Comparative Analysis of Ultra-Fine Bar Refining and Valley Beating on Softwood and Hardwood Kraft Pulps: Implications for Fiber Integrity and Paper Strength Enhancement

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

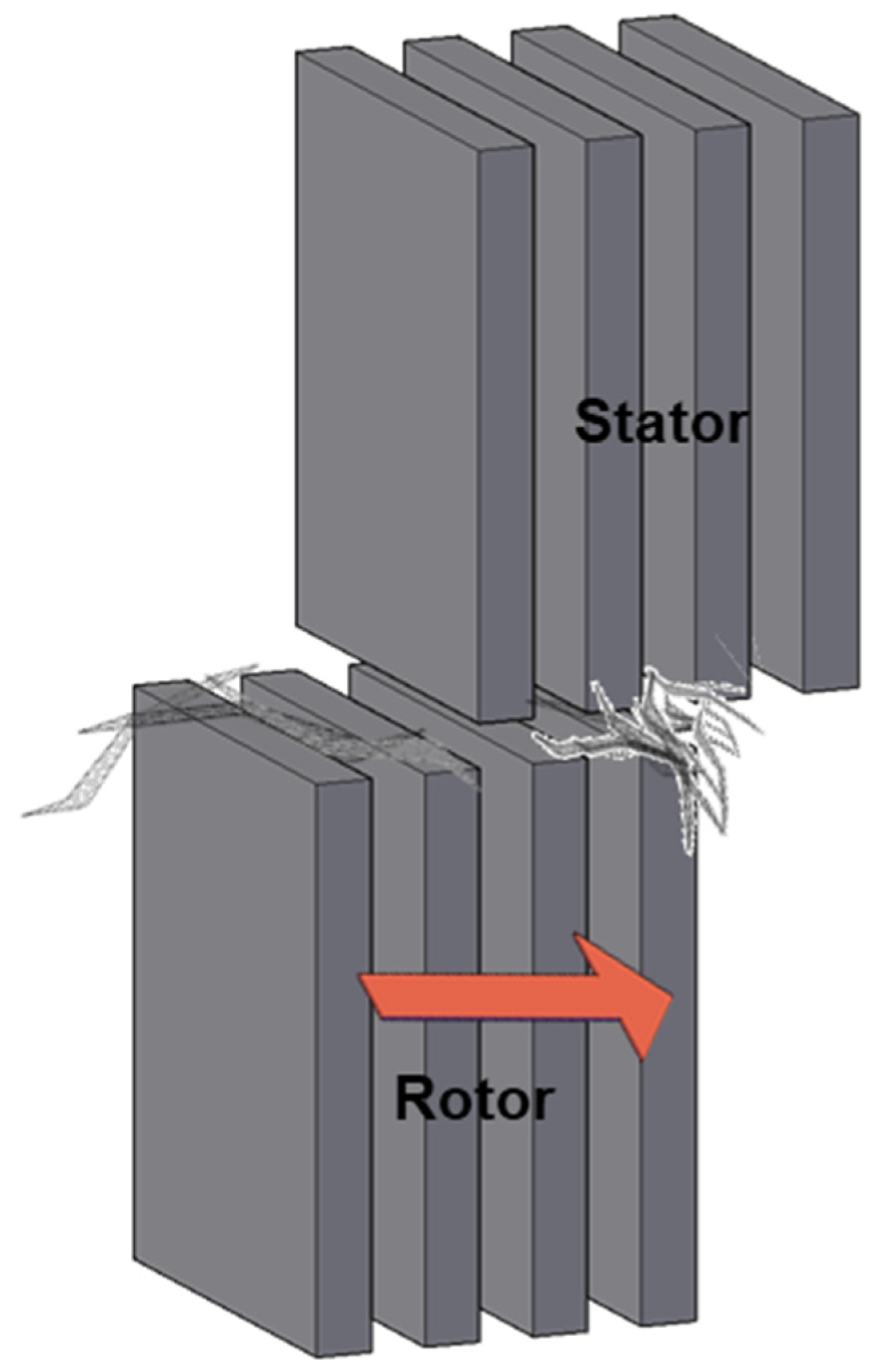

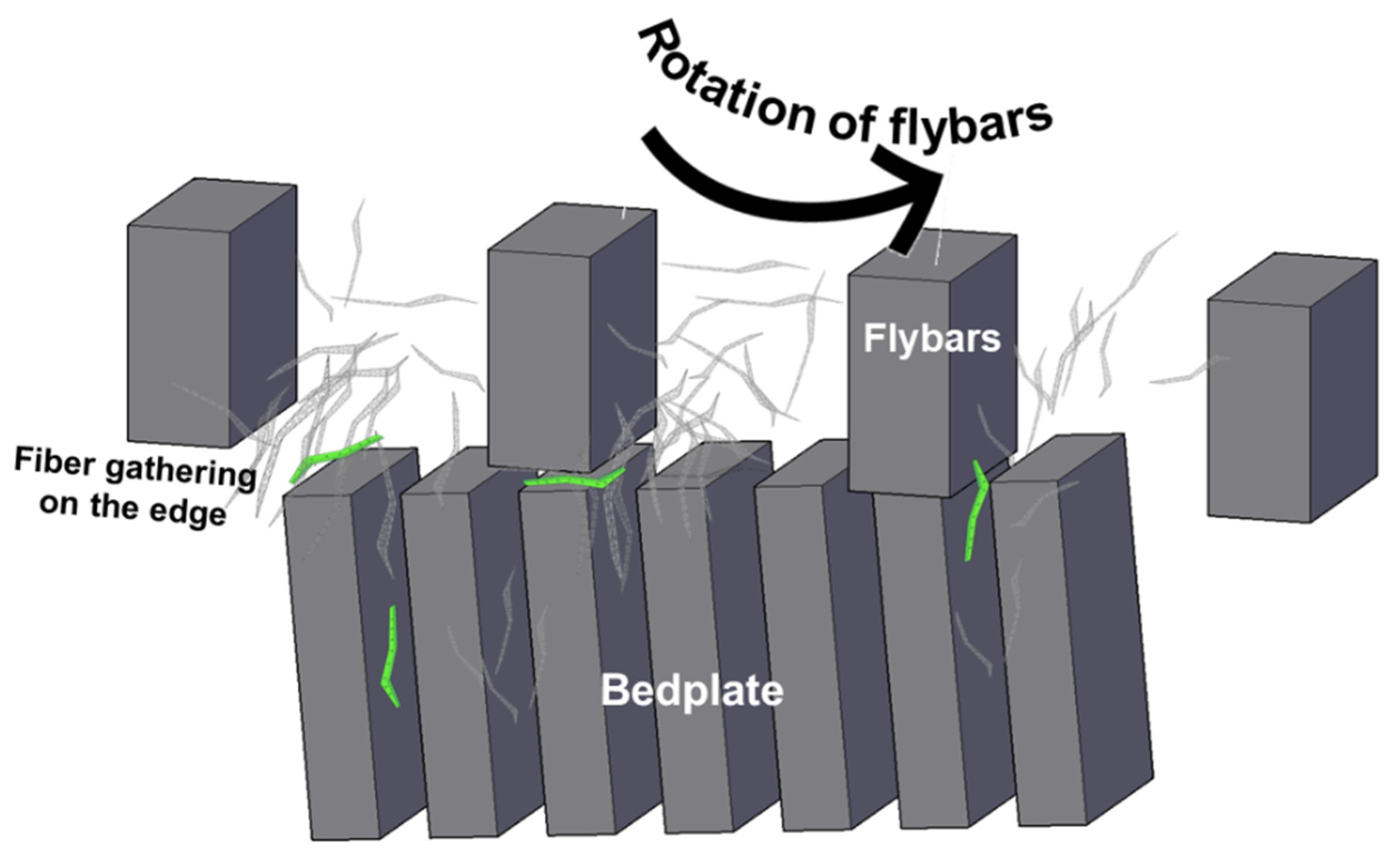

2.2. Beating and Refining

2.3. Analysis of Pulp and Paper Properties

3. Results

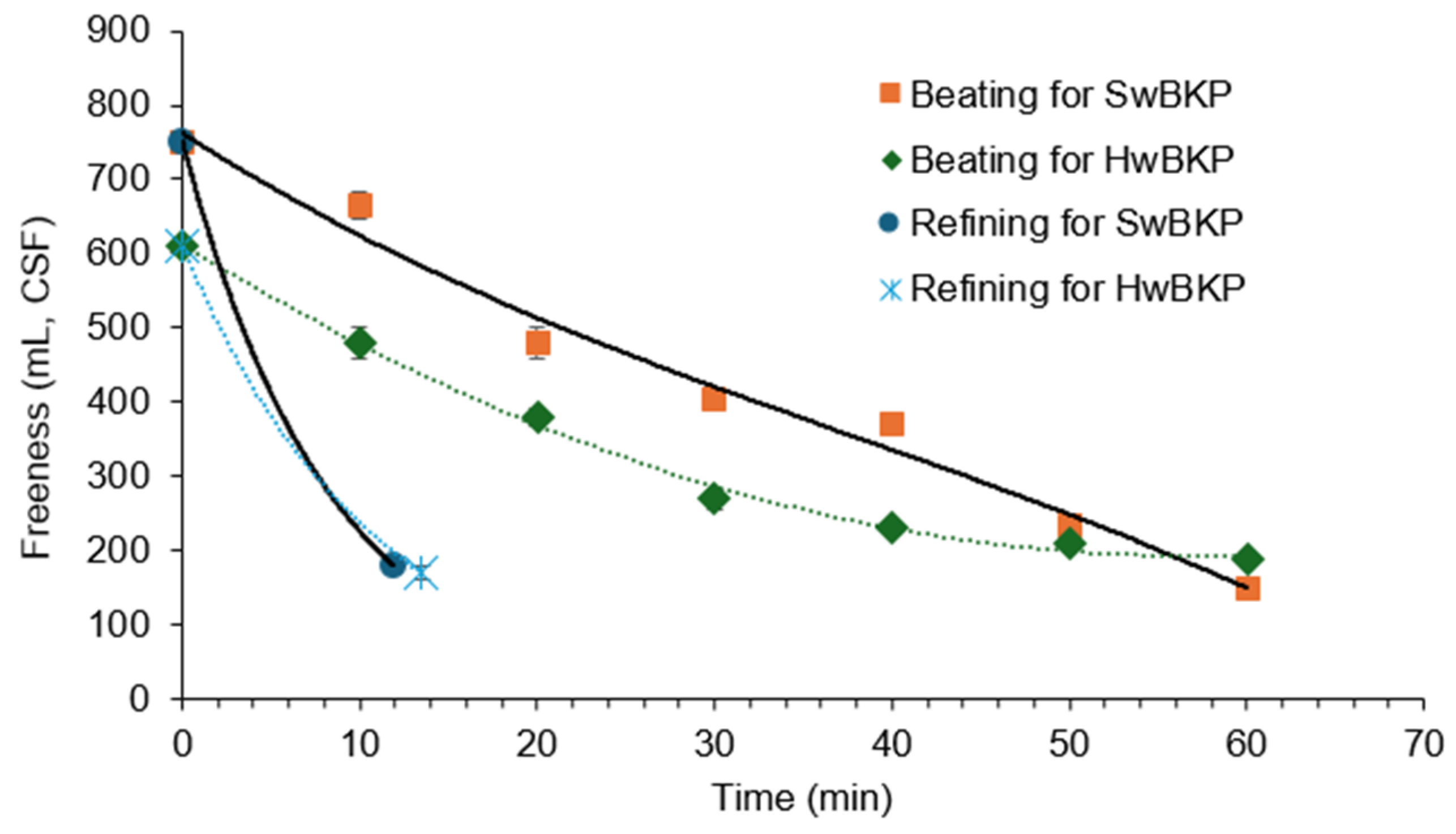

3.1. Freeness

3.2. Fiber Length

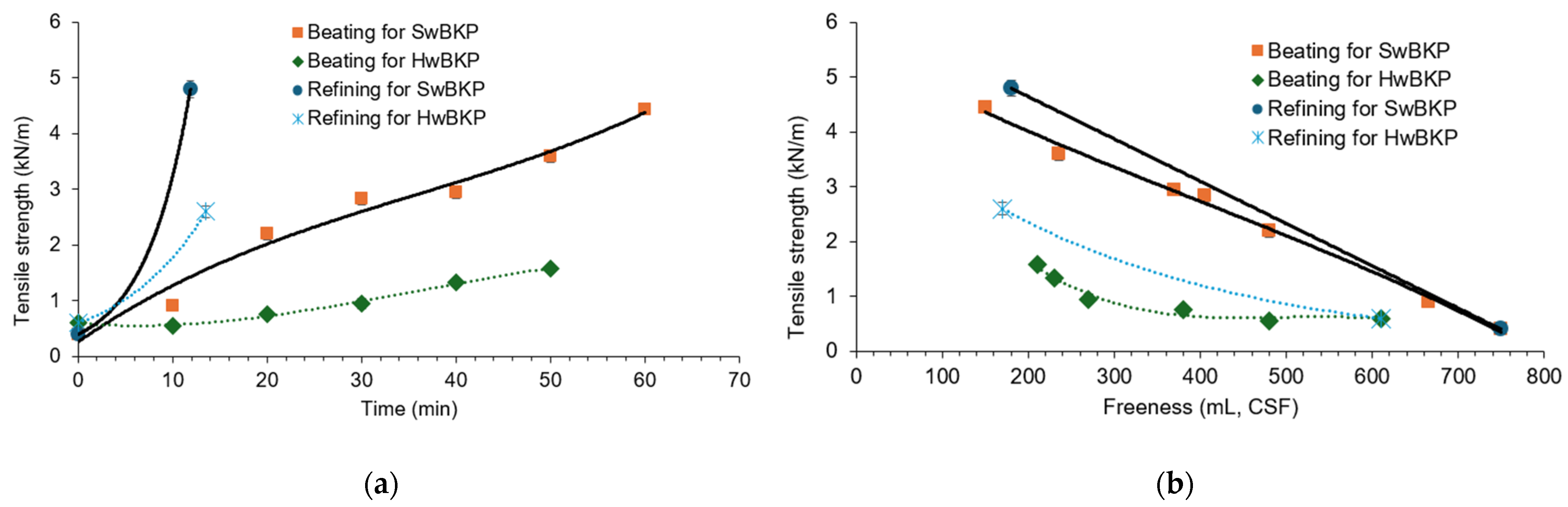

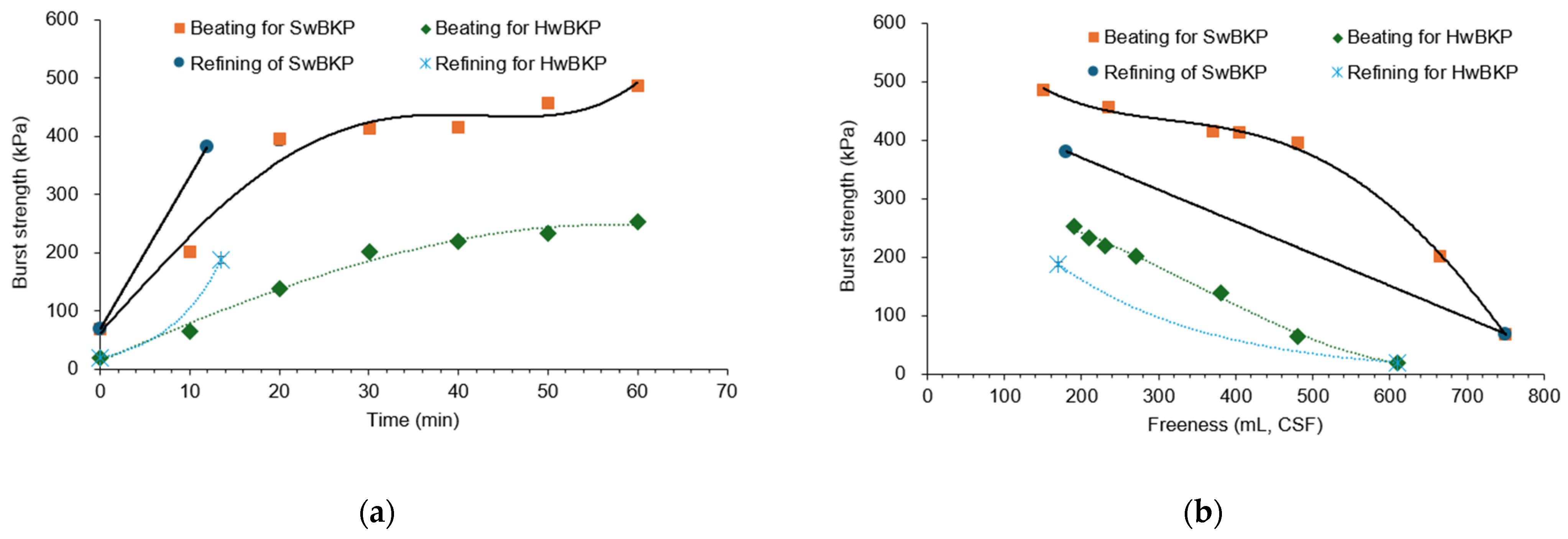

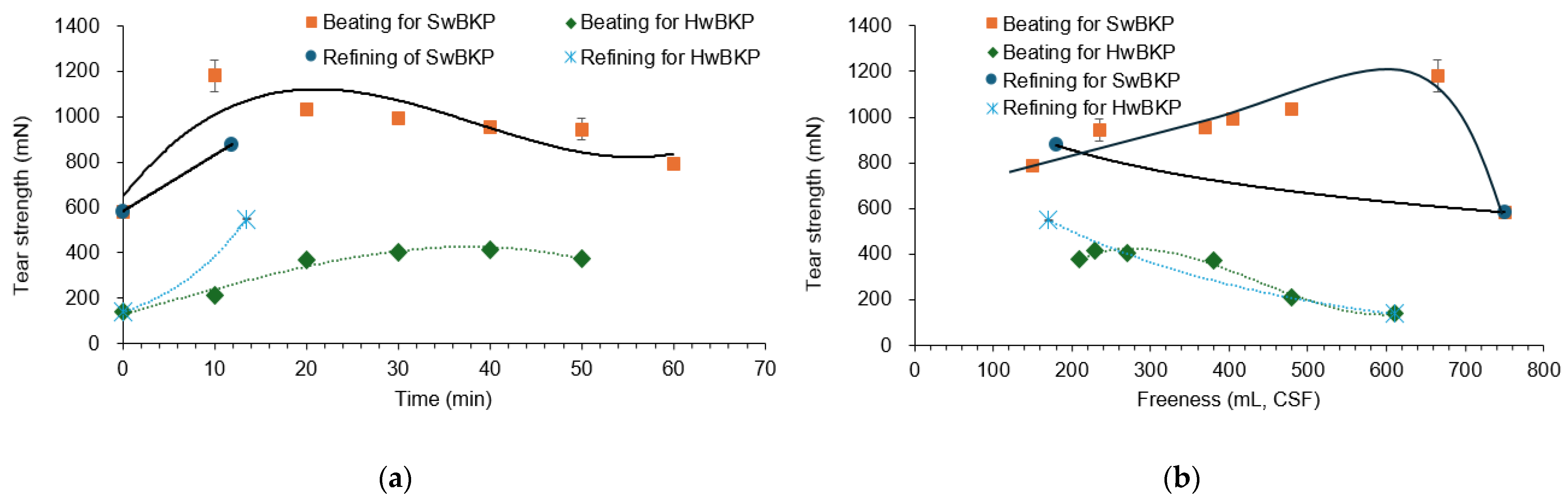

3.3. Physical Properties of Paper

3.4. Observation of Fiber Morphology Before and After Mechanical Treatment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Motamedian, H.R.; Halilovic, A.E.; Kulachenko, A. Mechanisms of strength and stiffness improvement of paper after PFI refining with a focus on the effect of fines. Cellulose 2019, 26, 4099–4124. [Google Scholar] [CrossRef]

- Hubbe, M.A. Paper’s strength: A review. BioResources 2007, 2, 739–788. [Google Scholar]

- Mandlez, D.; Koller, S.; Eckhart, R.; Kulachenko, A.; Bauer, W.; Hirn, U. Quantifying the contribution of fines production during refining to the resulting paper strength. Cellulose 2022, 29, 8811–8826. [Google Scholar] [CrossRef]

- Seth, R.S. The measurement and significance of fines. Pulp Pap. Can. 2003, 104, 41–44. [Google Scholar]

- Smook, G.A. Handbook for Pulp & Paper Technologists, 4th ed.; TAPPI Press: Atlanta, GA, USA, 2016. [Google Scholar]

- Gharehkhani, S.; Sadeghinezhad, E.; Kazi, S.N.; Yarmand, H.; Badarudin, A.; Safaei, M.R.; Zubir, M.N.M. Basic Effects of Pulp Refining on Fiber Properties—A Review. Carbohydr. Polym. 2015, 115, 785–803. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Dong, J.; Qi, K.; Guo, X.; Yan, Y.; Qiao, L.; Zhao, Z. Effect of Pulp Properties on the Power Consumption in Low Consistency Refining. J. Korean Wood Sci. Technol. 2020, 48, 869–877. [Google Scholar] [CrossRef]

- Banavath, H.N.; Bhardwaj, N.K.; Ray, A.K. A comparative study of the effect of refining on charge of various pulps. Bioresour. Technol. 2011, 102, 4544–4551. [Google Scholar] [CrossRef] [PubMed]

- Thompson, D.; Patel, R.; Kim, J. Optimization of Mixed Pulp Stocks for Paper Strength and Smoothness. J. Pulp Pap. Sci. 2018, 44, 233–241. [Google Scholar]

- Min, D.; Gu, Y.; Li, J. Lightweight Refiner Plate for Hardwood Kraft Pulp Fibers. Nord. Pulp Pap. Res. 2020, 35, 123–130. [Google Scholar]

- Min, B.G.; Lee, J.Y.; Kim, C.H.; Park, S.H.; Lee, M.S.; Gu, H.G.; Lee, C.Y. New technology for developing a lightweight refiner plate for hardwood kraft pulp fibers. BioResources 2020, 15, 9128–9142. [Google Scholar] [CrossRef]

- Gu, Y.; Min, D.; Li, J. Development of a lightweight vertical bar plate for softwood kraft pulp refining. BioResources 2021, 16, 5528–5542. [Google Scholar]

- Zhang, L.; Wang, Q.; Chen, S.; Li, H. Effects of Beating and Refining on Fiber Characteristics and Paper Properties of Hardwood-Softwood Blended Pulps. Materials 2021, 14, 5678. [Google Scholar]

- Thompson, D.; Green, P.; Miller, T. Optimization of Mixed Pulp Stocks for Enhanced Paper Properties. Nord. Pulp Pap. Res. 2018, 33, 567–575. [Google Scholar]

- Lehtinen, E. Papermaking Part 1, Stock Preparation and Wet end. In Papermaking Science and Technology; Tappi and PPI: Atlanta, GA, USA, 2000; pp. 81–122. [Google Scholar]

- ISO 5264-1:2016; Pulps—Laboratory Beating—Part 1: Valley Beater Method. ISO: Geneva, Switzerland, 2016.

- Lee, J.Y.; Kim, C.H.; Park, H.H.; Kwon, S.; Yim, H.H.; Gu, H.G.; Min, B.G. Study of Mixed Refining Behaviors of Softwood Kraft Pulps and Hardwood Kraft Pulps Using Different Bar Fillings. J. Korea TAPPI 2018, 50, 31–38. [Google Scholar] [CrossRef]

- Gu, H.G.; Min, B.G.; Lee, J.Y.; Park, S.H. Mechanical modification of softwood pulp fibers using a novel lightweight vertical bar plate. J. Korea TAPPI 2021, 20, 241–251. [Google Scholar] [CrossRef]

- Ryu, J.H.; Kim, C.H.; Lee, J.Y.; Lee, C.Y.; Park, J.H. Study of Refining Effect of Mixed Pulps Using Refiner Plates with Different Bar Pattern. Appl. Sci. 2022, 12, 11445. [Google Scholar] [CrossRef]

- ISO 5267-1:1999; Pulps—Determination of Drainability—Part 1: Schopper-Riegler Method. ISO: Geneva, Switzerland, 1999.

- ISO 5269-1:2005; Pulps—Preparation of Laboratory Sheets for Physical Testing—Part 1: Conventional Sheet-Former Method. ISO: Geneva, Switzerland, 2005.

- ISO 5270:2022; Pulps—Laboratory Sheets—Determination of Physical Properties. ISO: Geneva, Switzerland, 2022.

- Kerekes, R.J.; Senger, J.J. Characterizing the action of refiner bars. Pulp Pap. Can. 2006, 107, 41–45. [Google Scholar]

- Kerekes, R.J. Characterizing refining action in PFI mills. Appita J. 2005, 58, 114–121. [Google Scholar]

- Kerekes, R.J.; Meltzer, F. The influence of bar width on bar forces and fiber shortening in low-consistency pulp refining. Nord. Pulp Pap. Res. J. 2018, 33, 220–225. [Google Scholar] [CrossRef]

- Mohlin, U.B.; Miller, J.A. Effects of refining on pulp fiber structure. In Handbook of Physical Testing of Paper, 1st ed.; Marcel Dekker: New York, NY, USA, 1995; pp. 193–230. [Google Scholar]

- Brecht, W.; Siewert, W. The mechanism of the beating process. Tappi J. 1966, 49, 50–57. [Google Scholar]

- Steadman, R.G.; Luner, P. A comparison of Valley beating and PFI refining. Tappi J. 1985, 68, 94–98. [Google Scholar]

- Higgins, H.; Yong, J. The beating process: Primary effects and their influence on pulp and paper properties. In The Formation and Structure of Paper, Transactions of the 2nd Fundamental Research Symposium, Oxford, UK; Bolam, F., Ed.; FRC: Manchester, UK, 1961. [Google Scholar]

- Lumiainen, J. Papermaking Part 1, Refining of Chemical Pulp. 2000, pp. 86–122. Available online: https://turbulence-initiated.sites.olt.ubc.ca/files/2013/01/1998-Lumiainen-Ch4.pdf (accessed on 1 April 2025).

- Brecht, W.; Siewert, W. The proper evaluation of the beating of pulps. Das. Pap. 1966, 20, 45–50. [Google Scholar]

- Guo, X.; Dong, J.; Liu, H.; Duan, C.; Yang, R.; Qi, K. Effect of combined refining plates with different bar angles on paper properties during mixed pulp refining. J. Korean Wood Sci. Technol. 2020, 48, 581–590. [Google Scholar] [CrossRef]

| Arithmetic Mean Fiber Length (mm) | Length-Weighted Mean Fiber Length (mm) | Arithmetic Fines Contents (≤0.2 mm) (%) | Coarseness (mg/m) | |

|---|---|---|---|---|

| HwBKP | 0.5 | 0.7 | 31 | 5.8 |

| SwBKP | 1.3 | 2.3 | 28 | 15.5 |

| Cellulose (%) | Hemi-Cellulose (%) | Lignin (%) | Extractives (%) | |

|---|---|---|---|---|

| HwBKP | 83 ± 1.24 | 20 ± 0.91 | 0.3 ± 0.13 | 0.3 ± 0.13 |

| SwBKP | 86 ± 1.81 | 13 ± 0.45 | 0.3 ± 0.12 | 0.1 ± 0.11 |

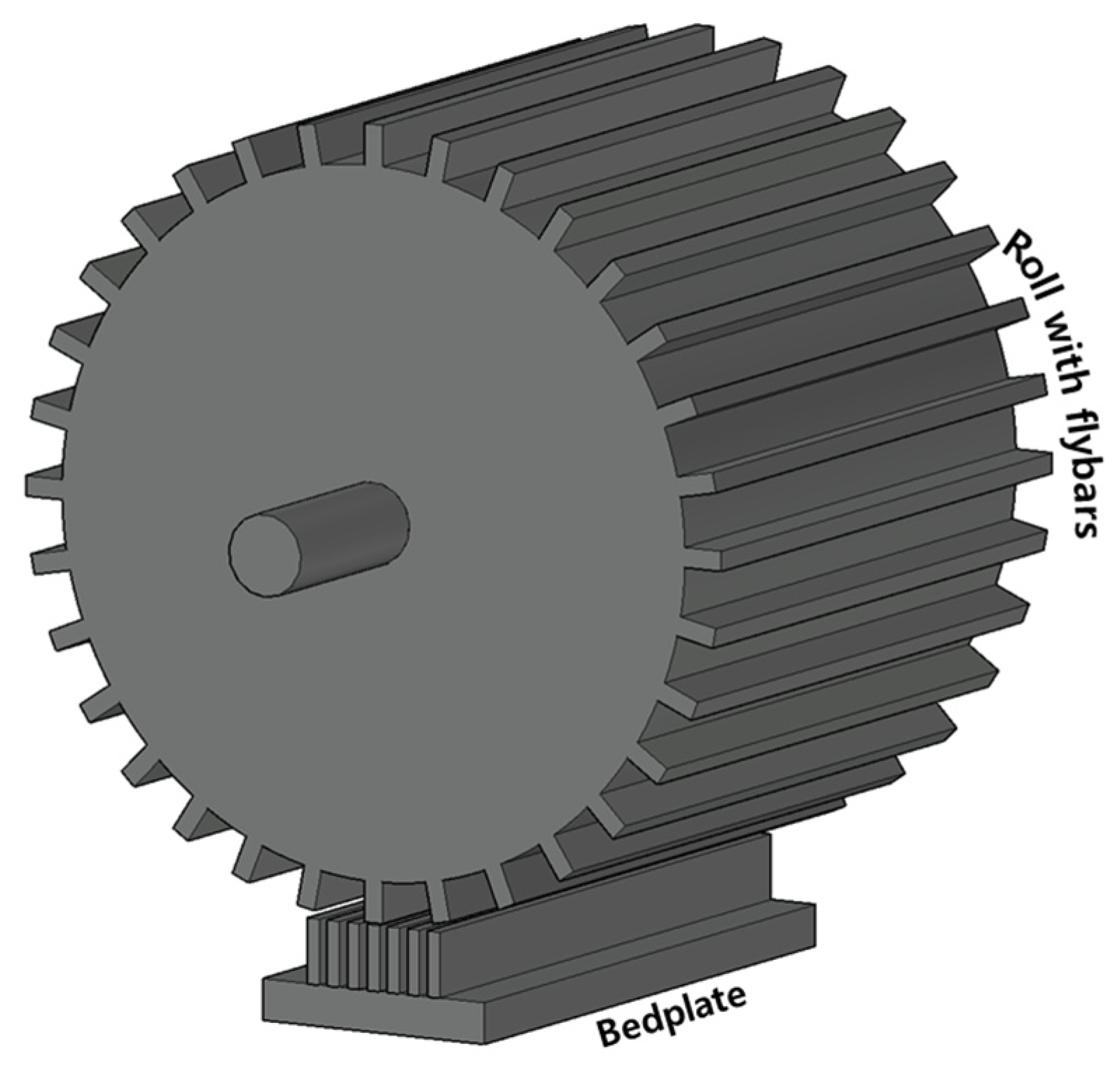

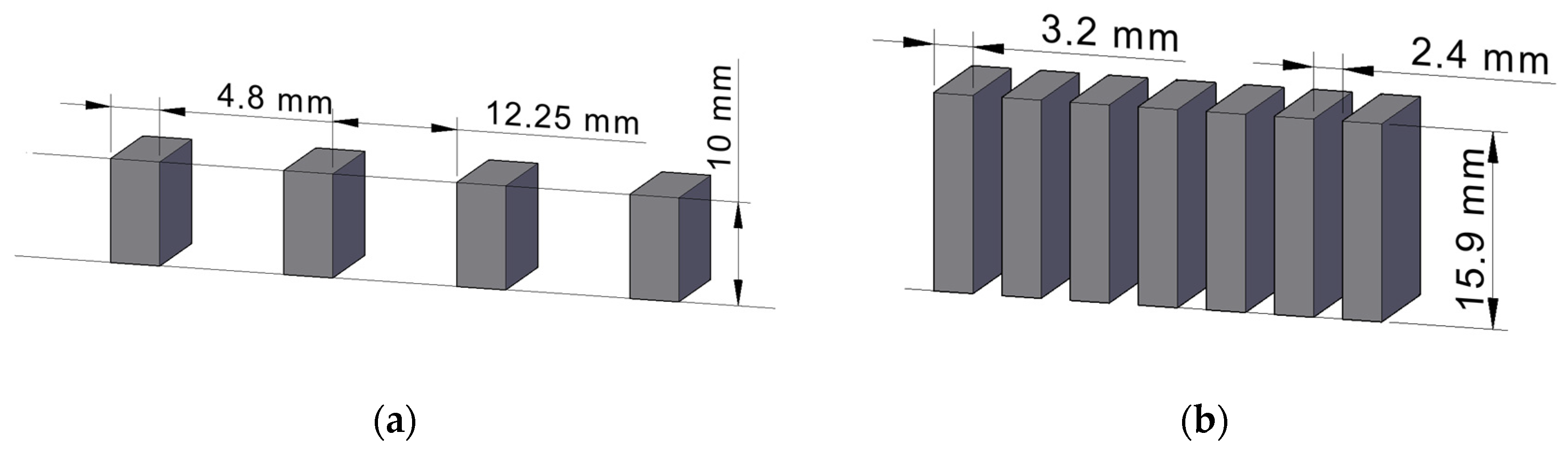

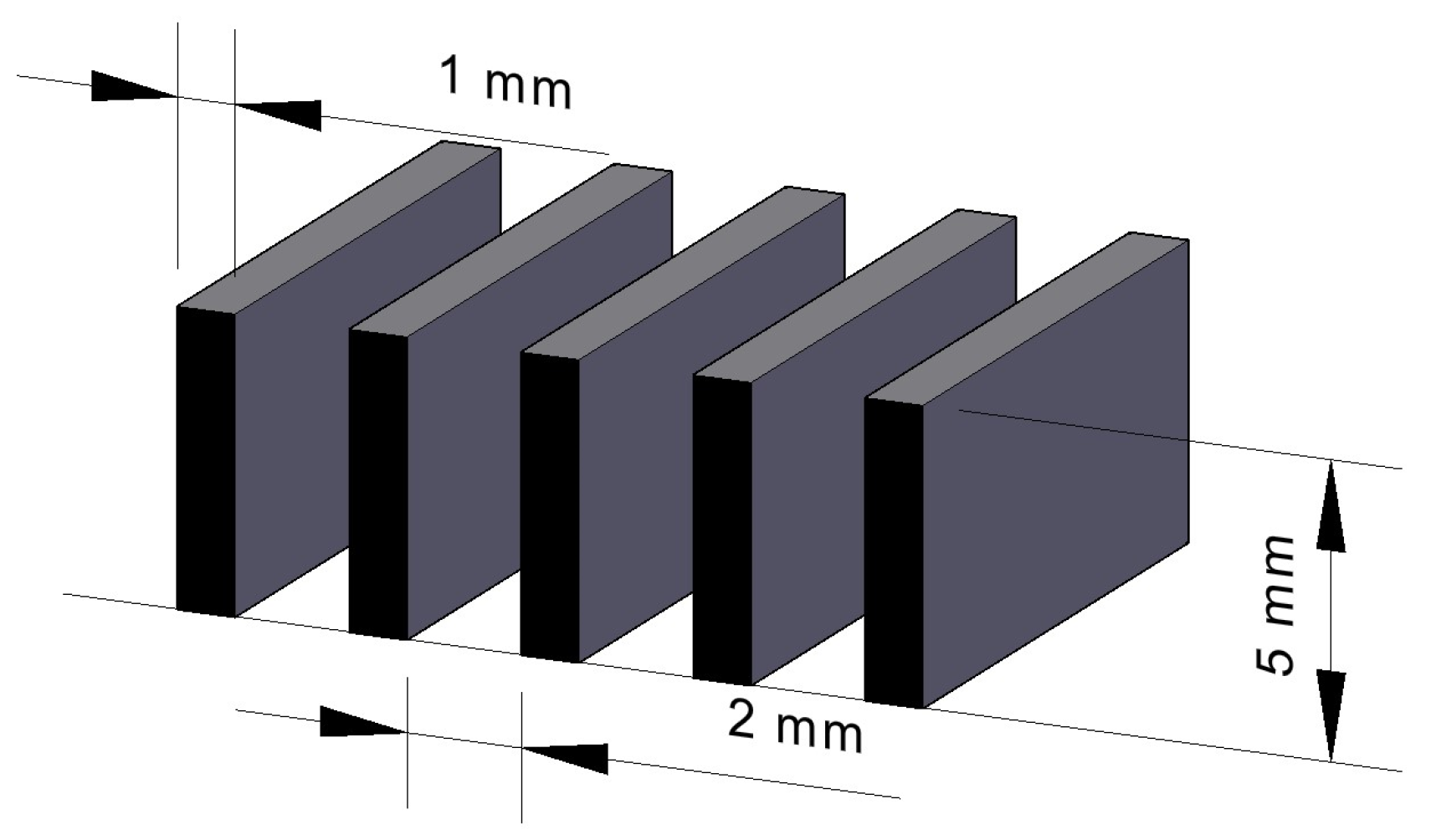

| Roll with Flybars | Bedplate |

|---|---|

| Roll diameter with fly bars: 193.8 mm | Number of bars: 7 |

| Roll width: 4.8 mm | Bar width: 3.2 mm |

| Roll length: 152.4 mm | Bar height: 159 mm |

| Number of flybars: 32 | Groove width: 2.4 mm |

| Flybar height: 10 mm | Angle between the roll axis and bed plate: 5° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, H.-H.; Kim, C.-H.; Park, J.-H.; Park, M.-S.; Lee, J.-S. Comparative Analysis of Ultra-Fine Bar Refining and Valley Beating on Softwood and Hardwood Kraft Pulps: Implications for Fiber Integrity and Paper Strength Enhancement. Appl. Sci. 2025, 15, 9160. https://doi.org/10.3390/app15169160

Park H-H, Kim C-H, Park J-H, Park M-S, Lee J-S. Comparative Analysis of Ultra-Fine Bar Refining and Valley Beating on Softwood and Hardwood Kraft Pulps: Implications for Fiber Integrity and Paper Strength Enhancement. Applied Sciences. 2025; 15(16):9160. https://doi.org/10.3390/app15169160

Chicago/Turabian StylePark, Hyeong-Hun, Chul-Hwan Kim, Ju-Hyun Park, Min-Sik Park, and Jae-Sang Lee. 2025. "Comparative Analysis of Ultra-Fine Bar Refining and Valley Beating on Softwood and Hardwood Kraft Pulps: Implications for Fiber Integrity and Paper Strength Enhancement" Applied Sciences 15, no. 16: 9160. https://doi.org/10.3390/app15169160

APA StylePark, H.-H., Kim, C.-H., Park, J.-H., Park, M.-S., & Lee, J.-S. (2025). Comparative Analysis of Ultra-Fine Bar Refining and Valley Beating on Softwood and Hardwood Kraft Pulps: Implications for Fiber Integrity and Paper Strength Enhancement. Applied Sciences, 15(16), 9160. https://doi.org/10.3390/app15169160