1. Introduction

Economically advanced nations are increasingly adopting the paradigm of

precision agriculture, with

precision irrigation representing a critical subdomain. Precision irrigation leverages a suite of advanced technologies, including remote sensing, real-time soil and crop-monitoring sensors, geographic information systems (GIS), satellite imaging, and distributed computing, to deliver site-specific, time-optimized water application strategies that enhance resource use efficiency and crop productivity [

1]. The core objective is to apply a precise volume of water at the optimal time, ensuring uniform distribution while responding to the spatial and temporal heterogeneity of the field [

2].

Recent developments integrate artificial intelligence (AI) and machine learning (ML) algorithms into precision irrigation systems [

3]. These models enable predictive analytics based on historical and real-time data, supporting dynamic decision-making under uncertainty [

4,

5]. Techniques such as deep learning, convolutional neural networks (CNNs) for image-based crop health analysis, and reinforcement learning for irrigation scheduling optimization are now being employed to refine water management strategies [

6]. AI-driven platforms aggregate multi-source data like meteorological forecasts, evapotranspiration rates, and soil moisture profiles in order to autonomously adjust irrigation protocols, reducing water waste while maximizing yield. Consequently, the operational management of agricultural water resources can now account for microclimatic conditions, plant phenology, and soil hydrodynamics at a granular level, fundamentally transforming traditional agronomic practices [

7]. However, AI-based systems involve costs that small-scale farmers cannot afford [

1]. Their complex infrastructure and high-tech components or software are difficult to operate, and for this reason many local producers prefer to use classic automated irrigation systems, which are versatile (can be adapted to various field conditions) and allow for real-time responsiveness to intra-field heterogeneity [

8].

The first automated irrigation system was patented in 1958, by Issac G. Jenkins, and was first practically implemented in 1965 [

9]. Interest in site-specific irrigation grew significantly in the 1990s, especially following the development of a four-span linear move irrigation machine at Fort Collins for research purposes [

10,

11]. Parallel advancements at the University of Idaho and the University of South Carolina led to patents for variable irrigation and chemical application [

12,

13]. Washington State University contributed a programmable control system for commercial center pivot systems in 1994 [

14], which evolved to include logic-based devices. In 2000, key component-level design techniques were introduced by Buchleiter (variable-rate sprinklers), Evans (control systems), and Sadler (overall design strategies) [

15].

Irrigation Control Systems (ICS) have evolved into three main categories: model-based, sensor-based, and integrated systems. Model-based ICS rely on daily step simulations of the soil–water balance, considering inflows (precipitation, irrigation, capillary rise, interception) and outflows (runoff, evaporation, plant uptake, drainage), using meteorological, soil, and crop-specific data [

16,

17]. Sensor-based ICS monitor parameters such as soil moisture, temperature, and dielectric permittivity in real time using Time Domain Reflectometers (TDR) or Frequency Domain Reflectometers (FDR) [

18,

19,

20,

21]. These measurements are transmitted to a central processing unit, which determines the optimal irrigation scheduling based on environmental conditions and crop development stage. Irrigation is typically triggered when thresholds for water content or plant stress are reached [

22].

Integrated ICS aims to combine the advantages of both models and real-time sensors, sometimes incorporating GIS or remote sensing to fine-tune irrigation scheduling. These systems enhance model accuracy through feedback from sensor data and are typically tailored for specific crops [

23,

24,

25]. Despite these advances, fully interoperable, AI-driven, and autonomous ICS remain underdeveloped.

However, several limitations still constrain adoption and effectiveness:

The Irrigation Modular System (IMS) developed in this study provides a cost-effective, modular and cell-individualized fertigation solution utilizing Power Line Communication (PLC). Its key features include the following:

Local irrigation control at the cell level via electromechanical solenoid valves;

Real-time nutrient dosing based on conductivity-driven feedback control;

A low-cost, low-latency communication protocol that leverages existing electrical infrastructure;

Integrated wind and rainfall compensation using predictive thresholds and sensor feedback.

The proposed IMS advances the current state of the art by enabling the simultaneous monitoring and control of both irrigation and fertigation, incorporating individualized cell-level operation and applying dynamic wind and water pressure correction. The use of PLC as a communication backbone further enhances its cost-efficiency and scalability.

Few existing systems offer real-time, localized control of irrigation and fertigation alongside a robust, low-cost communication infrastructure. This study addresses that shortcoming by presenting a modular irrigation control system (ICS) based on PLC and a distributed sensor–actuator architecture.

The goal of this research is to design, implement, and validate a modular and cost-effective irrigation system with integrated nutrient management, supported by real-time environmental sensing and PLC-based communication, to enhance water and nutrient use efficiency in precision agriculture.

2. Materials and Methods

2.1. Sensor Node Architecture and Communication Framework

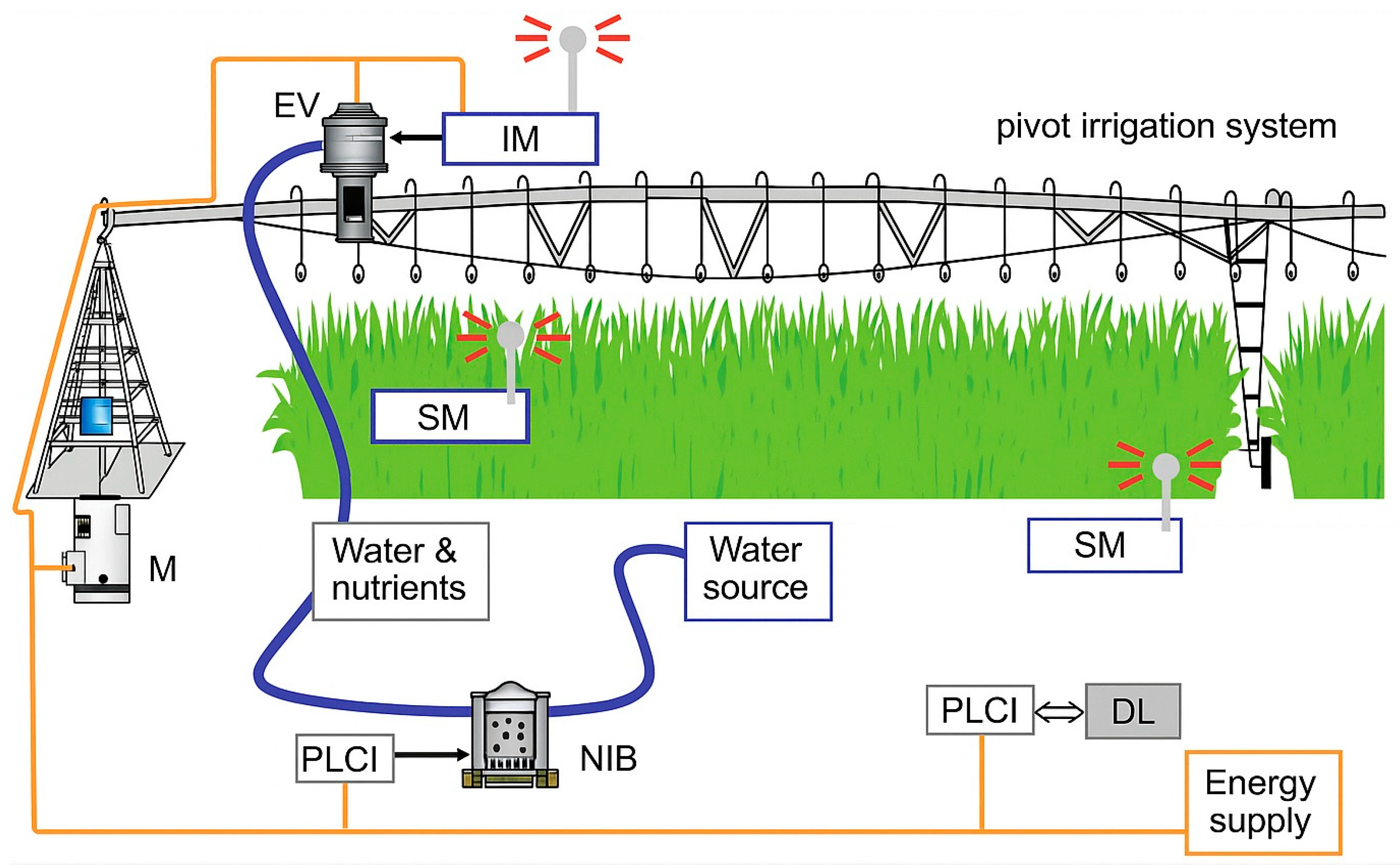

The general architecture of an automated irrigation system has two independent circuits—one for water supply and one for energy supply—as depicted in

Figure 1. The water supply circuit forms the linkage between the water source and nutrient injection batteries (NIB). This circuit becomes a combined supply circuit after the injection of nutrients and makes a connection with the spray nozzles of circular- (pivot) or linear-movement automated irrigation systems.

The energy circuit powers the pumps and the motors (M) of the automated irrigation system and provides the physical support for the data transmission. The batteries for nutrient injection are close to the pumps, as they share a common energy supply.

The IMS architecture is designed to allow for direct implementation to automated irrigation systems and is structured with the following main levels:

The level of sensor modules (SM), which are located at ground level, with the basic function of collecting the information using the attached sensors from the surrounding cell and transmitting it to the decisional level (DL);

The decisional level, based on information from the sensor modules, databases and models, sends commands to the nutrient injection batteries (NIB) regarding the concentration of nutrients and to the irrigation modules (IM) regarding the amount of the water–nutrient mixture to be sprinkled.

The irrigation module has two main functions: the radio reception of data from sensor modules and control of the water–nutrient mixture spring via electrovalves (EV).

The PLC level, based on PLC interfaces (PLCI), has as a physical support, the energy lines grid (which supplies the water pumps, electrovalves and motors) and transfers information between the decisional level on one side and the irrigation modules and nutrient injection batteries on the other side.

Preliminary tests of the PLC system showed a bit error rate (BER) of around 10−5 and effective communication of up to 500 m with typical signal attenuation (~12 dB per 100 m). Electromagnetic interference from nearby equipment was minimal, due to robust modulation and error correction.

The irrigation module is mounted on the mobile arms of the automated irrigation system and it is composed of a PLC interface, control device, radio receiver, and electrovalves. While the RF-emitted power of the sensor modules is limited to the cell radius, the irrigation module position related to cells is determined based on the maximum emission power criteria.

The irrigation control system integrates multiple sensor inputs (soil moisture, temperature, and humidity) through a rule-based decision layer to generate irrigation commands. The logic follows these steps:

Data Acquisition: Collect real-time data from all sensors.

Data Validation: Check sensor readings against predefined thresholds for plausibility.

Weighted Integration: Assign weights to each sensor based on crop requirements and environmental conditions, aggregating values into a unified irrigation need score.

Rule Application: Apply predefined irrigation rules based on the aggregated score and crop-specific parameters stored in the database.

Irrigation Command Generation: Produce irrigation timing and volume recommendations according to the evaluated rules.

At the decisional level, located on a computer server, decisions are taken in order to reach the threshold levels of nutrients and relative humidity required by the database. Through the PLC system, data are modulated using phase shift keying (PSK). The signal has a broadband spectrum and the physical channel allows multiple applications to be run on the same infrastructure.

The sensor module architecture consists of a set of specialized sensors to detect climatic parameters (temperature, humidity, dew point, air velocity and direction, and precipitation) and a specialized set of soil parameter measurements (conductivity and humidity). While air information related to humidity is used to predict the degree of evaporation of water from the soil, the information related to its velocity is used to compensate for the non-uniformity of irrigation caused by the wind. The irrigation that is interrupted upon the occurrence of precipitation based on soil moisture sensor has a time delay because of the water infiltration time. Thus, a rain sensor is used to overcome this delay. The conductivity value of complex soil dielectric permittivity measurements will provide input data for computing the concentration of nutrients.

This information is obtained directly through the conductivity sensor in Siemens per meter (S/m) and represents a measure of the dissolved nutrients. The database was created by virtual instrumentation techniques and includes the following crops: early tomatoes (Solanum lycopersicum) 25–35 T/ha production, onion chives (Allium schoenoprasum) and garlic (Allium sativum) 8–10 T/ha, direct-sowing onions 20–25 T/ha, late-growing carrots (Daucus carota), parsley (Petroselinum crispum) 25–35 T/ha, early carrot culture 15–20 T/ha, autumn cucumbers (Cucumis sativus) 5–15 T/ha, summer cucumbers 8–10 T/ha, early cucumbers 12–20 T/ha, cabbage (Brassica oleracea), autumn cauliflower (Brassica oleracea var. Botrytis) 35–40 T/ha, cabbage, early cauliflower 25–30 T/ha, aubergines (Solanum melongena) 25–30 T/ha, peppers—Capsicum annum (bell, long, green peppers) 35–40 T/ha, and summer–autumn tomatoes 35–40 T/ha.

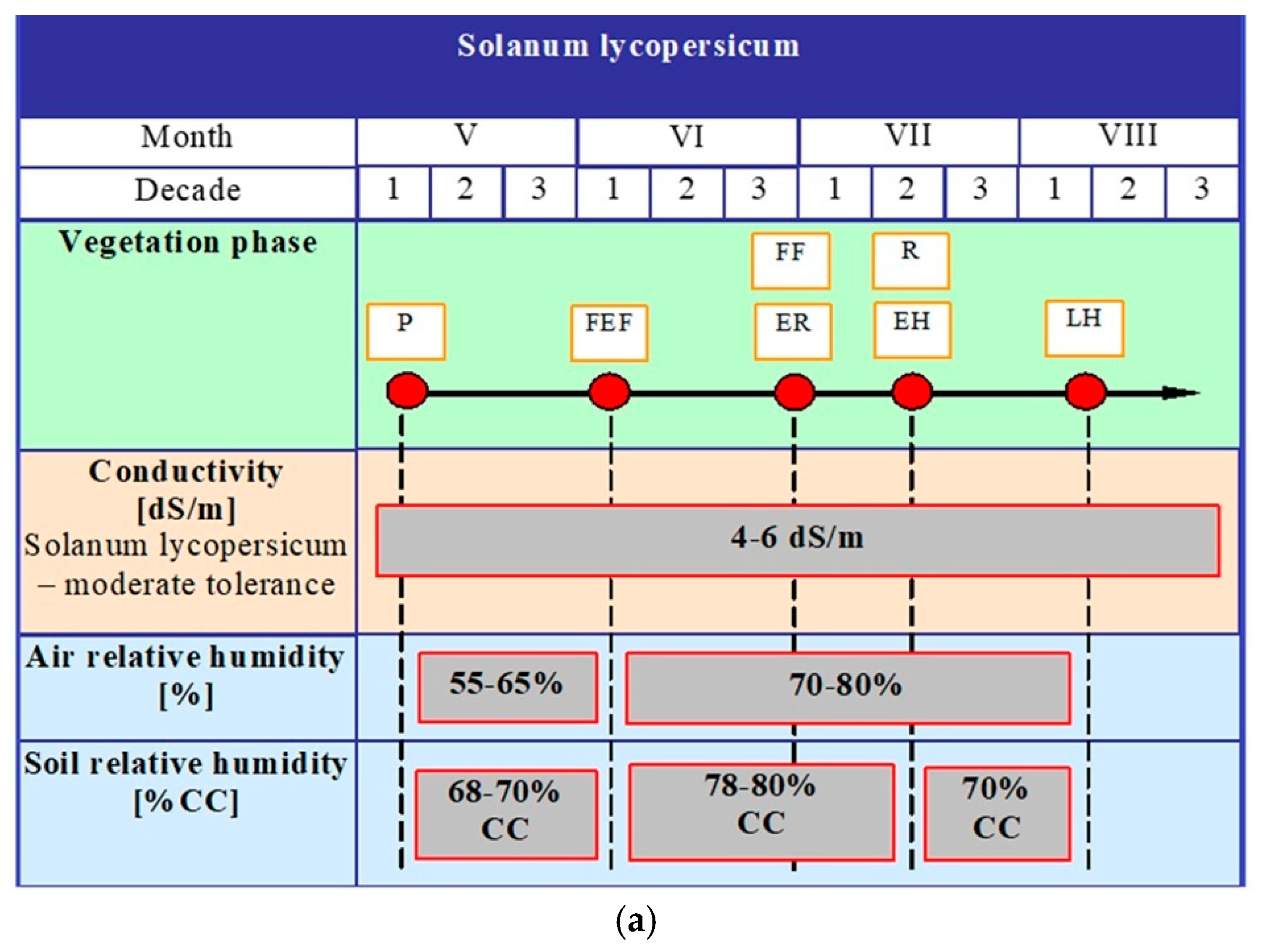

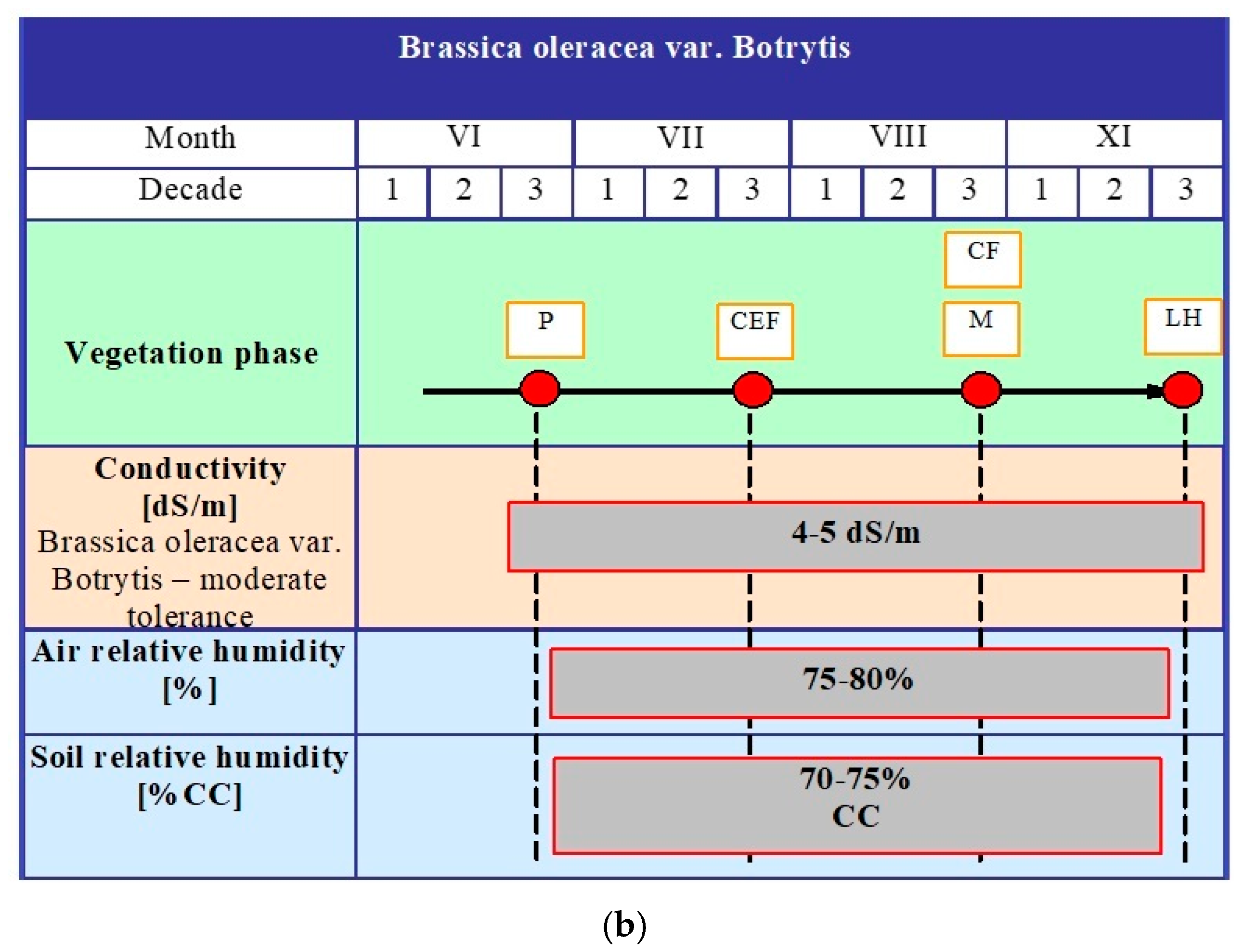

The database shown in

Figure 2 plays a critical role in the decision-making process of the IMS. It contains agronomic profiles for a variety of crops, including yield expectations (expressed in tons per hectare), nutrient requirements and phenological stages (plantation (P), fruit early formation (FEF), fruit formation (FF), early ripening (ER), ripening (R), early harvest (EH), last harvest (LH), cabbage early formation (CEF), cabbage formation (CF) and maturation (M)). These profiles are used by the decision-making unit to generate crop-specific irrigation and fertigation schedules tailored to real-time sensor inputs. The database used for decision-making was constructed using virtual instrumentation techniques (LabVIEW), but the testing and validation of the system were fully experimental. For instance, the early tomato and autumn cauliflower entries in the database reflect optimal production ranges and nutrient thresholds derived from field experiments and agronomic standards.

This data-driven approach allows the system to dynamically adjust nutrient concentrations and irrigation volumes, enhancing input efficiency while maintaining or increasing crop productivity. The modular design of the database also permits the future integration of additional crop types or localized agronomic recommendations, making the system adaptable to a wide range of agricultural environments.

2.2. Field Trial Design and Deployment Parameters

Field experiments were conducted near Iași, Romania (47.1321° N, 27.5819° E), in a soil environment composed of chernozem and clay–silty loam, conditions representative of a large fraction of Romanian arable land. The IMS was tested on two crops with different nutrient and water demands: early tomatoes and autumn cauliflower.

Each test consisted of two microplots (0.02 ha each):

- –

A reference plot, irrigated and fertilized using conventional constant-rate methods.

- –

An IMS plot, operated using dynamically adjusted fertigation profiles computed in real time based on the following:

- –

Soil moisture and conductivity sensors (measuring in S/m);

- –

Atmospheric sensors (humidity, temperature, wind, rainfall);

- –

Predefined crop-specific thresholds from a centralized agronomic database;

- –

Phase-Shift Keyed (PSK) data modulation over PLC for command dispatch.

The Pilot Sites are located on an area with low hills. The vicinity is composed of about 1000 ha agricultural land distributed among farms (up to 30 ha each) and over 200 ha forest. The majority of the soil is homogeneous, with between 2.5 and 4.0% comprising organic matter/chernozem and the rest being clay. The soil and location characteristics are representative of about 40% of Romanian agricultural area.

To evaluate the performances of the developed system, tests were performed for two crops: early tomato crop and autumn cauliflower crop. For both tests, reference sites Ref1 and Ref2 and investigated sites (IS1 and IS2) were used. To ensure accurate comparison, both IMS and reference plots used the same planting density, seed lot, and cultivation practices. Soil compaction, slope, and shading were checked to be uniform across the microplots. Sensor calibration was conducted weekly using standard reference solutions and portable handheld meters to confirm the in-field accuracy of conductivity and moisture readings. Irrigation inputs in the reference plot were delivered manually at fixed intervals and volumes derived from regional agronomic guides, while IMS commands were issued every 5 min based on rolling averages and thresholds.

Weather data during the trials (June–September for tomatoes; August–October for cauliflower) indicated typical seasonal conditions: average daytime temperature ranged from 18 to 29 °C, relative humidity fluctuated between 55 and 85%, and total rainfall was 128 mm (tomato test) and 91 mm (cauliflower test), with wind speeds rarely exceeding 20 km/h. No extreme weather events (e.g., hail, frost) were recorded during the growing period, ensuring consistent environmental exposure across test and control plots.

3. Results and Discussion

3.1. Test 1, Tomato Crop Results

Ultrasol 15:08:25 nutrient and 250 g/ha seed were used for both reference and investigated sites. For the reference site, a standard 1200 L/ha nutrient solution at 0.2% concentration and 3000 m3/ha sprinkler irrigation were applied. In contrast, the investigated site (IMS plot) dynamically adjusted nutrient and irrigation inputs based on real-time sensor feedback. Soil moisture and conductivity sensors, alongside atmospheric data (humidity, temperature, wind, and rainfall), informed evapotranspiration compensation and nutrient injection levels. Electrovalves operated via pulse-width modulation (PWM) with duty cycles modulated every 5 min based on moving average sensor data. The PLC infrastructure demonstrated over 98% reliability, with no signal loss during peak irrigation.

The input usage, crop yield, and calculated efficiency metrics for the tomato test plots are summarized in

Table 1a, while

Table 1b presents the derived performance indicators, including nutrient and water use efficiencies and their relative changes under the IMS-based system compared to the conventional method. It may be noted that, for the site on which the IMS was implemented, the production of tomatoes increased by 4.67%. The reduction in nutrients and irrigation water was calculated for the same quantity of tomatoes harvested in both sites: 624 kg. In this case, the reduction in nutrient consumption for the reference production of 624 kg was 24.63% and reduction in water consumption for the same tomato production was 18.88%.

When extrapolated from the 0.02 ha plot to a 1 ha scale (assuming homogeneity and scaling linearity), the IMS approach achieved a reduction of approximately 450 m3 of irrigation water and 250 L of nutrient solution (0.2%) per hectare. The results are based on standard fertigation and irrigation energy costs, with 0.15 EUR/m3 as the cost of delivering and applying 1 m3 of water for irrigation and 0.05 EUR/L representing the estimated cost of applying 1 L of diluted fertigation solution. This translates to the estimated per-hectare operational cost reduction detailed below:

- –

Water savings: 450 m3/ha × 0.15 €/m3 = 67.5 EUR/ha.

- –

Nutrient savings: 250 L × 0.2% = 0.5 L concentrate/ha.

- –

Total nutrient-related cost savings = 13.75 EUR/ha.

- –

Combined estimated operational cost savings: 81.25 EUR/ha.

3.2. Test 2, Autumn Cauliflower Crop Results

The second experimental test was conducted on autumn cauliflower, using the same plot layout (0.02 ha) as in the tomato trial. Both the reference and the IMS-assisted plots received 300 g/ha of seed and used Kristalon 18-18-18 as the nutrient source. At the reference site, fertilization was performed using a 0.2% standard nutrient solution applied at a rate of 1200 L/ha, while irrigation followed conventional sprinkler practices, delivering 1400 m3/ha. For the IMS-based site, nutrient dosing and irrigation volumes varied dynamically over the season, controlled by the decision engine in response to environmental and crop-stage-specific feedback. A rain sensor override ensured the instantaneous shutdown of irrigation to prevent waste, outperforming traditional soil-moisture-only-based stop triggers, which suffer from response delays due to infiltration lag. The decision engine factored in early-stage root zone water demands, applying micro-pulses of low-volume irrigation to stimulate root growth based on a calibrated agronomic logic layer.

Detailed input–output metrics and performance indicators for the autumn cauliflower crop under conventional and IMS-based irrigation–fertigation regimes are presented in

Table 2a,b. The data quantify yield gains, normalized resource use (per kg yield), and efficiency improvements in nutrient and water utilization, demonstrating the operational advantages of the IMS approach. It should be noted that for the site with the IMS, a 6.19% increase in the production of cauliflower was achieved. The reduction in nutrients and irrigation water was calculated for the same quantity of cauliflower harvested in both plots: 742 kg. In this case, the reduction in nutrient consumption reported for the reference production of 742 kg was 22.7% and the reduction in water consumption for the same cauliflower production was 23.15%.

Beyond the raw output increases, the comparative results between the control and IMS plots indicate a strong trend toward improved resource use efficiency. In both experimental crops, the system achieved meaningful reductions in nutrient and water consumption without sacrificing—and even slightly improving—yield. This confirms the viability of the IMS to fine-tune inputs according to real-time field conditions and crop-specific needs.

Based on the 0.02 ha test plot results, extrapolated savings at the per-hectare level indicate a reduction of approximately 250 m3 of irrigation water per hectare and 200 L of 0.2% nutrient solution per hectare when adopting the IMS-based system. Assuming average operational costs of 0.15 EUR/m3 for water pumping and 2.5 EUR/L for nutrient concentrate, the estimated per-hectare cost reduction amounts to approximately EUR 143.75, distributed as follows:

- –

Water savings: 250 m3/ha × 0.15 EUR/m3 = 37.5 EUR/ha.

- –

Nutrient savings: 200 L × 0.2% = 0.4 L concentrate/ha.

- –

Total nutrient-related cost savings: 11 WUR/ha.

- –

Combined estimated operational cost savings: 48.5 EUR/ha.

The operational performance of the IMS was evaluated against the crop-specific agronomic thresholds illustrated in

Figure 2. For both Solanum lycopersicum (tomato) and Brassica oleracea var. botrytis (cauliflower), the system maintained key environmental and fertigation parameters within the optimal target ranges throughout the vegetation cycle. Soil electrical conductivity remained within the recommended intervals: 4–6 dS/m for tomato and 4–5 dS/m for cauliflower, as reported in

Table 1b and

Table 2b. Air relative humidity (RH) and soil moisture were monitored via IMS-integrated sensors and found to consistently align with the optimal bands defined in

Figure 2. RH values averaged 72–75% for tomato and 76–78% for cauliflower, within the phase-specific targets of 55–80% and 75–80%, respectively. Similarly, soil relative humidity was stabilized within 71–76% of field capacity for tomato and 72–74% for cauliflower. These correspond to measured volumetric soil moisture values of 23–29% (tomato) and 22–28% (cauliflower), based on site-specific calibration.

These results demonstrate that the IMS achieved high-resolution environmental regulation, ensuring crop-specific moisture and nutrient delivery consistent with physiological requirements. Adherence to these thresholds is reflected in the improved yield and input efficiency metrics presented.

3.3. Technical Efficiency and Limitations

Although the pilot-scale trials involved small plots (0.02 ha), the percentage improvements—a 4.67% increase in tomato yield and 6.19% in cauliflower—suggest scalability potential, especially for medium to large farms with existing pivot or linear irrigation infrastructure. The reductions in nutrient consumption (24.63% for tomatoes and 22.7% for cauliflower) are particularly relevant in the context of sustainable fertilization and cost-saving practices. Similarly, reductions in irrigation water (18.88% and 23.15%, respectively) underscore the environmental benefits of implementing a more intelligent water delivery system under conditions of growing water scarcity.

No significant technical failures or data transmission interruptions were observed during the field trials, indicating that PLC is a feasible and reliable option for remote monitoring and control in agricultural environments with established electrical infrastructure. However, further trials on larger, heterogeneous fields and additional crop types are recommended to validate the system’s adaptability across different soil and climate conditions. Overall, the IMS demonstrated the following attributes:

Real-time, cell-level irrigation granularity, which is rare in existing commercial systems.

Reduced system latency (<2.5 s from sensor reading to valve response).

Low-power footprint (average 15 W/module, peak 28 W).

PLC robustness over up to 100 m, with broadband spectrum allowing for future protocol multiplexing (e.g., simultaneous irrigation + pest control systems).

These translate into the following:

Up to 25% input savings on fertilizer and water for high-yield vegetables;

A potential 15–20% reduction in operational costs;

Environmental benefits, such as reduced nitrate runoff and improved water table preservation.

The IMS demonstrated clear agronomic and sustainability gains. This translated into lower nutrient and water input per kilogram of produce, highlighting IMS’s resource efficiency. When compared to AI-augmented smart-irrigation systems, IMS delivers a competitive conservation performance at significantly lower cost. For example, AI-driven frameworks applying neural network-based soil moisture predictions have achieved water use reductions of up to 30% and fertilizer savings of 15–25%, while boosting yields by 10–15% [

29,

30,

31]. However, those systems typically require edge computing, cloud connectivity, and trained operators—making them expensive and less feasible for smaller farms. Likewise, LoRaWAN-based IoT platforms offer scalable long-range connectivity for remote irrigation control, but often face logistical constraints. Studies report that inconsistent network coverage and limited cellular infrastructure in rural areas can degrade data reliability and system effectiveness [

32]. In contrast, IMS’s Power Line Communication leverages existing electrical wiring, reducing hardware complexity and eliminating dependence on external connectivity. Combined with modular cell-level sensor–actuator control, PLC enables robust, low-cost deployment. The demonstrated yield improvements and resource savings affirm that IMS is well-suited for small to medium-sized farms, particularly in regions where network infrastructure is unreliable and cost is a limiting factor.

This study also presents limitations that should be addressed in future work. First, system validation was conducted exclusively on 0.02 ha test plots. Consequently, the hydraulic dynamics and signal propagation characteristics in larger-scale deployments remain unverified and require further investigation. Second, the current decision-making framework relies on rule-based logic; the integration of machine learning or artificial intelligence models has not yet been implemented. Such enhancements may improve adaptability and predictive capabilities in diverse environmental conditions. Finally, nutrient monitoring is presently based on electrical conductivity measurements. Although this method provides effective indirect feedback, future systems may benefit from cross-validation using ion-selective sensors to improve specificity and accuracy in nutrient assessments.

3.4. Possible Applications of the Research

The proposed IMS demonstrates strong suitability and broad applicability across a spectrum of agricultural scenarios, particularly within precision farming contexts that demand the localized and adaptive management of water and nutrient inputs. Its modular architecture—comprising independently functioning sensor modules, irrigation controllers, and nutrient injection units—enables flexible deployment and cell-level control, allowing for site-specific fertigation tailored to spatial and temporal field variability. This degree of granularity, achieved through real-time environmental monitoring and a centralized decision-making engine, enhances input-use efficiency and supports sustainable intensification by reducing water consumption, nutrient leaching, and chemical runoff. A key innovation lies in the system’s use of PLC for data transmission, which eliminates the need for costly wireless infrastructure and leverages existing electrical networks, thereby improving cost-effectiveness and deployment feasibility in rural or infrastructure-constrained regions. Furthermore, the IMS is fully compatible with existing pivot and linear displacement irrigation systems, enabling retrofitting without major capital investment—an advantage that is particularly relevant to medium- and large-scale farms. From a research and development perspective, the system also serves as a robust experimental platform for calibrating crop-specific irrigation thresholds, refining soil–plant–atmosphere interaction models, and facilitating future integration with AI-based decision support tools. Its open-system design ensures interoperability with digital agriculture platforms and Internet of Things (IoT) frameworks, reinforcing its long-term potential as a scalable, intelligent solution for both commercial and scientific applications in modern agriculture.

4. Conclusions

This study presents the design, implementation, and validation of a modular, cost-effective Irrigation Modular System (IMS) for precision fertigation management in small-scale agricultural settings. The system integrates Power Line Communication (PLC), localized sensor–actuator control, and conductivity-based nutrient dosing, offering an accessible alternative to more complex and costly AI or LoRaWAN-based platforms. Pilot trials demonstrated improved yield (4.67% for tomato and 6.19% for cauliflower) and significant reductions in both nutrient (up to 24.63%) and water use (up to 23.15%), indicating strong potential for enhancing resource efficiency in precision agriculture.

The promising results obtained from the pilot-scale trials on 0.02 ha plots provide a solid foundation for further validation under larger operational conditions, where the system’s scalability and robustness can be rigorously assessed. Although the current IMS prototype does not yet incorporate AI-driven forecasting or adaptive scheduling algorithms, its modular architecture is fully compatible with the future integration of such advanced predictive control strategies. Incorporating AI and machine learning techniques in subsequent iterations will enable more precise irrigation management tailored to spatiotemporal variability in weather and crop phenology, thereby enhancing resource use efficiency and crop productivity.

Future work will focus on upscaling the IMS for deployment on medium and large farms, particularly those using center pivot or linear irrigation systems. Further development will also explore the integration of predictive analytics and AI-driven decision support, aiming to combine the low-cost communication and control architecture of IMS with advanced environmental modeling. Long-term field trials under diverse agronomic and climatic conditions will be essential to evaluate system robustness, scalability, and economic viability across crop types and regions.