Multi-Probe Measurement Method for Error Motion of Precision Rotary Stage Based on Reference Plate

Abstract

1. Introduction

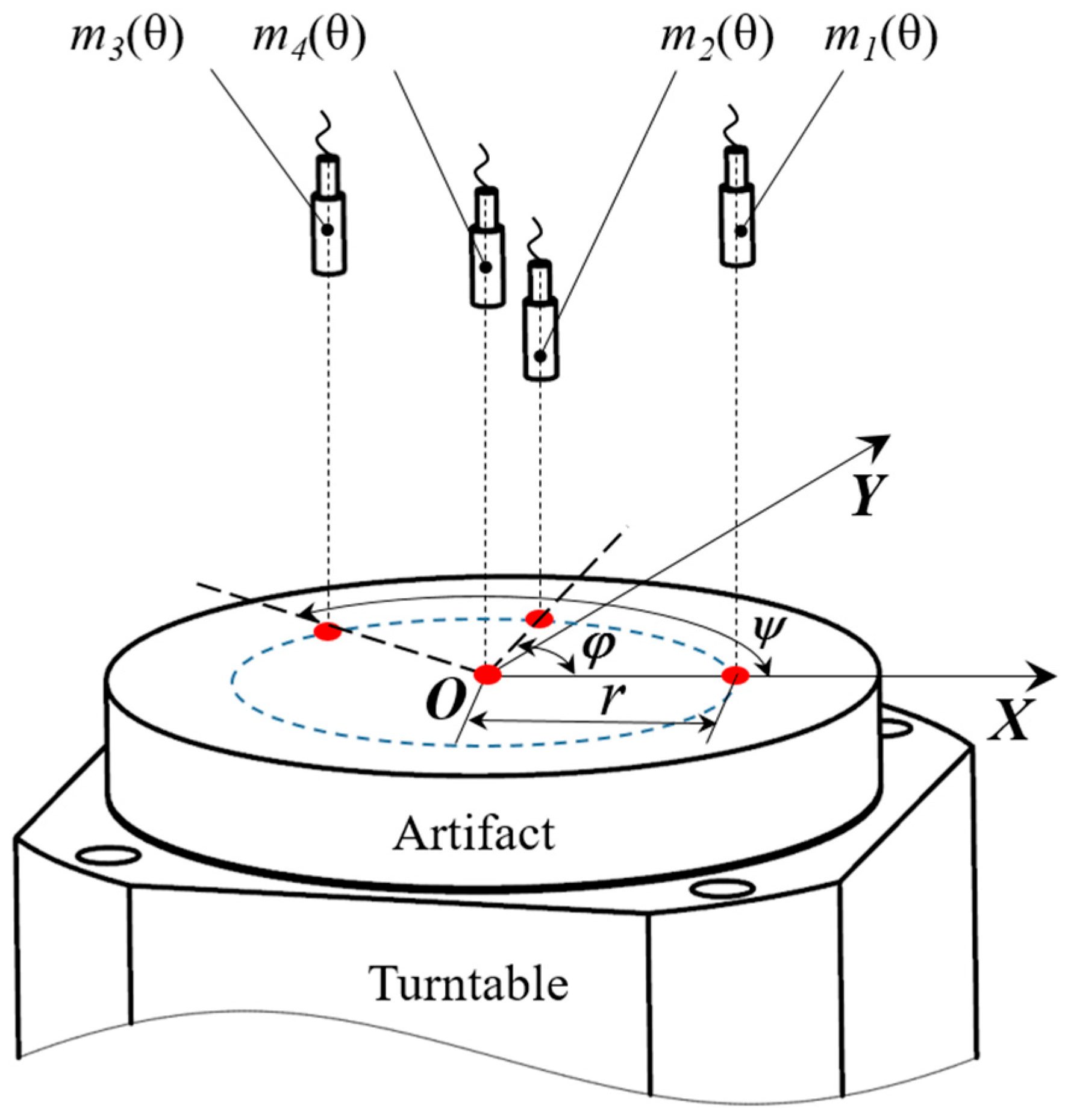

2. Multi-Probe Measurement Method for Error Motion Based on Reference Plate

2.1. Analysis of Conventional Three-Probe Measurement Method

2.2. Multi-Probe Measurement Method Based on Reference Plate

| : | axial error motion of the axis of rotation, coaxial to the axis; |

| : | fundamental synchronous axial error motion of the axis of rotation; |

| : | residual synchronous axial error motion of the axis of rotation; |

| : | asynchronous axial error motion of the axis of rotation; |

| : | form error of the reference plate as a function of the radial (r) and angular (θ) positions; |

| : | fundamental form error of the reference plate; |

| : | residual form error of the reference plate. |

3. Experimental Setup

4. Experimental Results and Discussion

5. Conclusions

- 1.

- Face error motion can be mathematically modeled as a function of its X-axis and Y-axis components.

- 2.

- Probe distribution with prime-numbered angular intervals demonstrates optimal efficacy in eliminating harmonic suppression issues.

- 3.

- The reference plate-based multi-probe measurement method enables in situ measurement of tilt and axial error motions, though its inability to simultaneously measure radial error motions presents a limitation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, J.; Shin, D.; Yun, D.; Han, C. The analysis of radial/axial error motion on a precision rotation stage. Int. J. Electr. Electron. Eng 2007, 1, 248–252. [Google Scholar]

- Masiji, S. Contribution of radial error motion to roundness profile of workspace in turning. J. Jpn. Soc. Precis. Eng 1980, 5, 93–98. [Google Scholar]

- Marsh, E.; Couey, J.; Vallance, R. Nanometer-level comparison of three spindle error motion separation techniques. J. Manuf. Sci. Eng. 2006, 128, 180–187. [Google Scholar] [CrossRef]

- Evans, C.J.; Hocken, R.J.; Estler, W.T. Self-calibration: Reversal, redundancy, error separation, and ‘absolute testing’. CIRP Ann. 1996, 45, 617–634. [Google Scholar] [CrossRef]

- Donaldson, R.R. A simple method for separating spindle error from test ball roundness error. Ann. CIRP 1972, 21, 125. [Google Scholar]

- Estler, W.T.; Evans, C.J.; Shao, L. Uncertainty estimation for multiposition form error metrology. Precis. Eng. 1997, 21, 72–82. [Google Scholar] [CrossRef]

- Chetwynd, D.; Siddall, G. Improving the accuracy of roundness measurement. J. Phys. E Sci. Instrum. 1976, 9, 537. [Google Scholar] [CrossRef]

- Whitehouse, D. Some theoretical aspects of error separation techniques in surface metrology. J. Phys. E Sci. Instrum. 1976, 9, 531. [Google Scholar] [CrossRef]

- Grejda, R.D. Use and Calibration of Ultraprecision Axes of Rotation with Nanometer Level Metrology. Ph.D. Thesis, The Pennsylvania State University, University Park, PA, USA, 2002. [Google Scholar]

- Xu, H.; Sun, Z.; Dai, Y.; Guan, C.; Hu, H.; Wang, Y. In situ measurement of spindle radial error for ultra-precision machining based on three-point method. Micromachines 2023, 14, 653. [Google Scholar] [CrossRef]

- Geng, Z.; Tong, Z.; Jiang, X. Review of geometric error measurement and compensation techniques of ultra-precision machine tools. Light. Adv. Manuf. 2021, 2, 211–227. [Google Scholar] [CrossRef]

- Liu, X.; Rui, X.; Mi, L.; Tang, Q.; Chen, H.; Xia, Y. Radial error motion measurement and its uncertainty estimation of ultra precision axes of rotation with nanometer level precision. Micromachines 2022, 13, 2121. [Google Scholar] [CrossRef]

- LionPrecision. Spindle Error Analyzer (SEA). Available online: https://www.lionprecision.com/products/spindle-error-analyzer/ (accessed on 18 June 2025).

- Lee, J.; Gao, W.; Shimizu, Y.; Hwang, J.; Oh, J.S.; Park, C.H. Spindle error motion measurement of a large precision roll lathe. Int. J. Precis. Eng. Manuf. 2012, 13, 861–867. [Google Scholar] [CrossRef]

- Salsbury, J.G. Implementation of the Estler face motion reversal technique. Precis. Eng. 2003, 27, 189–194. [Google Scholar] [CrossRef]

- Shi, S.; Lin, J.; Wang, X.; Zhao, M. A hybrid three-probe method for measuring the roundness error and the spindle error. Precis. Eng. 2016, 45, 403–413. [Google Scholar] [CrossRef]

- He, Z.; Fu, J.; Zhang, L.; Yao, X. A new error measurement method to identify all six error parameters of a rotational axis of a machine tool. Int. J. Mach. Tools Manuf. 2015, 88, 1–8. [Google Scholar] [CrossRef]

- Park, S.-R.; Hoang, T.-K.; Yang, S.-H. A new optical measurement system for determining the geometrical errors of rotary axis of a 5-axis miniaturized machine tool. J. Mech. Sci. Technol. 2010, 24, 175–179. [Google Scholar] [CrossRef]

- Bao, C.; Feng, Q.; Li, J. Simultaneous measurement method and error analysis of the six degrees-of-freedom motion errors of a rotary axis. Appl. Sci. 2018, 8, 2232. [Google Scholar] [CrossRef]

- Li, J.; Feng, Q.; Bao, C.; Zhao, Y. Method for simultaneous measurement of five DOF motion errors of a rotary axis using a single-mode fiber-coupled laser. Opt. Express 2018, 26, 2535–2545. [Google Scholar] [CrossRef]

- Liu, C.-S.; Hsu, H.-C.; Lin, Y.-X. Design of a six-degree-of-freedom geometric errors measurement system for a rotary axis of a machine tool. Opt. Lasers Eng. 2020, 127, 105949. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, Z.; Dong, D.; Feng, T.; Qiu, Q.; Meng, F.; Wang, G.; Cui, C.; Ji, R.; Pan, Y.; et al. A transit tilt and offset errors calibration method for improving laser tracker measurement accuracy based on the telecentric measurement system. Appl. Sci. 2024, 14, 2251. [Google Scholar] [CrossRef]

- Marsh, E.R.; Arneson, D.A.; Martin, D.L. A comparison of reversal and multiprobe error separation. Precis. Eng. 2010, 34, 85–91. [Google Scholar] [CrossRef]

- Liu, T.; Liu, Y.; Chen, S. Hydrostatic Gas Lubrication; Harbin Institute of Technology Press: Harbin, China, 1990. [Google Scholar]

| Components | Tx(θ).Sync /μrad | Tx(θ).Async /μrad | Ty(θ).Sync /μrad | Ty(θ).Async /μrad | Z(θ).Sync /nm | Z(θ).Async /nm |

|---|---|---|---|---|---|---|

| [0°,37°,313°] | 4.04 | 0.65 | 3.57 | 0.8 | 67.1 | 7.2 |

| [0°,90°,313°] | 3.74 | 0.44 | 3.62 | 0.52 | 68.1 | 5.1 |

| [0°,120°,163°] | 3.89 | 0.48 | 3.92 | 0.47 | 70.3 | 6.3 |

| [0°,120°,211°] | 4.02 | 0.49 | 3.62 | 0.68 | 70.1 | 4.9 |

| [0°,120°,313°] | 3.93 | 0.63 | 3.80 | 0.77 | 71.4 | 8.4 |

| [0°,163°,313°] | 3.98 | 0.72 | 3.89 | 0.63 | 68.5 | 7.8 |

| [0°,240°,313°] | 3.74 | 0.67 | 3.79 | 0.72 | 70.3 | 6.7 |

| Average | 3.91 | 0.58 | 3.74 | 0.66 | 69.4 | 6.6 |

| Max absolute error to average | 0.17 | 0.14 | 0.18 | 0.19 | 2.3 | 1.8 |

| Max relative error to average (%) | 4.24 | 24.51 | 4.69 | 28.32 | 3.31 | 26.72 |

| Items | Reversal | SEA | Interferometry | Multi-Probe |

|---|---|---|---|---|

| Setup simplicity | Yes | No | No | Yes |

| Measurement accuracy | Yes | Yes | Yes | Yes |

| Measurement repeatability | Yes | Yes | Yes | Yes |

| Low cost | No | No | No | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, X.; Zheng, T.; Zhang, D.; Ni, Z.; Zhang, L.; Mu, D. Multi-Probe Measurement Method for Error Motion of Precision Rotary Stage Based on Reference Plate. Appl. Sci. 2025, 15, 8643. https://doi.org/10.3390/app15158643

Zheng X, Zheng T, Zhang D, Ni Z, Zhang L, Mu D. Multi-Probe Measurement Method for Error Motion of Precision Rotary Stage Based on Reference Plate. Applied Sciences. 2025; 15(15):8643. https://doi.org/10.3390/app15158643

Chicago/Turabian StyleZheng, Xiaofeng, Tianhao Zheng, Daowei Zhang, Zhixue Ni, Lei Zhang, and Deqiang Mu. 2025. "Multi-Probe Measurement Method for Error Motion of Precision Rotary Stage Based on Reference Plate" Applied Sciences 15, no. 15: 8643. https://doi.org/10.3390/app15158643

APA StyleZheng, X., Zheng, T., Zhang, D., Ni, Z., Zhang, L., & Mu, D. (2025). Multi-Probe Measurement Method for Error Motion of Precision Rotary Stage Based on Reference Plate. Applied Sciences, 15(15), 8643. https://doi.org/10.3390/app15158643