Comparative Analysis of Multispectral LED–Sensor Architectures for Scalable Waste Material Classification

Abstract

1. Introduction

2. Materials

3. Methods

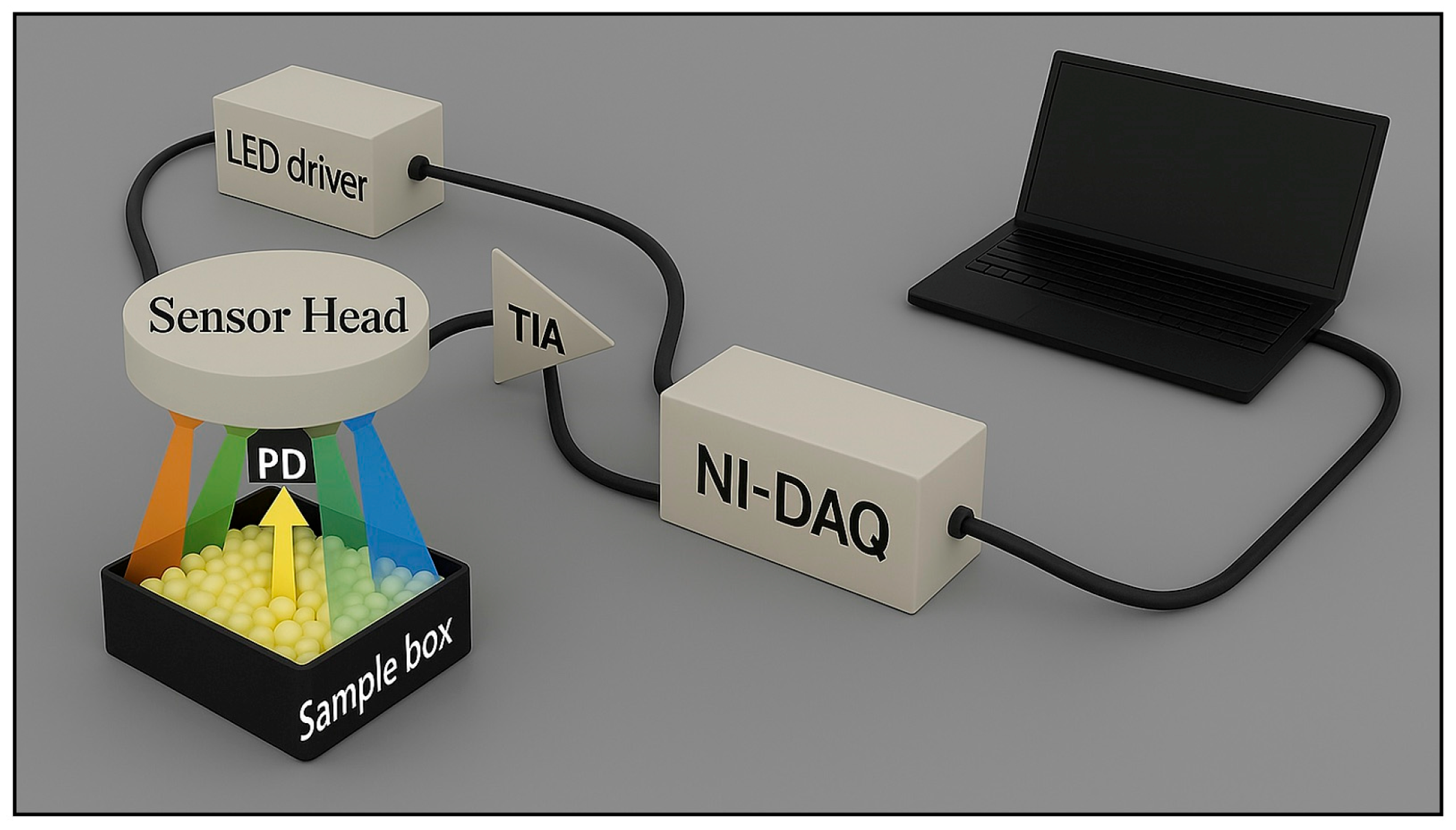

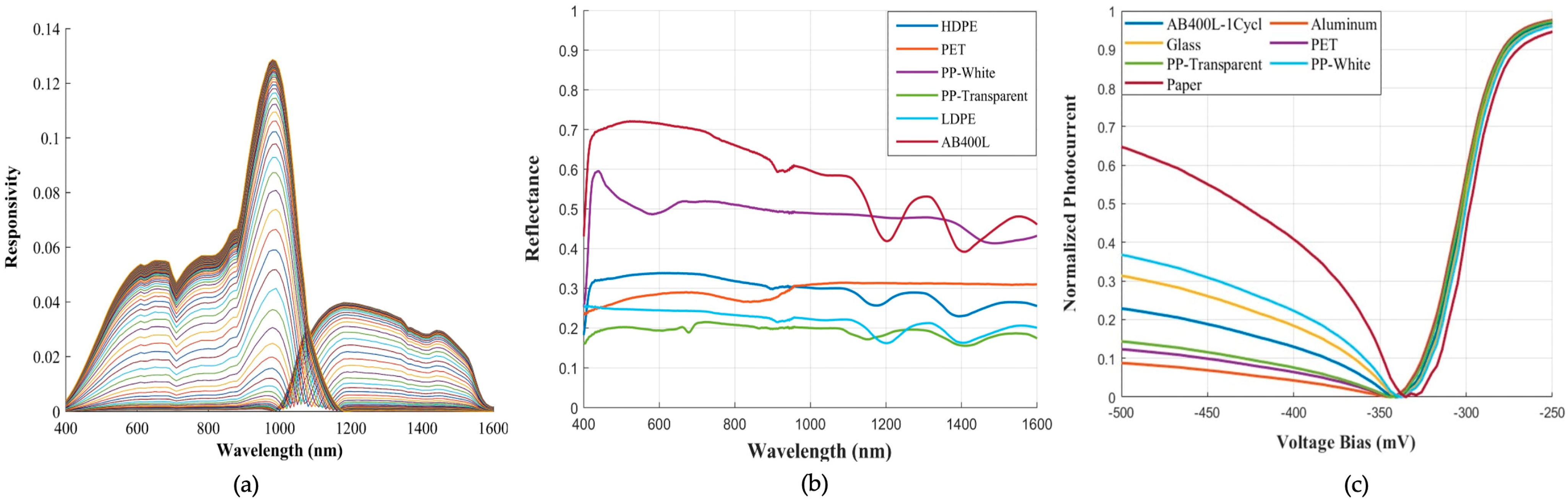

3.1. Method 1: SWIR Discrete Spectroscopy

3.1.1. Experimental Setup

3.1.2. LED Optimization and Simulation

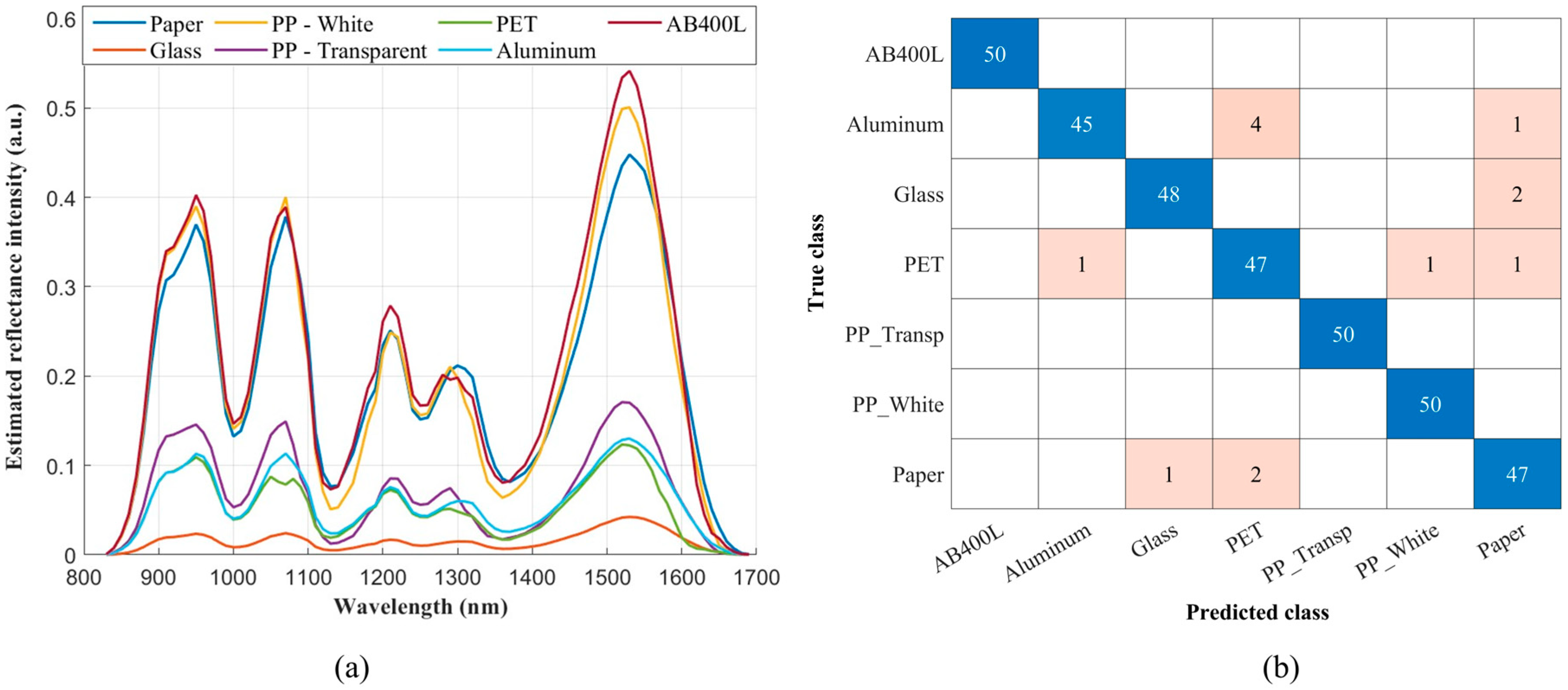

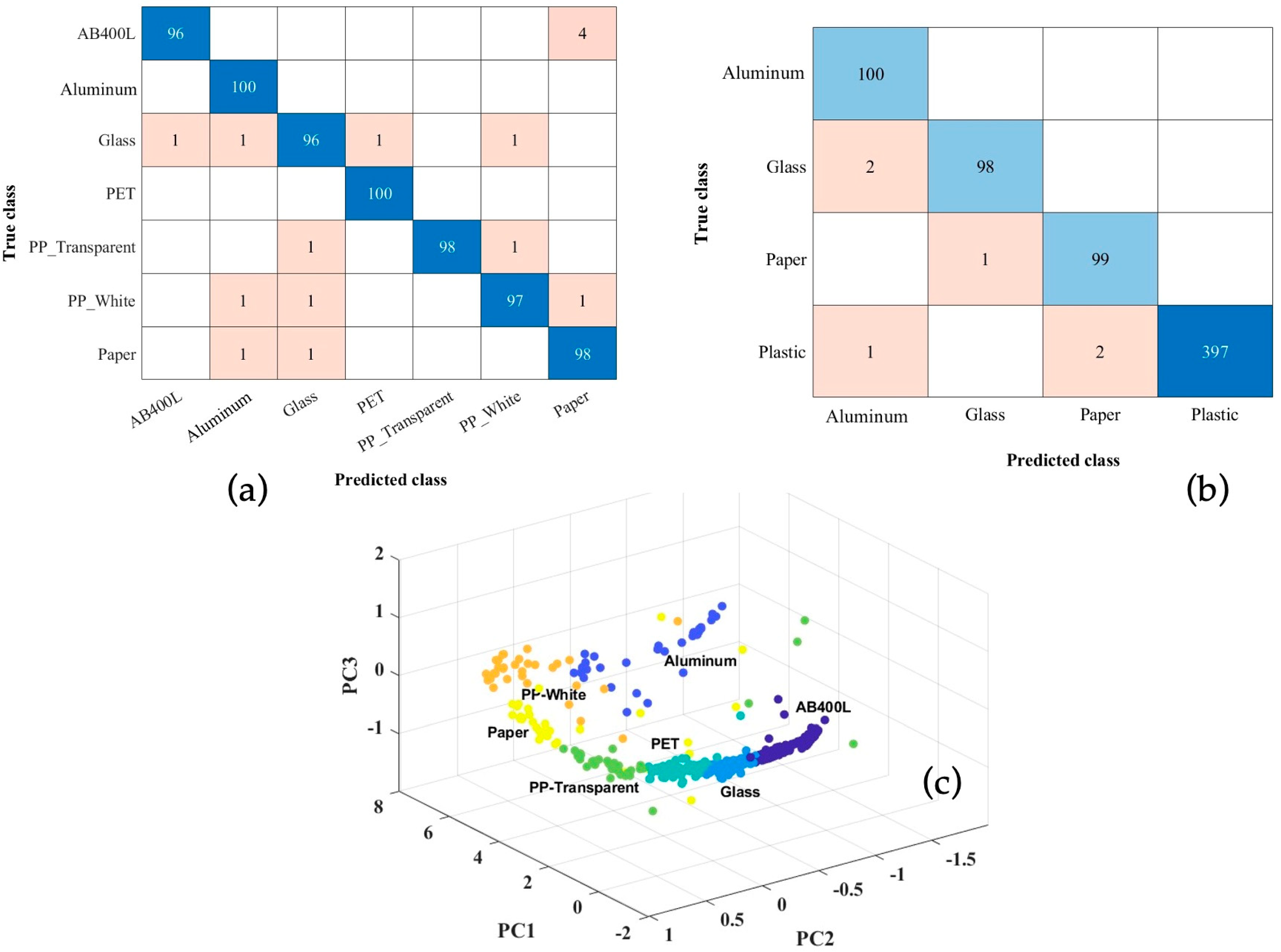

3.1.3. Results and Discussion

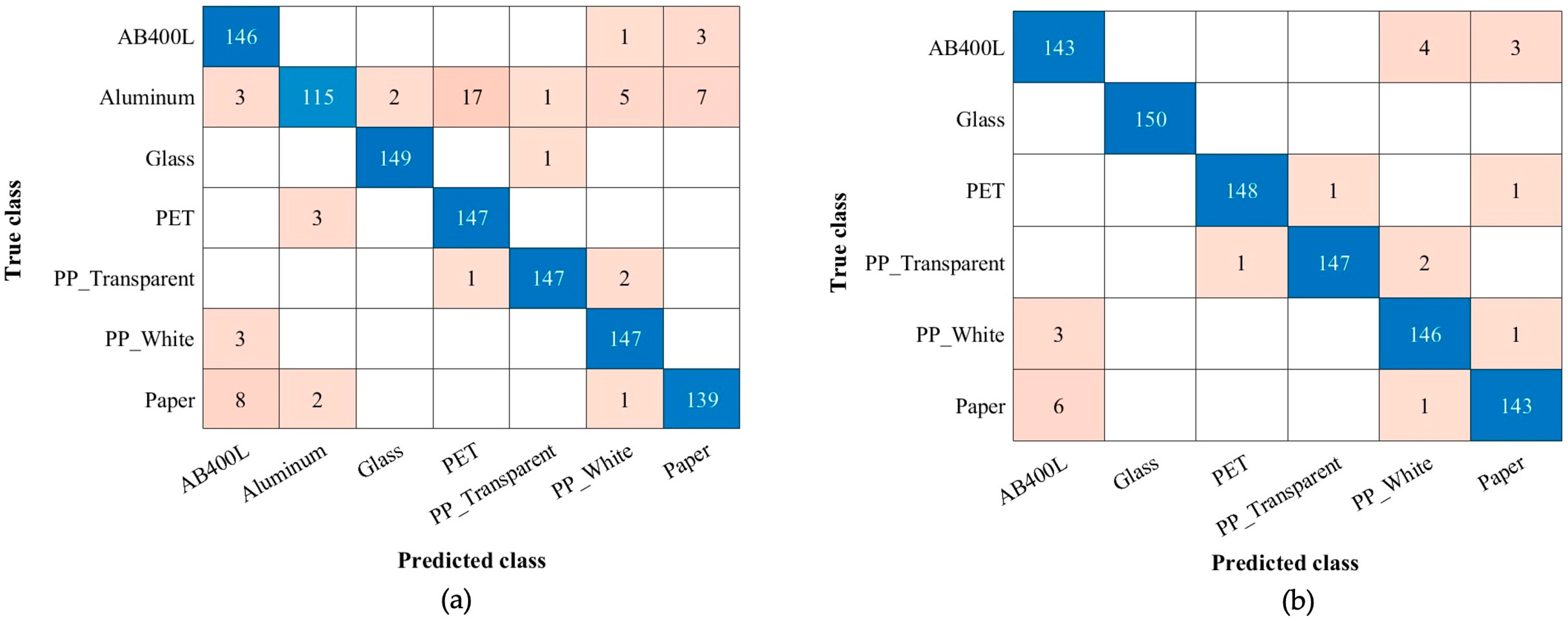

3.1.4. Classification Performance with Four LEDs

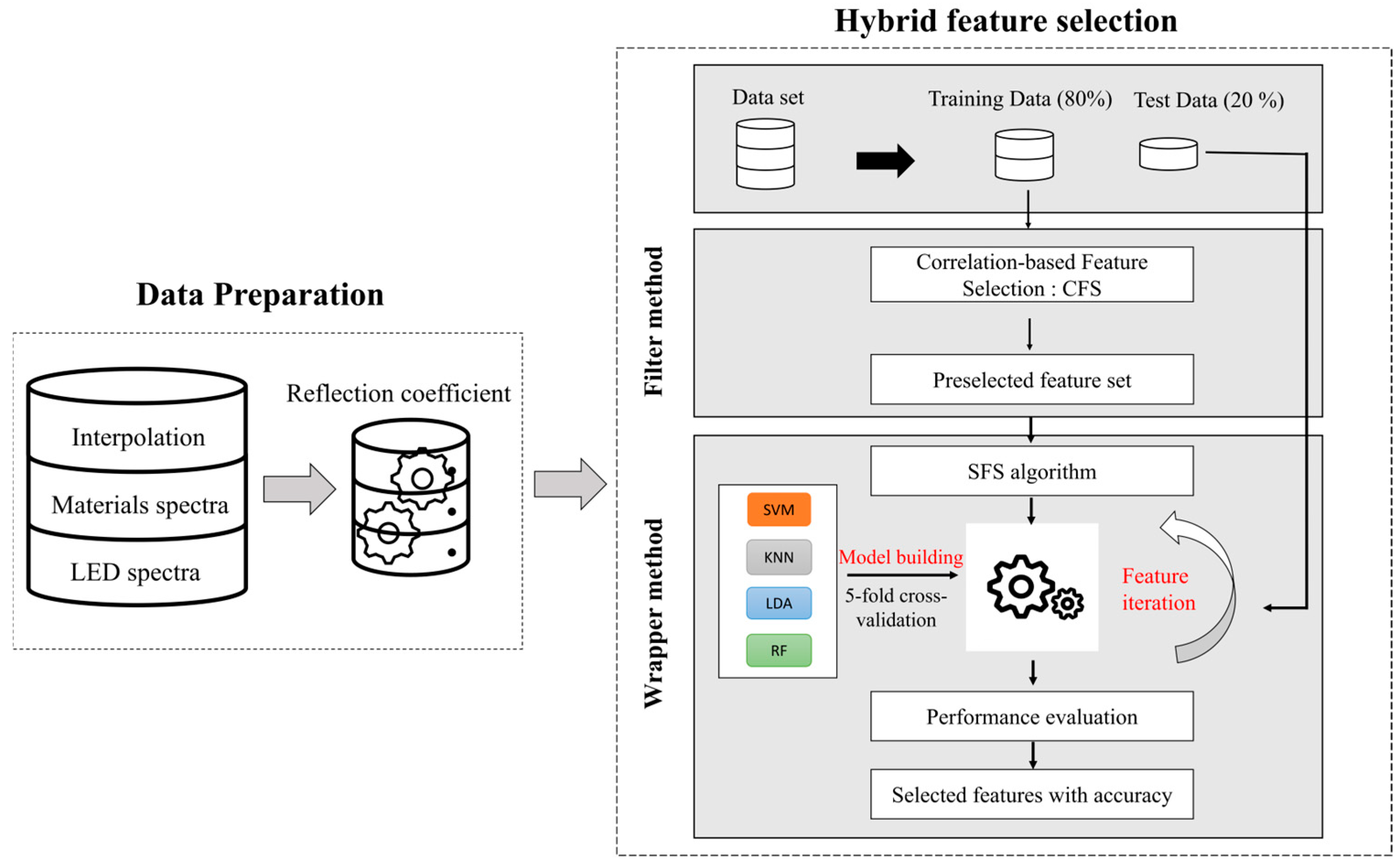

Hybrid Feature Approach

Data Analysis

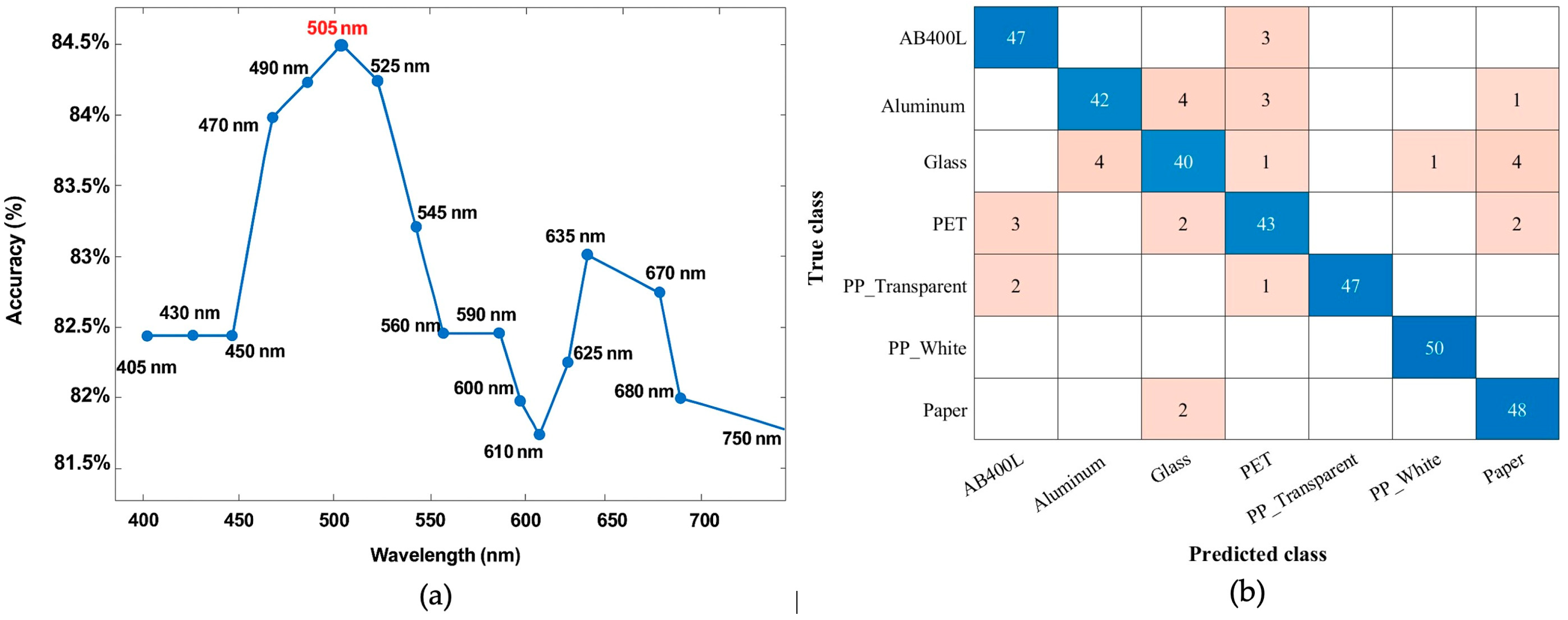

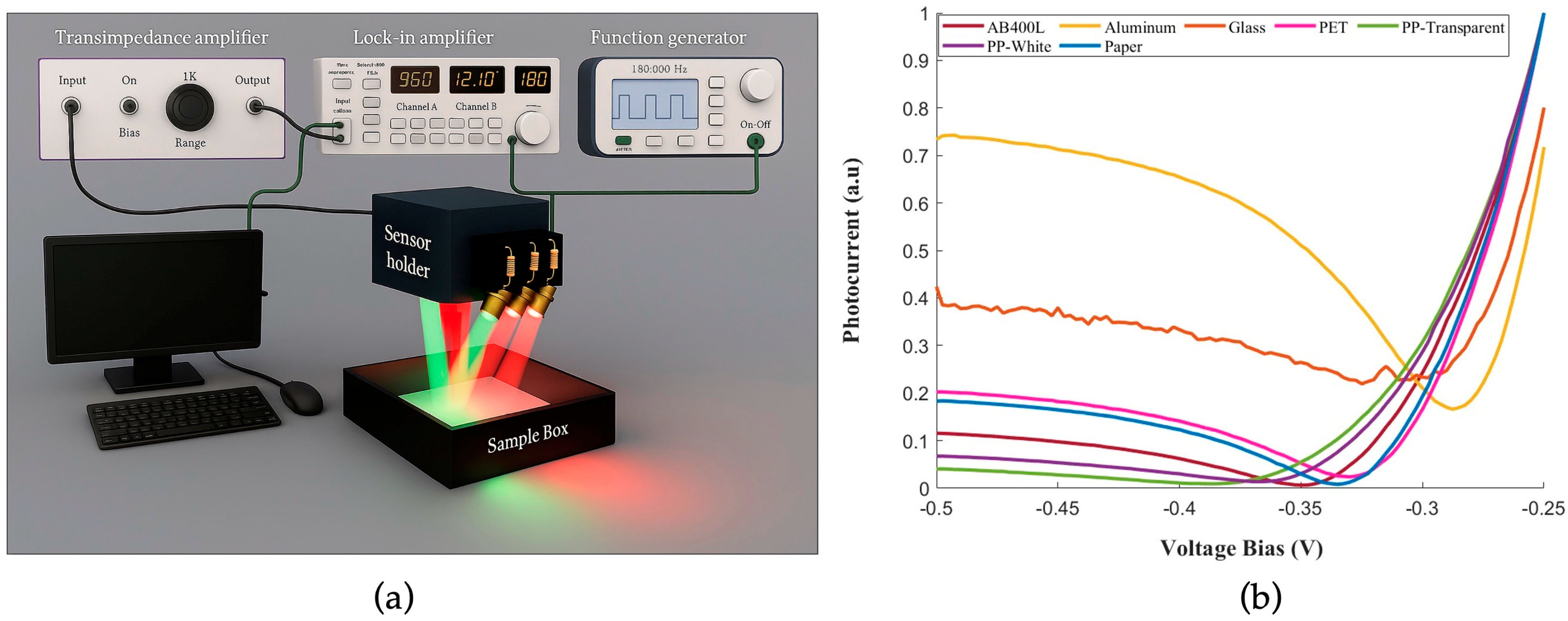

3.2. Method 2: Voltage-Tunable Sensor Approach

3.2.1. Dual-Band Photodetector

3.2.2. Photocurrent Simulation

3.2.3. Experimental Setup

3.2.4. Data Acquisition and Processing

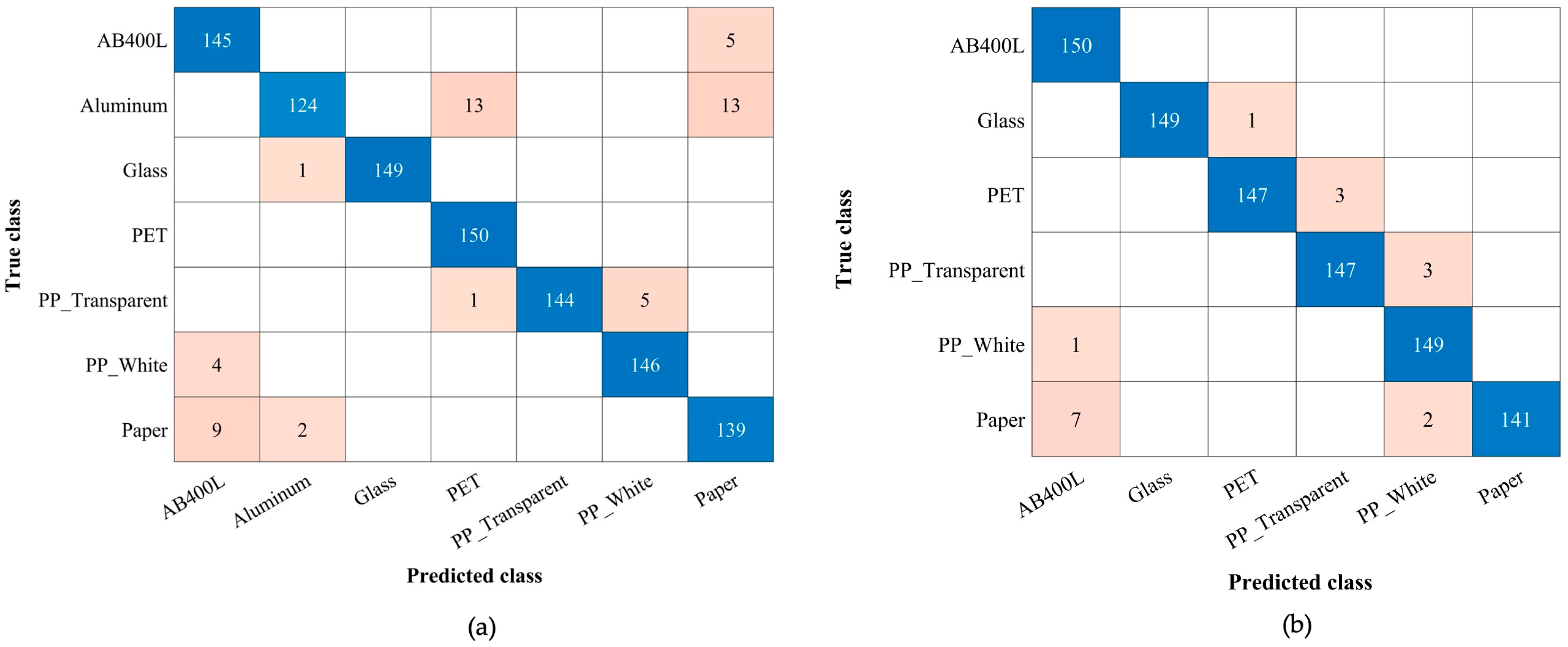

3.2.5. Results and Discussion

4. Comparative Analysis and Design Insights

- Optimized LED selection can reduce system complexity while maintaining performance.

- Bias-tunable photodetectors can replace more complex hardware for spectral adaptability.

- Material-specific surface characteristics (e.g., Aluminum) impact sensor architecture.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hardie, K.; Agne, S.; Kuntz, K.B.; Jennewein, T. Inexpensive LED-Based Spectrophotometer for Analyzing Optical Coatings. arXiv 2016, arXiv:1606.02774. [Google Scholar]

- Bonifazi, G.; Gasbarrone, R.; Serranti, S. Detecting Contaminants in Post-Consumer Plastic Packaging Waste by a Nir Hyperspectral Imaging-Based Cascade Detection Approach. Detritus 2021, 15, 94–106. [Google Scholar]

- Bonifazi, G.; Serranti, S. Imaging Spectroscopy Based Strategies for Ceramic Glass Contaminants Removal in Glass Recycling. Waste Manag. 2006, 26, 627–639. [Google Scholar] [CrossRef] [PubMed]

- Kutila, M.; Viitanen, J.; Vattulainen, A. Scrap Metal Sorting with Colour Vision and Inductive Sensor Array. In Proceedings of the Proceedings—International Conference on Computational Intelligence for Modelling, Control and Automation, CIMCA 2005 and International Conference on Intelligent Agents, Web Technologies and Internet, Vienna, Austria, 28–30 November 2005; Volume 2, pp. 725–729. [Google Scholar]

- Nansen, C.; Kolomiets, M.; Gao, X. Considerations Regarding the Use of Hyperspectral Imaging Data in Classifications of Food Products, Exemplified by Analysis of Maize Kernels. J. Agric. Food Chem. 2008, 56, 2933–2938. [Google Scholar] [CrossRef] [PubMed]

- Geladi, P.; Burger, J.; Lestander, T. Hyperspectral Imaging: Calibration Problems and Solutions. Chemom. Intell. Lab. Syst. 2004, 72, 209–217. [Google Scholar] [CrossRef]

- Rahman, M.O.; Hussain, A.; Scavino, E.; Hannan, M.A.; Basri, H. Segregating Recyclable Waste Papers Using Co-occurrence Features. In Proceedings of the 9th WSEAS international Conference on Applied Computer Science, ACS ’09, Genova, Italy, 17–19 October 2009; pp. 187–191. [Google Scholar]

- Wang, O.; Gunawardane, P.; Scher, S.; Davis, J. Material Classification Using BRDF Slices. In Proceedings of the 2009 IEEE Conference on Computer Vision and Pattern Recognition, CVPR 2009, Miami, FL, USA, 20–25 June 2009; pp. 2805–2811. [Google Scholar]

- Mukunda, D.C.; Joshi, V.K.; Mahato, K.K. Light Emitting Diodes (LEDs) in Fluorescence-Based Analytical Applications: A Review. Appl. Spectrosc. Rev. 2022, 57, 1–38. [Google Scholar] [CrossRef]

- Bui, D.A.; Hauser, P.C. Analytical Devices Based on Light-Emitting Diodes—A Review of the State-of-the-Art. Anal. Chim. Acta 2015, 853, 46–58. [Google Scholar] [CrossRef]

- Magnus, I.; Virte, M.; Thienpont, H.; Smeesters, L. Combining Optical Spectroscopy and Machine Learning to Improve Food Classification. Food Control 2021, 130, 108342. [Google Scholar] [CrossRef]

- Liu, C.; Gu, J. Discriminative Illumination: Per-Pixel Classification of Raw Materials Based on Optimal Projections of Spectral BRDF. IEEE Trans. Pattern Anal. Mach. Intell. 2014, 36, 86–98. [Google Scholar] [CrossRef]

- Lopez-Ruiz, N.; Granados-Ortega, F.; Carvajal, M.A.; Martinez-Olmos, A. Portable Multispectral Imaging System Based on Raspberry Pi. Sens. Rev. 2017, 37, 322–329. [Google Scholar] [CrossRef]

- Martinez-Hernandez, U.; West, G.; Assaf, T. Low-Cost Recognition of Plastic Waste Using Deep Learning and a Multi-Spectral Near-Infrared Sensor. Sensors 2024, 24, 2821. [Google Scholar] [CrossRef] [PubMed]

- Straller, A.; Gessler, B. Identification of Plastic Types Using Discrete Near Infrared Reflectance Spectroscopy, Preprint 2019. Available online: https://www.researchgate.net/publication/337868860 (accessed on 9 August 2025).

- Dong, Y.; Liu, X.; Mei, L.; Feng, C.; Yan, C.; He, S. LED-Induced Fluorescence System for Tea Classification and Quality Assessment. J. Food Eng. 2014, 137, 95–100. [Google Scholar] [CrossRef]

- Zhong, W.; Dong, Y.; Liu, X.; Lin, H.; Mei, L.; Yan, C. Classification Evaluation of Tobaccos Using LED-Induced Fluorescence Spectroscopy. In Proceedings of the Light-Emitting Diodes: Materials, Devices, and Applications for Solid State Lighting XVIII, San Francisco, CA, USA, 1–6 February 2014; SPIE: Bellingham, WA, USA, 2014; Volume 9003, p. 9003. [Google Scholar]

- Lastra-Mejías, M.; Torreblanca-Zanca, A.; Aroca-Santos, R.; Cancilla, J.C.; Izquierdo, J.G.; Torrecilla, J.S. Characterization of an Array of Honeys of Different Types and Botanical Origins through Fluorescence Emission Based on LEDs. Talanta 2018, 185, 196–202. [Google Scholar] [CrossRef] [PubMed]

- Manakkakudy, A.; De Iacovo, A.; Maiorana, E.; Mitri, F.; Colace, L. Material Classification Based on a SWIR Discrete Spectroscopy Approach. Appl. Opt. 2023, 62, 9228–9237. [Google Scholar] [CrossRef]

- Manakkakudy Kumaran, A.; De Iacovo, A.; Ballabio, A.; Frigerio, J.; Isella, G.; Colace, L. Waste Material Classification Based on a Wavelength-Sensitive Ge-on-Si Photodetector. Sensors 2024, 24, 6970. [Google Scholar] [CrossRef]

- Rozenstein, O.; Puckrin, E.; Adamowski, J. Development of a New Approach Based on Midwave Infrared Spectroscopy for Post-Consumer Black Plastic Waste Sorting in the Recycling Industry. Waste Manag. 2017, 68, 38–44. [Google Scholar] [CrossRef]

- Rückstieß, T.; Osendorfer, C.; Van Der Smagt, P. Sequential Feature Selection for Classification. In Proceedings of the Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Berlin/Heidelberg, Germany, 2011; pp. 132–141. [Google Scholar]

- Savitzky, A.; Golay, M.J.E. Smoothing and Differentiation of Data by Simplified Least Squares Procedures. Anal. Chem. 1964, 36, 1627–1639. [Google Scholar] [CrossRef]

- Jung, Y. Multiple Predicting K-Fold Cross-Validation for Model Selection. J. Nonparametr. Stat. 2018, 30, 197–215. [Google Scholar] [CrossRef]

- Theodoridis, S. Machine Learning: A Bayesian and Optimization Perspective, 2nd ed.; Academic Press: Cambridge, MA, USA, 2015. [Google Scholar]

- Cateni, S.; Colla, V.; Vannucci, M. A Hybrid Feature Selection Method for Classification Purposes. In Proceedings of the IEEE European Modelling Symposium, Pisa, Italy, 21–23 October 2014; pp. 39–44. [Google Scholar]

- Manakkakudy, A.; De Iacovo, A.; Maiorana, E.; Mitri, F.; Colace, L. Waste Material Classification: A Short-Wave Infrared Discrete-Light-Source Approach Based on Light-Emitting Diodes. Sensors 2024, 24, 809. [Google Scholar] [CrossRef]

- Colace, L.; Assanto, G. Germanium on Silicon for Near-Infrared Light Sensing. IEEE Photonics J. 2009, 1, 69–79. [Google Scholar] [CrossRef]

- Masini, G.; Cencelli, V.; Colace, L.; De Notaristefani, F.; Assanto, G. Linear Array of Si-Ge Heterojunction Photodetectors Monolithically Integrated with Silicon CMOS Readout Electronics. IEEE J. Sel. Top. Quantum Electron. 2004, 10, 811–815. [Google Scholar] [CrossRef]

- Simola, E.T.; De Iacovo, A.; Frigerio, J.; Ballabio, A.; Fabbri, A.; Isella, G.; Colace, L. Voltage-Tunable Dual-Band Ge/Si Photodetector Operating in VIS and NIR Spectral Range. Opt. Express 2019, 27, 8529–8539. [Google Scholar] [CrossRef]

- Zhu, S.; Chen, H.; Wang, M.; Guo, X.; Lei, Y.; Jin, G. Plastic Solid Waste Identification System Based on near Infrared Spectroscopy in Combination with Support Vector Machine. Adv. Ind. Eng. Polym. Res. 2019, 2, 77–81. [Google Scholar] [CrossRef]

- Patro, S.G.K.; Sahu, K.K. Normalization: A Preprocessing Stage. Int. Adv. Res. J. Sci. Eng. Technol. 2015, 2, 20–22. [Google Scholar] [CrossRef]

- Kurita, T. Principal component analysis (PCA). In Computer Vision: A Reference Guide; Springer International Publishing: Cham, Switzerland, 2021; pp. 1013–1016. [Google Scholar]

| Data Division Approach | All Materials (SVM) | Without Aluminum (SVM) | All Materials (LDA) | Without Aluminum (LDA) |

|---|---|---|---|---|

| 1st (Training) and 2nd (Testing) | 79% | 96.0% | 73.4% | 84.0% |

| 1st (Training) and 3rd (Testing) | 86% | 93.0% | 62.0% | 94.0% |

| 2nd (Training) and 1st (Testing) | 81% | 87.0% | 67.4% | 80.0% |

| 2nd (Training) and 3rd (Testing) | 94% | 95.0% | 81.0% | 93.7% |

| 3rd (Training) and 1st (Testing) | 76% | 83.0% | 67.0% | 89.0% |

| 3rd (Training) and 2nd (Testing) | 87% | 95.0% | 84.3% | 90.0% |

| Shuffled Data | 95.0% | 98.1% | 86.0% | 98.0% |

| Dataset | SVM | LDA | KNN | RF |

|---|---|---|---|---|

| 1st day | 95.7% | 96.0% | 94.3% | 92.9% |

| 2nd day | 94.6% | 93.4% | 92.6% | 88.6% |

| 3rd day | 93.4% | 92.9% | 89.7% | 90.0% |

| Shuffled | 94.3% | 93.0% | 88.0% | 90.3% |

| Classifier | Rank 1 SWIR LED (nm) | Rank 2 SWIR LED (nm) | VIS LED (nm) |

|---|---|---|---|

| SVM | 1200 | 1300 | 505 |

| KNN | 1300 | 970 | 505 |

| QDA | 1200 | 1300 | 505 |

| RF | 1200 | 1070 | 545 |

| Dataset | SVM | KNN | QDA | RF |

|---|---|---|---|---|

| 7 Class | 97.9% | 92.0% | 97.0% | 95.0% |

| 4 Class | 99.1% | 92.9% | 95.6% | 94.7% |

| Parameter | System 1: Discrete SWIR | System 2: Dual-Band PD | HSI/MSI (Hyperspectral/Multispectral Imaging) | LIBS (Laser-Induced Breakdown Spectroscopy | Raman Spectroscopy | XRF (X-Ray Fluorescence) |

|---|---|---|---|---|---|---|

| Spectral Range | 910–1600 nm | 505–1300 nm | 400–2500 nm (broadband) | UV-VIS-NIR | Visible/NIR | X-ray |

| Portability | High | Medium to high | Low to medium | Medium to high | Low to medium | Low to medium |

| Power Consumption | Low | Low | High | High | Medium | High |

| Component Complexity | Low | Low | High | High | High | High |

| Cost | Low to moderate | Low to moderate | High | High | High | High |

| Classification Accuracy | Up to 98% | Up to 99.1% | High (dependent on setup) | High (elemental precision) | High (material-specific) | High (element-specific) |

| Material Range | Plastics, paper, glass, Al | Plastics, paper, glass, aluminum | Wide, including complex mixtures | Mainly metals, some non metals | Wide, but sensitive to fluorescence | Elemental composition |

| Speed | Fast | Moderate | Moderate | Fast (single point), slower for scanning | Moderate | Moderate |

| Application Examples | Smart waste bins, small-scale industrial recycling | Smart waste bins, industrial recycling | Laboratory analysis, industrial sorting | Elemental analysis in metallurgy, recycling | Chemical/material identification | Elemental analysis, recycling |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manakkakudy Kumaran, A.; Elagib, R.; De Iacovo, A.; Ballabio, A.; Frigerio, J.; Isella, G.; Assanto, G.; Colace, L. Comparative Analysis of Multispectral LED–Sensor Architectures for Scalable Waste Material Classification. Appl. Sci. 2025, 15, 8964. https://doi.org/10.3390/app15168964

Manakkakudy Kumaran A, Elagib R, De Iacovo A, Ballabio A, Frigerio J, Isella G, Assanto G, Colace L. Comparative Analysis of Multispectral LED–Sensor Architectures for Scalable Waste Material Classification. Applied Sciences. 2025; 15(16):8964. https://doi.org/10.3390/app15168964

Chicago/Turabian StyleManakkakudy Kumaran, Anju, Rahmi Elagib, Andrea De Iacovo, Andrea Ballabio, Jacopo Frigerio, Giovanni Isella, Gaetano Assanto, and Lorenzo Colace. 2025. "Comparative Analysis of Multispectral LED–Sensor Architectures for Scalable Waste Material Classification" Applied Sciences 15, no. 16: 8964. https://doi.org/10.3390/app15168964

APA StyleManakkakudy Kumaran, A., Elagib, R., De Iacovo, A., Ballabio, A., Frigerio, J., Isella, G., Assanto, G., & Colace, L. (2025). Comparative Analysis of Multispectral LED–Sensor Architectures for Scalable Waste Material Classification. Applied Sciences, 15(16), 8964. https://doi.org/10.3390/app15168964