From Mathematical Modeling and Simulation to Digital Twins: Bridging Theory and Digital Realities in Industry and Emerging Technologies

Abstract

Featured Application

Abstract

1. Introduction

2. Foundations: Applied Mathematics and Computational Modeling

2.1. Overview of Computational Modeling Techniques

2.2. The Synergy of Theory and Computation for Complex Problem Solving

3. Modeling and Simulation in Industry and Emerging Technologies

3.1. Application Examples: Industrial Systems, Smart Manufacturing, and Innovative Services

3.2. Case Examples: Predictive Maintenance, Process Optimization, and System Prototyping

3.3. Role of High-Performance Computing (HPC) and Cloud Computing

4. From Simulation to Digital Twins

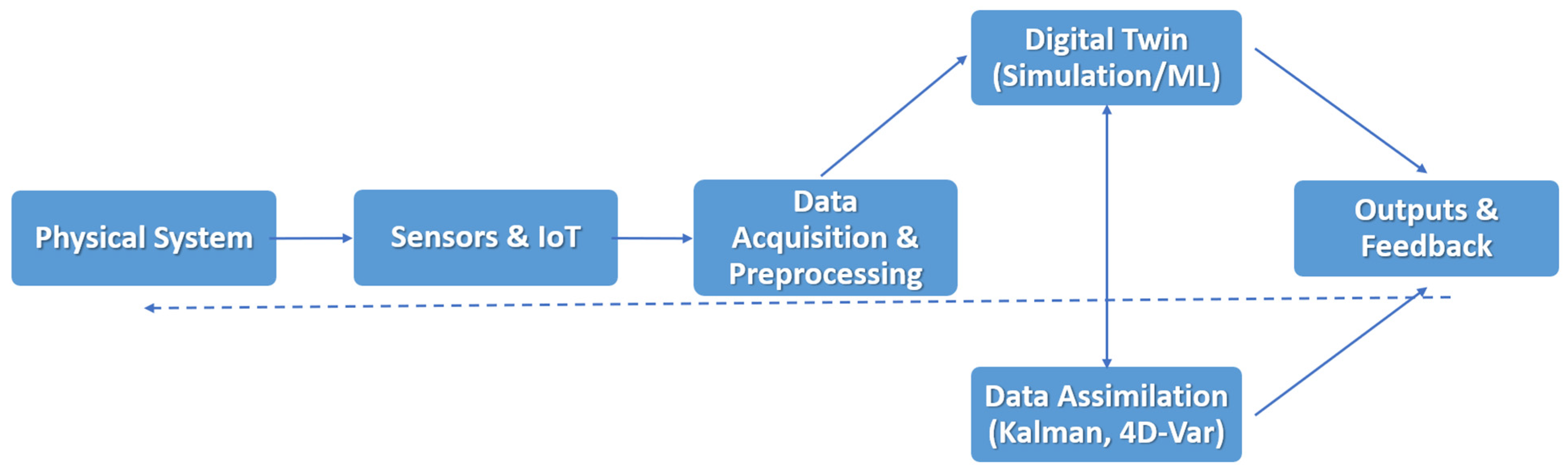

4.1. Defining a Digital Twin: Characteristics and Enabling Technologies

4.2. The Transition from Static Models to Dynamic Continuously Updated Virtual Replicas

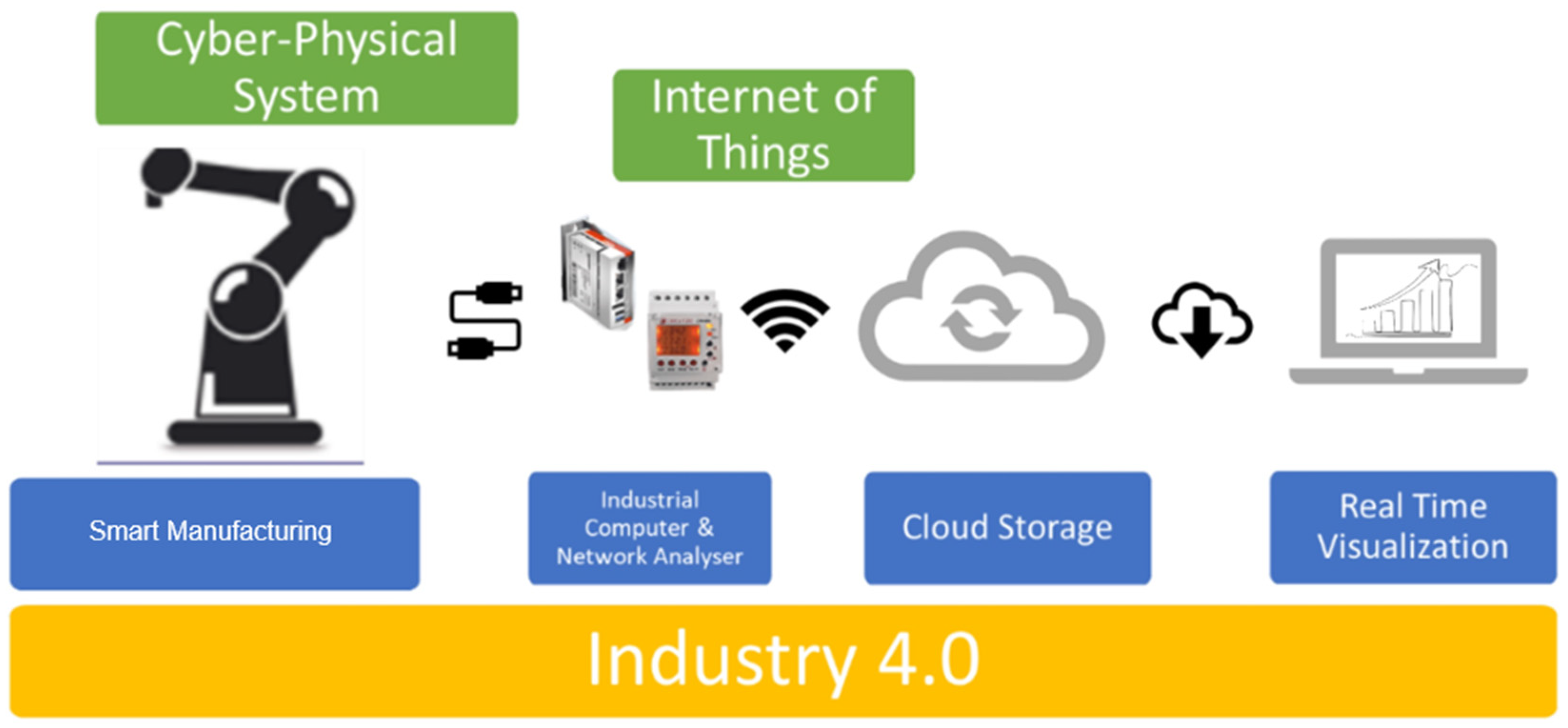

4.3. Examples of Digital Twin Architectures: Cyber–Physical Systems and IoT Integration

5. Challenges and Future Directions for Applied Mathematics in the Digital Twin Era

5.1. Algorithmic and Computational Challenges

5.2. Managing Uncertainty and Validation

5.3. Emerging Research Frontiers

5.4. Enabling Interdisciplinary Innovation

6. Future Perspectives

- The role of emerging technologies: AI, edge computing, and 5G/6G.

- Toward self-adaptive autonomous digital twins.

- Ethical, security, and governance aspects.

- Vision for academia–industry synergy and skill development.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| BIM | Building Information Modeling |

| CFD | Computational Fluid Dynamics |

| CPS | Cyber-Physical System |

| DT | Digital Twin |

| FEM | Finite Element Method |

| HPC | High-Performance Computing |

| IIoT | Industrial Internet of Things |

| IoT | Internet of Things |

| ML | Machine Learning |

| MBD | Model-Based Design |

| MLOps | Machine Learning Operations |

| PLC | Programmable Logic Controller |

| VR | Virtual Reality |

References

- Banerjee, S. Mathematical Modeling: Models, Analysis and Applications, 2nd ed.; Chapman & Hall/CRC: Boca Raton, FL, USA, 2021; ISBN 9781351022941. [Google Scholar]

- Rice, R.G.; Do, D.D.; Maneval, J.E. Maneval Applied Mathematics and Modeling for Chemical Engineers; John Wiley & Sons: New York, NY, USA, 2023; ISBN 9781119833857. [Google Scholar]

- Velten, K.; Schmidt, D.M.; Kahlen, K. Mathematical Modeling and Simulation: Introduction for Scientists and Engineers; John Wiley & Sons: New York, NY, USA, 2024; ISBN 9783527839407. [Google Scholar]

- Douglass, E.; Post, R.P.K. Creating and Using Virtual Prototyping Software: Principles and Practices; Addison Wesley Professional: Boston, MA, USA, 2021; ISBN 9780136567011. [Google Scholar]

- Albuquerque, G.; Fischer, P.M.; Azeem, S.M.; Bernstein, A.-C.; Utzig, S.; Gerndt, A. Digital Twins as Foundation for Augmented Reality Applications in Aerospace. In Springer Handbooks; Springer International Publishing: Cham, Switzerland, 2023; pp. 881–900. ISBN 9783030678210. [Google Scholar]

- Kantaros, A.; Ganetsos, T. Integration of Cyber-Physical Systems, Digital Twins and 3D Printing in Advanced Manufacturing: A Synergistic Approach. Am. J. Eng. Appl. Sci. 2024, 17, 1–22. [Google Scholar] [CrossRef]

- Piromalis, D.; Kantaros, A. Digital Twins in the Automotive Industry: The Road toward Physical-Digital Convergence. Appl. Syst. Innov. 2022, 5, 65. [Google Scholar] [CrossRef]

- Mishra, D.; Priyadarshi, A.; Das, S.M.; Shree, S.; Gupta, A.; Pal, S.K.; Chakravarty, D. Industry 4.0 Application in Manufacturing for Real-Time Monitoring and Control. J. Dyn. Monit. Diagn. 2022, 1, 176–187. [Google Scholar] [CrossRef]

- Tsaramirsis, G.; Kantaros, A.; Al-Darraji, I.; Piromalis, D.; Apostolopoulos, C.; Pavlopoulou, A.; Alrammal, M.; Ismail, Z.; Buhari, S.M.; Stojmenovic, M.; et al. A Modern Approach towards an Industry 4.0 Model: From Driving Technologies to Management. J. Sens. 2022, 2022, 5023011. [Google Scholar] [CrossRef]

- Apeiranthitis, S.; Zacharia, P.; Chatzopoulos, A.; Papoutsidakis, M. Predictive Maintenance of Machinery with Rotating Parts Using Convolutional Neural Networks. Electronics 2024, 13, 460. [Google Scholar] [CrossRef]

- Kim, I.; Kim, B.; Sidorov, D. Machine Learning for Energy Systems Optimization. Energies 2022, 15, 4116. [Google Scholar] [CrossRef]

- Bathla, G.; Bhadane, K.; Singh, R.K.; Kumar, R.; Aluvalu, R.; Krishnamurthi, R.; Kumar, A.; Thakur, R.N.; Basheer, S. Autonomous Vehicles and Intelligent Automation: Applications, Challenges, and Opportunities. Mob. Inf. Syst. 2022, 2022, 7632892. [Google Scholar] [CrossRef]

- Kantaros, A.; Soulis, E.; Ganetsos, T.; Petrescu, F.I.T. Applying a Combination of Cutting-Edge Industry 4.0 Processes towards Fabricating a Customized Component. Processes 2023, 11, 1385. [Google Scholar] [CrossRef]

- Mantalas, E.-M.; Sagias, V.D.; Zacharia, P.; Stergiou, C.I. Neuro-Fuzzy Model Evaluation for Enhanced Prediction of Mechanical Properties in AM Specimens. Appl. Sci. 2024, 15, 7. [Google Scholar] [CrossRef]

- Sagias, V.D.; Zacharia, P.; Tempeloudis, A.; Stergiou, C. Adaptive Neuro-Fuzzy Inference System-Based Predictive Modeling of Mechanical Properties in Additive Manufacturing. Machines 2024, 12, 523. [Google Scholar] [CrossRef]

- Kantaros, A.; Piromalis, D.; Tsaramirsis, G.; Papageorgas, P.; Tamimi, H. 3D Printing and Implementation of Digital Twins: Current Trends and Limitations. Appl. Syst. Innov. 2021, 5, 7. [Google Scholar] [CrossRef]

- Polyanin, A.D.; Sorokin, V.G.; Zhurov, A.I. Delay Ordinary and Partial Differential Equations; Chapman and Hall/CRC: Boca Raton, FL, USA, 2023; ISBN 9781003042310. [Google Scholar]

- Moghaddam, B.P.; Babaei, A.; Dabiri, A.; Galhano, A. Fractional Stochastic Partial Differential Equations: Numerical Advances and Practical Applications—A State of the Art Review. Symmetry 2024, 16, 563. [Google Scholar] [CrossRef]

- Ibrahimov, V.R.; Imanova, M.N. Finite Difference Methods with Improved Properties and Their Application to Solving Some Model Problems. In Proceedings of the 2022 International Conference on Computational Science and Computational Intelligence (CSCI), Las Vegas, NV, USA, 14–16 December 2022; IEEE: New York, NY, USA, 2022. [Google Scholar]

- Baião Raposo, A.; Hansen, M.T. Finite-Volume Scattering on the Left-Hand Cut. J. High Energy Phys. 2024, 2024, 75. [Google Scholar] [CrossRef]

- Dalla, L.; Papageorgiou, G.K. Metrics and Norms Used for Obtaining Sparse Solutions to Underdetermined Systems of Linear Equations. arXiv 2012, arXiv:1203.4579. [Google Scholar] [CrossRef]

- Joaquim, R.R.A.; Martins, A.N. Engineering Design Optimization; Cambridge University Press: Cambridge, UK, 2021; ISBN 9781108833417. [Google Scholar]

- Chong, E.K.P.; Lu, W.-S.; Zak, S.H. An Introduction to Optimization: With Applications to Machine Learning; John Wiley & Sons: New York, NY, USA, 2023; ISBN 9781119877653. [Google Scholar]

- Liu, W.K.; Li, S.; Park, H.S. Eighty Years of the Finite Element Method: Birth, Evolution, and Future. Arch. Comput. Methods Eng. 2022, 29, 4431–4453. [Google Scholar] [CrossRef]

- Kasereka, S.; Zohinga, G.; Kiketa, V.; Ngoie, R.-B.; Mputu, E.; Kasoro, N.; Kyandoghere, K. Equation-Based Modeling vs. Agent-Based Modeling with Applications to the Spread of COVID-19 Outbreak. Mathematics 2023, 11, 253. [Google Scholar] [CrossRef]

- Vuthi, P.; Peters, I.; Sudeikat, J. Agent-Based Modeling (ABM) for Urban Neighborhood Energy Systems: Literature Review and Proposal for an All Integrative ABM Approach. Energy Inform. 2022, 5, 55. [Google Scholar] [CrossRef]

- Axtell, R.L.; Farmer, J.D. Agent-Based Modeling in Economics and Finance: Past, Present, and Future. J. Econ. Lit. 2025, 63, 197–287. [Google Scholar] [CrossRef]

- Irastorza-Valera, L.; Soria-Gómez, E.; Benitez, J.M.; Montáns, F.J.; Saucedo-Mora, L. Review of the Brain’s Behaviour after Injury and Disease for Its Application in an Agent-Based Model (ABM). Biomimetics 2024, 9, 362. [Google Scholar] [CrossRef]

- Sato, H. Riemannian Conjugate Gradient Methods: General Framework and Specific Algorithms with Convergence Analyses. SIAM J. Optim. 2022, 32, 2690–2717. [Google Scholar] [CrossRef]

- Chiyonobu, M.; Takata, M.; Kimura, K.; Nakamura, Y. High-Speed Computation Method for Condition Numbers in the Range Restricted General Minimum Residual Method. J. Supercomput. 2025, 81, 707. [Google Scholar] [CrossRef]

- A Ceci, S.P. Numerical Tools for High-Fidelity. In Towards Effective Flow Control and Mitigation of Shock Effects in Aeronautical Applications; Springer Nature: Cham, Switzerland, 2025; pp. 34–55. ISBN 9783031866050. [Google Scholar]

- Owoyele, O.; Pal, P. ChemNODE: A Neural Ordinary Differential Equations Framework for Efficient Chemical Kinetic Solvers. Energy AI 2022, 7, 100118. [Google Scholar] [CrossRef]

- Huang, X.; Zhu, Y.; Vafaei, P.; Moradi, Z.; Davoudi, M. An Iterative Simulation Algorithm for Large Oscillation of the Applicable 2D-Electrical System on a Complex Nonlinear Substrate. Eng. Comput. 2021, 38, 3137–3149. [Google Scholar] [CrossRef]

- Vladimir Haasz, K.M. Advanced Data Acquisition and Intelligent Data Processing; CRC Press: Philadelphia, PA, USA, 2022; ISBN 9781000795301. [Google Scholar]

- Kantaros, A.; Piromalis, D. Setting up a Digital Twin Assisted Greenhouse Architecture. Am. J. Eng. Appl. Sci. 2022, 15, 230–238. [Google Scholar] [CrossRef]

- Zacharia, P.T.; Nearchou, A.C. Multi-Objective Fuzzy Assembly Line Balancing Using Genetic Algorithms. J. Intell. Manuf. 2012, 23, 615–627. [Google Scholar] [CrossRef]

- Papoutsidakis, M.; Priniotakis, G.; Chatzopoulos, A. Applications of Intellectual Systems to Packaging Systems in Industrial Environment. J. Multidiscip. Eng. Sci. Technol. 2019, 6, 11214–11218. [Google Scholar]

- Papoutsidakis, M.; Piromalis, D.; Priniotakis, G. Advanced Automation in Textile Industry Production Lines. Int. J. Eng. Appl. Sci. Technol. 2019, 4, 504–507. [Google Scholar] [CrossRef]

- Namjoshi, J.; Rawat, M. Role of Smart Manufacturing in Industry 4.0. Mater. Today 2022, 63, 475–478. [Google Scholar] [CrossRef]

- Kantaros, A.; Drosos, C.; Papoutsidakis, M.; Pallis, E.; Ganetsos, T. The Role of 3D Printing in Advancing Automated Manufacturing Systems: Opportunities and Challenges. Automation 2025, 6, 21. [Google Scholar] [CrossRef]

- Dehghan, S.; Sattarpanah Karganroudi, S.; Echchakoui, S.; Barka, N. The Integration of Additive Manufacturing into Industry 4.0 and Industry 5.0: A Bibliometric Analysis (Trends, Opportunities, and Challenges). Machines 2025, 13, 62. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.I.T.; Brachos, K.; Ganetsos, T.; Petrescu, N. Leveraging 3D Printing for Resilient Disaster Management in Smart Cities. Smart Cities 2024, 7, 3705–3726. [Google Scholar] [CrossRef]

- Rashid, M.M.; Seyedi, M.; Jung, S. Simulation of Pedestrian Interaction with Autonomous Vehicles via Social Force Model. Simul. Model. Pract. Theory 2024, 132, 102901. [Google Scholar] [CrossRef]

- Xiao, M.; Chen, L.; Feng, H.; Peng, Z.; Long, Q. Smart City Public Transportation Route Planning Based on Multi-Objective Optimization: A Review. Arch. Comput. Methods Eng. 2024, 31, 3351–3375. [Google Scholar] [CrossRef]

- Rådestad, M.; Holmgren, C.; Blidegård, E.L.; Montán, K.L. Use of Simulation Models When Developing and Testing Hospital Evacuation Plans: A Tool for Improving Emergency Preparedness. Scand. J. Trauma Resusc. Emerg. Med. 2023, 31, 43. [Google Scholar] [CrossRef] [PubMed]

- Kantaros, A.; Petrescu, F.; Abdoli, H.; Diegel, O.; Chan, S.; Iliescu, M.; Ganetsos, T.; Munteanu, I.; Ungureanu, L. Additive Manufacturing for Surgical Planning and Education: A Review. Appl. Sci. 2024, 14, 2550. [Google Scholar] [CrossRef]

- Sahai, R.; Al-Ataby, A.; Assi, S.; Jayabalan, M.; Liatsis, P.; Loy, C.K.; Al-Hamid, A.; Al-Sudani, S.; Alamran, M.; Kolivand, H. Insurance Risk Prediction Using Machine Learning. In Data Science and Emerging Technologies; Springer Nature: Singapore, 2023; pp. 419–433. ISBN 9789819907403. [Google Scholar]

- Fan, Y.; Schwartz, F.; Voß, S.; Woodruff, D.L. Catastrophe Insurance and Flexible Planning for Supply Chain Disruption Management: A Stochastic Simulation Case Study. Int. J. Prod. Res. 2024, 62, 1108–1125. [Google Scholar] [CrossRef]

- Kalathas, I.; Papoutsidakis, M. Predictive Maintenance Using Machine Learning and Data Mining: A Pioneer Method Implemented to Greek Railways. Designs 2021, 5, 5. [Google Scholar] [CrossRef]

- Achouch, M.; Dimitrova, M.; Ziane, K.; Sattarpanah Karganroudi, S.; Dhouib, R.; Ibrahim, H.; Adda, M. On Predictive Maintenance in Industry 4.0: Overview, Models, and Challenges. Appl. Sci. 2022, 12, 8081. [Google Scholar] [CrossRef]

- Serradilla, O.; Zugasti, E.; Rodriguez, J.; Zurutuza, U. Deep Learning Models for Predictive Maintenance: A Survey, Comparison, Challenges and Prospects. Appl. Intell. 2022, 52, 10934–10964. [Google Scholar] [CrossRef]

- Teoh, Y.K.; Gill, S.S.; Parlikad, A.K. IoT and Fog-Computing-Based Predictive Maintenance Model for Effective Asset Management in Industry 4.0 Using Machine Learning. IEEE Internet Things J. 2023, 10, 2087–2094. [Google Scholar] [CrossRef]

- Abidi, M.H.; Mohammed, M.K.; Alkhalefah, H. Predictive Maintenance Planning for Industry 4.0 Using Machine Learning for Sustainable Manufacturing. Sustainability 2022, 14, 3387. [Google Scholar] [CrossRef]

- Bortz, M.; Asprion, N. (Eds.) Simulation and Optimization in Process Engineering: The Benefit of Mathematical Methods in Applications of the Chemical Industry; Elsevier Science: Oxford, UK, 2022; ISBN 9780323850445. [Google Scholar]

- Feng, D.; Chen, Z.; Wu, K.; Li, J.; Dong, X.; Peng, Y.; Jia, X.; Li, X.; Wang, D. A Comprehensive Review on the Flow Behaviour in Shale Gas Reservoirs: Multi-scale, Multi-phase, and Multi-physics. Can. J. Chem. Eng. 2022, 100, 3084–3122. [Google Scholar] [CrossRef]

- Basu, S.; Shaw, A.R.; Venkatesh, M. Water Management in Petroleum Industries; Springer Nature: Cham, Switzerland, 2025; ISBN 9789811931598. [Google Scholar]

- Sagias, V.D.; Zacharia, P.; Tempeloudis, A.; Stergiou, C. Mechanical Properties Predictive Model of Additive Manufacturing Specimens Using ANFIS. Machines 2024, 12, 523. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Petrescu, F.I.T. Transforming Object Design and Creation: Biomaterials and Contemporary Manufacturing Leading the Way. Biomimetics 2024, 9, 48. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Zhang, Y.; Wu, L.; Zhao, Z.; Men, Z.; Yang, F. Developing the Optimized Control Scheme for Continuous and Layer-Wise DLP 3D Printing by CFD Simulation. Int. J. Adv. Manuf. Technol. 2023, 125, 1511–1529. [Google Scholar] [CrossRef]

- Tahmasebinia, F.; Jabbari, A.A.; Skrzypkowski, K. The Application of Finite Element Simulation and 3D Printing in Structural Design within Construction Industry 4.0. Appl. Sci. 2023, 13, 3929. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Pallis, E.; Papoutsidakis, M. Biomimetic Additive Manufacturing: Engineering Complexity Inspired by Nature’s Simplicity. Biomimetics 2025, 10, 453. [Google Scholar] [CrossRef] [PubMed]

- Andrikopoulos, K.-I.; Voerakos, G.; Tsainis, A.M.; Papazafeiropoulos, G.; Stergiou, C.; Vairis, A. Identification Method of Constitutive Material Parameters for Additively Manufactured Structures Using an Inverse Optimization Strategy. In Proceedings of the ASME 2023 International Mechanical Engineering Congress and Exposition, New Orleans, LA, USA, 29 October–2 November 2023; Volume 3: Advanced Manufacturing. American Society of Mechanical Engineers: New York, NY, USA, 2023. [Google Scholar]

- Antunes, B.; Hill, D.R.C. Reproducibility, Replicability and Repeatability: A Survey of Reproducible Research with a Focus on High Performance Computing. Comput. Sci. Rev. 2024, 53, 100655. [Google Scholar] [CrossRef]

- Deng, X. A Mixed Zero-Equation and One-Equation Turbulence Model in Fluid-Film Thrust Bearings. J. Tribol. 2024, 146, 034101. [Google Scholar] [CrossRef]

- Seupel, A.; Roth, S.; Kiefer, B. Phase-field Modeling of Chemically Reactive Multi-component and Multi-phase Systems. Proc. Appl. Math. Mech. 2023, 22, e202200154. [Google Scholar] [CrossRef]

- Liu, R.; Dobriban, E.; Hou, Z.; Qian, K. Dynamic Load Identification for Mechanical Systems: A Review. Arch. Comput. Methods Eng. 2022, 29, 831–863. [Google Scholar] [CrossRef]

- Yin, F.; Shi, F. A Comparative Survey of Big Data Computing and HPC: From a Parallel Programming Model to a Cluster Architecture. Int. J. Parallel Program. 2022, 50, 27–64. [Google Scholar] [CrossRef]

- Cebrian, J.M.; Imbernón, B.; Soto, J.; Cecilia, J.M. Evaluation of Clustering Algorithms on HPC Platforms. Mathematics 2021, 9, 2156. [Google Scholar] [CrossRef]

- Andriulo, F.C.; Fiore, M.; Mongiello, M.; Traversa, E.; Zizzo, V. Edge Computing and Cloud Computing for Internet of Things: A Review. Informatics 2024, 11, 71. [Google Scholar] [CrossRef]

- Shaji George, A.; Hovan George, A.S.; Baskar, T. Edge Computing and the Future of Cloud Computing: A Survey of Industry Perspectives and Predictions. Partn. Univers. Int. Res. J. 2023, 2, 19–44. [Google Scholar]

- Sharifzadeha, M.; Malekpoura, H.; Shojab, E. Cloud Computing and Its Impact on Industry 4.0: An Overview. In Industry 4.0 Vision for the Supply of Energy and Materials: Enabling Technologies and Emerging Applications; Wiley: Hoboken, NJ, USA, 2022; pp. 99–120. [Google Scholar]

- Ren, T.-F.; Zhou, M.-T.; Yv, C.-B.; Shen, F.; Li, J.; He, W. An Integrated Edge and Cloud Computing Platform for Multi-Industrial Applications. In Proceedings of the 2021 IEEE 1st International Conference on Digital Twins and Parallel Intelligence (DTPI), Beijing, China, 15 July–15 August 2021; IEEE: New York, NY, USA, 2021. [Google Scholar]

- Xiong, Y. The Impact of Cloud Computing and Big Data Technology on Digitalization in Financial Industry. Financ. Eng. Risk Manag. 2023, 6, 99–104. [Google Scholar] [CrossRef]

- Kammeyer, A.; Burger, F.; Lübbert, D.; Wolter, K. Developing a Digital Twin to Measure and Optimise HPC Efficiency. Measur. Sens. 2025, 38, 101481. [Google Scholar] [CrossRef]

- Kasztelnik, M.; Nowakowski, P.; Meizner, J.; Malawski, M.; Nowak, A.; Gadek, K.; Zajac, K.; Mattina, A.A.L.; Bubak, M. Digital Twin Simulation Development and Execution on HPC Infrastructures. In Lecture Notes in Computer Science; Springer Nature: Cham, Switzerland, 2023; pp. 18–32. ISBN 9783031360206. [Google Scholar]

- Scapin, M.; Peroni, L. Numerical Simulations of Components Produced by Fused Deposition 3D Printing. Materials 2021, 14, 4625. [Google Scholar] [CrossRef]

- Singh, M.; Fuenmayor, E.; Hinchy, E.; Qiao, Y.; Murray, N.; Devine, D. Digital Twin: Origin to Future. Appl. Syst. Innov. 2021, 4, 36. [Google Scholar] [CrossRef]

- Botín-Sanabria, D.M.; Mihaita, A.-S.; Peimbert-García, R.E.; Ramírez-Moreno, M.A.; Ramírez-Mendoza, R.A.; Lozoya-Santos, J.d.J. Digital Twin Technology Challenges and Applications: A Comprehensive Review. Remote Sens. 2022, 14, 1335. [Google Scholar] [CrossRef]

- Vrysouli, N.; Kotsifakos, D.; Douligeris, C. Digital Twins and Sustainability in Vocational Education and Training: The Case of Structural Environment and Architectural Design in Vocational High Schools. In Lecture Notes in Networks and Systems; Springer International Publishing: Cham, Switzerland, 2023; pp. 220–230. ISBN 9783031268755. [Google Scholar]

- Singh, M.; Srivastava, R.; Fuenmayor, E.; Kuts, V.; Qiao, Y.; Murray, N.; Devine, D. Applications of Digital Twin across Industries: A Review. Appl. Sci. 2022, 12, 5727. [Google Scholar] [CrossRef]

- Belik, M.; Rubanenko, O. Implementation of Digital Twin for Increasing Efficiency of Renewable Energy Sources. Energies 2023, 16, 4787. [Google Scholar] [CrossRef]

- Bofill, J.; Abisado, M.; Villaverde, J.; Sampedro, G.A. Exploring Digital Twin-Based Fault Monitoring: Challenges and Opportunities. Sensors 2023, 23, 7087. [Google Scholar] [CrossRef]

- Castro, H.F.; Carvalho, A.R.F.; Leal, F.; Gouveia, H. Assessing Industry 4.0 Readiness of Portuguese Companies. In Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2020; pp. 57–64. ISBN 9783030290405. [Google Scholar]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A.Y.C. Enabling Technologies and Tools for Digital Twin. J. Manuf. Syst. 2021, 58, 3–21. [Google Scholar] [CrossRef]

- De Felice, F.; De Luca, C.; Petrillo, A.; Forcina, A.; Ortiz Barrios, M.A.; Baffo, I. The Role of Digital Transformation in Manufacturing: Discrete Event Simulation to Reshape Industrial Landscapes. Appl. Sci. 2025, 15, 6140. [Google Scholar] [CrossRef]

- Knebel, F.P.; Trevisan, R.; do Nascimento, G.S.; Abel, M.; Wickboldt, J.A. A Study on Cloud and Edge Computing for the Implementation of Digital Twins in the Oil & Gas Industries. Comput. Ind. Eng. 2023, 182, 109363. [Google Scholar] [CrossRef]

- Chen, C.; Fu, H.; Zheng, Y.; Tao, F.; Liu, Y. The Advance of Digital Twin for Predictive Maintenance: The Role and Function of Machine Learning. J. Manuf. Syst. 2023, 71, 581–594. [Google Scholar] [CrossRef]

- Bárkányi, Á.; Chován, T.; Németh, S.; Abonyi, J. Modelling for Digital Twins—Potential Role of Surrogate Models. Processes 2021, 9, 476. [Google Scholar] [CrossRef]

- Gebhart, R.; Lepais, C. Novel Control-like Approach for the Robust Integration of Functional Mock-up Units into Digital Twins. In Proceedings of the EASN 2024, Thessaloniki, Greece, 8–11 October 2024; MDPI: Basel, Switzerland, 2025; p. 12. [Google Scholar]

- Wang, Y.; Tao, F.; Zhang, M.; Wang, L.; Zuo, Y. Digital Twin Enhanced Fault Prediction for the Autoclave with Insufficient Data. J. Manuf. Syst. 2021, 60, 350–359. [Google Scholar] [CrossRef]

- Werbińska-Wojciechowska, S.; Giel, R.; Winiarska, K. Digital Twin Approach for Operation and Maintenance of Transportation System-Systematic Review. Sensors 2024, 24, 6069. [Google Scholar] [CrossRef]

- Gejo-García, J.; Reschke, J.; Gallego-García, S.; García-García, M. Development of a System Dynamics Simulation for Assessing Manufacturing Systems Based on the Digital Twin Concept. Appl. Sci. 2022, 12, 2095. [Google Scholar] [CrossRef]

- Wu, D.; Zheng, A.; Yu, W.; Cao, H.; Ling, Q.; Liu, J.; Zhou, D. Digital Twin Technology in Transportation Infrastructure: A Comprehensive Survey of Current Applications, Challenges, and Future Directions. Appl. Sci. 2025, 15, 1911. [Google Scholar] [CrossRef]

- Muhammad-Sukki, F.; Farooq, H.; Abu-Bakar, S.H.; Ardila-Rey, J.A.; Sellami, N.; Kilpatrick, C.; Muhtazaruddin, M.N.; Bani, N.A.; Zulkipli, M. Mathematical Modelling of a Static Concentrating Photovoltaic: Simulation and Experimental Validation. Appl. Sci. 2021, 11, 3894. [Google Scholar] [CrossRef]

- Nica, E.; Popescu, G.H.; Poliak, M.; Kliestik, T.; Sabie, O.-M. Digital Twin Simulation Tools, Spatial Cognition Algorithms, and Multi-Sensor Fusion Technology in Sustainable Urban Governance Networks. Mathematics 2023, 11, 1981. [Google Scholar] [CrossRef]

- Armijo, A.; Zamora-Sánchez, D. Integration of Railway Bridge Structural Health Monitoring into the Internet of Things with a Digital Twin: A Case Study. Sensors 2024, 24, 2115. [Google Scholar] [CrossRef]

- Papatsaroucha, D.; Astyrakakis, N.; Pallis, E.; Grammatikis, P.I.R.; Sarigiannidis, P.G.; Markakis, E.K. A Cloud-Based Key Rolling Technique for Alleviating Join Procedure Replay Attacks in LoRaWAN-Based Wireless Sensor Networks. In Proceedings of the 2024 IEEE International Conference on Big Data (BigData), Washinton, DC, USA, 15–18 December 2024; IEEE: New York, NY, USA, 2024; pp. 2811–2820. [Google Scholar]

- Seo, J. Enabling Digital Twinning via Information-Theoretic Machine Learning-Based Inference Intelligence. Ph.D. Thesis, Purdue University, West Lafayette, Indiana, 2023. [Google Scholar]

- Ben Amor, S.; Elloumi, N.; Eltaief, A.; Louhichi, B.; Alrasheedi, N.H.; Seibi, A. Digital Twin Implementation in Additive Manufacturing: A Comprehensive Review. Processes 2024, 12, 1062. [Google Scholar] [CrossRef]

- Serôdio, C.; Mestre, P.; Cabral, J.; Gomes, M.; Branco, F. Software and Architecture Orchestration for Process Control in Industry 4.0 Enabled by Cyber-Physical Systems Technologies. Appl. Sci. 2024, 14, 2160. [Google Scholar] [CrossRef]

- Hamzah, M.; Islam, M.M.; Hassan, S.; Akhtar, M.N.; Ferdous, M.J.; Jasser, M.B.; Mohamed, A.W. Distributed Control of Cyber Physical System on Various Domains: A Critical Review. Systems 2023, 11, 208. [Google Scholar] [CrossRef]

- Hinojosa-Palafox, E.A.; Rodríguez-Elías, O.M.; Hoyo-Montaño, J.A.; Pacheco-Ramírez, J.H.; Nieto-Jalil, J.M. An Analytics Environment Architecture for Industrial Cyber-Physical Systems Big Data Solutions. Sensors 2021, 21, 4282. [Google Scholar] [CrossRef] [PubMed]

- Zahid, A.; Ferraro, A.; Petrillo, A.; De Felice, F. Exploring the Role of Digital Twin and Industrial Metaverse Technologies in Enhancing Occupational Health and Safety in Manufacturing. Appl. Sci. 2025, 15, 8268. [Google Scholar] [CrossRef]

- Chui, K.T.; Gupta, B.B.; Liu, J.; Arya, V.; Nedjah, N.; Almomani, A.; Chaurasia, P. A Survey of Internet of Things and Cyber-Physical Systems: Standards, Algorithms, Applications, Security, Challenges, and Future Directions. Information 2023, 14, 388. [Google Scholar] [CrossRef]

- Stoyanova, M.; Nikoloudakis, Y.; Panagiotakis, S.; Pallis, E.; Markakis, E.K. A Survey on the Internet of Things (IoT) Forensics: Challenges, Approaches, and Open Issues. IEEE Commun. Surv. Tutor. 2020, 22, 1191–1221. [Google Scholar] [CrossRef]

- Morawiec, P.; Sołtysik-Piorunkiewicz, A. ERP System Development for Business Agility in Industry 4.0—A Literature Review Based on the TOE Framework. Sustainability 2023, 15, 4646. [Google Scholar] [CrossRef]

- Lu, Q.; Shen, X.; Zhou, J.; Li, M. MBD-Enhanced Asset Administration Shell for Generic Production Line Design. IEEE Trans. Syst. Man Cybern. Syst. 2024, 54, 5593–5605. [Google Scholar] [CrossRef]

- Wu, Z.; Ma, C.; Zhang, L.; Gui, H.; Liu, J.; Liu, Z. Predicting and Compensating for Small-Sample Thermal Information Data in Precision Machine Tools: A Spatial-Temporal Interactive Integration Network and Digital Twin System Approach. Appl. Soft Comput. 2024, 161, 111760. [Google Scholar] [CrossRef]

- Astarita, V.; Guido, G.; Haghshenas, S.S.; Haghshenas, S.S. Risk Reduction in Transportation Systems: The Role of Digital Twins According to a Bibliometric-Based Literature Review. Sustainability 2024, 16, 3212. [Google Scholar] [CrossRef]

- Bourdena, A.; Mavromoustakis, C.X.; Kormentzas, G.; Pallis, E.; Mastorakis, G.; Yassein, M.B. A Resource Intensive Traffic-Aware Scheme Using Energy-Aware Routing in Cognitive Radio Networks. Future Gener. Comput. Syst. 2014, 39, 16–28. [Google Scholar] [CrossRef]

- Mazzetto, S. A Review of Urban Digital Twins Integration, Challenges, and Future Directions in Smart City Development. Sustainability 2024, 16, 8337. [Google Scholar] [CrossRef]

- Almirall, E.; Callegaro, D.; Bruins, P.; Santamaría, M.; Martínez, P.; Cortés, U. The Use of Synthetic Data to Solve the Scalability and Data Availability Problems in Smart City Digital Twins. arXiv 2022, arXiv:2207.02953. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, P.; Xu, X. Literature Review of Digital Twin Technologies for Civil Infrastructure. J. Infrastruct. Intell. Resil. 2023, 2, 100050. [Google Scholar] [CrossRef]

- Aziz, A.; Chouhan, S.S.; Schelén, O.; Bodin, U. Distributed Digital Twins as Proxies-Unlocking Composability and Flexibility for Purpose-Oriented Digital Twins. IEEE Access 2023, 11, 137577–137593. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Zhang, C. Advancements and Challenges of Digital Twins in Industry. Nat. Comput. Sci. 2024, 4, 169–177. [Google Scholar] [CrossRef]

- Iraola, E.; García-Lorenzo, M.; Lordan-Gomis, F.; Rossi, F.; Prieto-Araujo, E.; Badia, R.M. HP2C-DT: High-Precision High-Performance Computer-Enabled Digital Twin. arXiv 2025, arXiv:2506.10523. [Google Scholar]

- Ares de Parga, S.; Bravo, J.R.; Sibuet, N.; Hernandez, J.A.; Rossi, R.; Boschert, S.; Quintana-Ortí, E.S.; Tomás, A.E.; Tatu, C.C.; Vázquez-Novoa, F.; et al. Parallel Reduced-Order Modeling for Digital Twins Using High-Performance Computing Workflows. Comput. Struct. 2025, 316, 107867. [Google Scholar] [CrossRef]

- Acharya, S.; Khan, A.A.; Päivärinta, T. Interoperability Levels and Challenges of Digital Twins in Cyber–Physical Systems. J. Ind. Inf. Integr. 2024, 42, 100714. [Google Scholar] [CrossRef]

- Wang, F.Z.; Animasaun, I.L.; Muhammad, T.; Okoya, S.S. Recent Advancements in Fluid Dynamics: Drag Reduction, Lift Generation, Computational Fluid Dynamics, Turbulence Modelling, and Multiphase Flow. Arab. J. Sci. Eng. 2024, 49, 10237–10249. [Google Scholar] [CrossRef]

- Chowdhury, I.R.; Pemberton, R.; Summerscales, J. Developments and Industrial Applications of Basalt Fibre Reinforced Composite Materials. J. Compos. Sci. 2022, 6, 367. [Google Scholar] [CrossRef]

- Blanco, I. A Brief Review of the Applications of Selected Thermal Analysis Methods to 3D Printing. Thermo 2022, 2, 74–83. [Google Scholar] [CrossRef]

- Bilal, M.; Ahmed, A.E.-S.; El-Nabulsi, R.A.; Ahammad, N.A.; Alharbi, K.A.M.; Elkotb, M.A.; Anukool, W.; S. A., Z.A. Numerical Analysis of an Unsteady, Electroviscous, Ternary Hybrid Nanofluid Flow with Chemical Reaction and Activation Energy across Parallel Plates. Micromachines 2022, 13, 874. [Google Scholar] [CrossRef]

- Carvajal-Flores, D.F.; Abril-Jiménez, P.; Buhid, E.; Fico, G.; Cabrera Umpiérrez, M.F. Enhancing Industrial Digitalisation through an Adaptable Component for Bridging Semantic Interoperability Gaps. Appl. Sci. 2024, 14, 2309. [Google Scholar] [CrossRef]

- Xu, R.; Guo, Y.; Han, X.; Xia, X.; Xiang, H.; Ma, J. OpenCDA: An Open Cooperative Driving Automation Framework Integrated with Co-Simulation. In Proceedings of the 2021 IEEE International Intelligent Transportation Systems Conference (ITSC), Indianapolis, IN, USA, 19–22 September 2021; IEEE: New York, NY, USA, 2021; pp. 1155–1162. [Google Scholar]

- Thelen, A.; Zhang, X.; Fink, O.; Lu, Y.; Ghosh, S.; Youn, B.D.; Todd, M.D.; Mahadevan, S.; Hu, C.; Hu, Z. A Comprehensive Review of Digital Twin—Part 2: Roles of Uncertainty Quantification and Optimization, a Battery Digital Twin, and Perspectives. Struct. Multidiscipl. Optim. 2023, 66, 1. [Google Scholar] [CrossRef]

- Sel, K.; Hawkins-Daarud, A.; Chaudhuri, A.; Osman, D.; Bahai, A.; Paydarfar, D.; Willcox, K.; Chung, C.; Jafari, R. Survey and Perspective on Verification, Validation, and Uncertainty Quantification of Digital Twins for Precision Medicine. NPJ Digit. Med. 2025, 8, 40. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Qiang, X.; Xu, M.; Wu, T. Recent Advances in Surrogate Modeling Methods for Uncertainty Quantification and Propagation. Symmetry 2022, 14, 1219. [Google Scholar] [CrossRef]

- Lin, L.; Bao, H.; Dinh, N. Uncertainty Quantification and Software Risk Analysis for Digital Twins in the Nearly Autonomous Management and Control Systems: A Review. Ann. Nucl. Energy 2021, 160, 108362. [Google Scholar] [CrossRef]

- Hua, E.Y.; Lazarova-Molnar, S.; Francis, D.P. Validation of Digital Twins: Challenges and Opportunities. In Proceedings of the 2022 Winter Simulation Conference (WSC), Singapore, 11–14 December 2022; IEEE: New York, NY, USA, 2022. [Google Scholar]

- Lugaresi, G.; Gangemi, S.; Gazzoni, G.; Matta, A. Online Validation of Digital Twins for Manufacturing Systems. Comput. Ind. 2023, 150, 103942. [Google Scholar] [CrossRef]

- Kessels, B.M.; Fey, R.H.B.; van de Wouw, N. Uncertainty Quantification in Real-Time Parameter Updating for Digital Twins Using Bayesian Inverse Mapping Models. Nonlinear Dyn. 2024, 113, 7613–7637. [Google Scholar] [CrossRef]

- Bitencourt, J.; Wooley, A.; Harris, G. Verification and Validation of Digital Twins: A Systematic Literature Review for Manufacturing Applications. Int. J. Prod. Res. 2025, 63, 342–370. [Google Scholar] [CrossRef]

- Chen, F.; Huang, Q.; Song, M.; Liu, X.; Zeng, W.; Song, H.; Cheng, K. A Study on the Development of Digital Model of Digital Twin in Nuclear Power Plant Based on a Hybrid Physics and Data-Driven Approach. Appl. Therm. Eng. 2025, 271, 126289. [Google Scholar] [CrossRef]

- Qin, L.-F.; Ren, W.-X.; Guo, C.-R. A Physics-Data Hybrid Framework to Develop Bridge Digital Twin Model in Structural Health Monitoring. Int. J. Struct. Stab. Dyn. 2023, 23, 23400370. [Google Scholar] [CrossRef]

- Sahin, T.; Wolff, D.; von Danwitz, M.; Popp, A. Towards a Hybrid Digital Twin: Fusing Sensor Information and Physics in Surrogate Modeling of a Reinforced Concrete Beam. In Proceedings of the 2024 Sensor Data Fusion: Trends, Solutions, Applications (SDF), Bonn, Germany, 25–27 November 2024; IEEE: New York, NY, USA, 2024; pp. 1–8. [Google Scholar]

- Emmert-Streib, F. What Is the Role of AI for Digital Twins? AI 2023, 4, 721–728. [Google Scholar] [CrossRef]

- Shao, G.; Hightower, J.; Schindel, W. Credibility Consideration for Digital Twins in Manufacturing. Manuf. Lett. 2023, 35, 24–28. [Google Scholar] [CrossRef]

- Naeini, H.K.; Shomali, R.; Pishahang, A.; Hasanzadeh, H.; Mohammadi, M.; Asadi, S.; Varmaghani, A.; Lonbar, A.G. PINN-DT: Optimizing Energy Consumption in Smart Building Using Hybrid Physics-Informed Neural Networks and Digital Twin Framework with Blockchain Security. arXiv 2025, arXiv:2503.00331. [Google Scholar]

- Wang, Q.; Chen, L.; Xiao, G.; Wang, P.; Gu, Y.; Lu, J. Elevator Fault Diagnosis Based on Digital Twin and PINNs-e-RGCN. Sci. Rep. 2024, 14, 30713. [Google Scholar] [CrossRef] [PubMed]

- Maulik, S.; Riordan, D.; Walsh, J. Dynamic Reduction-Based Virtual Models for Digital Twins—A Comparative Study. Appl. Sci. 2022, 12, 7154. [Google Scholar] [CrossRef]

- Goodwin, T.; Xu, J.; Celik, N.; Chen, C.-H. Real-Time Digital Twin-Based Optimization with Predictive Simulation Learning. J. Simul. 2022, 18, 47–64. [Google Scholar] [CrossRef]

- Kapteyn, M.G.; Knezevic, D.J.; Huynh, D.B.P.; Tran, M.; Willcox, K.E. Data-driven Physics-based Digital Twins via a Library of Component-based Reduced-order Models. Int. J. Numer. Methods Eng. 2022, 123, 2986–3003. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, J.; Li, Q.; Tan, H. Research on Real-Time Robust Optimization of Perishable Supply-Chain Systems Based on Digital Twins. Sensors 2023, 23, 1850. [Google Scholar] [CrossRef]

- Xuan, D.T.; Van Huynh, T.; Hung, N.T.; Thang, V.T. Applying Digital Twin and Multi-Adaptive Genetic Algorithms in Human–Robot Cooperative Assembly Optimization. Appl. Sci. 2023, 13, 4229. [Google Scholar] [CrossRef]

- Liu, S.; Lu, Y.; Zheng, P.; Shen, H.; Bao, J. Adaptive Reconstruction of Digital Twins for Machining Systems: A Transfer Learning Approach. Robot. Comput. Integr. Manuf. 2022, 78, 102390. [Google Scholar] [CrossRef]

- Alazab, M.; Khan, L.U.; Koppu, S.; Ramu, S.P.; Iyapparaja, M.; Boobalan, P.; Baker, T.; Maddikunta, P.K.R.; Gadekallu, T.R.; Aljuhani, A. Digital Twins for Healthcare 4.0—Recent Advances, Architecture, and Open Challenges. IEEE Consum. Electron. Mag. 2023, 12, 29–37. [Google Scholar] [CrossRef]

- Kessels, B.M.; Fey, R.H.B.; van de Wouw, N. Real-Time Parameter Updating for Nonlinear Digital Twins Using Inverse Mapping Models and Transient-Based Features. Nonlinear Dyn. 2023, 111, 10255–10285. [Google Scholar] [CrossRef]

- Hasan, A. Online Parameter Estimation in Digital Twins for Real-Time Condition Monitoring. IEEE Access 2025, 13, 14789–14800. [Google Scholar] [CrossRef]

- Wieser, R.; Fan, Y.; Yu, X.; Braid, J.; Shaton, A.; Hoffman, A.; Spurgeon, B.; Gibbons, D.; Bruckman, L.S.; Wu, Y.; et al. Large Scale, Data Driven, Digital Twin Models: Outlier Detection and Imputation. In Proceedings of the 2024 IEEE 52nd Photovoltaic Specialist Conference (PVSC), Seattle, WA, USA, 9–14 July 2024; IEEE: New York, NY, USA, 2024; pp. 0902–0905. [Google Scholar]

- Wu, Y.; Zhou, L.; Zheng, P.; Sun, Y.; Zhang, K. A Digital Twin-Based Multidisciplinary Collaborative Design Approach for Complex Engineering Product Development. Adv. Eng. Inform. 2022, 52, 101635. [Google Scholar] [CrossRef]

- Zhong, X.; Babaie Sarijaloo, F.; Prakash, A.; Park, J.; Huang, C.; Barwise, A.; Herasevich, V.; Gajic, O.; Pickering, B.; Dong, Y. A Multidisciplinary Approach to the Development of Digital Twin Models of Critical Care Delivery in Intensive Care Units. Int. J. Prod. Res. 2022, 60, 4197–4213. [Google Scholar] [CrossRef]

- Rahimi, S.A.; Baradaran, A.; Khameneifar, F.; Gore, G.; Issa, A.M. DECIDE-Twin: A Framework for AI-Enabled Digital Twins in Clinical Decision-Making. IEEE J. Biomed. Health Inform. 2024. [Google Scholar] [CrossRef] [PubMed]

- Łukaniszyn, M.; Majka, Ł.; Grochowicz, B.; Mikołajewski, D.; Kawala-Sterniuk, A. Digital Twins Generated by Artificial Intelligence in Personalized Healthcare. Appl. Sci. 2024, 14, 9404. [Google Scholar] [CrossRef]

- Fathy, Y.; Jaber, M.; Nadeem, Z. Digital Twin-Driven Decision Making and Planning for Energy Consumption. J. Sens. Actuator Netw. 2021, 10, 37. [Google Scholar] [CrossRef]

- Kosacka-Olejnik, M.; Kostrzewski, M.; Marczewska, M.; Mrówczyńska, B.; Pawlewski, P. How Digital Twin Concept Supports Internal Transport Systems?—Literature Review. Energies 2021, 14, 4919. [Google Scholar] [CrossRef]

- Mylonas, G.; Kalogeras, A.; Kalogeras, G.; Anagnostopoulos, C.; Alexakos, C.; Munoz, L. Digital Twins from Smart Manufacturing to Smart Cities: A Survey. IEEE Access 2021, 9, 143222–143249. [Google Scholar] [CrossRef]

- Piras, G.; Agostinelli, S.; Muzi, F. Digital Twin Framework for Built Environment: A Review of Key Enablers. Energies 2024, 17, 436. [Google Scholar] [CrossRef]

- Alfaro-Viquez, D.; Zamora-Hernandez, M.; Fernandez-Vega, M.; Garcia-Rodriguez, J.; Azorin-Lopez, J. A Comprehensive Review of AI-Based Digital Twin Applications in Manufacturing: Integration across Operator, Product, and Process Dimensions. Electronics 2025, 14, 646. [Google Scholar] [CrossRef]

- Kang, M.-S.; Lee, D.-H.; Bajestani, M.S.; Kim, D.B.; Noh, S.D. Edge Computing-Based Digital Twin Framework Based on ISO 23247 for Enhancing Data Processing Capabilities. Machines 2024, 13, 19. [Google Scholar] [CrossRef]

- Ramirez, R.; Huang, C.-Y.; Liang, S.-H. 5G Digital Twin: A Study of Enabling Technologies. Appl. Sci. 2022, 12, 7794. [Google Scholar] [CrossRef]

- Poole, A.; Sutcliffe, M.; Pierce, G.; Gachagan, A. Autonomous, Digital-Twin Free Path Planning and Deployment for Robotic NDT: Introducing LPAS: Locate, Plan, Approach, Scan Using Low Cost Vision Sensors. Appl. Sci. 2022, 12, 5288. [Google Scholar] [CrossRef]

- Galuzin, V.; Galitskaya, A.; Grachev, S.; Larukhin, V.; Novichkov, D.; Skobelev, P.; Zhilyaev, A. Autonomous Digital Twin of Enterprise: Method and Toolset for Knowledge-Based Multi-Agent Adaptive Management of Tasks and Resources in Real Time. Mathematics 2022, 10, 1662. [Google Scholar] [CrossRef]

- Bolender, T.; Burvenich, G.; Dalibor, M.; Rumpe, B.; Wortmann, A. Self-Adaptive Manufacturing with Digital Twins. In Proceedings of the 2021 International Symposium on Software Engineering for Adaptive and Self-Managing Systems (SEAMS), Madrid, Spain, 18–24 May 2021; IEEE: New York, NY, USA, 2021. [Google Scholar]

- Helbing, D.; Argota Sanchez-Vaquerizo, J. Digital Twins: Potentials, Ethical Issues, and Limitations. SSRN Electron. J. 2022. [Google Scholar] [CrossRef]

- Alshammari, K.; Beach, T.; Rezgui, Y. Cybersecurity for Digital Twins in the Built Environment: Current Research and Future Directions. J. Inf. Technol. Constr. 2021, 26, 159–173. [Google Scholar] [CrossRef]

- Helbing, D.; Sánchez-Vaquerizo, J.A. Digital Twins: Potentials, Ethical Issues and Limitations. In Handbook on the Politics and Governance of Big Data and Artificial Intelligence; Edward Elgar Publishing: Cheltenham, UK, 2023; pp. 64–104. ISBN 9781800887374. [Google Scholar]

- Zoltick, M.M.; Maisel, J.B. Societal Impacts: Legal, Regulatory and Ethical Considerations for the Digital Twin. In The Digital Twin; Springer International Publishing: Cham, Switzerland, 2023; pp. 1167–1200. ISBN 9783031213427. [Google Scholar]

- Tripathi, N.; Hietala, H.; Xu, Y.; Liyanage, R. Stakeholders Collaborations, Challenges and Emerging Concepts in Digital Twin Ecosystems. Inf. Softw. Technol. 2024, 169, 107424. [Google Scholar] [CrossRef]

- Longo, F.; Padovano, A.; De Felice, F.; Petrillo, A.; Elbasheer, M. From “Prepare for the Unknown” to “Train for What’s Coming”: A Digital Twin-Driven and Cognitive Training Approach for the Workforce of the Future in Smart Factories. J. Ind. Inf. Integr. 2023, 32, 100437. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, J.; Tu, W.; Wang, M.; Yang, Y.; Qian, F.; Xu, Y. The Effectiveness of a Digital Twin Learning System in Assisting Engineering Education Courses: A Case of Landscape Architecture. Appl. Sci. 2024, 14, 6484. [Google Scholar] [CrossRef]

- Martínez-Gutiérrez, A.; Díez-González, J.; Verde, P.; Perez, H. Convergence of Virtual Reality and Digital Twin Technologies to Enhance Digital Operators’ Training in Industry 4.0. Int. J. Hum. Comput. Stud. 2023, 180, 103136. [Google Scholar] [CrossRef]

| Architecture Type | Key Features | Advantages | Limitations | Example Applications | Real-Time Updating Method |

|---|---|---|---|---|---|

| Centralized Cloud-Based | All model computation and data processing handled in cloud servers | Scalable resources; easy remote access; integration with big data analytics | Higher latency; dependence on internet connectivity; potential data security concerns; susceptibility to WiFi latency in large-scale settings | Predictive maintenance in distributed manufacturing | Batch assimilation of sensor data into weak form FEM via cloud-based Kalman filtering |

| Edge-Enhanced Digital Twin | Real-time computation on local edge devices with selective cloud offloading | Low latency; resilient to connectivity disruptions; supports time-critical decision making | Limited computational power at the edge; higher hardware cost | Adaptive control in additive manufacturing processes | Localized FEM matrix recalibration with streaming sensor input; reduced-order modeling |

| Hybrid Cloud–Edge Architecture | Tasks split between edge (real-time control) and cloud (heavy analytics, long-term optimization) | Combines scalability with responsiveness; optimized workload distribution | Requires sophisticated orchestration; increased system complexity; latency bottlenecks if reliant on WiFi in distributed deployments | Smart grids, autonomous vehicles | Moving-horizon estimation for edge-level updates; cloud-based assimilation of long-term data |

| On-Premises HPC-Integrated Digital Twin | High-performance computing clusters within organization’s infrastructure | Handles very large-scale simulations; ensures data sovereignty | High capital and maintenance costs; limited elasticity | Aerospace simulation, nuclear plant operations | High-fidelity FEM weak form recalibration using parallel solvers and data assimilation filters |

| Federated/Distributed Digital Twin Network | Multiple interconnected twins sharing models/data without centralization | Enables cross-domain integration; preserves local data privacy | Complex coordination; risk of inconsistent model states | Urban infrastructure management across city districts | Distributed Kalman filtering and consensus-based FEM updating across nodes |

| Aspect | Description | Representative Application | Associated Mathematical Techniques |

|---|---|---|---|

| Core Characteristics | Dynamic real-time virtual replica synchronized with its physical counterpart via continuous data feedback | Predictive asset management for wind turbines | Kalman Filtering (EKF, EnKF), Particle Filtering, Data Assimilation Schemes |

| Data Integration | High-resolution sensor networks, IoT-enabled data streams, seamless assimilation into computational models | Smart grids with real-time demand response | Bayesian Inference, Sensor Fusion Algorithms, Statistical Signal Processing |

| Computational Backbone | High-performance computing (HPC), cloud and edge computing for real-time simulation and analytics | Adaptive process control in additive manufacturing | Reduced-Order Modeling (POD, DMD), Parallel Numerical Solvers, Multi-Scale Simulation |

| Hybrid Modeling | Combination of physics-based models and data-driven algorithms for adaptive non-linear behavior | Condition monitoring and anomaly detection in complex machinery | Hybrid PDE–ML Frameworks, System Identification Methods, Neural ODEs |

| Cyber–Physical Architecture | Closed-loop feedback between physical systems and digital models through embedded control systems | Smart production lines with automated parameter adjustment | Optimal Control Theory, Model Predictive Control (MPC), Stability Analysis |

| Scalability and Interoperability | Integration with ERP systems, supply chain tools, and multi-stakeholder platforms | Urban infrastructure digital twins for bridges and tunnels | Graph Theory, Network Optimization, Distributed Computing Methods |

| Key Benefits | Enhanced operational efficiency, predictive maintenance, optimized resource allocation, risk mitigation | Oil and gas pipeline monitoring and failure prevention | Reliability Modeling, Probabilistic Risk Assessment, Uncertainty Quantification |

| Focus Area | Key Aspects | Illustrative Context |

|---|---|---|

| Real-Time Algorithms | Model updating, data assimilation, numerical stability | Continuous monitoring in smart grids |

| Scalability and Efficiency | HPC and cloud integration, surrogate modeling, computational cost reduction | Large-scale simulations for aerospace or energy systems |

| Multi-Physics Interoperability | Coupling of diverse models, modular frameworks, standardized data exchange | Co-simulation of thermal–structural interactions in engines |

| Uncertainty Management | Uncertainty quantification (UQ), risk assessment, propagation of parameter variability | Predictive maintenance for critical infrastructure |

| Calibration and Validation | Parameter estimation with sparse/noisy data, Bayesian inference, model trustworthiness | Industrial process control and fault detection |

| Hybrid Modeling Frontiers | Integration of machine learning with physics-based models, surrogate modeling, PINNs | Adaptive quality control in additive manufacturing |

| Real-Time Optimization | Model order reduction, fast scenario analysis, dynamic control synthesis | Autonomous robotics and smart factories |

| Adaptive Algorithms | Streaming data, online learning, anomaly detection, continuous decision support | Real-time urban mobility management |

| Interdisciplinary Collaboration | Synergy among mathematicians, engineers, and data scientists; open innovation frameworks; co-development tools | Multi-partner industrial–academic digital twin consortia |

| Societal and Industrial Impact | Decision support, automation, next-generation services | Smart cities, resilient infrastructure, personalized medicine |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kantaros, A.; Ganetsos, T.; Pallis, E.; Papoutsidakis, M. From Mathematical Modeling and Simulation to Digital Twins: Bridging Theory and Digital Realities in Industry and Emerging Technologies. Appl. Sci. 2025, 15, 9213. https://doi.org/10.3390/app15169213

Kantaros A, Ganetsos T, Pallis E, Papoutsidakis M. From Mathematical Modeling and Simulation to Digital Twins: Bridging Theory and Digital Realities in Industry and Emerging Technologies. Applied Sciences. 2025; 15(16):9213. https://doi.org/10.3390/app15169213

Chicago/Turabian StyleKantaros, Antreas, Theodore Ganetsos, Evangelos Pallis, and Michail Papoutsidakis. 2025. "From Mathematical Modeling and Simulation to Digital Twins: Bridging Theory and Digital Realities in Industry and Emerging Technologies" Applied Sciences 15, no. 16: 9213. https://doi.org/10.3390/app15169213

APA StyleKantaros, A., Ganetsos, T., Pallis, E., & Papoutsidakis, M. (2025). From Mathematical Modeling and Simulation to Digital Twins: Bridging Theory and Digital Realities in Industry and Emerging Technologies. Applied Sciences, 15(16), 9213. https://doi.org/10.3390/app15169213