Implementation of SMED Workshops: A Strategic Approach in the Automotive Sector

Abstract

1. Introduction

2. Theoretical Framework

2.1. Origin and Evolution of the Lean Concept

2.2. Waste

2.3. Principles and Objectives of the Lean Philosophy

2.4. Importance of Lean Philosophy in Organizations

2.5. Lean Tools

- SMED: It is a Lean methodology that was developed to reduce the setup times of a machine and/or equipment [12]. This will be explored in more depth, as it is the tool under study in this paper.

- 5S: This tool assists in the organization and improvement of the workplace by identifying and eliminating existing waste. It is important to recognize that this method is based on five words, which cannot be dissociated since their joint application is essential for correct implementation. Thus, it can be said that these words are sort, set, shine, standardize, and sustain [9,19,23].

- Kanban: This method uses a card system, combined with a visual board, which contains all the stages of the workflow, facilitating the tracking of information. In this way, organizations can know which stage is being carried out, as well as what materials are needed to proceed to the next stages [10,19].

- PDCA cycle: This tool was developed to continuously improve an organization’s production processes. To achieve the expected results, the four steps listed above must be established. First, you must start by planning all issues and improvements and identifying the methods used. The second step is to execute the plan (Do), and then all data must be analyzed and verified (Check). To complete this cycle, all steps must be adjusted (Act) according to the results obtained [24].

- KPI: This method provides essential benchmarks for performance analysis and decision-making within an organization. As its name suggests, this method is a key indicator that allows companies to measure their progress towards their strategic objectives [25].

- OEE: Quantitative tool used to assess the effectiveness of equipment in a production process and is based on three components: Availability, Efficiency, and Quality. According to its formula, a score of 100% represents perfect production, with the manufacture of quality products without waste [10].

2.6. SMED—Single Minute Exchange of Die

- Greater flexibility, as it is not necessary to have a very high stock of raw materials due to constant changes;

- Faster product deliveries, as the batches produced are smaller;

- Increased operational efficiency, due to reduced tool change times;

- Guaranteed better product quality and maintenance, due to reduced cycle times;

- Increased return on invested capital;

- Greater occupational efficiency of space reserved exclusively for stocks;

- Greater availability of machines and/or equipment;

- Greater production capacity;

3. Materials and Methods

3.1. Materials

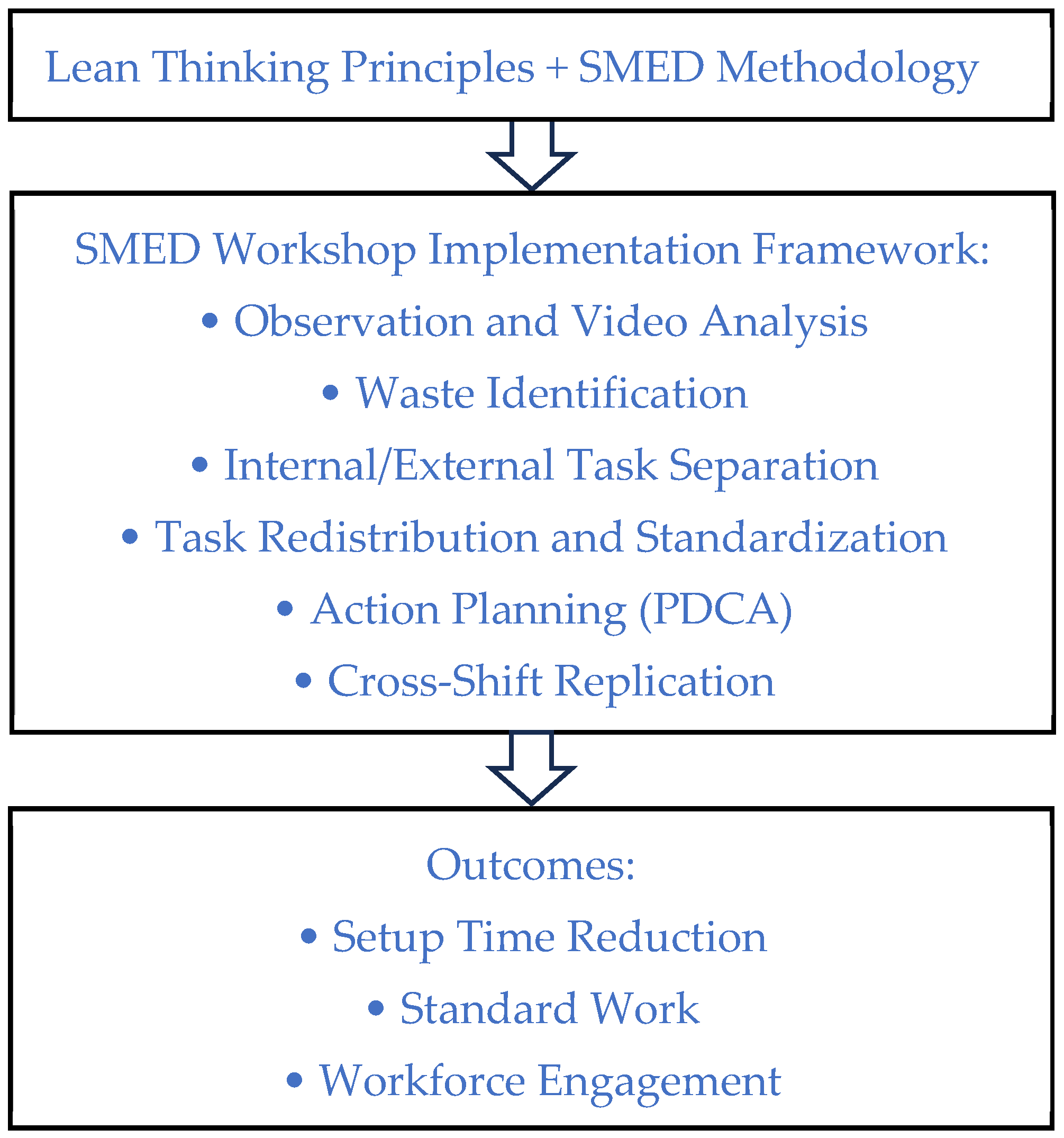

3.2. Methods

- Introduction to the first phase of the SMED Workshop;

- Presentation of the objectives of the SMED Workshop;

- Introduction to the company’s new system;

- Presentation and explanation of the SMED methodology;

- Viewing and analysis of example videos;

- Viewing videos on the change in reference of the line under study and validation of the sequence of initial tasks and their respective times;

- Identification of waste resulting from the tasks involved in the change in reference to be produced;

- Identification of internal and external tasks;

- Analysis of waste to be reduced and/or eliminated;

- Analysis of the possibility of transforming internal tasks into external ones;

- Analysis of the balance of operations between technicians;

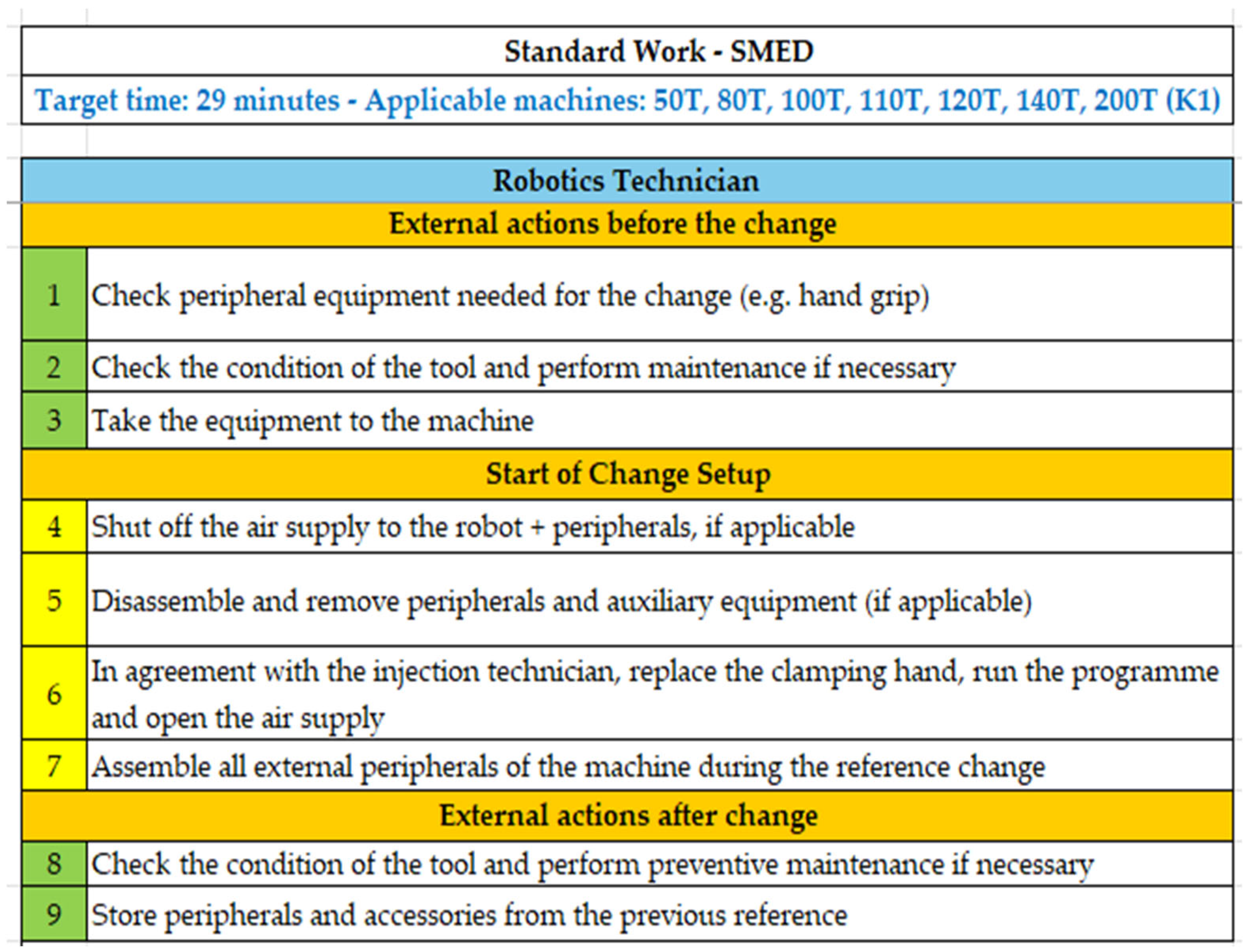

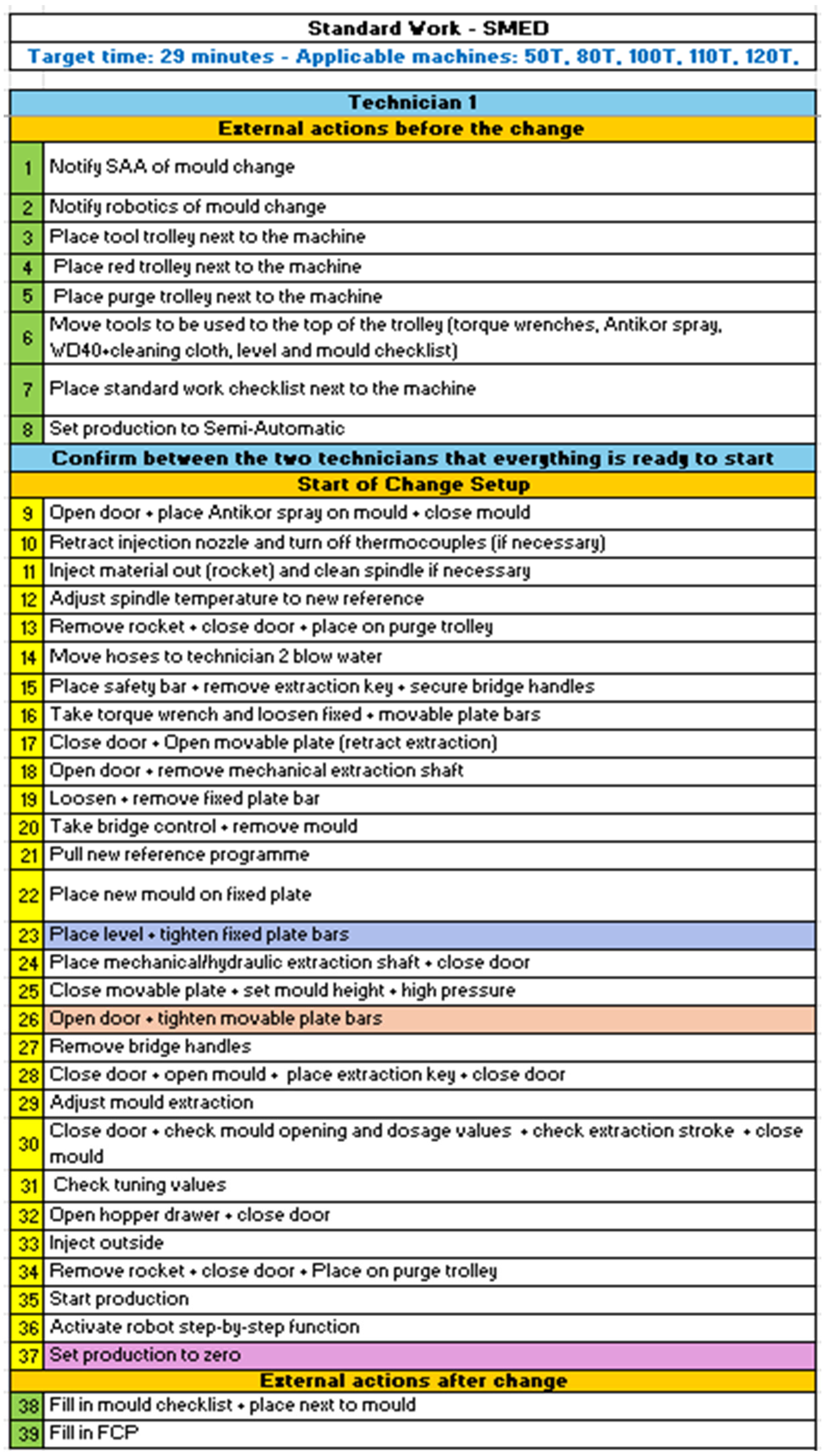

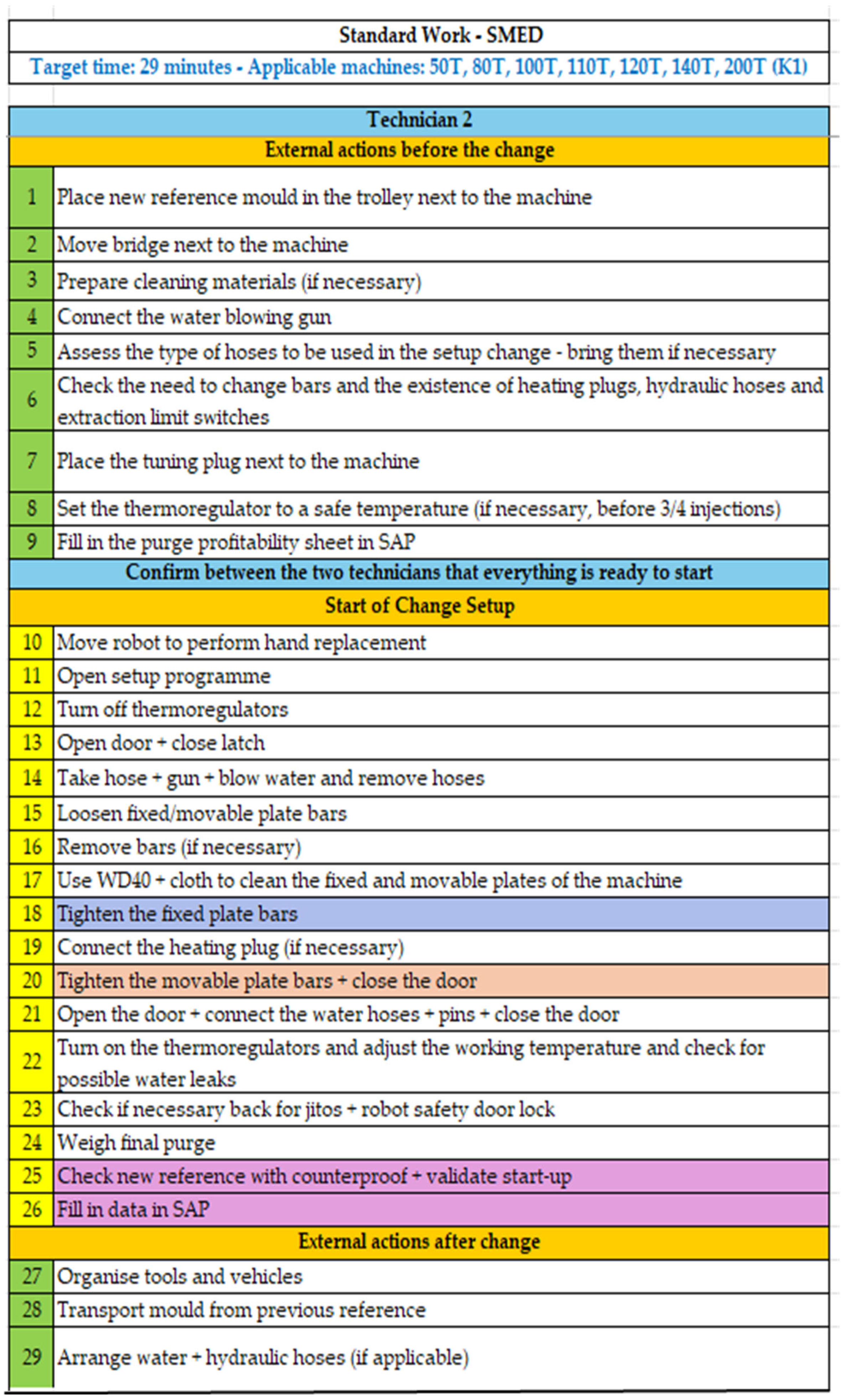

- Definition of the standard work sequence (Standardized Work);

- Creation of an immediate and medium-term corrective/preventive action plan–PDCA;

- Planning training and testing of the solution;

- Planning of application to other shifts;

- Validation of all activities;

- Conclusion of the SMED Workshop.

3.2.1. SMED Workshop Planning

3.2.2. Description of the Methods Applied in the SMED Workshop

Description of the First Phase of the SMED Workshop

Description of the Second Phase of the SMED Workshop

Description of the Third Phase of the SMED Workshop

4. Analysis and Discussion of Results

4.1. Results of the First Phase of the SMED Workshop

4.2. Results of the Second Phase of the SMED Workshop

4.3. Results of the Third Phase of the SMED Workshop

- Define in the Standard Work that the SAA Technician must be at the machine at the start of the change—action No. 1;

- Create a table per machine with the amount of excess purge weight—action No. 2;

- Include in the Standard Work the phases in which SAP records must be made—action No. 3;

- Define the number of technicians to be used in a setup change, 1 or 2 technicians—action No. 6;

- Include in the Standard Work the phase of filling out the mold checklist at the end of the change, as an external action—action No. 13;

- Analyze the cleaning of the machine plate—with bars or without bars?—action No. 14;

- Include in the Standard Work, before the change, bringing the tuning sheet to the machine monitor—action No. 15;

- Train first shift technicians for the defined Standard Work—action No. 19;

- Monitor and validate setup changes with the first shift according to the Standard Work—action No. 20.

4.4. Critical Reflections, Challenges, and Theoretical Integration

4.5. SMED Workshop Conclusions and Suggestions for Future Work

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Silva, A.; Sá, J.C.; Santos, G.; Silva, F.J.G.; Ferreira, L.P.; Pereira, M.T. Implementation of SMED in a cutting line. Procedia Manuf. 2020, 51, 1355–1362. [Google Scholar] [CrossRef]

- Díaz-Reza, J.R.; García-Alcaraz, J.L.; Gil-López, A.J.; Realyvasquez-Vargas, A. Lean manufacturing tools as drivers of social sustainability in the Mexican maquiladora industry. Comput. Ind. Eng. 2024, 196, 110516. [Google Scholar] [CrossRef]

- Costa, F.; Alemsan, N.; Bilancia, A.; Tortorella, G.L.; Staudacher, A.P. Integrating industry 4.0 and lean manufacturing for a sustainable green transition: A comprehensive model. J. Clean. Prod. 2024, 465, 142728. [Google Scholar] [CrossRef]

- Monteiro, C.; Ferreira, L.P.; Fernandes, N.O.; Sá, J.C.; Ribeiro, M.T.; Silva, F.J.G. Improving the Machining Process of the Metalworking Industry Using the Lean Tool SMED. Procedia Manuf. 2019, 41, 555–562. [Google Scholar] [CrossRef]

- Vieira, T.; Sá, J.C.; Lopes, M.P.; Santos, G.; Félix, M.J.; Ferreira, L.P.; Silva, F.J.G.; Pereira, M.T. Optimization of the cold profiling process through SMED. Procedia Manuf. 2019, 38, 892–899. [Google Scholar] [CrossRef]

- Aljuwaied, M.; Almanei, M.; Litos, L.; Salonitis, K. Lean Thinking and Resource Efficiency in the Design of Public Services. Procedia CIRP 2024, 128, 894–899. [Google Scholar] [CrossRef]

- Deshmukh, M.; Gangele, A.; Gope, D.K.; Dewangan, S. Study and implementation of lean manufacturing strategies: A literature review. Mater. Today Proc. 2022, 62, 1489–1495. [Google Scholar] [CrossRef]

- Tetteh, M.G.; Gupta, S.; Kumar, M.; Trollman, H.; Salonitis, K.; Jagtap, S. Pharma 4.0: A deep dive top management commitment to successful Lean 4.0 implementation in Ghanaian pharma manufacturing sector. Heliyon 2024, 10, e36677. [Google Scholar] [CrossRef]

- Wang, P.; Wu, P.; Chi, H.L.; Li, X. Adopting lean thinking in virtual reality-based personalized operation training using value stream mapping. Autom. Constr. 2020, 119, 103355. [Google Scholar] [CrossRef]

- Sivaraman, P.; Nithyanandhan, T.; Lakshminarasimhan, S.; Manikandan, S.; Saifudheen, M. Productivity enhancement in engine assembly using lean tools and techniques. Mater. Today Proc. 2020, 33, 201–207. [Google Scholar] [CrossRef]

- Nandini, T.S.; MohanRam, M.; Shekar, G.L. Modeling 4Ps of Toyota way principles in MSMEs supply Chain-an empirical approach. Mater. Today Proc. 2023, 92, 284–290. [Google Scholar] [CrossRef]

- Martins, M.; Godina, R.; Pimentel, C.; Silva, F.J.G.; Matias, J.C.O. A Practical Study of the Application of SMED to Electron-beam Machining in Automotive Industry. Procedia Manuf. 2018, 17, 647–654. [Google Scholar] [CrossRef]

- Afonso, M.; Gabriel, A.T.; Godina, R. Proposal of an innovative ergonomic SMED model in an automotive steel springs industrial unit. Adv. Ind. Manuf. Eng. 2022, 4, 100075. [Google Scholar] [CrossRef]

- Naciri, L.; Mouhib, Z.; Gallab, M.; Nali, M.; Abbou, R.; Kebe, A. Lean and industry 4.0: A leading harmony. Procedia Comput. Sci. 2022, 200, 394–406. [Google Scholar] [CrossRef]

- Reke, E.; Powell, D.; Mogos, M.F. Applying the fundamentals of TPS to realize a resilient and responsive manufacturing system. Procedia CIRP 2022, 107, 1221–1225. [Google Scholar] [CrossRef]

- Frédéric, R.; Florian, M.; Laurent, J.; Forget, P.; Pellerin, R.; Samir, L. Lean 4.0: Typology of scenarios and case studies to characterize Industry 4.0 autonomy model. IFAC-PapersOnLine 2022, 55, 2073–2078. [Google Scholar] [CrossRef]

- Toyota. Visão e Filosofia da Toyota. Toyota Portugal. Available online: https://www.toyota.pt/mundo-toyota/sobre-a-toyota/visao-e-filosofia (accessed on 29 November 2024).

- Bizuneh, B.; Omer, R. Lean waste prioritisation and reduction in the apparel industry: Application of waste assessment model and value stream mapping. Cogent Eng. 2024, 11, 2341538. [Google Scholar] [CrossRef]

- Rodrigues, I.; Alves, W. Integrating Lean Thinking into Project Management: A Conceptual Model for the IT Sector. Procedia Comput. Sci. 2024, 239, 1604–1611. [Google Scholar] [CrossRef]

- Kurganov, V.; Sai, V.; Gryaznov, M.; Dorofeev, A. The Emergence and Development of Lean Thinking in Transport Services. Transp. Res. Procedia 2021, 54, 309–319. [Google Scholar] [CrossRef]

- Habib, M.A.; Rizvan, R.; Ahmed, S. Implementing lean manufacturing for improvement of operational performance in a labeling and packaging plant: A case study in Bangladesh. Results Eng. 2023, 17, 100818. [Google Scholar] [CrossRef]

- Yeh, S.T.; Arthaud-Day, M.; Turvey-Welch, M. Propagation of lean thinking in academic libraries. J. Acad. Libr. 2021, 47, 102357. [Google Scholar] [CrossRef]

- Maraqa, M.J.; Sacks, R.; Spatari, S. Strategies for reducing construction waste using lean principles. Resour. Conserv. Recycl. Adv. 2023, 19, 200180. [Google Scholar] [CrossRef]

- Raza, M.; Malik, A.A.; Bilberg, A. PDCA integrated simulations enable effective deployment of collaborative robots: Case of a manufacturing SME. Procedia CIRP 2021, 104, 1518–1522. [Google Scholar] [CrossRef]

- Gautam, A.; Khan, Z.A.; Gani, A.; Asjad, M. Identification, ranking and prioritization of Key Performance Indicators for evaluating greenness of manufactured products. Green Technol. Sustain. 2025, 3, 100114. [Google Scholar] [CrossRef]

- Vieira, M.; Silva, F.J.G.; Campilho, R.D.S.G.; Ferreira, L.P.; Sá, J.C.; Pereira, T. SMED methodology applied to the deep drawing process in the automotive industry. Procedia Manuf. 2020, 51, 1416–1422. [Google Scholar] [CrossRef]

- Bhade, S.; Hegde, S. Improvement of Overall Equipment Efficiency of Machine by SMED. Mater. Today Proc. 2020, 24, 463–472. [Google Scholar] [CrossRef]

- Rosa, C.; Silva, F.J.G.; Ferreira, L.P.; Campilho, R. SMED methodology: The reduction of setup times for Steel Wire-Rope assembly lines in the automotive industry. Procedia Manuf. 2017, 13, 1034–1042. [Google Scholar] [CrossRef]

- Marcella, C.A.; Widjajati, K. Analysis of Lean Manufacturing Implementation through the Single Minute Exchange of Dies (SMED) Method to Reduce Setup Time in the Injection Molding Machine Process. Adv. Sci. Comput. Intell. 2024, 5, 87–95. [Google Scholar] [CrossRef]

- Dora, M.; Kumar, M.; Goubergen, D.V.; Molnar, A.; Gellynck, X. Operational Performance and Critical Success Factors of Lean Manufacturing in European Food Processing SMEs. Trends Food Sci. Technol. 2013, 31, 156–164. [Google Scholar] [CrossRef]

- McIntosh, R.I.; Culley, S.J.; Mileham, A.R.; Owen, G.W. A critical evaluation of Shingo’s ‘SMED’ (Single Minute Exchange of Die) methodology. Int. J. Prod. Res. 2000, 38, 2377–2395. [Google Scholar] [CrossRef]

- Shah, R.; Ward, P.T. Defining and developing measures of lean production. J. Oper. Manag. 2007, 25, 785–805. [Google Scholar] [CrossRef]

- Vinodh, S.; Joy, D. Structural Equation Modelling of lean manufacturing practices. Int. J. Prod. Res. 2011, 50, 1598–1607. [Google Scholar] [CrossRef]

- Abdi, M.R.; Labib, A.W.; Delavari Edalat, F.; Abdi, A. RMS value chain architecture. In Integrated Reconfigurable Manufacturing Systems and Smart Value Chain; Springer: Cham, Germany, 2018. [Google Scholar] [CrossRef]

- Cakmakci, M. Process improvement: Performance analysis of the setup time reduction-SMED in the automobile industry. Int. J. Adv. Manuf. Technol. 2009, 41, 168–179. [Google Scholar] [CrossRef]

- Vieira, S.M.O.; Lopes, R.B. Improving Production Systems with Lean: A Case Study in a Medium-Sized Manufacturer. J. Manuf. Technol. Manag. 2019, 33, 162–180. [Google Scholar] [CrossRef]

- Khakpour, R.; Ebrahimi, A.; Hosseini, S.; Mohammad, S. SMED 4.0: A development of single minute exchange of die in the era of Industry 4.0 technologies to improve sustainability. J. Manuf. Technol. Manag. 2024, 35, 568–589. Available online: https://search.lib.uiowa.edu/primo-explore/fulldisplay?docid=TN_cdi_emerald_primary_10_1108_JMTM-08-2023-0333&context=PC&vid=01IOWA&lang=en_US&search_scope=default_scope&adaptor=primo_central_multiple_fe&query=sub,exact,buro&facet=citedby,exact,cdi_FETCH-LOGICAL-c342t-e187c26e1ed269ada07993ee9875eb330b4934c34cf798eba07740f5b3a692633&offset=20 (accessed on 29 November 2024). [CrossRef]

- Womack, J.P.; Jones, D.T. Lean Thinking: Banish Waste and Create Wealth in Your Corporation. J. Oper. Res. Soc. 1996, 48, 1148. [Google Scholar] [CrossRef]

- Shingo, S. A Revolution in Manufacturing: The SMED System; Routledge: New York, NY, USA, 1985. [Google Scholar] [CrossRef]

| Waste | Definition |

|---|---|

| Overproduction | Waste from making more products than customers demand |

| Waiting Times | Waste of time spent waiting for the next step to occur or when the machine is inactive. |

| Transportation | Wasted time, resources, and costs when unnecessarily moving products and materials |

| Motion | Wasted time and effort related to unnecessary movements by people |

| Inventory | Waste resulting from excess products and materials that are not processed |

| Overprocessing | Waste related to more work or higher quality than is required |

| Defects | Waste from a product or service failure to meet customer expectations |

| Unused Talent | Waste due to the underutilization of people’s talents, skills, and knowledge |

| Technician 1 | Technician 2 | |||

|---|---|---|---|---|

| Category | No. | Time [min:s] | No. | Time [min:s] |

| Wastes | 5 | 11:27 | 6 | 13:14 |

| Internal Tasks (setup) | 44 | 48:30 | 31 | 30:57 |

| External Tasks | 2 | 2:45 | 0 | 0:00 |

| Total Tasks (Int + Ext) | 46 | 51:15 | 31 | 51:15 |

| Technician 1 | |||||

|---|---|---|---|---|---|

| Category | No. (Initial) | No. (Final) | Time (Initial) [min:s] | Time (Final) [min:s] | Potential Improvement |

| Wastes | 5 | 0 | 11:27 | 0:00 | 23.6% |

| Internal Tasks (setup) | 44 | 39 | 48:30 | 37:30 | |

| Technician 2 | |||||

|---|---|---|---|---|---|

| Category | No. (Initial) | No. (Final) | Time (Initial) [min:s] | Time (Final) [min:s] | Potential Improvement |

| Wastes | 6 | 2 | 13:14 | 2:41 | 34.1% |

| Internal Tasks (setup) | 31 | 27 | 30:57 | 20:24 | |

| Technician 1 | |||||

|---|---|---|---|---|---|

| Category | No. (Initial) | No. (Final) | Time (Initial) [min:s] | Time (Final) [min:s] | Potential Improvement |

| Internal Tasks (setup) | 44 | 34 | 48:30 | 29:41 | 38.8% |

| External Tasks | 2 | 6 | 2:45 | 9:51 | |

| Technician 2 | |||||

|---|---|---|---|---|---|

| Category | No. (Initial) | No. (Final) | Time (Initial) [min:s] | Time (Final) [min:s] | Potential Improvement |

| Internal Tasks (setup) | 31 | 19 | 30:57 | 16:14 | 47.5% |

| External Tasks | 0 | 4 | 0:00 | 2:25 | |

| Before SMED Workshop | After SMED Workshop | |||

|---|---|---|---|---|

| Machine | Average SAP Time [min] | Real Time [min] Round 1 | Real Time [min] Round 2 | % Improvement |

| A | 58.5176 | 25 | 40 | 44.46% |

| B | 59.0462 | 33 | 44.11% | |

| C | 57.1059 | 33 | 42.21% | |

| D | 49.3714 | 36 | 24 | 39.24% |

| E | 73.2522 | 30 | 45 | 48.81% |

| F | 66.2538 | 35 | 47.17% | |

| G | 86.3250 | 40 | 53.66% | |

| H | 47.3077 | 40 | 30 | 26.02% |

| I | 50.3182 | 25 | 50.32% | |

| SMED Best Practice | Description | Applied in This Case Study |

|---|---|---|

| Separate internal and external setup | Identify which tasks require machine stoppage | Video analysis and task classification worksheets |

| Convert internal to external setup | Reorder activities to be performed while the machine runs | 38.8% setup reduction via re-sequencing |

| Use of visual aids | Standardized work charts and video learning | Used whiteboards, flipcharts, sequence guides |

| Cross-functional team involvement | Engage operators, engineers, planners | Multidisciplinary team from 4 departments |

| Standardize setup procedures | Define consistent setup routines | Created detailed Standard Work for 2 shifts |

| Continuous improvement cycles | Apply PDCA to identify and implement changes | 23 actions created, tracked, validated |

| Data-driven decision-making | Measure and benchmark all changes | Compared setup times pre/post using SAP data |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sousa, S.; Silva, M.M.; Gaspar, P.D. Implementation of SMED Workshops: A Strategic Approach in the Automotive Sector. Appl. Sci. 2025, 15, 8943. https://doi.org/10.3390/app15168943

Sousa S, Silva MM, Gaspar PD. Implementation of SMED Workshops: A Strategic Approach in the Automotive Sector. Applied Sciences. 2025; 15(16):8943. https://doi.org/10.3390/app15168943

Chicago/Turabian StyleSousa, Sofia, Miguel M. Silva, and Pedro D. Gaspar. 2025. "Implementation of SMED Workshops: A Strategic Approach in the Automotive Sector" Applied Sciences 15, no. 16: 8943. https://doi.org/10.3390/app15168943

APA StyleSousa, S., Silva, M. M., & Gaspar, P. D. (2025). Implementation of SMED Workshops: A Strategic Approach in the Automotive Sector. Applied Sciences, 15(16), 8943. https://doi.org/10.3390/app15168943