RBF Neural Network-Based Anti-Disturbance Trajectory Tracking Control for Wafer Transfer Robot Under Variable Payload Conditions

Abstract

1. Introduction

- (1)

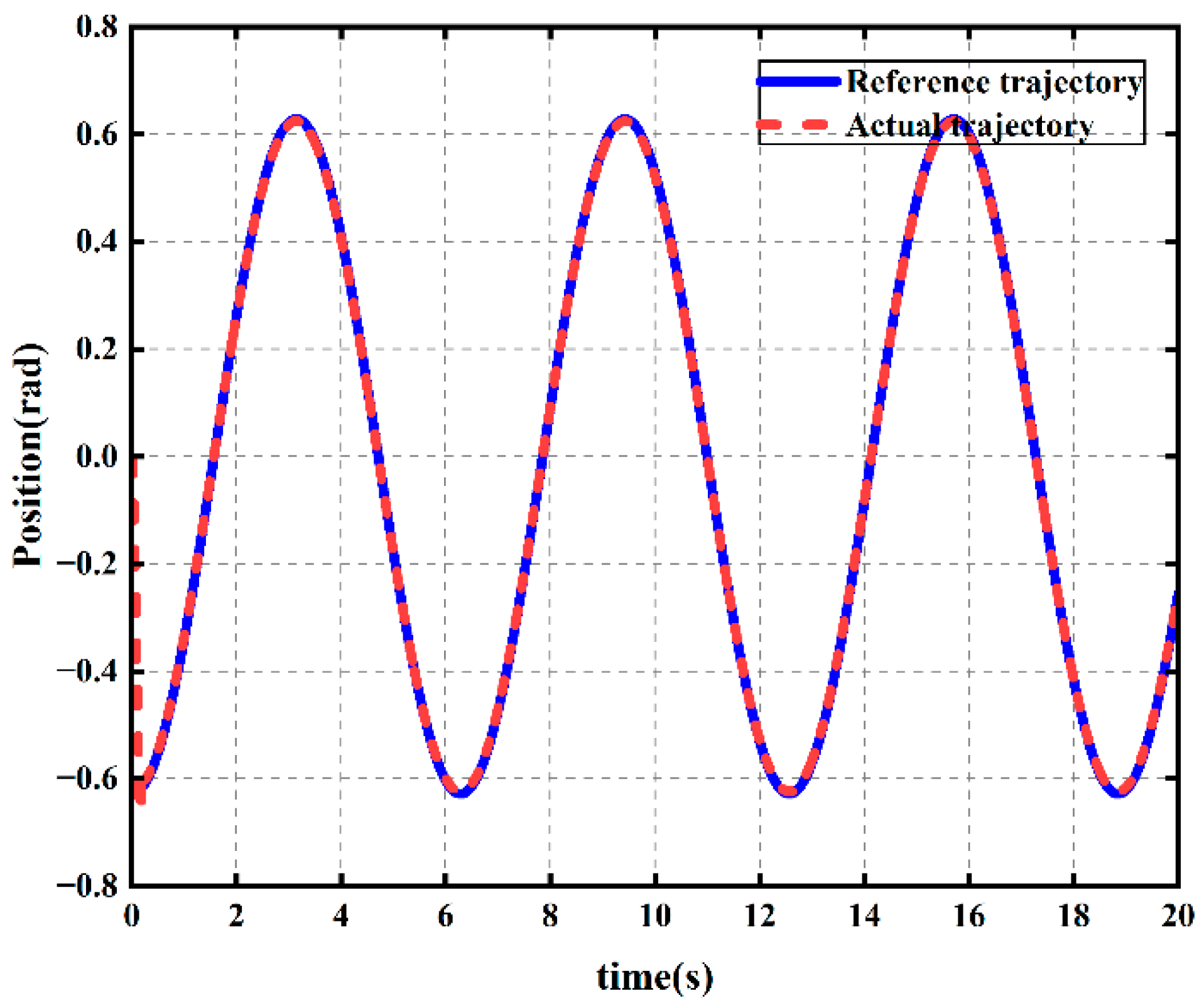

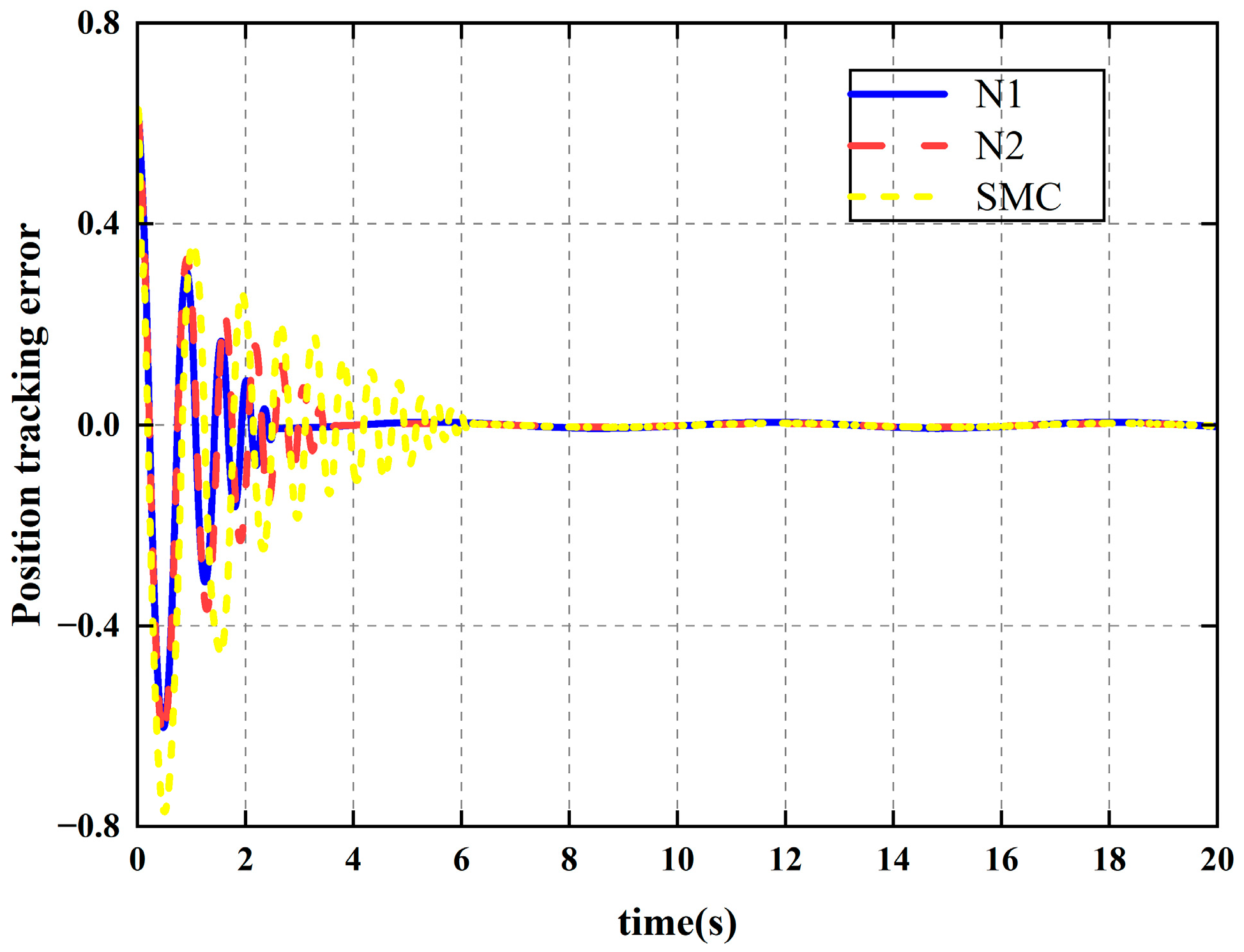

- This work is the first to apply RBFNN to time-varying load control in wafer transfer robot. Leveraging RBFNN’s nonlinear approximation capability, we design an adaptive control law based on a backstepping framework. By estimating system nonlinear dynamics and compensating for time-varying load disturbances online, trajectory tracking accuracy is significantly enhanced, with the steady-state error reduced by about 50%. The UUB of the closed-loop system is rigorously proven via Lyapunov theory.

- (2)

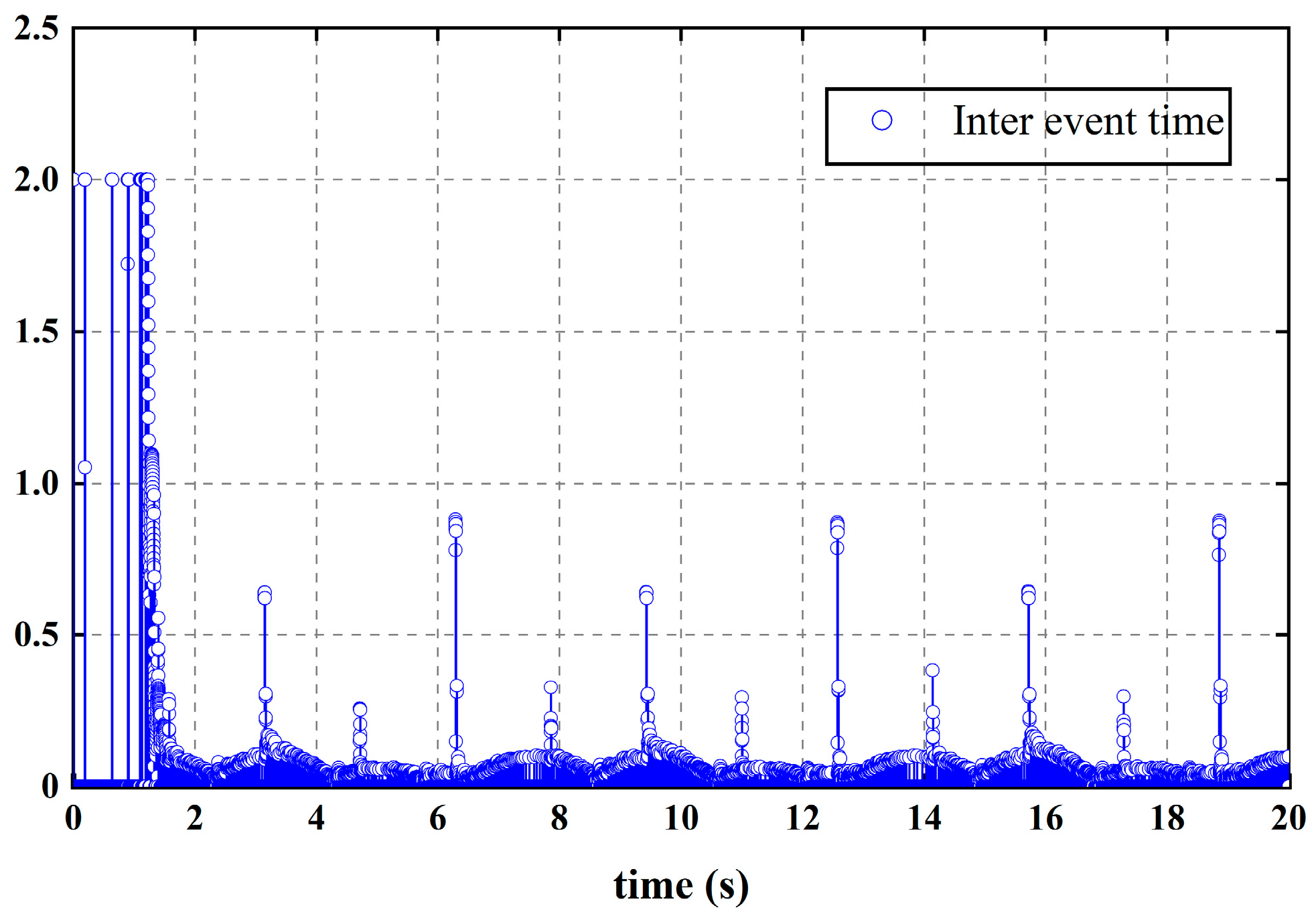

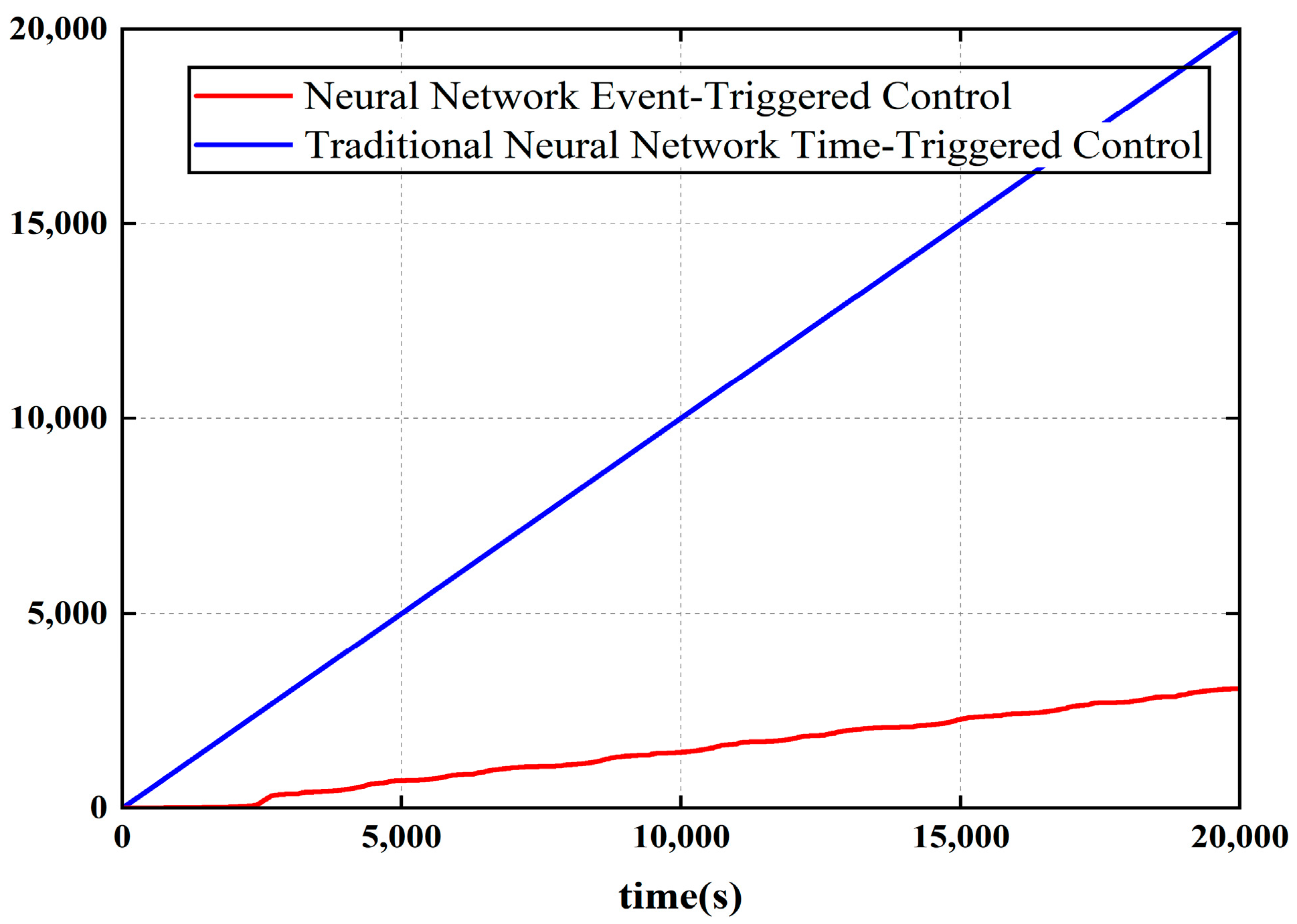

- We further innovatively introduce an event-triggered mechanism with a dynamic triggering condition. This strategy updates the controller only when triggering requirements are met, reducing the number of updates from 20,000 (periodic control) to 3057, directly mitigating energy consumption.

2. Problem Description and Preliminaries

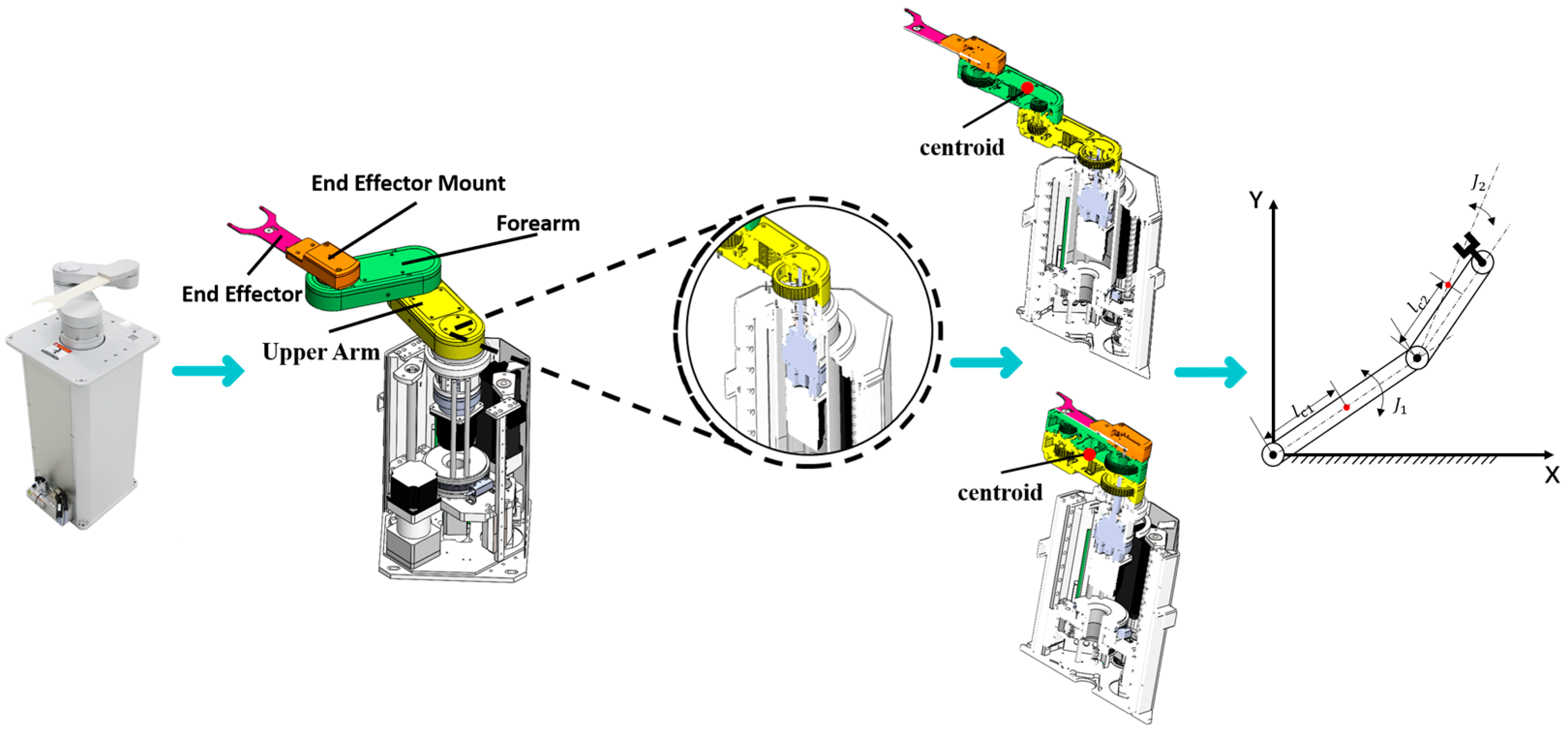

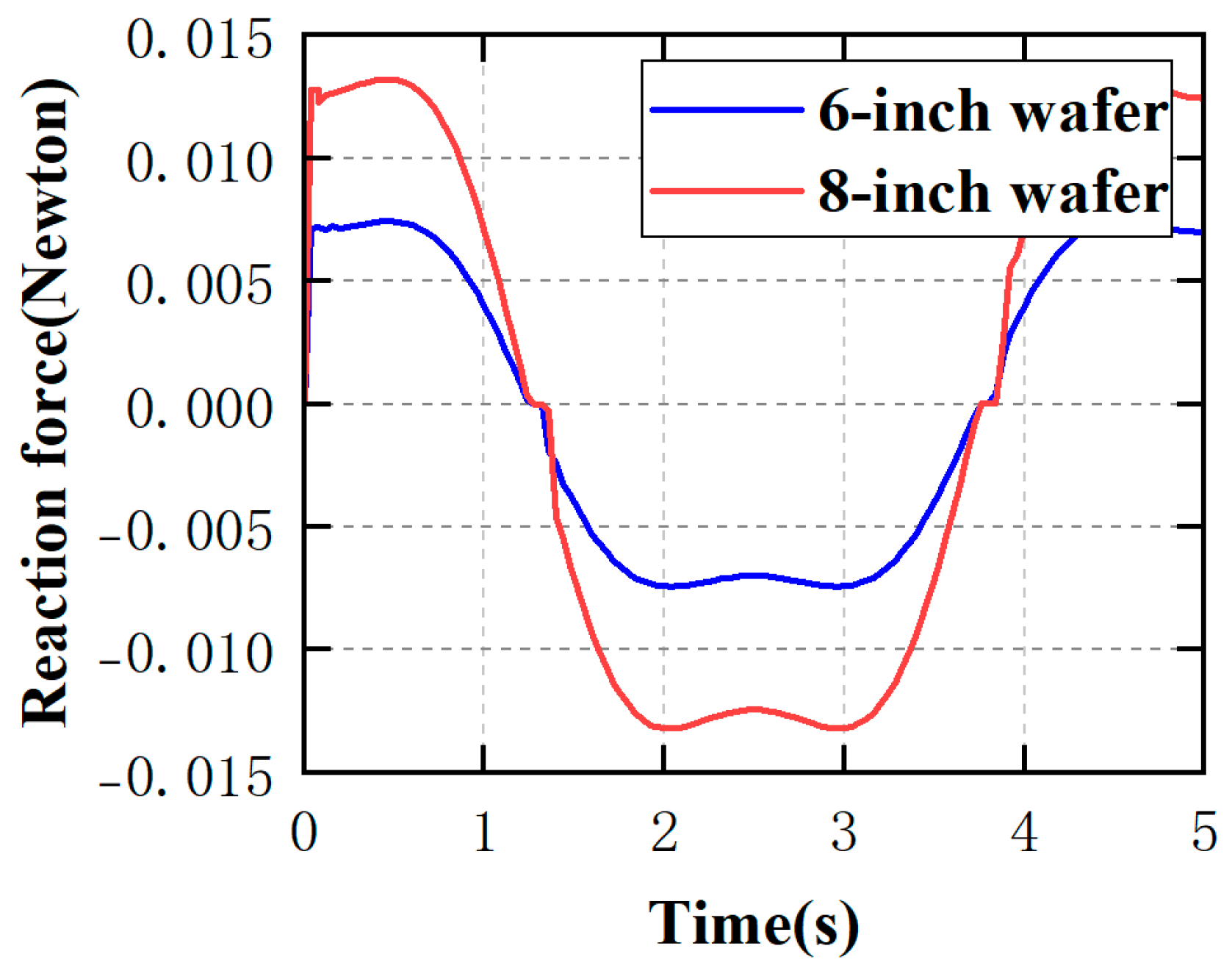

2.1. Variable-Load Characteristics of Wafer Transfer Robots

2.2. Dynamic Model of the Wafer Transfer Robot

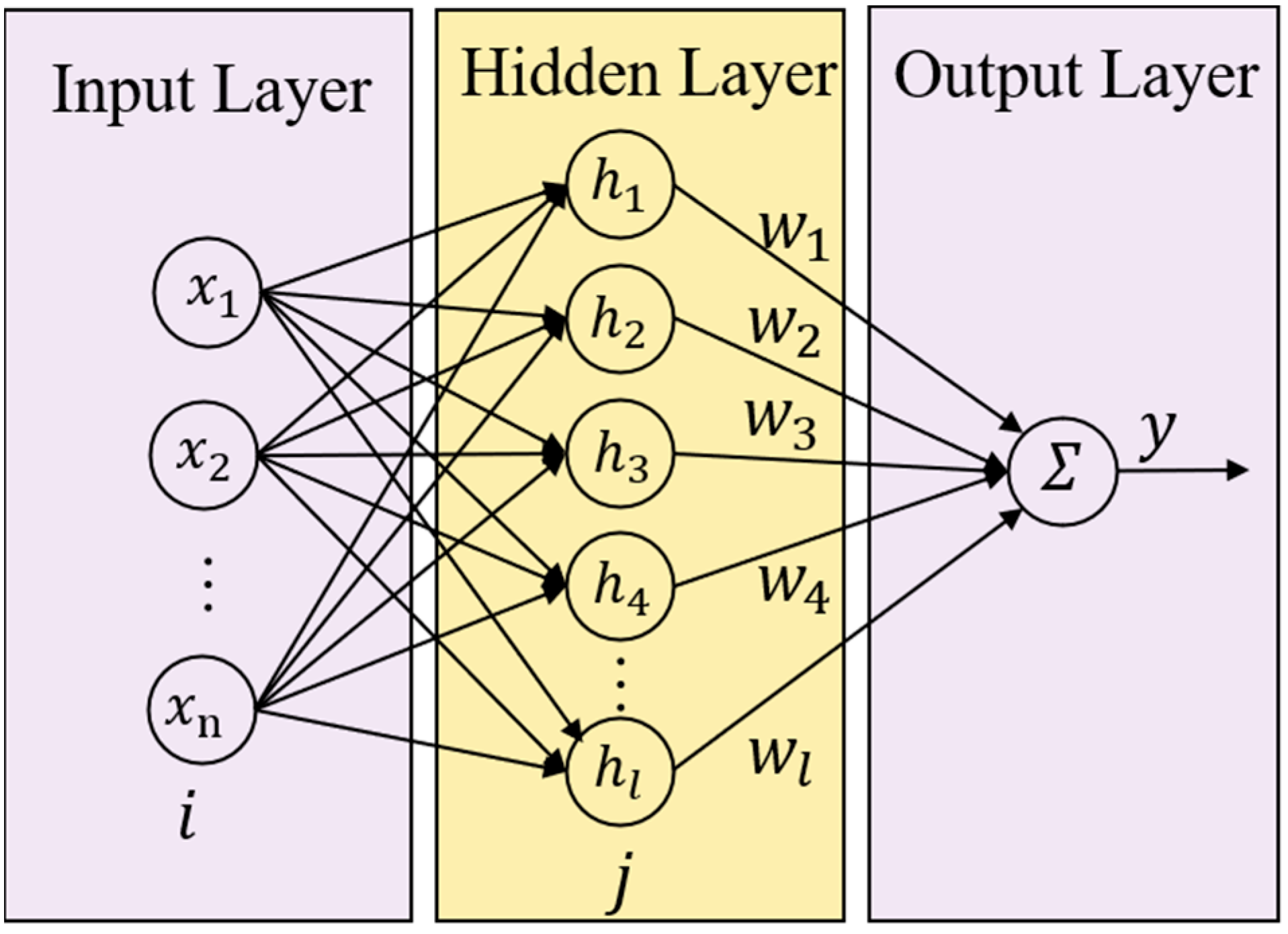

2.3. RBFNN

2.4. Event-Triggered Control

2.5. Properties, Assumptions, and Lemmas

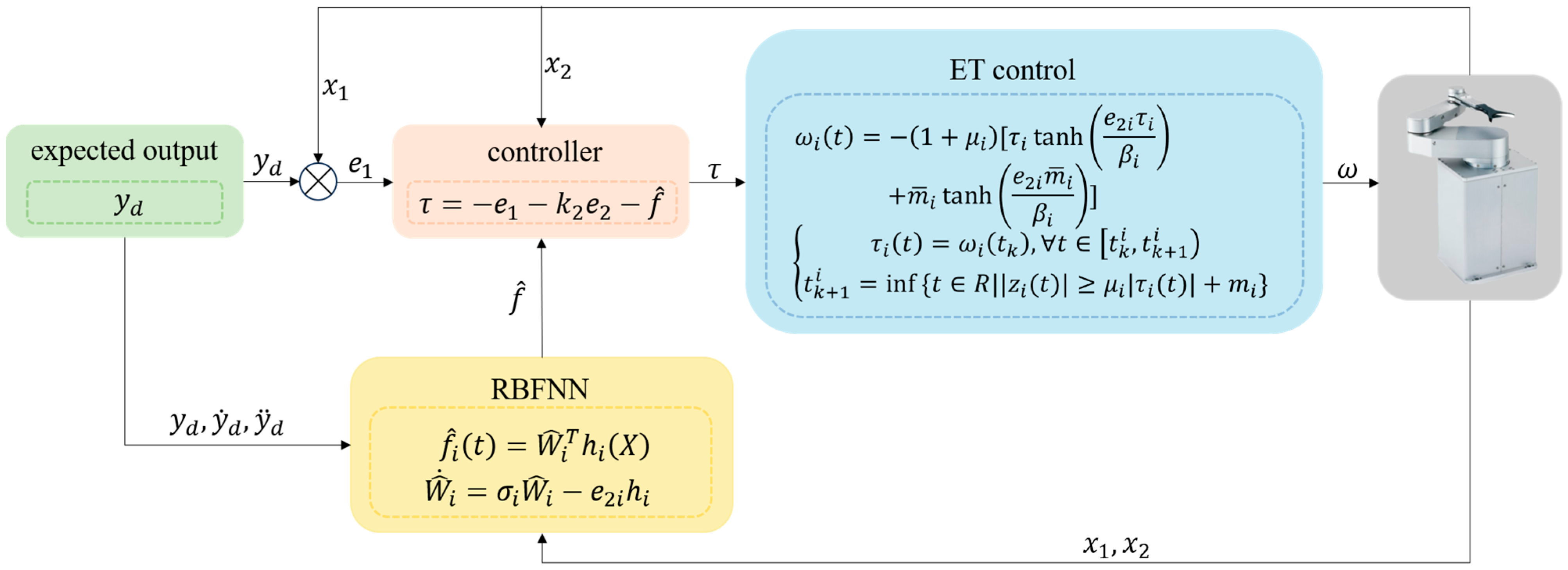

3. Control Design

3.1. Controller Design

3.2. Event Triggering

4. Stability Analysis

5. Simulation and Results

6. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RBFNN | Radial Basis Function Neural Network |

| UUB | Uniformly Ultimately Bounded |

| SMC | sliding mode control |

| NN | neural networks |

| ETC | event-triggered control |

| COM | center of mass |

| ITSE | integral of time-weighted squared error |

| IAE | integral of absolute error |

| ITAE | integral of time-weighted absolute error |

| RMSE | root mean square error |

Appendix A

| Parameter Variation | Number of Controller Updates | Change from Baseline |

|---|---|---|

| Baseline | 3057 | - |

| − 10% | 4047 | +32.4% |

| + 10% | 3827 | +25.2% |

| − 10% | 3307 | +8.2% |

| + 10% | 3075 | +0.6% |

| − 5% | 4064 | +32.9% |

| + 5% | 4990 | +63.2% |

References

- Cong, M.; Yu, X.; Shen, B.H.; Liu, J. Research on a Novel R-θ Wafer-Handling Robot. In Proceedings of the IEEE International Conference on Automation and Logistics, Jinan, China, 18–21 August 2007; pp. 597–602. [Google Scholar] [CrossRef]

- Liu, Y.; Cao, Y.; Sun, L.; Zheng, X. Accurate and Steady Control on Trajectory Tracking for the Wafer Transfer Robot. Ind. Robot. 2010, 37, 552–561. [Google Scholar] [CrossRef]

- Joo, Y.H.; Park, H.; Kim, H.; Choe, R.; Kang, Y.; Jung, J.-Y. Traffic Flow Speed Prediction in Overhead Transport Systems for Semiconductor Fabrication Using Dense-UNet. Processes 2022, 10, 1580. [Google Scholar] [CrossRef]

- Jiang, H.; Zhao, Y.; Zhu, L.; Zhang, J.; Liu, C. Review on Vibration Control of Wafer Handling Robot. Intell. Sustain. Manuf. 2025, 2, 10007. [Google Scholar] [CrossRef]

- Hu, S.; Liu, H.; Kang, H.; Ouyang, P.; Liu, Z.; Cui, Z. High Precision Hybrid Torque Control for 4-DOF Redundant Parallel Robots under Variable Load. Actuators 2023, 12, 232. [Google Scholar] [CrossRef]

- Xiao, B.; Cao, L.; Xu, S.; Liu, L. Robust Tracking Control of Robot Manipulators with Actuator Faults and Joint Velocity Measurement Uncertainty. IEEE/ASME Trans. Mechatron. 2020, 25, 1354–1365. [Google Scholar] [CrossRef]

- Thien, R.T.Y.; Kim, Y. Decentralized Formation Flight via PID and Integral Sliding Mode Control. IFAC-PapersOnLine 2018, 51, 13–15. [Google Scholar] [CrossRef]

- Nohooji, H.R. Constrained Neural Adaptive PID Control for Robot Manipulators. J. Franklin Inst. 2020, 357, 3907–3923. [Google Scholar] [CrossRef]

- Chen, M.; Jiang, B. Robust Attitude Control of Near Space Vehicles with Time-Varying Disturbances. Int. J. Control Autom. Syst. 2013, 11, 182–187. [Google Scholar] [CrossRef]

- Awan, S.Z.; Ali, K.; Iqbal, J.; Mehmood, A. Adaptive Backstepping Based Sensor and Actuator Fault Tolerant Control of a Manipulator. J. Electr. Eng. Technol. 2019, 14, 2497–2504. [Google Scholar] [CrossRef]

- Omer, S.; Faisal, A.; Jamshed, I. Complex Fractional-Order LQIR for Inverted-Pendulum-Type Robotic Mechanisms: Design and Experimental Validation. Mathematics 2023, 11, 913. [Google Scholar] [CrossRef]

- Huynh, V.N.S.; Ngo, H.Q.T.; Nguyen, T.P.; Nguyen, H. High Performance of an Adaptive Sliding Mode Controller under Varying Loads for Lifting-Type Autonomous Grounded Robot. Appl. Sci. 2020, 10, 5858. [Google Scholar] [CrossRef]

- Käppler, M.; Mamaev, I.; Alagi, H.; Stein, T.; Deml, B. Optimizing human-robot handovers: The impact of adaptive transport methods. Front. Robot. AI 2023, 10, 1155143. [Google Scholar] [CrossRef] [PubMed]

- Ali, K.; Ullah, S.; Mehmood, A.; Mostafa, H.; Marey, M.; Iqbal, J. Adaptive FIT-SMC Approach for an Anthropomorphic Manipulator With Robust Exact Differentiator and Neural Network-Based Friction Compensation. IEEE Access 2022, 10, 3378–3389. [Google Scholar] [CrossRef]

- Han, J.; Wang, F.; Sun, C. Trajectory Tracking Control of a Manipulator Based on an Adaptive Neuro-Fuzzy Inference System. Appl. Sci. 2023, 13, 1046. [Google Scholar] [CrossRef]

- Zhu, Q.; Sun, W.; Shen, Y.; Fu, G.; Yang, Y.; Li, J. A Novel Combined Control of Flexible Single-Link Manipulator Based on Singularly Perturbed Theory. Robot. Intell. Autom. 2024, 44, 806–816. [Google Scholar] [CrossRef]

- Yin, F.; Wen, C.; Ji, Q.; Zhang, H.; Shao, H. A Compensation Sliding Mode Control for Machining Robotic Manipulators Based on Nonlinear Disturbance Observer. Trans. Inst. Meas. Control 2022, 44, 2336–2349. [Google Scholar] [CrossRef]

- Saaideh, M.A.; Al-Rawashdeh, Y.M.; Aljanaideh, K.; Zhang, L.; Boker, A.; Janaideh, M.A. Output Feedback Control of Variable-Loaded Four-Joint Manipulators with Unknown Saturated Actuator Dynamics. Int. J. Control Autom. Syst. 2024, 22, 3694–3707. [Google Scholar] [CrossRef]

- Shu, X.; Ni, F.; Min, K.; Liu, Y.; Liu, H. A Novel Dual-Arm Adaptive Cooperative Control Framework for Carrying Variable Loads and Active Anti-Overturning. ISA Trans. 2024, 148, 477–489. [Google Scholar] [CrossRef]

- Kumar, N. Force/Position Control of Constrained Mobile Manipulators with Fast Terminal Sliding Mode Control and Neural Network. J. Control Autom. Electr. Syst. 2023, 34, 1145–1158. [Google Scholar] [CrossRef]

- Rani, S.; Kumar, A.; Kumar, N.; Singh, H.P. Adaptive Robust Motion/Force Control of Constrained Mobile Manipulators Using RBF Neural Network. Int. J. Dyn. Control 2024, 12, 3379–3391. [Google Scholar] [CrossRef]

- Gaidhane, P.J.; Nigam, M.J.; Kumar, A.; Pradhan, P.M. Design of Interval Type-2 Fuzzy Precompensated PID Controller Applied to Two-DOF Robotic Manipulator with Variable Payload. ISA Trans. 2019, 89, 169–185. [Google Scholar] [CrossRef]

- Zhang, J.; Zheng, Y. Predefined Performance Course Tracking Control of Unmanned Surface Vehicle via the Upper Bounded and Dynamic Event-Triggered Technique. Ocean Eng. 2025, 333, 121532. [Google Scholar] [CrossRef]

- Wang, Z.; Qiu, Y.; Hao, Y.; Bai, Y.; Qiu, L.; Zhang, G. Event-Triggered Three-Dimensional Adaptive Anti-Disturbance IGC Method for a Class of Flight Vehicles. Aerosp. Sci. Technol. 2025, 162, 110233. [Google Scholar] [CrossRef]

- Li, J.; Fan, Y. Fixed-Time Event-Triggered Fault-Tolerant Formation-Containment Control for Underactuated USVs with Uncertain Dynamics. Nonlinear Dyn. 2025, 113, 21435–21454. [Google Scholar] [CrossRef]

- Li, M.; Li, T.; Gao, X.; Shan, Q.; Chen, C.L.P.; Xiao, Y. Adaptive NN Event-Triggered Control for Path Following of Underactuated Vessels with Finite-Time Convergence. Neurocomputing 2019, 379, 203–213. [Google Scholar] [CrossRef]

- Fu, L.; An, L. Adaptive Event-Triggered Obstacle Avoidance Control for Unmanned Vehicles via Distance-Velocity Barrier Functions. Inf. Sci. 2025, 702, 121910. [Google Scholar] [CrossRef]

- Li, R.; Li, T.; Bai, W.; Du, X. An Adaptive Neural Network Approach for Ship Roll Stabilization via Fin Control. Neurocomputing 2016, 173, 953–957. [Google Scholar] [CrossRef]

- Luo, W.; Hu, B.; Li, T. Neural Network Based Fin Control for Ship Roll Stabilization with Guaranteed Robustness. Neurocomputing 2016, 230, 210–218. [Google Scholar] [CrossRef]

- Wang, W.; Tong, S. Distributed Adaptive Fuzzy Event-Triggered Containment Control of Nonlinear Strict-Feedback Systems. IEEE Trans. Cybern. 2019, 50, 3973–3983. [Google Scholar] [CrossRef]

- Selmic, R.R.; Lewis, F.L. Deadzone Compensation in Motion Control Systems Using Neural Networks. IEEE Trans. Autom. Control 2000, 45, 602–613. [Google Scholar] [CrossRef]

- Polycarpou, M.M. Stable Adaptive Neural Control Scheme for Nonlinear Systems. IEEE Trans. Autom. Control 1996, 41, 447–451. [Google Scholar] [CrossRef]

- Qiu, X.; Hua, C.; Chen, J.; Zhang, Y.; Guan, X. Event-Triggered Based Adaptive Neural Network Control of a Robotic Manipulator with Output Constraints and Disturbance. Int. J. Syst. Sci. 2021, 52, 2415–2426. [Google Scholar] [CrossRef]

- Diao, S.; Sun, W.; Su, S.-F.; Xia, J. Adaptive Fuzzy Event-Triggered Control for Single-Link Flexible-Joint Robots with Actuator Failures. IEEE Trans. Cybern. 2021, 52, 7231–7241. [Google Scholar] [CrossRef] [PubMed]

- Slotine, J.J.E.; Li, W.P. Applied Nonlinear Control; China Machine Press: Beijing, China, 1991. [Google Scholar]

- Hyun, K. AudioGuard: Speech Recognition System Robust against Optimized Audio Adversarial Examples. Multimed. Tools Appl. 2023, 83, 57943–57962. [Google Scholar] [CrossRef]

| Performance Metric | N1 | N2 | SMC |

|---|---|---|---|

| 0.5689 | 0.6796 | 1.0702 | |

| 0.1775 | 0.2114 | 0.3675 | |

| 1.1227 | 1.1286 | 2.2189 | |

| 0.1038 | 0.1564 | 0.3759 | |

| 0.0943 | 0.1028 | 0.1356 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, B.; Yuan, L.; Yu, H. RBF Neural Network-Based Anti-Disturbance Trajectory Tracking Control for Wafer Transfer Robot Under Variable Payload Conditions. Appl. Sci. 2025, 15, 9193. https://doi.org/10.3390/app15169193

Xu B, Yuan L, Yu H. RBF Neural Network-Based Anti-Disturbance Trajectory Tracking Control for Wafer Transfer Robot Under Variable Payload Conditions. Applied Sciences. 2025; 15(16):9193. https://doi.org/10.3390/app15169193

Chicago/Turabian StyleXu, Bo, Luyao Yuan, and Hao Yu. 2025. "RBF Neural Network-Based Anti-Disturbance Trajectory Tracking Control for Wafer Transfer Robot Under Variable Payload Conditions" Applied Sciences 15, no. 16: 9193. https://doi.org/10.3390/app15169193

APA StyleXu, B., Yuan, L., & Yu, H. (2025). RBF Neural Network-Based Anti-Disturbance Trajectory Tracking Control for Wafer Transfer Robot Under Variable Payload Conditions. Applied Sciences, 15(16), 9193. https://doi.org/10.3390/app15169193