Modification of Typical Headland Manoeuvres Using Transition Curves

Abstract

1. Introduction

2. Materials and Methods

2.1. Object of Analysis

2.2. Transition Curves

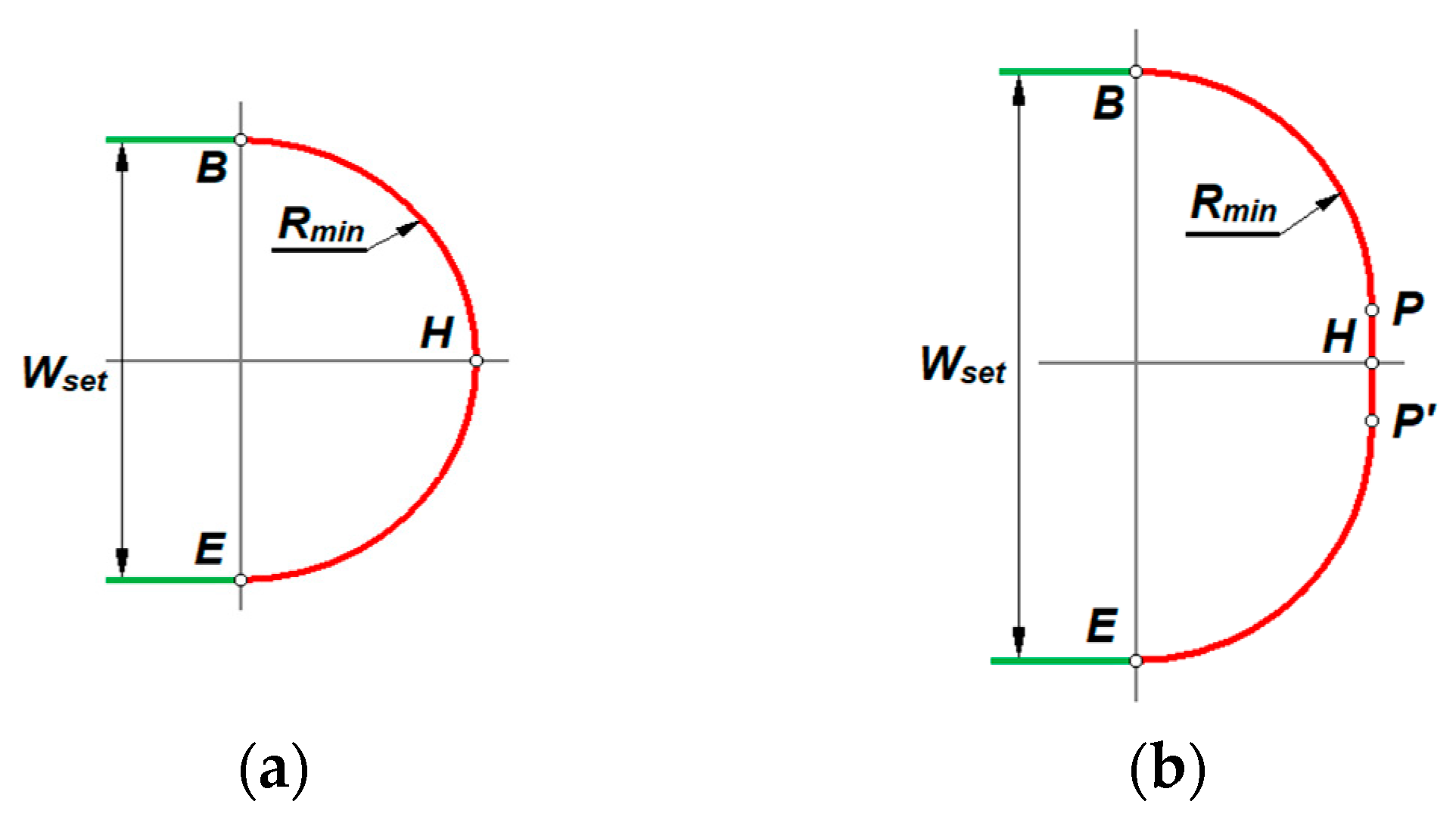

2.3. U-Turn Modification

- The first transition curve (segment P0-P1) introduces a gradual increase in the curvature from 0 to 1/Rmin, reaching a tangent angle of π/4 at point P1;

- The second transition curve (segment P1-P2) decreases the curvature from 1/Rmin to 0, while simultaneously increasing the tangent angle at point P2 to π/2;

- Straight-line segment (segment P2-H).

- Based on the minimum turning radius Rmin and the range of change in angle θ, calculate the length of the transition curves:

- Taking into account the required length of the straight-line segment P2 to H is equal to L3, determine the motion times for each path segment:

- Assuming that the initial time T0 = 0, calculate the total motion time Tn for the successive segments:

- -

- The curvature;

- -

- The tangent angle to the curve;

- -

- The displacements (coordinates of the path points).

2.4. Ω-Turn Modification

- The first transition curve (segment P0-P1) introduces a gradual increase in the curvature from 0 to 1/Rmin reaching a tangent angle of θ at point P1;

- The second transition curve (segment P1-P2) decreases the curvature from 1/Rmin to 0, while simultaneously increasing the tangent angle at point P2 to 2θ;

- The third transition curve (segment P2-P3) again increases the curvature to 1/Rmin while gradually reducing the tangent angle to 0 at point P3;

- The circular arc (segment P3-H) corresponds to a quarter of a circle and is characterised by a constant curvature of 1/Rmin.

- Based on the minimum turning radius Rmin and the required change in angle θ, calculate the length of the transition curves and the length of the circular arc:

- Calculate the motion times for the successive path segments and the cumulative times using Equations (10) and (11), for i = 1, 2, 3, 4;

- Express the curvature, the tangent angle to the curve, and the displacements as functions of time within the defined intervals [Ti−1, Ti] for i = 1, 2, 3, 4.

2.5. Kinematic Models of Steering Configurations

3. Results

- Calculate the segment lengths Li and motion times ti for the first two path segments, assuming θ = π/4;

- Calculate the cumulative times Tn for n = 1 and n = 2;

- Calculate the y-coordinate of point P2;

- Calculate the working width based on the following equation:

- Assume the initial angle value θinit and the angle increment Δθ;

- Calculate the angles θi, lengths Li, and motion times ti for the first three segments of the path;

- Calculate the cumulative times Tn for n = 1, n = 2, n = 3;

- Calculate the y-coordinate of point P3;

- Calculate the working width based on the following formula:

| Algorithm 1. Exemplary pseudocode of the algorithm for calculating the angle θ with a precision of Δθ. |

| function θ (θinit, ∆θ, Rmin, v, Wset) θ←θinit κ←1/Rmin // Define curvature as the inverse of the minimum turning radius repeat θ←θ+∆θ // Define angles for each segment θ[1]←θ θ[2]←θ θ[3]←2*θ // Calculate lengths and travel times for each segment for i from 1 to 3 do L[i] ←2*Rmin*θ[i] t[i]←L[i]/v end for // Compute cumulative times T0←0 T1←t[1] T2←T1+t[2] T3←T2+t[3] // Compute y-coordinates at characteristic points y_P1 ← v*∫ from T0 to T1 of sin(κ/2*(v*t-L[1]/π*sin(π*v*t/L[1])))dt y_P2 ← y_P1+v*∫ from T1 to T2 of sin(θ+κ/2*(v*(t-T1)+L[2]/π*sin(π*v*(t-T1)/L[2])))dt y_P3 ← y_P2+v*∫ from T2 to T3 of sin(2*θ-κ/2*(v*(t-T2)-L[3]/π*sin(π*v*(t-T2)/L[3])))dt // Compute the working width based on the y-coordinate of point P3 W←2*(Rmin-y_P3) until (W <= Wset) return θ end function |

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GPS | Global Positioning System |

| SCM | Spiral Connection Method |

| GNSS | Global Navigation Satellite System |

| RTK | Real-Time Kinematic |

| IMU | Inertial Measurement Unit |

References

- Zhu, Z.; Chen, J.; Yoshida, T.; Torisu, R.; Song, Z.; Mao, E. Path tracking control of autonomous agricultural mobile robots. J. Zhejiang Univ.-Sci. A 2007, 8, 1596–1603. [Google Scholar] [CrossRef]

- Bochtis, D.D.; Vougioukas, S.G. Minimising the Non-Working Distance Travelled by Machines Operating in a Headland Field Pattern. Biosyst. Eng. 2008, 101, 1–12. [Google Scholar] [CrossRef]

- Huang, P.; Luo, X.; Zhang, Z. Headland turning control method simulation of autonomous agricultural machine based on improved pure pursuit model. In Computer and Computing Technologies in Agriculture III, Proceedings of the III IFIP TC 12 International Conference 2009, Beijing, China, 14–17 October 2009; Li, D., Zhao, C., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 176–184. [Google Scholar]

- Backman, J.; Oksanen, T.; Visala, A. Nonlinear Model Predictive Trajectory Control in Tractor-Trailer System for Parallel Guidance in Agricultural Field Operations. IFAC Proc. Vol. 2010, 43, 133–138. [Google Scholar] [CrossRef]

- Backman, J.; Oksanen, T.; Visala, A. Path Generation Method with Steering Rate Constraint. In Proceedings of the ICPA 2012, Indianapolis, IN, USA, 15–18 July 2012; p. 15. [Google Scholar]

- Cariou, C.; Lenain, R.; Thuilot, B.; Humbert, T.; Berducat, M. Maneuvers automation for agricultural vehicle in headland. In Proceedings of the AgEng 2010 Conference on Agricultural Engineering, Clermont-Ferrand, France, 6–8 September 2010; pp. 1–10. [Google Scholar]

- Jensen, M.A.F.; Bochtis, D. Automatic Recognition of Operation Modes of Combines and Transport Units Based on GNSS Trajectories. In Proceedings of the 4th IFAC Conference on Modelling and Control in Agriculture, Horticulture and Post Harvest Industry, Espoo, Finland, 27–30 August 2013; pp. 213–218. [Google Scholar] [CrossRef]

- Song, M.Z.; Kang, S.W.; Chung, S.O. Development of path planning algorithm for an autonomous mower tractor. In Proceedings of the 4th IFAC Conference on Modelling and Control in Agriculture, Horticulture and Post Harvest Industry, Espoo, Finland, 27–30 August 2013; pp. 154–158. [Google Scholar] [CrossRef]

- Sabelhaus, D.; Röben, F.; zu Helligen, L.P.M.; Lammers, P.S. Using continuous-curvature paths to generate feasible headland turn manoeuvres. Biosyst. Eng. 2013, 116, 399–409. [Google Scholar] [CrossRef]

- Sabelhaus, D.; Lammers, P.S.; Peter, L.; Röben, F. Path planning of headland turn manoeuvres. Landtechnik 2015, 70, 123–131. [Google Scholar] [CrossRef]

- Koc, W. Analytical method of modelling the geometric system of communication route. Math. Probl. Eng. 2014, 2014, 679817. [Google Scholar] [CrossRef]

- Backman, J.; Piirainen, P.; Oksanen, T. Smooth turning path generation for agricultural vehicles in headlands. Biosyst. Eng. 2015, 139, 76–86. [Google Scholar] [CrossRef]

- Cariou, C.; Gobor, Z.; Seiferth, B.; Berducat, M. Mobile Robot Trajectory Planning Under Kinematic and Dynamic Constraints for Partial and Full Field Coverage. J. Field Robot. 2017, 34, 1297–1312. [Google Scholar] [CrossRef]

- Conesa-Muñoz, J.; Bengochea-Guevara, J.M.; Andujar, D.; Ribeiro, A. Route planning for agricultural tasks: A general approach for fleets of autonomous vehicles in site-specific herbicide applications. Comput. Electron. Agric. 2016, 127, 204–220. [Google Scholar] [CrossRef]

- Zhang, C.; Noguchi, N.; Yang, L.L. Leader–follower system using two robot tractors to improve work efficiency. Comput. Electron. Agric. 2016, 121, 269–281. [Google Scholar] [CrossRef]

- Hameed, I.A. Coverage path planning software for autonomous robotic lawn mower using Dubins’ curve. In Proceedings of the 2017 IEEE International Conference on Real-time Computing and Robotics (RCAR), Okinawa, Japan, 14–18 July 2017; pp. 517–522. [Google Scholar]

- Plessen, M.M.G.; Bemporad, A. Reference trajectory planning under constraints and path tracking using linear time-varying model predictive control for agricultural machines. Biosyst. Eng. 2017, 153, 28–41. [Google Scholar] [CrossRef]

- Paraforos, D.S.; Hübner, R.; Griepentrog, H.W. Automatic determination of headland turning from auto-steering position data for minimising the infield non-working time. Comput. Electron. Agric. 2018, 152, 393–400. [Google Scholar] [CrossRef]

- Trendafilov, K.; Delchev, N. Headland turns using the tractor’s “fifth wheel” steering device instead of front steering wheels. Bulg. J. Agric. Sci. 2018, 24, 1137–1147. [Google Scholar]

- Yang, Y.; Zhang, G.; Chen, Z.; Wen, X.; Cheng, S.; Ma, Q.; Qi, J.; Zhou, Y.; Chen, L. An independent steering driving system to realize headland turning of unmanned tractors. Comput. Electron. Agric. 2022, 201, 107278. [Google Scholar] [CrossRef]

- Yin, X.; Du, J.; Geng, D.; Jin, C. Development of an automatically guided rice transplanter using RTK-GNSS and IMU. IFAC Pap. 2018, 51, 374–378. [Google Scholar] [CrossRef]

- Yin, X.; Du, J.; Noguchi, N.; Yang, T.X.; Jin, C.Q. Development of autonomous navigation system for rice transplanter. Int. J. Agric. Biol. Eng. 2018, 11, 89–94. [Google Scholar] [CrossRef]

- Bulgakov, V.; Pascuzzi, S.; Beloev, H.; Ivanovs, S. Theoretical Investigations of the Headland Turning Agility of a Trailed Asymmetric Implement-and-Tractor Aggregate. Agriculture 2019, 9, 224. [Google Scholar] [CrossRef]

- Tu, X.; Tang, L. Headland turning optimisation for agricultural vehicles and those with towed implements. J. Agric. Food Res. 2019, 1, 100009. [Google Scholar] [CrossRef]

- Guevara, L.; Michałek, M.M.; Cheein, F.A. Headland turning algorithmization for autonomous N-trailer vehicles in agricultural scenarios. Comput. Electron. Agric. 2020, 175, 105541. [Google Scholar] [CrossRef]

- Trendafilov, K.; Tihanov, G. Comparative analysis of the headland width when making t-turns by a mounted machine-tractor unit on an irregularly-shaped field. INMATEH—Agric. Eng. 2022, 67, 221–232. [Google Scholar] [CrossRef]

- Chen, T.; Xu, L.; Ahn, H.S.; Lu, E.; Liu, Y.; Xu, R. Evaluation of headland turning types of adjacent parallel paths for combine harvesters. Biosyst. Eng. 2023, 233, 93–113. [Google Scholar] [CrossRef]

- He, Z.; Bao, Y.; Yu, Q.; Lu, P.; He, Y.; Liu, Y. Dynamic path planning method for headland turning of unmanned agricultural vehicles. Comput. Electron. Agric. 2023, 206, 107699. [Google Scholar] [CrossRef]

- Li, B.; Ni, K.; Li, Y.; Pan, J.; Huang, W.; Jiang, H.; Liu, F. Control strategy of shuttle shifting process of agricultural tractor during headland turn. IEEE Access 2023, 11, 38436–38447. [Google Scholar] [CrossRef]

- Wang, M.; Niu, C.; Wang, Z.; Jiang, Y.; Jian, J.; Tang, X. Study on Path Planning in Cotton Fields Based on Prior Navigation Information. Agriculture 2024, 14, 2067. [Google Scholar] [CrossRef]

- Peng, C.; Wei, P.; Fei, Z.; Vougioukas, S.G. Optimization-based motion planning for autonomous agricultural vehicles turning in constrained headlands. J. Field Robot. 2024, 41, 1984–2008. [Google Scholar] [CrossRef]

- Wu, X.; Bai, J.; Li, X.; Hao, F. Smooth path planning method of agricultural vehicles based on improved Hybrid A*. In Proceedings of the 2023 IEEE 3rd International Conference on Information Technology Big Data and Artificial Intelligence ICIBA 2023, Chongqing, China, 26–28 May 2023; pp. 664–668. [Google Scholar] [CrossRef]

- Chen, H.; Xie, H.; Sun, L.; Shang, T. Research on tractor optimal obstacle avoidance path planning for improving navigation accuracy and avoiding land waste. Agriculture 2024, 13, 934. [Google Scholar] [CrossRef]

- Yin, X.; Wang, Y.X.; Chen, Y.L.; Jin, C.Q.; Du, J. Development of autonomous navigation controller for agricultural vehicles. Int. J. Agric. Biol. Eng. 2020, 13, 70–76. [Google Scholar] [CrossRef]

- Olcay, E.; Rui, X.; Wang, R. Headland Turn Automation Concept for Tractor-Trailer System with Deep Reinforcement Learning. In Proceedings of the 2023 IEEE 19th International Conference on Automation Science and Engineering (CASE), Auckland, New Zealand, 26–30 August 2023; pp. 1–7. [Google Scholar] [CrossRef]

- Höffmann, M.; Patel, S.; Büskens, C. Optimal coverage path planning for agricultural vehicles with curvature constraints. Agriculture 2023, 13, 2112. [Google Scholar] [CrossRef]

- Vahdanjoo, M.; Gislum, R.; Sørensen, C.A.G. Three-dimensional area coverage planning model for robotic application. Comput. Electron. Agric. 2024, 219, 108789. [Google Scholar] [CrossRef]

- Dubins, L.E. On Curves of Minimal Length with a Constraint on Average Curvature, and with Prescribed Initial and Terminal Positions and Tangents. Am. J. Math. 1957, 79, 497–516. [Google Scholar] [CrossRef]

- Reeds, J.A.; Shepp, L.A. Optimal Paths for a Car That Goes Both Forwards and Backwards. Pac. J. Math. 1990, 145, 367–393. [Google Scholar] [CrossRef]

| Points of the Path | Curvature κ | Tangent Angle θ |

|---|---|---|

| P0 | 0 | 0 |

| P1 | 1/Rmin | π/4 |

| P2 | 0 | π/2 |

| H | 0 | π/2 |

| Points of the Path | Curvature κ | Tangent Angle θ |

|---|---|---|

| P0 | 0 | 0 |

| P1 | 1/Rmin | θ |

| P2 | 0 | 2θ |

| P3 | 1/Rmin | 0 |

| H | 1/Rmin | −π/2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boryga, M.; Kołodziej, P.; Gołacki, K. Modification of Typical Headland Manoeuvres Using Transition Curves. Appl. Sci. 2025, 15, 8817. https://doi.org/10.3390/app15168817

Boryga M, Kołodziej P, Gołacki K. Modification of Typical Headland Manoeuvres Using Transition Curves. Applied Sciences. 2025; 15(16):8817. https://doi.org/10.3390/app15168817

Chicago/Turabian StyleBoryga, Marek, Paweł Kołodziej, and Krzysztof Gołacki. 2025. "Modification of Typical Headland Manoeuvres Using Transition Curves" Applied Sciences 15, no. 16: 8817. https://doi.org/10.3390/app15168817

APA StyleBoryga, M., Kołodziej, P., & Gołacki, K. (2025). Modification of Typical Headland Manoeuvres Using Transition Curves. Applied Sciences, 15(16), 8817. https://doi.org/10.3390/app15168817