1. Introduction

Distributed reinforcement in the form of single, short fibres is used in concrete elements, mortars and cement grouts. They first appeared in Polish construction in the 1990s. At that time, two groups of products appeared simultaneously: materials for structural reinforcement and micro-bars for concrete reinforcement. In Poland, products for strengthening and reinforcing concrete elements were initially met with considerable resistance from the engineering community. The main objections were related to the rheology and durability of structures containing fibre materials. Today, after more than thirty years of experience in Poland, scientific research and practical applications, it is clear that these materials are reliable [

1,

2,

3]. By using different types of fibres, we can influence the parameters and properties of materials [

4,

5]. Here, we discuss cracks that appear in the rather brittle cement matrix. These cracks can damage the element, affecting its durability and, in many cases, the safety of the entire structure [

6,

7]. Given the brittleness of the cement matrix, it is impossible to avoid cracks. It is therefore important to avoid cracks that can penetrate the main reinforcement [

2,

8]. The most effective way to deal with the formation of dangerous cracks is to use dispersed reinforcement in the form of fibres. The popularisation of these solutions has led to the inclusion of fibres in the PN-EN 206:2014-04 standard for concrete [

9]. In this standard, we can find only two types of fibres in terms of material. These are steel and polymer fibres. There are no standard guidelines for other fibres [

10,

11]. Among the applicable guidelines of the American Society for Testing and Materials, ASTM C1116/C1116M-10a [

12] standards have been developed for requirements for different fibres, depending on the material from which they are made. The classification includes four types. Type I is steel fibre-reinforced concrete, type II is glass fibre-reinforced concrete. Type III describes concrete reinforced with synthetic fibres, while type IV is concrete reinforced only with natural fibres [

12].

The properties of the composite depend mainly on the orientation of the fibres, their arrangement in the element, and the repeatability of the quality of the fibres used. Despite great care and quality control during fibre production, minor problems may arise at the microscopic level of the fibre structure, which may affect the overall properties of the fibre composite. Excessive fibre clusters at a given point, as well as their absence in other places, can lead to significant changes in the properties of a given material. Fibres are characterised by high stiffness and strength, significantly exceeding the value of a given material in the form of mass. The tensile strength of structural steels ranges from 0.2 to 0.7 GPa, while the strength of thin steel fibres reaches approximately 4 GPa [

13,

14]. This difference is probably due to the fact that the crystal structure of the fibres themselves is more developed, and the iron crystals are only oriented along the axis of the fibre. The number of defects in the fibres themselves, which are small in volume, is significantly lower than in the same material with a larger volume. The fibres produced are characterised by diameters often not exceeding 15 µm. This is due to the fact that fibres with smaller diameters are generally much more resistant in terms of bending strength. Studies conducted by scientists [

15,

16] show that tensile strength increases rapidly when the diameter of the tested fibre is less than 15 µm. With smaller diameters, there is less risk of defects on the fibre surface, such as microcracks or faults. In other words, the smaller the fibre diameter, the less likely it is to have defects, which translates into its strength parameters [

17,

18,

19,

20].

Concrete with dispersed steel fibres is used for industrial floors exposed to high loads and abrasion. Glass fibres improve the watertightness and fire resistance of concrete. They are used in the construction of concrete elements exposed to water and moisture from the air. Concrete with the addition of basalt fibres is characterised by good mechanical properties and high resistance to abrasion. It is also a good thermal and electrical insulator. It is resistant to corrosion and high and low temperatures [

21,

22,

23,

24]. Currently, concrete or mortars with dispersed reinforcement are increasingly used in single-family housing construction [

25,

26,

27,

28]. Solutions and applications for reinforced concrete are constantly evolving. Concrete elements made using this technology are significantly more durable, waterproof, long-lasting, malleable and easier to shape into any form [

29,

30,

31]. Concrete products and architectural elements blend in perfectly with the surrounding space, creating an aesthetic whole. In addition, they are characterised by above-average resistance to particularly adverse external factors, including low temperatures, sunlight, and all types of concrete corrosion. Fibre-reinforced concrete products are ideal for use in modern, industrialised and aggressive urban and industrial environments [

32,

33,

34]. Examples of such structures include the metro in the Qatari capital, Doha, and the expansion of the Crossrail metro network in London. These structures are examples of the most spectacular and large-scale tunnel infrastructure projects in recent years on a global scale. The consumption of concrete and steel during the implementation of such huge investments would be very high. However, it could be reduced by using steel fibres as the only reinforcement for the tunnel lining segments [

35,

36,

37].

Innovation in fibres is a rapidly growing field that encompasses new technologies, materials and production methods aimed at improving the properties and functionality of fibres. These innovations are crucial for many industries, improving the functionality, durability and sustainability of products. The development of these technologies is driven by the growing demand for advanced construction materials. Steel, basalt and glass fibres are the most common alternatives to traditional reinforcement. These fibres increase bending resistance, making them an excellent choice for more demanding construction projects. Above all, the selection of the right fibres is extremely important. It is worth noting that investing in selected fibres can lead to significant savings in the long term. Thanks to the increased durability of the structure, you can save on maintenance and repair costs. The innovative aspect of this research lies in comparing selected rheological properties and hardened mortar parameters between steel, glass and basalt fibres. Fibres added to mortars are currently widely available on the construction market.

The aim of this research was to determine the physical and mechanical parameters of mortars with the addition of currently produced steel, glass and basalt fibres. The types of fibres for this research were selected due to the changes in the relevant parameters of these fibres, which are currently being produced, compared to those that were available on the market several decades ago. The results of this scientific research may differ significantly from those obtained in the 2000s. The effect of fibre addition on the compressive and flexural strength, water absorption and capillary rise of mortars was investigated. The rheological properties of mortars, i.e., consistency and volume density, were also investigated. Compressive and flexural strength was tested after 7, 28 and 56 days, while capillary rise and water absorption were tested after 28 days of curing. The frost resistance of mortars was also tested in accordance with the standard PN-88/B-06250 [

38]. Full statistics were compiled for the test results obtained.

2. Materials and Methods

The research programme involved four mortar series: one without fibres and three with steel, glass and basalt fibres. Portland CEM I 42.5 R cement was used following PN-EN 197-1:2011 [

39]. Quartz sand (0–2 mm) was used as aggregate according to PN-EN 12620+A1:2010 [

40], along with tap water [

41] and a single type of fibre per series. All tests were conducted in laboratories at the Kielce University of Technology. The mortar mix followed a standardised water-to-cement ratio (w/c = 0.5) and was prepared according to EN 196-1:2016-07 [

42]: cement and water were mixed for 30 s and then sand was added during the next 30 s, followed by another 30 s of mixing. Then, fibres were introduced, and the mixture rested for 90 s before a final 60 s of mixing. Samples (4 cm × 4 cm × 16 cm) were then cast. The specimen codes were as follows: “SW” for plain mortar, “SZ” for glass fibre, “SB” for basalt fibre, and “ST” for steel fibre.

The steel fibres (12.5 mm length, 1 mm diameter, straight shape) met EN 14889-1:2007 [

43] requirements. Their elastic modulus was ≥180 GPa and their tensile strength was 1020 N/mm

2. The recommended dosage was 20–40 kg/m

3, with 25 kg/m

3 used in this study (

Figure 1a,

Table 1).

The glass fibres (12 mm length, 14 µm diameter, <0.6% moisture, 1% binder, green colour) followed ISO 9001:2016 [

44], ISO 3344:1977 [

45], and ISO 1887:1980 [

46]. The manufacturer recommended 5–10 kg/m

3, with 5 kg/m

3 applied here (

Figure 1b,

Table 1).

The basalt fibres, known for their high chemical resistance, had a density of 2.65 g/cm

3, a tensile strength of 3.0 GPa, and an elastic modulus of 90 GPa. They measured 10 mm in length and 0.01 mm in diameter. The recommended dosage was 1 kg per 100 kg of cement, which was used in this study (

Figure 1c,

Table 1).

The different proportions of fibres added to the mortars result from our own experience in laboratory testing and the recommendations of the manufacturers of the fibres tested. This is due to the fact that each type of fibre has different parameters.

Basic information on the properties of CEM I 42.5 R cement is provided in

Table 2.

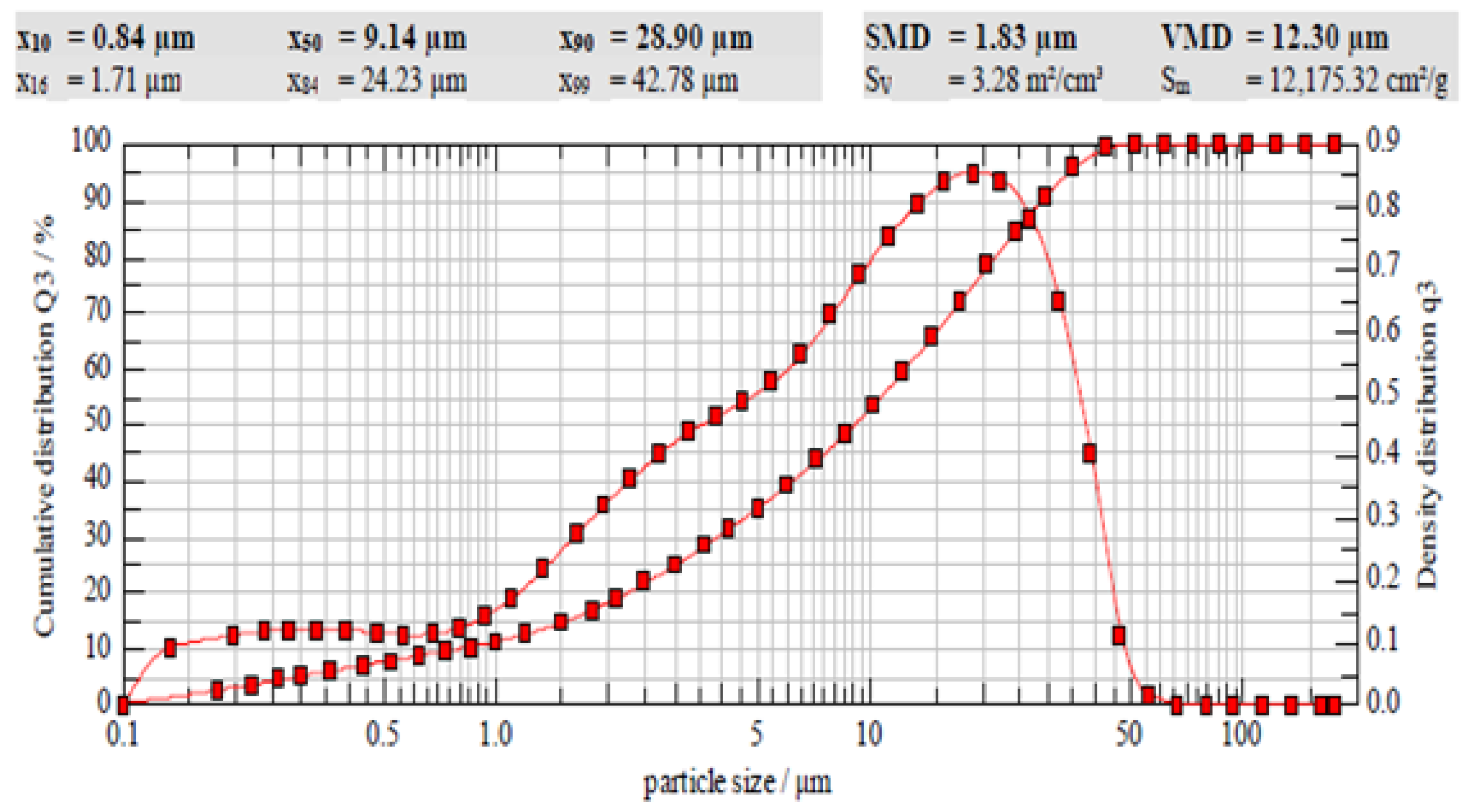

Analysis of the granulometric study of the cement (

Figure 2) showed that the particle size of 50% of the cement is smaller than 9.14 µm. However, the highest concentration of particles is found in the fraction range from 1 µm to 40 µm.

Based on the data presented in the sand granulometric analysis (

Figure 3), it can be concluded that half of the particles (50%) are smaller than 330.63 µm. Furthermore, the highest concentration of particles occurs in the fraction ranging from 150 µm to 350 µm, which indicates a dominant particle size distribution in this range.

The laboratory tests examined the effect of curing time and fibre type on selected parameters: compressive and flexural strength, water absorption and capillary rise. Additionally, fresh mortar properties such as consistency and bulk density were analysed.

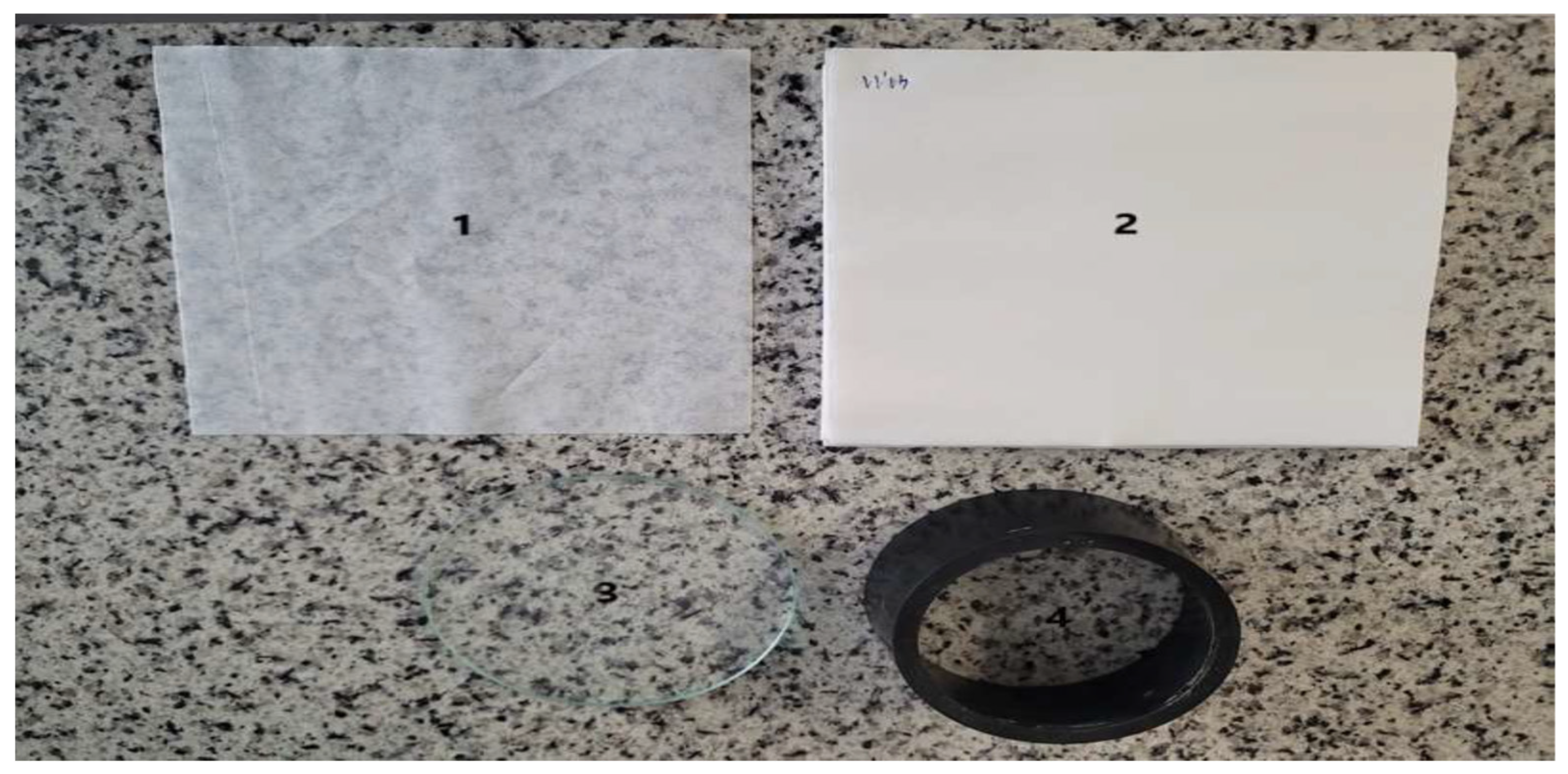

The mixed mortar was transferred to moulds, enabling the preparation of samples measuring 4 cm × 4 cm × 16 cm. The moulded samples were placed above water for 24 h and covered with foil to prevent evaporation of the mixing water. After 24 h, the samples were removed from the moulds and placed in water for the curing period, so that their entire surface was submerged. The water temperature was +18 °C ± 2 °C (

Figure 4a,b).

2.1. Compressive and Flexural Strength Testing

Compressive and flexural strength tests were conducted on standard 4 × 4 × 16 cm specimens according to PN-EN 1015-11:2020-04 [

48]. After casting, the specimens were cured in water at +18 ± 2 °C for the entire maturation period. Compressive strength was tested after 7, 28 and 56 days, with six specimens per series tested at each interval.

2.2. Capillary Rise Test

Capillary rise was evaluated following PN-88/B-06250 [

38] using 4 × 4 × 16 cm specimens. After casting, the specimens were cured in water at +18 ± 2 °C for 7 days, then stored in air at +18 ± 2 °C. Mass gain was monitored after 28 days. Before testing, specimens were placed in a climatic chamber at +40 °C for 96 h. After removal, mass gain was recorded 15 min, 30 min, 1 h and 4 h after water contact, followed by 24 h intervals. Throughout the test, the specimens were immersed in 3 mm of water.

2.3. Water Absorption Test

Water absorption testing was performed according to PN-88/B-06250 [

38] on 4 × 4 × 16 cm specimens. After 7 days of water curing at +18 ± 2 °C, the samples were stored for 21 days in air at +18 ± 2 °C before testing. The specimens were dried to a constant mass in a +40 °C climatic chamber for 96 h. Then, they were partially submerged up to half their height for 24 h. After one day, the water level was increased to 1 cm above the specimen height. Mass gain was monitored every 24 h until no further increase was observed.

Each series included three specimens for water absorption and capillary rise measurements.

2.4. Frost Resistance of Fibre-Reinforced Mortars

Frost resistance was tested in accordance with PN-88/B-06250 [

38]. This method involves estimating the loss of mass and compressive strength of the tested samples, which were subjected to cyclic freezing and thawing. Before placing the samples in the chamber, they were saturated with water. The samples were then weighed and placed in a climate chamber. The samples were frozen for 4 h at a temperature of −18 °C ± 2 °C and then completely immersed in water and thawed for 4 h at a temperature of +18 °C ± 2 °C. A total of 25 cycles were performed.

2.5. Testing the WRV10 Water Retention Index of Mortars

The water retention index was determined in accordance with the method described in publication [

49]. The measurements were carried out using the setup shown in

Figure 3. The filter papers together with the complete set (

Figure 5) were weighed before the analysis. The freshly prepared mortar was placed in a Vicat ring. After this, the whole system was weighed. After a set time (in this case 10 min), the ring with the mortar and additional filter paper was removed. Then, the set of filter papers soaked with water from the mortar was weighed. Four samples were prepared for testing, one of each type of mortar. The amount of dry ingredients was reduced by half compared to the main compositions, i.e., from 1800 g to 900 g (sand and cement). The total amount of water for each sample was 112.5 g.

The WRV10 index was calculated using the following formulas [

49]:

where

W1—water content in the tested mortar [%];

m5—total mass of water in fresh mortar [g];

m6—mass of dry mortar components [g].

W2—water content in the mortar in the plastic ring [g];

m7—mass of mortar in the plastic ring before testing [g];

m2—mass of the empty set, i.e., glass plate, filter paper set and plastic ring [g];

m3—mass of the set (glass plate, set of filter papers and plastic ring) filled with mortar [g].

W3—mass of water absorbed by the set of filter papers [g];

m1—mass of the dry filter paper set [g];

m4—mass of the filter paper set saturated with water [g].

The water retention index was designated as WRV10, i.e., the index tested after 10 min of measurement (determined 10 min after the samples were formed). The final results were calculated in %, accurate to 0.1%, [

50].

3. Results

The rheological tests were performed to determine the consistency based on the PN-EN 1015-6:2000 standard [

50] using the flow table method, and the volume density of fresh mortar was determined. The test was carried out in accordance with PN-EN 1015-3:2000 [

51] (

Table 3).

According to PN-EN 1015-6:2000 [

50], mortars with a spread value of less than 140 mm belong to the group of dense-plastic mortars.

The addition of fibres to mortars significantly changed the volumetric density of the mortars. This study showed that the contribution of glass, basalt and steel fibres resulted in an increase in volumetric density compared to the reference series. When glass fibres were used, the volumetric density increased by 7.67% relative to the SW sample, while for steel fibres, there was an increase of as much as 14.44% relative to the reference series (

Table 3).

Based on scientific research conducted to date, it can be concluded that the rheological properties of mortars with fibre additives depend primarily on the parameters of the fibres and the W/C ratio. With the addition of fibres, the rheological properties of mortars deteriorate. Similar conclusions were reached by L. Kucharska and A.M. Brand [

52].

The results of the WRV10 water retention index tests for all mortars tested, together with data and auxiliary calculation results, are presented in

Table 4 and

Table 5.

The water retention (

Table 4 and

Table 5) index of the reference mortar SW after 10 min of measurement was 89.0%. The lowest WRV10 index was recorded for mortar with glass fibres added. WRV10 for the reference mortar was 4.38% higher than for mortar with glass fibres. The highest index was recorded for mortar with basalt fibres. It is 3.36% higher than the reference series.

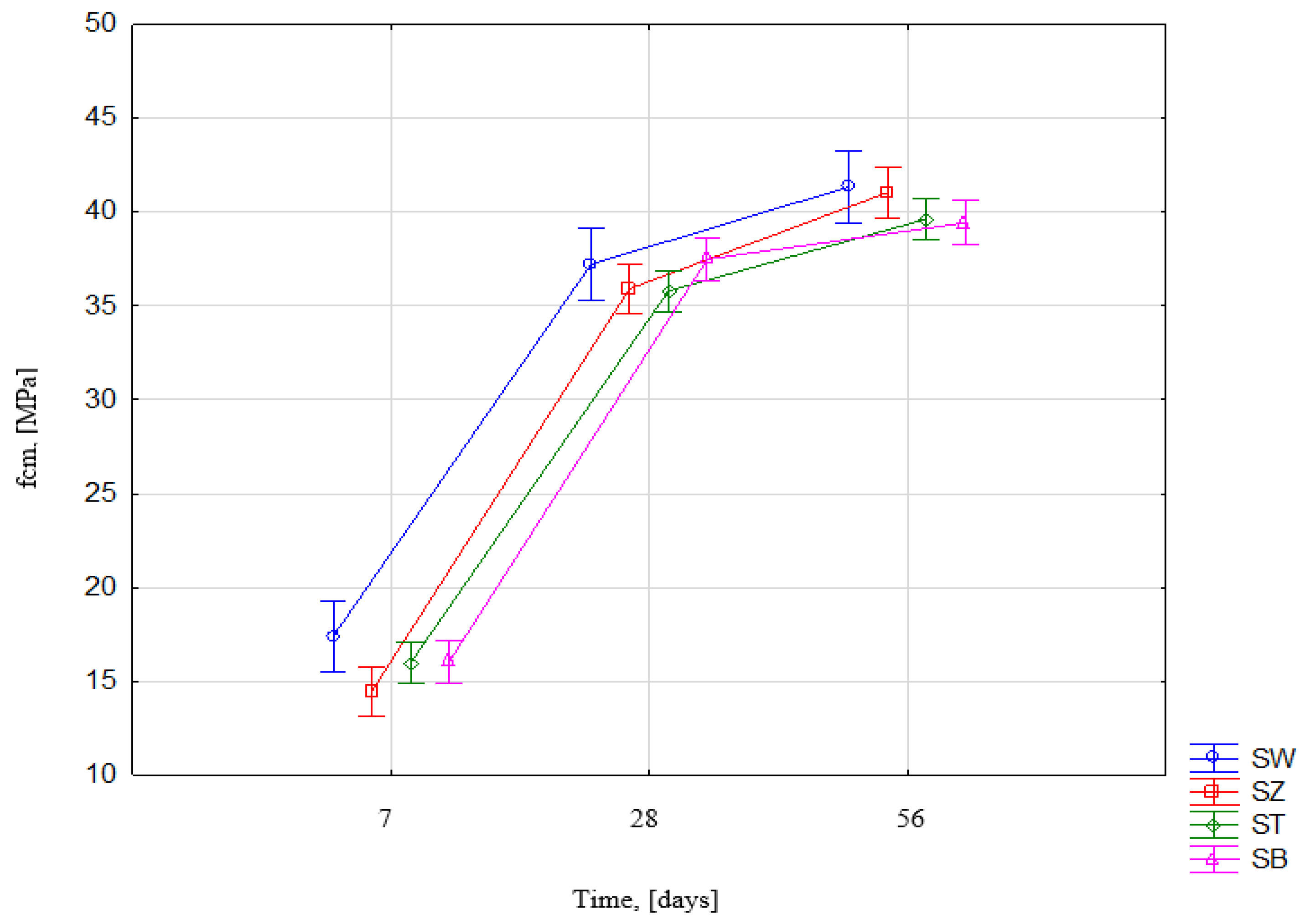

Figure 6 shows the average increase in compressive strength for the tested series of mortars with the addition of selected fibres. The determination of compressive and flexural strength was performed on three standard specimens of 4 cm × 4 cm × 16 cm according to PN-EN 1015-11:2020-04 [

48].

An analysis of the results of tests conducted by Głodkowska and Kobak [

7] on compressive strength shows that steel fibres added in quantities of up to 1% of the volume effectively increase this strength. Above this level, there is no significant increase in compressive strength. The addition of steel fibres in an amount of up to 1% increases compressive strength by approx. 33% compared to the material without fibres. The results obtained indicate that, in economic terms, the maximum steel fibre content in terms of compressive strength is 1%.

Statistical calculations of compressive strength gain were performed using StatisticaStatSoft 13.00 software for an assumed significance level of α = 0.05. When comparing measurable variables with a normal distribution and homogeneous variance within groups, the ANOVA test was used, while Welch’s F-test was applied if the variance was not homogeneous. In addition, for dependent variables with a normal distribution, the ANOVA test for repeated measures was used. A detailed assessment of differences between groups was performed using Tukey’s post hoc multiple comparisons test. Correlation analysis was calculated using Pearson’s correlation coefficient.

The calculated analysis (

Table 6 and

Table 7) showed a significantly statistical relationship for the SW, SZ, ST and SB samples after 7 days (

p < 0.001). In addition, there were differences (Tukey’s post hoc test) between SW and SZ (

p < 0.001); SW and ST (

p = 0.023); SW and SB (

p = 0.029); SZ and ST (

p = 0.013); and SZ and SB (

p = 0.010) (

Table 6). The highest compressive strength was found in the SW mortar (17.37 ± 0.90), while the lowest was found in the SZ mortar (14.46 ± 0.52). The fcm values for the SW, SZ, ST and SB specimens were the same for experiments conducted after 28 days (

p = 0.149) and after 56 days (

p = 0.370). In summary, the compressive strengths of the above mortars (SW; SZ; ST and SB) tested after 28 and 56 days are not significantly different from each other.

There are significant statistical differences between compressive strength for the SW (

p < 0.001); SZ (

p < 0.001); ST (

p < 0.001); and SB (

p < 0.001) series after 7, 28 and 56 days (

Table 8).

Using Tukey’s test, we obtained differences between the compressive strength for the SW series between 7 and 28 days (

p < 0.001); 7 and 56 days (

p < 0.001); and 28 and 56 days (

p = 0.046;). The SZ series’ strength varied between 7 and 28 days (

p < 0.001); 7 and 56 days (

p < 0.001); and 28 and 56 days (

p = 0.002). The ST series’ strength varied between 7 and 28 days (

p < 0.001); 7 and 56 days (

p < 0.001); and 28 and 56 days (

p = 0.001). The SB fibre type varied between 7 and 28 days (

p < 0.001) and 7 and 56 days (

p < 0.001). Using Tukey’s test, we obtained differences between the compressive strength for the SW, SZ, ST and SB series between 7 and 28 days (

p < 0.001) and 7 and 56 days (

p < 0.001), while between 28 and 56 days, the same relationship occurred for the parameters of the SW (

p = 0.046), SZ (

p = 0.002), and ST (

p = 0.001) series. In addition, the average value of fcm [MPa] for the SW, SZ, ST and SB series increased with maturation time after 7, 28 and 56 days (

Table 6). The addition of basalt fibres to mortars resulted in an increase in compressive strength over the entire period studied by an average of about 5%.

The results obtained indicate that glass fibres and steel fibres did not improve the compressive strength of the mortar. The results are quite similar, and the difference ranged from 1 to 3 MPa (

Table 9).

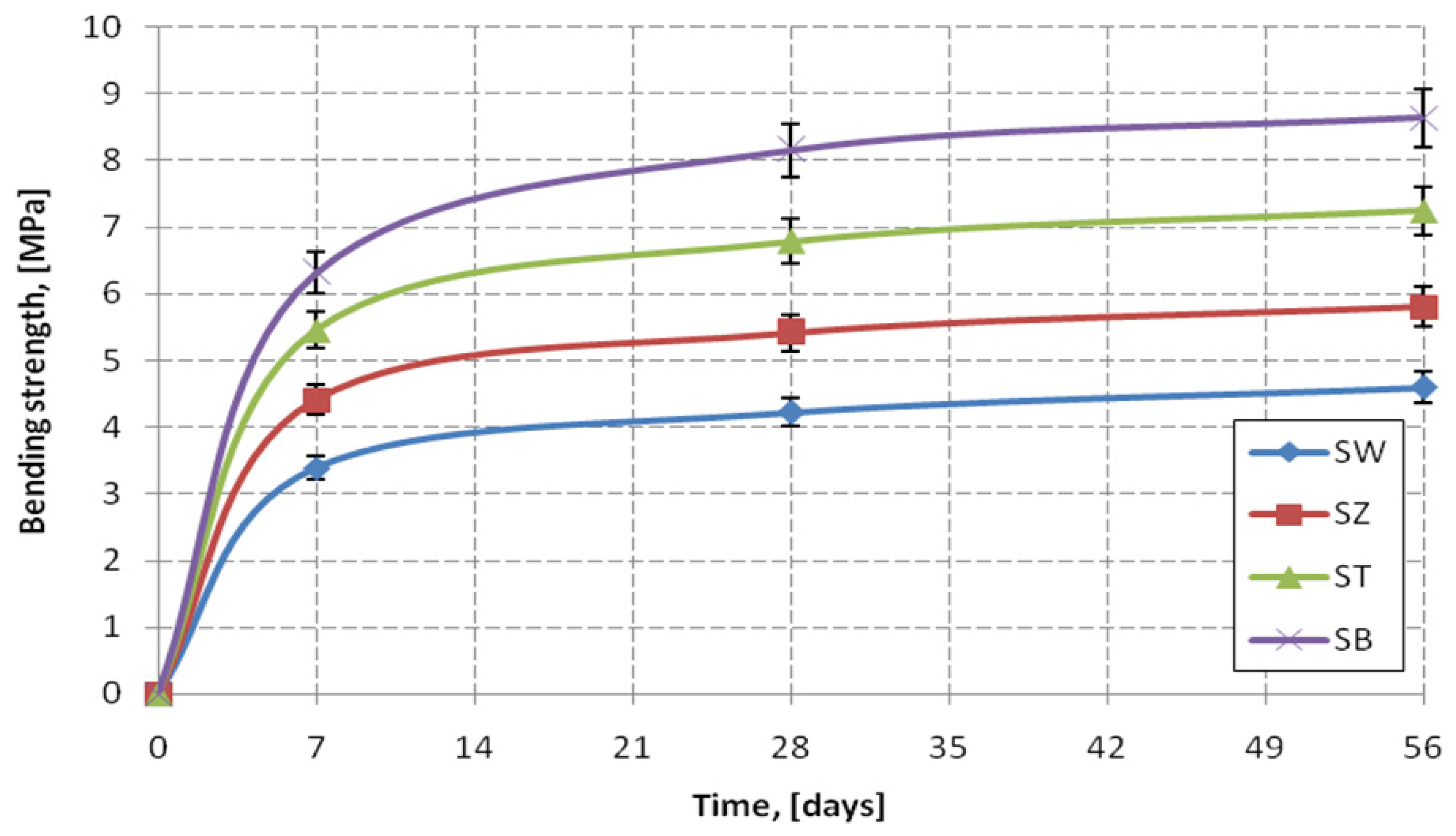

Mortars with basalt fibres showed the highest increase in flexural strength over time compared to the reference series. Samples with these fibres achieved a flexural strength of 8.64 MPa after 56 days of curing. A slightly lower increase was observed in samples enriched with steel fibres—7.56 MPa. The worst bending strength results were obtained for samples without fibre additives. After 56 days, the decrease in strength between the SW and SB series was almost 48% [

Figure 7].

The flexural strength of mortars without fibre additives after 28 days was 4 ÷ 5.4 MPa in the 20th century. In the case of mortars with glass fibres comprising 20% of the cement matrix in relation to the reference mortars, this has increased by 1.3 MPa. In the case of basalt fibres, the results were obtained at 6.5 MPa with approximately 0.5 kg of fibres per 100 kg of cement. In the case of steel fibres, the flexural strength was 6 ÷ 7.5 MPa, with an optimal fibre content of 15 kg/

3 [

52,

53].

The flexural strength test concerns static conditions, which means that the system is not subject to any changes over time. Some researchers have gone further, such as Chen Y., Zhang L., Xu, L. et al. [

6], and studied materials under dynamic conditions. Dynamic loads are crucial for ensuring the safety and durability of structures, especially in situations where sudden or short-term forces occur. Dynamic changes over time show a U-shaped effect in the tested materials. Their strength depends on the material used, the depth of the impact and the forces acting at a given time.

According to research conducted by Lin J., Huang C., Liu C., Chen C., Lin Z., and Lou C. [

54], it appears that dosing steel fibres below 20 kg/m

3 slightly improves strength, which does not increase proportionally to the amount of fibres dosed. The best results were obtained for fibre contents of 25–50 kg/m

3. A fibre dosage above 50 kg/m

3 does not increase strength. Therefore, a dosage of 25 kg/m

3 was used in this study.

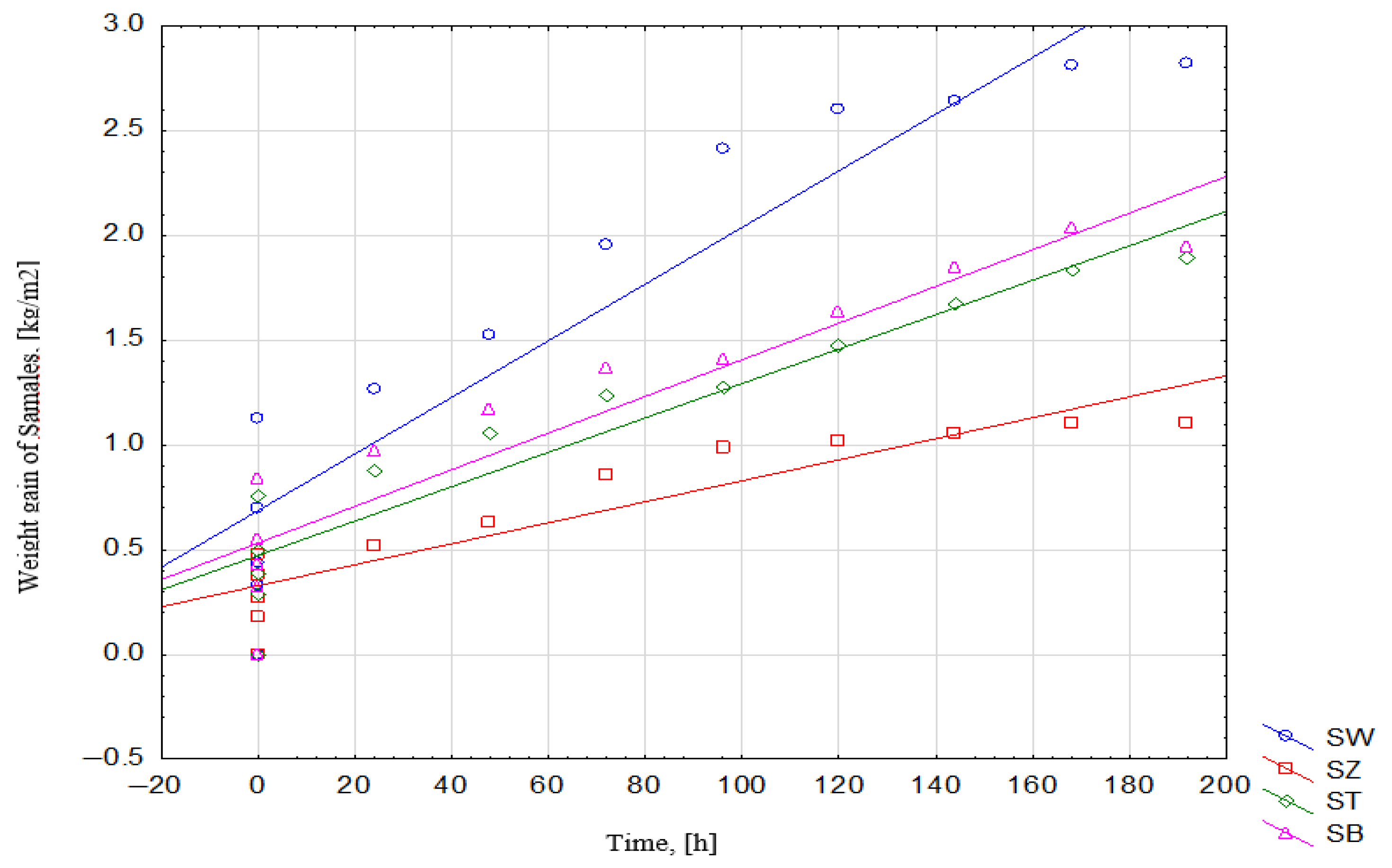

Absorption and capillary rise tests were performed on three barrels from each series of 4 cm × 4 cm × 16 cm mortars after 28 days of maturation [

Figure 8].

There is a statistically significantly high correlation between time and the weight gain of the SW (

p < 0.001), SZ (

p < 0.001), ST (

p < 0.001) and SB (

p < 0.001) samples. The calculated correlation coefficient is positive and therefore the weight gain of the SW, SZ, ST and SB samples increases with time (

Table 10,

Figure 8).

The weight gain of the samples [kg/m

2] differs depending on the type of fibres used in the given SW, SZ, ST or SB series (

p = 0.018). Using the Tukey test, we obtain statistically significant differences between SW and SZ (

p = 0.009). In addition, an equal weight gain of samples was observed between SW and ST (

p = 0.188); SW and SB (

p = 0.336); SZ and ST (

p = 0.576); SZ and SB (

p = 0.373); and ST and SB (

p = 0.986). The largest increase in the weight of samples [kg/m

2] occurred for the SW samples (1.59 ± 1.02),while the smallest occurred for the SZ series (0.66 ± 0.38) (

Table 11,

Figure 9).

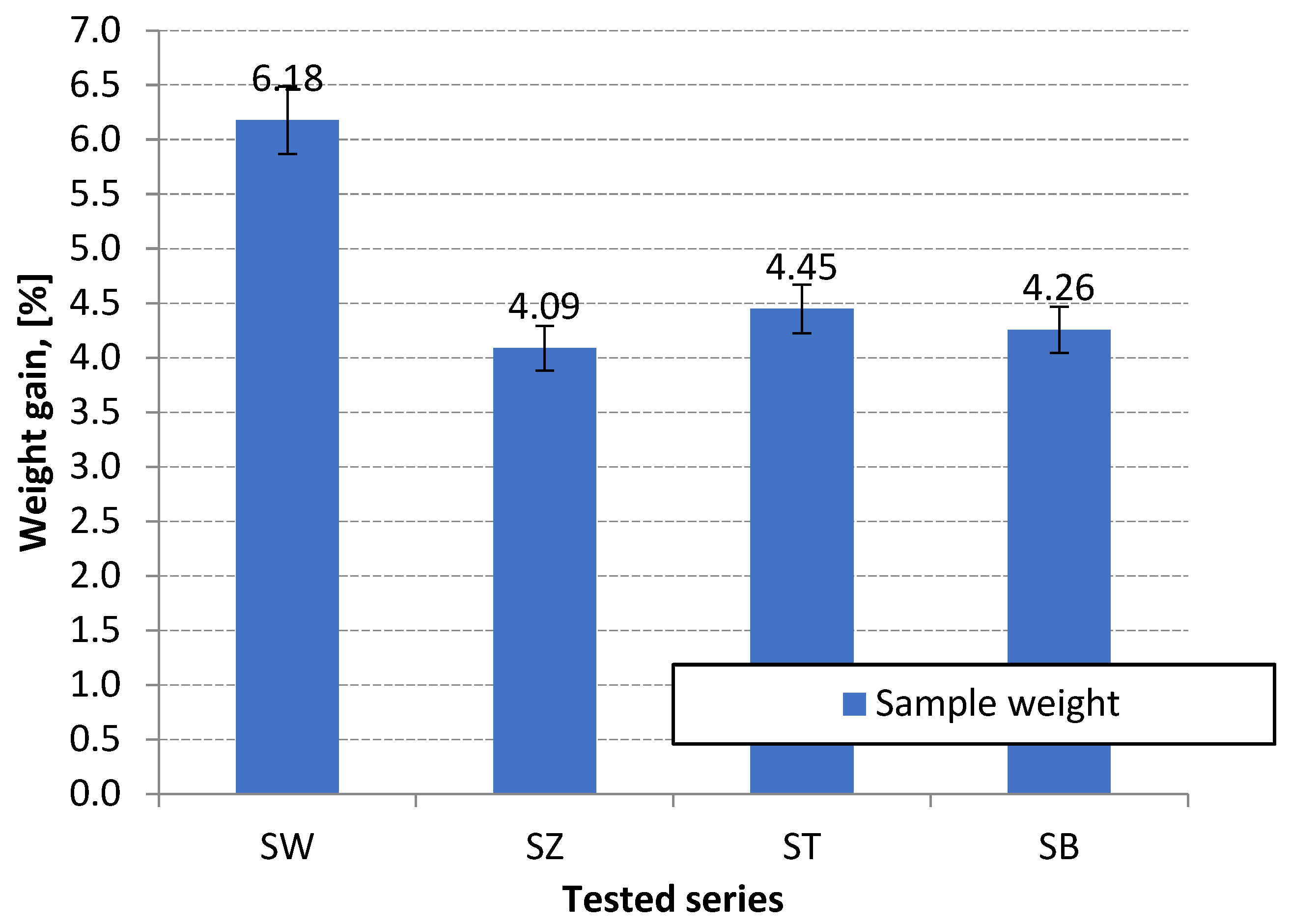

Analysing the results for the weight gain of the samples in the capillary rise and saturation tests (

Figure 10,

Table 12), it can be observed that for the mortars with fibre additives, the weight gain after 28 days of maturation was significantly lower compared to the reference series. For mortars with the addition of fibres, the weight gain was lower by about 30% in the capillary rise test. The addition of fibres to the mortars reduced the water absorption capacity of the mortars tested. For mortars with the addition of fibres, there was a smaller weight gain in the absorbency test by about 2 percentage points for all the mortars with the fibres considered.

In

Figure 11, a linear relationship is developed between absorbability and capillary rise and between compressive strength and flexural strength after 28 days of maturation for the tested series of mortars with steel, glass and basalt fibres. Instead of estimating two parameters, we can perform one laboratory test and estimate the second parameter based on linear relationships.

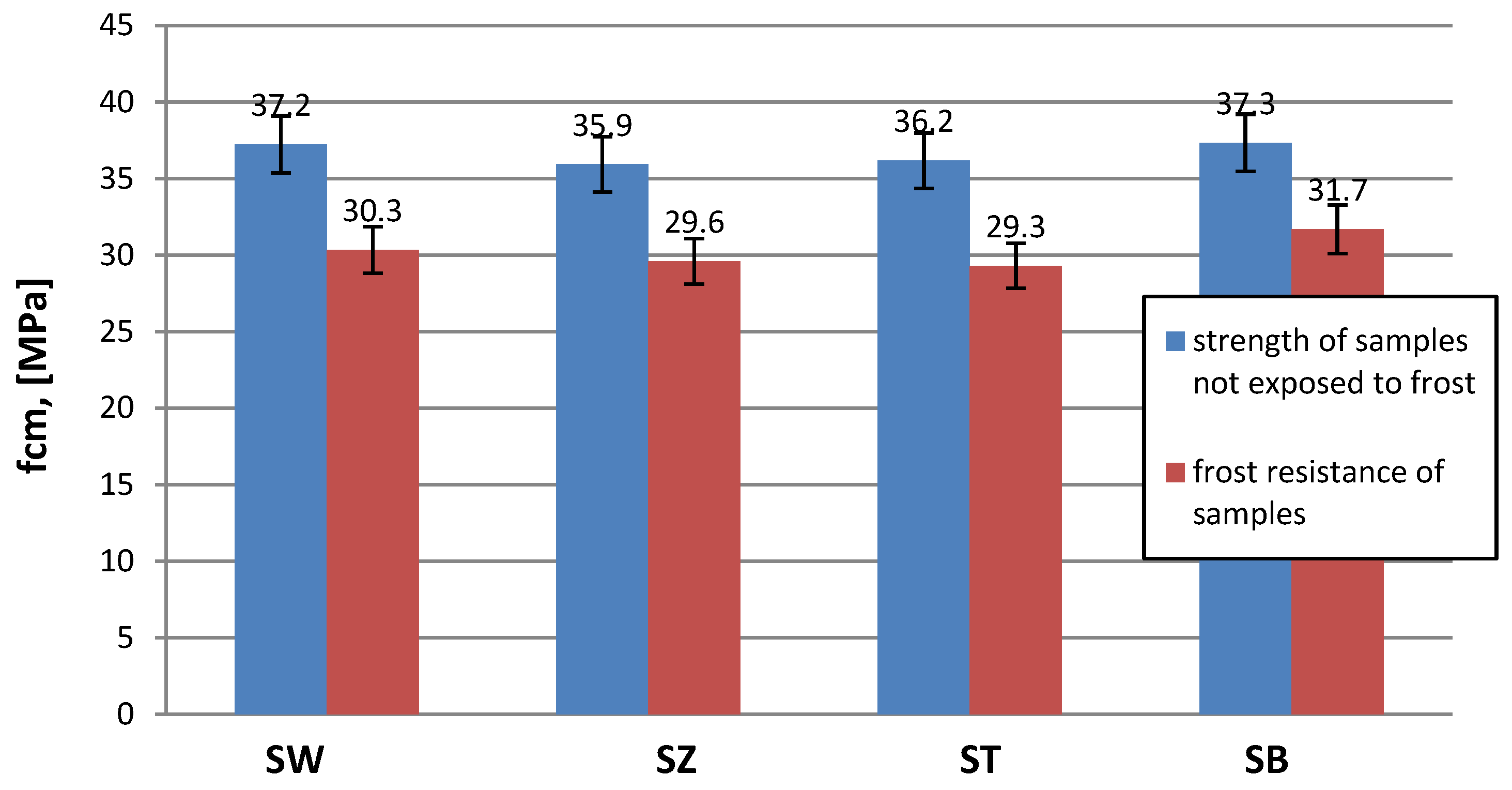

The samples were subjected to 25 cycles. After this time, a decrease in flexural strength was observed, which was greatest for the reference mortar. The mortar with steel fibres proved to be the most frost-resistant. The decrease in flexural strength was approximately 15%.

Based on the presented tests, it can be observed that the mortar with steel fibres exhibits the best frost resistance. This mortar, when exposed to frost after 28 days of curing, showed a 15.1% decrease in compressive strength compared to the reference series. The greatest decrease in compressive strength was recorded for the reference series. After 25 cycles, this decrease was 18.5% [

Figure 13,

Table 14].

After the frost resistance test, the mortars showed comparable mass loss after 25 freeze–thaw cycles (

Table 15).

4. Discussion

After conducting laboratory tests, i.e., on mortars with a standard composition and the addition of steel (ST), glass (SZ) and basalt (SB) fibres, it should be concluded that the issue raised in the article—whether the use of any fibre available on the market will improve all the rheological properties and parameters of hardened mortars—remains open. If we are interested in two parameters, which fibres should we choose? Does the addition of fibres impair any properties of fresh or hardened mortars? Is there a change in the parameters currently being tested compared to those tested twenty years ago on fibres with partially different parameters?

Adding fibres to mortars reduces the slump of fresh mortars in the consistency test conducted on a slump table. For glass fibres, this flow was the lowest. It can be concluded that basalt fibres have the least impact on this parameter. Here, the use of a chemical admixture should also be considered in the case of a mortar with a higher fibre content and low workability. The addition of fibres to mortars significantly affected the change in their volume density. The test showed that the addition of fibres to mortars increased the bulk density compared to the reference series. When glass fibres were used, the volume density increased by 7.7% compared to the SW sample, while for steel fibres, an increase of as much as 14.4% was recorded in relation to the reference series. Fibres in a cement matrix are usually distributed evenly and randomly, both in terms of position and direction. This distribution is mainly due to the difficulty of predicting local tensile stress distributions during the service life of the component. In practice, the distribution of fibres is mainly influenced by the smallest dimension of the component, for example, the thickness of the board. In thin plates, the fibres are usually arranged parallel to their surface, which ensures optimal mechanical properties. Disturbances in the uniform distribution of fibres can occur for various reasons, such as excessive vibration or a concrete mix that is too liquid. To improve the strength properties, it is possible to deliberately order the fibre distribution if the tensile stress distribution in the matrix that will arise during use is known. Based on sample fractures, no agglomeration or clustering of fibres was observed in the tested mortars.

In summary, the compressive strength of the mortars with fibre additives tested after 28 and 56 days of curing did not differ significantly. The differences in the compressive strength increase ranged from 1 to 3 MPa. Here, the type of fibre used did not affect this parameter. The positive effect of fibres on compressive strength is due to the likelihood of the fibre itself being located along the crack path leading to the destruction of the sample at a position that still allows them to be bridged.

In the flexural strength test, the type of fibre used in the mortar is very important. Compared to the reference series (SW), mortars with basalt fibres achieved the highest increase in flexural strength: by 48% after 28 days and by 47% after 56 days of curing. The extended curing time of the mortars did not affect the trend in flexural strength gain. The next mortars to achieve higher flexural strength gains were those with steel fibres. Their flexural strength was lower by 16.7% than that of the mortars with basalt fibres after 28 days of curing. The differences in strength between individual samples with different fibre contents described above indicate the clear influence of the fibres used and their content on the strength of concrete. While there are differences in the assessment of the increase in bending strength, the vast majority of authors confirm the beneficial effect of fibres on improving this parameter. The increase in this parameter results from the type and amount of fibre introduced. In general, the brittleness of cement mortar in this case is improved by introducing a specific type of fibre. Each type of fibre used in mortar with the same composition produces different bending strength values.

In the capillary pull-up test, the series with steel fibres showed the lowest mass increase compared to the other tested series. Compared to the reference series, this decrease was 60.6%. In general, all series with fibre additives showed a lower mass increase in the capillary pull-up test. In the water absorption test, a similar trend was observed, with glass fibre mortar samples showing the lowest mass increase. Compared to the reference series, this decrease was 33.8%. All tested series were characterised by water absorption below 5%. Therefore, they can be used in places exposed to moisture. This is because fibres limit the formation of microcracks and shrinkage cracks, which promote water migration in mortars. In addition, fibres improve the tightness and homogeneity of mortars, which also contributes to reducing water absorption.

Laboratory tests are also time-consuming. In order to avoid performing more laboratory tests, relationships between individual parameters for the analysed series can be developed. This allows conclusions to be drawn about other parameters based on the results of a single test, thereby reducing the number of tests required. This article presents such relationships for the analysed series, enabling more effective and economical testing.

A statistical analysis was also performed for the results obtained for two parameters: compressive strength and capillary pull-up. Depending on the parameters we want to improve in the mortars, we can select a specific fibre type. Glass fibres primarily reduce the capillary pull-up and water absorption of mortars. If we want to achieve the highest possible flexural strength, we should choose mortars with basalt fibres. Mortars modified with basalt fibres are also less resistant to moisture than mortars modified with glass fibres.

In the next stage of our planned research, we will focus on the analysis of the microstructure of mortars. We will discuss the theoretical aspects of the issue under consideration. We will focus on theoretical analyses and model cause-and-effect relationships. These issues will be the subject of further scientific research.

5. Conclusions

The test results provide a basis for the following conclusions:

The addition of basalt fibres to the mortar increased its compressive strength by approximately 5%. The compressive strength results are quite similar, with a difference ranging from 1 to 3 MPa.

The mortars with basalt fibres showed the greatest increase in flexural strength after 7, 28 and 56 days of curing. Comparable results were obtained for the mortars enriched with steel fibres. The reference mortar showed the worst bending strength results. A statistical analysis was performed, which allowed us to conclude that the fcm values for the SW, SZ, ST and SB samples were the same for tests carried out after 28 days (p = 0.149) and after 56 days (p = 0.370). In summary, the compressive strengths of the mortars under consideration (SW, SZ, ST and SB) tested after 28 and 56 days did not differ from each other.

In the capillary pull-up test, it could be observed that for mortars with fibre additives, the weight gain after 28 days of curing was approximately 30% lower. The weight gain of the samples differed depending on the type of fibre used: SW, SZ, ST or SB (p = 0.018). In addition, the same weight gain was observed between SW and ST (p = 0.188); SW and SB (p = 0.336); SZ and ST (p = 0.576); SZ and SB (p = 0.373); and ST and SB (p = 0.986). The highest weight gain [kg/m2] was observed for the SW samples (1.59 ± 1.02), while the lowest was observed for the SZ series (0.66 ± 0.38).

In the water absorption test, the mortars with fibre additives were characterised by a lower weight gain of approximately 2% compared to the mortars without fibre additives.

The air pore characteristics have an impact on the improvement in the water absorption and capillary rise parameters of mortars. In mortars with dispersed reinforcement, there is a favourable reduction in the pore distribution index, L. The main mechanism influencing the improvement in these parameters seems to be so-called microcrack bridging by fibres. Thanks to this phenomenon, there is a lower increase in the mass of mortars.

Linear relationships between compressive strength and flexural strength, as well as between water absorption and capillary pull-up, were developed for the mortars tested. These relationships allow only one parameter to be tested in the laboratory, while the others can be estimated on the basis of a linear relationship.

When determining the decrease in compressive strength, the most frost-resistant mortar was found to be the steel fibre mortar, whose compressive strength decreased by 15.1% after 28 days. The greatest decrease in compressive strength was observed in the reference series. After 25 cycles, this decrease was 18.5%. After the frost resistance test, the mortars showed a comparable loss of mass after 25 freeze–thaw cycles, amounting to less than 5%.

Steel fibre is the fibre with the highest modulus of elasticity and stiffness among commonly used fibres. Therefore, the use of steel fibres can significantly improve the mortar’s compressive and flexural strength. Steel fibre-reinforced mortar is characterised by greater resistance to freezing and thawing, as it reduces the number of microcracks in the cement matrix. It also reduces weight gain when in contact with water by hindering its transport to other parts of the mortar. The addition of steel fibres strengthens structural elements by improving their load-bearing capacity and durability, but they can also be used to reinforce existing structures undergoing repairs.