The Characterization of Commercial and Historical Textiles Using a Combination of Micro-Chemical, Microscopic and Infrared Spectroscopic Methods

Abstract

1. Introduction

2. Background: Established Methods for Analysis of Natural and Artificial Textile Materials

2.1. Feeling Test

2.2. Burning and Solubility Tests

2.3. Micro-Chemical Tests

2.4. Optical Microscopy

2.5. Scanning Electron Microscopy

2.6. IR Spectroscopy

3. Materials and Methods

4. Results

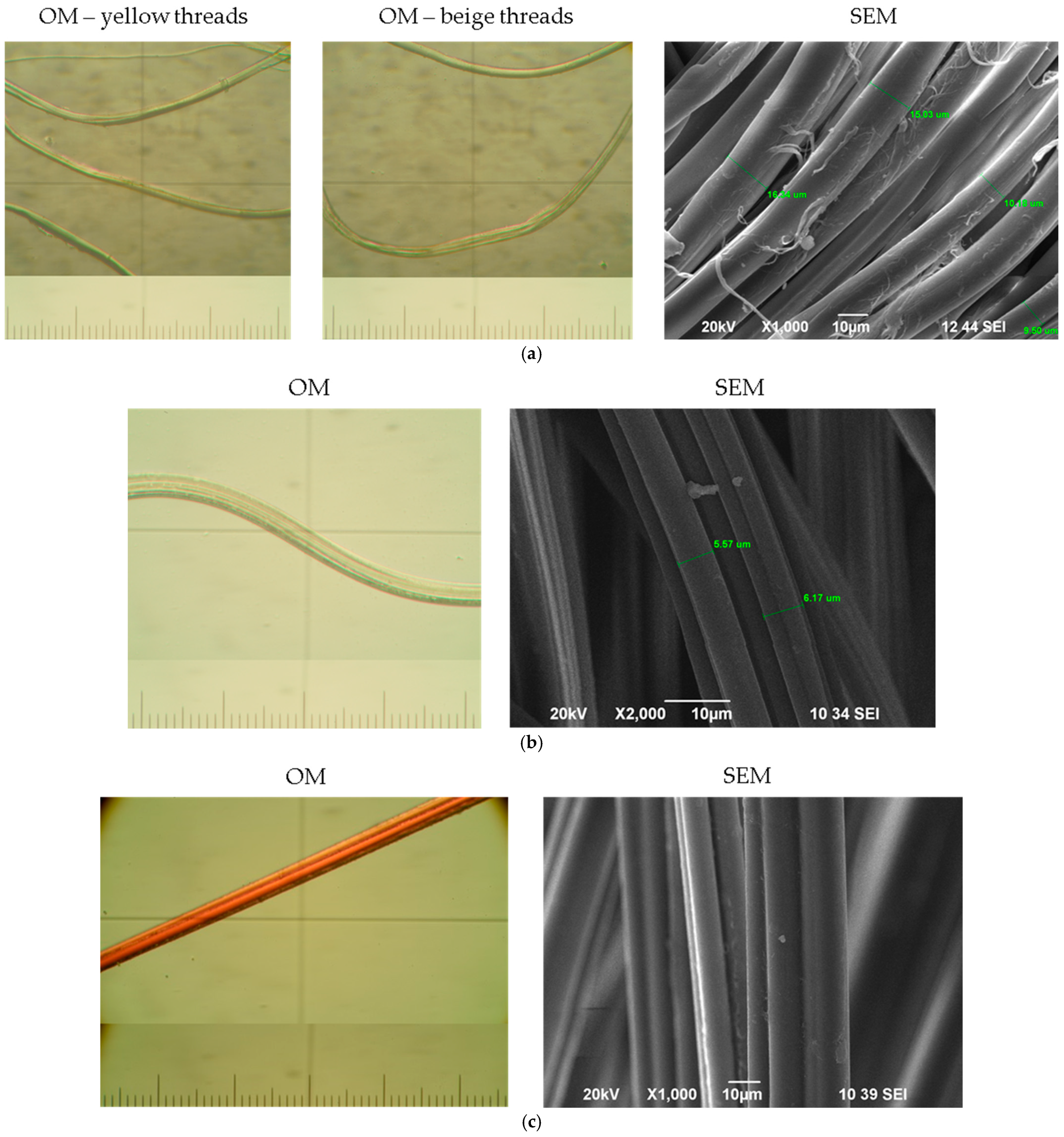

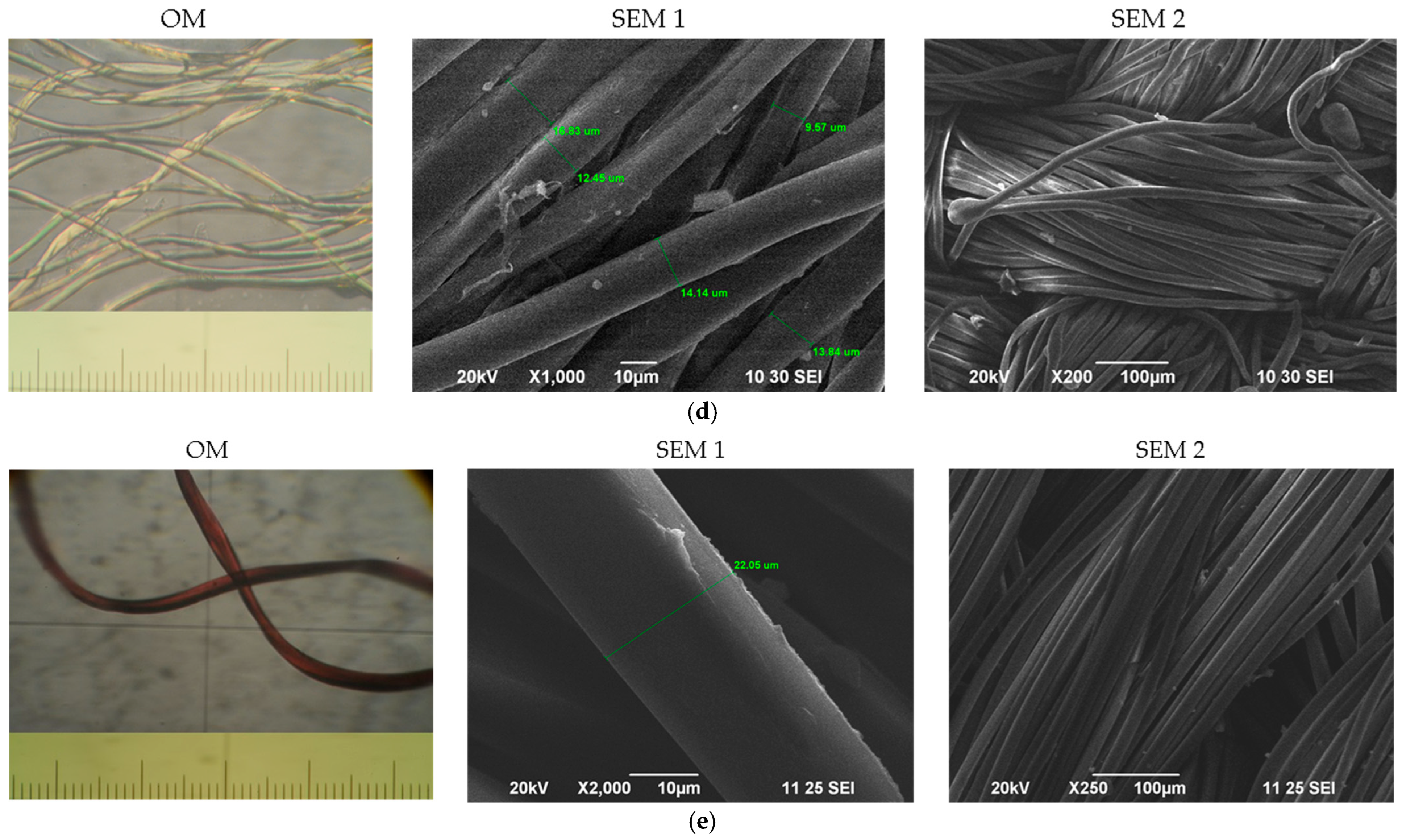

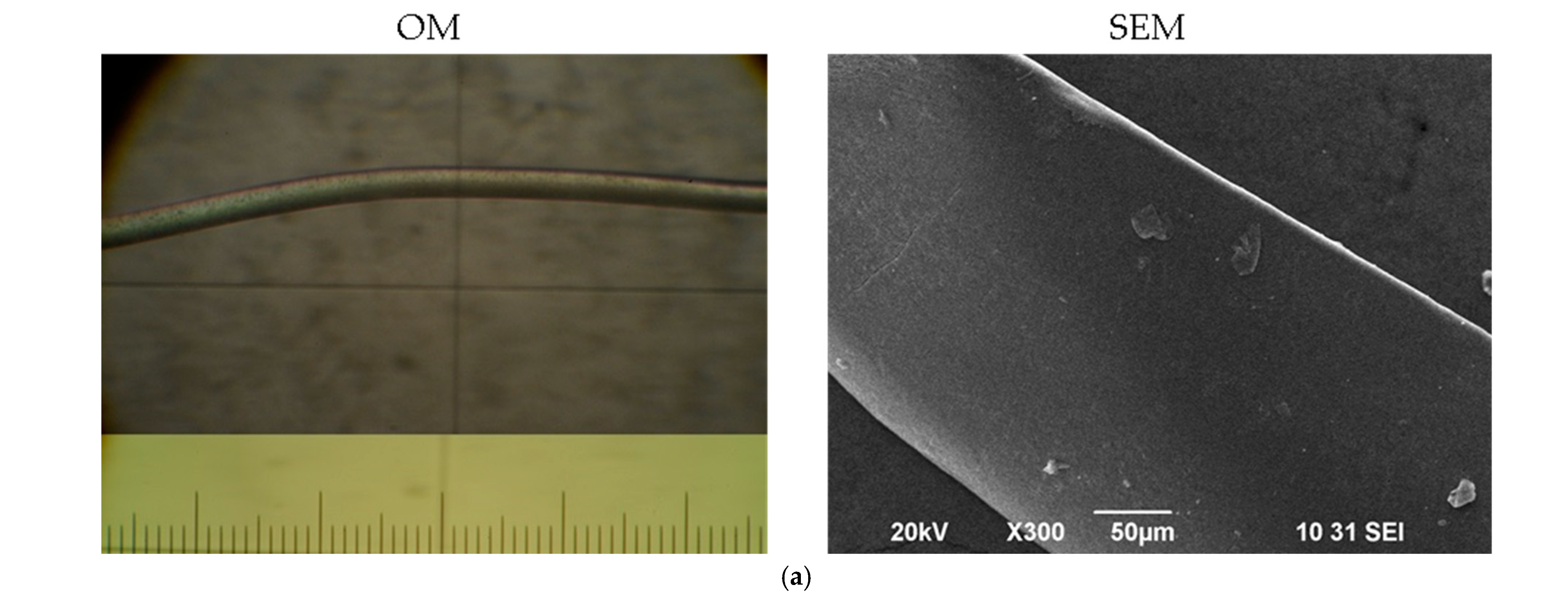

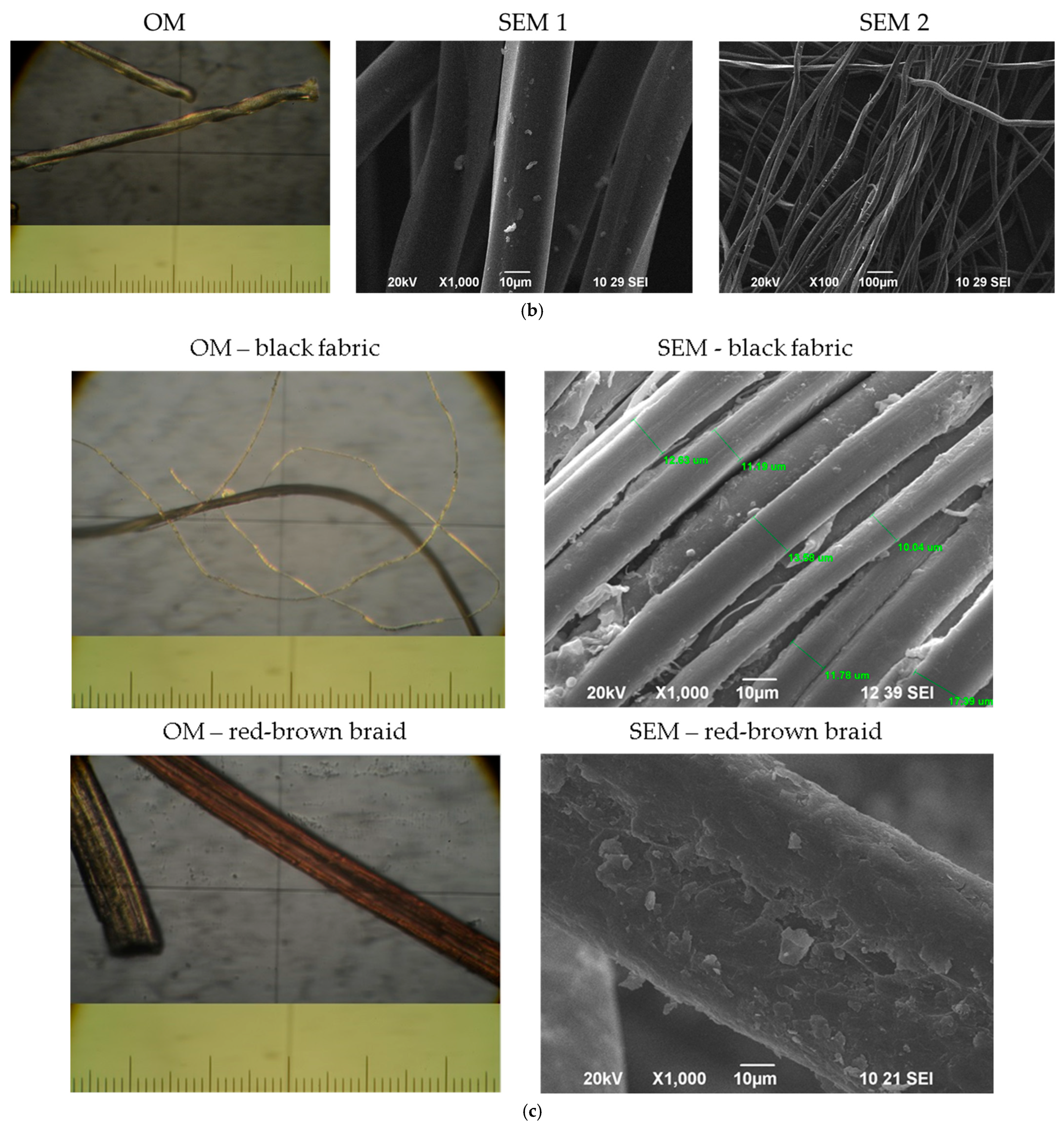

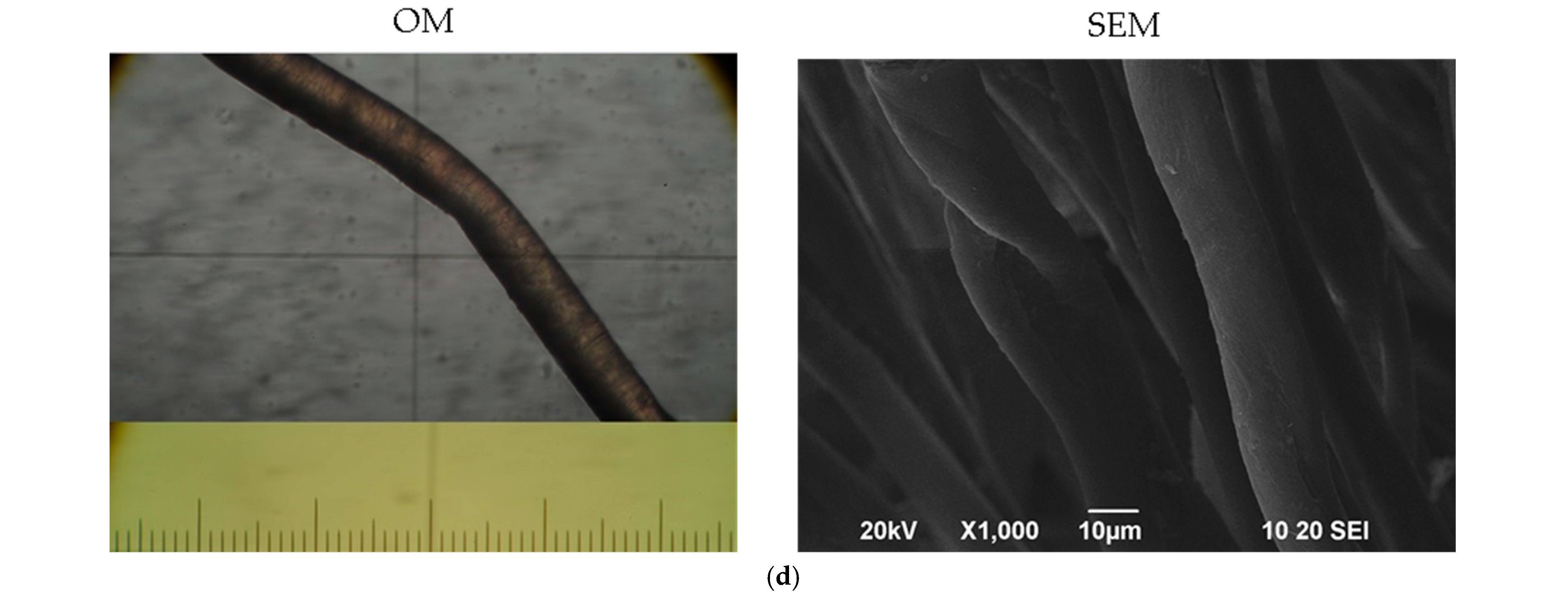

4.1. Optical Microscopy and SEM-EDS Analysis

4.2. Solubility Testing

4.3. Micro-Chemical Testing

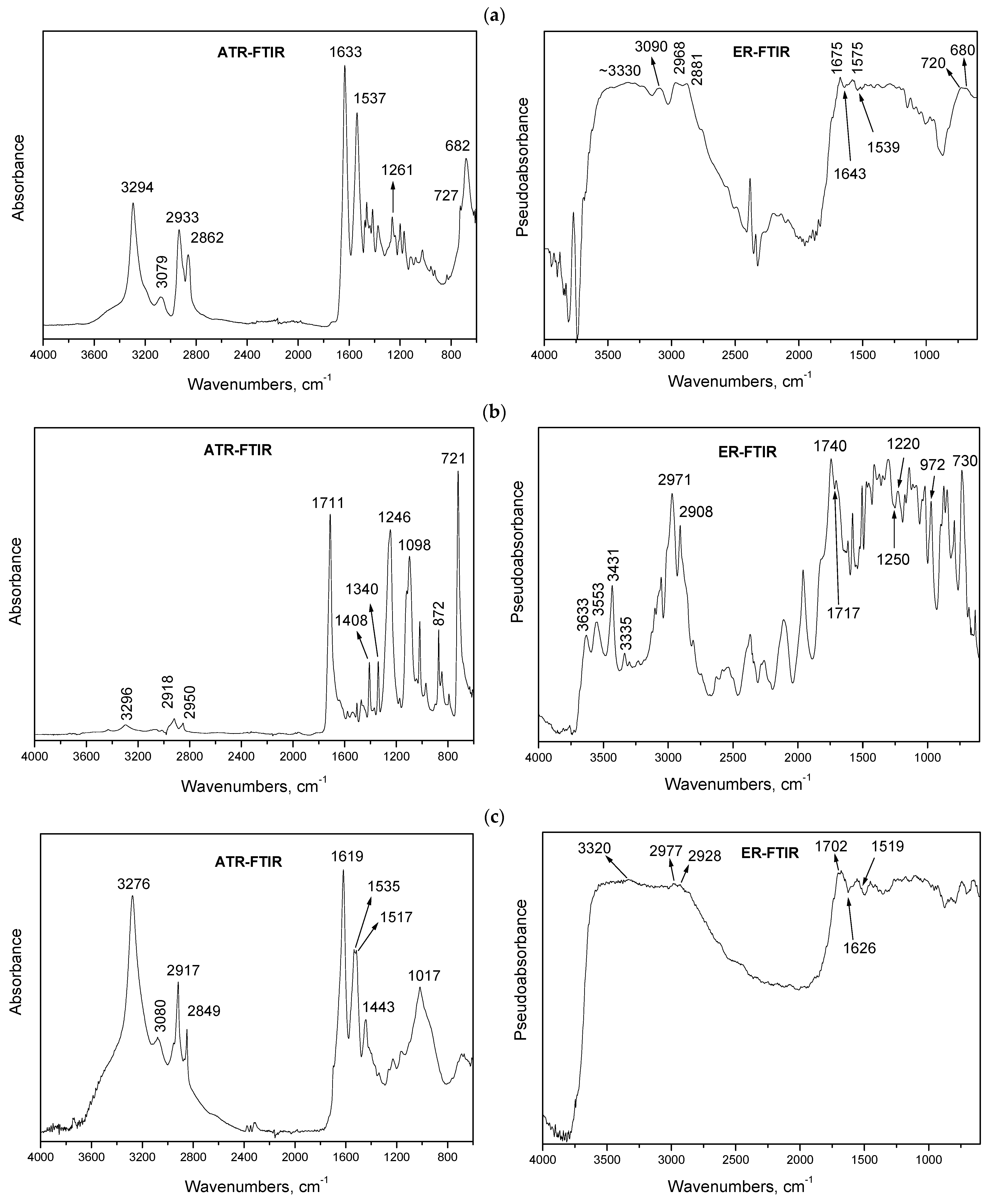

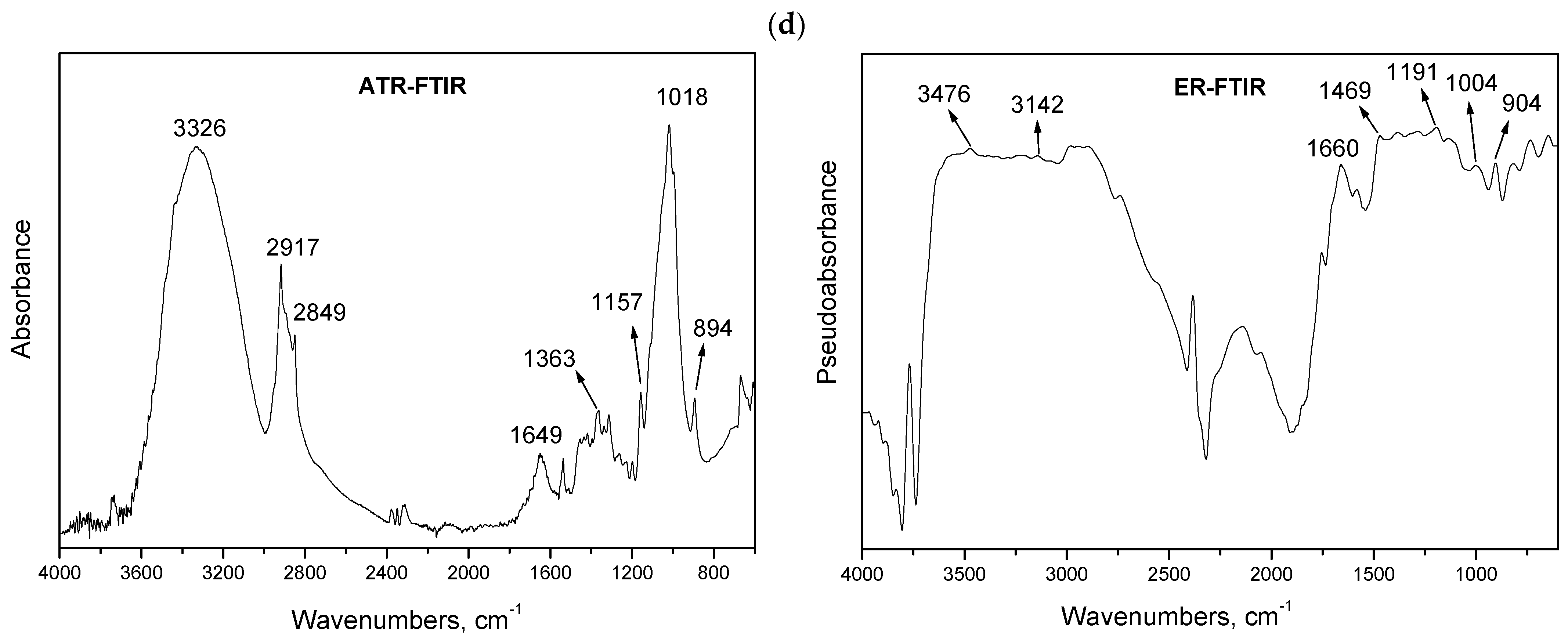

4.4. IR Measurements

5. Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| OM | Optical microscopy |

| SEM | Scanning electron microscopy |

| EDS | Energy-dispersive X-ray spectroscopy |

| FTIR | Fourier transform infrared |

| ATR | Attenuated total reflectance |

| ER | External reflectance |

| IR | Infrared |

References

- Kazlacheva, Z.; Ilieva, J.; Dineva, P.; Stoykova, V.; Zlatev, Z. Digital Color Images as a Tool for the Sustainable Use of Embroidery Elements from Folk Costumes. Heritage 2023, 6, 5750–5778. [Google Scholar] [CrossRef]

- Veleva, M.G.; Blagoeva, S.D. Bulgarian National Costumes and Folk Jewellery; Septemvri: Sofia, Bulgaria, 1983. [Google Scholar]

- Ganeva, P. Bulgarian Folk Costumes, Symbols and Traditions. Bulg. Dipl. Rev. 2003, 3, 1–321. [Google Scholar]

- Komitska, A.; Borisova, V. Bulgarian Folk Costumes; Borika: Sofia, Bulgaria, 2000. [Google Scholar]

- Cherkezova, M. Women’s Bulgarian National Costumes; Nikolov, K., Ed.; Septemvri: Sofia, Bulgaria, 1981. [Google Scholar]

- Available online: https://www.omda.bg/public/engl/ethnography/female_costumes_en.htm (accessed on 25 August 2025).

- Garside, P. The role of fibre identification in textile conservation. In Identification of Textile Fibers; Max, M., Ed.; Houck Woodhead Publishing: Cambridge, UK, 2009; pp. 335–365. [Google Scholar]

- Schaffer, E. Fiber identification in ethnological textile artefacts. Stud. Conserv. 1981, 26, 119–129. [Google Scholar] [CrossRef]

- Toncheva, V. The Unknown Gora (Original Title: (Nepoznatata Gora); IIK Pod: Sofia, Bulgaria, 2012. [Google Scholar]

- Textile Coach, Identification of Textile Fibers. 2021. Available online: https://www.textilecoach.net/post/identification-of-textile-fibers (accessed on 25 August 2025).

- Khan, A.N.; Abir, N.; Rakib, M.A.N.; Bhuiyan, E.M.S.; Howlader, M.R. A Review Paper on Textile Fiber Identification. IOSR J. Polym. Textile Eng. 2017, 4, 14–20. [Google Scholar] [CrossRef]

- Committee on Paper Testing. Paper Testing Methods, 2nd ed.; Technical Association of the Pulp and Paper Industry: New York, NY, USA, 1924. [Google Scholar]

- Kostadinovska, M.; Spirovska, Z.J.; Taylor, T. A procedure for identifying cellulose fibers in paper artifacts. In Proceedings of the 4th International Virtual Conference on Advanced Scientific Results (SCIECONF-2016), Zilina, Slovakia, 6–10 June 2016; Mokrys, M., Badura, S., Eds.; EDIS: Zilina, Slovakia, 2016; pp. 156–162. [Google Scholar]

- Kostadinovska, M.; Spirovska, Z.J. Implementation of methods for examination of paper-based library materials. Vjesn. Bibl. Hrvat. 2015, 58, 119–133. [Google Scholar]

- Graff, H. Color Atlas for Fiber Identification; The Institute of Paper Chemistry: Appleton, WI, USA, 1940. [Google Scholar]

- Friedman, M. Applications of the Ninhydrin Reaction for Analysis of Amino Acids, Peptides, and Proteins to Agricultural and Biomedical Sciences. J. Agric. Food Chem. 2004, 52, 385–406. [Google Scholar] [CrossRef] [PubMed]

- Kerr, N. Advantages and Limitations of the Ninhydrin Test for Analysis of Historic Wool Fibers. MRS Online Proc. Libr. 1995, 352, 233–244. [Google Scholar] [CrossRef]

- McCrone, W.C. Polarised light microscopy in conservation: A personal perspective. J. Am. Inst. Conserv. 1994, 33, 101–114. [Google Scholar] [CrossRef]

- Peacock, E.E. Biodegradation and characterisation of water-degraded archaeological textiles created for conservation research. Int. Biodeterior. Biodegrad. 1996, 38, 49–59. [Google Scholar] [CrossRef]

- Perry, R. Identification of Textile Materials, 7th ed.; The Textile Institute: Manchester, UK, 1985. [Google Scholar]

- Ryder, M.L.; Gabra-Sanders, T. The application of microscopy to textile history. Text. Hist. 1985, 16, 123–140. [Google Scholar] [CrossRef]

- Lukesova, H.; Holst, B. Identifying plant fibres in cultural heritage with optical and electron microscopy: How to present results and avoid pitfalls. Herit. Sci. 2024, 12, 12. [Google Scholar] [CrossRef]

- Markova, I. Textile Fiber Microscopy—A Practical Approach; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2019. [Google Scholar]

- Coletti, F.; Romani, M.; Ceres, G.; Zammit, U.; Guidi, M.C. Evaluation of Microscopy Techniques and ATR-FTIR Spectroscopy on Textile Fibers from the Vesuvian Area: A Pilot Study on Degradation Processes That Prevent the Characterization of Bast Fibers. J. Archaeol. Sci. Rep. 2021, 36, 102794. [Google Scholar] [CrossRef]

- Luo, Y.; Wang, Y.; Zhang, X. A Combination of Techniques to Study Chinese Traditional Lajian Paper. J. Cult. Herit. 2019, 38, 75–81. [Google Scholar] [CrossRef]

- Bergfjord, C.; Holst, B. A Procedure for Identifying Textile Bast Fibres Using Microscopy: Flax, Nettle/Ramie, Hemp and Jute. Ultramicroscopy 2010, 110, 1192–1197. [Google Scholar] [CrossRef]

- Corti, C.; Motella De Carlo, S.; Rampazzi, L. The Intimate Soul of the Pyres: New Archaeological Data from the Terre di Rogo (Pyre Debris) of Pre-Roman Necropolis in Padua (Northern Italy). Heritage 2023, 6, 849–866. [Google Scholar] [CrossRef]

- Tamburini, D.; Dyer, J.; Cartwright, C.; Green, A. Changes in the production materials of Burmese textiles in the nineteenth century—Dyes, mordants and fibres of Karen garments from the British Museum’s collection. Herit. Sci. 2023, 11, 150–180. [Google Scholar] [CrossRef]

- Margariti, C. The application of FTIR microspectroscopy in a non-invasive and non-destructive way to the study and conservation of mineralised excavated textiles. Herit. Sci. 2019, 7, 63–76. [Google Scholar] [CrossRef]

- Peets, P.; Kaupmees, K.; Vahur, S.; Leito, I. Reflectance FT-IR spectroscopy as a viable option for textile fiber identification. Herit. Sci. 2019, 7, 93. [Google Scholar] [CrossRef]

- Akyuz, S.; Akyuz, T.; Cakan, B.; Basaran, S. Investigations of the historic textiles excavated from Ancient Ainos (Enez—Turkey) by multiple analytical techniques. J. Mol. Struct. 2014, 1073, 37–43. [Google Scholar] [CrossRef]

- Geminiani, L.; Campione, F.P.; Corti, C.; Luraschi, M.; Motella, S.; Recchia, S.; Rampazzi, L. Differentiating between Natural and Modified Cellulosic Fibres Using ATR-FTIR Spectroscopy. Heritage 2022, 5, 4114–4139. [Google Scholar] [CrossRef]

- Kavkler, K.; Gunde-Cimermann, N. FTIR Spectroscopy of Biodegraded Historical Textiles. Polym. Degrad. Stab. 2011, 96, 574–580. [Google Scholar] [CrossRef]

- Raditoiu, V.; Chican, I.E.; Raditoiu, A.; Fierascu, I.; Fierascu, R.C.; Fotea, P. Application of Fourier-Transform Infrared Spectroscopy (FTIR) for the Study of Cultural Heritage Artifacts. In Proceedings of the VR Technologies in Cultural Heritage, VRTCH 2018, Brasov, Romania, 29–30 May 2018; Duguleană, M., Carrozzino, M., Gams, M., Tanea, I., Eds.; Communications in Computer and Information Science. Springer: Cham, Switzerland, 2019; Volume 904. [Google Scholar]

- Petroviciu, I.; Teodorescu, I.; Albu, F.; Virgolici, M.; Nagoda, E.; Medvedovici, A. Dyes and biological sources in nineteenth to twentieth century ethnographic textiles from Transylvania, Romania. Herit. Sci. 2019, 7, 15–29. [Google Scholar] [CrossRef]

- Colantonio, C.; Lanteri, L.; Ciccola, A.; Serafini, I.; Postorino, P.; Censorii, E.; Rotari, D.; Pelosi, C. Imaging Diagnostics Coupled with Non-Invasive and Micro-Invasive Analyses for the Restoration of Ethnographic Artifacts from French Polynesia. Heritage 2022, 5, 215–232. [Google Scholar] [CrossRef]

- Kim, H.J.; Liu, Y.; Zeng, L. Fourier Transform Infrared (FT-IR) Spectroscopy and Simple Algorithm Analysis for Rapid and Non-Destructive Assessment of Cotton Fiber Maturity and Crystallinity for Plant Mapping. Sensors 2024, 24, 2888. [Google Scholar] [CrossRef]

- Dave, H.; Ledwani, L.; Chandwani, N.; Kikani, P.; Desai, B.; Nema, S.K. Surface modification of polyester fabric by non-thermal plasma treatment and its effect on coloration using natural dye. J. Polym. Mat. 2013, 30, 291–303. [Google Scholar]

- Caban, R.; Gnatowski, A. Structural and Thermal Examinations of Polyamide Modified with Fly Ash from Biomass Combustion. Materials 2023, 16, 5277. [Google Scholar] [CrossRef]

- Peets, P.; Leito, I.; Pelt, J.; Vahur, S. Identification and classification of textile fibres using ATR-FT-IR spectroscopy with chemometric methods. Spectrochim. Acta A 2017, 173, 175–181. [Google Scholar] [CrossRef]

- Geminiani, L.; Campione, F.P.; Corti, C.; Giussani, B.; Gorla, G.; Luraschi, M.; Recchia, S.; Rampazzi, L. Non-invasive identification of historical textiles and leather by means of external reflection FTIR spectroscopy. Spectrochim. Acta A 2025, 326, 125184. [Google Scholar] [CrossRef]

- Brunello, V.; Corti, C.; Sansonetti, A.; Tedeschi, C.; Rampazzi, L. Non-invasive FTIR study of mortar model samples: Comparison among innovative and traditional techniques. Eur. Phys. J. Plus 2019, 134, 270–286. [Google Scholar] [CrossRef]

- Izzo, F.; Germinario, C.; Grifa, C.; Langella, A.; Mercurio, M. External reflectance FTIR dataset (4000–400 cm−1) for the identification of relevant mineralogical phases forming Cultural Heritage materials. Infrared Phys. Technol. 2020, 106, 103266. [Google Scholar] [CrossRef]

- Volpi, F.; Vagnini, M.; Vivani, R.; Malagodi, M.; Fiocco, G. Non-invasive identification of red and yellow oxide and sulfide pigments in wall-paintings with portable ER-FTIR spectroscopy. J. Cult. Her. 2023, 63, 158–168. [Google Scholar] [CrossRef]

- Nodari, L.; Ricciardi, P. Non-invasive identification of paint binders in illuminated manuscripts by ER-FTIR spectroscopy: A systematic study of the influence of different pigments on the binders’ characteristic spectral features. Herit. Sci. 2019, 7, 7–29. [Google Scholar] [CrossRef]

- Wang, Z.; Yin, Y.; Shan, Z.; Cui, Q.; Zhang, W.; Chai, B.; Li, D.; Yu, Z.; Su, B. In-situ non-invasive analysis of conservation materials on mural paintings: A systematic approach in Dahuting Han Dynasty Tomb. Herit. Sci. 2024, 12, 51. [Google Scholar] [CrossRef]

| Sample | Solubility in 70% H2SO4 | Micro-Chemical Tests | |

|---|---|---|---|

| Ninhydrin | Herzberg | ||

| industrial fabric 1 (yellow threads) | Dissolves | Positive | Negative |

| industrial fabric 1 (beige threads) | Does not dissolve | Negative | Positive |

| industrial fabric 2 | Dissolves | - | Positive |

| industrial threads 3 | Dissolves | - | Not detected a |

| industrial fabric 4 | Dissolves partially | Negative | Positive |

| industrial fabric 5 | Does not dissolve | Negative | - |

| white shirt from Gora | Dissolves | Positive | - |

| white skirt from Gora | Do not dissolve | Negative | - |

| black waist-band with red braid from Bulgaria (black threads) | Dissolves | Positive | - |

| black waist-band with red braid from Bulgaria (red threads) | Dissolves | Negative | Positive |

| pink headscarf from Bulgaria | Dissolves | Positive | - |

| Samples | Identified Material | Methods Used | |||||

|---|---|---|---|---|---|---|---|

| OM | SEM | Sol | MCh | ATR-IR | Refl-IR | ||

| Industrial textiles | |||||||

| industrial fabric 1 (yellow threads) | Silk | Silk Regenerated Synthetic | Synthetic | No polyester or polyethylene fibers | Protein and/or polyamide | Silk | Silk |

| industrial fabric 1 (beige threads) | Polyester Viscose Silk | Regenerated Synthetic | Synthetic | Polyester or polyethylene fibers | Cellulose | Polyester Viscose Silk | Polyester Viscose Silk |

| industrial fabric 2 | Viscose | Regenerated | Synthetic or regenerated | No polyester or polyethylene fibers | Cellulose | Viscose | Viscose |

| industrial threads 3 | Cellulose acetate | Regenerated | Synthetic or regenerated | No polyester or polyethylene fibers | Cellulose | Cellulose acetate | Cellulose acetate |

| industrial fabric 4 | Polyester Cotton | Synthetic Cotton | Synthetic Cotton | Polyester or polyethylene, other natural, semisynthetic or synthetic fibers | Cellulose | Polyester Cotton | Polyester Cotton |

| industrial fabric 5 | Polyester | Synthetic | Synthetic | Polyester or polyethylene fibers | No polyamide | Polyester | Polyester |

| Historic textiles | |||||||

| shirt from Gora | Polyamide | Synthetic | Synthetic | No polyester or polyethylene fibers | Polyamide | Polyamide | Polyamide |

| skirt from Gora | Polyester | Synthetic | Synthetic | Polyester or polyethylene fibers | No polyamide | Polyester | Polyester |

| waist-band from Bulgaria (black threads) | Silk Viscose | Silk Synthetic | Silk | No polyester or polyethylene fibers | Protein and/or polyamide | Silk Viscose | Silk Viscose |

| waist-band from Bulgaria (brown-red threads | Viscose | Regenerated | Synthetic | No polyester or polyethylene fibers | Cellulose | Viscose | Viscose |

| pink headscarf from Bulgaria | Polyamide | Synthetic | Synthetic | No polyester or polyethylene fibers | Polyamide | Polyamide | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yancheva, D.; Stoyanova-Dzhambazova, E.; Atanasova-Vladimirova, S.; Kyuranova, D.; Stamboliyska, B. The Characterization of Commercial and Historical Textiles Using a Combination of Micro-Chemical, Microscopic and Infrared Spectroscopic Methods. Appl. Sci. 2025, 15, 9367. https://doi.org/10.3390/app15179367

Yancheva D, Stoyanova-Dzhambazova E, Atanasova-Vladimirova S, Kyuranova D, Stamboliyska B. The Characterization of Commercial and Historical Textiles Using a Combination of Micro-Chemical, Microscopic and Infrared Spectroscopic Methods. Applied Sciences. 2025; 15(17):9367. https://doi.org/10.3390/app15179367

Chicago/Turabian StyleYancheva, Denitsa, Ekaterina Stoyanova-Dzhambazova, Stela Atanasova-Vladimirova, Dennitsa Kyuranova, and Bistra Stamboliyska. 2025. "The Characterization of Commercial and Historical Textiles Using a Combination of Micro-Chemical, Microscopic and Infrared Spectroscopic Methods" Applied Sciences 15, no. 17: 9367. https://doi.org/10.3390/app15179367

APA StyleYancheva, D., Stoyanova-Dzhambazova, E., Atanasova-Vladimirova, S., Kyuranova, D., & Stamboliyska, B. (2025). The Characterization of Commercial and Historical Textiles Using a Combination of Micro-Chemical, Microscopic and Infrared Spectroscopic Methods. Applied Sciences, 15(17), 9367. https://doi.org/10.3390/app15179367