Yin T. Dynamic Mode I Fracture Toughness and Damage Mechanism of Dry and Saturated Sandstone Subject to Microwave Radiation. Applied Sciences. 2025; 15(17):9500. https://doi.org/10.3390/app15179500

Chicago/Turabian StyleWang, Pin, Yinqi Lin, Duo Chen, and Tubing Yin. 2025. "Dynamic Mode I Fracture Toughness and Damage Mechanism of Dry and Saturated Sandstone Subject to Microwave Radiation" Applied Sciences 15, no. 17: 9500. https://doi.org/10.3390/app15179500

APA StyleWang, P., Lin, Y., Chen, D., & Yin, T. (2025). Dynamic Mode I Fracture Toughness and Damage Mechanism of Dry and Saturated Sandstone Subject to Microwave Radiation. Applied Sciences, 15(17), 9500. https://doi.org/10.3390/app15179500