1. Introduction

The significant decline in bread consumption in recent years has driven the baking industry to seek innovative strategies to diversify its product range and enhance overall bread quality [

1,

2]. At the same time, growing consumer awareness of the connection between diet and health has fueled demand for clean-label bakery products with functional or nutritional benefits [

3]. In traditional breadmaking, dairy ingredients such as cow’s milk have often been used as natural improvers, contributing positively to crumb softness, loaf volume, and sensory appeal. However, the increasing prevalence of food allergies and intolerances, as well as the rising popularity of plant-based diets, has created a strong impetus for the development of dairy-free alternatives [

4].

Among plant-based substitutes, both cereal- and nut-based beverages have gained attention for their nutritional and functional potential. Cereal beverages such as those derived from oat, millet, and spelt have shown promising results in improving fiber content, antioxidant activity, and water-binding properties in bread [

5,

6,

7]. These beverages not only influence the nutritional profile of the final product, but also affect key dough properties—such as water absorption, mixing tolerance, gluten network development, and gas retention—that are essential for baking performance and bread shelf life. Tools such as farinograph analysis and texture profile analysis (TPA) provide valuable insights into these changes, guiding formulation strategies for functional breadmaking.

In parallel, nut-based beverages produced from almonds, hazelnuts, and walnuts offer a rich matrix of nutrients, including unsaturated fatty acids, dietary fiber, vitamins, and polyphenols [

8]. Their use in baking applications may improve not only the nutritional value but also the rheological behavior of dough and the texture, aroma, and visual appeal of bread. Yet, research on the application of nut-based beverages in breadmaking remains limited compared to cereal-based alternatives.

The objective of this study was to evaluate the effects of replacing water with nut-based beverages—specifically those derived from almonds, hazelnuts, and walnuts—on the technological quality and sensory acceptability of wheat bread. The investigation included a comprehensive analysis of dough rheology, baking performance, crumb texture and porosity, color attributes, chemical composition, and consumer acceptance. By integrating nutritional and technological perspectives, this research contributes to the development of functional, plant-forward bakery products in alignment with current health and sustainability trends.

2. Materials and Methods

2.1. Materials

The wheat flour used as the main ingredient in this study was type 750 and was sourced from a local supermarket in Lublin, Poland. Its analytical parameters were as follows: moisture content of 12.9% ± 0.5, ash content of 0.74% on a dry basis (d.b.), wet gluten content of 25.0% ± 1.1, dry gluten content of 8.9% ± 0.3, gluten water absorption capacity of 16.2% ± 1.1, gluten index of 99.0 ± 0.5, and a falling number of 290 ± 18 s. In terms of granulation, 99% of the flour particles were smaller than 0.2 mm. According to the manufacturer’s nutritional declaration (per 100 g of product), the flour contained 1.8 g of fat (including 0.4 g of saturated fatty acids), 71 g of carbohydrates (with sugars < 0.5 g), 2.9 g of dietary fiber, 12 g of protein, less than 0.01 g of salt, and an energy value of 1427 kJ.

The plant-based beverages employed in this experiment comprised commercially available walnut (BW), hazelnut (BH), and almond (BA) beverages, all produced by OraSi, Unigra S.r.l., based in Conselice, Italy.

The walnut beverage was formulated with water, 3.8% walnuts, cane sugar, calcium carbonate, stabilizing agents (locust bean gum, gellan gum), sea salt, flavorings, and vitamins E, B2, D, and B12. As per the label, 100 mL of the beverage contained 2.6 g of fat (including 0.2 g saturated fatty acids), 4.3 g of carbohydrates (3.9 g sugars), 0.4 g of dietary fiber, 0.6 g of protein, 0.13 g of salt, and provided 179 kJ of energy. It also delivered 3.6 mg of vitamin E, 0.21 mg of vitamin B2, 0.75 µg of vitamin D, 0.38 µg of vitamin B12, and 120 mg of calcium. The product was free from lactose.

The hazelnut beverage contained water, 3.5% hazelnuts, cane sugar, calcium carbonate, stabilizers (locust bean gum and gellan gum), sea salt, flavorings, and vitamins E, riboflavin (B2), D, and B12. Its nutritional content per 100 mL was as follows: 2 g of fat (0.1 g saturated fatty acids), 3.8 g of carbohydrates (3.3 g sugars), 0.5 g of dietary fiber, 0.5 g of protein, 0.18 g of salt, and an energy value of 160 kJ. Additionally, it contained 1.8 mg of vitamin E, 0.21 mg of vitamin B2, 0.75 µg of vitamin D, 0.38 µg of vitamin B12, and 120 mg of calcium. Lactose was not present.

The almond-based beverage included water, 4.5% almonds, cane sugar, calcium carbonate, locust bean gum and gellan gum as stabilizers, sea salt, natural flavorings, and vitamins E, B2, D, and B12. According to the manufacturer’s data, 100 mL of the beverage provided 2.5 g of fat (of which 0.2 g were saturated fatty acids), 5.2 g of carbohydrates (4.9 g sugars), 0.6 g of fiber, 1 g of protein, and 0.15 g of salt. The energy value was 203 kJ. It also contained 1.8 mg of vitamin E, 0.21 mg of vitamin B2, 0.75 µg of vitamin D, 0.38 µg of vitamin B12, 120 mg of calcium, and no lactose.

2.2. Bread Making Procedure

In total, 13 bread variants were developed, differing in the percentage of water replaced with one of the plant-based beverages: BW (walnut), BH (hazelnut), or BA (almond). The reference sample (CON) consisted solely of wheat flour and water, without the addition of any plant-derived beverage. For each beverage type, four experimental formulations were created by substituting water at levels of 25%, 50%, 75%, and 100%. Each formula was used to bake three loaves in two independent baking sessions, yielding six loaves per formulation. The sample codes reflect the beverage type and level of substitution (e.g., BW25, BW50, BW75, BW100).

The base bread formulation included 600 g of wheat flour, 9 g of salt, and 18 g of compressed yeast (Saccharomyces cerevisiae), along with a defined quantity of liquid—either water or a water–plant-based beverage mixture—adjusted individually for each formula. Liquid amounts were calibrated according to farinograph-derived water absorption (WA) values to achieve a dough consistency of 500 Brabender Units.

The bread-making procedure followed a straight dough method adapted from Zarzycki et al. [

9]. Ingredients were mixed using a BEAR Varimixer Teddy 5 L (Varimixer A/S, Brondby, Denmark), starting with 3 min at low speed (setting 1), then continuing at high speed until the optimal dough structure was obtained. Mixing time varied and was determined based on farinographic analysis to ensure proper gluten network formation. The dough was fermented in a proofing chamber (Tefi Klima Pro 100, De-bag, Bautzen, Germany) at 30 °C and 85 ± 2% relative humidity for a total of 90 min. After 60 min of fermentation, the dough underwent a short punching process (30 s at low speed). Subsequently, it was manually portioned into 290 ± 5 g pieces, shaped, and placed in baking tins measuring 18 × 7.5 × 7.0 cm. The final proofing lasted 30 min under the same controlled conditions. Fermentation time was individually recorded for each variant.

Baking was carried out using a Helios Pro 100 oven (De-bag, Germany) at 230 °C for 30 min. After baking, the loaves were cooled at room temperature (approx. 20 °C) for 1 h, weighed, individually packed in sealed plastic bags, and stored at ambient conditions (20 °C, 50% RH) until further testing.

2.3. Farinograph Properties of Dough

Farinographic analysis was conducted to determine the rheological characteristics of wheat doughs prepared using either water or mixtures of water and plant-based beverages at substitution levels of 0%, 25%, 50%, 75%, and 100%. The evaluated parameters included water absorption (WA), defined as the amount of liquid required to achieve a dough consistency of 500 farinograph units (FUs); dough development time (DDT), indicating the time needed to reach maximum consistency; stability time (ST), representing the duration during which the dough maintains its peak consistency; dough softening (DS), measured as the reduction in dough resistance 12 min after the peak is reached; and the farinograph quality number (FQN), which serves as a composite indicator of overall dough quality.

All measurements were performed using a Farinograph-TS (Brabender, model 816100, Duisburg, Germany) in accordance with AACC Method 54-21 [

10]. The procedure was based on a constant flour mass, with each determination using 300 ± 0.1 g of flour standardized to 14% moisture content. To ensure analytical precision and result reproducibility, each measurement was carried out in triplicate.

2.4. Evaluation of Bread Quality Characteristics

Evaluation of bread quality encompassed a set of physical and structural characteristics, including bread yield (BY, Equation (1)), baking loss (BL, Equation (2)), loaf volume, specific volume, crumb porosity, and crumb moisture content. All measurements were performed 24 h post-baking, with the exception of crumb moisture, which was additionally assessed after 72 h of storage. Each analysis was conducted in triplicate to ensure data reliability.

The moisture content of the bread crumb was determined in accordance with AACC Method 44-15.02 [

10]. Loaf volume was established using the rapeseed displacement technique, following AACC Method 10-05.01. Specific volume was calculated as the ratio of loaf volume (in cm

3) to loaf weight (in grams).

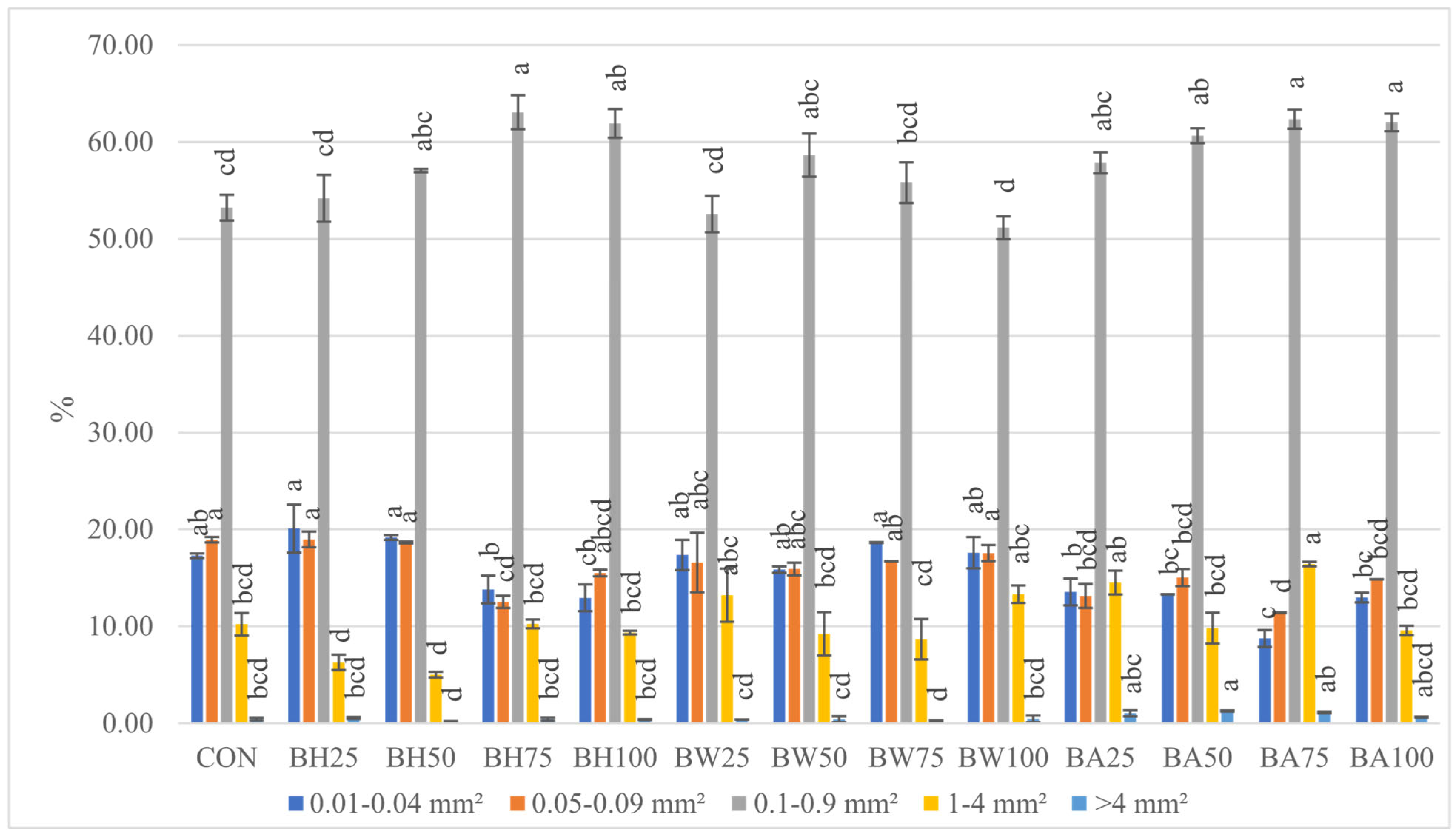

Crumb porosity was analyzed using a VHX-7000 digital microscope (Keyence, Osaka, Japan) equipped with dedicated image analysis software. Measurements were carried out on 4 × 4 cm cross-sections obtained from the central region of each bread slice. Imaging was performed at 20× magnification, with 0° viewing angle and ring-light illumination. Pore structure was evaluated using the automatic grain measurement function based on brightness thresholding, further refined with a hole-filling algorithm to enhance detection accuracy. Only pores with a diameter of at least 0.01 mm were included in the analysis. Each bread formulation was analyzed in triplicate. For each sample, both the number and total area of pores were recorded. Pore sizes (expressed in mm2) were classified into five categories: 0.01–0.04 mm2, 0.05–0.09 mm2, 0.1–0.9 mm2, 1–4 mm2, and above 4 mm2. Within each category, the number of pores and their cumulative surface area were calculated and expressed as a percentage of the total pore count and total pore area.

The formulas used to calculate bread yield and baking loss were as follows:

In these equations, W1 denotes the mass of the baked bread measured one hour after baking, W2 refers to the mass of flour used for a single loaf, and W3 represents the mass of the dough prior to baking (recorded immediately before insertion into the oven).

2.5. Evaluation of Color Parameters of Bread Crumb

Crumb color was assessed using the method outlined by Wirkijowska et al. [

11]. The measurements were performed with a spherical spectrophotometer (Chroma Meter CR-5, Konica Minolta, Sakai, Osaka, Japan), which recorded the L*, a*, and b* coordinates within the CIE Lab color system. The L* value corresponds to brightness (ranging from 0 for black to 100 for white), a* reflects the red–green axis (positive values indicate red, negative indicate green), and b* describes the yellow–blue axis (positive for yellow, negative for blue). Each bread variant enriched with nut-based beverages (BW, BH, and BA) was subjected to 12 independent measurements.

Prior to analysis, the spectrophotometer was calibrated using standard white and black reference tiles. Color data were collected under standardized conditions, including D65 illumination, a 10° standard observer, and an 8 mm aperture size.

The overall color difference (ΔE*) between control and test samples was computed according to Equation (3), where L

c*, a

c*, and b

c* denote the color values of the control sample, and Li*, ai*, and bi* correspond to the values of the enriched samples. In addition, indices such as whiteness (WI), yellowness (YI), and browning (BI) were calculated based on L*, a*, and b* values, following Equations (4), (5), and (6), respectively, in accordance with the method described by Felisiak et al. [

12].

2.6. Texture Profile Analysis (TPA) of Bread

The texture profile of the bread crumb was evaluated following the methodology adapted from Wirkijowska et al. [

11]. In preparation for the analysis, loaves were sliced into sections 20 mm thick, from which the crust was carefully removed. Cuboid samples measuring 30 × 30 × 20 mm were then cut from the crumb for testing. A double compression test was performed using a Brookfield AMETEK CTX texture analyzer (Brookfield, Middleboro, MA, USA), equipped with a flat cylindrical probe (50 mm diameter) and configured to apply a maximum force of 500 N.

The testing protocol included compression to 50% of the original sample height, a crosshead speed of 1 mm/s, and a trigger load set at 0.98 N. From the generated force–deformation curves, key textural attributes were derived using Texture Pro software (version 1.0.19 Standard Edition). These parameters included hardness [N], defined as the peak force during the initial compression; springiness [–], calculated as the ratio of the second deformation height to the first; cohesiveness [–], representing the ratio of the area under the second compression curve to that of the first; and chewiness [N], determined as the product of hardness, springiness, and cohesiveness.

Texture measurements were performed at two time points—24 and 72 h after baking. Each bread variant was analyzed in eight independent replicates to ensure robustness and repeatability of the data.

2.7. Sensory Evaluation of Bread

Sensory evaluation was carried out to assess the quality of wheat bread enriched with nut-based plant beverages—specifically walnut, hazelnut, and almond—used as partial or complete substitutes for water. The assessment employed a five-point hedonic scale (1 = “dislike extremely”, 5 = “like extremely”) and was conducted in accordance with the ISO 8586:2012 [

13] guidelines concerning the recruitment and training of sensory panelists, as well as ISO 8589:2007 [

14] standards governing the environmental conditions of sensory laboratories.

The evaluation panel comprised 12 trained individuals (9 women and 3 men), all affiliated with the University of Life Sciences in Lublin. Eligibility criteria for participation included frequent bread consumption (at least four times weekly), good overall health status, and absence of gluten intolerance. The study protocol received ethical approval from the institutional Bioethics Committee (Resolution No. UKE/09/2023).

All sensory tests were performed under standardized laboratory conditions with controlled lighting, temperature, and humidity. Bread loaves were mechanically sliced into 1 cm-thick portions, which were then randomly coded and presented to the panelists in a randomized sequence. Still mineral water was provided to cleanse the palate between sample evaluations.

Panelists assessed the following sensory attributes: external appearance, crumb color, elasticity and porosity, aroma, flavor, and overall acceptability. Each sample was evaluated twice by each participant. Final scores were calculated as the arithmetic mean of all ratings obtained for a given sample across all assessed attributes.

In interpreting the results, an average sensory score above 3.75 was considered indicative of high acceptability. This value corresponds to an acceptability index (AI) of 75%, which, according to the classification proposed by Lukas et al. [

15], is the threshold at which a product is deemed sensorially acceptable. This benchmark was used to determine whether each bread variant could be classified as acceptable or highly acceptable from a consumer perspective.

2.8. Chemical Composition of Raw Materials and Breads

The chemical composition of both the initial raw materials and the final bread products obtained from different formulations was determined in accordance with standardized procedures outlined by the AACC and AOAC [

10,

16]. The analyses included the measurement of moisture content (AACC Method 44-15A), ash content (AACC Method 08-01), and total protein using the Kjeldahl method (AACC Method 46-08), applying a nitrogen-to-protein conversion factor of N × 5.7. Fat determination was conducted following AACC Method 30-26. Total dietary fiber content was assessed using AOAC protocols 991.43 and 985.29, supported by corresponding AACC methods (32-07, 32-21, and 32-05).

The available carbohydrate content was estimated by difference, subtracting the total values of protein, fat, moisture, ash, and dietary fiber from the fresh weight of the sample. The energy content was calculated using the Atwater conversion factors: 4 kcal/g for protein and carbohydrates, 9 kcal/g for fat, and 2 kcal/g for dietary fiber. All compositional analyses were carried out in triplicate to ensure accuracy and reproducibility of the results.

2.9. Statistical Analysis

All results are presented as arithmetic means with corresponding standard deviations. Statistical differences among the samples were evaluated using one-way analysis of variance (ANOVA), followed by Tukey’s post hoc test to determine significant pairwise differences. A significance level of p ≤ 0.05 was adopted for all comparisons. Data analysis was conducted using Statistica software (version 13.3, StatSoft Inc., Tulsa, OK, USA). To ensure reliability and reproducibility, each parameter was determined in a minimum of three independent replicates.

3. Results and Discussion

3.1. Farinograph Properties of Dough

The replacement of water with nut-based plant beverages significantly affected the farinographic characteristics of wheat dough (

Table 1). All tested beverages—hazelnut, walnut, and almond—led to an increase in water absorption (WA), with values ranging from 58.0% in BH25 to 64.2% in BW100, compared to 56.9% in the control sample (CON). This increase can be attributed to the presence of hydrophilic compounds such as soluble dietary fiber, proteins, and emulsifiers commonly found in nut beverage formulations, which enhance the dough’s water-binding capacity [

8,

17,

18].

Dough development time (DDT) also increased with higher substitution levels, particularly in samples containing walnut beverage. The longest DDT was observed in BW100 (5.9 min), compared to 4.1 min in the control dough. This effect may be linked to the delayed formation of the gluten network due to interactions between gluten and proteins or polysaccharides present in the walnut beverage. Dough stability (ST) also improved significantly, reaching 10.8 min in BW100, versus 7.3 min in the control. Similar trends were observed, although to a lesser extent, in BH and BA formulations. Enhanced stability indicates a stronger and more tolerant dough structure, likely supported by lipid content and protein-polysaccharide interactions from the nut-based beverages.

A longer DDT and higher stability time are both indicative of improved gluten strength, enhanced dough tolerance to mixing, and better capacity to retain CO

2 during fermentation—properties that are favorable for breadmaking [

17,

19]. In contrast, Rashed et al. [

20] reported an opposite trend when using oat beverage residue flour, observing a significant (

p < 0.05) reduction in both dough development time and stability. This negative effect was attributed to the high solid content in the oat residue, which likely diluted gluten proteins and impaired dough structure.

Dough softening (DS) was generally reduced in the experimental variants, especially those with walnut beverage, where values dropped to as low as 49 FU in BW100 compared to 61.5 FU in the control. Lower DS values indicate improved dough resistance to mechanical stress, which enhances processing tolerance and helps maintain dough quality during standard or slightly extended mixing conditions in industrial production.

The farinograph quality number (FQN), a composite indicator of overall dough performance, was significantly enhanced in walnut-enriched samples—reaching 124 in BW100 and 121 in BW75—demonstrating the positive impact of walnut beverage on dough functionality. Almond and hazelnut beverages also contributed to FQN improvement, albeit to a lesser extent (101 for BH100, 88 for BA100).

These results suggest that nut-based beverages—especially walnut beverage—have the potential to function as partial water substitutes in wheat dough formulations, particularly at higher substitution levels (75–100%), where improvements in dough rheology and processing tolerance were observed.

3.2. Evaluation of Bread Quality Characteristics

The substitution of water in bread formulations with nut-based plant beverages had a marked effect on the physical properties of the bread. A positive correlation was observed between the amount of plant beverage added and bread yield, which is consistent with findings reported in the literature [

21]. Compared to the control sample (CON), which exhibited a baking yield of 139.9%, all tested variants with nut-based beverages showed a higher yield (

Table 2). The greatest increases were recorded in breads with 100% walnut beverage (BW100–147.6%) and almond beverage (BA100–146.7%).

This effect can be attributed to improved water-binding capacity in the dough, likely due to the presence of hydrophilic components such as soluble dietary fiber and emulsifiers, which are commonly used in the production of these beverages to stabilize their suspensions [

8,

22]. Additionally, the protein properties of plant-based beverages may also influence water absorption and, consequently, bread yield. Studies have demonstrated that protein fibers in walnut beverages exhibit higher viscosity and gelation ability than unmodified proteins, due to the formation of entangled network structures [

23]. These protein characteristics may also contribute to the observed reduction in baking losses.

Notably, breads enriched with the highest levels of almond beverage (BA75, BA100) exhibited significantly lower baking losses (11.4%) compared to the control, potentially indicating improved moisture retention during thermal processing. This effect may be partially related to the presence of lipids and stabilizing additives naturally present in commercial almond beverage formulations (e.g., gums and emulsifiers), which may contribute to improved moisture retention during baking [

8,

24].

Specific loaf volume, a key quality indicator reflecting aeration and crumb structure, did not differ significantly between the control sample (3.09 cm

3/g) and the breads supplemented with nut beverages. This suggests that nut-based beverages, particularly at moderate to high levels, may support the formation of a porous crumb structure—likely through the contribution of additional lipids acting as surface-active agents [

25].

Moisture content in the crumb after 24 h of storage did not differ significantly between the control sample (43.3%) and the nut beverage-enriched breads, with the exception of samples BH100 and BA100 (

Table 2). After 72 h of storage, no significant differences were observed—all samples maintained moisture within the range of 40.4–42.4%. This high crumb moisture content likely results from the incorporation of dietary fiber, gums, and emulsifiers via the nut beverages, which are known for their gelling and water-retaining properties [

22,

23].

In all analyzed samples, the most numerous group of pores were those with a surface area of 0.1–0.9 mm

2. The share of this fraction in the total number of pores ranged from 51.16% (BW100) to 63.06% (BH75), indicating the dominant presence of medium-sized pores regardless of the sample composition (

Figure 1). Simultaneously, this fraction also contributed the most to the total pore surface area, which increased with the level of substitution, reaching as much as 62.14% in the BA100 sample. This structure highlights the key role of medium-sized pores in crumb architecture and bread volume. The abundance of pores of this size facilitates uniform gas distribution in the dough and positively influences the texture and elasticity of the crumb, as previously shown in studies on the structure of wheat bread [

26].

In the control sample (CON), the proportion of 0.1–0.9 mm

2 pores accounted for 53.2% of the total pore number and 37.66% of the total surface area. However, the highest surface percentage was attributed to larger pores in the 1–4 mm

2 range (43.34%), which may suggest a more open structure with fewer but larger pores (

Figure 2). A similar trend was observed in the hazelnut beverage samples at lower substitution levels (BH25 and BH50), where the surface contribution of the 1–4 mm

2 fraction was 31.48% and 28.17%, respectively. However, with increasing substitution levels in BH75 and BH100, a progressive increase in the share of 0.1–0.9 mm

2 pores was observed both in number (up to 63.06%) and in surface area (up to 46.52%), accompanied by a decrease in the share of the largest pores. This suggests that hazelnut beverage stabilized the crumb structure by promoting the development of more uniform pores, possibly due to the presence of proteins and lipids [

27,

28].

In the samples with walnut beverage (BW), the share of 0.1–0.9 mm2 pores in total pore number was also high (up to 58.65% in BW50), and the surface share of this fraction increased to 49.54% in BW100. A distinctive feature of these samples was the high contribution of pores in the 1–4 mm2 range—especially in BW25 and BW100 (47.17% and 47.54%). At the same time, the share of pores >4 mm2 remained low.

The most pronounced differences were observed in the almond beverage samples (BA). In terms of pore number, the 0.1–0.9 mm

2 fraction dominated at all substitution levels, reaching a maximum of 62.35% in BA75. A similar trend was observed for pore surface area, with the highest values of this fraction recorded in BA100 (62.14%). Simultaneously, the share of the largest pores (>4 mm

2) increased significantly in BA25 and BA75, accounting for 12.1% and 11.62% of the total pore surface area, respectively—these being the highest values among all samples tested. Such a structure may result from the high content of simple sugars and low protein content in almond beverage, which promotes more intense fermentation and the formation of larger gas bubbles (

Table 3) [

29].

3.3. Texture Profile Analysis (TPA) of Bread

The texture profile analysis (TPA) of wheat breads enriched with nut-based beverages was conducted at 24 and 72 h after baking, with results summarized in

Table 3. Four key texture parameters were evaluated: hardness, springiness, cohesiveness, and chewiness. As expected, storage time significantly influenced all textural attributes, with marked differences depending on the type and level of substitution.

Hardness, an indicator of crumb firmness and staling, increased significantly over time across all variants. At 24 h, the hardness of the control sample was 9.7 N, while samples ranged from 8.2 N (BA100) to 10.8 N (BH50). Notably, breads containing hazelnut beverage (BH25 and BH75) exhibited the highest hardness after 72 h (17.2 N and 17.9 N, respectively), suggesting accelerated staling. This effect may be linked to phenolic compounds in hazelnuts, which can reduce water mobility and strengthen protein-starch interactions. These findings are consistent with previous studies where fiber-rich or polyphenol-containing ingredients contributed to a firmer crumb structure during storage. Bartkiene et al. [

7] also reported a reduction in hardness over time with fermented and ultrasonicated almond, oat, and chickpea by-products, suggesting that specific processing methods can mitigate crumb firming.

Springiness, reflecting crumb elasticity, was well preserved in most samples. The control remained stable (0.86) over 72 h, and comparable values were observed in walnut- and almond-based breads, especially BW25–BW50 and BA50 (0.89–0.90). However, samples with high hazelnut beverage content (BH75–BH100) exhibited a reduction in springiness to 0.83–0.85, likely due to impaired gluten network development. This trend mirrors earlier findings by Rashed et al. [

20] and Dürrenberger et al. [

30], where increased fiber or non-gluten protein components reduced crumb elasticity due to dough densification and reduced gas retention.

Cohesiveness, representing the internal structural integrity, showed a slight decline during storage in all samples. The control sample maintained the highest cohesiveness (0.62 at 24 h), while BH75 dropped to 0.39 after 72 h—indicating possible disruptions to the gluten matrix by hazelnut-derived components. In contrast, breads with almond and walnut beverages demonstrated more stable cohesiveness, aligning with Bartkiene et al. [

7], who observed that fermented almond and oat by-products helped maintain structural stability during extended storage.

Chewiness, a compound measure derived from hardness, springiness, and cohesiveness, was highest in BH25 and BH50 at 24 h (5.83 and 5.28 N, respectively), indicating denser, more resistant crumbs. After 72 h, chewiness slightly increased in most BH variants, while a decline was observed in BA100 and BW50. These changes reflect the interplay of firmness and elasticity over time, with BA- and BW-enriched breads offering greater resilience to staling. This finding is in agreement with studies on cereal-based breads where higher chewiness was associated with faster crumb firming, particularly in samples with lower fiber or lipid contributions.

Overall, the data suggests that walnut and almond beverages at moderate substitution levels (25–50%) enhance textural stability during storage, preserving softness and elasticity. Conversely, high levels of hazelnut beverage may compromise structural resilience, especially over extended periods. These observations align with prior reports that emphasize the role of beverage composition—especially fiber and emulsifier content—in modulating bread texture during storage.

3.4. Evaluation of Color Parameters of Bread Crumb

Crumb color is an essential sensory attribute of bread that strongly influences consumer perception and acceptability [

31]. In this study, crumb lightness (L*) was significantly affected by the type and proportion of the nut-based beverage used for water substitution (

Table 4). The lightest crumb was observed in the BH50 sample (65.0), while the darkest was recorded in BW100 (51.1). A progressive decrease in lightness was evident with increasing levels of walnut beverage (BW), which can be attributed to the naturally darker pigmentation of the beverage. This dark tone results from pigments such as juglone, found in walnut shells, which impart a brownish hue [

32]. In contrast, breads prepared with hazelnut (BH) and almond (BA) beverages maintained L* values close to that of the control sample (63.7), particularly at lower substitution levels.

Analysis of the a* parameter (red–green axis) revealed that walnut beverage substantially increased crumb redness, peaking in the BW100 sample (4.9). This can be linked to the presence of anthocyanins in walnuts [

33]. Other samples, including those with hazelnut and almond beverages, retained low a* values near the control level (0.7), indicating that these beverages had minimal impact on red pigmentation.

Regarding the b* parameter (yellowness), a significant increase was observed in samples with hazelnut and almond beverages—particularly in BA50 (17.5) and BH100 (16.6). This effect likely stems from the natural presence of carotenoids in almonds and hazelnuts, which impart a yellowish tint [

34,

35]. In contrast, the lowest b* values were recorded in breads with walnut beverage, especially BW25 (11.3), suggesting limited influence on yellow coloration.

The total color difference (ΔE), calculated relative to the control, confirmed the visible impact of walnut beverage on crumb appearance. The ΔE value in BW100 reached 13.3, indicating a strong and clearly perceptible color shift. In contrast, ΔE values in BH and BA samples remained below 5, suggesting a more subtle deviation from the control crumb color.

The whiteness index (WI) followed a similar pattern: the lowest WI values were found in BW100 (49.0) and BW75 (50.1), consistent with the darkening effect observed in L* values. BH and BA samples retained WI values comparable to the control, further confirming their limited impact on crumb brightness.

The browning index (BI) reached its highest level in BW100 (37.7), indicating increased Maillard reaction activity and caramelization, likely influenced by the presence of reducing sugars and polyphenols in walnut beverage [

36,

37]. On the other hand, the yellowness index (YI) was highest in BH75 (40.5) and BA50 (38.8), reflecting the naturally light-yellow hue of the corresponding nut-based beverages.

3.5. Sensory Evaluation of Bread

The sensory evaluation of bread enriched with plant-based beverages derived from hazelnuts, walnuts, and almonds (used as water substitutes at 25–100%) revealed consistently high consumer acceptance across all tested formulations. All bread variants achieved average acceptability scores exceeding 4.3 on a 5-point hedonic scale for attributes including appearance, color, aroma, taste, crumb elasticity, and porosity (

Table 5), indicating a generally favorable sensory profile.

The highest sensory ratings were recorded for bread made with 100% walnut beverage substitution (BW100), which received the maximum score for appearance, flavor, and aroma, and very high ratings for crumb elasticity and porosity. This suggests a positive contribution of walnut beverage to the sensory properties of bread, likely due to its fat content and naturally aromatic compounds, which enhance both the texture and the flavor-aroma profile. Samples with partial walnut beverage substitution (BW50 and BW75) also achieved high scores across all evaluated criteria, confirming the favorable impact of walnut beverage at both moderate and high levels of inclusion.

Almond beverage–based samples (BA) were similarly well accepted by the sensory panel. All substitution levels yielded high scores (4.3–4.7), with the BA50 and BA75 variants rated particularly well for crumb porosity and elasticity (4.7 and 4.6, respectively), and an overall acceptability of 4.5. These outcomes may be attributed to the emulsifying properties and lipid content of almond beverage, which likely support gluten structure formation and impart a mild, pleasant flavor [

8,

22]. These findings align with previous reports by Bart Kiene et al. [

7], which demonstrated that the use of plant-based additives, including fermented oat and almond beverage by-products, improves overall bread acceptability without compromising aroma or crumb structure.

In contrast, breads made with hazelnut beverage (BH) received slightly lower ratings across all sensory attributes. The overall acceptability of BH variants declined with increasing substitution levels, reaching the lowest value in BH100 (4.3), which was significantly lower than the control. This reduction in sensory appeal may be linked to reduced gluten compatibility and the presence of phenolic compounds in hazelnuts. While beneficial from a nutritional standpoint, such compounds can impart bitterness and negatively affect flavor perception [

38]. Similar sensory limitations were reported by Gul et al. [

39] in hazelnut beverage–enriched yogurt formulations.

Interestingly, no adverse changes in visual appearance were reported across any nut beverage variant, despite the lack of reducing sugars that typically participate in Maillard reactions. This contrasts with earlier observations by Iuga et al. [

40], who found intensified crust browning in breads enriched with milk or acid whey due to lactose-driven Maillard reactions. In the present study, the pleasant crust coloration observed in nut beverage breads may be due to natural pigments and lipid–amino acid interactions that mimic Maillard-like effects during baking.

In summary, the substitution of water with nut-based beverages did not negatively affect bread’s sensory characteristics. On the contrary, walnut and almond beverages notably enhanced flavor, aroma, and crumb structure, offering a promising alternative for clean-label bakery products with high consumer acceptance.

3.6. Chemical Composition of Raw Materials and Bread

The chemical composition of the raw materials used in bread production revealed notable differences between wheat flour and the nut-based plant beverages. The ash content of wheat flour (WF) was 0.79% d.b., while in the plant-based beverages it ranged from 1.63% d.b. for walnut (BW) and almond (BA) beverages to 2.82% d.b. in the hazelnut beverage (BH)—representing a more than 3.5-fold increase compared to wheat flour. These variations were reflected in a significant increase in the ash content of the breads as the substitution level increased (

Table 6). The highest ash content was recorded in BH100 (2.39% d.b.). These results align with previous findings by Alozie Yetunde and Udofia [

41], who reported an ash content of 3 g/100 mL in almond milk. The protein content of the tested ingredients also varied considerably, ranging from 7.49% d.b. in hazelnut beverage (BH) to 13.43% d.b. in wheat flour. Among the beverages, BA had the highest protein content (11.44% d.b.). These values are notably lower than those reported by Oh and Lee [

42], who observed higher protein contents in almond (18.91%), hazelnut (18.11%), and walnut beverages (15.57%)—differences that may stem from variability in raw material concentration and processing techniques. As expected, the plant-based beverages exhibited high fat contents, ranging from 26.25% d.b. in BA to 32.38% d.b. in BW. These findings are consistent with known nutritional profiles of nuts, which are rich in unsaturated fatty acids: monounsaturated fatty acids (MUFAs) predominate in almonds and hazelnuts, while polyunsaturated fatty acids (PUFAs), particularly omega-6, are dominant in walnuts [

43]. The highest total dietary fiber content was found in BA (6.35% d.b.), though still lower than the 8.99% reported by Alozie Yetunde and Udofia [

41]. The carbohydrate content across all beverages was similar, ranging between 53.12% and 54.43% d.b. In contrast, the energy value differed based on fat levels—ranging from 36.71 kcal/100 g d.b. in BH to 49.11 kcal/100 g d.b. in BA.

In the bread samples, ash content increased proportionally with the substitution level, with statistically significant differences compared to the control (CON) observed at 50% substitution in BH and BA groups, and at 100% in BW (

p ≤ 0.05). Protein content in the bread decreased slightly with increasing levels of plant-based beverage substitution, reflecting the lower protein content of the beverages compared to wheat flour. However, these changes were not statistically significant. In contrast, fat content in bread increased significantly with any addition of plant-based beverage. Compared to the control, fat levels rose by 17% in BH25 and up to 92% in BW100. A corresponding trend was observed in the energy value of the breads, which increased from 1% (BA25) to 4% (BA100). Although modest, this increase may affect consumer perception, as products with higher caloric content are often viewed less favorably; however, it is important to note that the added energy derives primarily from nutritionally valuable unsaturated fats [

44].

4. Conclusions

The substitution of water with hazelnut, walnut, and almond beverages significantly affected the technological, structural, and chemical properties of wheat bread. All variants showed increased bread yield without compromising loaf volume or crumb moisture, while almond and walnut beverages reduced baking losses and improved water retention due to their hydrophilic components.

Nut-based beverages influenced crumb structure, with medium-sized pores (0.1–0.9 mm2) dominating across samples. Almond beverage, in particular, promoted a uniform crumb. Walnut beverage darkened the crumb due to natural pigments, whereas hazelnut and almond beverages maintained crumb lightness and enhanced yellowness.

Chemically, nut-based beverages increased ash and fat contents, with walnut breads showing the highest fat and energy values. The caloric increase was primarily due to health-promoting unsaturated fatty acids.

Overall, almond and walnut beverages demonstrate the greatest potential as functional water substitutes, enhancing both nutritional value and quality in clean-label, plant-based bread formulations.