Study of Performance and Engineering Application of D-RJP Jet Grouting Technology in Anchorage Foundation Reinforcement for Deep Suspension Bridge Excavations

Abstract

1. Introduction

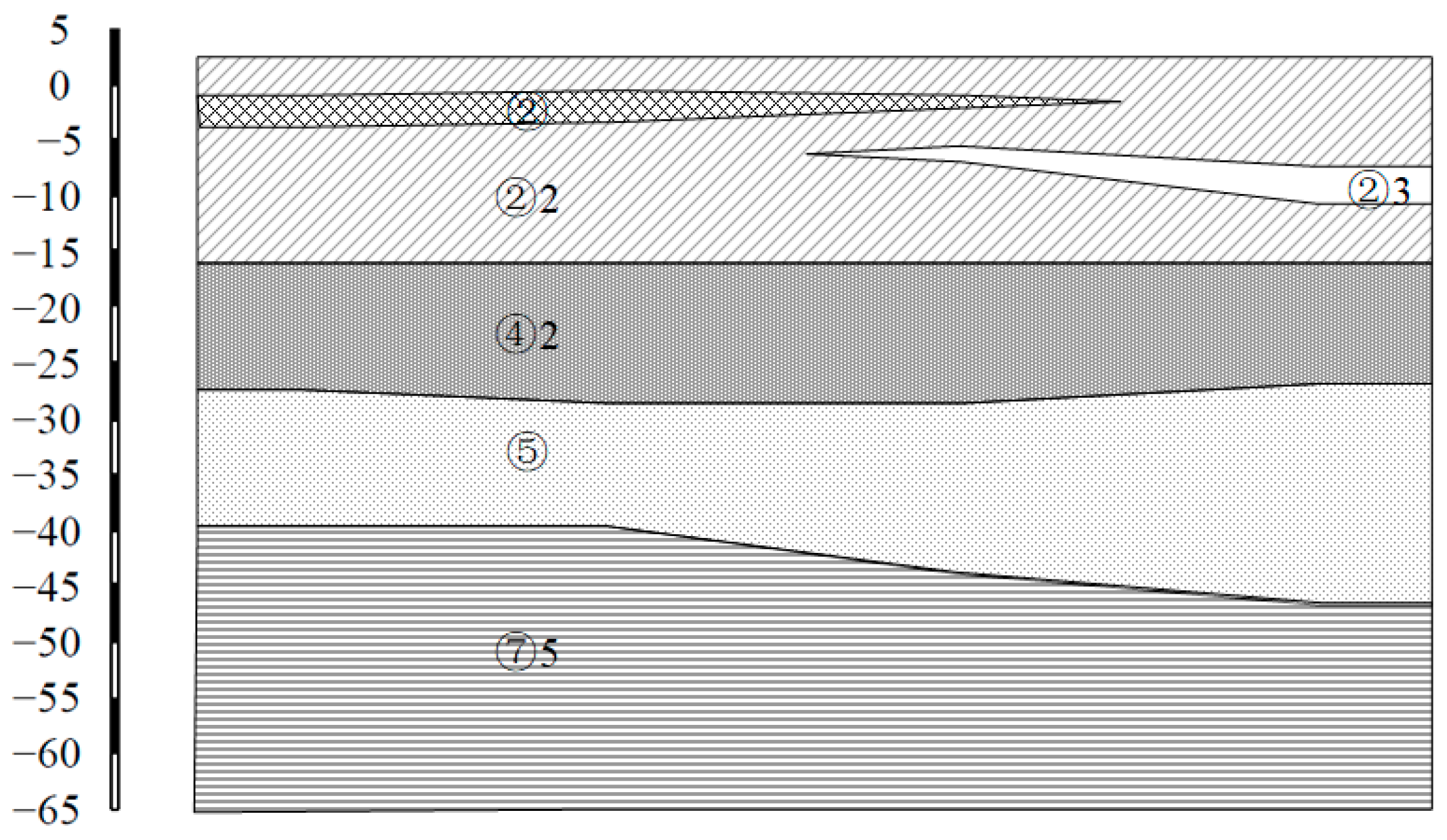

2. Project Overview

2.1. Foundation Pit Overview

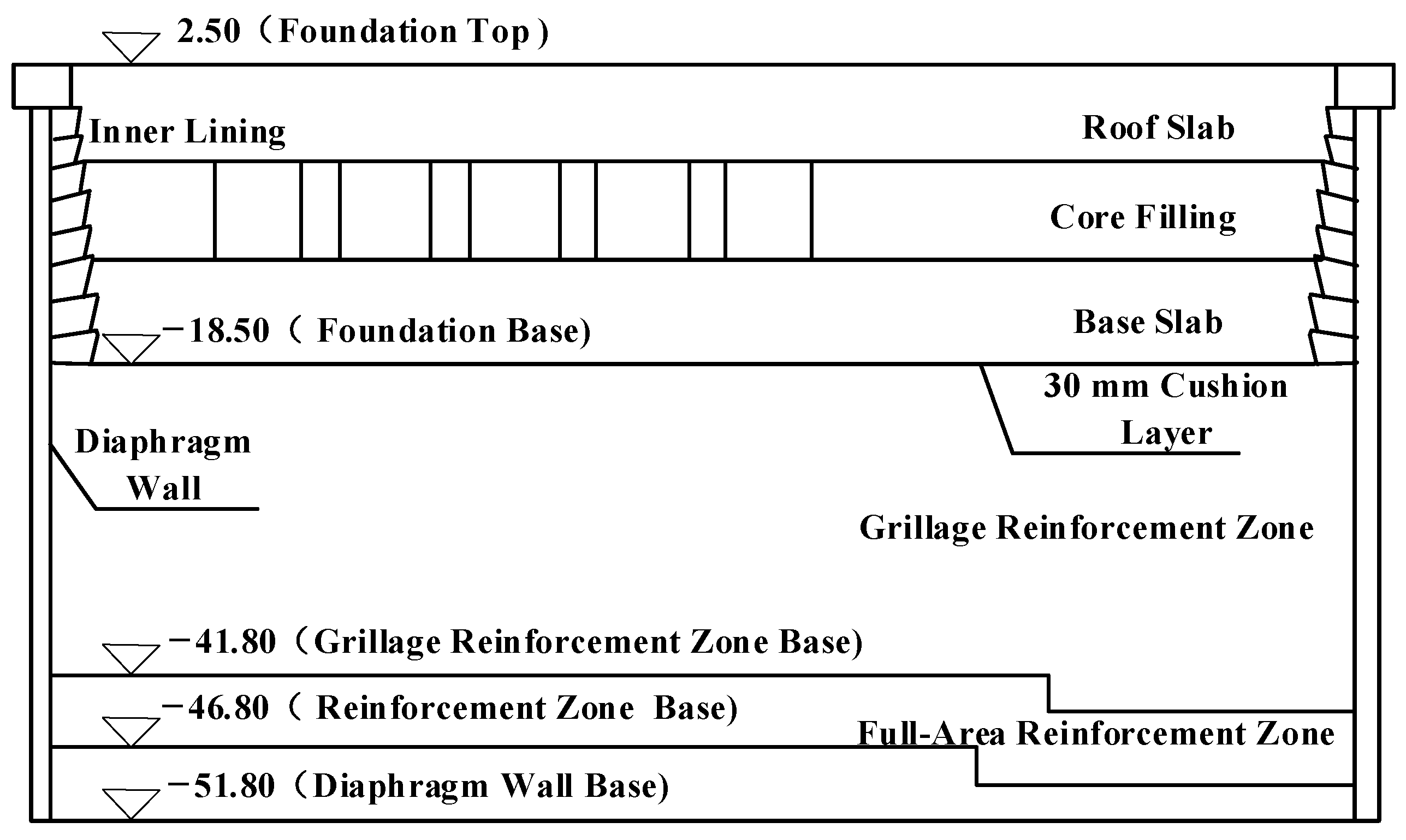

2.2. Foundation Reinforcement Overview

2.3. Overview of the D-RJP High-Pressure Rotary Jet Grouting Method

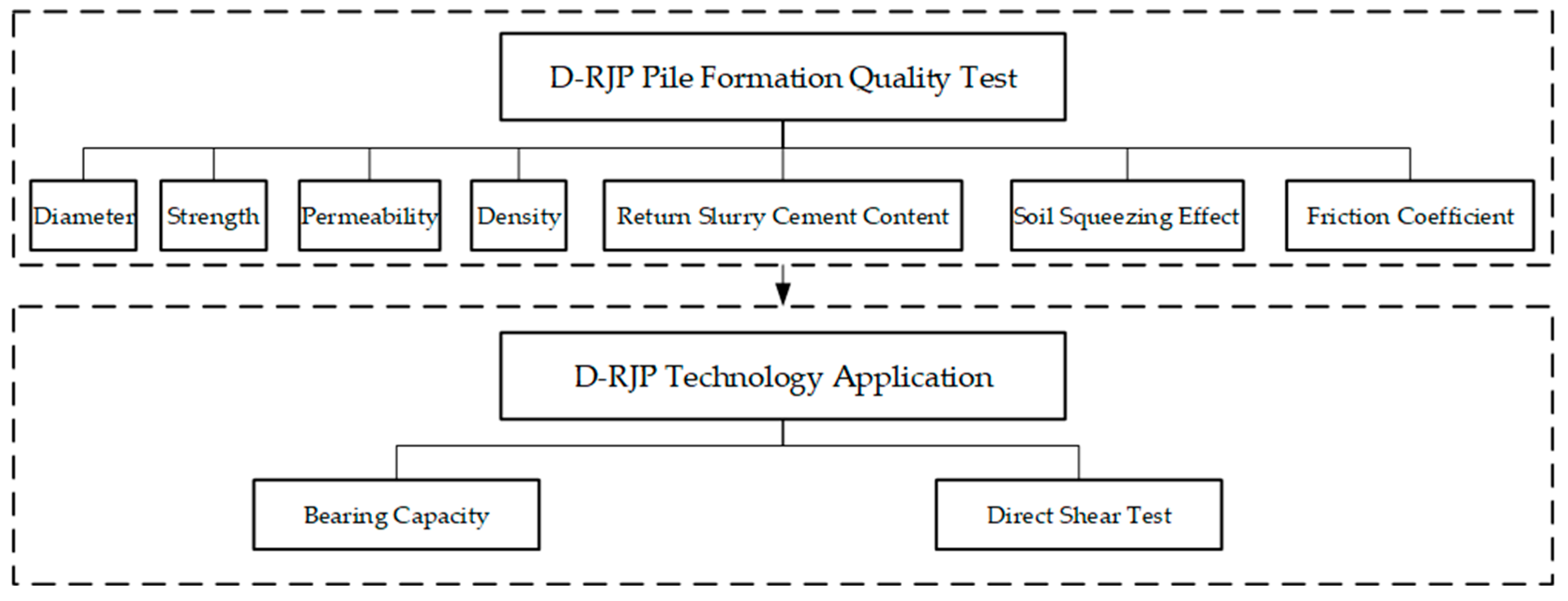

3. D-RJP High-Pressure Rotary Jet Pile Formation Quality Test

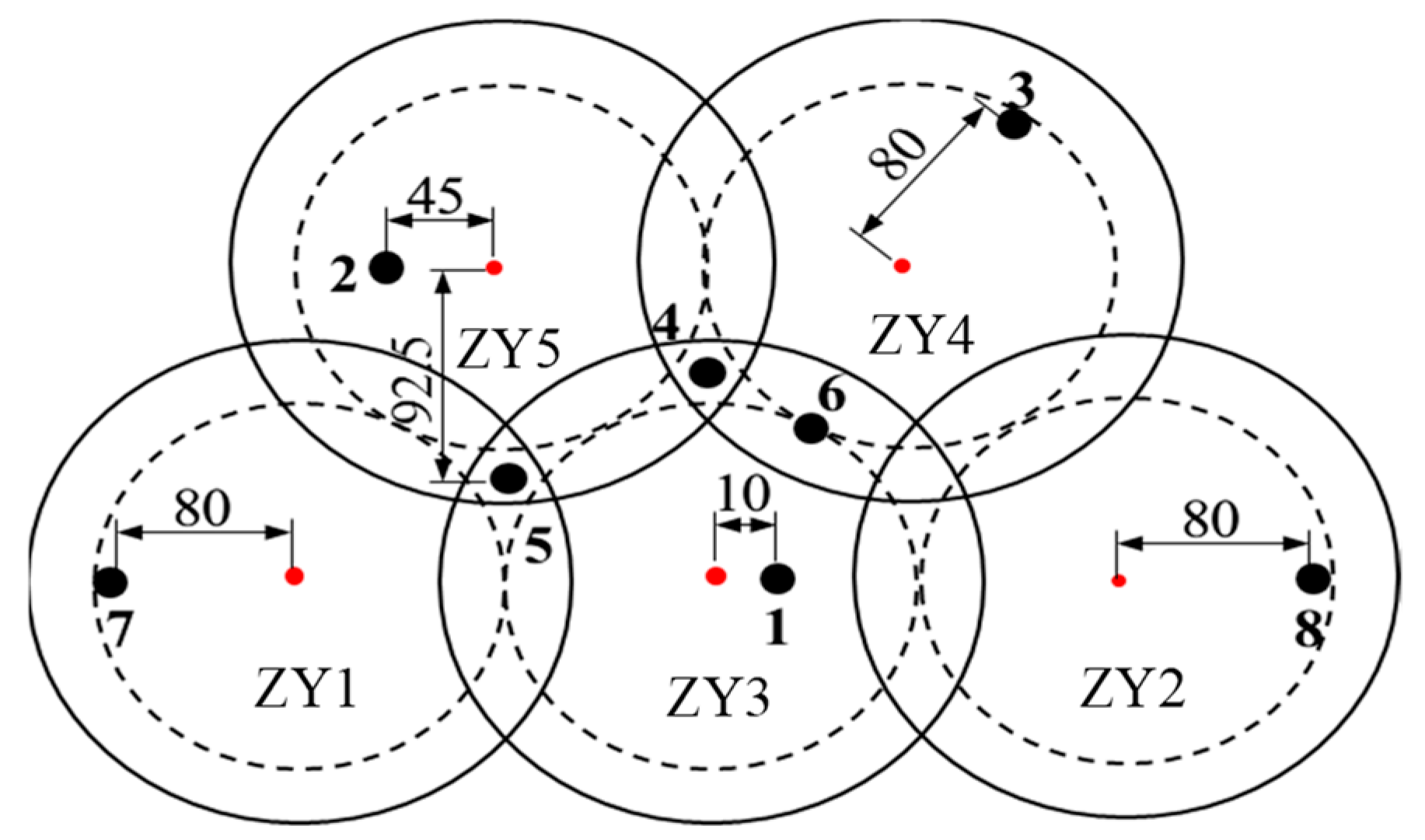

3.1. Test Plan

3.2. Testing Methods

3.3. Analysis of Test Results

3.3.1. Pile Diameter

3.3.2. Pile Strength

3.3.3. Permeability Coefficient

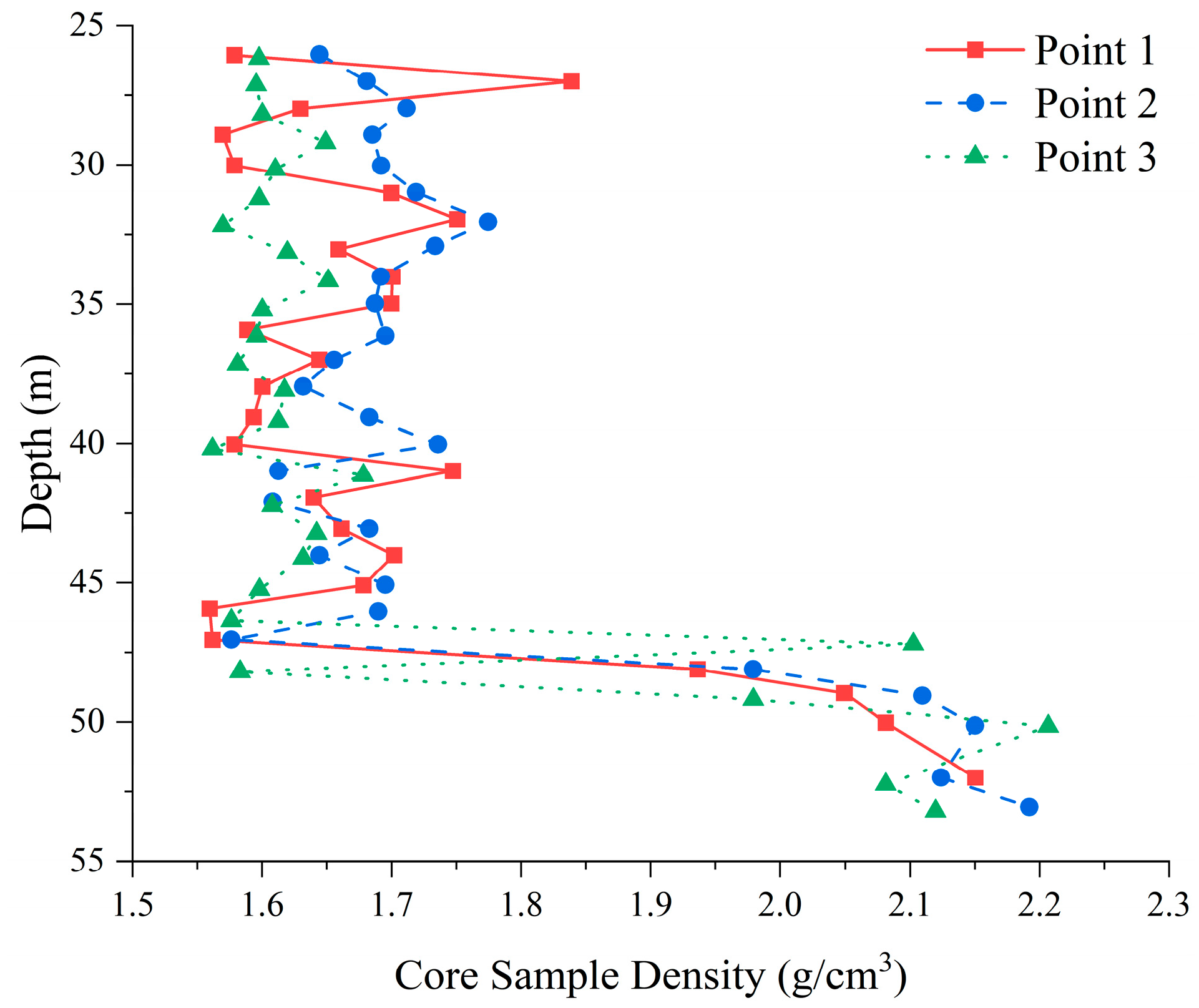

3.3.4. Reinforced Body Density

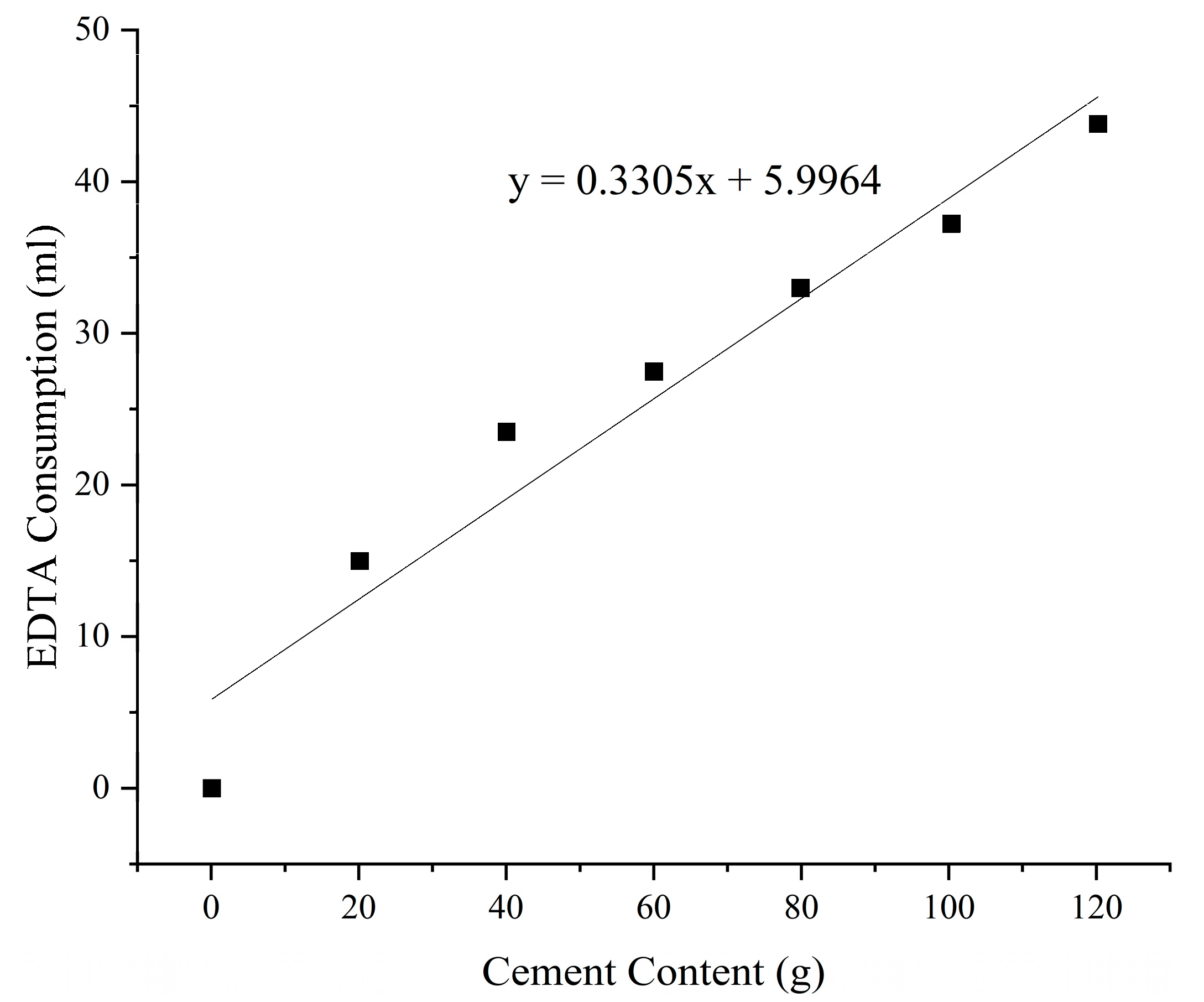

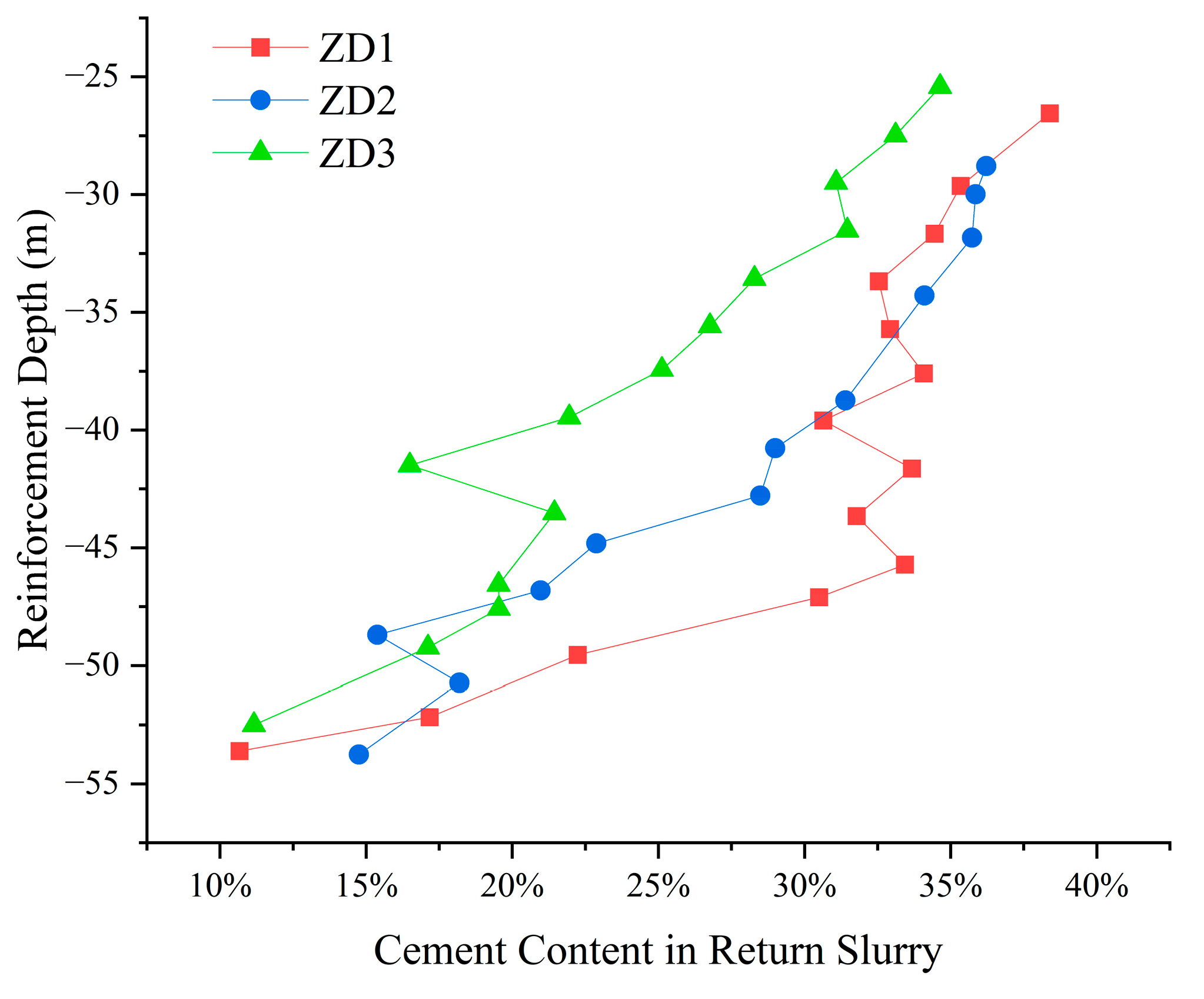

3.3.5. Return Slurry Cement Content

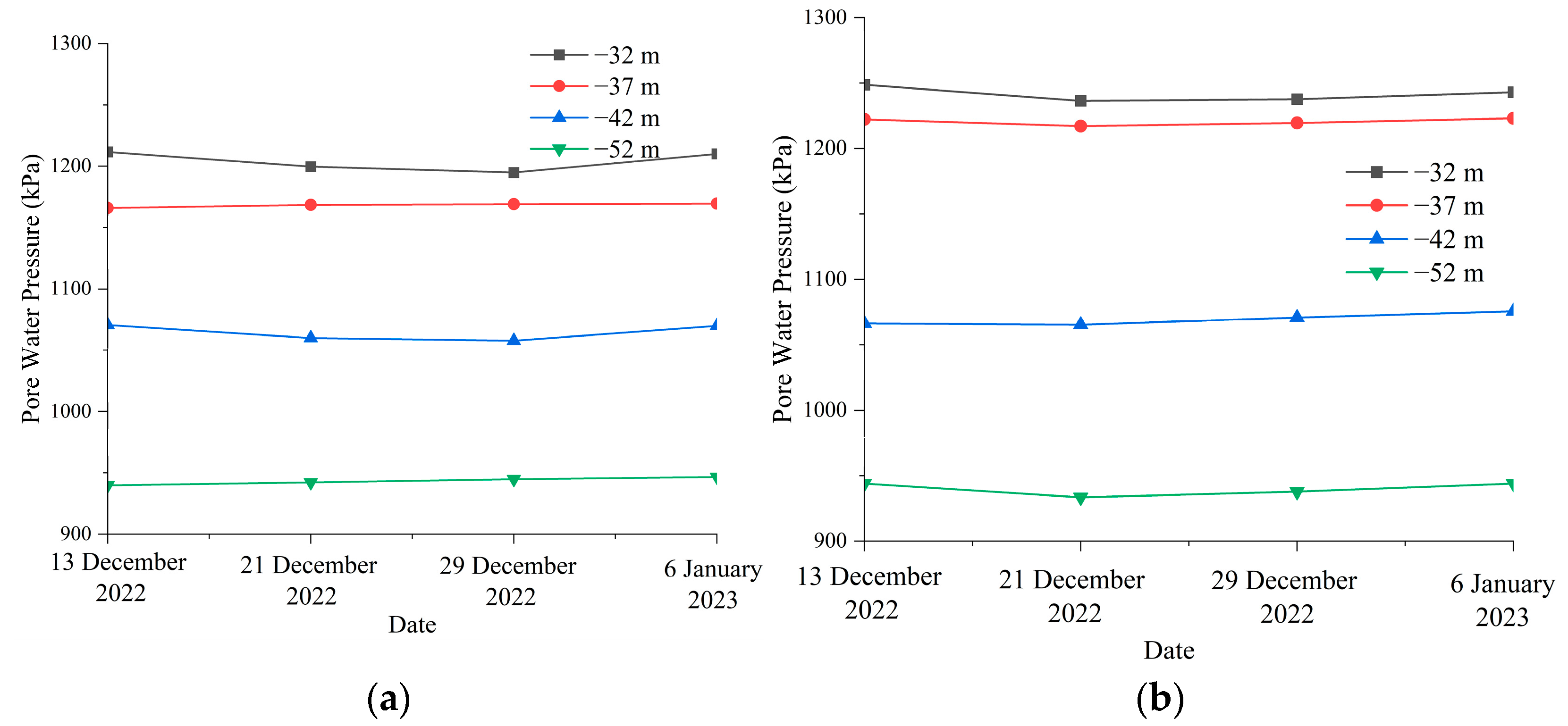

3.3.6. Soil Squeezing Effect

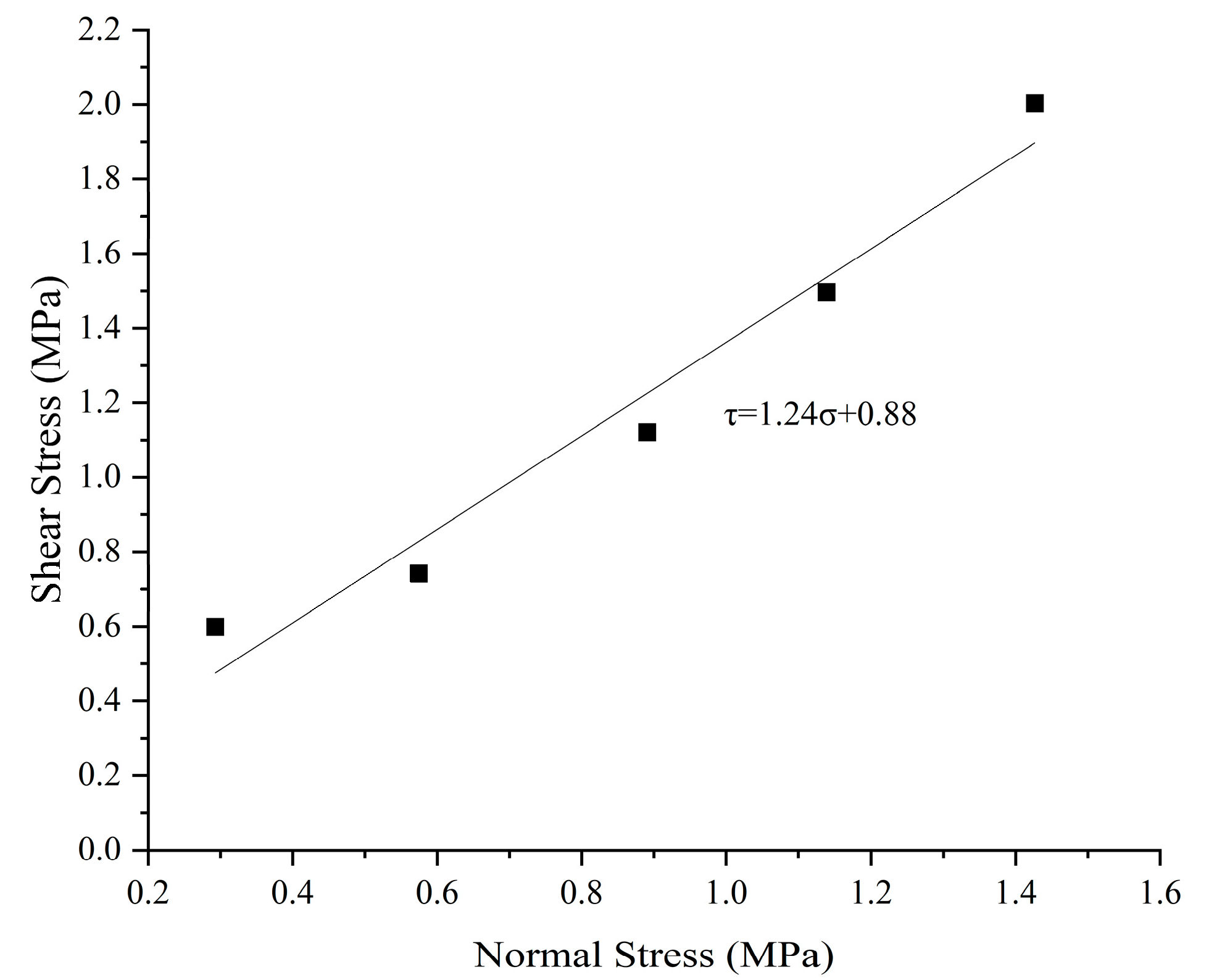

3.3.7. Friction Coefficient

4. D-RJP High-Pressure Rotary Jet Pile Artificial Composite Foundation Bearing Capacity and Direct Shear Test

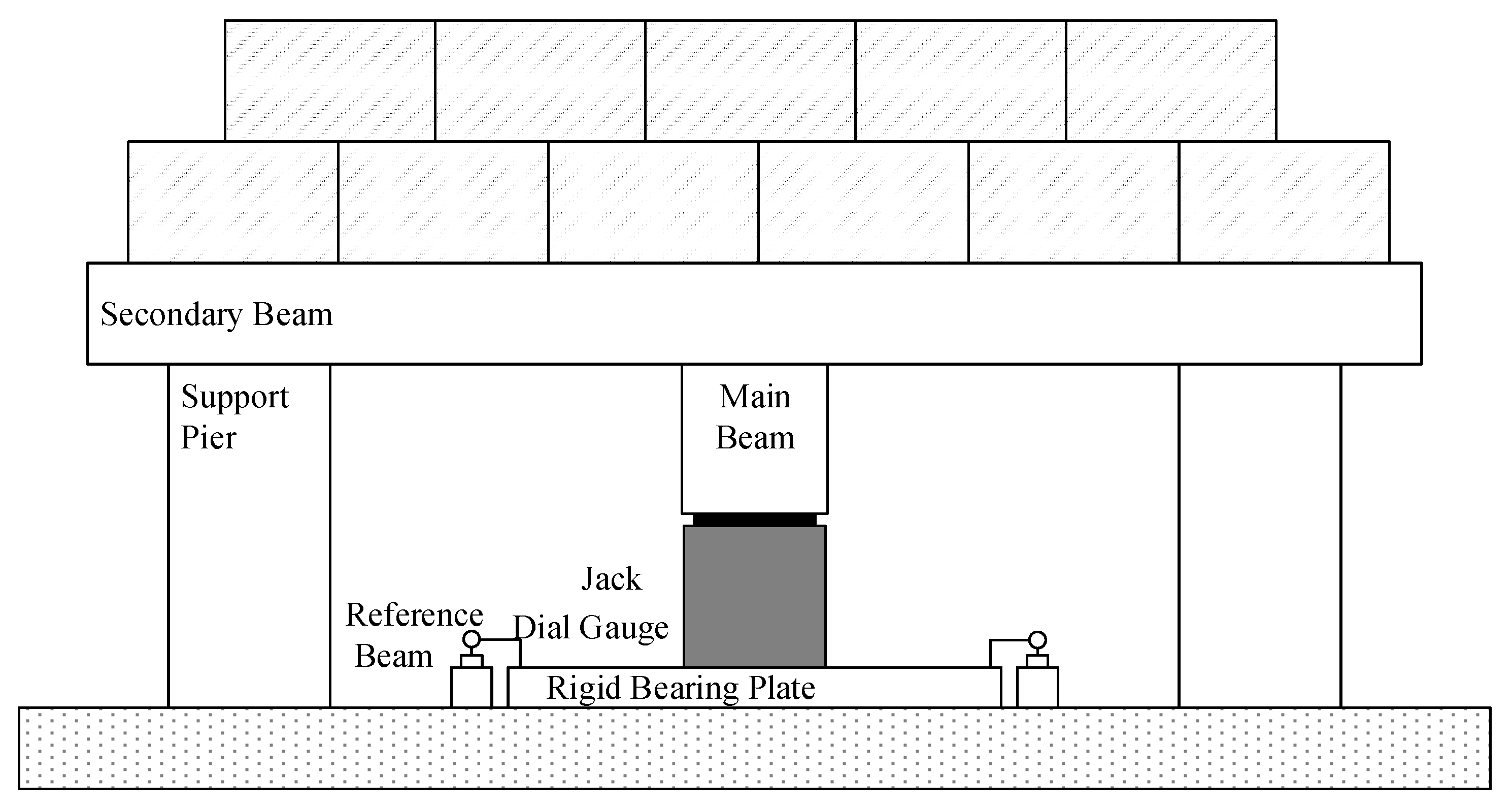

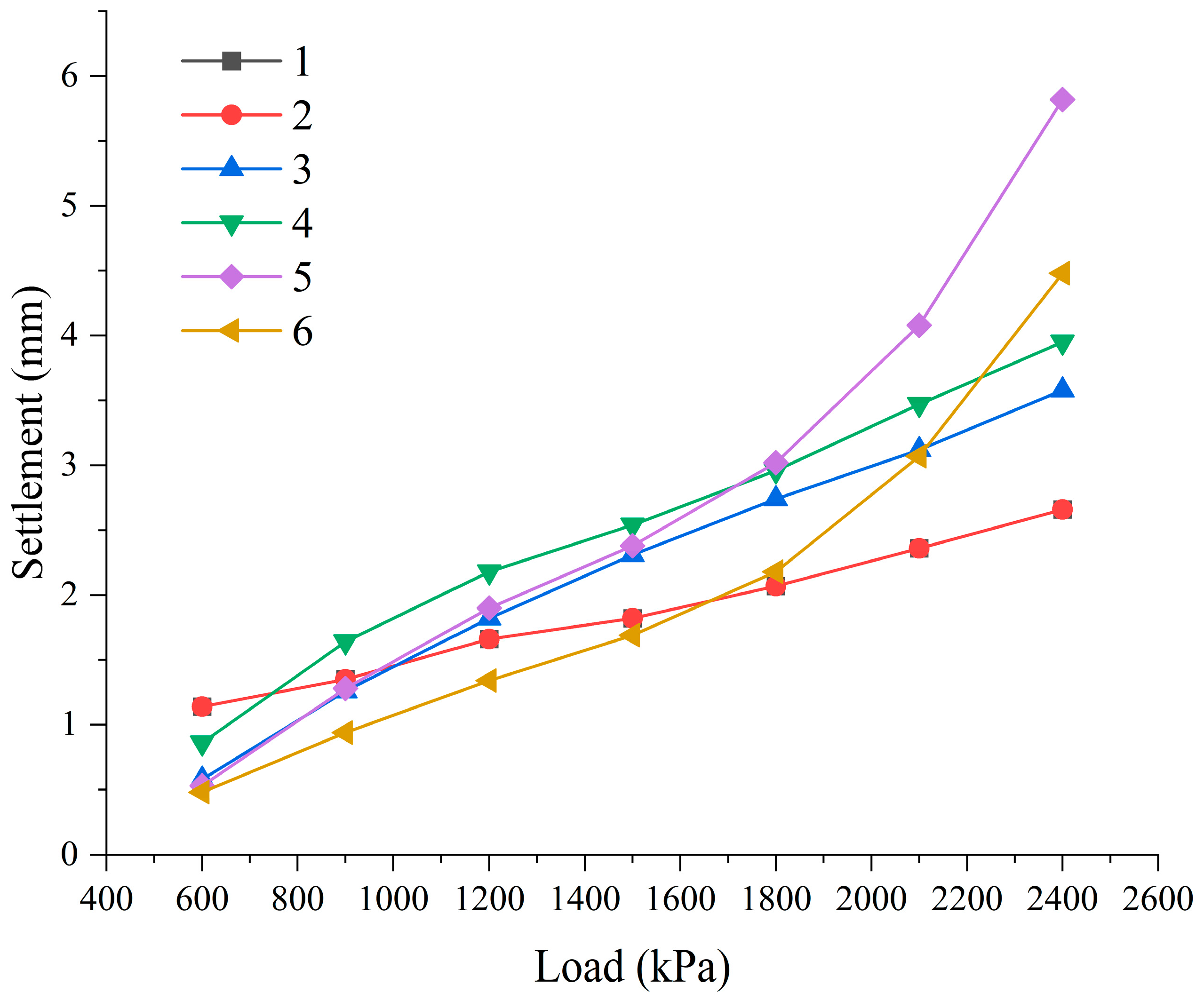

4.1. Composite Foundation Bearing Capacity Test

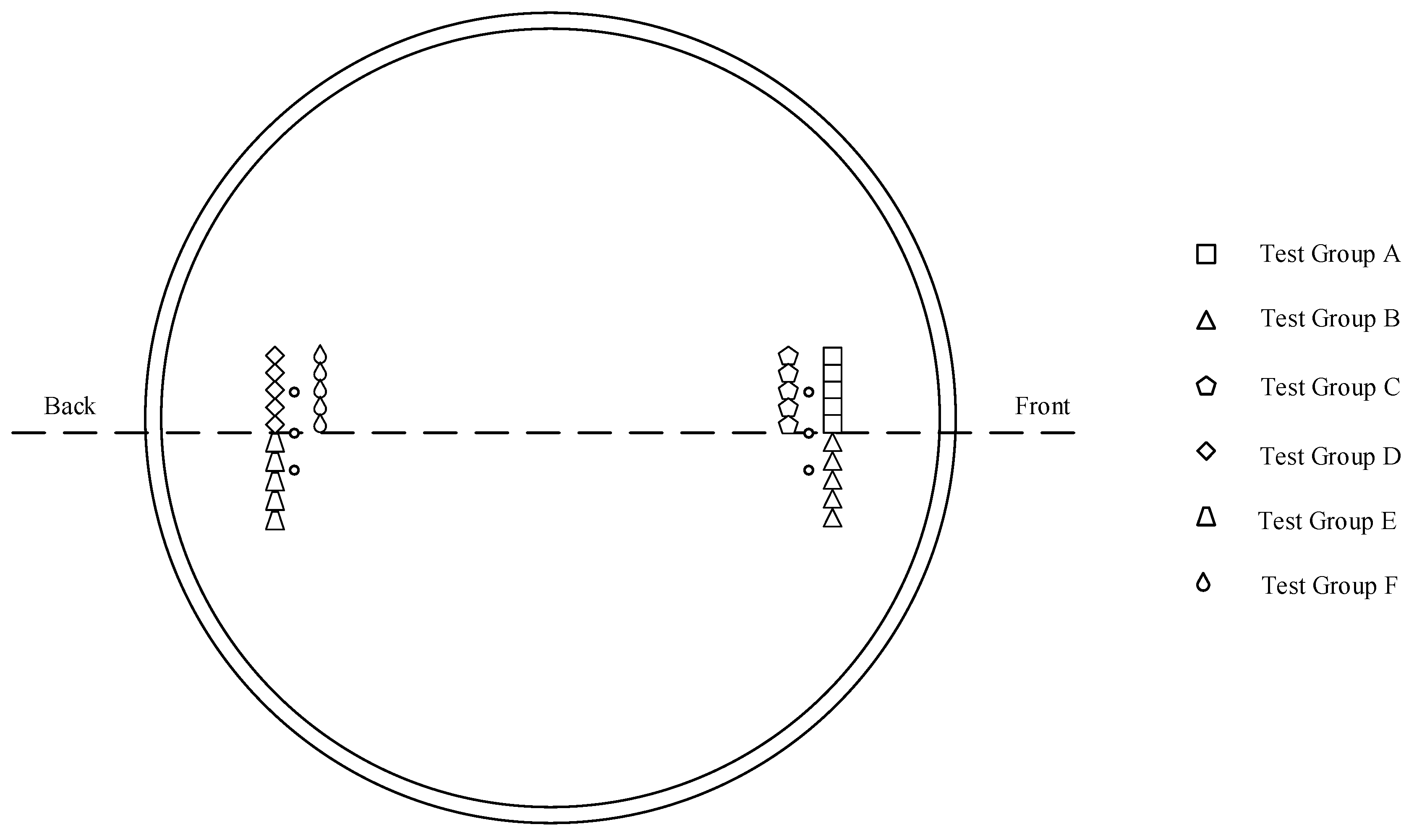

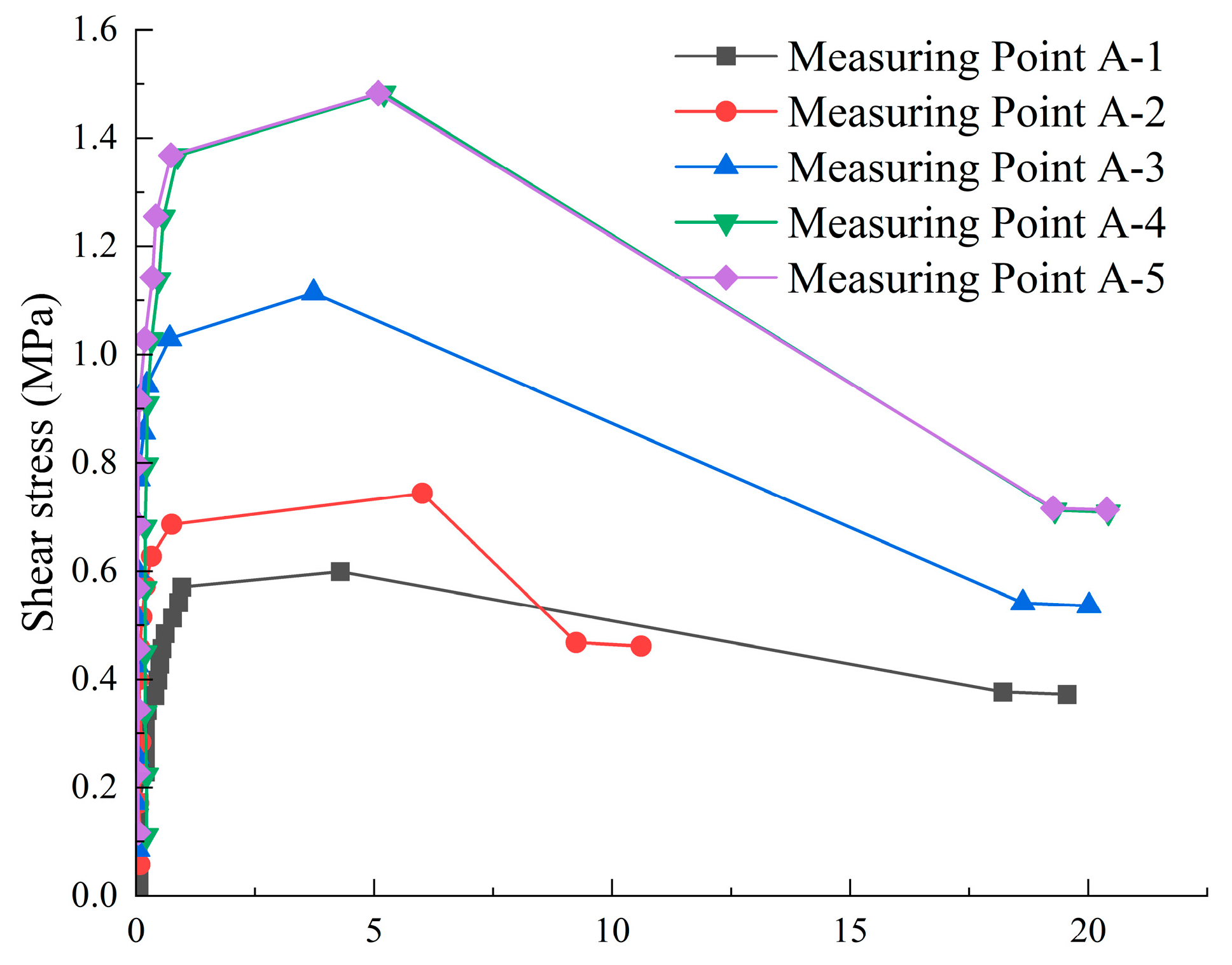

4.2. Direct Shear Test at the Foundation Base

5. Conclusions

- (1)

- The core samples of the high-pressure jet grout columns formed by the D-RJP process exhibited good integrity and continuity; in the silty sand layer, the 90-day unconfined compressive strength of the column core sample reached 8.21 MPa, and in the silty clay layer, it reached 5.45 MPa, which is significantly higher than the expected strength level and meets the foundation strength requirements of the foundation pit.

- (2)

- The measured maximum average permeability coefficient of the high-pressure jet grout columns was 2.52 × 10−7 cm/s, which is significantly better than the expected value of 1.0 × 10−6 cm/s; the permeability coefficient showed an increasing trend from the center to the edge of the column, indicating the good grout diffusion uniformity and effectively improving the anti-seepage and anti-water inrush performance of the pit bottom.

- (3)

- The density of the foundation soil changed, and the foundation interface friction performance was excellent. After reinforcement, the average density of the silty clay layer sample decreased by 7.7%, while the silty sand layer increased by 5.5%, indicating changes in soil compactness. The foundation interface friction coefficient ranged from 0.44 to 0.47, which was significantly higher than the expected value of 0.37, indicating good interface friction performance.

- (4)

- The material utilization efficiency was high, and construction disturbance control was effective. The grout return analysis showed that the cement return rates of the core samples from the high-pressure jet grout columns in the silty clay and silty sand layers were 27% and 18%, respectively. No obvious soil squeezing effect was seen during the construction process. The D-RJP process can enable green, efficient, full-process quality and disturbance control during construction.

- (5)

- The bearing capacity and shear strength of the high-pressure jet grout composite foundation met expectations. The static load test results showed that the characteristic bearing capacity of the composite foundation exceeded 1200 kPa, meeting the expected foundation bearing capacity requirements. The direct shear tests indicated that the minimum internal friction angle of the composite foundation was 24.23°, and the minimum cohesion was 180 kPa. The overall mechanical performance was excellent, providing reliable shear resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yamazaki, J.; Chao, K.C.; Wong, R.; Wang, M. Development of the Jet Grouting Method: Evolutionary History, Mechanism Insights, Innovative Approaches, and Future Prospects. Geotech. Eng. 2024, 55, 11–23. [Google Scholar] [CrossRef]

- Botto, G. Developments in the techniques of jet-grouting. In XII Ciclo di Conferenze di Geotecnica; Associazione Geotecnica Italiana: Torino, Italy, 1985. [Google Scholar]

- Inazumi, S.; Shakya, S. A Comprehensive Review of Sustainable Assessment and Innovation in Jet Grouting Technologies. Sustainability 2024, 16, 4113. [Google Scholar] [CrossRef]

- Ho Chu, E. Fluid-Soil Interaction Model for Jet Grouting. In Grouting for Ground Improvement; Proceedings; ASCE: Reston, VA, USA, 2012; pp. 1–10. [Google Scholar]

- Zhao, L.-S.; Qi, X.; Tan, F.; Chen, Y. A new prediction model of the jet grouting column diameter for three jet grouting systems. Comput. Geotech. 2023, 163, 105753. [Google Scholar] [CrossRef]

- Liu, G.; Wang, B. Study on the Effect of Jet Grouting Pile Reinforcing Soft Soil Subgrade. Adv. Mater. Res. 2012, 594–597, 1420–1428. [Google Scholar] [CrossRef]

- Shan, Y.; Luo, J.; Wang, B.; Zhou, S.; Zhang, B. Critical application zone of the jet grouting piles in the vicinity of existing high-speed railway bridge in deep soft soils with medium sensibility. Soils Found. 2024, 64, 101407. [Google Scholar] [CrossRef]

- Shen, S.; Wang, Z.; Cheng, W. Estimation of lateral displacement induced by jet grouting in clayey soils. Géotechnique 2017, 67, 621–630. [Google Scholar] [CrossRef]

- Liu, D.; Ye, Z.-W.; Xie, W.-J.; Gao, J.-L.; Hu, S.-T.; Li, Y.; Chen, F. Numerical simulation study on the construction of cut off walls using high-pressure jet grouting based on SPH method. Front. Earth Sci. 2024, 12, 1491583. [Google Scholar] [CrossRef]

- Liang, M.; Jin, C.; Hou, J.; Wang, M.; Shi, Y.; Dong, Z.; Yang, X.; Zhou, J.; Cai, J. Research and Application of High-Pressure Rotary Jet Method in the Seepage Treatment of Heavy Metal Tailing Ponds of Southwest China. Materials 2023, 16, 3450. [Google Scholar] [CrossRef] [PubMed]

- Guan, C.; Yang, Y. Field study on the waterstop of the rodin jet pile method in a water-rich sandy gravel stratum. Appl. Sci. 2019, 9, 1709. [Google Scholar] [CrossRef]

- Fan, H.; Xu, Q.; Lai, J.; Liu, T.; Zhu, Z.; Zhu, Y.; Gao, X. Stability of the loess tunnel foundation reinforced by jet grouting piles and the influence of reinforcement parameters. Transp. Geotech. 2023, 40, 100965. [Google Scholar] [CrossRef]

- Brill Gary, T.; Burke George, K.; Ringen Alan, R. A Ten-Year Perspective of Jet Grouting: Advancements in Applications and Technology. In Grouting and Ground Treatment; Proceedings; ASCE: Reston, VA, USA, 2012; pp. 218–235. [Google Scholar]

- Wang, J.-L.; Wang, J.-W. The Application of Jet Grouting in Shanghai Foundation Pit Projects; Missouri University of Science and Technology: Rolla, MO, USA, 2004. [Google Scholar]

- Daramalinggam, J.; Annam, M.K. Overcoming Geotechnical Challenges in Rail and Metro Projects Using Ground Improvement. In Geotechnics for Transportation Infrastructure: Recent Developments, Upcoming Technologies and New Concepts; Springer: Singapore, 2019; Volume 2, pp. 539–556. [Google Scholar]

- Tang, K.; Cheng, L.; Wang, X.; Pan, C.; Lin, L.; Dong, L.; Li, B. Research on Digital Monitoring Technology for Airport High-Pressure Rotary Jet Piles. IEEE Access 2023, 11, 112731–112752. [Google Scholar] [CrossRef]

- Wang, T.; Liu, X.; Liu, L.; Xiong, W.; Li, Z. Research on the Reinforcement Effect and Bearing Characteristics of High-Pressure Jet-Grouting Piles on Covered Road Composite Ground in Landfill Sites. Buildings 2024, 14, 444. [Google Scholar] [CrossRef]

- Njock, P.G.A.; Chen, J.; Modoni, G.; Arulrajah, A.; Kim, Y.H. A review of jet grouting practice and development. Arab. J. Geosci. 2018, 11, 459. [Google Scholar] [CrossRef]

- Xiong, W.; Jiang, C.; Wang, T.; Wang, R.; Zhou, X. Safety-Margin Design for Gravity-Type Anchorage of Suspension Bridges over 2,000 m Long Based on Target Reliability. J. Bridge Eng. 2024, 29, 04024003. [Google Scholar] [CrossRef]

- Yi, Z.; Zhang, Q.; Huang, X.; Xu, A.; Ning, S.; Shen, Q.; Ru, X.; Liu, Y.; Liu, Y. Analysis of Monitoring Priorities for Long-Span Suspension Bridges in Complex Environments. ce/papers 2025, 8, 1563–1579. [Google Scholar] [CrossRef]

- Wang, C.; Han, H.; Wang, H.; Zhang, X.; Liu, X.; Leng, X.; Qin, W.; Fang, K. Load-bearing behaviors of the composite gravity-type anchorage: Insights from physical model and numerical tests. Eng. Fail. Anal. 2025, 167, 108959. [Google Scholar] [CrossRef]

- Wardrop, J.; Pennington, D. Use of stone columns as ground improvement beneath a bridge and embankment—A case study. Aust. Geomech. J. 2003, 38, 135–140. [Google Scholar]

- Xu, H.; Li, S. Safety Analysis of Deep Foundation Excavation in Water-Rich Soft Soils Based on BIM. Math. Probl. Eng. 2020, 2020, 4923984. [Google Scholar] [CrossRef]

- Wang, W.; Han, Z.; Deng, J.; Zhang, X.; Zhang, Y. Study on soil reinforcement param in deep foundation pit of marshland metro station. Heliyon 2019, 5, e02836. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.B.; Hu, Q.; Huang, T.M.; Chen, Y.; Shen, W.M.; Hu, M.Y. Seepage failure of a foundation pit with confined aquifer layers and its reconstruction. Eng. Fail. Anal. 2022, 138, 106366. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, J.; Hu, K.; Li, Y.; Liu, L. Adaptability Evaluation of Rotary Jet Grouting Pile Composite Foundation for Shallow Buried Collapsible Loess Tunnel. Appl. Sci. 2023, 13, 1570. [Google Scholar] [CrossRef]

- Borges, J.; Gonçalves, M. Jet-grout column-reinforced soft soils incorporating multilayer geosynthetic-reinforced platforms. Soils Found. 2016, 56, 57–72. [Google Scholar] [CrossRef]

- Yi, Z.; Lv, X.; Jiao, H.; Duan, R.; Shi, X.; Wu, H. Water Inrush Control and Effect Evaluation of Weak Fault Fracture Zones in Fushui High-Speed Railway Tunnel. In Application and Development of Data Simulation and Mechanical Analysis in Civil Engineering; Springer: Cham, Switzerland, 2025; pp. 370–381. [Google Scholar]

- Zhai, J.Q.; Wang, Q.; Wang, S.S.; Zhang, Z.B.; Wan, J.C. Design, construction, and monitored behavior of two large-diameter cylindrical diaphragm walls on an offshore reclamation island. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2024; Volume 1336, p. 012016. [Google Scholar] [CrossRef]

- Shinsaka, T.; Yamazaki, J. Development of high-speed type jet grouting method. In Proceedings of the Geotechnics for Sustainable Development, Hanoi, Vietnam, 28–30 November 2013; Volume 28, p. 29. [Google Scholar]

- Cheng, S.-H.; Liao, H.-J.; Yamazaki, J.; Wong, R.K.N.; Iwakubo, T. Alignment of Vertical and Inclined Jet Grout Columns for Waterproofing. Geotech. Test. J. 2020, 43, 325–338. [Google Scholar] [CrossRef]

- Al-Kinani, A.; Ahmed, M. Field study of the effect of jet grouting parameters on strength based on tensile and unconfined compressive strength. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 737, p. 012083. [Google Scholar] [CrossRef]

- Gökalp, A.; Düzceer, R. Ground Improvement by jet grouting technique for foundations of a natural gas combined cycle power plant in Turkey. In Proceedings of the Ninth International Conference & Exhibition on Piling and Deep Foundations, DFI, Nice, France, 16–18 November 2022. [Google Scholar]

- GB/T 50123-2019; Standard for Geotechnical Testing Method. National Standardization Administration of China: Beijing, China, 2019.

| No. | Soil Type | ω (%) | Il | Quick Direct Shear Test | Permeability Coefficient (×10−6 cm/s) | SPT N-Value | |

|---|---|---|---|---|---|---|---|

| cq (kPa) | φq (°) | ||||||

| ② | Silty sand | 25.6 | − | 3.1 | 27.9 | 636.3 | 6.3 |

| ②2 | Silty clay | 35.0 | 1.13 | 12.8 | 7.9 | 0.231 | 4.5 |

| ④2 | Silty clay | 34.2 | 1.06 | 11.5 | 7.6 | 0.231 | 6.8 |

| ⑤ | Silty clay | 31.3 | 0.88 | 14.5 | 9.2 | 0.231 | 9.1 |

| ⑦5 | Silty sand | 17.9 | − | 3.3 | 29.0 | 1351.3 | 32.5 |

| Parameter | Single-Pile Test | Interlocked Pile Test | ||||||

|---|---|---|---|---|---|---|---|---|

| ZD1 | ZD2 | ZD3 | ZY1 | ZY2 | ZY3 | ZY4 | ZY5 | |

| Pilot hole diameter (mm) | 650 | 650 | ||||||

| Water–cement ratio | 1 | 1 | 1 | 0.8 | 0.8 | 0.8 | ||

| High-pressure water pressure (MPa) | 38 | 38 (0) | ||||||

| High-pressure water flow rate (L/min) | 200 | 200 (0) | ||||||

| Auxiliary air pressure (MPa) | 1.05 | 1.05 (0) | ||||||

| Auxiliary air flow rate (Nm3/min) | 5 | 5.0 (0) | ||||||

| Cement grout pressure (MPa) | 40 | 40 (40) | ||||||

| Cement grout flow rate (L/min) | 95 | 95 (40) | ||||||

| Lifting speed (min/m) | 20 | 25 | 30 | Grid zone (silty clay): 20 (10) Interlocked zone (silty sand): 25 | ||||

| Stroke interval (mm) | 25 | 25 | 33 | |||||

| Rotation speed (r/step) | 4 | 4 (2) | ||||||

| No. | Test Objective | Test Method | Representative Core Sample Numbers |

|---|---|---|---|

| 1 | Jet grouting pile diameter | Core drilling | 3, 5, 6, 7, 8 |

| 2 | Pile body quality inspection | Core drilling | 1, 2, 3, 5, 6, 7 |

| 3 | Pile permeability coefficient | Laboratory permeability test | 1, 2, 3, 4, 5, 6, 7 |

| Point Number | Average Strength (MPa) | Range (MPa) | Standard Deviation (MPa) | Coefficient of Variation |

|---|---|---|---|---|

| Point 1 | 7.05 | 3.21–12.54 | 2.21 | 0.31 |

| Point 2 | 5.6 | 2.69–10.42 | 1.95 | 0.35 |

| Point 3 | 4.7 | 2.03–9.87 | 1.78 | 0.38 |

| Point 5 | 4.32 | 1.72–7.08 | 1.49 | 0.35 |

| Point 6 | 4.98 | 2.02–9.83 | 2.18 | 0.44 |

| Point 7 | 3.01 | 1.69–4.65 | 0.77 | 0.25 |

| Silty Clay | 5.45 | − | 1.95 | 0.36 |

| Silty Sand | 8.21 | − | 2.77 | 0.34 |

| Sampling Location | Average Permeability Coefficient (cm/s) | Range (cm/s) | Standard Deviation (cm/s) | Coefficient of Variation |

|---|---|---|---|---|

| Core axis | 1.09 × 10−7 | 0.62−1.91 | 3.64 × 10−8 | 0.33 |

| Middle section | 1.64 × 10−7 | 0.78−2.12 | 7.92 × 10−8 | 0.48 |

| Edge | 2.82 × 10−7 | 0.68−5.42 | 1.82 × 10−7 | 0.65 |

| Location | No. | Elevation | Vertical Stress (kPa) | Friction Coefficient | Average | Standard Deviation | Range | ||

|---|---|---|---|---|---|---|---|---|---|

| 500 | 1000 | 1500 | |||||||

| 5 cm | 1 | −23.4 | 275.6 | 548.2 | 794.5 | 0.52 | 0.47 | 0.025 | 0.43–0.52 |

| 2 | −23.9 | 256.4 | 489.7 | 728.9 | 0.47 | ||||

| 3 | −24.9 | 247.6 | 478.6 | 700.2 | 0.45 | ||||

| 4 | −25.3 | 214.8 | 445.2 | 645.1 | 0.43 | ||||

| 5 | −33.5 | 236.5 | 468.2 | 699.1 | 0.46 | ||||

| 6 | −34.2 | 208.9 | 439.4 | 689.5 | 0.48 | ||||

| 7 | −44.9 | 238.5 | 489.7 | 721.5 | 0.48 | ||||

| 8 | −45.2 | 204.8 | 445.8 | 699.4 | 0.49 | ||||

| 45 cm | 1 | −23.2 | 242.6 | 499.6 | 706.4 | 0.46 | 0.46 | 0.018 | 0.43–0.49 |

| 2 | −24.3 | 256.4 | 489.7 | 728.9 | 0.47 | ||||

| 3 | −24.8 | 242.6 | 499.6 | 706.4 | 0.46 | ||||

| 4 | −25.3 | 232 | 487.6 | 721.5 | 0.49 | ||||

| 5 | −26.5 | 248.7 | 469.7 | 714.9 | 0.46 | ||||

| 6 | −37.3 | 214.8 | 445.2 | 645.1 | 0.43 | ||||

| 80 cm | 1 | −22.2 | 264.3 | 438.4 | 704.1 | 0.44 | 0.45 | 0.016 | 0.43–0.48 |

| 2 | −23.1 | 269.4 | 458.7 | 716.3 | 0.45 | ||||

| 3 | −23.3 | 259.8 | 467.3 | 720.4 | 0.46 | ||||

| 4 | −23.9 | 214.8 | 445.2 | 645.1 | 0.43 | ||||

| 5 | −44.5 | 236.5 | 468.2 | 699.1 | 0.46 | ||||

| 6 | −46.2 | 221.3 | 447.6 | 703.4 | 0.48 | ||||

| Test Group | Cohesion (kPa) | Internal Friction Angle (°) |

|---|---|---|

| A | 200 | 24.23 |

| B | 220 | 25.64 |

| C | 290 | 24.7 |

| D | 220 | 25.64 |

| E | 190 | 26.1 |

| F | 180 | 25.64 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, X.; Zhao, W.; Fang, S.; Zhao, J.; Dai, G.; Chen, Z.; Zhu, W. Study of Performance and Engineering Application of D-RJP Jet Grouting Technology in Anchorage Foundation Reinforcement for Deep Suspension Bridge Excavations. Appl. Sci. 2025, 15, 8985. https://doi.org/10.3390/app15168985

Zhu X, Zhao W, Fang S, Zhao J, Dai G, Chen Z, Zhu W. Study of Performance and Engineering Application of D-RJP Jet Grouting Technology in Anchorage Foundation Reinforcement for Deep Suspension Bridge Excavations. Applied Sciences. 2025; 15(16):8985. https://doi.org/10.3390/app15168985

Chicago/Turabian StyleZhu, Xiaoliang, Wenqing Zhao, Sheng Fang, Junchen Zhao, Guoliang Dai, Zhiwei Chen, and Wenbo Zhu. 2025. "Study of Performance and Engineering Application of D-RJP Jet Grouting Technology in Anchorage Foundation Reinforcement for Deep Suspension Bridge Excavations" Applied Sciences 15, no. 16: 8985. https://doi.org/10.3390/app15168985

APA StyleZhu, X., Zhao, W., Fang, S., Zhao, J., Dai, G., Chen, Z., & Zhu, W. (2025). Study of Performance and Engineering Application of D-RJP Jet Grouting Technology in Anchorage Foundation Reinforcement for Deep Suspension Bridge Excavations. Applied Sciences, 15(16), 8985. https://doi.org/10.3390/app15168985