Impact of Adaptive Process Control on Mechanical Properties of Plastic Parts and Process Robustness

Abstract

1. Introduction

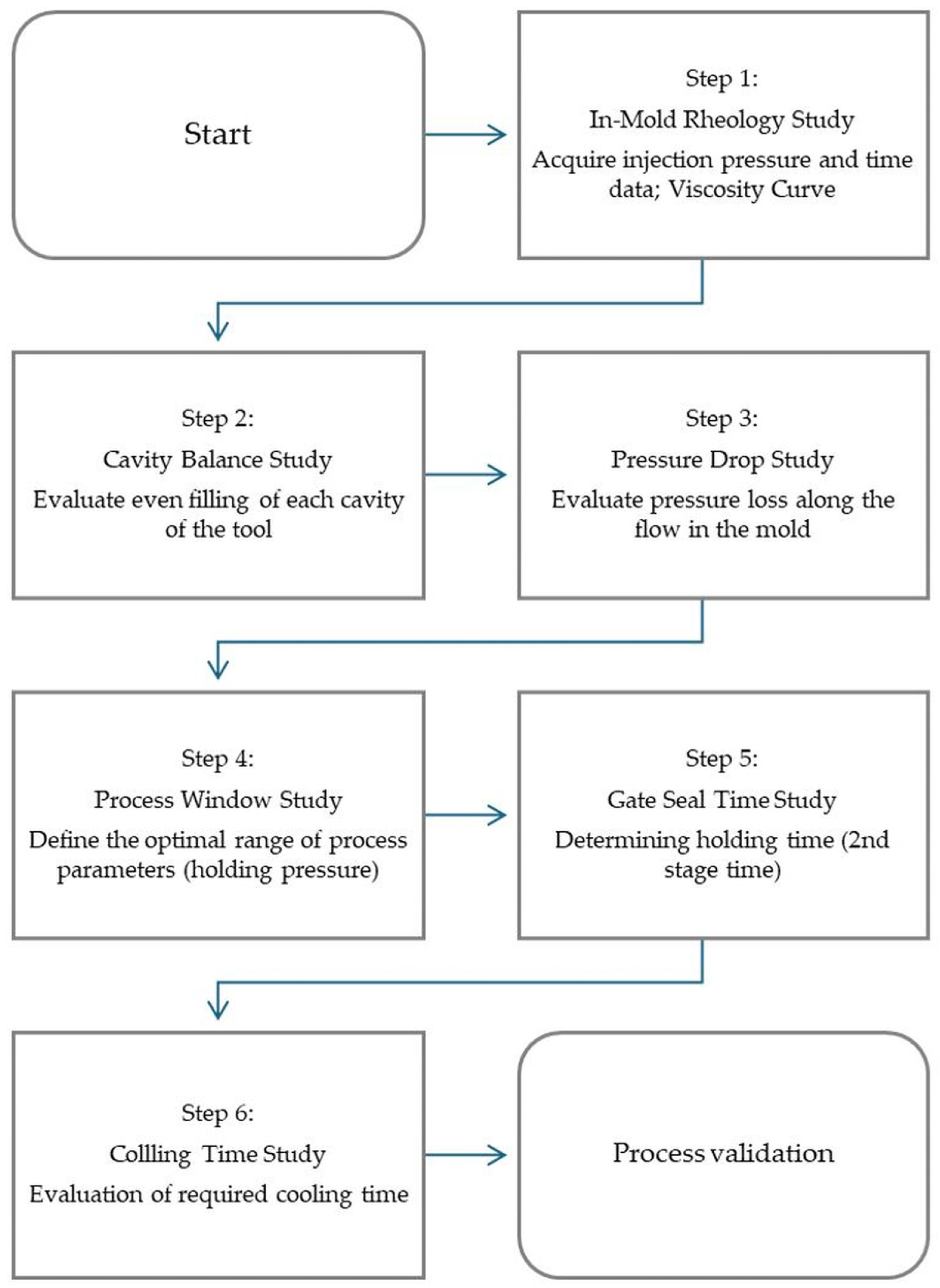

1.1. Injection Molding Process and Systematic Six-Step Process Development

1.2. Optimizing Injection Molding with AI Systems Integration

2. Materials and Methods

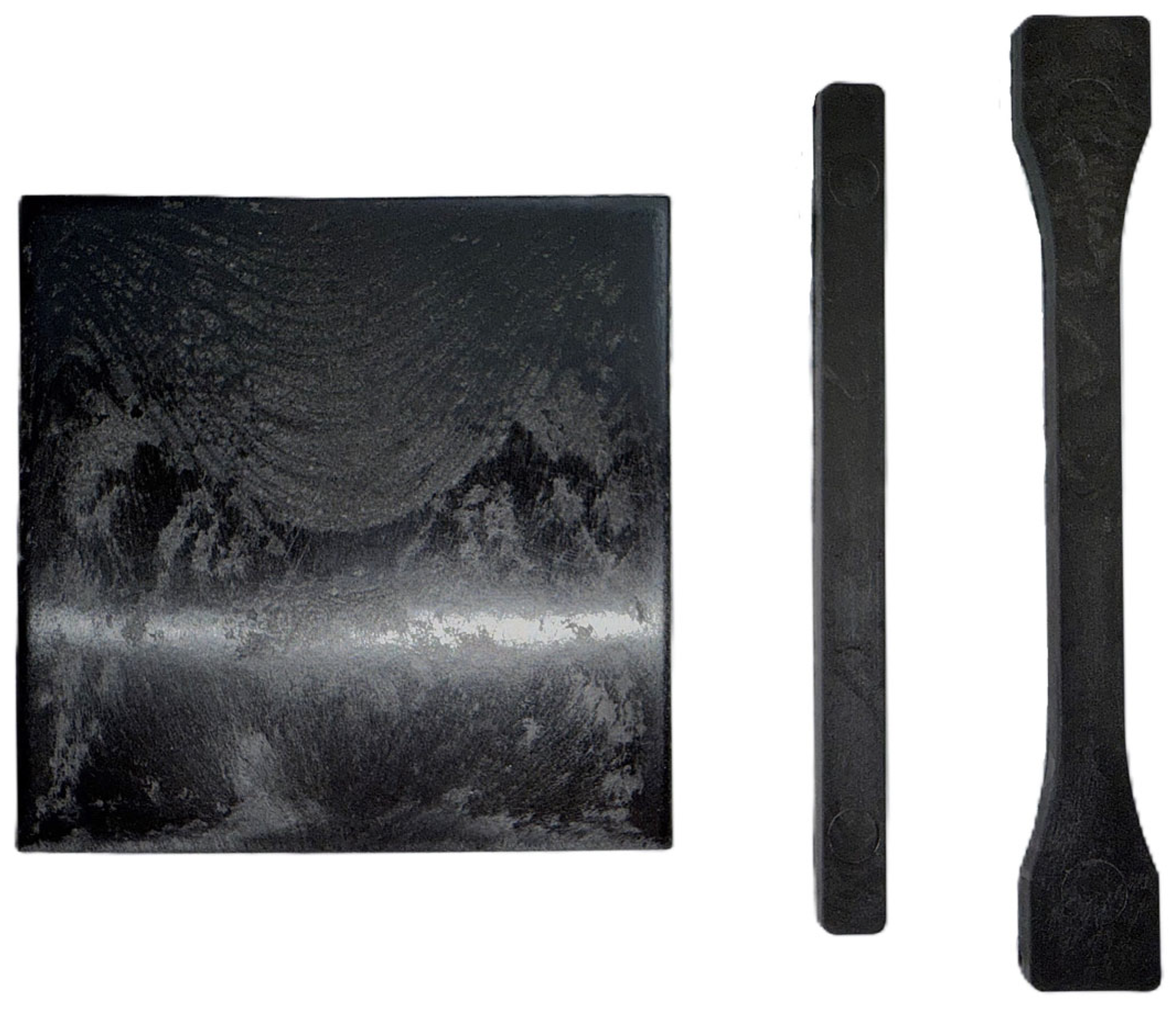

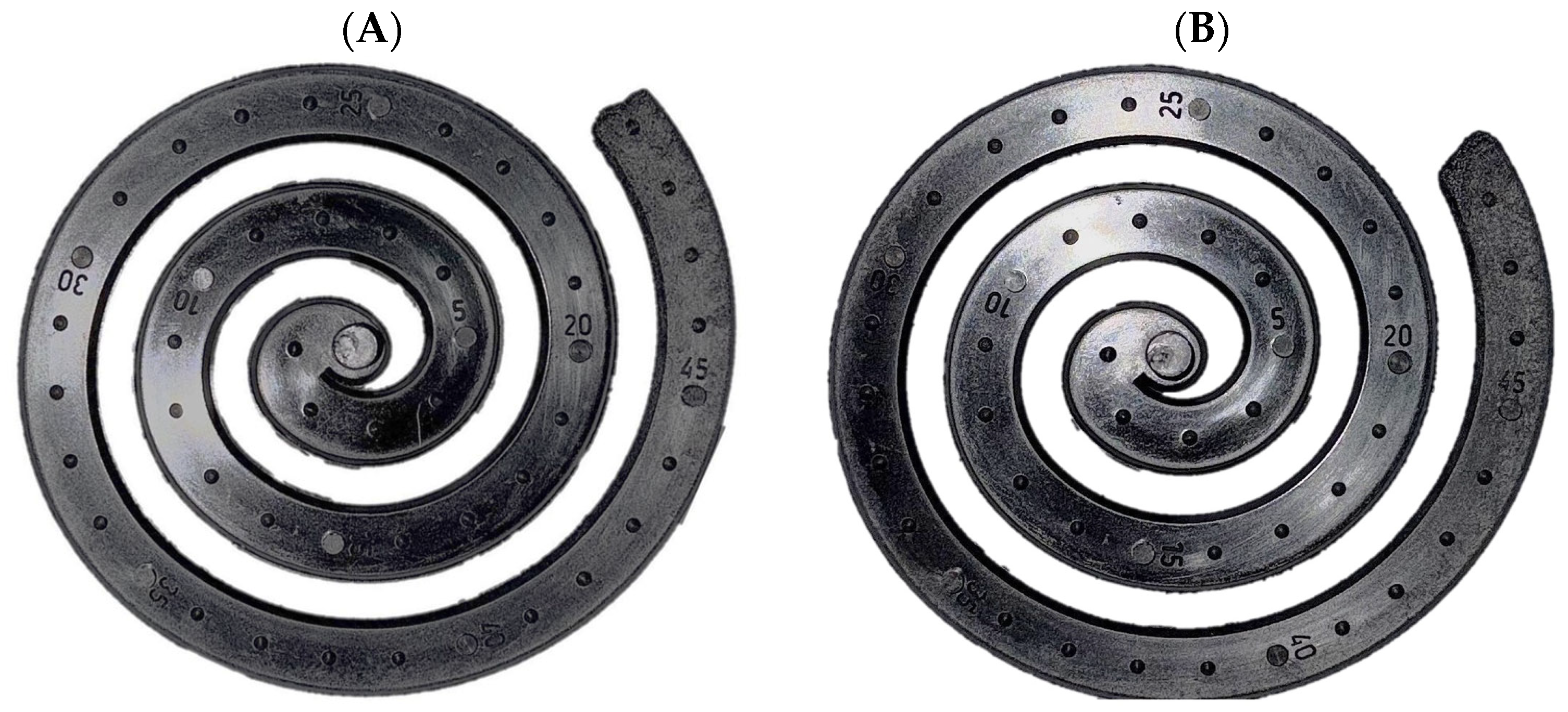

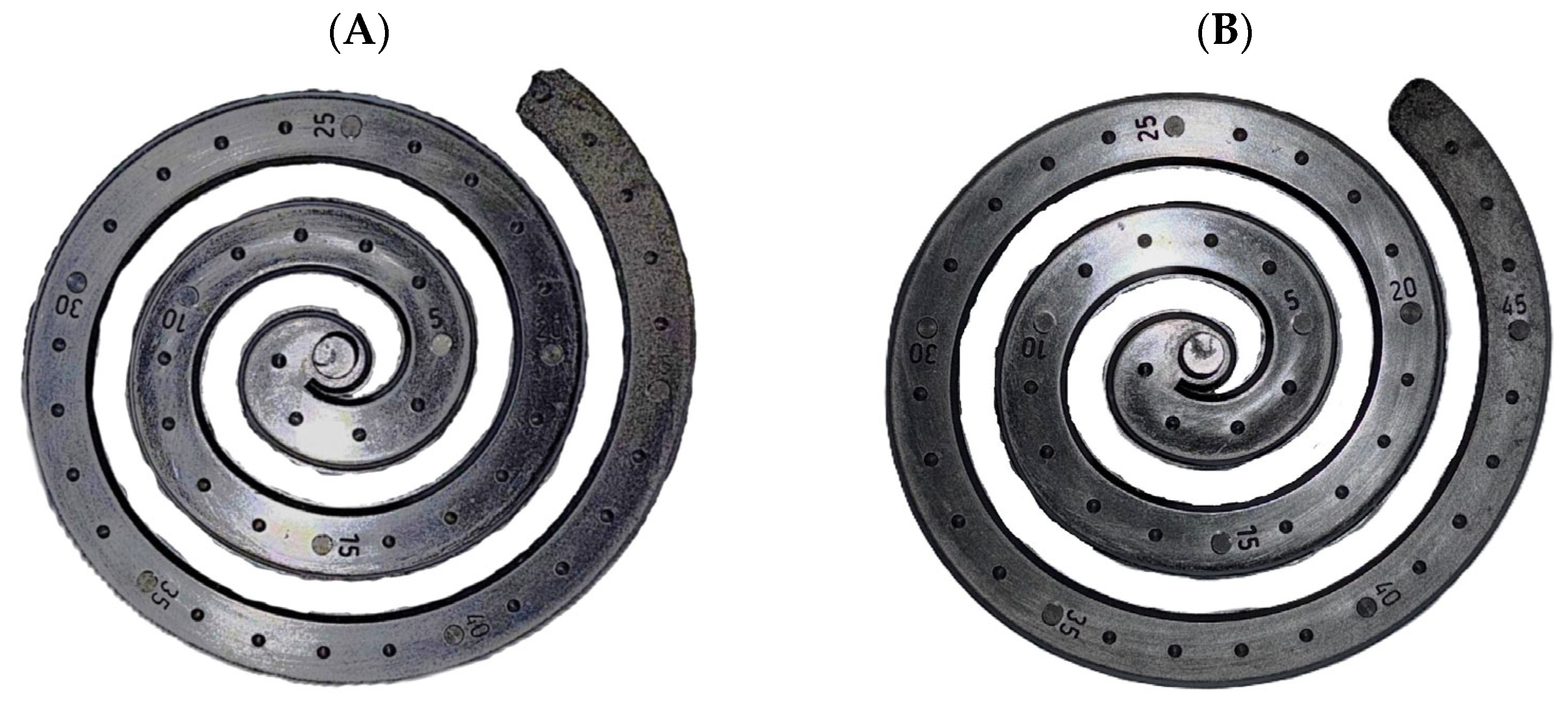

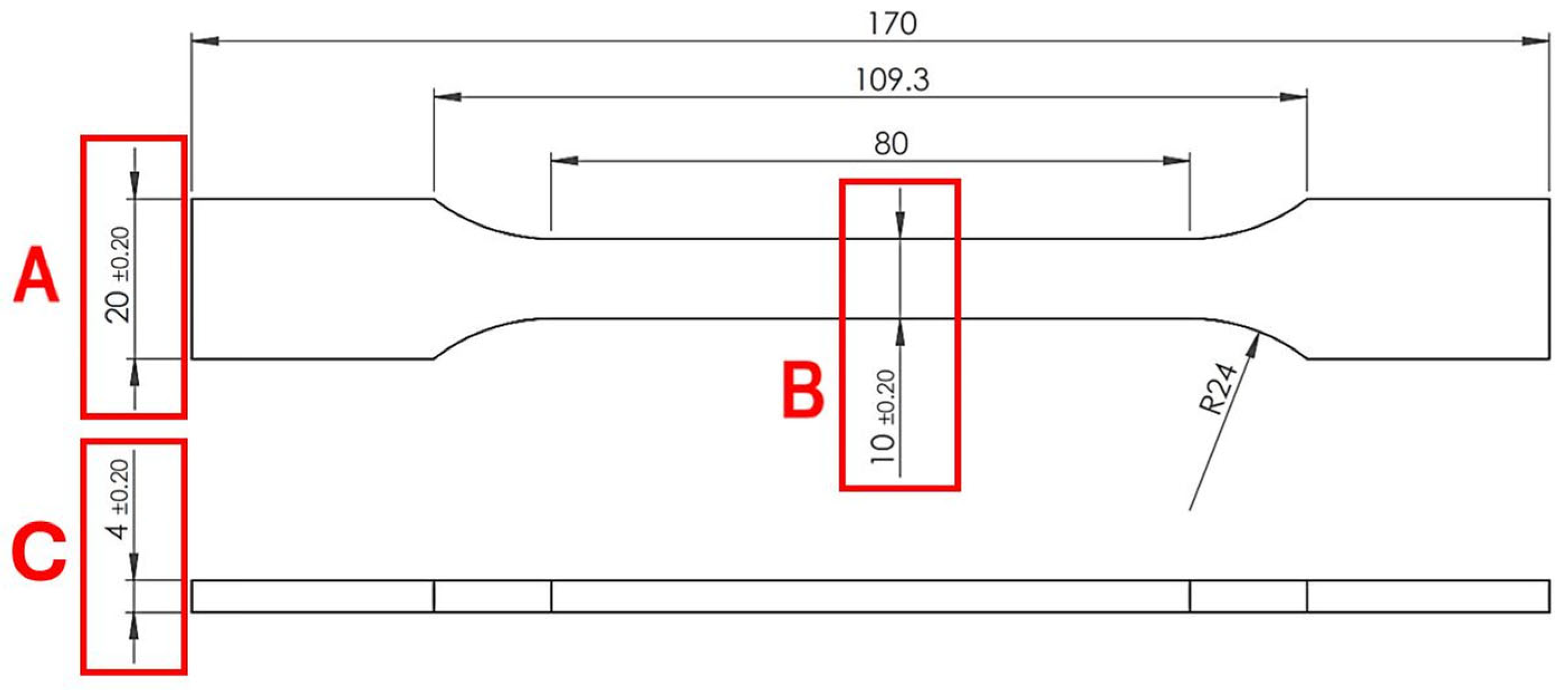

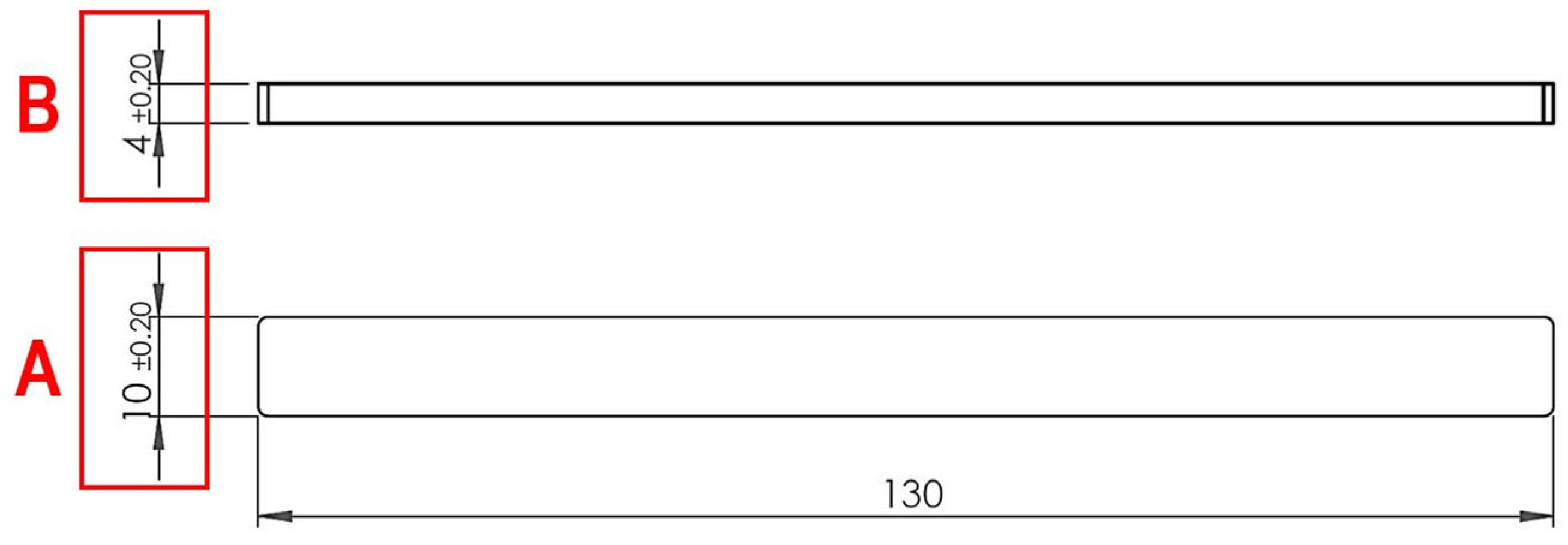

2.1. Materials and Sample Preparation

2.2. Methods

3. Results

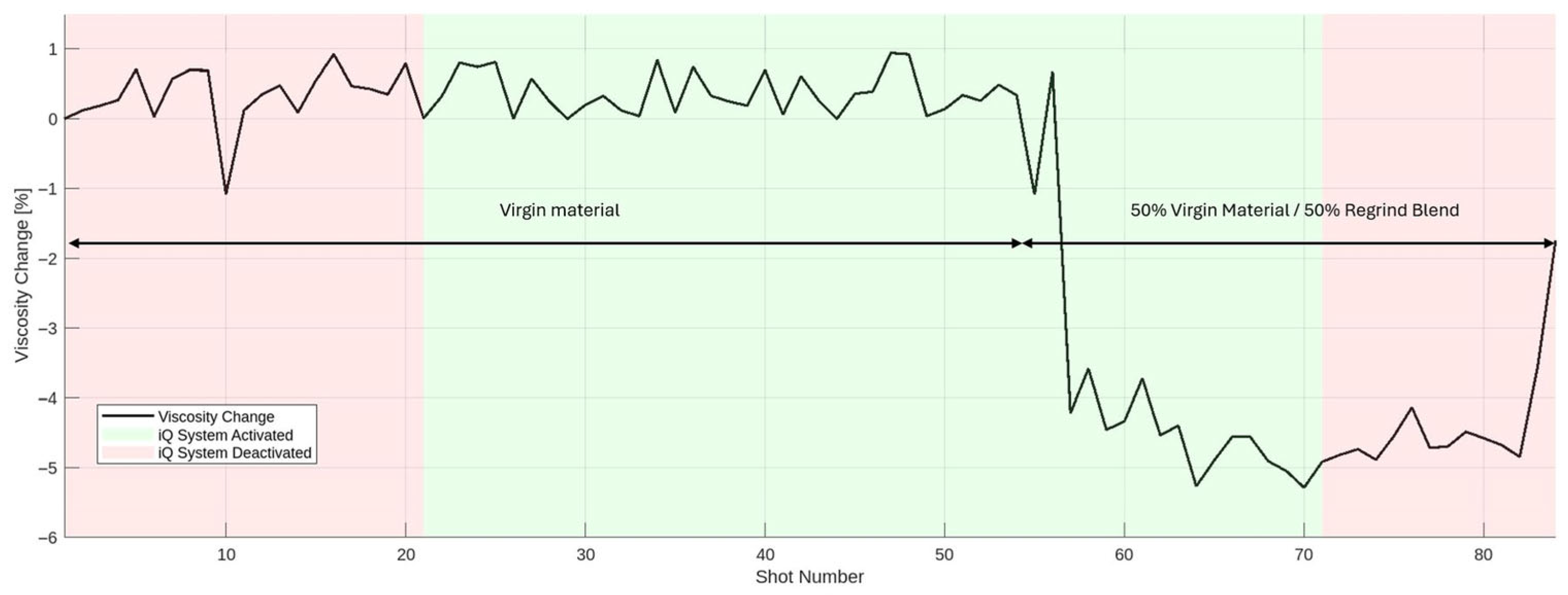

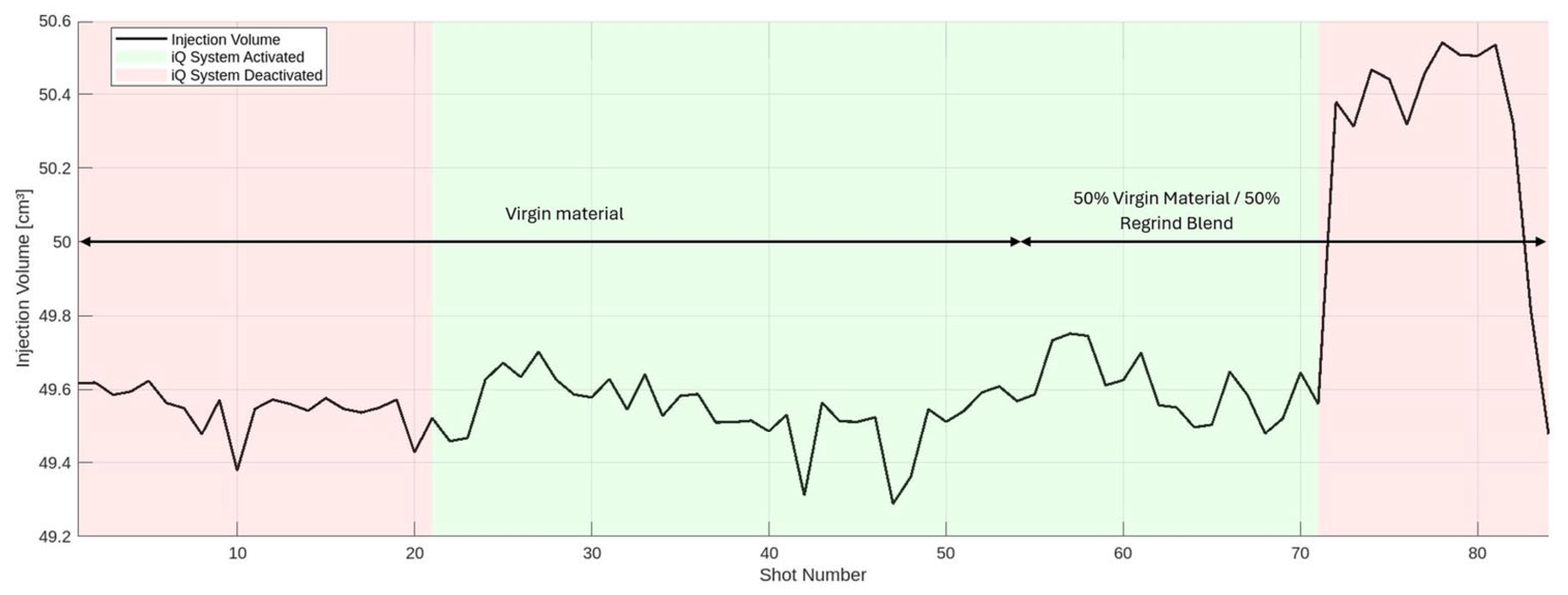

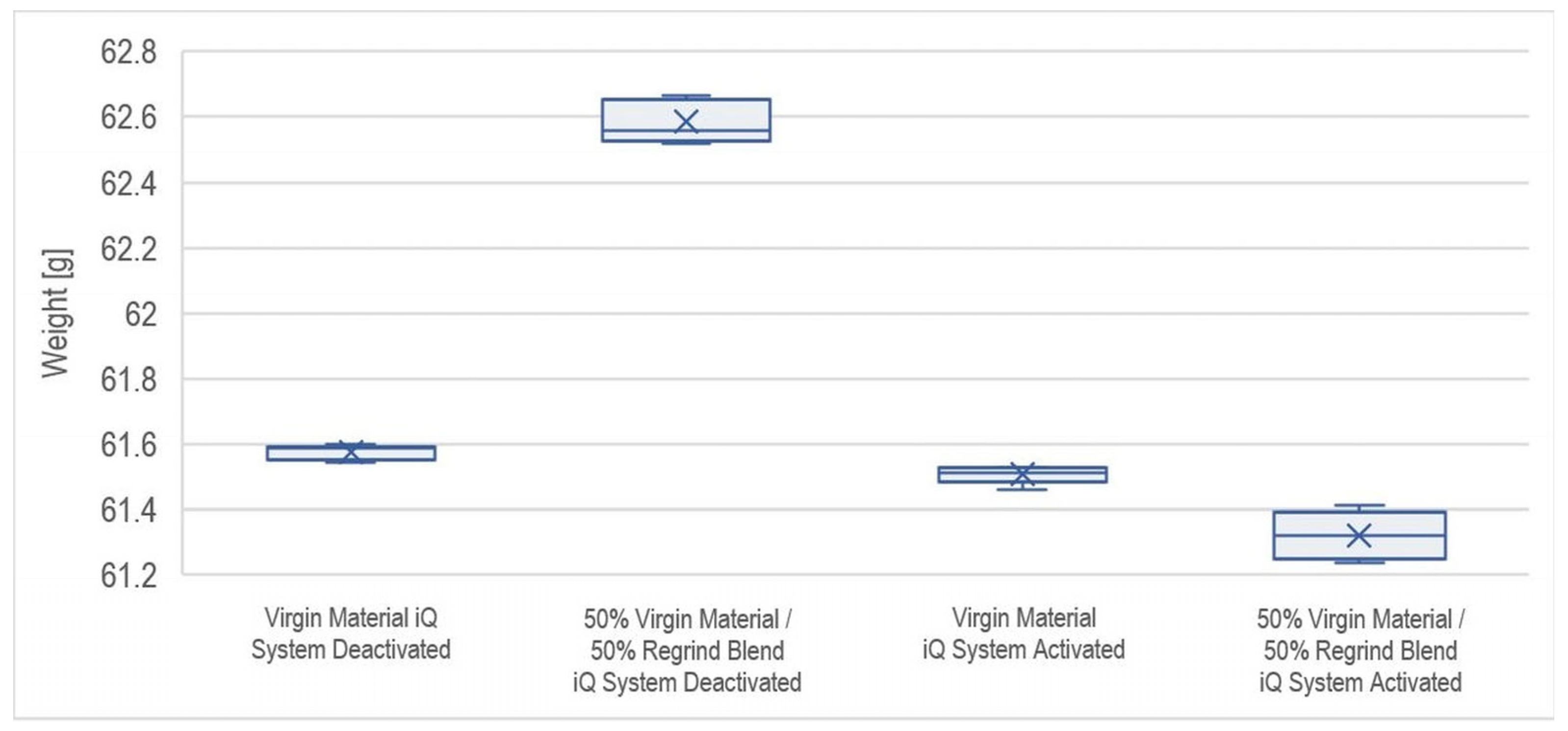

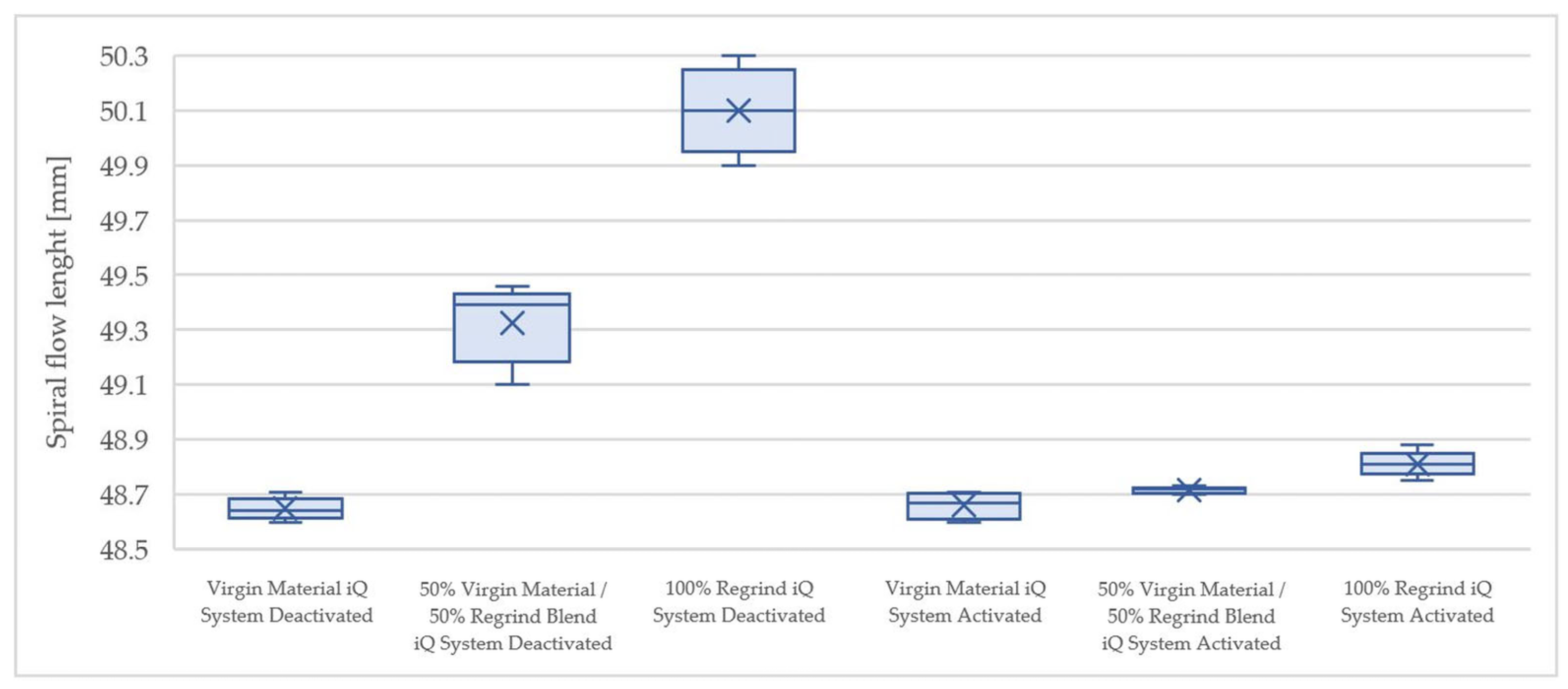

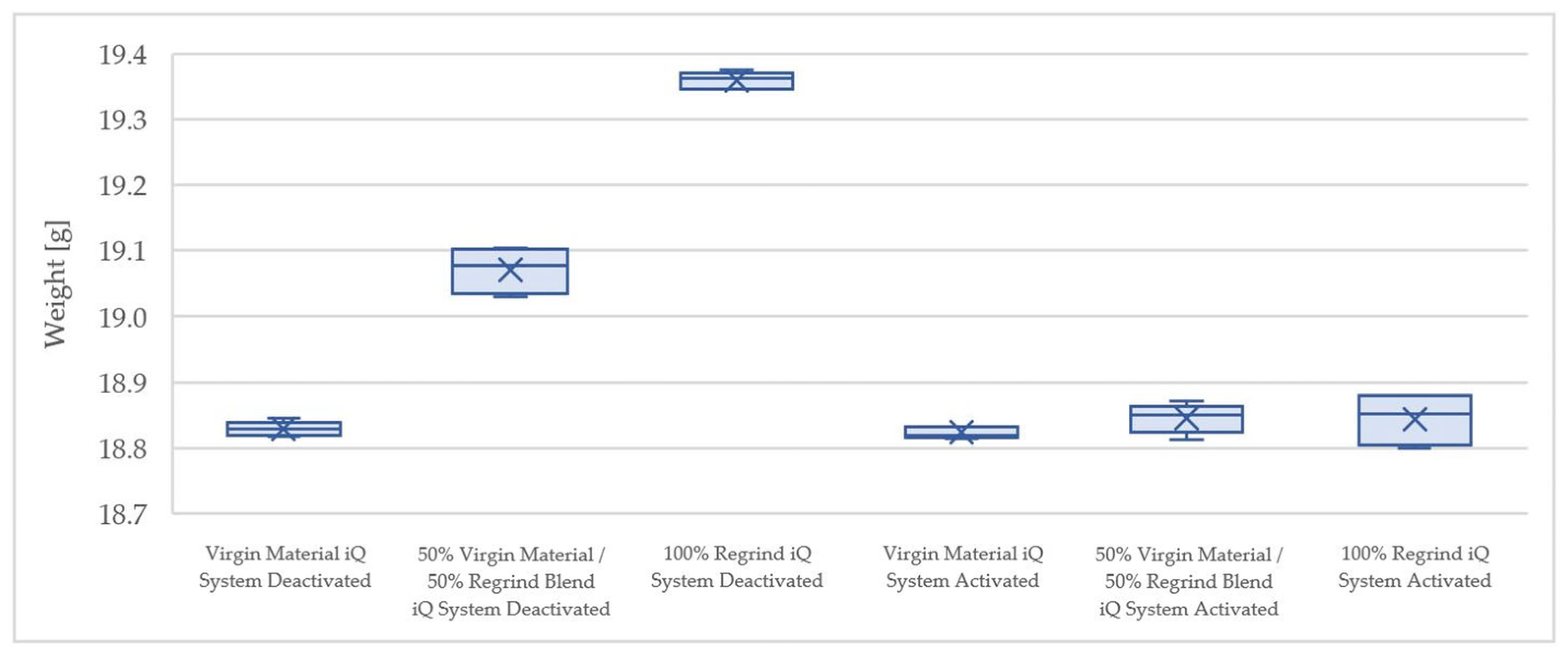

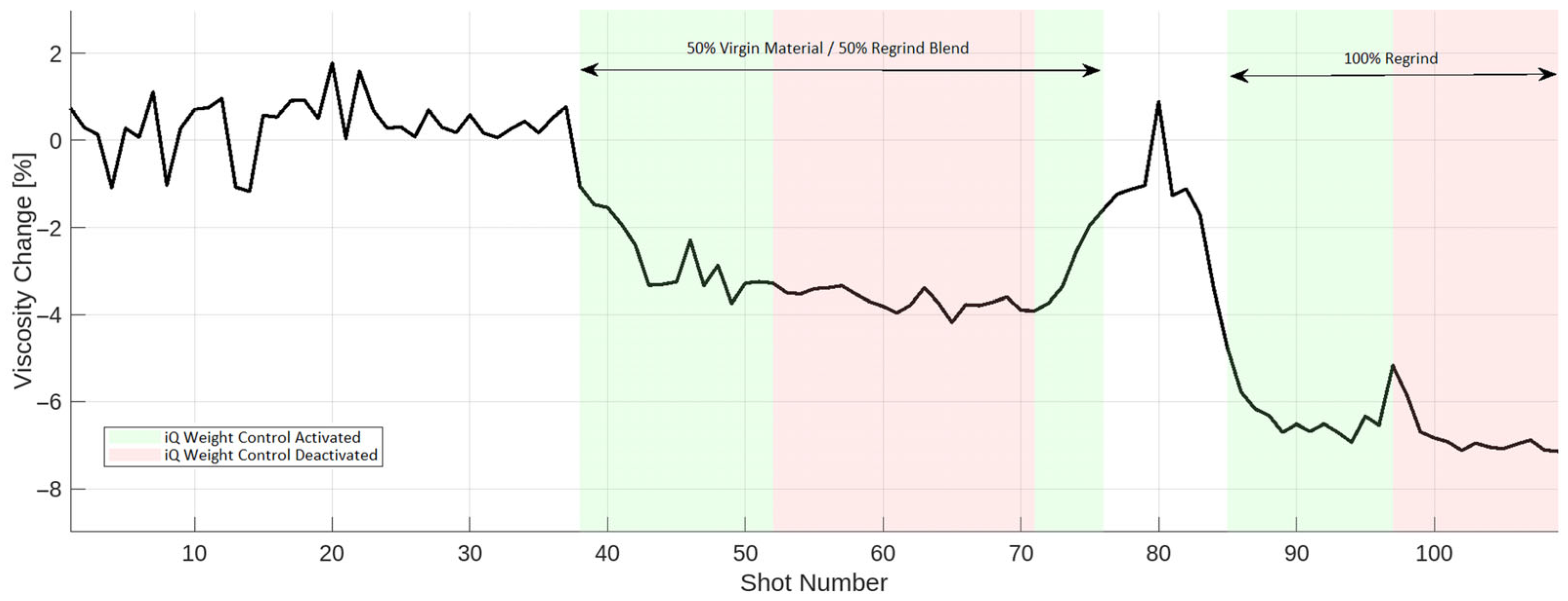

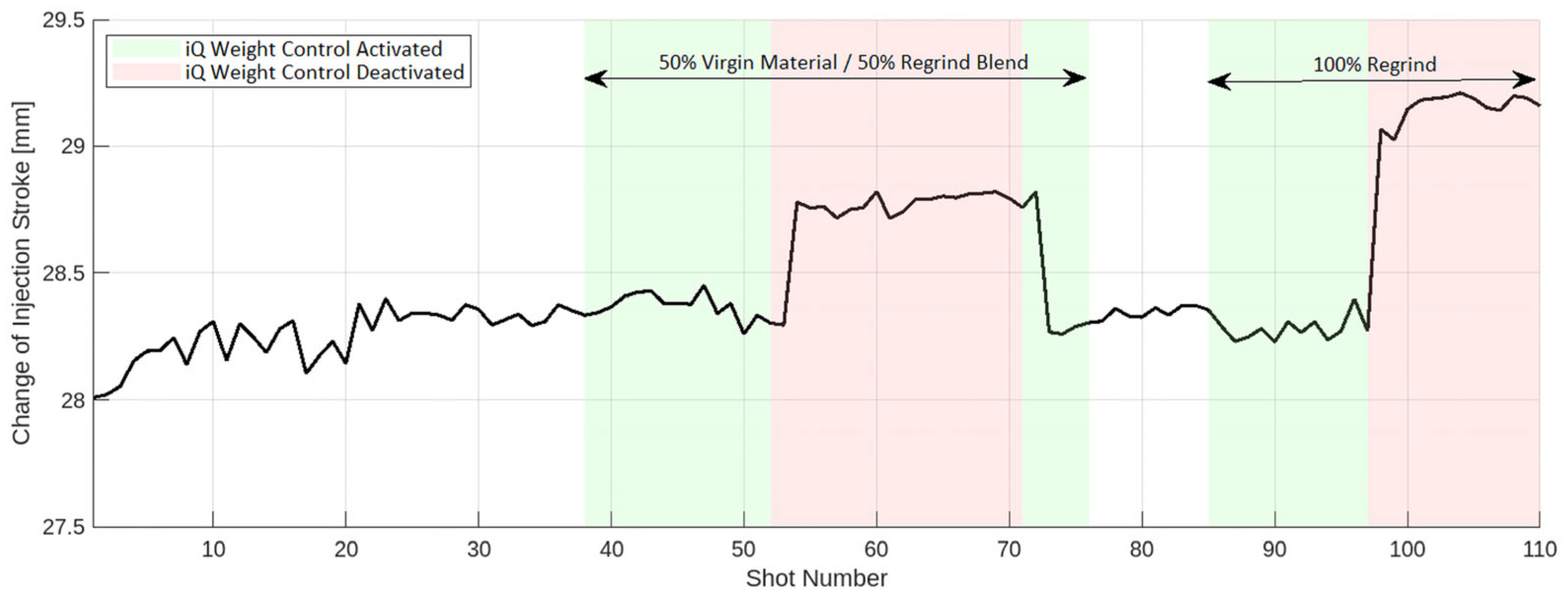

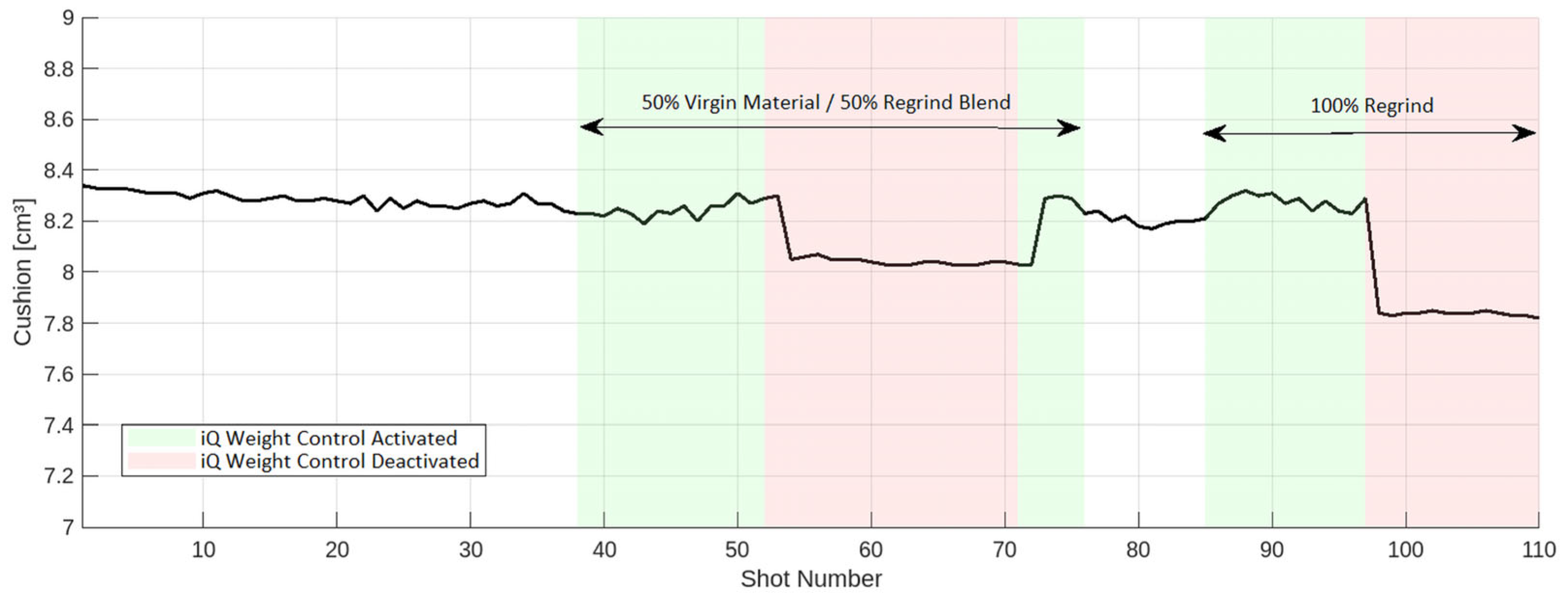

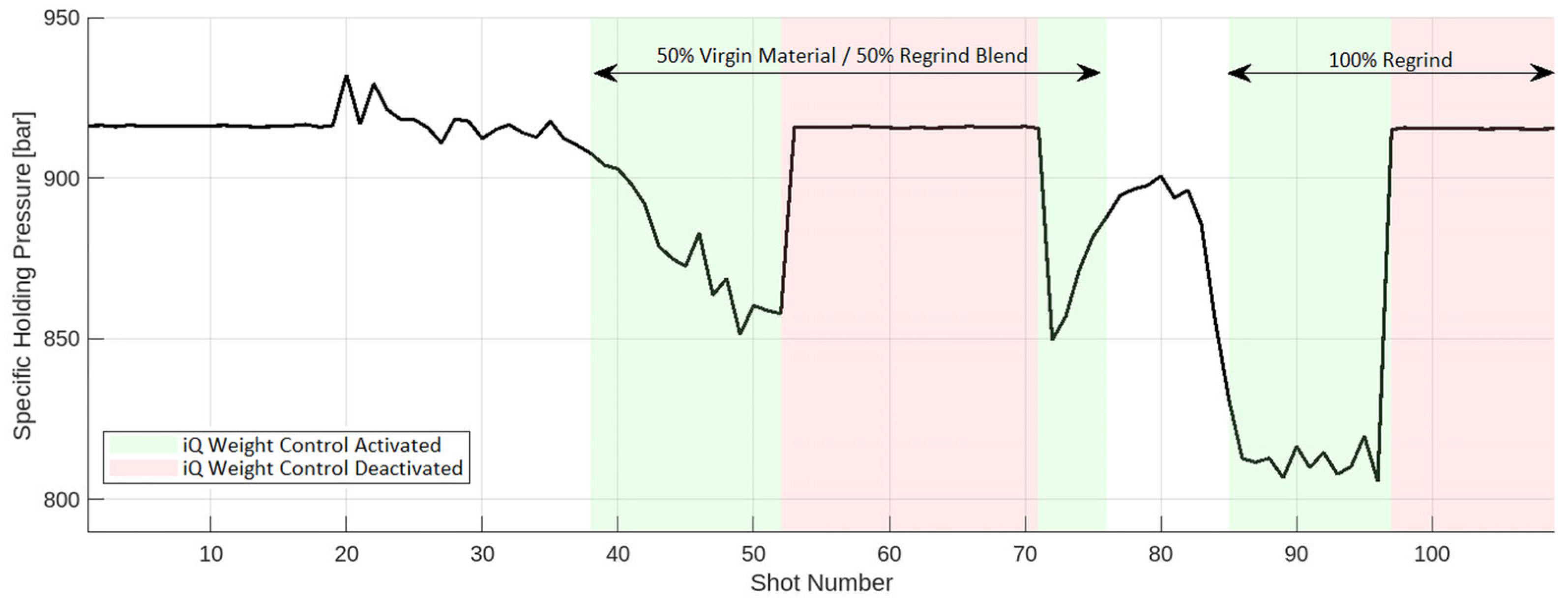

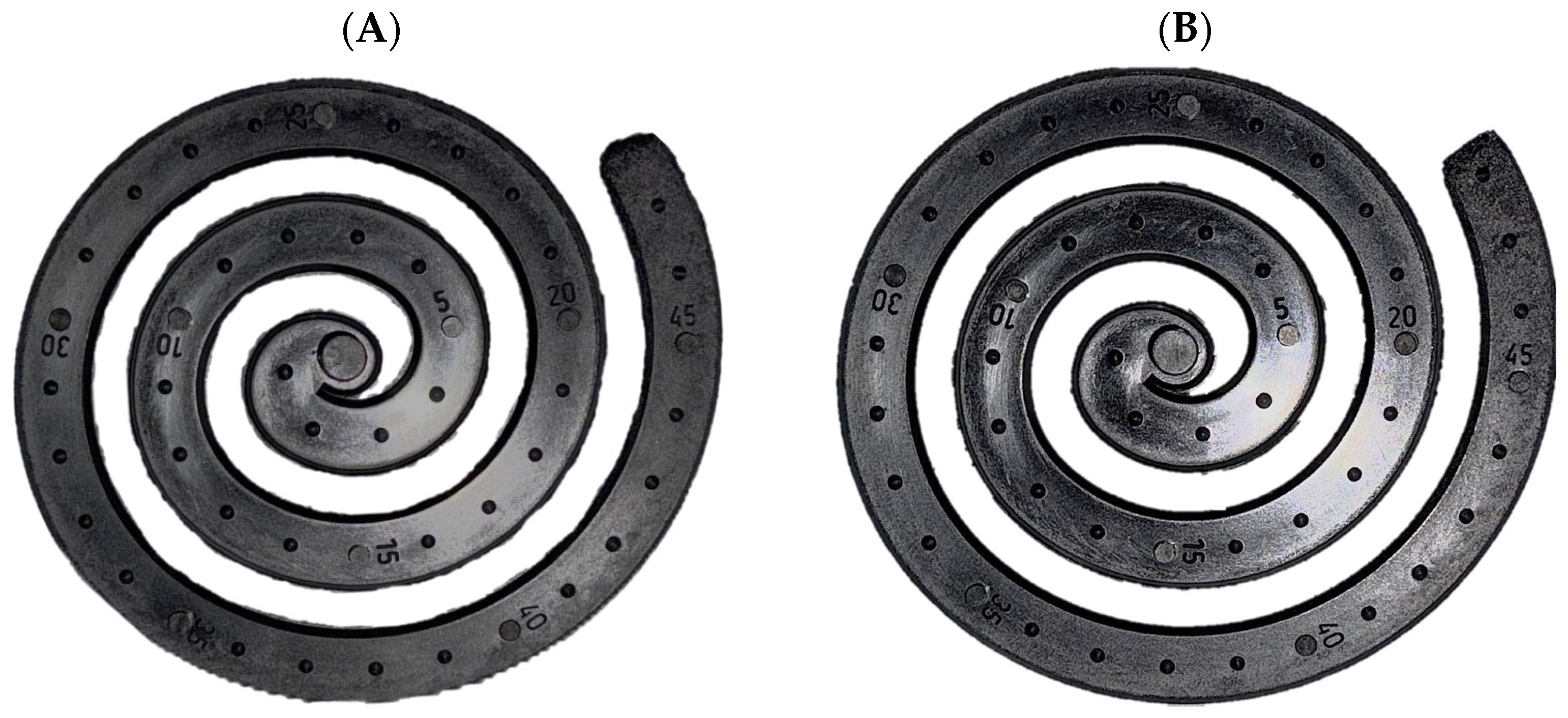

3.1. Mass Consistency and Process Robustness

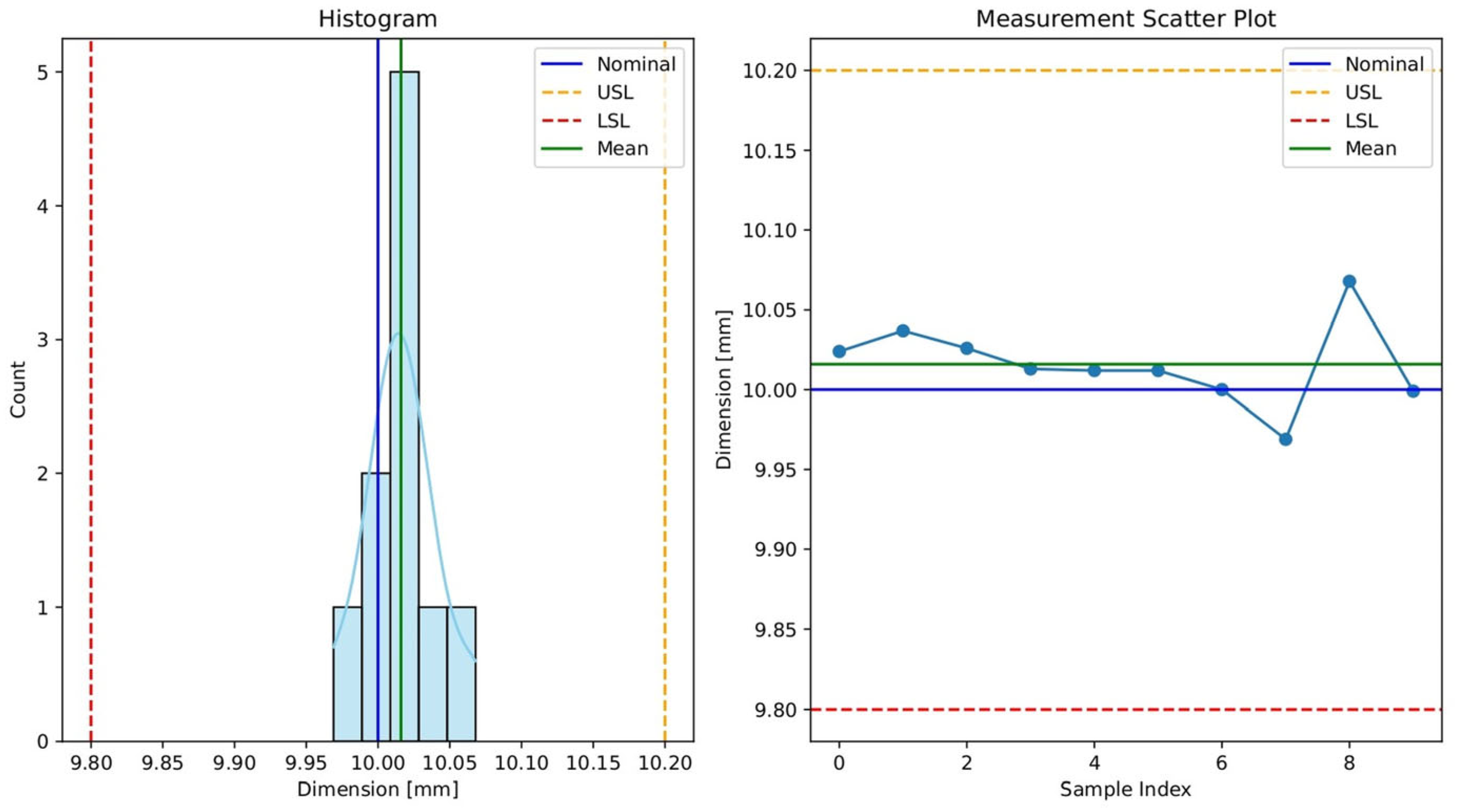

3.2. Dimensional Stability

3.3. Impact Strength

3.4. Tensile Strength

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Czepiel, M.; Bańkosz, M.; Sobczak-Kupiec, A. Advanced Injection Molding Methods: Review. Materials 2023, 16, 5802. [Google Scholar] [CrossRef]

- Lebreton, L.; Andrady, A. Future Scenarios of Global Plastic Waste Generation and Disposal. Palgrave Commun. 2019, 5, 1–11. [Google Scholar] [CrossRef]

- Olszewski, T.; Matykiewicz, D.; Barczewski, M.; Andrzejewski, J. Efficient Use of Secondary Raw Material from the Production of Polyamide Construction Products. Processes 2024, 12, 1304. [Google Scholar] [CrossRef]

- Park, H.S.; Phuong, D.X.; Kumar, S. AI Based Injection Molding Process for Consistent Product Quality. Procedia Manuf. 2019, 28, 102–106. [Google Scholar] [CrossRef]

- Kulkarni, S. Robust Process Development and Scientific Molding; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2016. [Google Scholar]

- Schiller, G.F. A Practical Approach to Scientific Molding; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2018. [Google Scholar]

- MacKenzie, G. A Closer Look at Scientific Molding Theory. Available online: https://www.plasticstoday.com/injection-molding/a-closer-look-at-scientific-molding-theory (accessed on 5 July 2025).

- Catignani, U. Moving Beyond the Relative Viscosity Curv—Determining Optimum Plastic Flow Rates: Part 1. Available online: https://www.ptonline.com/articles/moving-beyond-the-relative-viscosity-curve-determining-optimum-plastic-flow-rates-part-1 (accessed on 5 July 2025).

- Gerlach, M. Critical Skill Shortage in Plastics Processing Industries Intensifies/Germany Needs Almost 500,000 Foreigners Per Year; Shortage of Working Migrants in Italy and Spain—Study/PIE Talks to Industry Experts. Available online: https://pieweb.plasteurope.com/Default.aspx?pageid=19990&docid=254890 (accessed on 5 July 2025).

- Hanna, K. Skills Gap Highlights Need for Training. Available online: https://www.plasticsmachinerymanufacturing.com/manufacturing/article/53073243/skills-gap-highlights-need-for-training (accessed on 5 July 2025).

- Bin Akhtar, Z. Artificial Intelligence (AI) within Manufacturing: An Investigative Exploration for Opportunities, Challenges, Future Directions. Metaverse 2024, 5, 2731. [Google Scholar] [CrossRef]

- Blume, E. Artificial Intelligence in the Plastics Industry: Sustainability Through Technology. Available online: https://www.k-online.com/en/media_news/k-mag/digitalisation/artificial-intelligence/ai-plastics-industry-sustainability (accessed on 5 July 2025).

- Kavanaugh, C. Putting the Intelligence in AI for the Plastics Industry. Available online: https://www.plasticsnews.com/news/putting-intelligence-ai (accessed on 11 July 2024).

- Chen, J.C.; Kakati, A. Development of E-Dart-Based Artificial Neural Network for Multiple Quality Characteristic Online Defect Detection System in Injection Molding Processes. Int. J. Adv. Manuf. Technol. 2025, 136, 951–960. [Google Scholar] [CrossRef]

- Chen, Y.-S.; Wu, K.-T.; Tsai, M.-H.; Hwang, S.-J.; Lee, H.-H.; Peng, H.-S.; Chu, H.-Y. Adaptive Process Control of the Changeover Point for Injection Molding Process. J. Low Freq. Noise Vib. Act. Control 2021, 40, 383–394. [Google Scholar] [CrossRef]

- Su, C.-W.; Su, W.-J.; Cheng, F.-J.; Liou, G.-Y.; Hwang, S.-J.; Peng, H.-S.; Chu, H.-Y. Optimization Process Parameters and Adaptive Quality Monitoring Injection Molding Process for Materials with Different Viscosity. Polym. Test. 2022, 109, 107526. [Google Scholar] [CrossRef]

- Chen, J.-Y.; Zhuang, J.-X.; Huang, M.-S. Enhancing the Quality Stability of Injection Molded Parts by Adjusting V/P Switchover Point and Holding Pressure. Polymer 2021, 213, 123332. [Google Scholar] [CrossRef]

- Krantz, J.; Nieduzak, Z.; Licata, J.; O’Meara, S.; Gao, P.; Masato, D. In-mold Rheology and Automated Process Control for Injection Molding of Recycled Polypropylene. Polym. Eng. Sci. 2024, 64, 4112–4127. [Google Scholar] [CrossRef]

- Stable Injection Moulding Processes with IQ Weight Control. Available online: https://www.engelglobal.com/en/blog/stable-injection-moulding-processes-with-iq-weight-control (accessed on 5 July 2025).

- Schiffers, R.; Kruppa, S.; Moser, S. The Right Changeover Point for Each Shot. J. Kunststoffe 2014, 11, 26–29. [Google Scholar]

- Chang, C.H.; Ke, K.-C.; Huang, M.-S. Cross-Machine Predictions of the Quality of Injection-Molded Parts by Combining Machine Learning, Quality Indices, and a Transfer Model. Int. J. Adv. Manuf. Technol. 2024, 133, 4981–4998. [Google Scholar] [CrossRef]

- Kurt, M.; Saban Kamber, O.; Kaynak, Y.; Atakok, G.; Girit, O. Experimental Investigation of Plastic Injection Molding: Assessment of the Effects of Cavity Pressure and Mold Temperature on the Quality of the Final Products. Mater. Des. 2009, 30, 3217–3224. [Google Scholar] [CrossRef]

- de Souza, J.M.; de Holanda, G.M.; Henriques, H.A.; Furukawa, R.H. Modified Control Charts Monitoring Long-Term Semiconductor Manufacturing Processes; Springer International Publishing: Cham, The Switzerland, 2021; pp. 80–87. [Google Scholar]

- Weusten, J.; Hu, J. Predictive Ppk Calculations for Biologics and Vaccines Using a Bayesian Approach—A Tutorial. Pharm. Stat. 2025, 24, e2380. [Google Scholar] [CrossRef]

- Piñero, N. Estimating Process Capability Indexes through Random Samples in CVG-Bauxilum. In Proceedings of the Technical Sessions Presented by the TMS Aluminum Committee at the TMS 2009 Annual Meeting & Exhibition, San Francisco, CA, USA, 15–19 February 2009; pp. 145–149. [Google Scholar]

- Lynch, D.P. Setting the Record Straight with Capability Indices. SAE Int. 2004, 1, 1747. [Google Scholar]

- Zaneldin, E.; Ahmed, W.; Mansour, A.; Hassan, A. El Dimensional Stability of 3D Printed Objects Made from Plastic Waste Using FDM: Potential Construction Applications. Buildings 2021, 11, 516. [Google Scholar] [CrossRef]

- Senvar, O.; Sennaroglu, B. Comparing Performances of Clements, Box-Cox, Johnson Methods with Weibull Distributions for Assessing Process Capability. J. Ind. Eng. Manag. 2016, 9, 634–656. [Google Scholar] [CrossRef]

- Ozkaya, B.Y.; Testik, M.C. On the Expected Parts per Million Nonconforming Levels Obtained from Estimated Process Capability Indices. Qual. Reliab. Eng. Int. 2010, 26, 817–829. [Google Scholar] [CrossRef]

- Monter-Pozos, A.; González-Estrada, E. On Testing the Skew Normal Distribution by Using Shapiro–Wilk Test. J. Comput. Appl. Math. 2024, 440, 115649. [Google Scholar] [CrossRef]

- Jiang, B.; Zou, Y.; Liu, T.; Wu, W. Characterization of the Fluidity of the Ultrasonic Plasticized Polymer Melt by Spiral Flow Testing under Micro-Scale. Polymers 2019, 11, 357. [Google Scholar] [CrossRef]

- Rubin, I.I. Injection Molding of Thermoplastics. In SPI Plastics Engineering Handbook of the Society of the Plastics Industry, Inc.; Springer: Boston, MA, USA, 1991; pp. 133–178. [Google Scholar]

- Chaciński, T.; Jaskólski, P.; Pałubicki, M. Study of Process Stability in Injection Molding Based on Product Weight. J. Mech. Energy Eng. 2022, 6, 21–26. [Google Scholar] [CrossRef]

- Gijsman, P.; Meijers, G.; Vitarelli, G. Comparison of the UV-Degradation Chemistry of Polypropylene, Polyethylene, Polyamide 6 and Polybutylene Terephthalate. Polym. Degrad. Stab. 1999, 65, 433–441. [Google Scholar] [CrossRef]

- Pötschke, P.; Fornes, T.D.; Paul, D.R. Rheological Behavior of Multiwalled Carbon Nanotube/Polycarbonate Composites. Polymer 2002, 43, 3247–3255. [Google Scholar] [CrossRef]

- Arabeche, K.; Abdelmalek, F.; Delbreilh, L.; Zair, L.; Berrayah, A. Physical and Rheological Properties of Biodegradable Poly(Butylene Succinate)/Alfa Fiber Composites. J. Thermoplast. Compos. Mater. 2022, 35, 1709–1727. [Google Scholar] [CrossRef]

- Thomason, J.L. Structure–Property Relationships in Glass Reinforced Polyamide, Part 2: The Effects of Average Fiber Diameter and Diameter Distribution. Polym. Compos. 2007, 28, 331–343. [Google Scholar] [CrossRef]

- Fernandez, E.; Edeleva, M.; Fiorio, R.; Cardon, L.; D’hooge, D.R. Increasing the Sustainability of the Hybrid Mold Technique through Combined Insert Polymeric Material and Additive Manufacturing Method Design. Sustainability 2022, 14, 877. [Google Scholar] [CrossRef]

- Korkees, F.; Aldrees, A.; Barsoum, I.; Alshammari, D. Functionalised Graphene Effect on the Mechanical and Thermal Properties of Recycled PA6/PA6,6 Blends. J. Compos. Mater. 2021, 55, 2211–2224. [Google Scholar] [CrossRef]

- Chen, C.-W.; Ranganathan, P.; Mutharani, B.; Shiu, J.-W.; Rwei, S.-P.; Chang, Y.-H.; Chiu, F.-C. Synthesis of High-Value Bio-Based Polyamide 12,36 Microcellular Foams with Excellent Dimensional Stability and Shape Recovery Properties. Polymers 2024, 16, 159. [Google Scholar] [CrossRef]

- Yekymov, Y.; Lebedev, V.; Tykhomyrova, T.; Cherkashina, H.; Kariev, A. Design and Research of a Construction-Grade Engineering Plastic Based on Recycled Polyamides and Polyphthalamides. IOP Conf. Ser. Earth Environ. Sci. 2025, 1499, 012016. [Google Scholar] [CrossRef]

| Weight [g] | ||

|---|---|---|

| Material | iQ Weight Control System Deactivated | iQ Weight Control System Activated |

| Virgin Material | 61.576 ± 0.024 | 61.507 ± 0.027 |

| 50% Regrind Blend | 62.585 ± 0.067 | 61.320 ± 0.074 |

| Material | Measured Parameter | iQ Weight Control System Deactivated | iQ Weight Control System Activated |

|---|---|---|---|

| Virgin Material | Weight [g] | 18.83 ± 0.01 | 18.82 ± 0.01 |

| Flow Length [mm] | 48.65 ± 0.04 | 48.66 ± 0.05 | |

| 50% Regrind Blend | Weight [g] | 19.07 ± 0.03 | 18.85 ± 0.02 |

| Flow Length [mm] | 49.32 ± 0.14 | 48.72 ± 0.01 | |

| 100% Regrind | Weight [g] | 19.36 ± 0.01 | 18.84 ± 0.04 |

| Flowe Length [mm] | 50.10 ± 0.16 | 48.81 ± 0.05 |

| iQ Weight Control Deactivated | iQ Weight Control Activated | ||||

|---|---|---|---|---|---|

| Dimension | Virgin Material | 50% Virgin Material/50% Regrind Blend | Virgin Material | 50% Virgin Material/50% Regrind Blend | |

| Dog-bone Specimen | A | 20.0647 ± 0.0080 | 20.0437 ± 0.0111 | 20.0563 ± 0.0203 | 20.0314 ± 0.0236 |

| B | 10.0532 ± 0.0185 | 10.0601 ± 0.0222 | 10.0399 ± 0.0119 | 10.0194 ± 0.0140 | |

| C | 4.0591 ± 0.0096 | 4.0464 ± 0.0085 | 4.0612 ± 0.0071 | 4.0348 ± 0.0085 | |

| Rectangular Specimen | A | 10.0158 ± 0.0259 | 9.9779 ± 0.0169 | 9.9654 ± 0.0207 | 9.9749 ± 0.0204 |

| B | 4.0053 ± 0.0106 | 3.9989 ± 0.0119 | 3.9985 ± 0.0149 | 3.9962 ± 0.0081 | |

| iQ Weight Control System Deactivated | iQ Weight Control System Activated | ||||

|---|---|---|---|---|---|

| Indicator | Virgin Material | 50% Virgin Material/50% Regrind Blend | Virgin Material | 50% Virgin Material/50% Regrind Blend | |

| Dog-bone Specimen | PpA | 8.1861 | 6.0914 | 2.8386 | 3.313 |

| PpkA | 5.5297 | 4.7513 | 2.3887 | 2.3754 | |

| Rectangular Specimen | PpA | 2.5599 | 3.9583 | 3.2502 | 3.2726 |

| PpkA | 2.3551 | 3.5249 | 2.6912 | 2.8651 | |

| Material/System Activation Status | Fmax [N] | ak [kJ/m2] |

|---|---|---|

| Virgin Material/iQ System Deactivated | 547.56 ± 38.43 | 9.50 ± 1.09 |

| Virgin Material/iQ System Activated | 584.24 ± 33.78 | 10.78 ± 1.43 |

| 50% Virgin Material/ 50% Regrind Blend iQ/System Deactivated | 519.39 ± 14.46 | 9.26 ± 0.74 |

| 50% Virgin Material/ 50% Regrind Blend/iQ System Activated | 588.72 ± 59.20 | 9.73 ± 1.08 |

| iQ Weight Control Deactivated | iQ Weight Control Activated | |||

|---|---|---|---|---|

| Parameter | Virgin Material | 50% Virgin Material/ 50% Regrind | Virgin Material | 50% Virgin Material/ 50% Regrind |

| Tensile Strength [MPa] | 197.8 ± 1.3 | 185.4 ± 0.9 | 194.6 ± 1.1 | 188.4 ± 0.9 |

| Young’s Modulus [MPa] | 8684 ± 731 | 4982 ± 1110 | 3364 ± 982 | 2750 ± 577 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olszewski, T.; Matykiewicz, D.; Jakubowicz, M. Impact of Adaptive Process Control on Mechanical Properties of Plastic Parts and Process Robustness. Appl. Sci. 2025, 15, 8829. https://doi.org/10.3390/app15168829

Olszewski T, Matykiewicz D, Jakubowicz M. Impact of Adaptive Process Control on Mechanical Properties of Plastic Parts and Process Robustness. Applied Sciences. 2025; 15(16):8829. https://doi.org/10.3390/app15168829

Chicago/Turabian StyleOlszewski, Tomasz, Danuta Matykiewicz, and Michał Jakubowicz. 2025. "Impact of Adaptive Process Control on Mechanical Properties of Plastic Parts and Process Robustness" Applied Sciences 15, no. 16: 8829. https://doi.org/10.3390/app15168829

APA StyleOlszewski, T., Matykiewicz, D., & Jakubowicz, M. (2025). Impact of Adaptive Process Control on Mechanical Properties of Plastic Parts and Process Robustness. Applied Sciences, 15(16), 8829. https://doi.org/10.3390/app15168829