Research on Identification and Application of Joint Surface Characteristic Parameters

Abstract

1. Introduction

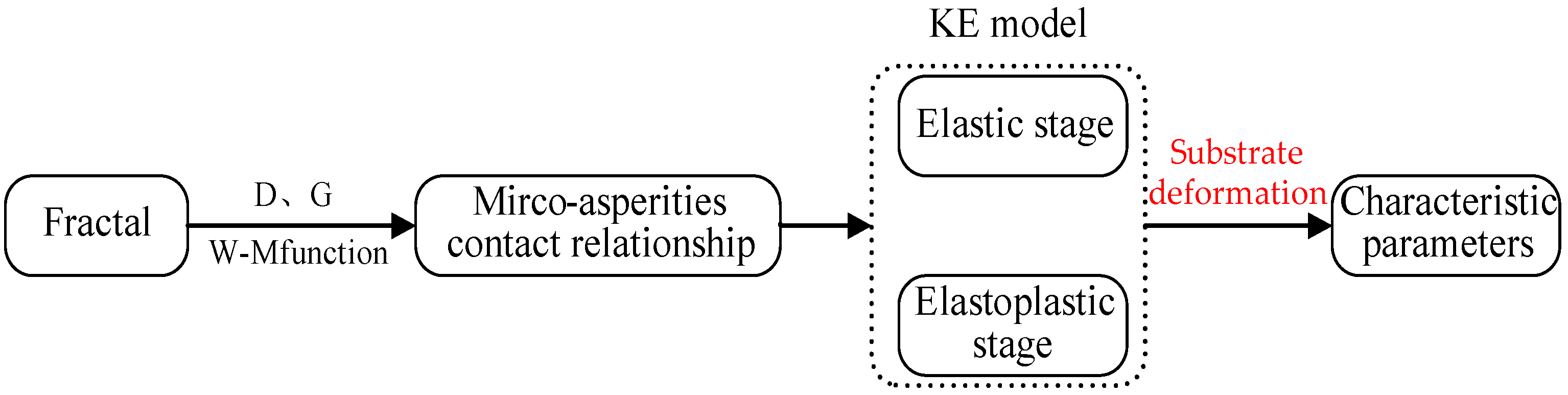

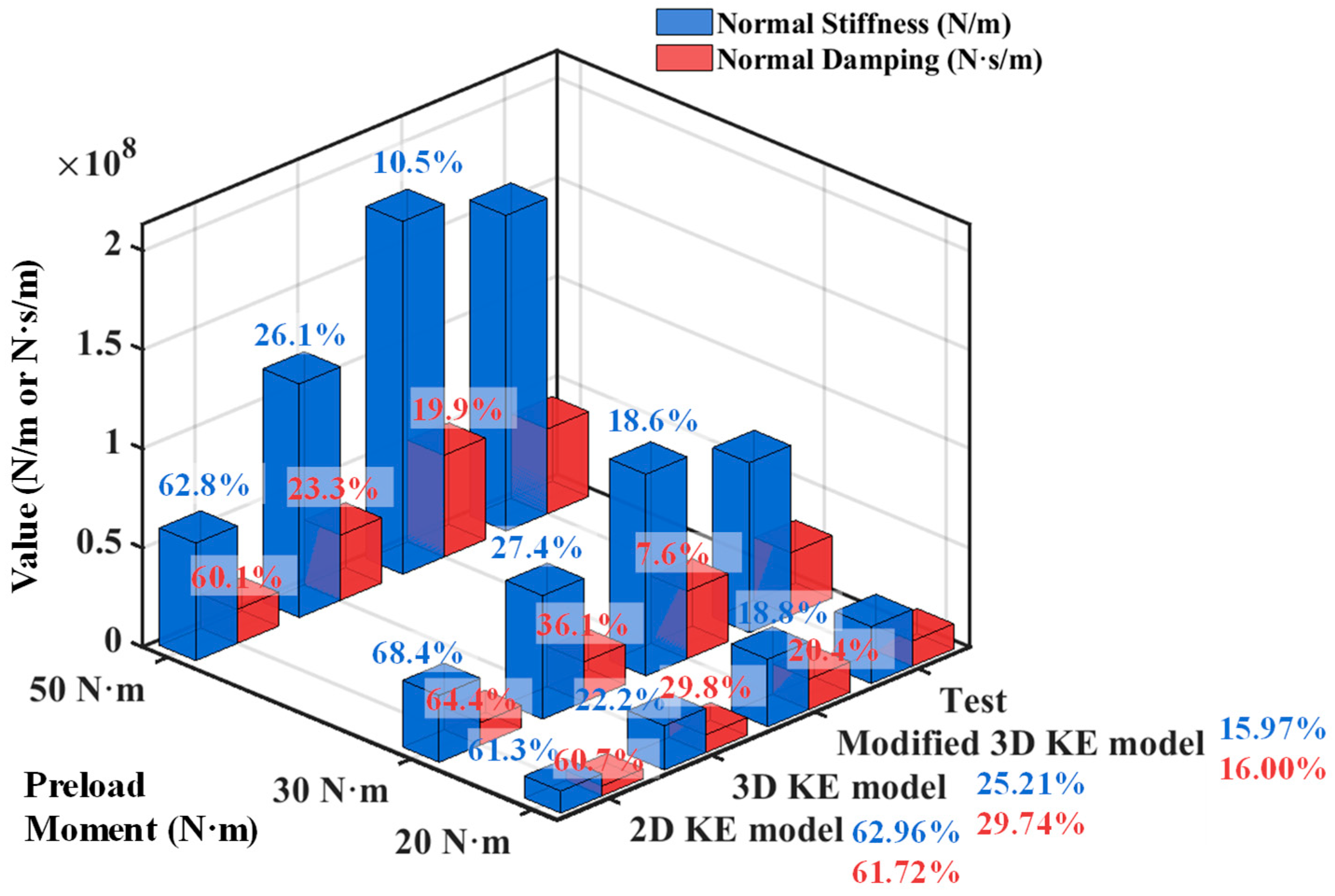

2. Refinement of the Joint Surface Characteristic Parameter Model

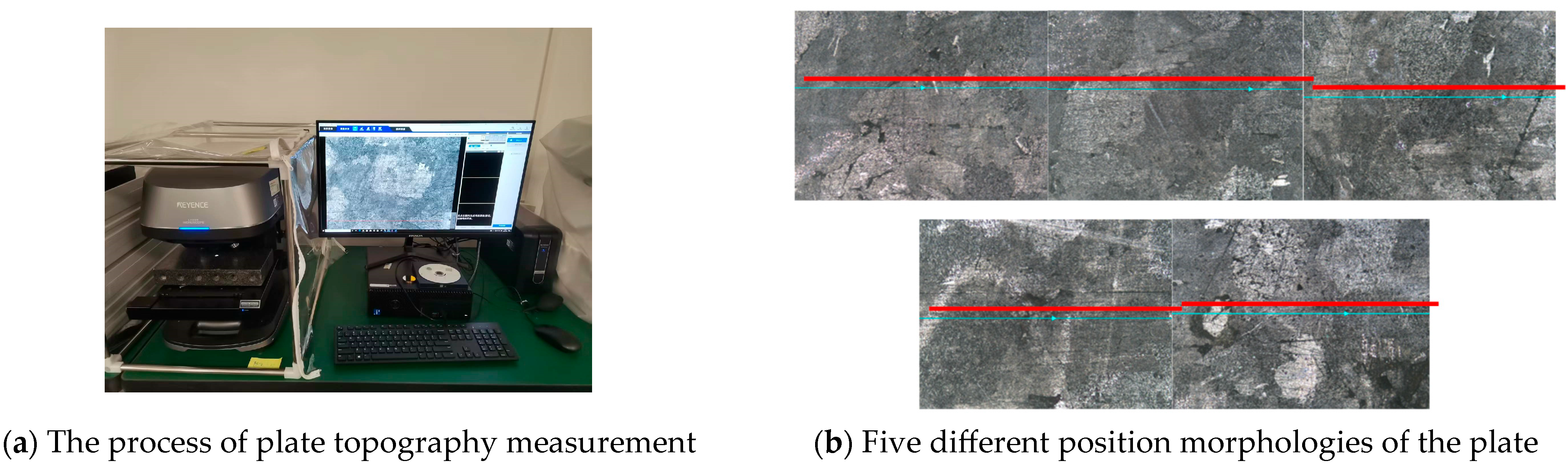

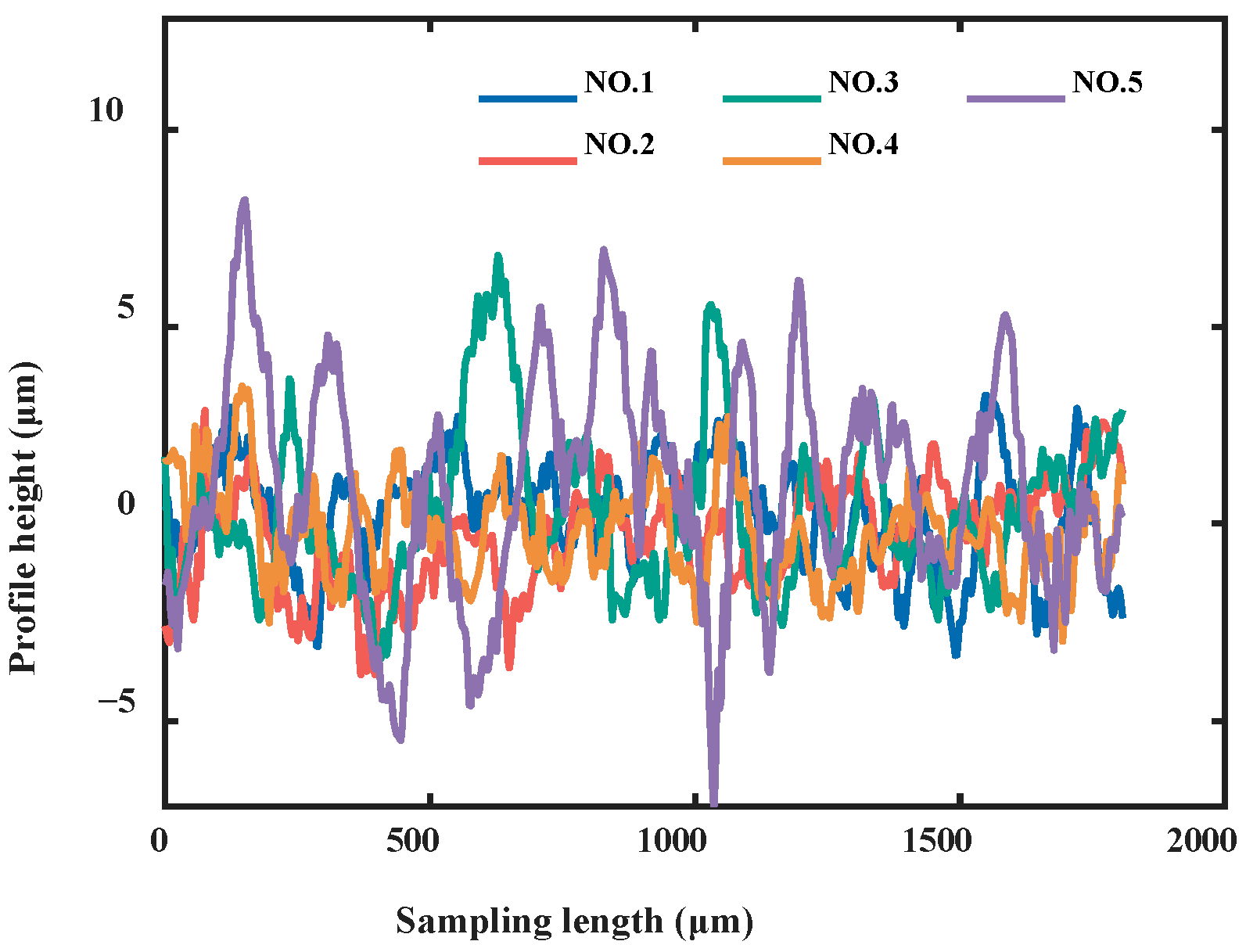

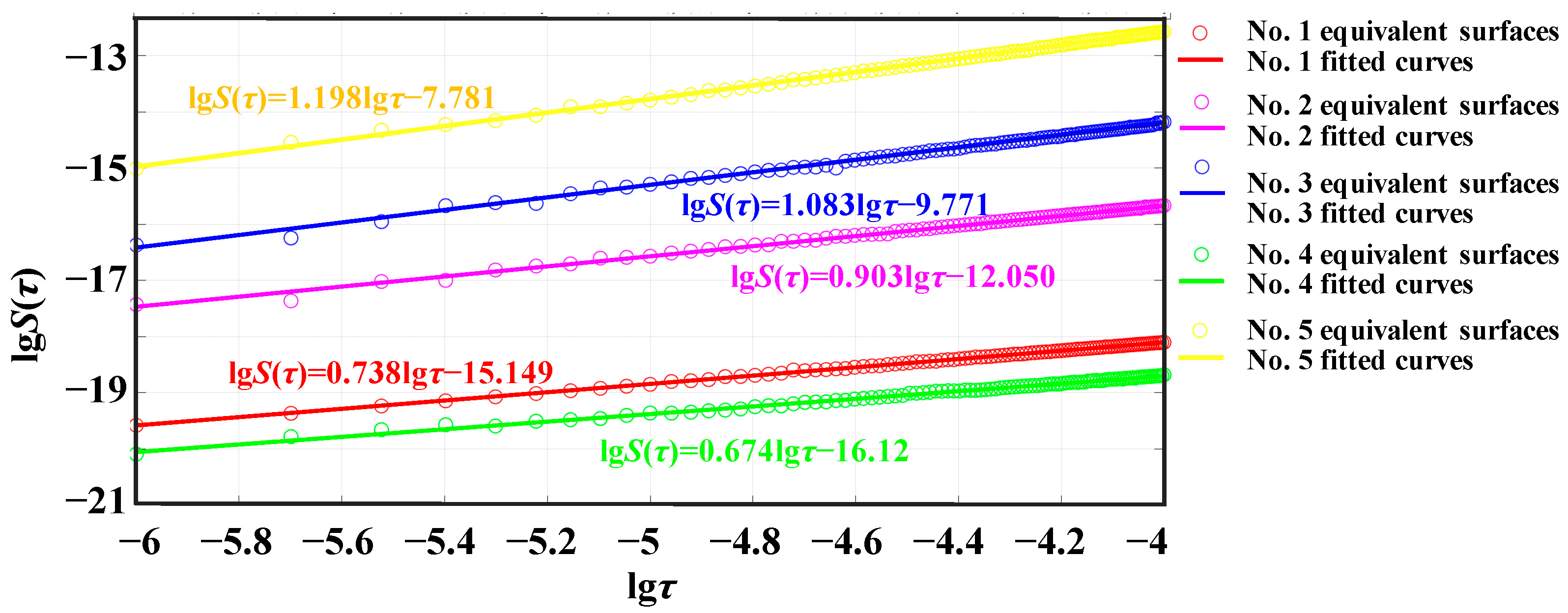

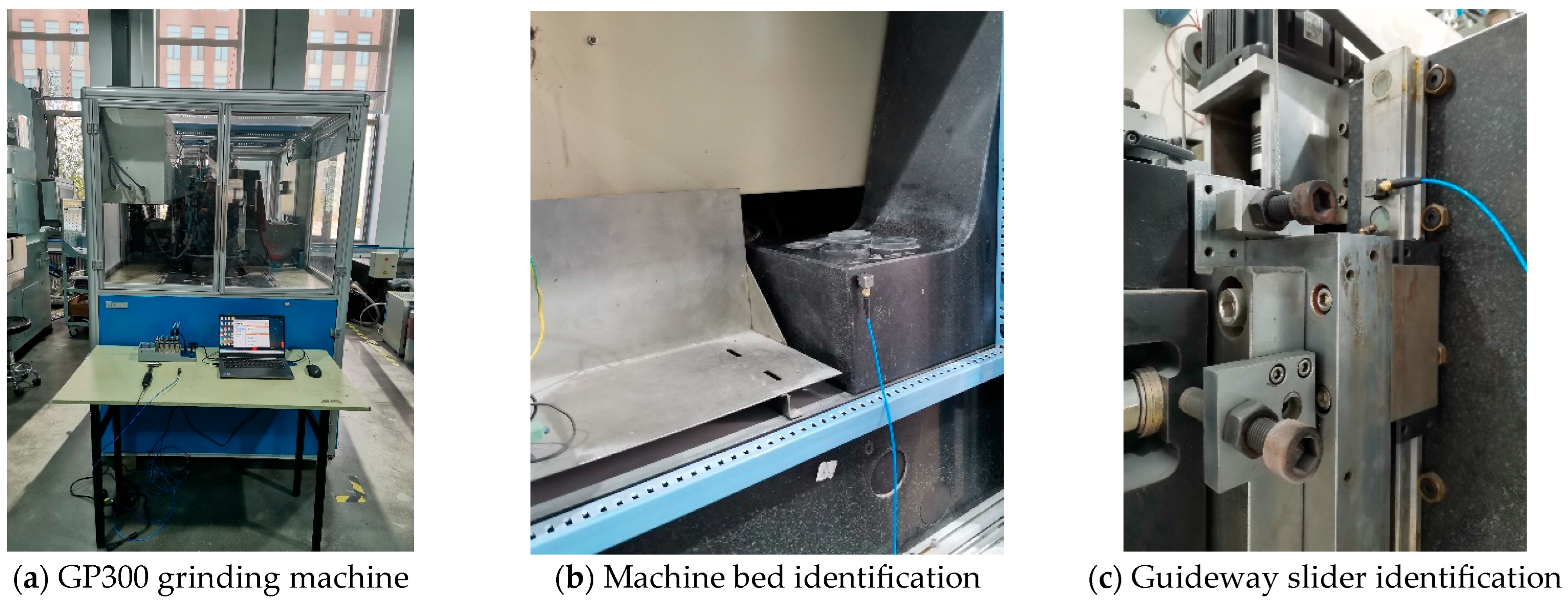

3. Direct Validation Methodology for Joint Surface Characteristic Parameter Models

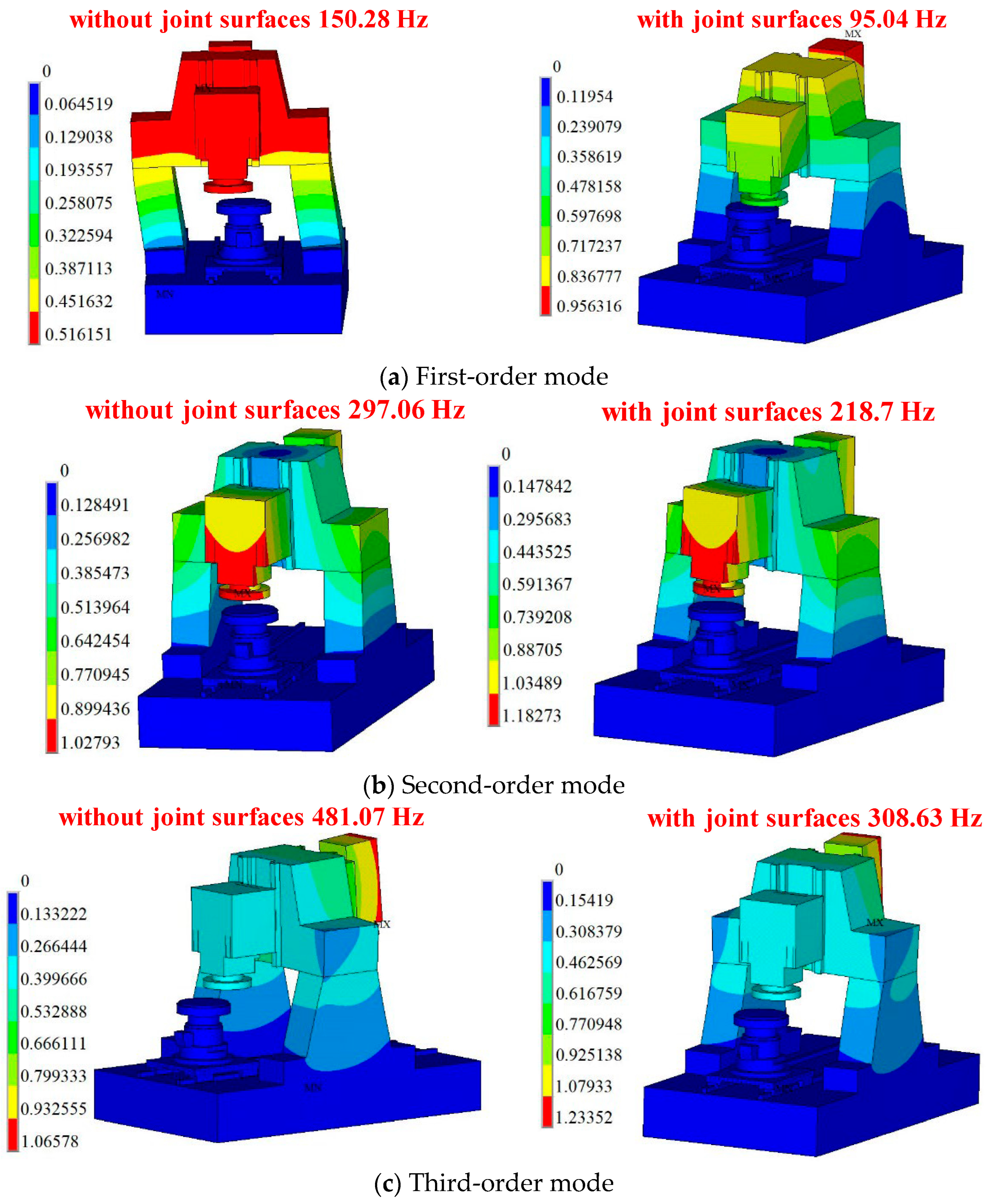

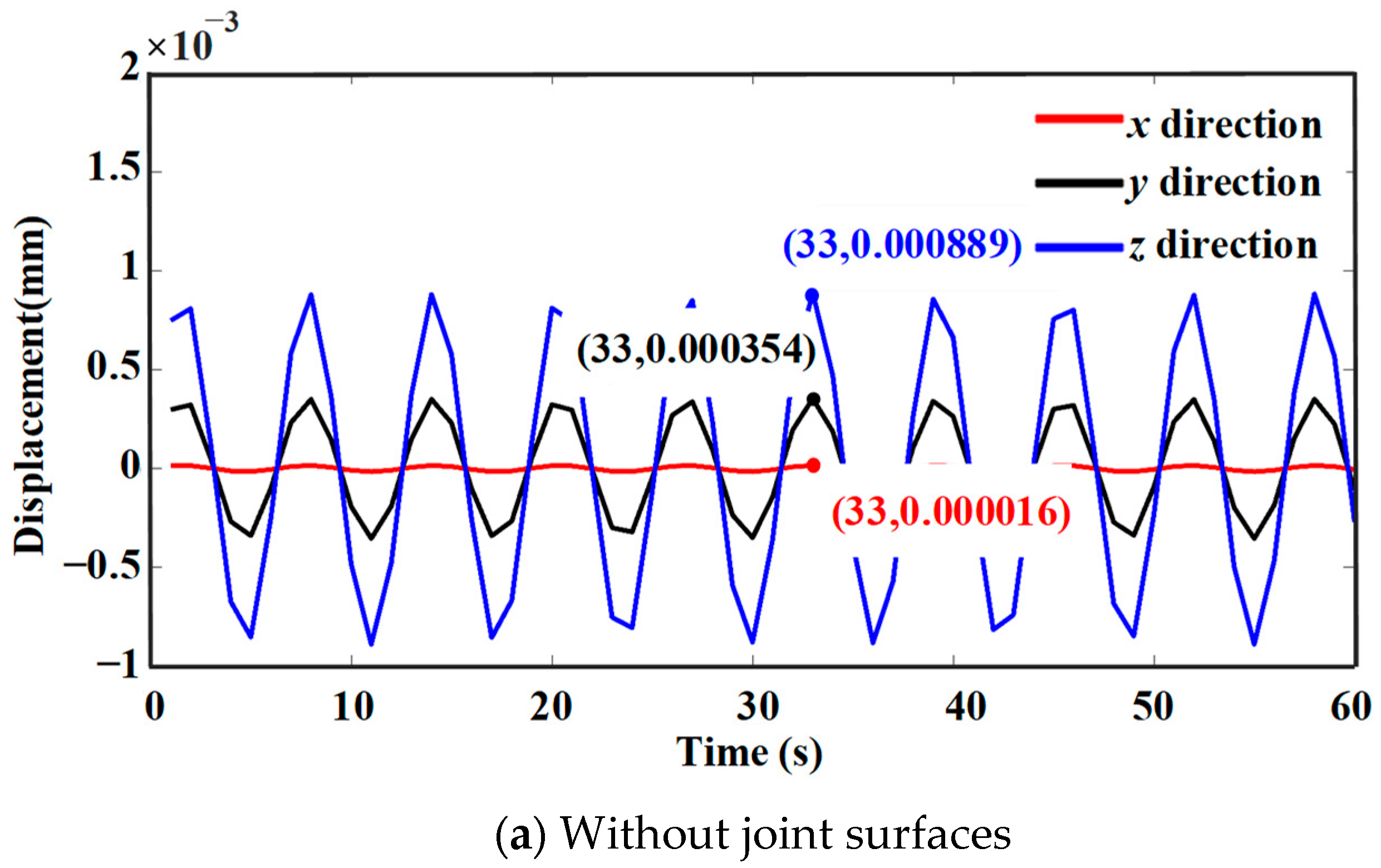

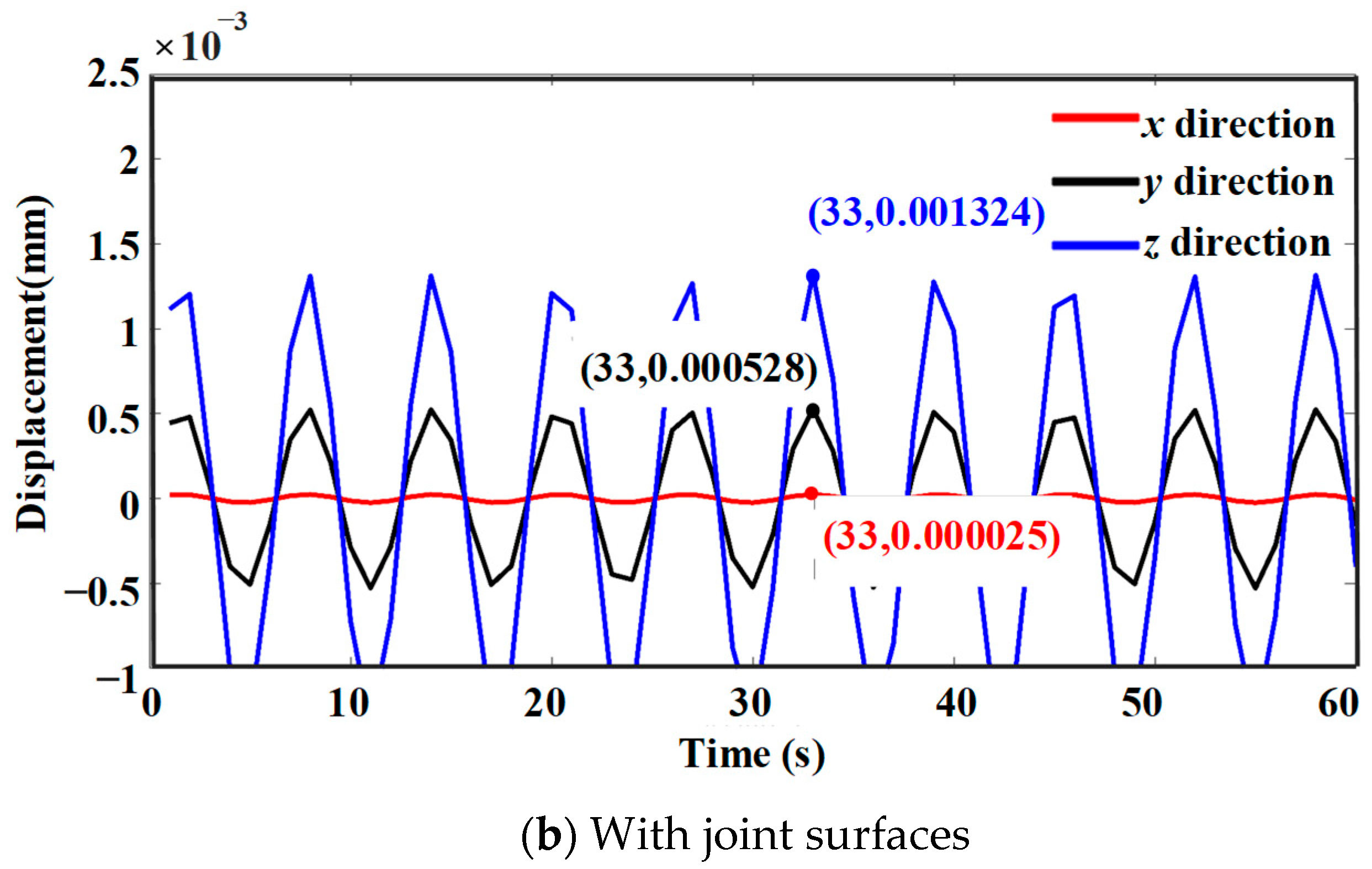

4. Analysis of Machine Tool Integrated Dynamic Performance

5. Conclusions

- (1)

- The proposed model is applicable to mechanical fixed joint surfaces of various materials, and also has important guiding significance for the performance analysis of other complex mechanical structures outside machine tools.

- (2)

- Due to the limitations of traditional continuum mechanics theory in describing microscale deformation behavior, the accuracy of the proposed model still needs further improvement. Using microscale mechanics such as crystal plasticity theory or strain gradient theory to model the joint surface should be an effective means to further improve the accuracy of the model, but it is necessary to solve the uncertainties of parameters and boundary conditions, as well as cross-scale characterization problems.

- (3)

- The impact of precision maintenance on high-end machine tools is worth discussing, which requires in-depth research into characterizing and dynamically identifying the wear of key joint parts of machine tools under working conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Definition | Unit | Relevant Section |

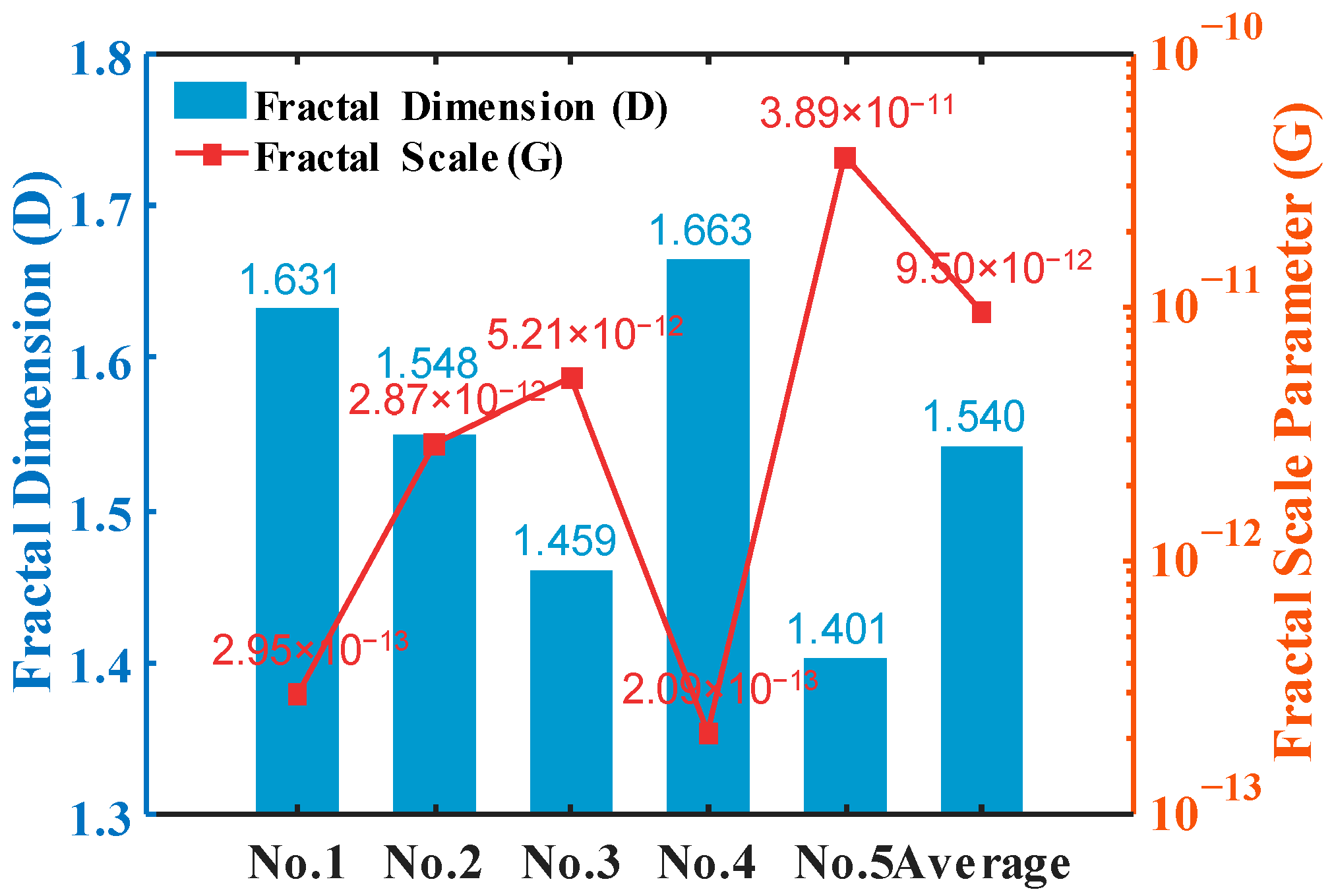

| D | 2D Fractal dimension (surface roughness) | – | Section 2, Equation (6) |

| Ds | 3D Fractal dimension (Ds = D + 1Ds = D + 1) | – | Section 3, Figure 8 |

| G | Fractal length-scale parameter | m | Section 2, Equation (4) |

| S(τ) | Structure function of surface profile | m2 | Section 3, Equation (9) |

| τ | Spatial shift in structure function | m | Section 3, Equation (9) |

| γ | Scaling constant (γ ≈ 1.5 γ ≈ 1.5) | – | Section 3, Equation (10) |

| R | Radius of curvature at asperity summit | m | Section 2, Equation (4) |

| a | Contact area of a single micro-asperity | m2 | Section 2, Equation (6) |

| ac | Critical contact area for deformation transition | m2 | Section 2, Equation (7) |

| al | Largest asperity contact area | m2 | Section 2, Equation (6) |

| Ar | Real contact area of joint surface | m2 | Section 2, Figure 3 |

| δ | Total deformation of a micro-asperity | m | Section 2, Equation (1) |

| Δd | Displacement of mean plane due to interactions | m | Section 2, Equation (2) |

| E | Elastic modulus of joint surface material | Pa | Section 2, Equation (2) |

| ν | Poisson’s ratio | – | Table 1 |

| H | Material hardness | Pa | Implicit (Section 1) |

| K | Normal stiffness of joint surface | N/m | Section 2, Equation (8) |

| Kx, Ky, Kz | Tangential stiffness components | N/m | Section 4, Figure 10 |

| C | Damping coefficient | N·s/m | Section 3 |

| Cx, Cy, Cz | Tangential damping components | N·s/m | Section 4, Figure 10 |

| η | Damping loss factor (η = Wd/Weη = Wd/We) | – | Implicit (Section 1) |

| z | Asperity peak height from mean plane (pre-contact) | m | Section 2, Figure 2 |

| d | Mean plane to rigid plane distance (pre-contact) | m | Section 2, Figure 2 |

| dn | Mean plane to rigid plane distance (post-contact) | m | Section 2, Figure 2 |

| F | Contact load on micro-asperity | N | Section 2, Equation (4) |

| Fc | Grinding force amplitude | N | Section 4 |

| Fx, Fy, Fz | Grinding force components | N | Section 4 |

| t | Time | s | Section 4 |

References

- Yao, K.; Chen, D.; Pan, C.; Lin, C.L. The development trends of computer numerical control (CNC) machine tool technology. Mathematics 2024, 12, 1923. [Google Scholar] [CrossRef]

- Tomassi, A.; Falegnami, A.; Romano, E. Unveiling simplexity: A new paradigm for understanding complex adaptive systems and driving technological innovation. Innovation 2025, 6, 100954. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, X.; Zhao, W. Research on the multi-physical coupling characteristics of the machine tool and milling process based on the systematically integrated model. J. Manuf. Process. 2023, 105, 46–69. [Google Scholar] [CrossRef]

- Cheng, Q.; Qi, B.; Liu, Z.; Zhang, G.; Zhang, C.; Chen, H. A Detachable Design Method of Large-sized Structure for Heavy Duty Machine Tool Based on Joint Surface Dynamics Characteristic Analysis. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 4476–4489. [Google Scholar] [CrossRef]

- Zha, Y.; Zhang, J.; Yu, D.; Feng, P.; Lin, Z. Modeling Method for Bolted Joint Interfaces Based on Transversely Isotropic Virtual Materials. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Auckland, New Zealand, 9–12 July 2018; pp. 1118–1123. [Google Scholar]

- Yin, Q.; Dong, G.H.; Yin, G.F.; Heng, L.; Wang, L. Research on modeling and identification of machine tool joint dynamic characteristics. J. Adv. Mech. Des. Syst. Manuf. 2019, 13, JAMDSM0023. [Google Scholar] [CrossRef]

- Xiao, H.F.; Sun, Y.Y. On the normal contact stiffness and contact resonance frequency of rough surface contact based on asperity micro-contact statistical models. Eur. J. Mech. A Solids 2019, 75, 450–460. [Google Scholar] [CrossRef]

- Miao, H.H.; Wang, C.Y.; Li, C.Y.; Song, W.; Zhang, X.; Xu, M. Nonlinear dynamic modeling and vibration analysis of whole machine tool. Int. J. Mech. Sci. 2023, 245, 108122. [Google Scholar] [CrossRef]

- Ahmadian, H.; Mottershead, J.E.; James, S.; Friswell, M.I.; Reece, C.A. Modelling and updating of large surface-to-surface joints in the AWE-MACE structure. Mech. Syst. Signal Process. 2006, 20, 868–880. [Google Scholar] [CrossRef]

- Dreher, T.; Brake, M.R.W.; Seeger, B.; Krack, M. In situ, real-time measurements of contact pressure internal to jointed interfaces during dynamic excitation of an assembled structure. Mech. Syst. Signal Process. 2021, 160, 107859. [Google Scholar] [CrossRef]

- Parl, K.S.; Paynter, R.J.; Nowell, D. Linear relationship of normal and tangential contact stiffness with load. Proc. R. Soc. A Math. Phys. Eng. Sci. 2020, 476, 20200329. [Google Scholar] [CrossRef]

- Luo, W.; Lu, B.; Chen, F.; Song, Y. FRF prediction modeling and joint parameter identification of motorized spindle-tool handle. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 303. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, G.; Lv, Z.; Chen, K. Tangential stiffness model of the joint surface considering contact angles between asperities based on fractal theory. Appl. Math. Model. 2025, 144, 116088. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, Q.A.; Mo, J.; Xiang, Z.; Wang, Q.; Zhai, C.; Zhu, S. Analysis of contact characteristics and dynamic response of joint interface with surface micro-grooved texture based on fractal theory. Mech. Syst. Signal Process. 2024, 218, 111553. [Google Scholar] [CrossRef]

- Sun, W.; Lan, G.; Zhang, X. Modeling of normal stiffness of mechanical joint based on anisotropic fractal theory. J. Mech. Sci. Technol. 2023, 37, 4193–4205. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985; pp. 1–15. [Google Scholar]

- Matthews, J.R. Indentation Hardness and Hot Pressing. Acta Metall. 1980, 28, 311–318. [Google Scholar] [CrossRef]

- Abbott, E.J.; Firestone, F.A. Specifying Surface Quality A Method Based on Accurate Measurement and Comparison. Mech. Eng. 1933, 55, 569–572. [Google Scholar]

- Kogut, L.; Etsion, I. A Finite Element Based Elastic-Plastic Model for the Contact of Rough Surfaces. Tribol. Trans. 2003, 46, 383–390. [Google Scholar] [CrossRef]

- Zirngibl, C.; Schleich, B.; Wartzack, S. Approach for the automated and data-based design of mechanical joints. Proc. Des. Soc. 2021, 1, 521–530. [Google Scholar] [CrossRef]

- Jamia, N.; Jalali, H.; Taghipour, J.; Friswell, M.I.; Khodaparast, H.H. An Equivalent Model of a Nonlinear Bolted Flange Joint. Mech. Syst. Signal Process. 2021, 153, 107507. [Google Scholar] [CrossRef]

- Liu, Z.; Jiang, K.; Zhang, C.; Zhao, Y.; Tian, Y. A Stiffness Model of a Joint Surface with Inclination Based on Fractal Theory. Precis. Eng. 2020, 62, 47–61. [Google Scholar] [CrossRef]

- Yin, D.; Zhang, X.; Chen, Y.; Lan, G.; Wang, Y.; Wen, S. Statistical Model of Normal Contact Stiffness of Fixed Joint Surface During Unloading after First Loading. Adv. Mater. Sci. Eng. 2021, 2021, 6626727. [Google Scholar] [CrossRef]

- Zhu, L.; Chen, J.; Zhang, Z.; Hong, J. Normal Contact Stiffness Model Considering 3D Surface Topography and Actual Contact Status. Mech. Sci. 2021, 12, 41–50. [Google Scholar] [CrossRef]

- Liu, K.; Liu, J.; Wang, L.; Zhao, Y.; Li, F. A Modified Model for Identifying the Characteristic Parameters of Machine Joint Interfaces. Appl. Sci. 2023, 13, 11680. [Google Scholar] [CrossRef]

- Arora, V. Structural Damping Identification Method Using Normal FRFs. Int. J. Solids Struct. 2014, 51, 133–143. [Google Scholar] [CrossRef]

- Kartal, M.E.; Mulvihill, D.M.; Nowell, D.; Hills, D.A. Determination of the Frictional Properties of Titanium and Nickel Alloys Using the Digital Image Correlation Method. Exp. Mech. 2011, 51, 359–371. [Google Scholar] [CrossRef]

- Mulvihill, D.M.; Brunskill, H.; Kartal, M.E.; Dwyer-Joyce, R.S.; Nowell, D. A Comparison of Contact Stiffness Measurements Obtained by the Digital Image Correlation and Ultrasound Techniques. Exp. Mech. 2013, 53, 1245–1263. [Google Scholar] [CrossRef]

- An, Q.; Wang, W.; Huang, M.; Suo, S.; Liu, Y.; Wang, S. A Novel Contact Resistance Model for the Spherical–Planar Joint Interface Based on Three Dimensional Fractal Theory. Fractal Fract. 2024, 8, 503. [Google Scholar] [CrossRef]

- Zhang, C.X.; Li, X.; He, J.L.; Cheng, Y.; Liu, Z.; Li, Y. Static friction coefficient model of joint surface based on the modified fractal model and experimental investigation. Int. J. Adv. Manuf. Technol. 2023, 124, 4415–4429. [Google Scholar] [CrossRef]

| Structural | Material | Density (kg/m3) | Elastic Modulus/GPa | Poisson’s Ratio |

|---|---|---|---|---|

| Spindle, grinding wheel, slide table | Structural steel | 7850 | 200 | 0.3 |

| Bed, column, crossbeam | Marble | 2600 | 55 | 0.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Liu, K.; Liu, Q.; Li, Y.; Chen, W.; Liu, J. Research on Identification and Application of Joint Surface Characteristic Parameters. Appl. Sci. 2025, 15, 9040. https://doi.org/10.3390/app15169040

Zhou Y, Liu K, Liu Q, Li Y, Chen W, Liu J. Research on Identification and Application of Joint Surface Characteristic Parameters. Applied Sciences. 2025; 15(16):9040. https://doi.org/10.3390/app15169040

Chicago/Turabian StyleZhou, Yufang, Kexian Liu, Qingheng Liu, Yuhang Li, Wenhui Chen, and Junfeng Liu. 2025. "Research on Identification and Application of Joint Surface Characteristic Parameters" Applied Sciences 15, no. 16: 9040. https://doi.org/10.3390/app15169040

APA StyleZhou, Y., Liu, K., Liu, Q., Li, Y., Chen, W., & Liu, J. (2025). Research on Identification and Application of Joint Surface Characteristic Parameters. Applied Sciences, 15(16), 9040. https://doi.org/10.3390/app15169040