Effect of Preparation Method on the Optical Properties of Novel Luminescent Glass-Crystalline Composites

Abstract

1. Introduction

2. Materials and Methods

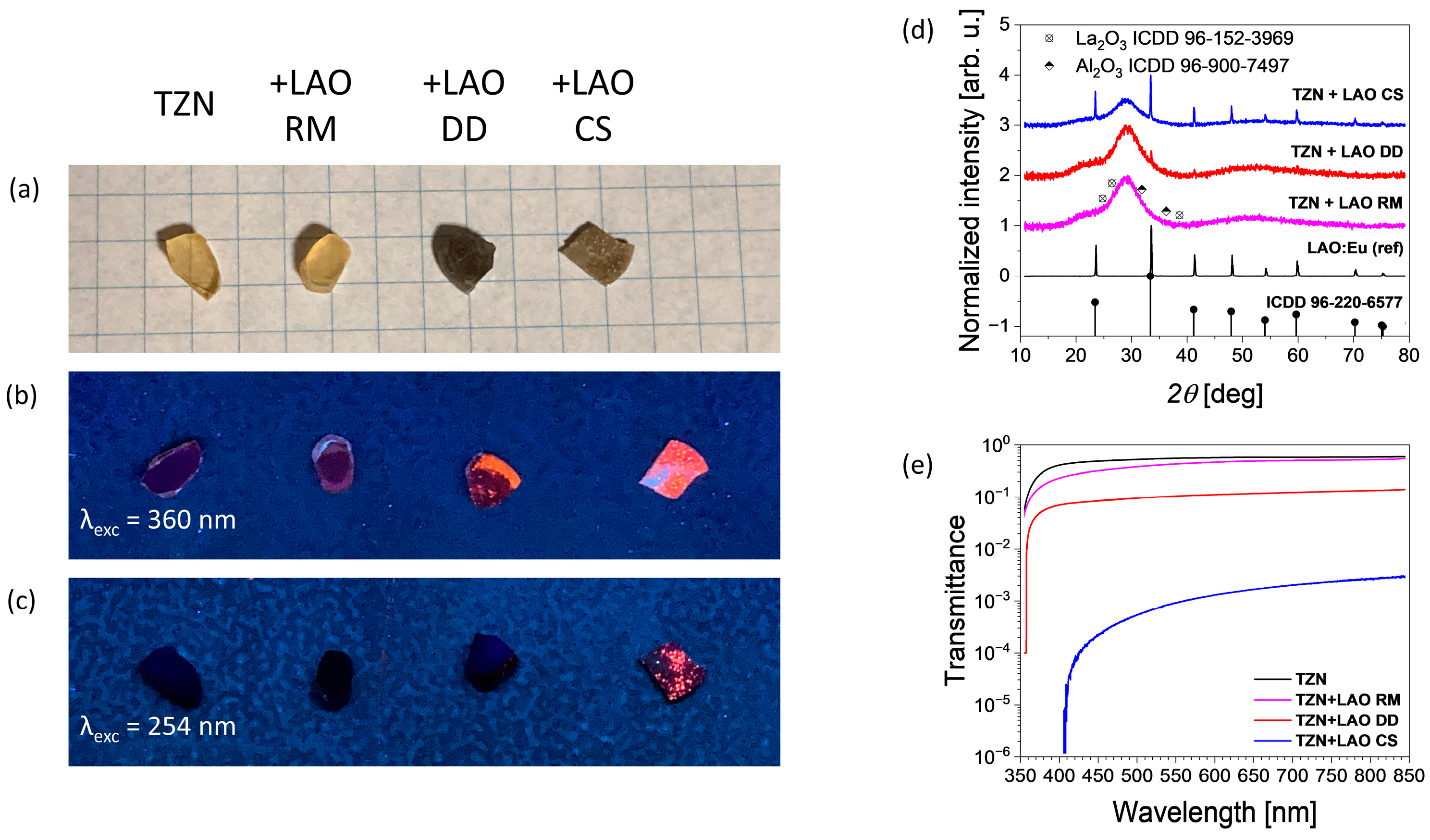

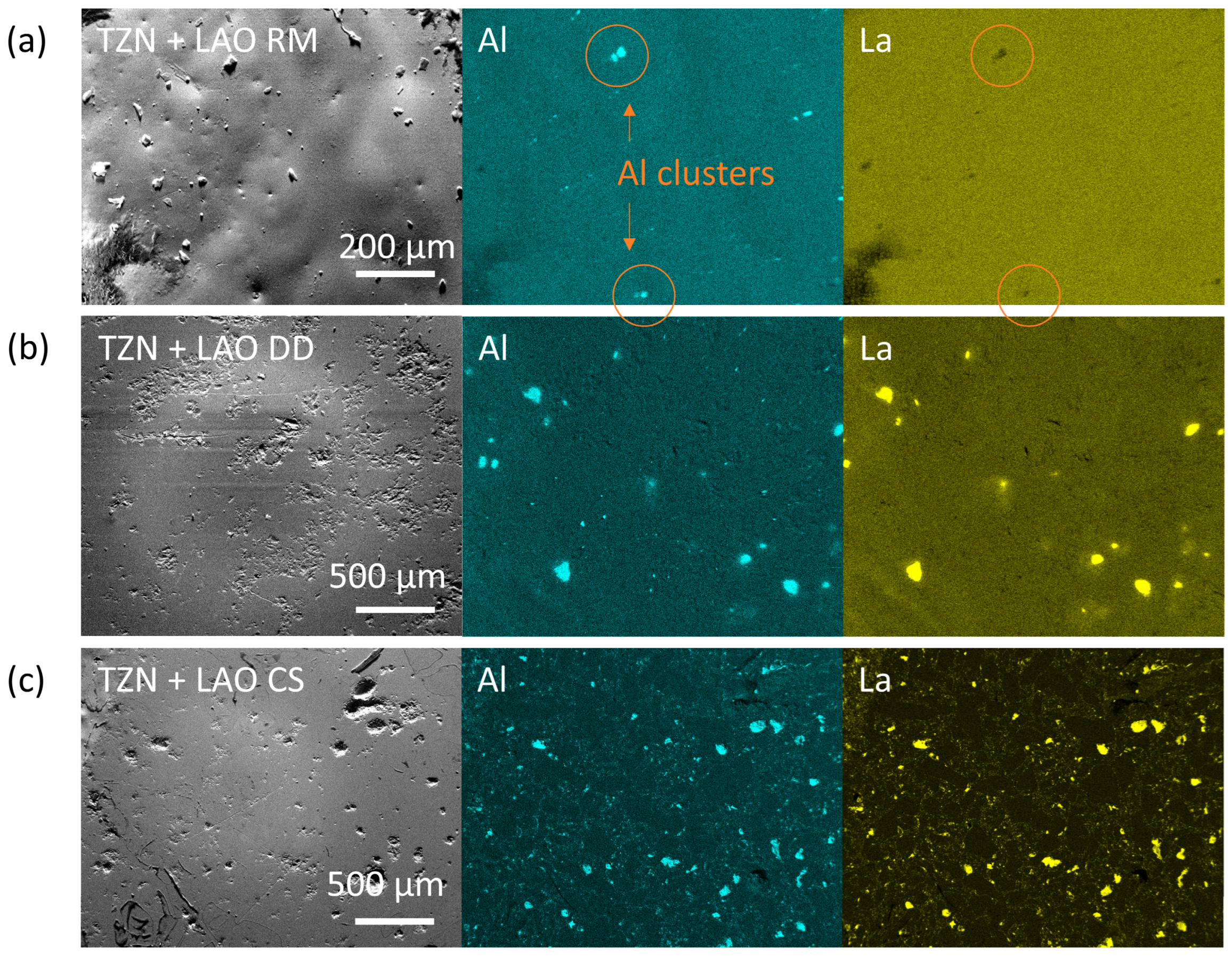

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- McKittrick, J.; Shea-Rohwer, L.E. Review: Down Conversion Materials for Solid-State Lighting. J. Am. Ceram. Soc. 2014, 97, 1327–1352. [Google Scholar] [CrossRef]

- Roh, H.S.; Han, G.S.; Lee, S.; Kim, S.; Choi, S.; Yoon, C.; Lee, J.K. New Down-Converter for UV-Stable Perovskite Solar Cells: Phosphor-in-Glass. J. Power Sources 2018, 389, 135–139. [Google Scholar] [CrossRef]

- Merízio, L.G.; Lodi, T.A.; Bonturim, E.; de Camargo, A.S.S. Persistent Luminescent Phosphor-in-Glass Composites Based on NaPO3-Ga2O3 Glasses Loaded with Sr2MgSi2O7: Eu2+,Dy3+. Opt. Mater. 2022, 134, 113046–113104. [Google Scholar] [CrossRef]

- Bao, S.; Liang, Y.; Wang, L.; Wang, L.; Xu, L.; Wang, Y.; Liang, X.; Xiang, W. Superhigh-Luminance Ce: YAG Phosphor in Glass and Phosphor-in-Glass Film for Laser Lighting. ACS Sustain. Chem. Eng. 2022, 10, 8105–8114. [Google Scholar] [CrossRef]

- Tian, J.; Liu, H.; Guo, R.; Sun, H.; Chen, Y.; Wang, Y.; Xu, Q.; Zhu, Y.; Yao, Q. Large Size Lenticular Shaped Phosphors-in-Glass by Isobam-APS Gel Casting to Act for Converting and Condensing in LCD Projector. Ceram. Int. 2023, 49, 7753–7760. [Google Scholar] [CrossRef]

- Qi, Y.; Ye, R.; Hua, Y.; Huang, L.; Jin, C.; Jiang, T.; Zhao, J.; Cai, M.; Li, B.; Bai, G.; et al. High Efficiency and Thermal Stability LuAG: Ce3+ Converter Based on Phosphor-in-Glass-Ceramics for Laser-Driven Lighting. Ceram. Int. 2025, 51, 31609–31617. [Google Scholar] [CrossRef]

- Sun, X.; Liang, Y.; Zheng, J.; Zhao, C.; Fang, Z.; Tian, T.; Liang, X.; Huan, W.; Xiang, W. Advancing Laser Lighting: High-Brightness and High-Stability Ce: YAG Phosphor-in-Glass. Ceram. Int. 2024, 50, 48909–48917. [Google Scholar] [CrossRef]

- Niu, L.; Liu, C.; Zhang, K.; Wang, C.; Liu, L.; Chu, Y.; Ren, J.; Zhang, J. Net Gain at the Near-Infrared from CsPbBr3 Quantum Dots Sensitized Nd3+-activated Tellurite Glass Under Solar Excitation. Adv. Opt. Mater. 2024, 12, 2302953–2302960. [Google Scholar] [CrossRef]

- Massera, J.; Gaussiran, M.; Głuchowski, P.; Lastusaari, M.; Petit, L.; Hölsä, J.; Hupa, L. Effect of the Glass Melting Condition on the Processing of Phosphate-Based Glass-Ceramics with Persistent Luminescence Properties. Opt. Mater. 2016, 52, 56–61. [Google Scholar] [CrossRef]

- Xia, L.; Xiao, Q.; Ye, X.; You, W.; Liang, T. Erosion Behavior and Luminescence Properties of Y3Al5O12: Ce3+-Embedded Calcium Bismuth Borate Glass-Ceramics for WLEDs. J. Am. Ceram. Soc. 2019, 102, 2053–2065. [Google Scholar] [CrossRef]

- Hasnat, M.; Lahti, V.; Byron, H.; Lastusaari, M.; Petit, L. Micro-Luminescence Measurement to Evidence Decomposition of Persistent Luminescent Particles during the Preparation of Novel Persistent Luminescent Tellurite Glasses. Scr. Mater. 2021, 199, 113864. [Google Scholar] [CrossRef]

- Ojha, N.; Nguyen, H.; Laihinen, T.; Salminen, T.; Lastusaari, M.; Petit, L. Decomposition of Persistent Luminescent Microparticles in Corrosive Phosphate Glass Melt. Corros. Sci. 2018, 135, 207–214. [Google Scholar] [CrossRef]

- Subramaniyam, V.; Saravanan, B.A.; Pichumani, M. Scattering Effects on the Optical Performance of LEDs. In Organic and Inorganic Light Emitting Diodes; CRC Press: Boca Raton, FL, USA, 2023; pp. 67–89. [Google Scholar]

- Dorosz, D.; Kochanowicz, M.; Lesniak, M.; Müller, R.; Lorenz, M.; Kobelke, J.; Wondraczek, K.; Valiente, R.; Diego-Rucabado, A.; Cano, I.; et al. Glass Powder Doping of Nanocrystal-Doped Fibres: Challenges and Results. In Proceedings of the Fiber Lasers and Glass Photonics: Materials Through Applications III, Strasbourg, France, 3 April–23 May 2022; Taccheo, S., Ferrari, M., Seddon, A.B., Eds.; SPIE: Bellingham, WA, USA, 2022; pp. 12142–12143. [Google Scholar]

- Yamashita, M.; Imamura, T.; Matsumoto, S.; Murakami, M.; Hongo, T.; Akai, T.; Iwamoto, Y. Enhancement of Afterglow Luminescence of Long-Lasting Phosphor-Glass Composite by Using Refractive Index Matched Glass. Key Eng. Mater. 2016, 702, 113–117. [Google Scholar] [CrossRef]

- Kowalska, K.; Kuwik, M.; Pisarska, J.; Pisarski, W.A. Near-IR Luminescence of Rare-Earth Ions (Er3+, Pr3+, Ho3+, Tm3+) in Titanate-Germanate Glasses under Excitation of Yb3+. Materials 2022, 15, 3660. [Google Scholar] [CrossRef]

- Wu, Y.; Niu, C.; Wang, L.; Yang, M.; Zhang, S. Structural, Luminescence, and Temperature Sensing Properties of the Er3+-Doped Germanate-Tellurite Glass by Excitation at Different Wavelengths. J. Lumin. 2024, 266, 120323. [Google Scholar] [CrossRef]

- Bardins, M.; Vakula, N.; Petit, L. Emission Efficiency at 1 Μm from Low Yb3+ Concentrated Tellurite Glass-Ceramics: Alternative Materials for the Future Rare-Earth Metal Shortage. Scr. Mater. 2025, 255, 116355. [Google Scholar] [CrossRef]

- Sangwan, V.; Jayasimhadri, M.; Haranath, D. Colour-Tunable Features in Thermally Stable Tb3+/Eu3+ Co-Doped Telluro Tungstate Glasses for Photonic Applications. J. Phys. D Appl. Phys. 2024, 57, 195301. [Google Scholar] [CrossRef]

- Lemiere, A.; Bondzior, B.; Aromäki, I.; Petit, L. Study of Visible, NIR, and MIR Spectroscopic Properties of Er3+-Doped Tellurite Glasses and Glass-Ceramics. J. Am. Ceram. Soc. 2022, 105, 7186–7195. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Y.; Chen, W.; Jiang, Q.; Chen, D.; Dong, G.; Xia, Z. Rapid Synthesis of Phosphor-Glass Composites in Seconds Based on Particle Self-Stabilization. Nat. Commun. 2024, 15, 1033. [Google Scholar] [CrossRef]

- Blasse, G.; Bril, A.; De Poorter, J.A. Radiationless Transitions in the Eu3+ Center in LaAlO3. J. Chem. Phys. 1970, 53, 4450–4453. [Google Scholar] [CrossRef]

- Hreniak, D.; Stręk, W.; Dereń, P.; Bednarkiewicz, A.; Łukowiak, A. Synthesis and Luminescence Properties of Eu3+-Doped LaAlO3 Nanocrystals. J. Alloys Compd. 2006, 408, 828–830. [Google Scholar] [CrossRef]

- Talari, S.; Chirauri, S.K.; Rambabu, A.; Ramachandra Rao, K. Development of Single Phase Pink Light-Emitting Bi3+/Eu3+ Co-Doped LaAlO3 Phosphors for LED Applications. Mater. Res. Innov. 2023, 27, 61–68. [Google Scholar] [CrossRef]

- Shaik, E.B.; Kumar, B.V.N.; Chirauri, S.K.; Rao, K.R. Realization of Effective Energy Transfer and Color Tunability between Tb3+ and Eu3+ Ions in LaAlO3 Host for LED Display Applications. J. Mater. Sci. 2022, 33, 105–114. [Google Scholar] [CrossRef]

- Lee, S.H.; Du, P.; Bharat, L.K.; Yu, J.S. Ultraviolet Radiation Excited Strong Red-Emitting LaAlO3: Eu3+ Nanophosphors: Synthesis and Luminescent Properties. Ceram. Int. 2017, 43, 4599–4605. [Google Scholar] [CrossRef]

- Jakka, S.K.; Silva, M.M.P.; Soares, M.J.; Pavani, K. Exploring the Potential of Eu3+ and Mn4+ Activated LaAlO3 Phosphors as Red and Far-Red Emitters for Horticulture Lighting. RSC Adv. 2023, 13, 31314–31320. [Google Scholar] [CrossRef]

- Shan, G.; Xu, H.; Chen, Q. EPR, NMR, DFT and XPS Study on LaAlO3 Phase Transition in Glass and Influence on Glass Structure and Properties. Ceram. Int. 2023, 49, 6790–6804. [Google Scholar] [CrossRef]

- Liu, Y.; Frenkel, A.; Garrett, G.A.; Whitaker, J.F.; Fahy, S.; Uher, C.; Merlin, R. Impulsive Light Scattering by Coherent Phonons in LaAlO3: Disorder and Boundary Effects. Phys. Rev. Lett. 1995, 75, 334–337. [Google Scholar] [CrossRef]

- Đorđević, V.; Antić, Ž.; Nikolić, M.G.; Dramićanin, M.D. Comparative Structural and Photoluminescent Study of Eu3+-Doped La2O3 and La(OH)3 Nanocrystalline Powders. J. Phys. Chem. Solids 2014, 75, 276–282. [Google Scholar] [CrossRef]

- Klement, R.; Drdlíková, K.; Kachlík, M.; Drdlík, D.; Galusek, D.; Maca, K. Photoluminescence and Optical Properties of Eu3+/Eu2+-Doped Transparent Al2O3 Ceramics. J. Eur. Ceram. Soc. 2021, 41, 4896–4906. [Google Scholar] [CrossRef]

- Zhunusbekov, A.M.; Karipbayev, Z.T.; Tolegenova, A.; Kumarbekov, K.K.; Nurmoldin, E.E.; Baizhumanov, M.M.; Kotlov, A.; Popov, A.I. Comparative VUV Synchrotron Excitation Study of YAG: Eu and YAG: Cr Ceramics. Crystals 2024, 14, 897. [Google Scholar] [CrossRef]

- Binnemans, K.; Görller-Walrand, C. Magnetic Circular Dichroism and Optical Absorption Spectra of Eu3+ in Y3Al5O12 (YAG). J. Chem. Soc. Faraday Trans. 1996, 92, 2487–2493. [Google Scholar] [CrossRef]

- Ojha, N.; Tuomisto, M.; Lastusaari, M.; Petit, L. Upconversion from Fluorophosphate Glasses Prepared with NaYF4: Er3+,Yb3+ Nanocrystals. RSC Adv. 2018, 8, 19226–19236. [Google Scholar] [CrossRef]

- Santos Magalhães, E.; Sedda, A.; Bondzior, B.; Vuori, S.; Van der Heggen, D.; Smet, P.F.; Lastusaari, M.; Petit, L. Glass-Based Composites Comprised of CaWO4: Yb3+, Tm3+ Crystals and SrAl2O4: Eu2+, Dy3+ Phosphors for Green Afterglow after NIR Charging. Ceram. Int. 2023, 49, 41150–41157. [Google Scholar] [CrossRef]

- Zhang, M.; Wu, Y.; Zhang, L.; Zhang, H.; Cui, B.; Sun, Z. Photoluminescence Properties of Eu3+-Doped Stalk-like Al2O3 via a Hydrothermal Route Followed by Heat Treatment. Adv. Appl. Ceram. 2018, 117, 264–268. [Google Scholar] [CrossRef]

- Monteiro, M.A.F.; Brito, H.F.; Felinto, M.C.F.C.M.; Brito, G.E.S.; Teotonio, E.E.S.; Vichi, F.M.; Stefani, R. Photoluminescence Behavior of Eu3+ Ion Doped into γ- and α-Alumina Systems Prepared by Combustion, Ceramic and Pechini Methods. Microporous Mesoporous Mater. 2008, 108, 237–246. [Google Scholar] [CrossRef]

- Mirdda, J.N.; Mukhopadhyay, S.; Sahu, K.R.; Goswami, M.N. Enhancement of Optical Emission and Dielectric Properties of Eu3+-Doped Na2O-ZnO-TeO2 Glass Material. Glass Phys. Chem. 2020, 46, 218–227. [Google Scholar] [CrossRef]

| Compound | CTB (eV) | ED/MD Ratio | Source |

|---|---|---|---|

| La2O3 | 4.38 | 8.5 | [30] |

| Al2O3 | 4.23 | 3.4–3.6 | [31] |

| Y3Al5O12 (YAG) | 6.64 | 0.7 | [32,33] |

| LaAlO3 (LAO) | 3.94 | 1.4 | [22], this work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lisiecki, R.; Miniajluk-Gaweł, N.; Bondzior, B. Effect of Preparation Method on the Optical Properties of Novel Luminescent Glass-Crystalline Composites. Appl. Sci. 2025, 15, 8877. https://doi.org/10.3390/app15168877

Lisiecki R, Miniajluk-Gaweł N, Bondzior B. Effect of Preparation Method on the Optical Properties of Novel Luminescent Glass-Crystalline Composites. Applied Sciences. 2025; 15(16):8877. https://doi.org/10.3390/app15168877

Chicago/Turabian StyleLisiecki, Radosław, Natalia Miniajluk-Gaweł, and Bartosz Bondzior. 2025. "Effect of Preparation Method on the Optical Properties of Novel Luminescent Glass-Crystalline Composites" Applied Sciences 15, no. 16: 8877. https://doi.org/10.3390/app15168877

APA StyleLisiecki, R., Miniajluk-Gaweł, N., & Bondzior, B. (2025). Effect of Preparation Method on the Optical Properties of Novel Luminescent Glass-Crystalline Composites. Applied Sciences, 15(16), 8877. https://doi.org/10.3390/app15168877