3.1. Overall Impacts and Contribution Analysis

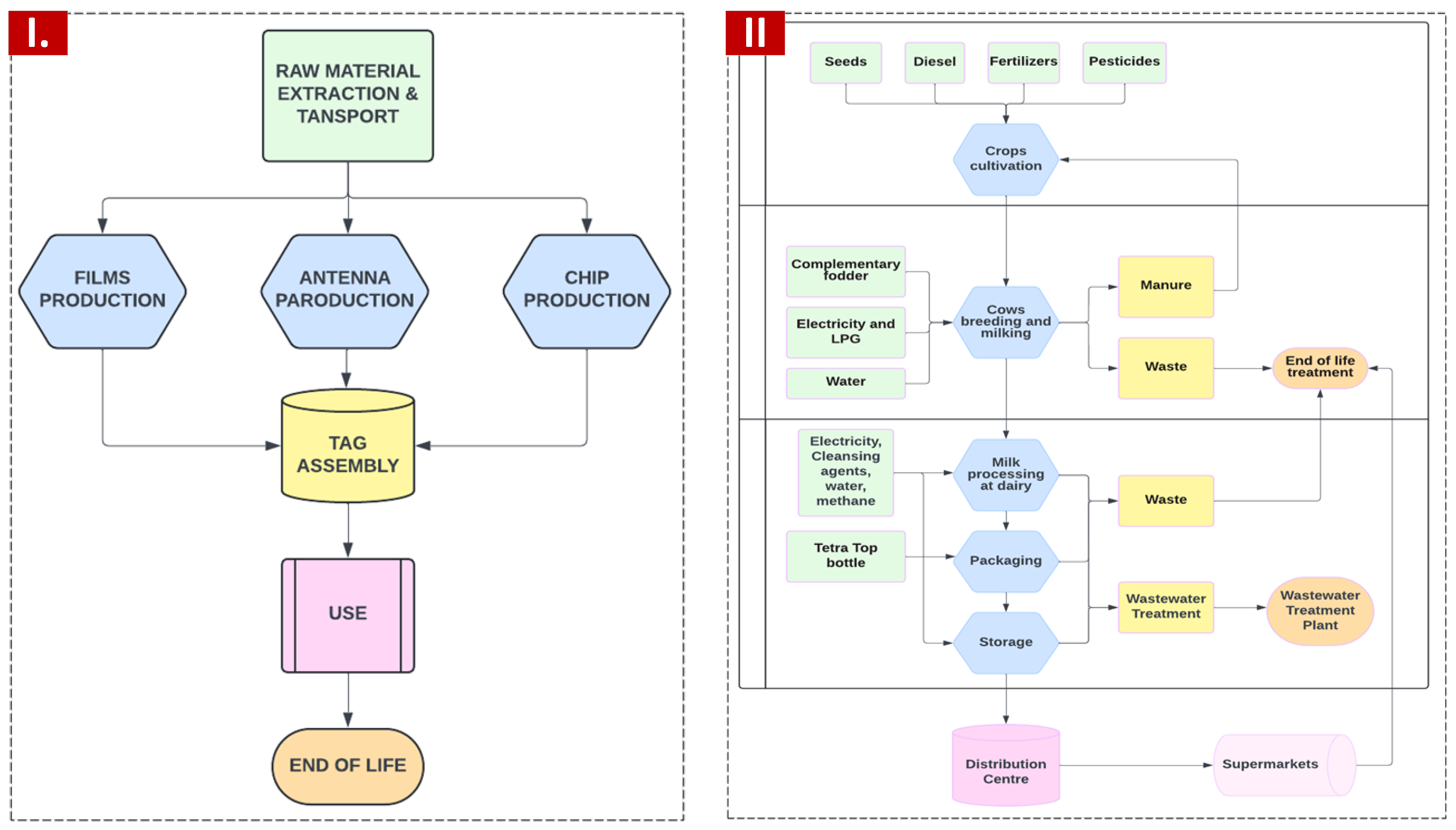

Both the benefits and drawbacks of using RFID tags for fresh milk are examined. This begins with analyzing two models: one assessing the environmental impact of producing a single RFID tag, and the other evaluating the life cycle of one liter of milk ending up in a landfill.

Figure 2 provides a detailed breakdown, showing how RFID implementation affects each milk case. The negative impact is equivalent to 8.3% of a tag’s life cycle, considering that RFID tags are attached to cases with 12 items. The “Avoided milk waste” column quantifies the benefits of RFID, representing 2.6% of the milk’s life cycle.

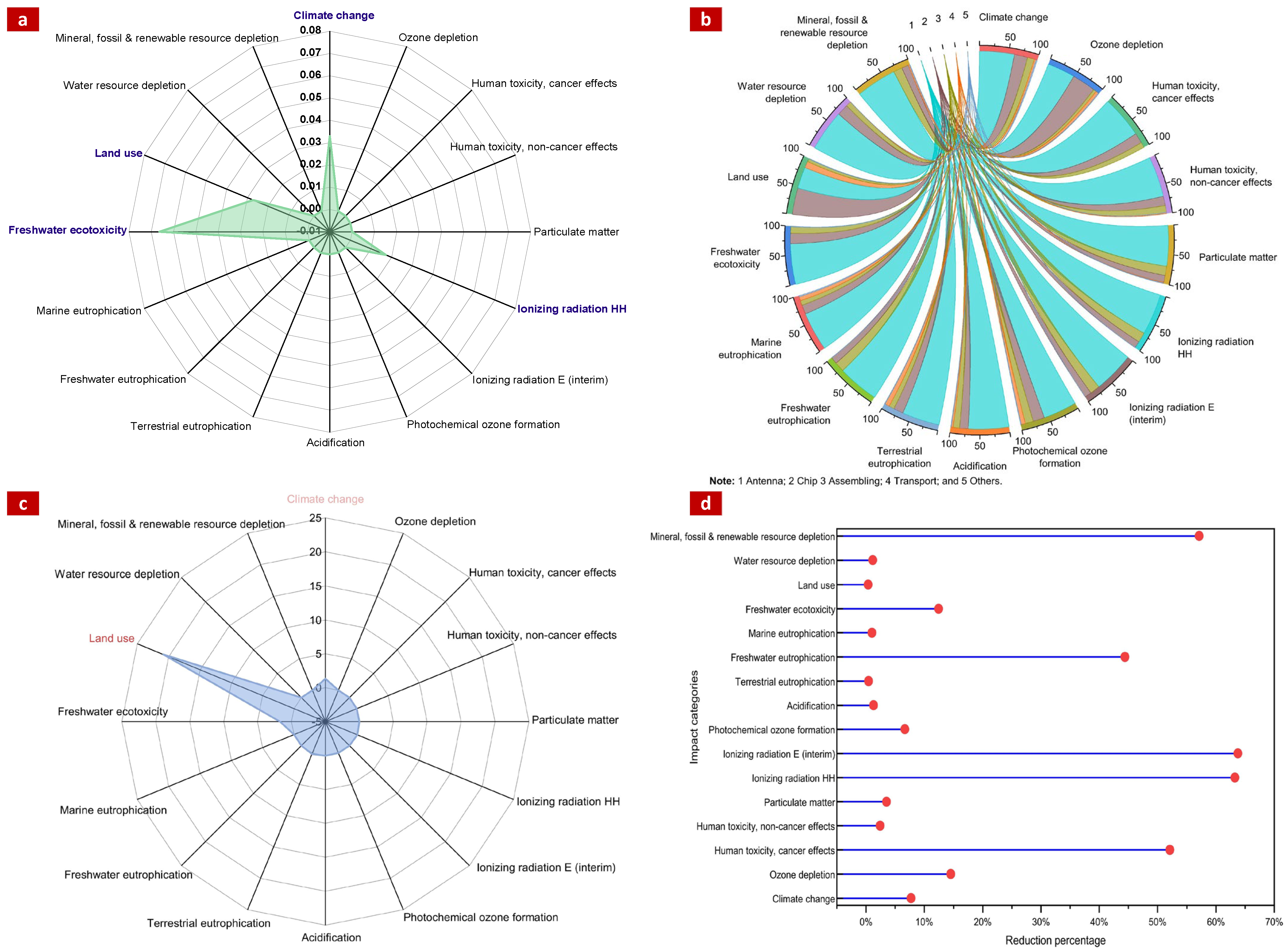

Figure 2a presents the impact assessment results for one RFID tag, showing the environmental burden of its entire life cycle. The climate change impact, measured at 0.0329 kg CO

2-eq, highlights substantial GHG emissions from RFID production, underscoring the need for energy reduction strategies. Ionizing radiation is also a concern, reflecting the burden of nuclear energy used in production. Freshwater ecotoxicity is one of the most significant impacts, indicating potential harm to aquatic ecosystems due to toxic substances released during the production of RFID tags. These substances can contaminate water bodies, affecting aquatic life and disrupting ecosystems. Addressing the sources of these toxic releases is crucial to mitigate their impact on freshwater environments. Emissions of volatile organic compounds contribute to photochemical ozone formation. Resource use, including water and minerals, is moderate but noteworthy. Significant reductions are observed in acidification and eutrophication, with RFID reducing the need for excessive fertilizers.

Figure 2b provides a visual representation of these results, emphasizing how each process contributes to the overall environmental impact of the tag. Among the processes, antenna manufacturing has the most significant impact, contributing between 36% and 73% across all categories, with an average of 64%. Chip manufacturing also plays a substantial role, contributing between 11% and 43%, with an average of 20%. The assembly process makes a notable contribution as well, averaging 11%, while transport activities have a smaller impact, averaging 3%. Other processes combined contribute less than 2% to the total environmental burden.

Figure 2c demonstrates that the environmental impacts of 1 L of fresh milk are assessed across multiple categories, covering its entire life cycle, from production to disposal. The climate change impact, measured at 1.34 kg CO

2-eq, highlights substantial GHG emissions from RFID production, underscoring the need for energy reduction strategies. Land use presents a significant environmental burden, measured at 20.9 kg C deficit, indicating substantial resource occupation during the RFID tag’s life cycle. Prioritizing the reduction of land use impact is crucial, as optimizing land use practices can help minimize negative impacts on ecosystems and biodiversity. Ionizing radiation is also a concern, reflecting the burden of nuclear energy used in production. Freshwater ecotoxicity has another significant impact, with a value of 1.70 CTUe, indicating potential harm to aquatic ecosystems due to toxic substances released during production. Addressing the sources of these toxic releases is crucial to mitigating their impact on freshwater environments. Emissions of volatile organic compounds contribute to photochemical ozone formation. Resource use, including water and minerals, is moderate but noteworthy. Despite these impacts, RFID helps improve resource utilization by preventing milk loss, which reduces the need for additional production and associated resource use. Significant reductions are observed in acidification and eutrophication, primarily due to RFID’s role in reducing milk loss, which in turn reduces the need for additional production and excessive fertilizer use.

Figure 2d assesses the environmental trade-off analysis of RFID technology for tagging milk product cases involving a thorough evaluation of both the positive and negative environmental impacts. A particularly important outcome demonstrates that RFID technology leads to a net decrease of approximately 32 g of CO

2-eq per FU (0.0027 kg CO

2-eq from the RFID tag vs. 0.0349 kg CO

2-eq avoided through reduced milk waste). This reduction is critical in light of global efforts to reduce GHG emissions and combat climate change. Furthermore, examining the data shows that RFID deployment leads to significant reductions across various environmental impact categories. Notable improvements are observed in categories such as terrestrial eutrophication, land use, acidification, human toxicity (non-cancer effects), particulate matter, and water resource depletion. These categories show substantial progress in environmental performance. For instance, reductions of over 50% are evident in human toxicity (cancer effects), human health ionizing radiation, ionizing radiation (ecosystems), freshwater eutrophication, and mineral, fossil, and renewable resource depletion. On average, the benefits outweigh the impacts by a factor of five, demonstrating a clear net positive outcome from RFID technology implementation. These reductions emphasize RFID’s potential to mitigate environmental damage across multiple dimensions, making it a key contributor to sustainability efforts and reducing the environmental footprint in industries such as milk production.

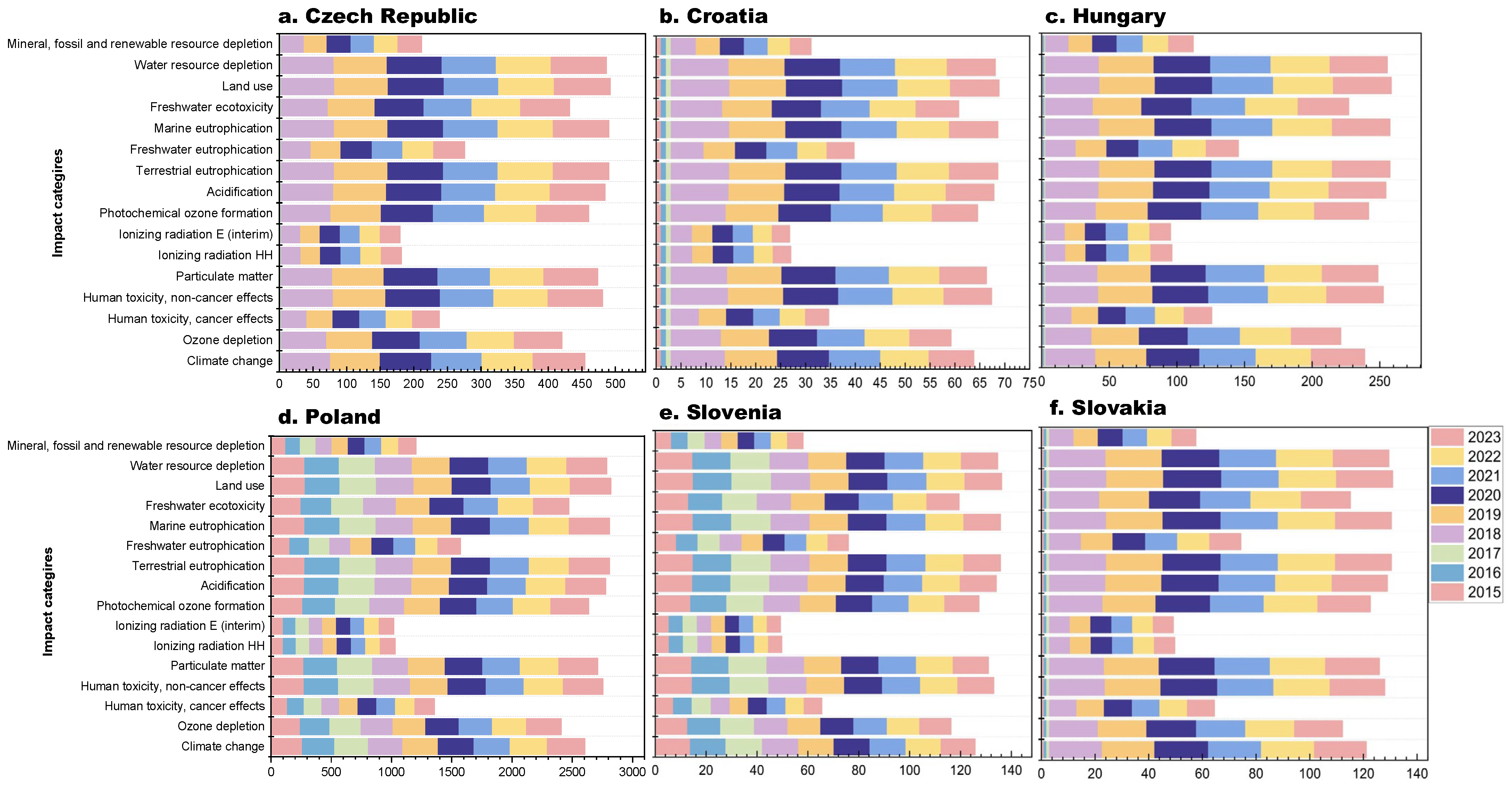

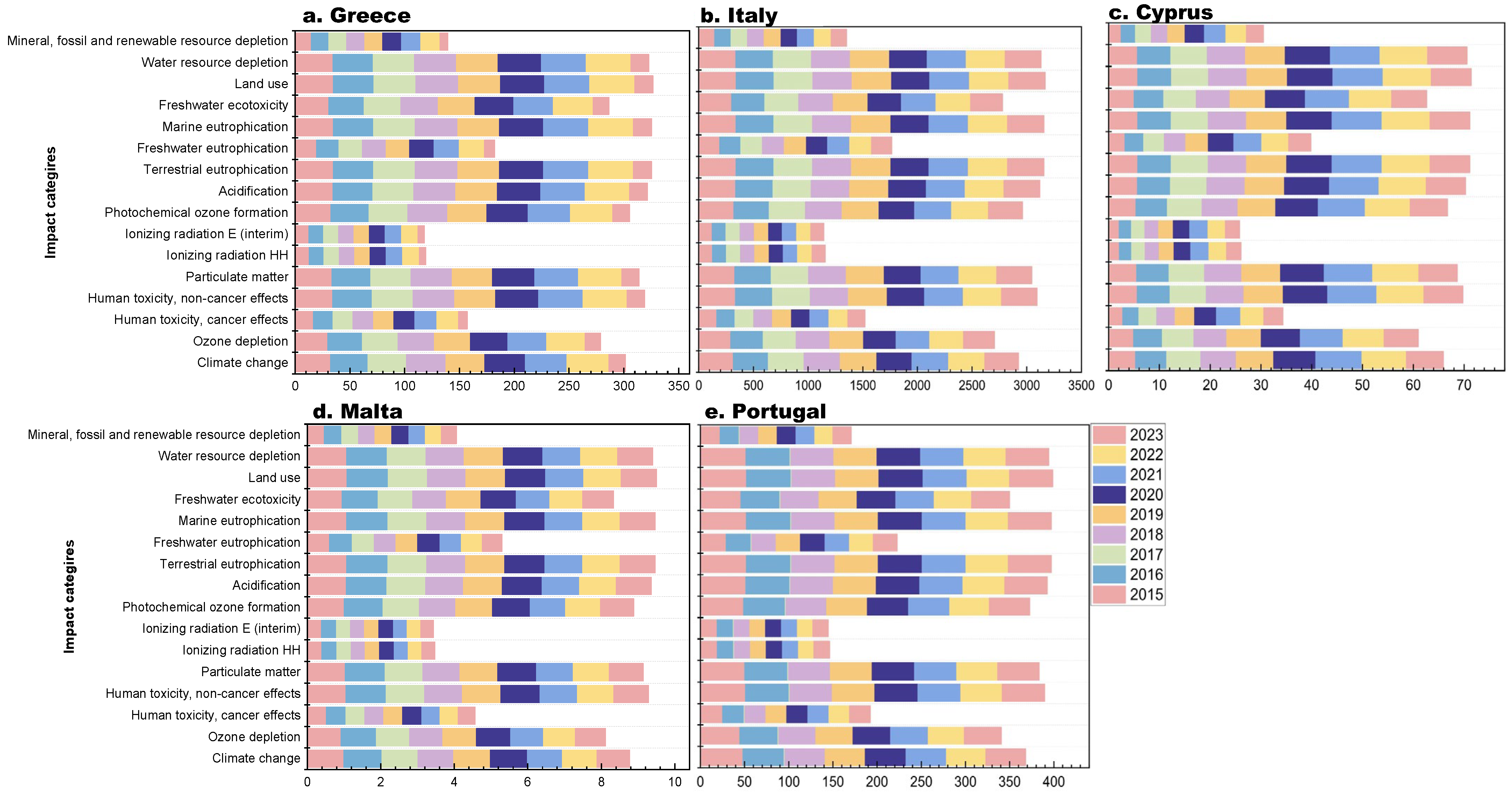

3.2. Spatio-Temporal Environmental Impacts in the EU Milk Supply Chain

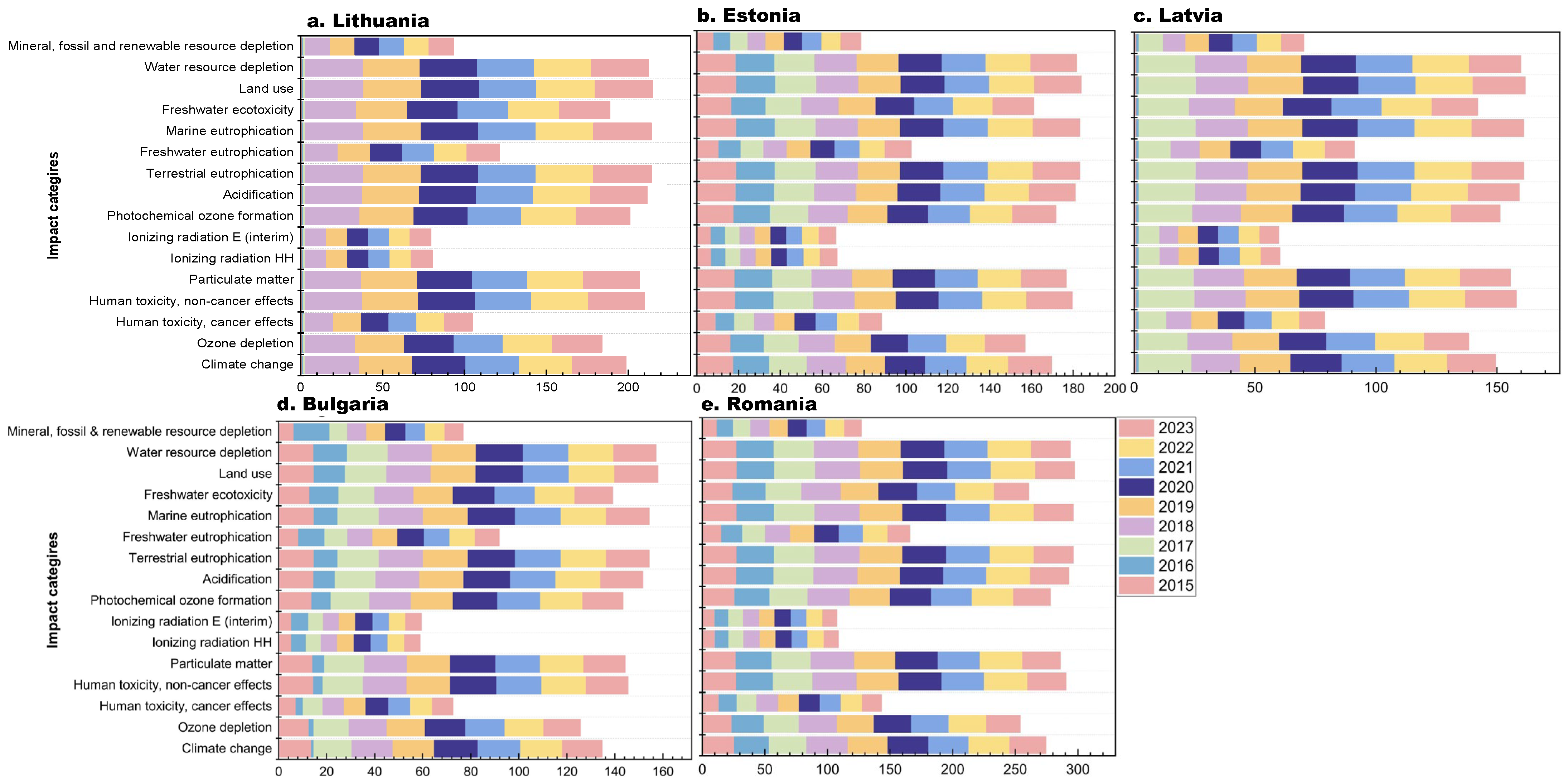

This section outlines the potential impacts of RFID tags on the fresh milk supply chain across different EU regions from 2015 to 2023, as shown in

Figure 3,

Figure 4,

Figure 5,

Figure 6 and

Figure 7. Furthermore,

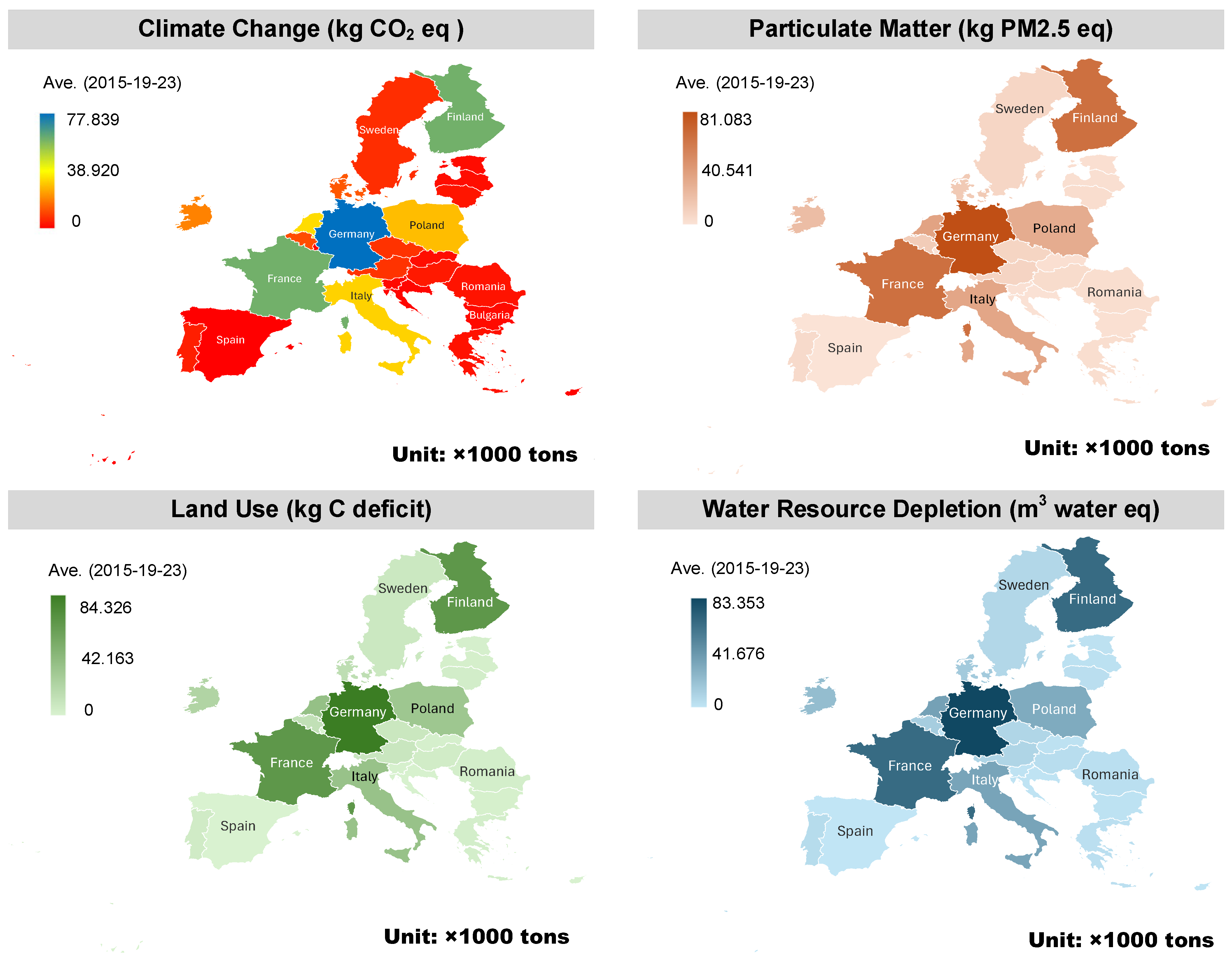

Figure 8 summarizes four key impact indicators—climate change, particulate matter, land use, and water resource depletion—chosen for their substantial contributions to the fresh milk supply chain’s overall environmental impact. The year 2024 was not included in the temporal analysis due to the unavailability of harmonized and complete datasets across EU countries at the time of modeling. This exclusion was made to ensure methodological consistency and reliable comparability of results across the full 2015–2023 time series.

Figure 3 demonstrates that from 2015 to 2023, a general trend of declining environmental impacts could be observed across various categories, including climate change, land use, and water resource depletion in the four northern EU countries (Denmark, Ireland, Finland, and Sweden). This decline suggests that the hypothetical deployment of RFID technology could significantly improve supply chain efficiency, reduce milk waste, and thereby bring about net environmental benefits. The color coding (from pink in 2015 to light pink in 2023) illustrates variations in environmental impacts across different years. For example, between 2016 and 2019, certain categories, such as photochemical ozone formation and acidification, show fluctuations across multiple countries. However, from 2019 onwards, there is a general declining trend, suggesting that despite variations in policy enforcement in different years, the gradual promotion and use of RFID technology had a positive impact on controlling environmental impacts.

Ireland and Finland show relatively high levels of water resource depletion, peaking in 2017 and 2018, followed by a gradual decline. This may be attributed to increased dairy production demand during this period, while the deployment of RFID helped reduce water wastage in production and logistics, resulting in subsequent significant reductions. Denmark and Sweden exhibit notable reductions in mineral, fossil, and renewable resource depletion, especially from 2019 to 2023, indicating that RFID technology could optimize resource management and reduce energy and material waste. In key environmental impact categories, such as climate change, particulate matter, acidification, and water resource depletion, all four countries show significant reductions. For instance, Denmark and Finland demonstrate a notable decrease in climate change impacts, indicating that using RFID technology to reduce milk loss has effectively lowered greenhouse gas emissions. This trend is associated with the enhanced transparency and efficiency of the supply chain, reducing the need for additional production caused by expiration or waste. Furthermore, the result analysis shows a clear trend of annual improvements, particularly in freshwater and marine eutrophication, as well as terrestrial eutrophication. This reflects that, with the hypothetical use of RFID technology in the supply chain, harmful emissions during logistics and storage processes have been reduced. These environmental benefits are likely linked to the increased efficiency of product management brought by RFID, which reduces resource waste and pollutant emissions.

The five western EU countries (

Figure 4) show a declining trend across multiple environmental impact categories, including climate change, water resource depletion, and land use. Particularly, the Netherlands and France demonstrate significant year-by-year reductions in climate change and particulate matter impacts. This suggests that the hypothetical deployment of RFID technology could mitigate these environmental burdens by reducing waste and improving supply chain efficiency, resulting in net positive environmental outcomes. The color coding, ranging from pink in 2015 to light pink in 2023, visually represents the variations in environmental impacts across different years. For instance, between 2016 and 2019, impacts such as photochemical ozone formation and human toxicity (non-cancer effects) showed some fluctuations across countries, but overall impacts have decreased significantly since 2020. This consistent decline indicates that the introduction of RFID technology can help control environmental burdens despite variations in policy enforcement across different years.

The data show missing information for Germany from 2015 to 2017, which introduces certain limitations in analyzing changes during this period. However, from 2018 onwards, Germany exhibits significant reductions in multiple categories, particularly in water resource depletion and land use. Given that Germany is one of Europe’s largest milk producers, this trend could be linked to the potential of RFID technology to enhance supply chain efficiency. Besides, Belgium shows noticeable improvements in freshwater and marine eutrophication, particularly after 2018, with significant reductions in eutrophication impacts. This trend may be associated with enhanced supply chain transparency and reduced milk loss due to RFID technology. Moreover, Austria’s acidification and terrestrial eutrophication indicators have significantly decreased since 2019, suggesting that RFID technology could help mitigate harmful emissions in production and supply chain activities. The Netherlands demonstrates a marked reduction in mineral, fossil, and renewable resource depletion, especially from 2021 to 2023, highlighting the benefits of supply chain optimization in reducing resource dependence, potentially related to minimized waste-driven production demands.

Significant reductions are observed across key environmental impact categories, such as climate change, particulate matter, water resource depletion, and acidification in France, the Netherlands, and Belgium. For example, France’s continuous decline in climate change impacts suggests that reducing milk loss and improving logistics efficiency through the hypothetical deployment of RFID technology can help significantly lower greenhouse gas emissions. Additionally, Austria’s improvements in acidification and particulate matter categories indicate that enhancing supply chain transparency and reducing losses could contribute to lowering pollutant emissions, positively impacting air quality and soil health.

Figure 5 presents the potential impacts of RFID tags on the fresh milk supply chain across six central EU countries, Czech Republic, Croatia, Hungary, Poland, Slovenia, and Slovakia, from 2015 to 2023. Overall, the general trend indicates a consistent decline in several environmental impact categories, including climate change, water resource depletion, and acidification. Particularly, Poland shows significant year-over-year reductions in climate change and water resource depletion impacts. This suggests that the hypothetical deployment of RFID technology could effectively reduce environmental burdens by minimizing waste and optimizing supply chain processes, resulting in positive environmental outcomes. The color coding, ranging from pink in 2015 to light pink in 2023, highlights the year-to-year variations in environmental impacts. For instance, from 2016 to 2019, categories such as photochemical ozone formation and marine eutrophication exhibit fluctuations across different countries, but a marked overall reduction is observed from 2020 onwards. This consistent decline suggests that introducing RFID technology could help manage environmental burdens effectively, regardless of the variations in regional policies.

By countries, Poland demonstrates notable improvements in mineral, fossil, and renewable resource depletion, particularly after 2020. This trend reflects the potential of RFID technology to reduce dependency on these resources through enhanced supply chain management. Slovenia shows improvements in terrestrial eutrophication and particulate matter, especially since 2019, indicating that RFID deployment could help mitigate emissions and reduce pollutants. The Czech Republic displays a steady reduction in climate change impacts, suggesting that optimizing logistics and minimizing milk waste through RFID technology could have a positive effect on reducing greenhouse gas emissions. The missing data for the Czech Republic, Croatia, Hungary, and Slovakia between 2015 and 2017 presents some limitations in fully understanding the trends during this period. However, from 2018 onwards, these countries generally show reductions in multiple environmental categories. Notably, Hungary exhibits a significant decrease in acidification and freshwater eutrophication, indicating that RFID technology could improve supply chain efficiency by reducing resource consumption and minimizing waste.

Across key environmental impact categories, such as climate change, particulate matter, acidification, and water resource depletion, Croatia, Hungary, and Poland exhibit significant reductions. For example, Hungary’s decline in acidification impacts suggests that, by reducing milk waste and optimizing supply chain operations, RFID technology could contribute to lower emissions of acidifying substances. Slovenia’s reduction in particulate matter further underscores the potential for RFID technology to enhance supply chain transparency, reduce inefficiencies, and ultimately minimize emissions, thus contributing positively to air quality.

Figure 6 illustrates the potential impacts of RFID tags on the fresh milk supply chain across five southern EU countries—Greece, Italy, Cyprus, Malta, and Portugal—from 2015 to 2023, excluding Spain. Overall, the trend shows a steady reduction in several environmental impact categories, including climate change, water resource depletion, and land use. By countries, Italy demonstrates a significant reduction in mineral, fossil, and renewable resource depletion, particularly after 2020. This suggests that RFID technology could contribute to decreasing dependency on these resources through better supply chain management and waste minimization. Cyprus and Malta show noticeable reductions in freshwater eutrophication and acidification, indicating improvements in resource management efficiency and a decline in harmful emissions as a result of the potential RFID technology implementation. Across key environmental impact categories, such as climate change, particulate matter, and water resource depletion, Greece, Italy, and Portugal show significant reductions. For instance, Greece’s continuous decline in climate change impacts highlights that RFID technology could play a critical role in reducing greenhouse gas emissions by improving logistics efficiency and minimizing waste. Portugal’s improvement in particulate matter emissions demonstrates that better transparency and supply chain optimization through RFID could lead to a reduction in harmful pollutants, ultimately benefiting air quality.

Figure 7 presents the potential impacts of RFID tags on the fresh milk supply chain across five eastern EU countries, Lithuania, Estonia, Latvia, Bulgaria, and Romania, from 2015 to 2023. By country, Romania shows significant improvements in freshwater eutrophication and acidification, particularly after 2020, suggesting that RFID technology could improve resource management efficiency and reduce harmful emissions. Lithuania demonstrates marked reductions in photochemical ozone formation, highlighting the potential for improved logistics and minimized waste to reduce environmental burdens. Across key environmental impact categories such as climate change, particulate matter, and water resource depletion, Bulgaria, Estonia, and Latvia show significant reductions. For example, Bulgaria’s continuous decline in climate change impacts demonstrates that the hypothetical deployment of RFID technology could help reduce greenhouse gas emissions by improving logistics efficiency and minimizing waste. Estonia’s reduction in particulate matter highlights the potential for RFID technology to reduce air pollutants, contributing positively to air quality.

Figure 8 illustrates the spatial distribution of total avoided environmental impacts—that is, the benefits—achieved through RFID implementation in the fresh milk supply chain across EU countries from 2015 to 2023. The four impact categories presented—climate change, particulate matter formation, land use, and water resource depletion—were selected due to their critical relevance to dairy production and their substantial contribution to the overall life cycle footprint of milk. These maps visualize cumulative environmental savings over time and offer insight into the regionally uneven distribution of RFID’s potential benefits. Notably, the figures reflect absolute reductions (i.e., in tons or cubic meters), which inherently correlate with national production volumes. As such, larger milk-producing countries exhibit higher absolute benefits; however, this does not necessarily indicate greater efficiency or higher relative impact avoidance.

Germany records the highest absolute reduction in GHG emissions, with avoided impacts approaching 80,000 tons CO2-eq, followed by Finland and France at approximately 60,000 tons CO2-eq each. Moderate reductions are observed in the Netherlands, Italy, and Poland (around 30,000 tons CO2-eq), while smaller milk-producing nations such as Estonia, Lithuania, and Bulgaria show values under 10,000 tons CO2-eq. Reductions in PM2.5-equivalent emissions also vary significantly. Germany again leads with over 81,000 tons PM2.5-eq avoided, followed by France and Finland with over 60,000 tons each. Poland demonstrates moderate reductions (~30,000 tons), while many Eastern and Southeastern European countries display lower or negligible reductions, highlighting either a lower baseline spoilage rate or limited RFID adoption and implementation in those regions. Moreover, the analysis of avoided land occupation measured in carbon deficit (C-deficit) equivalents, similarly shows Germany, France, and Finland exceeding 60,000 tons each. Poland (~31,000 tons) and Italy (~29,000 tons) follow, while countries in Eastern Europe contribute marginally. This pattern reflects both national production volumes and land-use intensity of feed and dairy operations. Additionally, Germany also achieves the greatest reduction in freshwater-equivalent usage (~80,000 m3), with Finland and France trailing closely. Italy, Poland, and the Netherlands report moderate benefits (20,000–30,000 m3). Smaller dairy-producing countries such as Lithuania and Bulgaria generate fewer savings—not due to inefficiency, but due to lower modeled milk production volumes.

3.3. Environmental Benefits Potentials of EU’s Milk Industry by RFID Uses in 2035

By 2035, milk production in the EU is projected to decline at an average annual rate of 0.2%, primarily due to sustainability pressures, stricter environmental regulations, and reductions in dairy herd sizes. Simultaneously, productivity growth is expected to slow to 0.9% annually as the historical gains from technological intensification diminish. Within this evolving context, the deployment of RFID technology in the milk supply chain may play an increasingly strategic role, offering operational efficiencies that reduce milk loss and associated environmental burdens.

Figure 9 illustrates the projected environmental benefits of RFID-enabled waste reduction under this 2035 scenario, with particular focus on climate change, land use, and water resource depletion. Strong correlations between these categories reflect the resource-intensive nature of dairy production: land is required for feed cultivation, water is consumed across milking and processing stages, and emissions arise from livestock, energy use, and fertilizer application.

Under the modeled scenario, the total GHG emissions associated with both milk losses and RFID tag use are projected to fall from 3.62 Mt CO2-eq in 2023 to 3.53 Mt CO2-eq in 2035. Although modest, this reduction demonstrates how RFID-enabled logistics improvements can meaningfully contribute to climate change mitigation by reducing overproduction. Similarly, avoided land use impacts are estimated at 3.93 Mt C-deficit in 2035, driven by reduced feed demand and pasture utilization. Water resource depletion is also projected to decline, reflecting lower demand for irrigation, cleaning, and processing due to less wasted milk. Together, these avoided impacts underscore RFID’s capacity to enhance per-unit resource efficiency throughout the supply chain.

However, it is important to note that the 2035 projections rely on linear extrapolations and static assumptions, including constant RFID tag composition, fixed waste reduction rates, and present-day energy profiles. Dynamic factors such as decarbonization of the EU energy mix, innovations in tag materials and design, efficiencies in digital infrastructure, and changes in consumer behavior are not captured in this scenario. Therefore, the results should be interpreted as indicative estimates that illustrate potential benefits rather than predictive forecasts.

Overall, the findings suggest that, even under conservative assumptions, RFID technology can support the EU dairy sector in achieving its climate and resource efficiency goals. By reducing milk loss at upstream and retail stages, RFID offers a viable pathway to mitigate environmental burdens without requiring significant structural changes in production. Nevertheless, future research should adopt a more dynamic, systems-level modeling approach to fully capture the complex interplay of policy, technology, and market trends beyond 2035.