Influence of Wetting and Drying Conditions on the Mechanical Behavior of Brittle Sandstone Containing Folded Cracks

Abstract

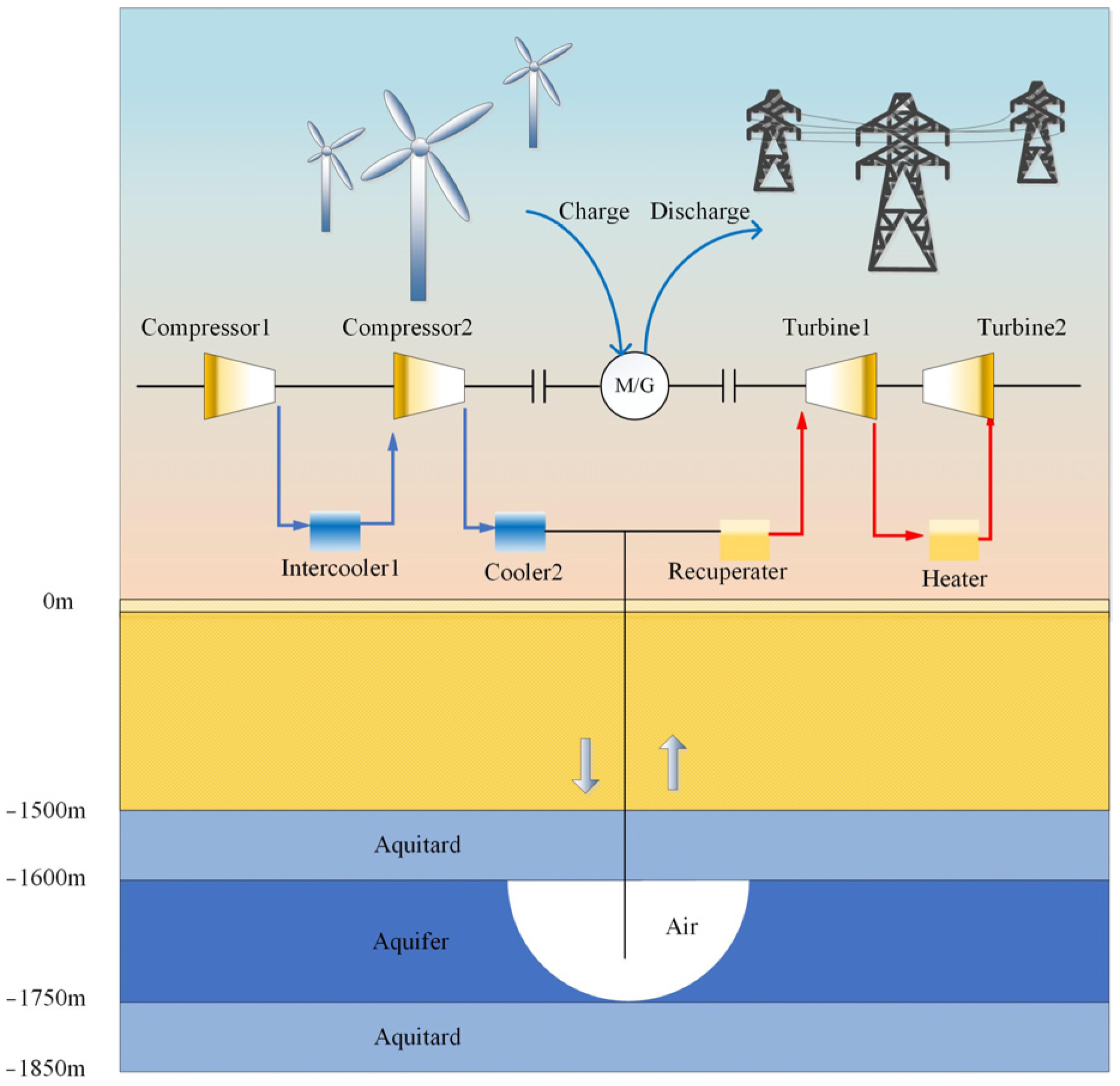

1. Introduction

2. Materials and Methods

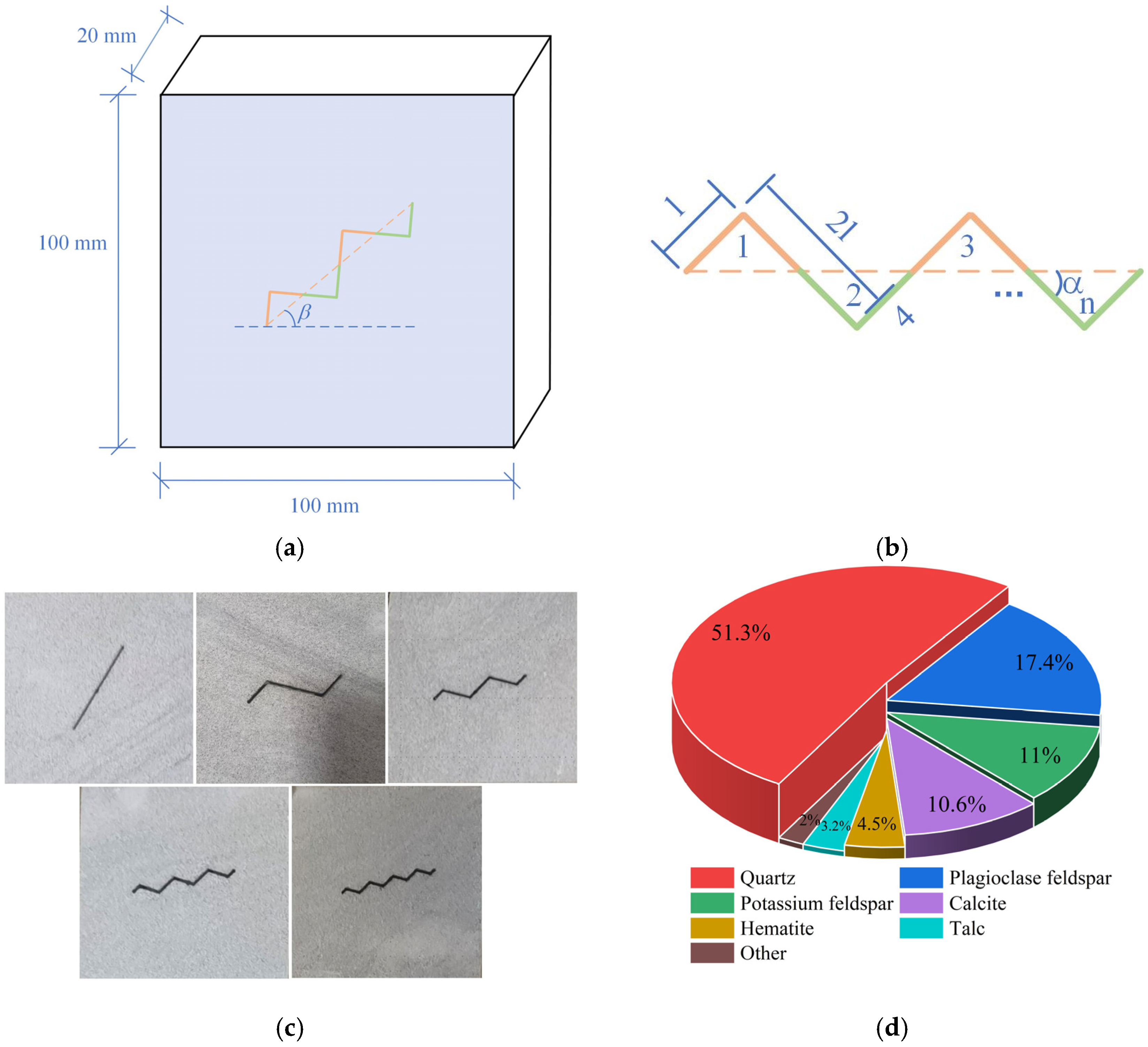

2.1. Specimen Preparation

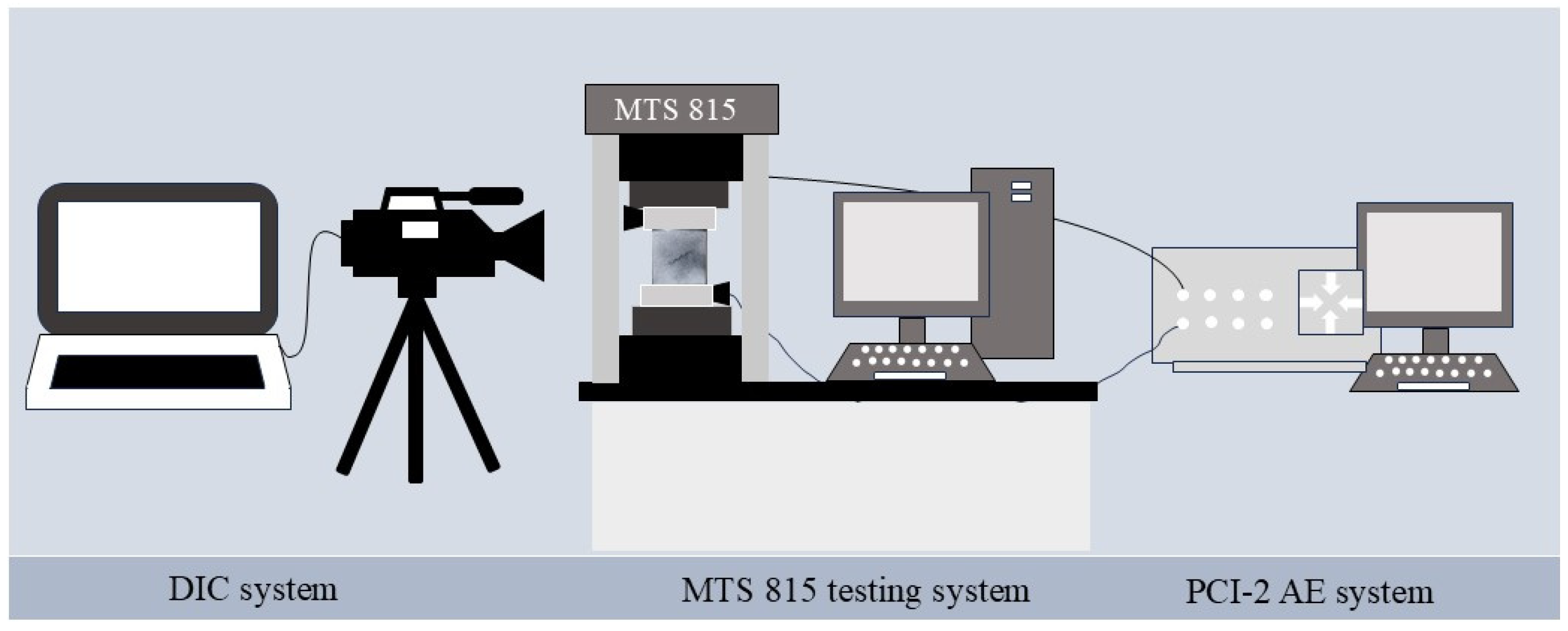

2.2. Test Equipment and Method

3. Results

3.1. Mechanical Characteristics of the Folded-Crack Rock Specimen

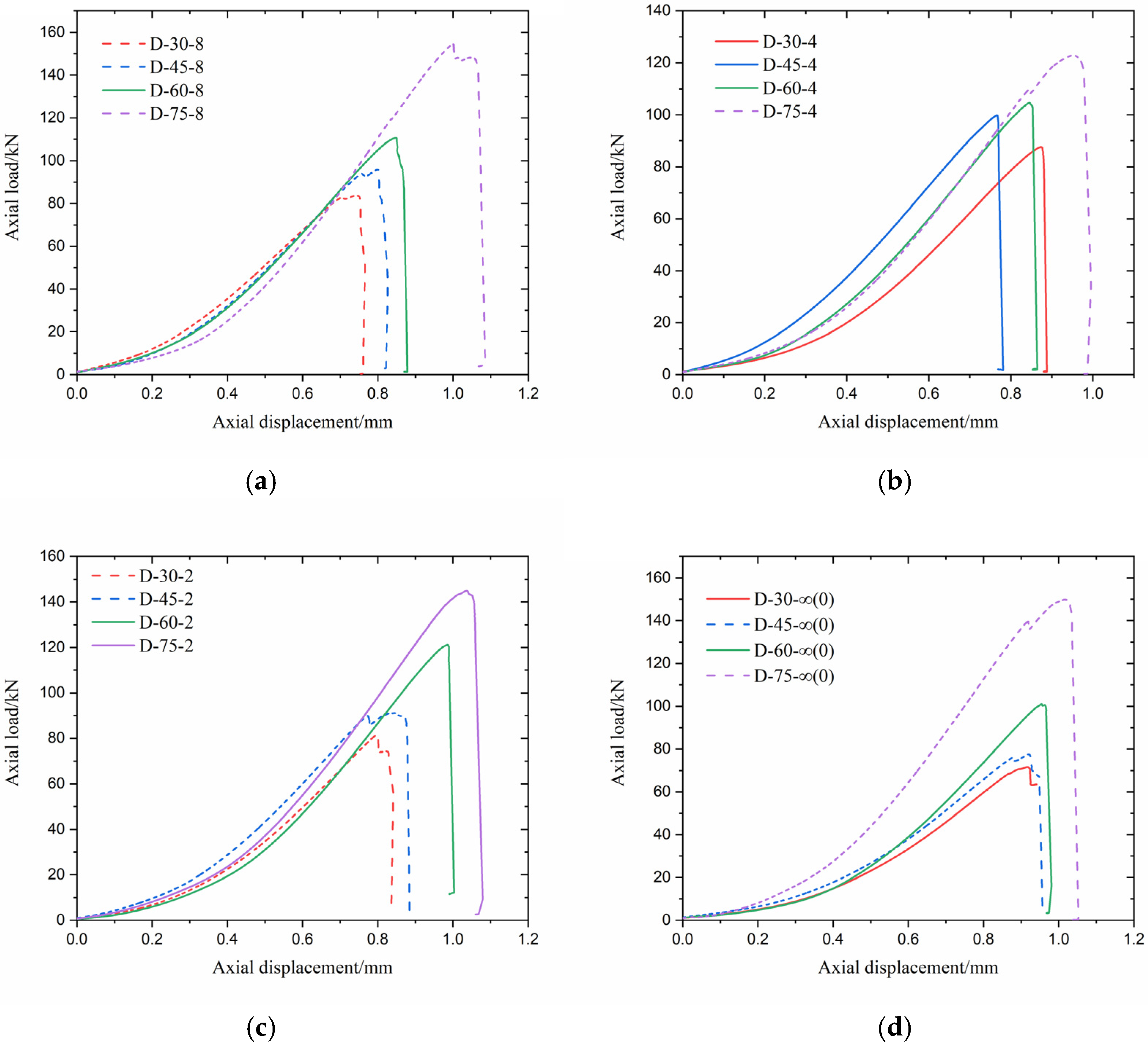

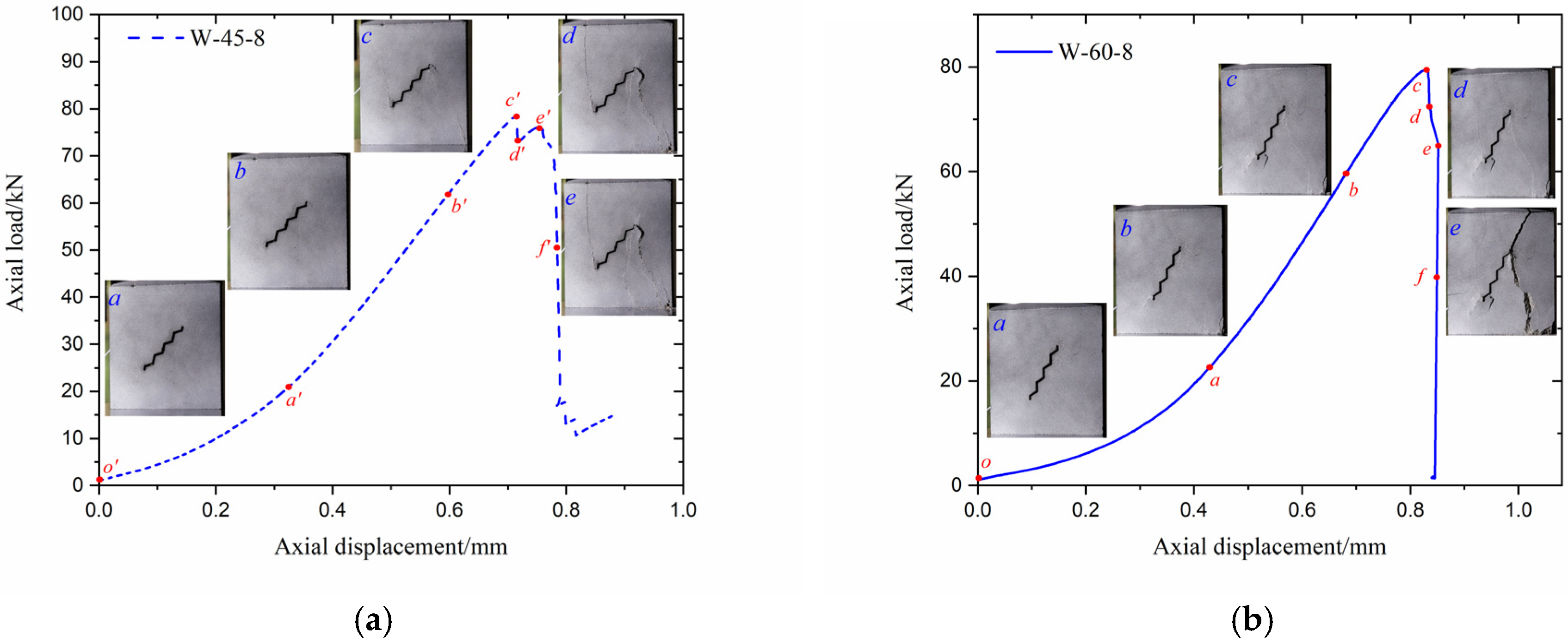

3.1.1. Deformation Behavior

3.1.2. Peak Strength Evolution

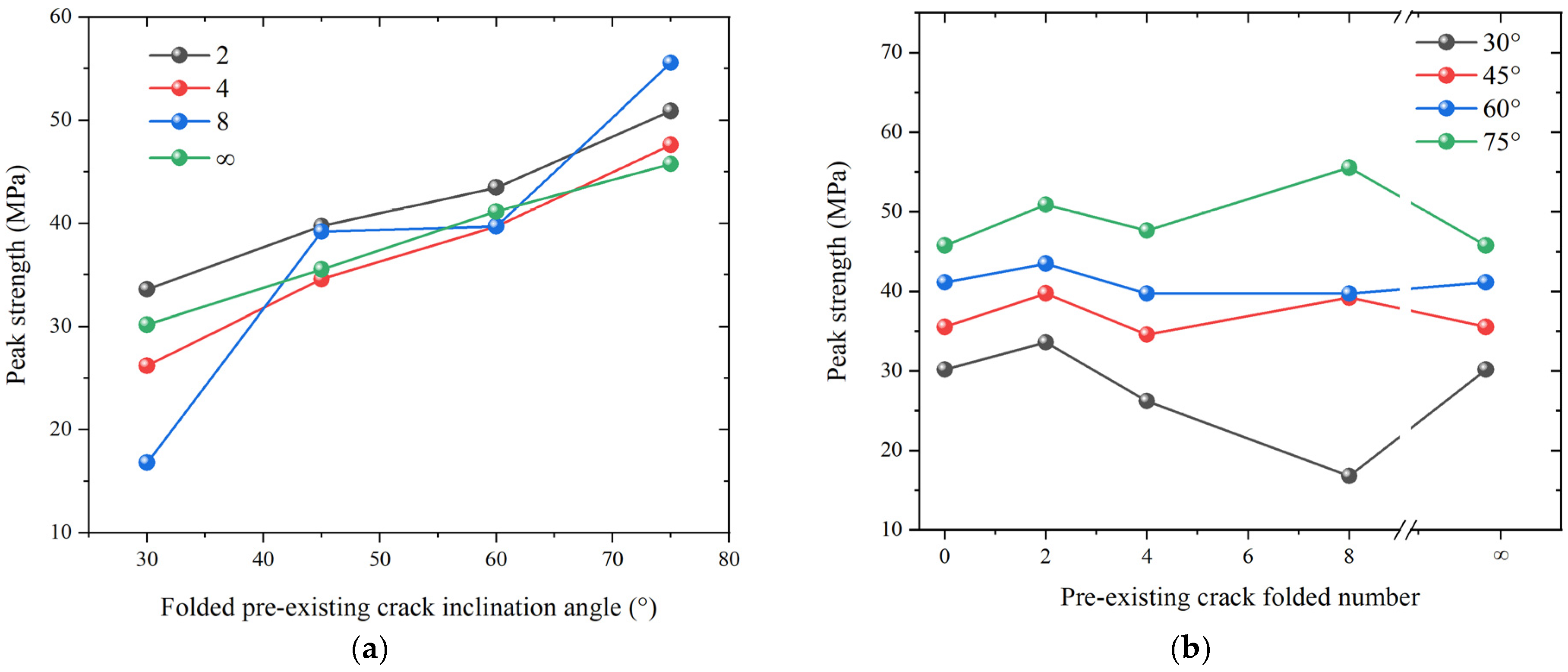

- (1)

- Peak strength under wetting condition

- (2)

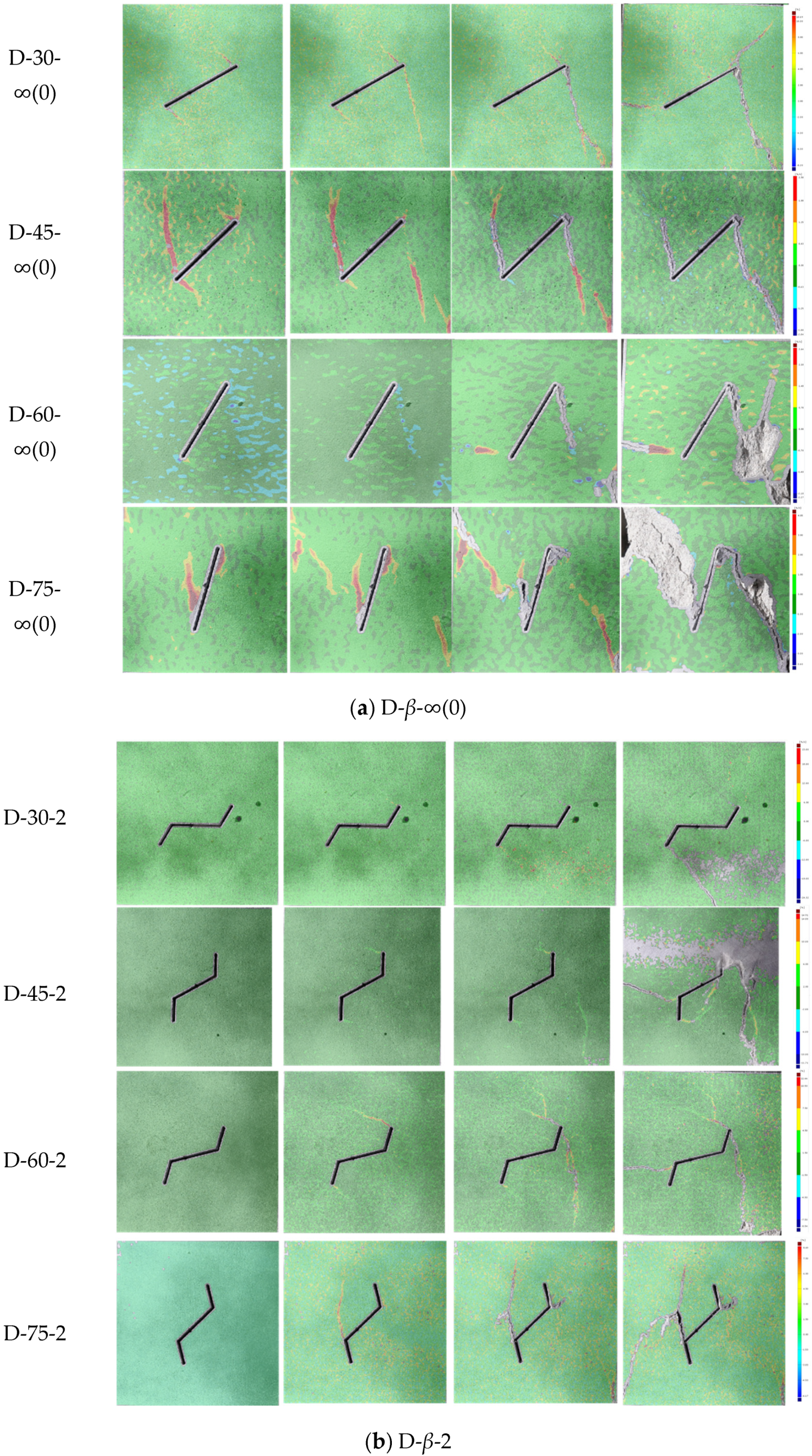

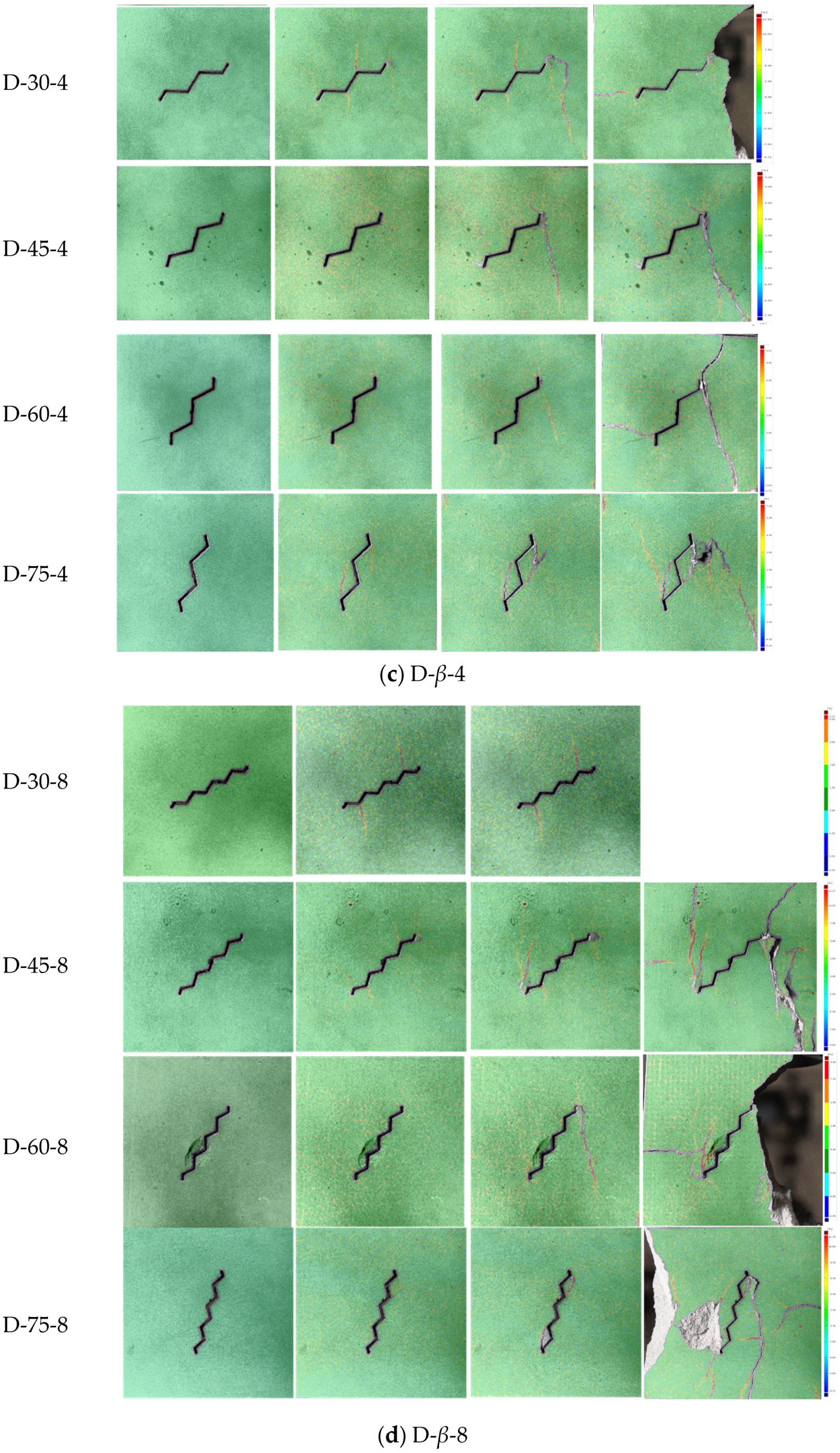

- Peak strength under drying condition

- (3)

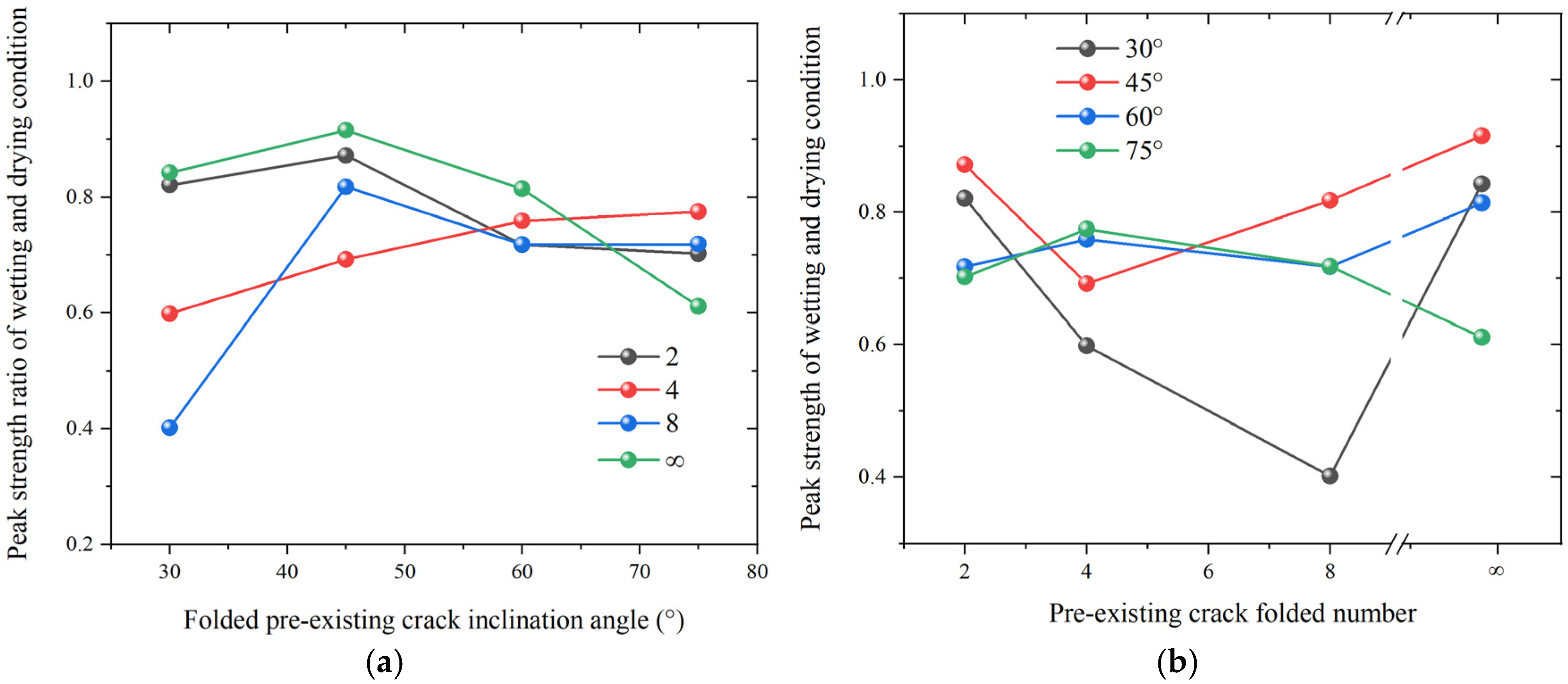

- Comparison of peak strengths under dry and wet conditions

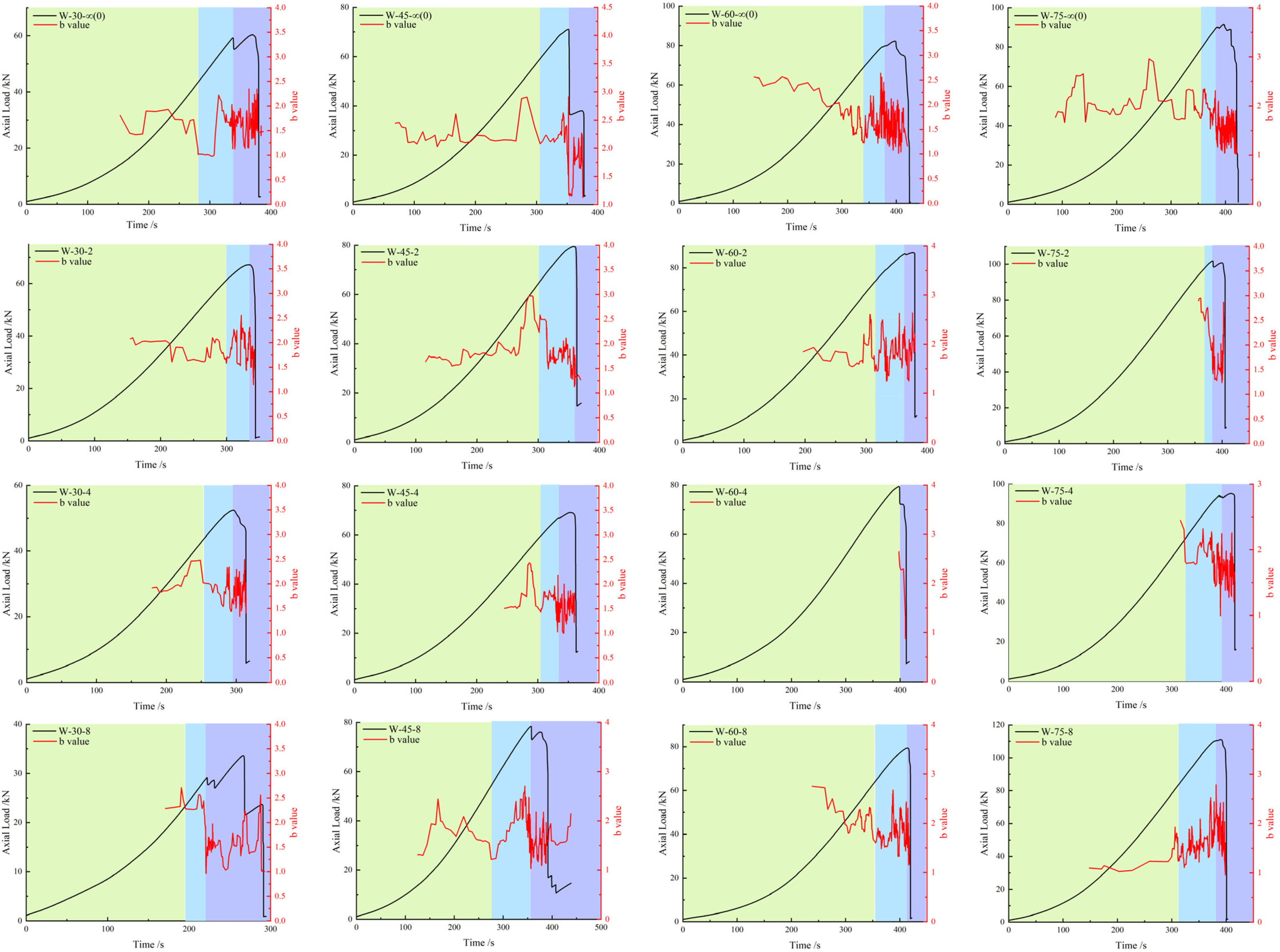

3.2. Acoustic Emission Characteristics

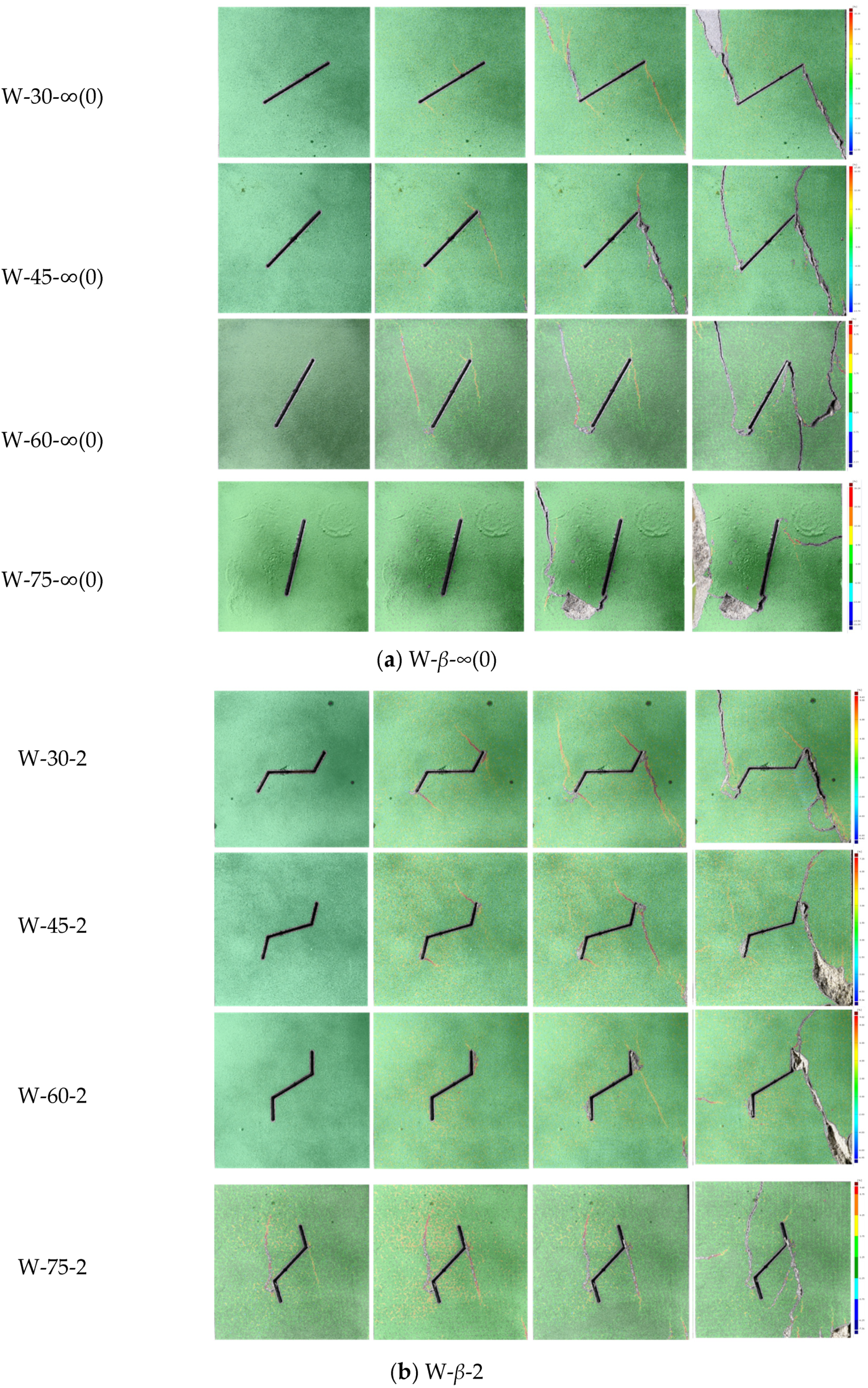

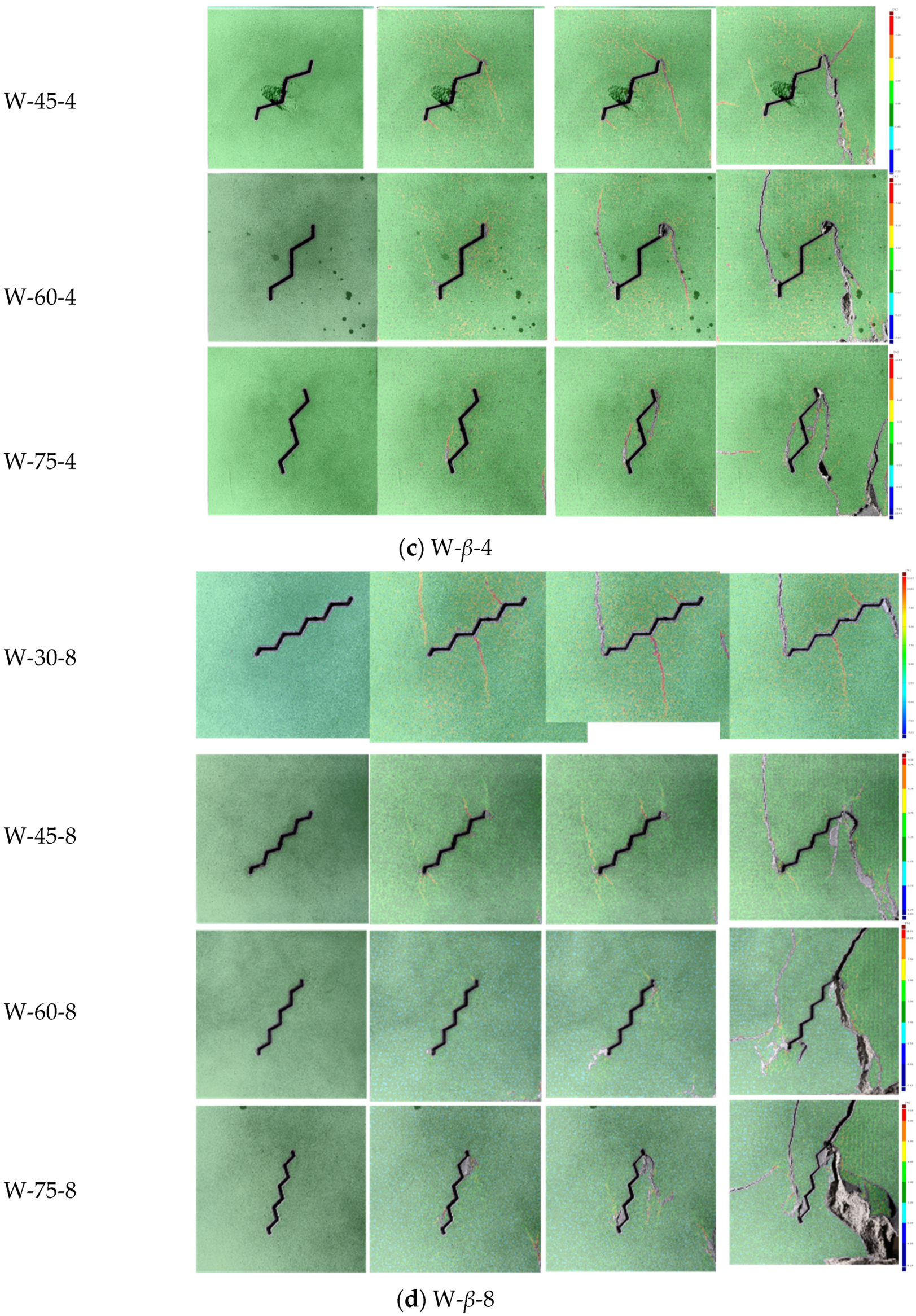

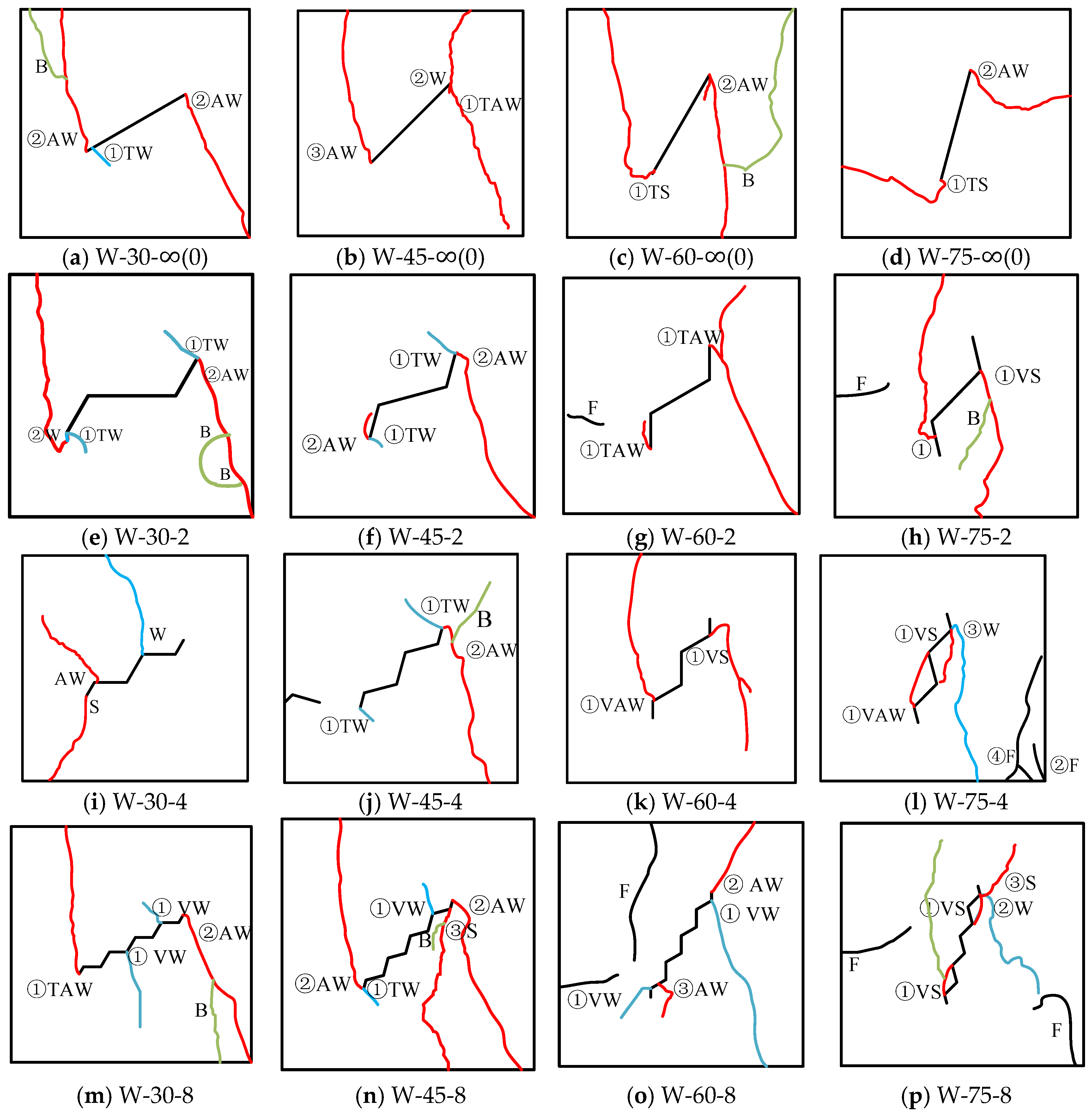

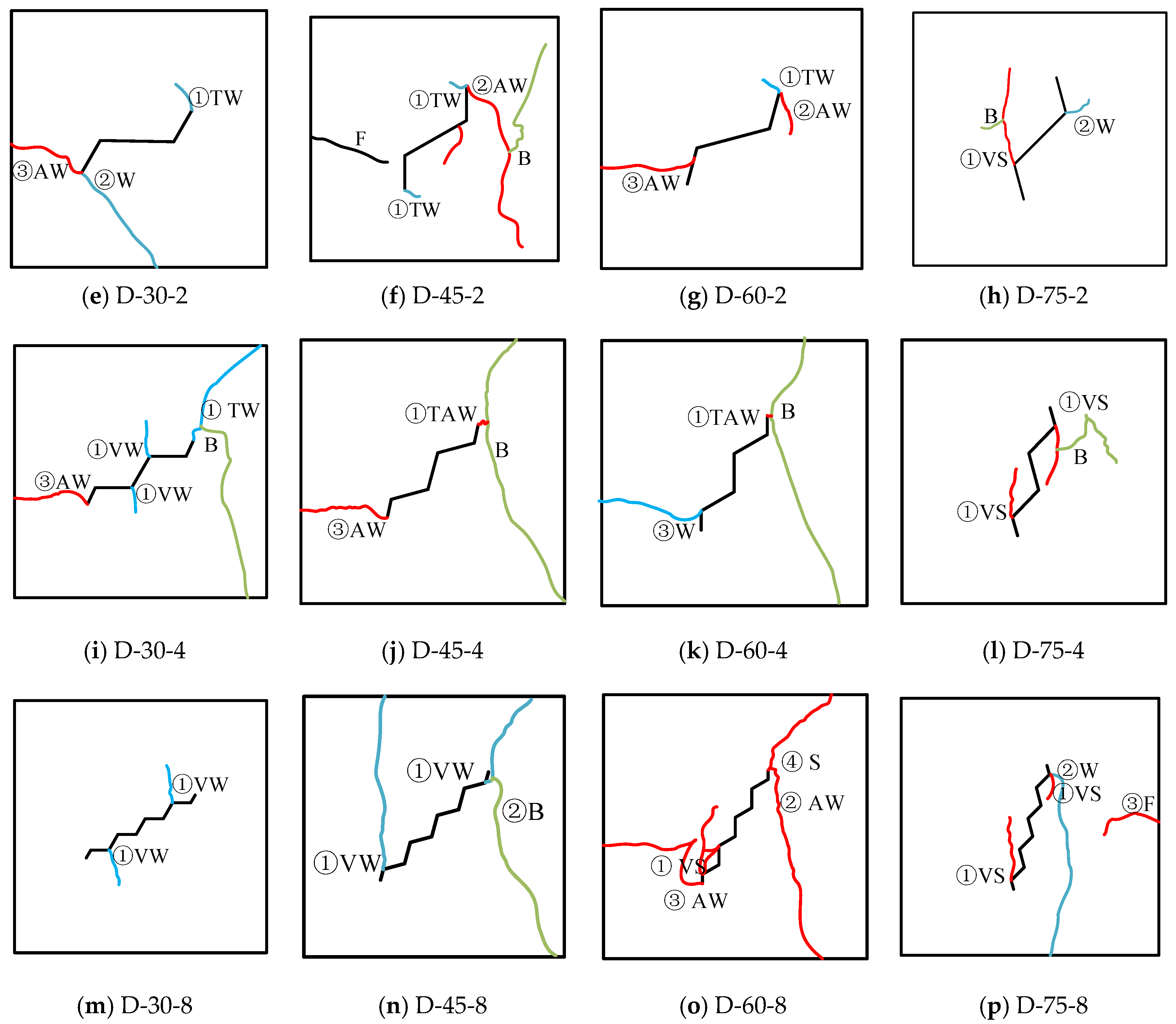

3.3. Crack Initiation and Coalescence Modes

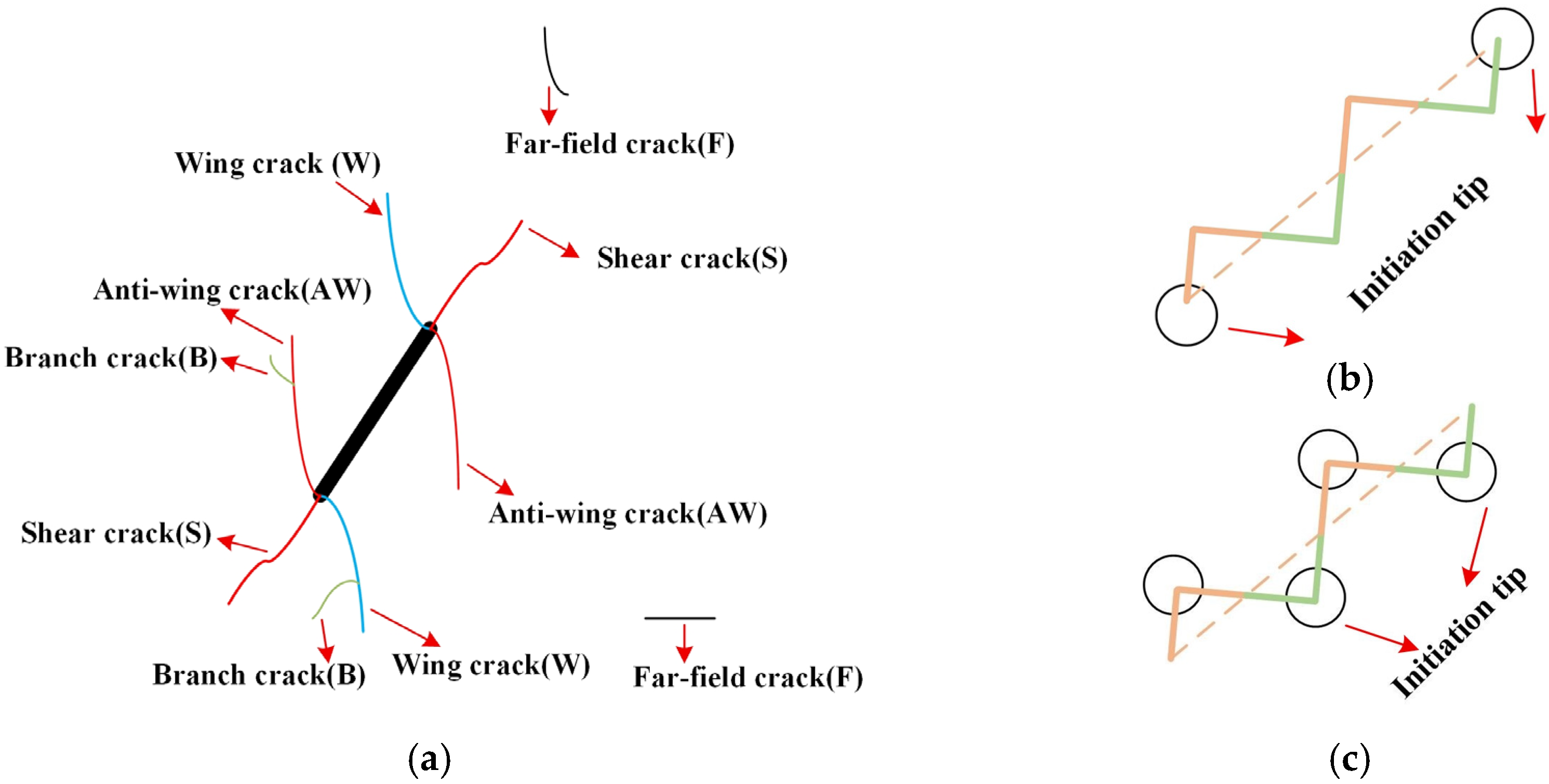

3.3.1. Crack Initiation Mode

3.3.2. Crack Coalescence Mode

4. Conclusions

- (1)

- For the folded-crack rock specimens, the axial compressive axial load–displacement curves can be categorized into multimodal and single-peak types. While no clear quantitative relationship was observed between curve type and either crack inclination angle (β) or folded number (n), multimodal responses were more frequently observed under wetting conditions than under drying conditions.

- (2)

- Under both drying and wetting conditions, the peak strength generally increased with increasing β, whereas the effect of n was less significant in comparison. However, the magnitude of variation in peak strength was more pronounced under drying conditions, while the effect of n on the peak strength was not apparent in comparison with that of β. Furthermore, wetting conditions consistently reduced the peak strength for specimens with identical folded-crack configurations.

- (3)

- The crack initiation modes of folded-crack rocks can be classified into six types: Type TW, TAW, TS, VW, VAW, and VS, based on the crack initiation position (tip or vertex) and failure mechanism (tensile or shear). The crack coalescence modes can be categorized into two types: no coalescence and direct coalescence.

- (4)

- The uniaxial compression test of folded-crack rock specimens under wetting and drying conditions can provide helpful engineering guidance for the anti-cracking optimal design of the CAES lining cavern, especially for CAES-containing aquifers. Future studies will expand to a comparative analysis of different lithologies and investigate the long-term damage evolution laws of folded cracks under wetting–drying cycles, aiming to provide a more comprehensive understanding of the stability evaluation and design optimization of CAES projects under various geological conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, D.Y.; Ma, Y.; Rao, Q.H.; Yi, W.; Shen, K. A new semi-analytic method for calculating the thermal-mechanical coupling stress intensity factor of interfacial crack. Theor. Appl. Fract. Mech. 2023, 128, 104156. [Google Scholar] [CrossRef]

- Ma, Y.; Rao, Q.; Huang, D.; Li, P.; Yi, W.; Sun, D. A new theoretical model of thermo-gas-mechanical (TGM) coupling field for underground multi-layered cavern of compressed air energy storage. Energy 2022, 257, 124646. [Google Scholar] [CrossRef]

- Zhao, K.; Ma, H.; Li, H.; Yang, C.; Li, P.; Liu, Y.; Li, H.; Zeng, Z.; Wang, X. Stability analysis of CAES salt caverns using a creep-fatigue model in Yunying salt district, China. J. Energy Storage 2023, 62, 124646. [Google Scholar] [CrossRef]

- Jiang, Z.; Li, P.; Tang, D.; Zhao, H.; Li, Y. Experimental and Numerical Investigations of Small-Scale Lined Rock Cavern at Shallow Depth for Compressed Air Energy Storage. Rock Mech. Rock Eng. 2020, 53, 2671–2683. [Google Scholar] [CrossRef]

- Wan, J.F.; Sun, Y.Q.; He, Y.X.; Ji, W.D.; Li, J.C.; Jiang, L.L.; Jurado, M.J. Development and technology status of energy storage in depleted gas reservoirs. Int. J. Coal Sci. Technol. 2024, 11, 29. [Google Scholar] [CrossRef]

- Aydin, H.; Merey, S. Potential of geothermal energy production from depleted gas fields: A case study of Dodan Field, Turkey. Renew. Energy 2021, 164, 1076–1088. [Google Scholar] [CrossRef]

- Colas, E.; Kukla, P.A.; Amann, F.; Back, S. Geological and mining factors influencing further use of abandoned coal mines—A multi-disciplinary workflow towards sustainable underground storage. J. Energy Storage 2025, 108, 115101. [Google Scholar] [CrossRef]

- Guo, C.B.; Pan, L.H.; Zhang, K.N.; Oldenburg, C.M.; Li, C.; Li, Y. Comparison of compressed air energy storage process in aquifers and caverns based on the Huntorf CAES plant. Appl. Energy 2016, 181, 342–356. [Google Scholar] [CrossRef]

- Yang, L.C.; Cai, Z.S.; Li, C.; He, Q.C.; Ma, Y.; Guo, C.B. Numerical investigation of cycle performance in compressed air energy storage in aquifers. Appl. Energy 2020, 269, 115044. [Google Scholar] [CrossRef]

- Li, Y.; Wang, H.; Wang, J.S.; Hu, L.T.; Wu, X.H.; Yang, Y.B.; Gai, P.; Liu, Y.N.; Li, Y. The underground performance analysis of compressed air energy storage in aquifers through field testing. Appl. Energy 2024, 366, 123329. [Google Scholar] [CrossRef]

- Li, Y.; Yu, H.; Tang, D.; Li, Y.; Zhang, G.J.; Liu, Y.N. A comparison of compressed carbon dioxide energy storage and compressed air energy storage in aquifers using numerical methods. Renew. Energy 2022, 187, 1130–1153. [Google Scholar] [CrossRef]

- Xia, C.; Xu, Y.; Zhou, S.; Qin, S.; He, X. Fracture initiation and propagation in the lined underground caverns for compressed air energy storage: Coupled thermo-mechanical phase-field modeling. Comput. Geotech. 2023, 157, 105329. [Google Scholar] [CrossRef]

- Han, P.H.; Zhao, Y.X.; Zhang, C.; Wang, X.J.; Wang, W. Effects of water on mechanical behavior and acoustic emission characteristics of coal in Brazilian tests. Theor. Appl. Fract. Mech. 2022, 122, 103636. [Google Scholar] [CrossRef]

- Wróbel, M.; Kalina, J. Preliminary evaluation of CAES system concept with partial oxidation gas turbine technology. Energy 2019, 183, 766–775. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, Z.X.; Chen, J.; Jiang, D.Y.; Wei, F.; Fan, J.Y.; Li, Y.P. Feasibility evaluation of large-scale underground hydrogen storage in bedded salt rocks of China: A case study in Jiangsu province. Energy 2020, 198, 117348. [Google Scholar] [CrossRef]

- Zhou, A.H.; Li, P.; Fan, L.Y.; Yi, Z.W.; Tang, X.B.; Fei, W.B. Influence of drainage system on the stability of underground CAES gas storage under different lateral pressure coefficients. Tunn. Undergr. Space Technol. 2025, 159, 106444. [Google Scholar] [CrossRef]

- Xu, Y.J.; Zhou, S.W.; Xia, C.C.; Zhao, H.O.; Xue, X.D. Three-dimensional thermo-mechanical analysis of abandoned mine drifts for underground compressed air energy storage: A comparative study of two construction and plugging schemes. J. Energy Storage 2021, 39, 102696. [Google Scholar] [CrossRef]

- Li, D.X.; Wang, E.Y.; Kong, X.G.; Ali, M.; Wang, D.M. Mechanical behaviors and acoustic emission fractal characteristics of coal specimens with a pre-existing flaw of various inclinations under uniaxial compression. Int. J. Rock Mech. Min. Sci. 2019, 116, 38–51. [Google Scholar] [CrossRef]

- Zhuang, X.Y.; Zhou, S.W. An Experimental and Numerical Study on the Influence of Filling Materials on Double-Crack Propagation. Rock Mech. Rock Eng. 2020, 53, 5571–5591. [Google Scholar] [CrossRef]

- Yang, S.Q.; Yang, D.S.; Jing, H.W.; Li, Y.H.; Wang, S.Y. An Experimental Study of the Fracture Coalescence Behaviour of Brittle Sandstone Specimens Containing Three Fissures. Rock Mech. Rock Eng. 2012, 45, 563–582. [Google Scholar] [CrossRef]

- Zhou, X.P.; Cheng, H.; Feng, Y.F. An Experimental Study of Crack Coalescence Behaviour in Rock-Like Materials Containing Multiple Flaws Under Uniaxial Compression. Rock Mech. Rock Eng. 2014, 47, 1961–1986. [Google Scholar] [CrossRef]

- Zhu, D.; Jing, H.W.; Yin, Q.; Zong, Y.J.; Tao, X.L. Experimental study on mechanical characteristics of sandstone containing arc fissures. Arab. J. Geosci. 2018, 11, 637. [Google Scholar] [CrossRef]

- Ma, G.W.; Dong, Q.Q.; Fan, L.F.; Gao, J.W. An investigation of non-straight fissures cracking under uniaxial compression. Eng. Fract. Mech. 2018, 191, 300–310. [Google Scholar] [CrossRef]

- Yang, S.Q.; Yang, Z.; Zhang, P.C.; Tian, W.L. Experiment and peridynamic simulation on cracking behavior of red sandstone containing a single non-straight fissure under uniaxial compression. Theor. Appl. Fract. Mech. 2020, 108, 102637. [Google Scholar] [CrossRef]

- Dong, Q.Q.; Xiong, C.W.; Ma, C.L.; Wei, H.J. Experimental Study on Cracking Behaviour of Intermittent Double S-shaped Fissures under Uniaxial Compression. KSCE J. Civ. Eng. 2019, 23, 2483–2494. [Google Scholar] [CrossRef]

- Wu, S.Y.; Huang, Y.H. Macro and meso crack evolution of granite specimens with non-straight fissures: A comparison between two bond models. Theor. Appl. Fract. Mech. 2023, 125, 103890. [Google Scholar] [CrossRef]

- Fan, W.C.; Yang, H.; Jiang, X.L.; Cao, P. Experimental and numerical investigation on crack mechanism of folded flawed rock-like material under uniaxial compression. Eng. Geol. 2021, 291, 106210. [Google Scholar] [CrossRef]

- Zhou, X.P.; Niu, Y.; Cheng, H.; Berto, F. Cracking behaviors and chaotic characteristics of sandstone with unfilled and filled dentate flaw. Theor. Appl. Fract. Mech. 2021, 112, 102876. [Google Scholar] [CrossRef]

- Liu, X.H.; Pan, Z.; Wang, J.; Hu, Q.; Xiong, W.; Zhang, K. Quantitative investigation of the cracking mechanism of 3D sand-printed rock containing a fold flaw. Mater. Des. 2023, 236, 112523. [Google Scholar] [CrossRef]

- Wang, M.; Lu, Z.; Zhao, Y.; Wan, W. Experimental and numerical study on peak strength, coalescence and failure of rock-like materials with two folded preexisting fissures. Theor. Appl. Fract. Mech. 2023, 125, 103830. [Google Scholar] [CrossRef]

- Ma, Y.; Rao, Q.; Huang, D.; Liu, Z.; Yi, W.; Li, P. Gas-mechanical coupled crack initiation analysis for local air-leakage of compressed air energy storage (CAES) cavern with consideration of seepage effect. Theor. Appl. Fract. Mech. 2023, 125, 103827. [Google Scholar] [CrossRef]

| Cavern Types | Advantage | Disadvantage | Case |

|---|---|---|---|

| Salt cavern | Low cost Long life No sealing layer required | Geographical limitations | Huntorf, Germany, and McIntosh, United States [14] Jintan, Jiangsu, and Feicheng, Shandong [15] |

| Artificial lining cavern | Without geographical limitations | Sealing layer is required | Pingjiang, Hunan, and Chaoyang, Liaoning [16] |

| Depleted oil and gas field | Low cost | Geographical limitations | Engineering demonstration and testing stage [5] |

| Abandoned coal mine | Low cost | Geographical limitations | Abandoned tunnel CAES power station in mine in Yungang, Datong [17] |

| Aquifer | Low cost Without geographical limitations | - | Engineering demonstration and testing stage |

| Group | No. | β/◦ | n | l/mm | Group | No. | β/◦ | n | l/mm |

|---|---|---|---|---|---|---|---|---|---|

| W | W-30-2 | 30 | 2 | 14.43 | D | D-30-2 | 30 | 2 | 14.43 |

| W-30-4 | 4 | 7.22 | D-30-4 | 4 | 7.22 | ||||

| W-30-8 | 8 | 3.61 | D-30-8 | 8 | 3.61 | ||||

| W-30-∞(0) | ∞(0) | 50 | D-30-∞(0) | ∞(0) | 50 | ||||

| W-45-2 | 45 | 2 | 14.43 | D-45-2 | 45 | 2 | 14.43 | ||

| W-45-4 | 4 | 7.22 | D-45-4 | 4 | 7.22 | ||||

| W-45-8 | 8 | 3.61 | D-45-8 | 8 | 3.61 | ||||

| W-45-∞(0) | ∞(0) | 50 | D-45-∞(0) | ∞(0) | 50 | ||||

| W-60-2 | 60 | 2 | 14.43 | D-60-2 | 60 | 2 | 14.43 | ||

| W-60-4 | 4 | 7.22 | D-60-4 | 4 | 7.22 | ||||

| W-60-8 | 8 | 3.61 | D-60-8 | 8 | 3.61 | ||||

| W-60-∞(0) | ∞(0) | 50 | D-60-∞(0) | ∞(0) | 50 | ||||

| W-75-2 | 75 | 2 | 14.43 | D-75-2 | 75 | 2 | 14.43 | ||

| W-75-4 | 4 | 7.22 | D-75-4 | 4 | 7.22 | ||||

| W-57-8 | 8 | 3.61 | D-57-8 | 8 | 3.61 | ||||

| W-75-∞(0) | ∞(0) | 50 | D-75-∞(0) | ∞(0) | 50 |

| No. | Types of Axial Load–Displacement Curves | No. | Types of Axial Load–Displacement Curves | ||

|---|---|---|---|---|---|

| Multimodal | Single Peak | Multimodal | Single Peak | ||

| D-30-2 | ✓ | W-30-2 | ✓ | ||

| D-30-4 | ✓ | W-30-4 | ✓ | ||

| D-30-8 | ✓ | W-30-8 | ✓ | ||

| D-30-∞ | ✓ | W-30-∞ | ✓ | ||

| D-45-2 | ✓ | W-45-2 | ✓ | ||

| D-45-4 | ✓ | W-45-4 | ✓ | ||

| D-45-8 | ✓ | W-45-8 | ✓ | ||

| D-45-∞ | ✓ | W-45-∞ | ✓ | ||

| D-60-2 | ✓ | W-60-2 | ✓ | ||

| D-60-4 | ✓ | W-60-4 | ✓ | ||

| D-60-8 | ✓ | W-60-8 | ✓ | ||

| D-60-∞ | ✓ | W-60-∞ | ✓ | ||

| D-75-2 | ✓ | W-75-2 | ✓ | ||

| D-75-4 | ✓ | W-75-4 | ✓ | ||

| D-75-8 | ✓ | W-75-8 | ✓ | ||

| D-75-∞ | ✓ | W-75-∞ | ✓ | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Guo, J.; Liu, Z. Influence of Wetting and Drying Conditions on the Mechanical Behavior of Brittle Sandstone Containing Folded Cracks. Appl. Sci. 2025, 15, 8905. https://doi.org/10.3390/app15168905

Ma Y, Guo J, Liu Z. Influence of Wetting and Drying Conditions on the Mechanical Behavior of Brittle Sandstone Containing Folded Cracks. Applied Sciences. 2025; 15(16):8905. https://doi.org/10.3390/app15168905

Chicago/Turabian StyleMa, Yan, Jiangyuan Guo, and Zelin Liu. 2025. "Influence of Wetting and Drying Conditions on the Mechanical Behavior of Brittle Sandstone Containing Folded Cracks" Applied Sciences 15, no. 16: 8905. https://doi.org/10.3390/app15168905

APA StyleMa, Y., Guo, J., & Liu, Z. (2025). Influence of Wetting and Drying Conditions on the Mechanical Behavior of Brittle Sandstone Containing Folded Cracks. Applied Sciences, 15(16), 8905. https://doi.org/10.3390/app15168905