1. Introduction

Bridges constitute a vital component of modern transportation infrastructure, facilitating the efficient movement of people and goods and thereby contributing significantly to economic growth and societal development. However, over time, bridges are subjected to various deteriorative factors, including material aging, environmental conditions, excessive traffic loads, and natural hazards. These factors collectively contribute to the structural degradation of bridges, potentially compromising their safety, functionality, and serviceability. In extreme cases, such deterioration may culminate in catastrophic failures, such as partial or total collapse [

1,

2]. To mitigate these risks and ensure structural integrity throughout the bridge’s service life, continuous and reliable monitoring is essential [

3,

4,

5]. Structural Health Monitoring (SHM) systems have emerged as a key tool in this regard, enabling real-time assessment of structural responses to both operational and environmental loads [

6]. Traditionally, wired sensor networks have been employed in SHM applications [

7,

8]. However, such systems are often constrained by complex installation procedures, high maintenance costs, and limited scalability due to extensive cabling requirements. In response to these limitations, wireless sensor networks (WSNs) have gained increasing attention in the field of SHM. Wireless monitoring systems offer significant advantages in terms of cost efficiency, ease of deployment, and scalability. Moreover, recent advancements in wireless communication technologies and low-power embedded systems have further enhanced the feasibility of implementing real-time, high-resolution data acquisition systems for large-scale civil infrastructure. Consequently, wireless SHM has become a promising alternative to conventional wired systems for bridge monitoring applications.

Straser and Kiremidjian (1998) [

9] were among the first to explore the application of Wireless Sensor Networks (WSNs) in SHM, proposing a modular SHM system based on wireless sensor nodes. Their seminal work laid the foundation for a broad range of subsequent research and experimental validation efforts. By decoupling the system into distinct modules—namely, sensors, wireless transmitters, and data processing units—they introduced a flexible architecture capable of adapting to diverse structural configurations and environmental conditions. This modular approach has since been recognized for its practical advantages, particularly in terms of deployment scalability and maintenance efficiency. Despite its pioneering contributions, the study was limited to small-scale structures and short-range communication scenarios. Critical challenges, such as wireless signal attenuation, multipath interference, and a restricted communication range, remained unresolved. Moreover, the issue of time synchronization across multiple wireless nodes—an essential requirement for accurate vibration characterization and modal comparison—was insufficiently addressed. Although sensor data were transmitted wirelessly, the system architecture relied predominantly on offline data storage and post-processing, thereby falling short of achieving true real-time SHM capabilities. Consequently, while the proposed system represented a significant conceptual advancement, its practical implementation revealed notable limitations in scalability, synchronization fidelity, and real-time responsiveness.

From the early 2000s through the subsequent decade, significant research efforts were directed toward addressing the inherent limitations of early wireless communication in SHM systems. These efforts included the adoption of low-power wireless communication protocols, such as LoRa, Bluetooth Low Energy (BLE), and Narrowband Internet of Things (NB-IoT), as well as the integration of energy harvesting technologies and the development of intelligent sensor nodes equipped with embedded signal processing and data analysis capabilities [

10,

11,

12,

13,

14,

15].

Rice et al. (2010) [

3] developed a real-time SHM system based on a wireless smart sensor platform and deployed it on a full-scale bridge. Utilizing the Imote2 platform, their system effectively tackled critical engineering challenges, including onboard data processing, time synchronization, power optimization, and inter-node communication. This work represented a major step forward in the practical implementation of wireless SHM. However, the limited communication range between nodes and the inability to support a robust mesh network posed significant challenges for long-span bridges and high-rise structures. Furthermore, while data processing was conducted locally within the sensor nodes, the final decision-making processes for damage detection and structural evaluation relied on external servers, limiting the system’s autonomy. The reliance on battery-powered nodes also presented a key obstacle to long-term, maintenance-free operation. In a large-scale field study, Pakzad et al. (2008) [

16] installed 64 wireless sensors on the deck of California’s Golden Gate Bridge, deploying dozens of nodes over several hundred meters to enable long-term structural monitoring. Their work provided a compelling demonstration of wireless sensor networks (WSNs) applied to large-scale civil infrastructure, incorporating essential design considerations, such as scalability, data integrity, time synchronization, and power efficiency. The system successfully captured ambient vibrations over extended periods and extracted critical structural parameters, including natural frequencies, damping ratios, and mode shapes. Each node featured an integrated architecture combining sensing, processing, and communication functionalities, which facilitated ease of maintenance and modular expansion. Nevertheless, the continued dependence on battery-powered operation necessitated periodic maintenance and posed limitations for long-term deployment. Moreover, comprehensive analyses of cost-effectiveness, life-cycle maintenance demands, and comparisons with traditional wired systems were lacking, leaving practical feasibility an open issue. Cho et al. (2010) [

17,

18] customized the Imote2 platform for deployment in South Korea and implemented a wireless smart sensor-based SHM system on an in-service bridge. By integrating various functions, such as FFT, multi-hop communication protocols, distributed data processing techniques, and numerical analysis algorithms into the Imote2-based platform, a distributed smart sensor system was implemented that goes beyond simple measurement, reducing wireless data transmission and demonstrating the potential for real-time monitoring. Despite these advances, the system was only evaluated under short-term testing conditions (ranging from several hours to a few days), leaving questions about long-term durability and data fidelity unaddressed. While the embedded algorithms facilitated preliminary onboard analysis, real-time damage detection and autonomous warning capabilities were not fully realized. Additionally, as the system relied on battery power, long-term deployment on civil infrastructure remained challenged by energy supply constraints. Synchronization and latency issues, particularly in dense or complex structural networks, also persisted as limiting factors to scalability and real-time performance.

According to the FHWA report FHWA-HRT-17-043 (2017) [

19], recent advancements in wireless structural health monitoring have emphasized the development of self-powered wireless sensor systems aimed at enabling continuous monitoring of bridge structures and facilitating early damage detection. In collaboration with Michigan State University (MSU), the University of Washington, and the University of Southern California, researchers explored the use of Piezoelectric Floating-Gate (PFG) sensors to transduce structural strain into electrical signals. These systems, capable of operating without external power sources, enabled long-term deployment and real-time detection of structural anomalies. While they contributed meaningfully by minimizing data transmission requirements and reducing communication costs, significant limitations remain. In particular, the lack of standardized data formats and communication protocols impede interoperability across heterogeneous sensing platforms, and the long-term durability and reliability of the sensor units require further empirical validation. Zhu et al. (2018) [

20] addressed performance bottlenecks of conventional wireless sensors by developing a high-sensitivity, energy-efficient wireless accelerometer system for real-time SHM. By integrating the Seiko Epson M-A351 digital MEMS accelerometer into the Xnode platform, they achieved precise measurements of low-amplitude vibrations, with a resolution of 0.06 μg/LSB and a noise density of 0.5 μg/√Hz. Comparative testing with a high-precision wired reference sensor (PCB393B12, PCB Piezotronics) under laboratory and ambient vibration conditions demonstrated the feasibility of capturing both high- and ultra-low-amplitude dynamic responses (ranging from 0.5 g to 10~20 μg). Despite these performance gains, the Xnode platform exhibited limited flexibility due to its proprietary hardware–software architecture, which restricts integration with third-party modules and complicates system scalability and maintenance over extended lifecycles. Komarizadehasl et al. (2022) [

21] introduced the Low-cost Adaptable Reliable Accelerometer (LARA), a cost-effective wireless acceleration sensing system designed for SHM applications. Built on open-source platforms such as Arduino and Raspberry PI, LARA achieved a sampling frequency of 333 Hz and a noise density of 51 μg/√Hz, while employing Network Time Protocol (NTP) to ensure accurate inter-sensor time synchronization. Data were locally stored on SD cards and transmitted wirelessly via a 4G USB dongle, enabling autonomous operation. Validation experiments, both in laboratory settings and on a short-span pedestrian bridge in Barcelona, revealed eigenfrequency estimation errors of less than 1.28% compared to commercial-grade sensors (HI-INC). These findings underscore the system’s potential as a practical and scalable solution for economically viable wireless SHM. Nonetheless, additional studies are needed to evaluate long-term operational stability, environmental resilience, and the system’s full-scale applicability. Zhang et al. (2023) [

22] proposed an innovative approach to overcome the spatial constraints of fixed sensor deployments by integrating wireless sensor nodes with mobile robotic platforms. Their system leveraged optimization algorithms, such as Particle Swarm Optimization (PSO) and Ant Colony Optimization (ACO), to dynamically determine sensor trajectories and maximize spatial coverage. Unlike prior simulation-only studies, the proposed method was experimentally validated using a scaled bridge model, effectively linking theoretical design with empirical implementation. However, practical applications on long-span bridges remain untested, and key issues such as environmental durability (e.g., resistance to wind, humidity, and vibrations), energy consumption of mobile units, and real-time data communication stability require further exploration. Hasani et al. (2024) [

23] developed a low-cost wireless data acquisition platform optimized for Operational Modal Analysis (OMA) of bridges. The system utilizes the ADXL355 MEMS accelerometer from Analog Devices in conjunction with the ESP32 microcontroller from Espressif Systems, offering a balanced trade-off between low power consumption and computational performance. Designed for extended operations exceeding five years, the system supports in-node data preprocessing, precise time synchronization, and a user-friendly configuration through a web-based interface. Laboratory testing involving a four-story shear-frame structure validated the system’s ability to extract modal parameters using Frequency Domain Decomposition (FDD) and Stochastic Subspace Identification (SSI), which were further corroborated through finite element modeling. Field deployment on the Lamberti Bridge in Parma, Italy—with 30 installed nodes—demonstrated the system’s potential for long-term, remote SHM through continuous OMA and displacement estimation via Kalman filtering. Despite these achievements, further efforts are needed to verify the system’s performance on large-scale structures and to develop efficient algorithms for processing the large volumes of acquired data for actionable performance evaluation.

In recent years, the demand for structural monitoring systems tailored to the increasing complexity and diversity of civil infrastructure has led to a paradigm shift from proprietary, closed platforms to open-source-based wireless sensing technologies. In particular, there is growing interest in the development of integrated wireless monitoring systems that support autonomous modular configurations, enable rapid high-volume data transmission via 5G communication, and facilitate the fusion of multiple sensor modalities for comprehensive structural assessment.

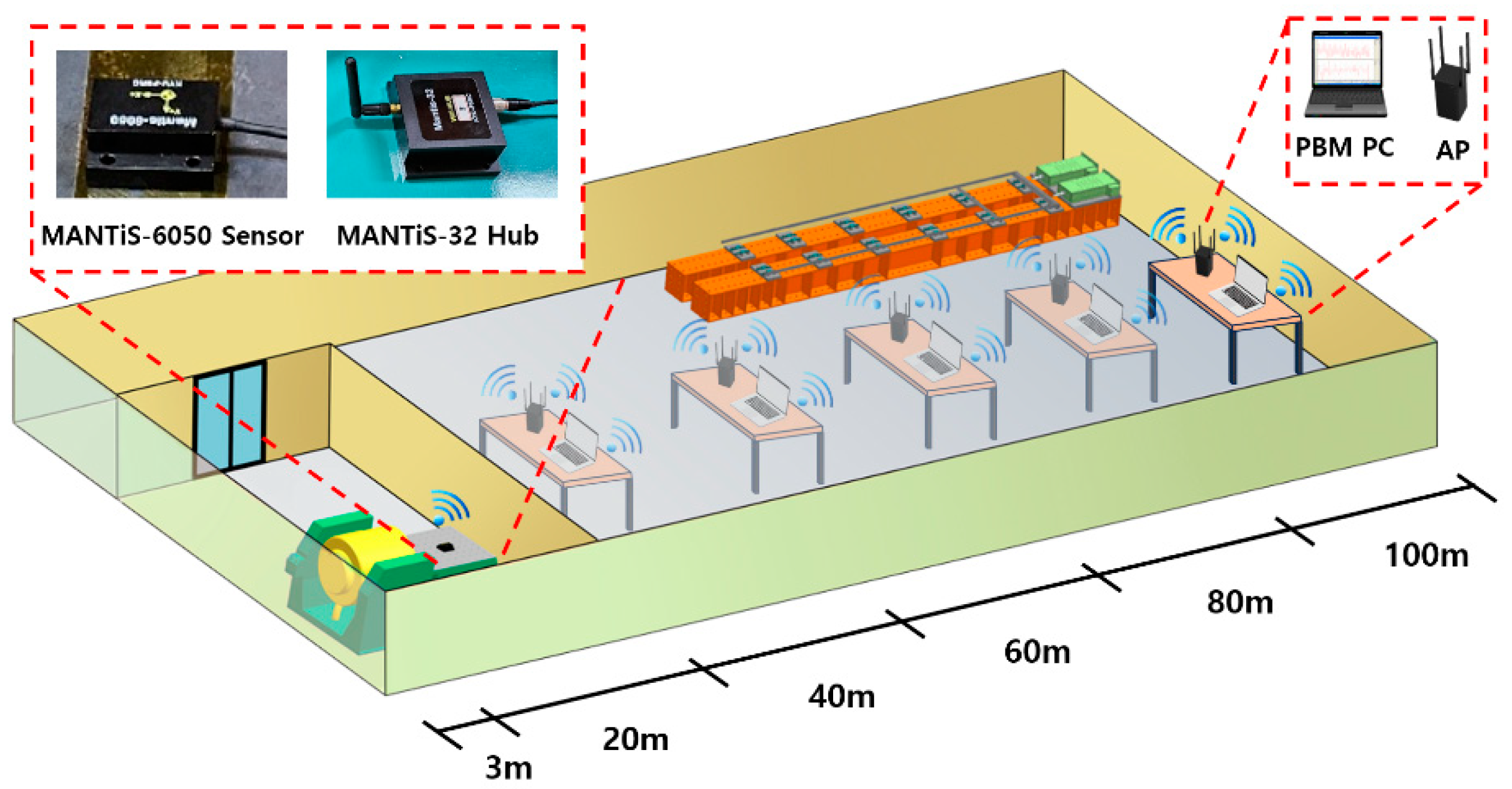

In this context, the present study introduces the development of the MANTiS-32 wireless sensing system, which leverages an open-source platform built on the ESP32 microcontroller in conjunction with MPU-6050 sensors. The system is designed to provide scalable, real-time structural response monitoring with an emphasis on modularity, cost efficiency, and field applicability. To verify the fundamental performance of the MANTiS-32 system, a series of evaluations were conducted focusing on its capabilities in acceleration and frequency response measurement, wireless communication stability, and real-time data acquisition between the MANTiS-32 hub and eight connected MPU-6050 units via RS485 communication.

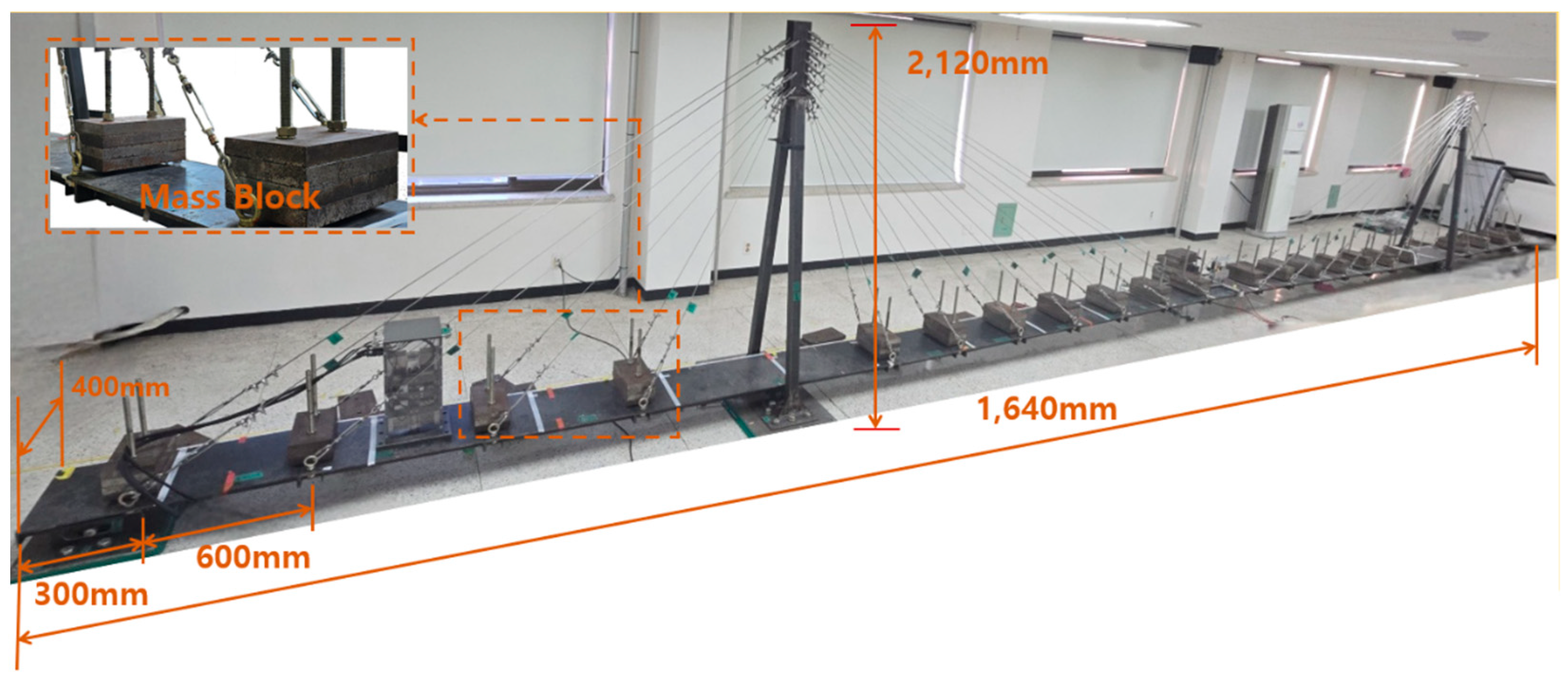

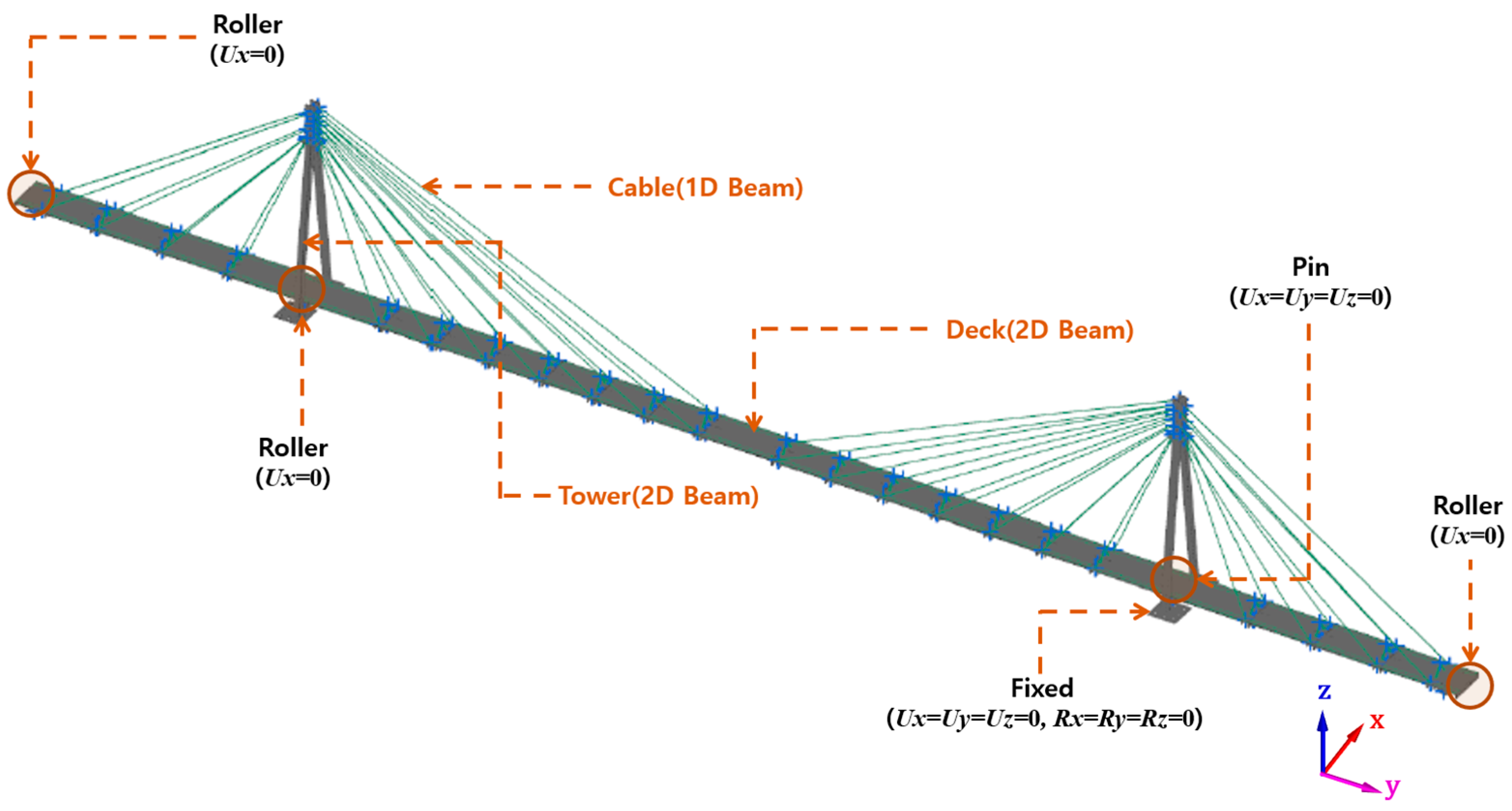

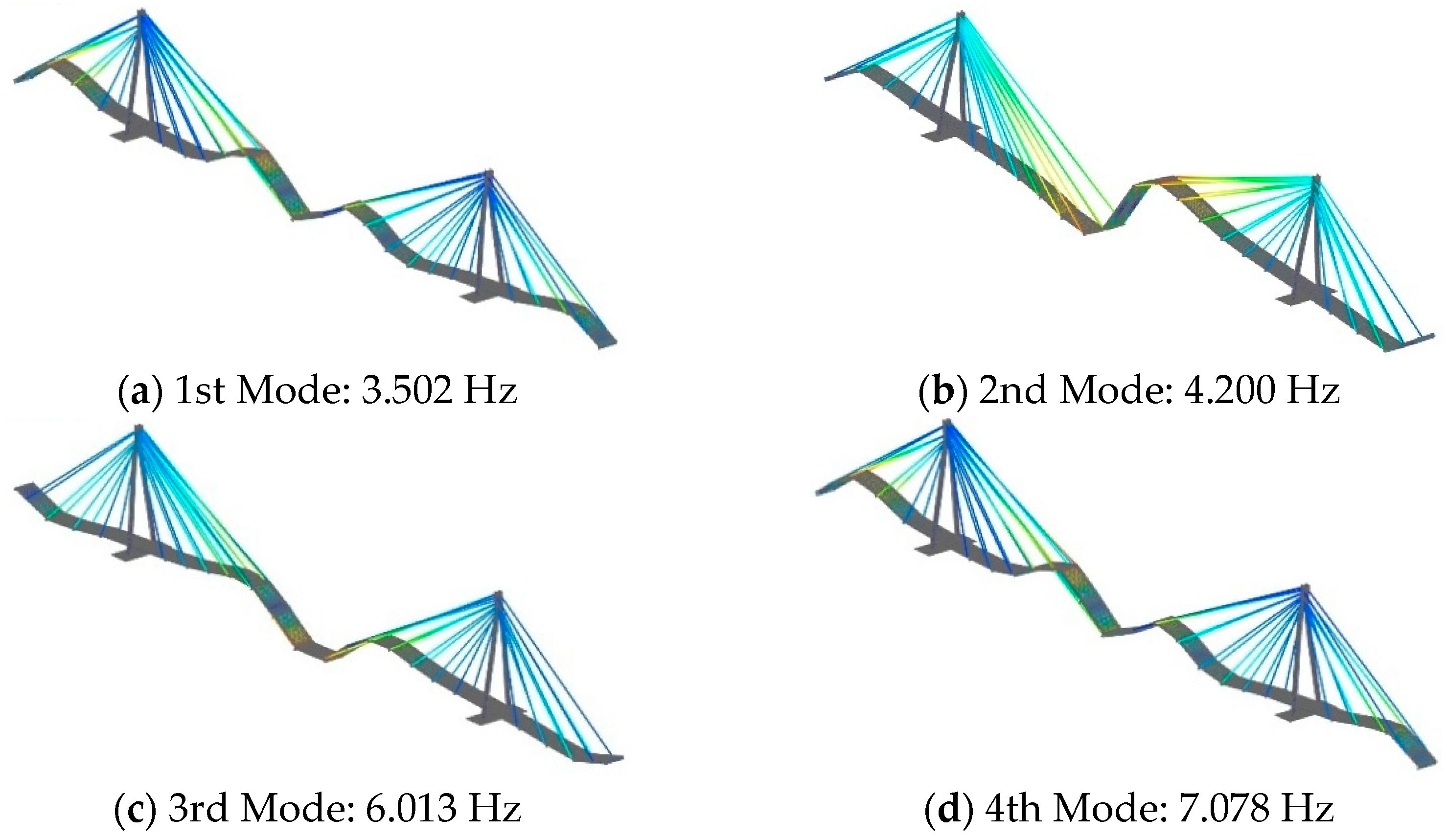

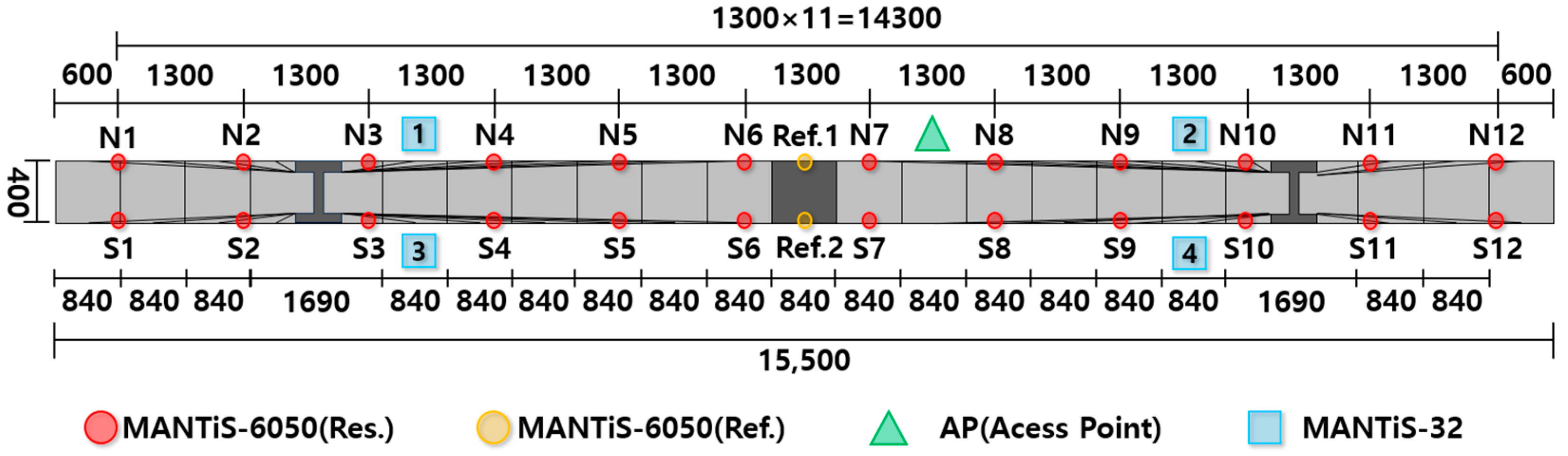

Furthermore, to assess the applicability of the system in a realistic structural setting, four MANTiS-32 units were deployed on a lab-scale cable-stayed bridge model designed to reflect the dynamic characteristics of small- to medium-span long-span bridges. The system’s ability to capture and transmit dynamic response data in real time was successfully demonstrated, thereby validating its effectiveness for structural performance monitoring.

Table 1 summarizes key technical distinctions between recent SHM platforms and the proposed MANTiS-32 system, with a focus on synchronization methodology, timing accuracy, and sensing capabilities. As shown in the comparison, MANTiS-32 exhibits a less than 1 ms synchronization error and sampling rates up to 200 Hz while maintaining a per-node of USD 70~80, offering high performance at a low cost.

The subsequent sections provide a detailed account of the system architecture, implementation methodology, and performance validation experiments.

2. MANTiS-32 Wireless Measurement System Design

To facilitate real-time structural health monitoring of bridge structures, this study presents the development of a modular, integrated wireless sensing system, termed MANTiS-32, based on an open-source platform architecture capable of high-throughput data transmission. The MANTiS-32 system is specifically designed to interface with MANTiS-6050 sensor nodes via RS485 communication, enabling efficient collection, processing, and evaluation of dynamic structural response data. The system architecture is built upon the ESP32-C3 dual-core microcontroller, which offers both high computational performance and robust wireless communication capabilities. The MANTiS-32 platform supports real-time signal acquisition, wireless data transmission, and edge-level data processing, thereby allowing simultaneous data measurement and structural performance evaluation with low latency and high reliability. In addition, the open-source development environment provides a high degree of flexibility and scalability, permitting the modification and enhancement of system performance parameters to meet diverse structural and environmental conditions encountered in bridge monitoring applications. From an energy-efficiency standpoint, the system is optimized for long-term autonomous operation through a deep sleep mode, in which current consumption can be reduced to the microampere level. This low-power design, combined with the system’s favorable cost-to-performance ratio, underscores its practical applicability for large-scale deployment in wireless SHM of civil infrastructure.

2.1. System Architecture and Functional Roles of the MANTiS-32 Wireless Sensing Platform

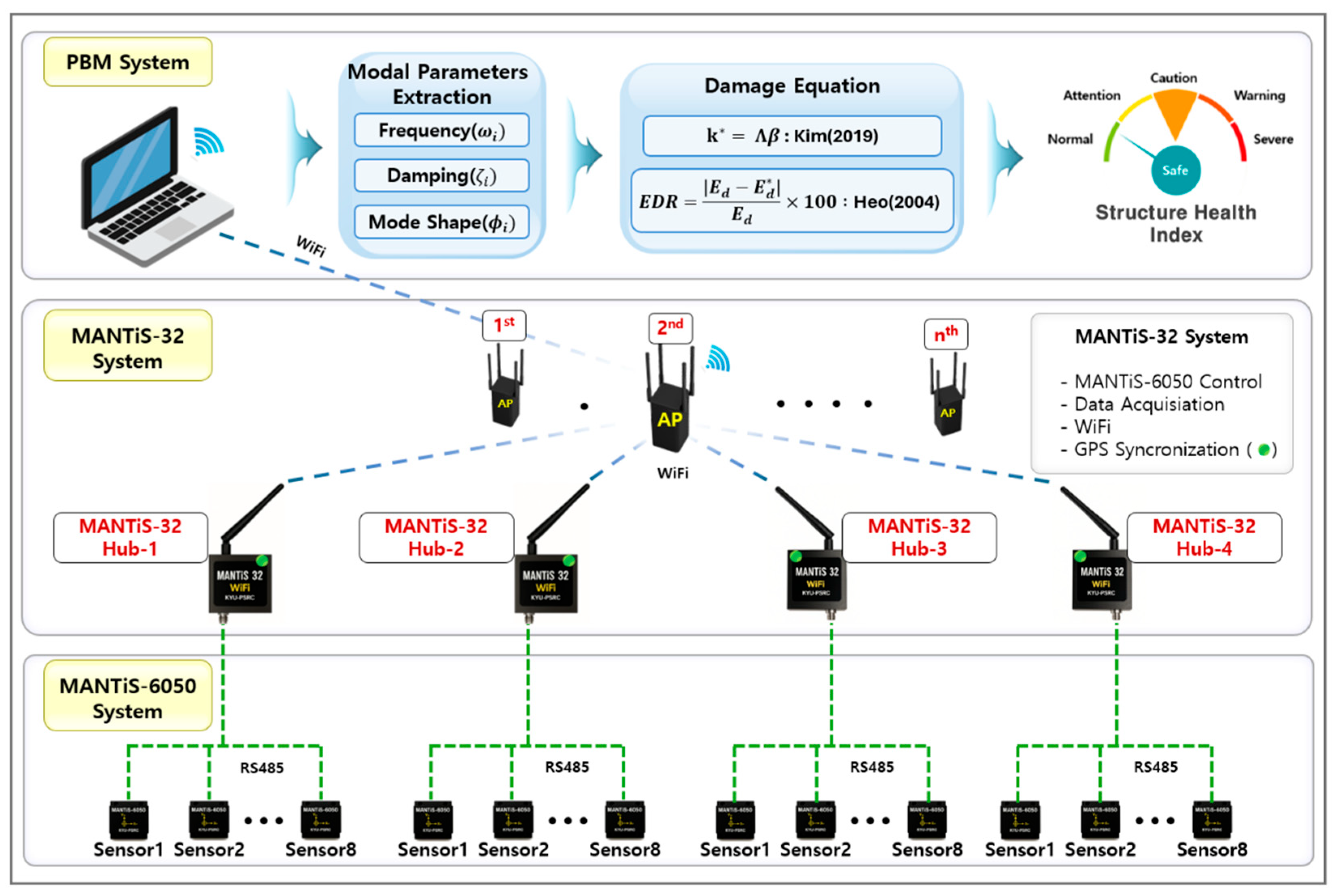

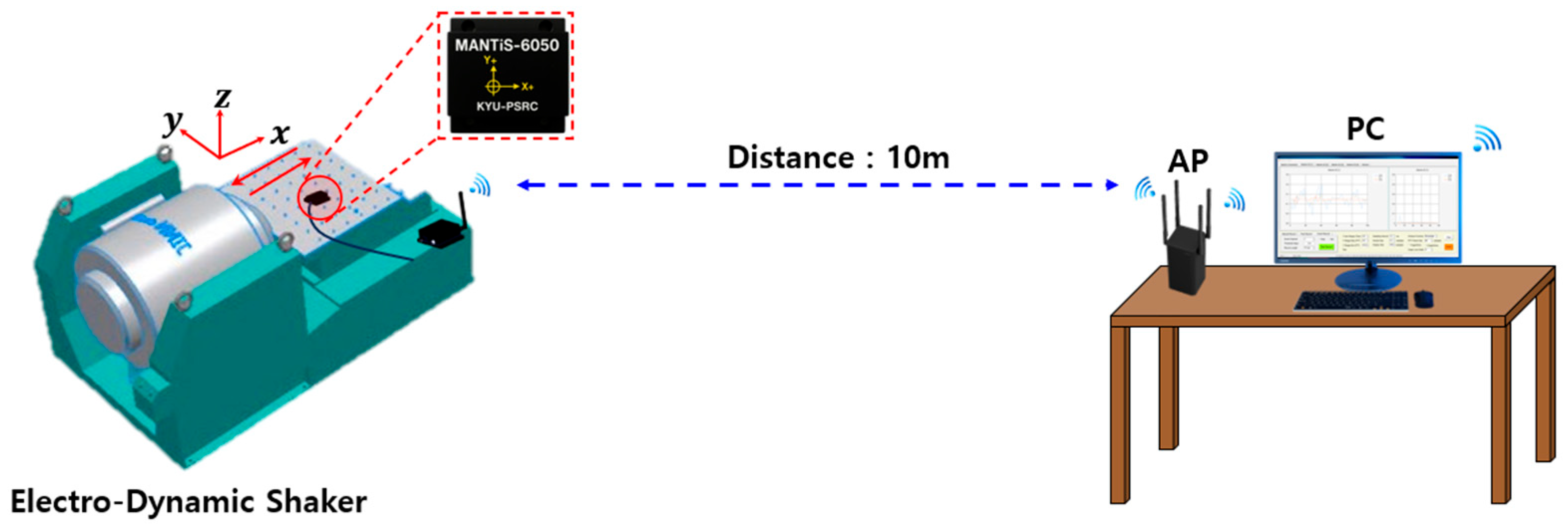

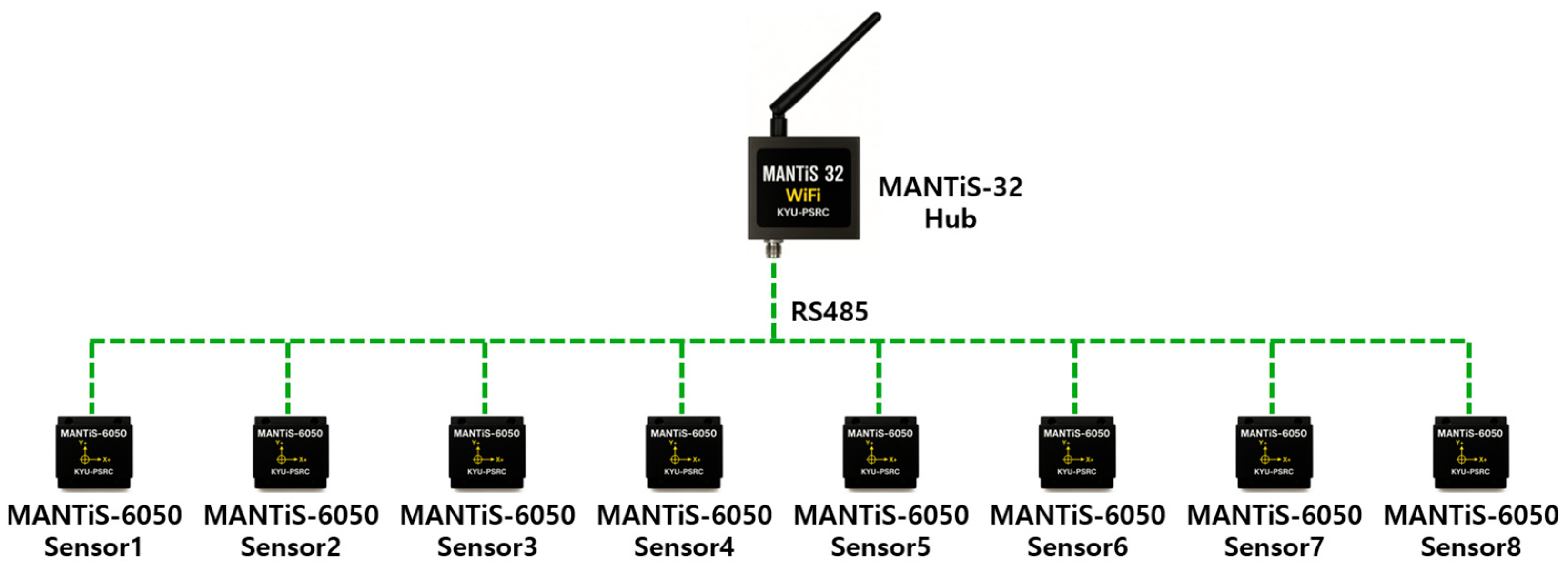

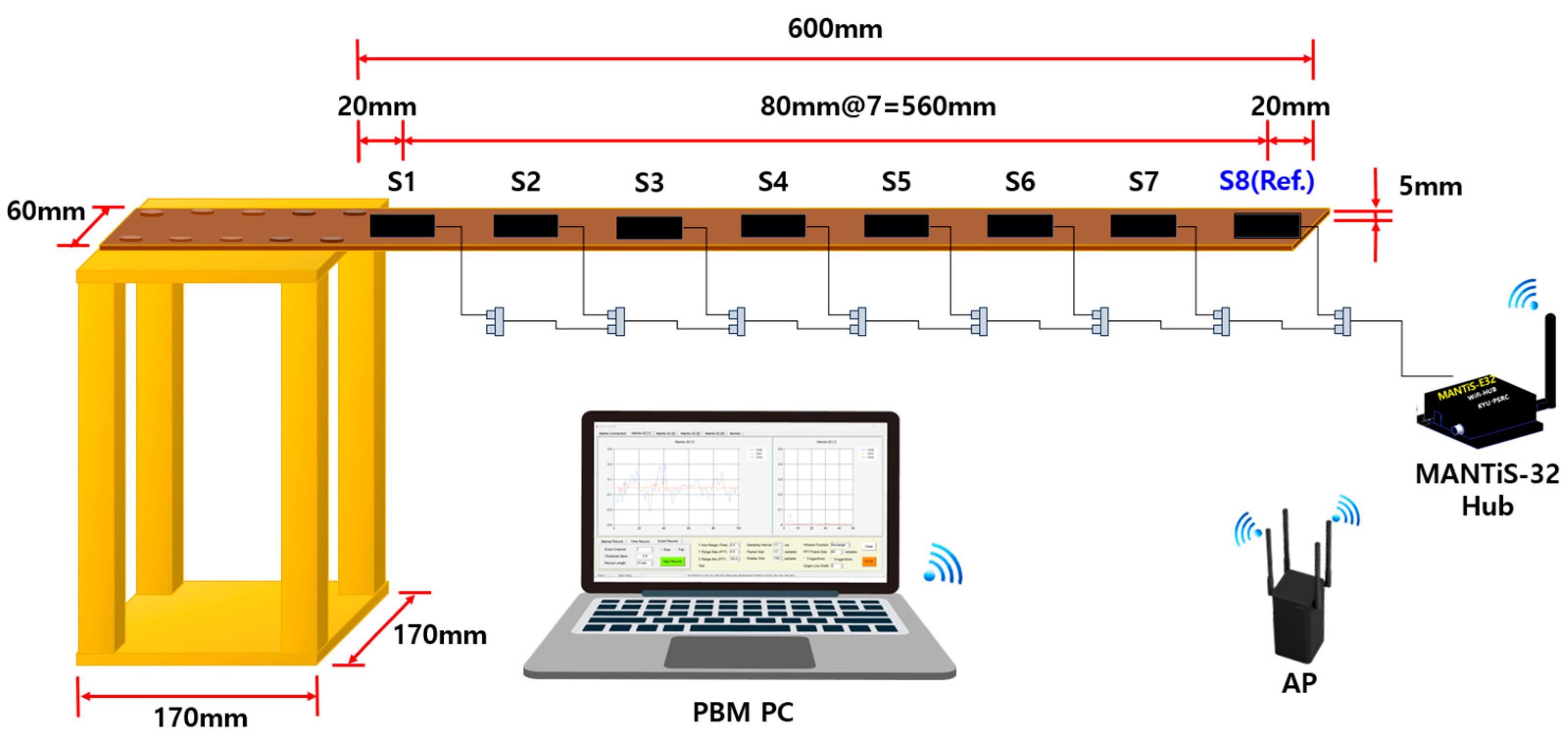

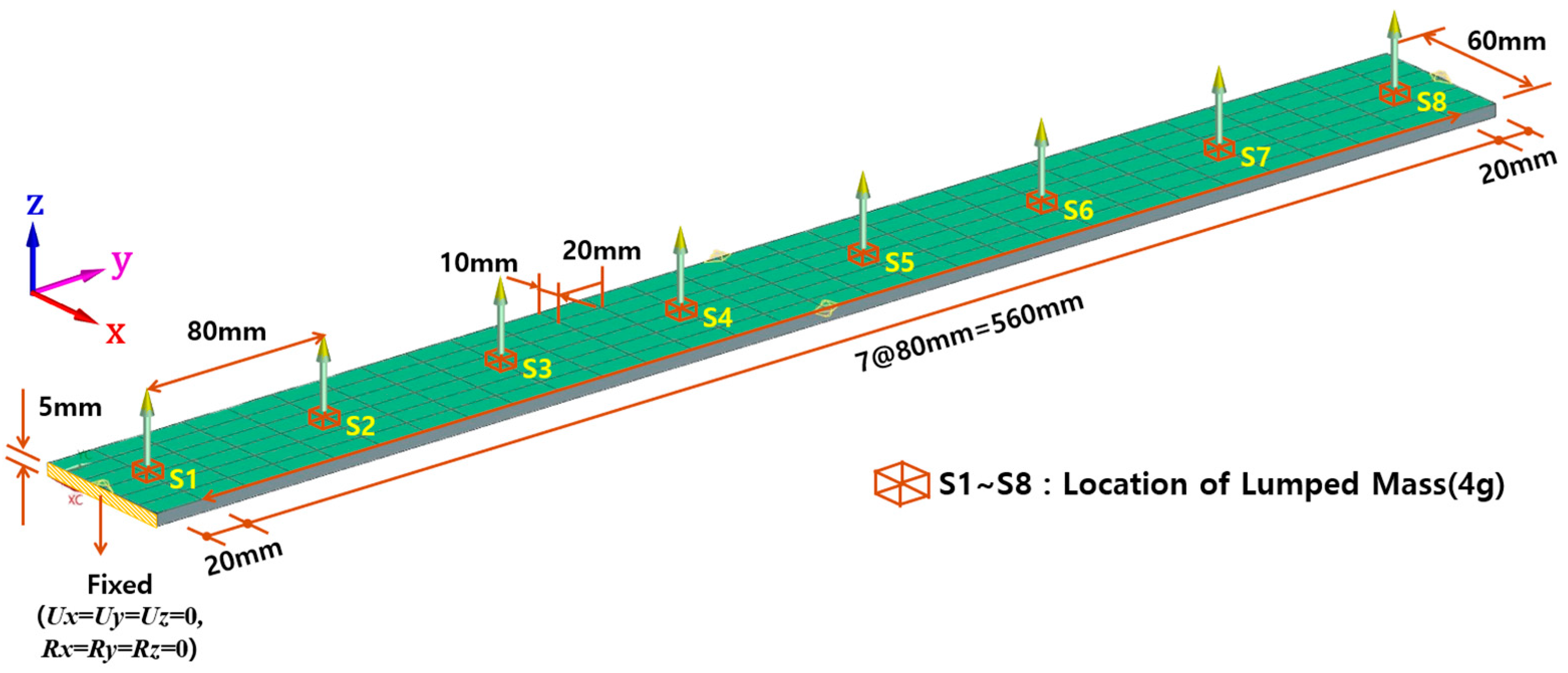

The MANTiS-32 wireless sensing system is engineered to acquire structural response data from MANTiS-6050 sensor units and wirelessly transmit the collected data to a Performance-Based Monitoring (PBM) platform via its integrated access point (AP). The transmitted data are then processed to compute real-time damage indices, enabling continuous assessment of structural integrity and facilitating proactive maintenance strategies. Leveraging a high-performance wireless communication framework, the MANTiS-32 system offers rapid deployment, enhanced scalability, and seamless integration into complex structural configurations. Furthermore, the incorporation of GPS-based time synchronization ensures precise coordination across multiple sensing nodes, thereby supporting accurate, distributed, and synchronized monitoring of structural behavior under dynamic loading conditions. As illustrated in

Figure 1, the MANTiS-6050 system is configured by connecting up to eight MPU-6050 sensors (InvenSense Inc., San Jose, CA, USA) to a single MANTiS-32 hub. Each MANTiS-6050 module is equipped with a PIC16 microcontroller, which handles sensor control and data acquisition. The measured data are transmitted to the hub via RS485 communication. A total of four MANTiS-32 units are deployed, each managing eight sensor modules, resulting in a synchronized sensing network composed of 32 individual sensors capable of real-time data acquisition and monitoring.

The sensor data collected by each MANTiS-32 hub is transmitted wirelessly to the Performance-Based Monitoring system via Wi-Fi, utilizing their respective access points (APs). Notably, each MANTiS-32 hub is equipped with a GPS-based time synchronization module, enabling precise temporal alignment of data from distributed sensors. This modular architecture allows for scalable expansion of the sensing network as required by structural monitoring applications. At the top level, the PBM system—implemented as a PC-based analytical platform—performs real-time analysis of the measured vibration data to extract key dynamic characteristics, such as natural frequency (ω), the damping ratio (ζ), and mode shapes (φ). Using established damage detection equations (e.g., Kim, 2019 [

24]; Heo, 2004 [

25]), the system evaluates changes in structural performance and estimates the progression of damage through a computed Structural Health Index (SHI). This information can then be utilized to support data-driven maintenance and decision-making processes for bridge infrastructure.

2.2. Design and Operation of the MPU-6050 Sensor Module

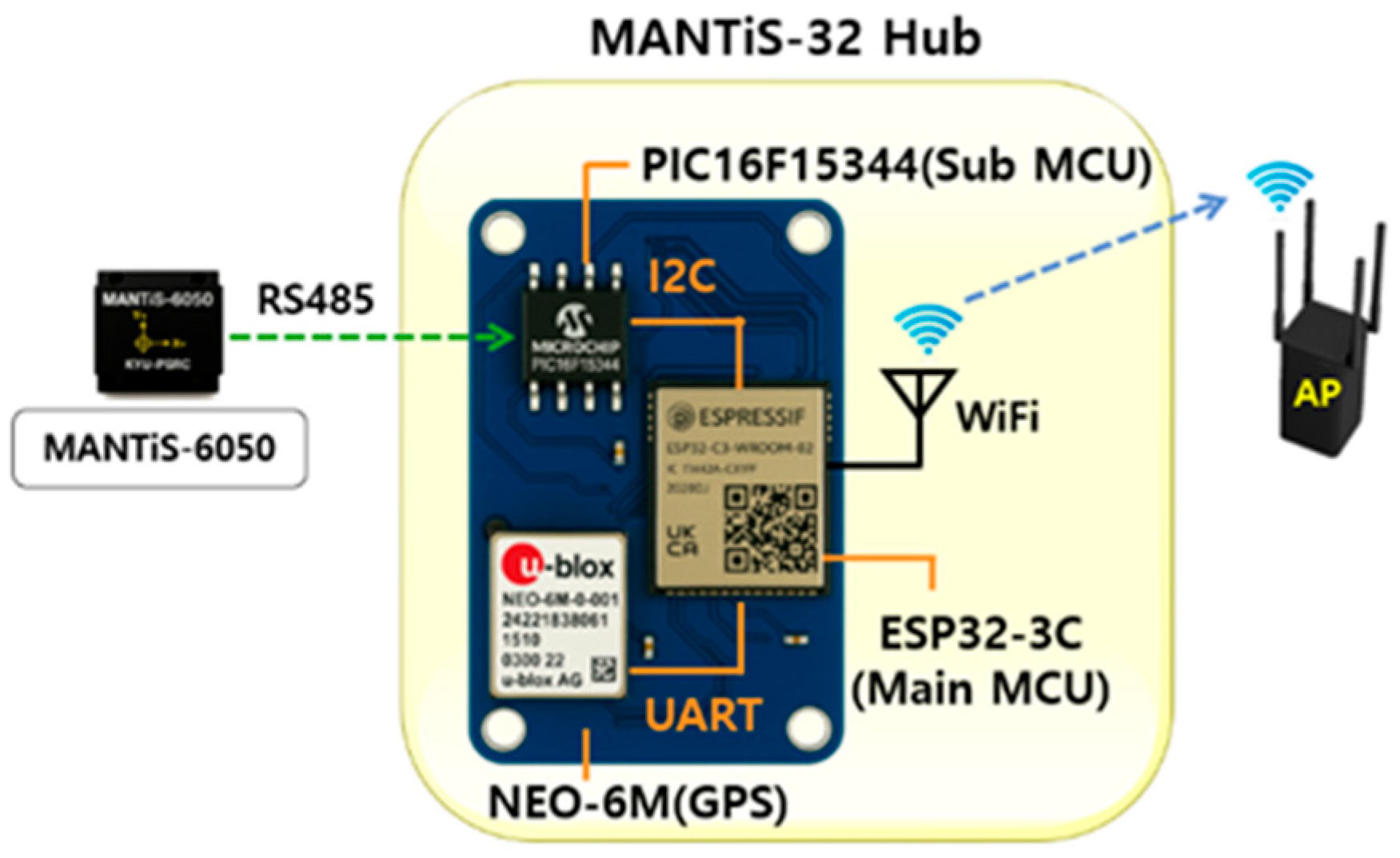

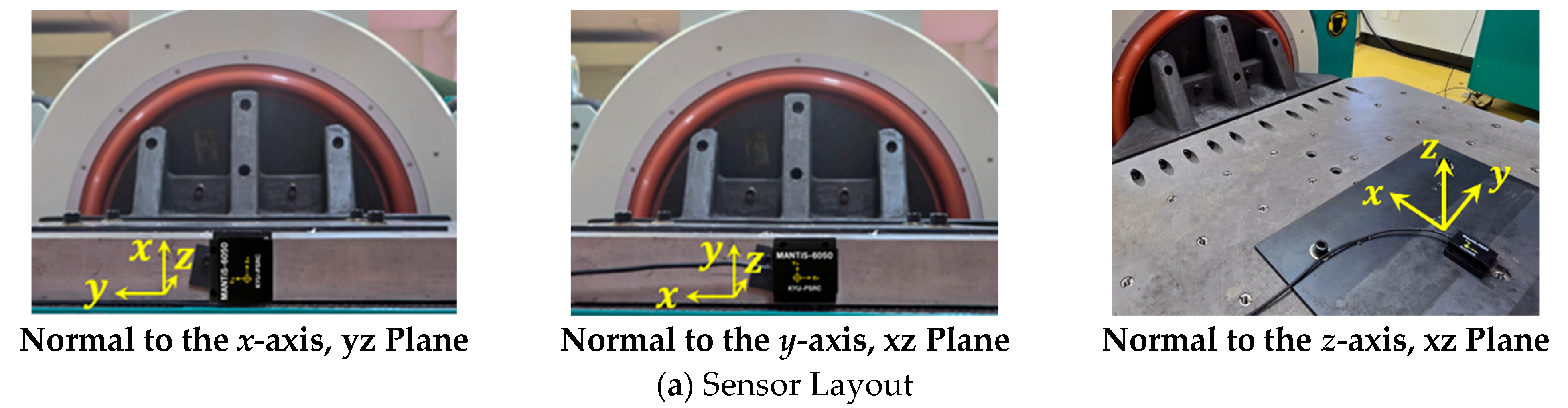

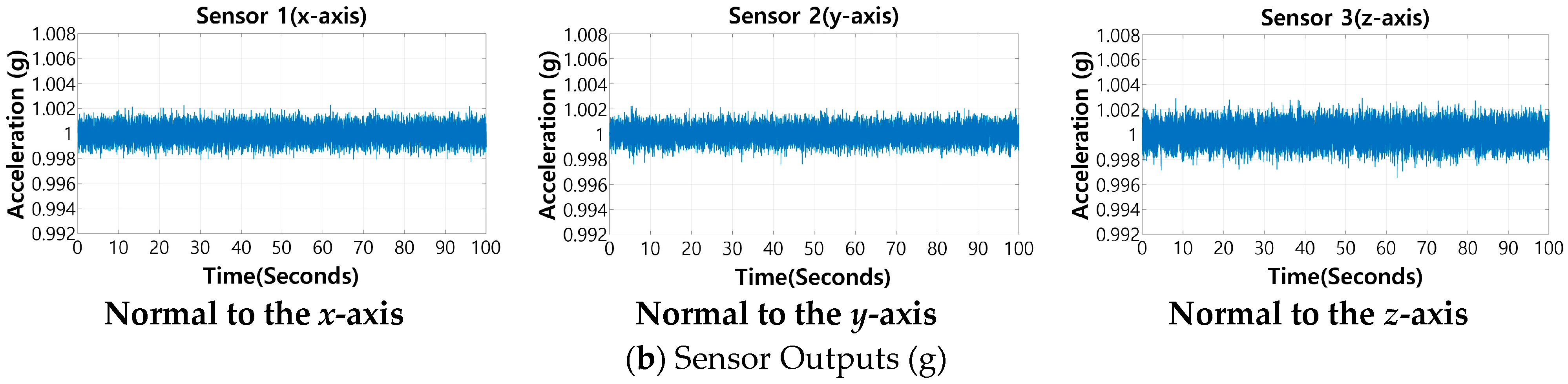

As depicted in

Figure 2, the MPU-6050 sensors affixed to the structure are designed to continuously capture real-time vibration data. These signals are acquired via an I2C interface by the onboard PIC16F15344 microcontroller (Microchip Technology Inc., Chandler, AZ, USA), which subsequently encodes the data using the RS485 communication protocol for robust transmission to the MANTiS-32 hub. The transmitted data are then relayed wirelessly to the PBM system through Wi-Fi communication. To ensure high-precision temporal alignment across all sensor nodes, the system integrates GPS-based time synchronization. This synchronization capability significantly enhances the accuracy of data correlation, thereby enabling precise identification of structural dynamic characteristics and supporting high-fidelity, real-time SHM of the target infrastructure.

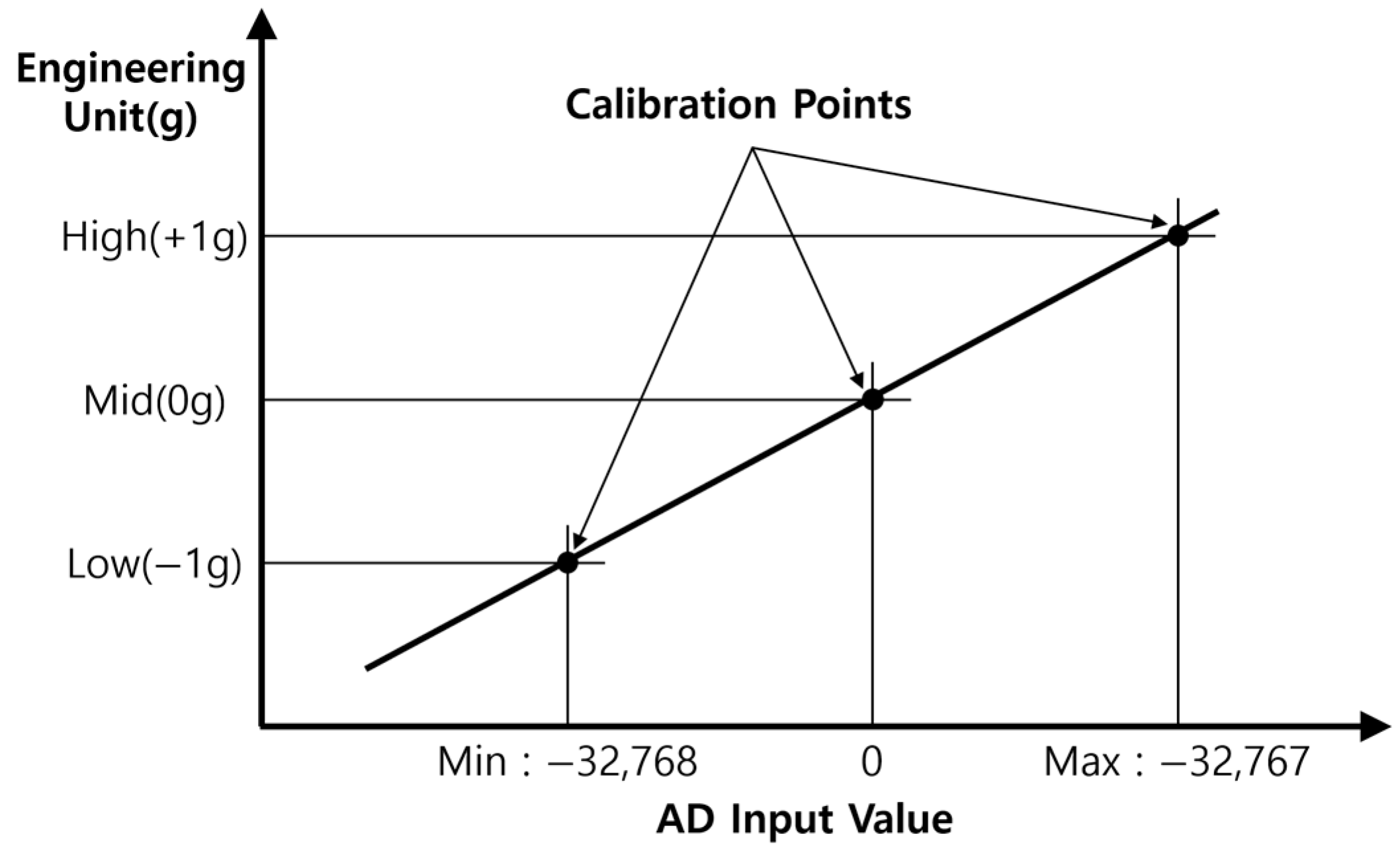

The MPU-6050 sensor’s measurement range was configured to ±2 g, optimized for capturing ambient vibrations typically exhibited by in-service bridge structures. This range selection was based on empirical observations of operational vibration amplitudes, ensuring sufficient resolution and sensitivity for structural health monitoring under service-level conditions. Furthermore, the sensor’s integrated FIFO buffer, with a maximum capacity of 1024 bytes, enables efficient block-based data acquisition and transmission. This design facilitates precise temporal synchronization across multiple sensor nodes, thereby improving data integrity and the overall performance of the wireless sensing network.

2.3. MANTiS-32 Wireless Networking Architecture

MANTiS-32 serves as a wireless data aggregation hub, designed to collect structural vibration data from distributed MANTiS-6050 sensor (InvenSense Inc., San Jose, CA, USA) modules and transmit the acquired signals to a centralized PBM system via Wi-Fi communication. Engineered as a high-fidelity dynamic measurement platform with robust wireless capabilities, MANTiS-32 is optimized for real-time structural condition assessment and modal parameter identification. Its modular design ensures ease of deployment and scalability, enabling flexible integration across a wide spectrum of SHM applications, including small- to medium-span bridges, structural test specimens, and industrial plant systems.

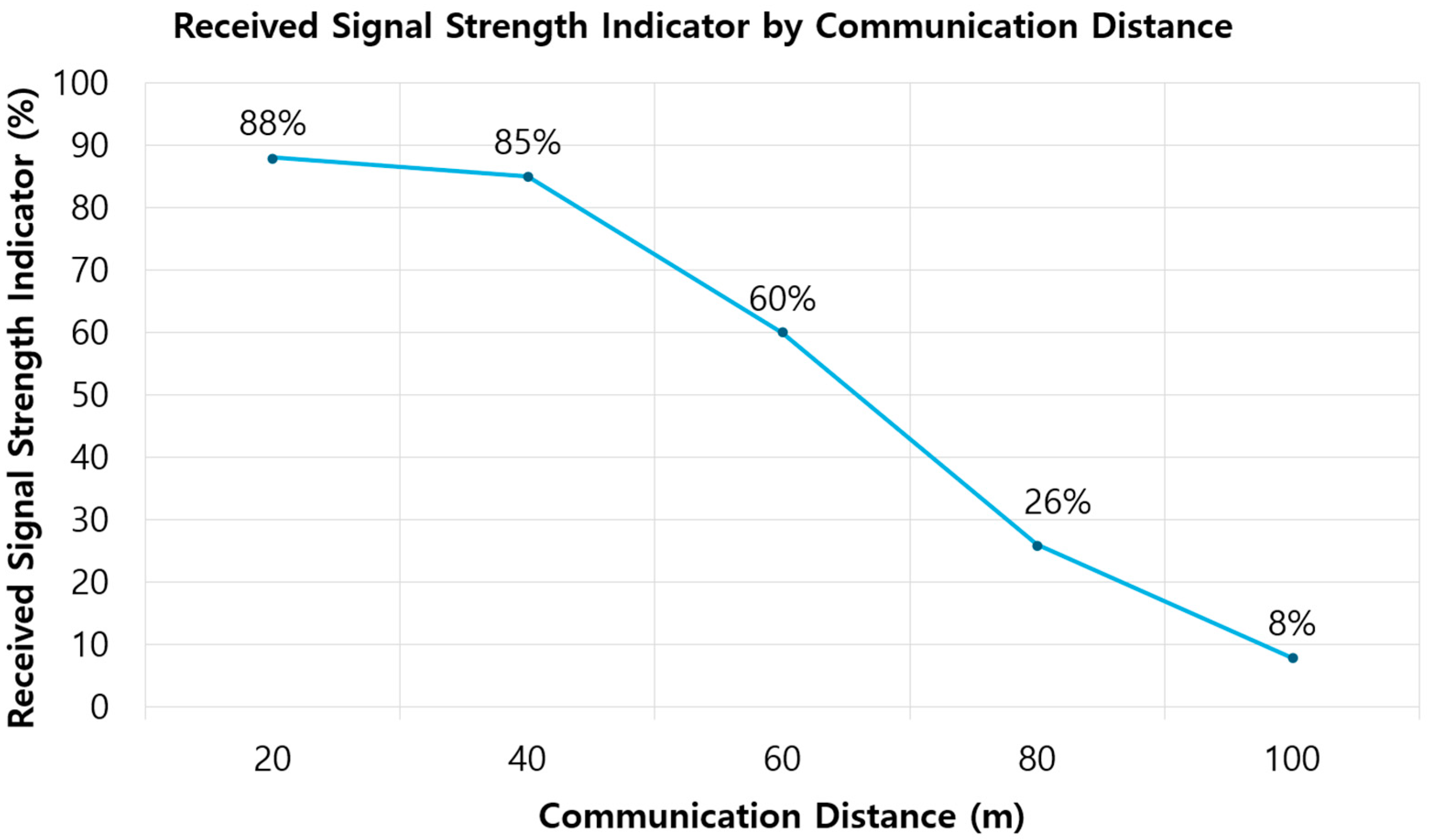

As illustrated in

Figure 3, MANTiS-32 is configured to receive data from up to eight MANTiS-6050 sensor (InvenSense Inc., San Jose, CA, USA) nodes via RS485 communication, managed by an onboard PIC16F15344 microcontroller (Microchip Technology Inc., Chandler, AZ, USA). Inter-component communication within the system is established using the I2C protocol, allowing seamless coordination between sensor modules and the ESP32-C3 microcontroller (Espressif Systems, Shanghai, China) for signal processing and configuration control.

To enable high-precision temporal synchronization among multiple hubs and sensor nodes, the system incorporates a NEO-6M GPS module. This module communicates with the ESP32-C3 microcontroller through an interface, providing Real-time Location (UART) and time data. The integration of GPS-based timestamping facilitates accurate alignment of distributed sensor data, thereby enhancing the reliability of time-domain correlation and improving the fidelity of subsequent modal analysis. Wireless data transmission is executed by the ESP32-C3 microcontroller, which communicates with the PBM system through a designated AP using Wi-Fi. This architecture supports synchronized, high-throughput, and low-latency data transfer, forming a comprehensive and scalable framework for real-time wireless structural health monitoring.

2.3.1. Wireless Communication Architecture of the MANTiS-32 Sensing System with MANTiS-6050 Modules

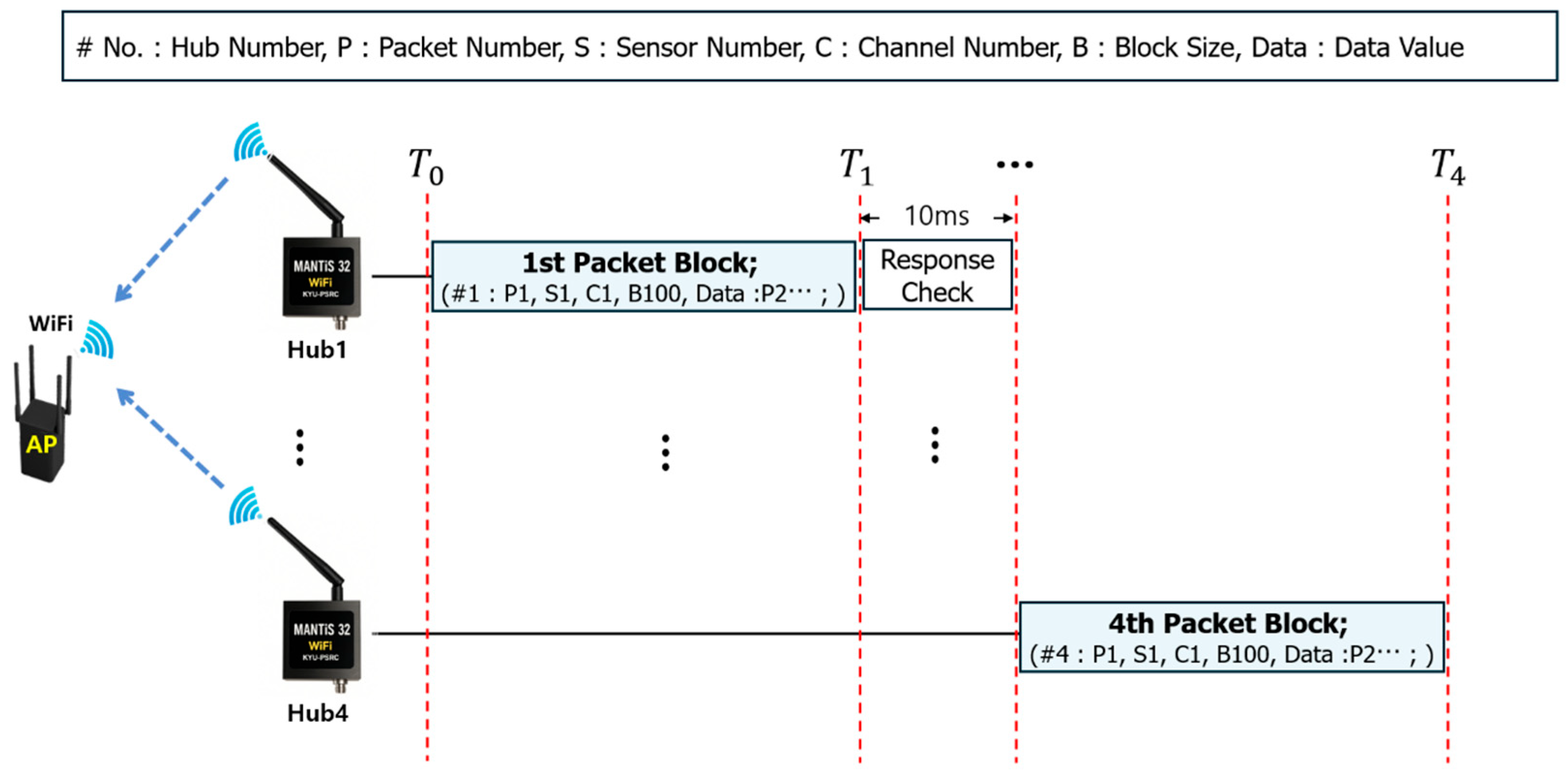

The MANTiS-32 wireless sensing system adopts a hybrid tree-bus topology to achieve enhanced scalability, flexibility, and communication reliability across the sensor network. By synchronizing precise timestamps with each MANTiS-6050 sensor, the system enables orderly, sequential data transmission from each channel. This ensures deterministic communication over the RS485 bus, eliminating data collisions and maintaining high temporal fidelity. As shown in

Figure 4, the MANTiS-32 hub is architected to poll data from eight MANTiS-6050 sensor modules at fixed intervals of 0.52 ms. Each sensor’s response is acknowledged before the hub proceeds to the next node, and the aggregated data are subsequently transmitted to the upper-tier PBM system via Wi-Fi. This tightly coordinated, multi-node communication scheme enables highly stable, high-resolution structural monitoring. With a complete sensor sweep across all eight channels achievable in under 4 ms, the system is particularly well-suited for high-frequency vibration measurement and real-time modal analysis.

Each MANTiS-6050 sensor is connected to the MANTiS-32 hub via an RS485 bus, as depicted in

Figure 4. Sensor 1 initiates data transmission immediately without delay. Each packet includes a metadata-enriched header comprising the Packet Number (P), Sensor Number (S), and Channel Number (C), followed by sensor measurements encoded in ASCII-format hexadecimal values. Upon completion of transmission, the appearance of a semicolon (;) on the RS485 line is interpreted as the end-of-packet delimiter. This triggers a fixed latency of 0.52 ms before the next sensor node initiates transmission. This time-slotted, collision-free communication strategy ensures orderly access to the shared RS485 bus, facilitating precise time alignment and efficient high-throughput data acquisition across the sensor array.

2.3.2. Communication Between the MANTiS-32 Hub and AP

The communication architecture between the MANTiS-32 hub and the AP is implemented using a hierarchical tree topology over Wi-Fi, enabling scalable and structured data aggregation from distributed sensing units. Each MANTiS-32 hub collects vibration data packets from its connected MANTiS-6050 sensor nodes and assembles them into predefined packet blocks for transmission. As illustrated in

Figure 5, each packet block consists of a header containing key metadata—such as Hub Number (#), Packet Number (P), and Block Size (B)—followed by the sensor data payload. Sensor readings are encoded in hexadecimal ASCII format and delimited by a colon (:) to ensure clear separation and traceability.

Data transmission is performed sequentially on a per-block basis. For example, once Hub #1 initiates its transmission without delay, subsequent hubs monitor the RS485 or Wi-Fi network for a terminal semicolon (;) indicating the end of the preceding packet block. Upon detection, they introduce a fixed 10 ms delay before commencing their own transmissions. During this interval, each hub performs a brief wireless channel assessment to avoid collisions, ensuring reliable and orderly communication even under intermittent network instability. This time-synchronized, block-based transmission strategy ensures that sensor data from multiple hubs is delivered without overlaps, maintaining both temporal coherence and high data fidelity. The sequential protocol not only mitigates data loss and transmission conflict but also supports scalable expansion across a wide range of monitoring environments.

The MANTiS-32 system is architected as a high-performance, wireless SHM network, specifically tailored for deployment in spatially distributed infrastructure, such as long-span bridges, high-rise buildings, and industrial facilities. In such applications, multiple MANTiS-32 hubs can be deployed across key structural zones, each wirelessly transmitting synchronized, high-resolution sensor data to a centralized AP. This configuration enables the accurate reconstruction of global dynamic behavior (including mode shapes and natural frequencies) in a time-aligned manner, thereby supporting real-time damage detection and early-warning capabilities essential for condition-based maintenance and operational safety.

5. Conclusions

This study presents the development and validation of the MANTiS-32 wireless sensing system, a low-cost, high-precision monitoring solution tailored for performance-based maintenance of small- to medium-span bridges. Built upon an open-source platform, the system integrates ESP32 microcontrollers with MPU-6050 inertial sensors and supports real-time data transmission via Wi-Fi communication. Each MANTiS-32 hub is capable of interfacing with up to eight MPU-6050 units, enabling scalable deployment across bridge structures.

Initial validation confirmed the system’s fundamental sensing capabilities, including accurate acceleration measurements under both impulse loads and ambient excitations, such as human footsteps. The MANTiS-6050 sensors demonstrated sufficient sensitivity for dynamic response capture, and the MANTiS-32 hub processed and transmitted the data with no observable latency or signal bottlenecks.

Wireless communication between MANTiS-32 hubs and the access point was executed using predefined packet blocks, effectively mitigating synchronization issues. Reliable data acquisition was achieved in real time, even when concurrently streaming from 26 distributed sensors across four hubs. The system maintained stable performance at up to an 80 m communication range, and the potential for further extension was verified by the scalable use of additional APs.

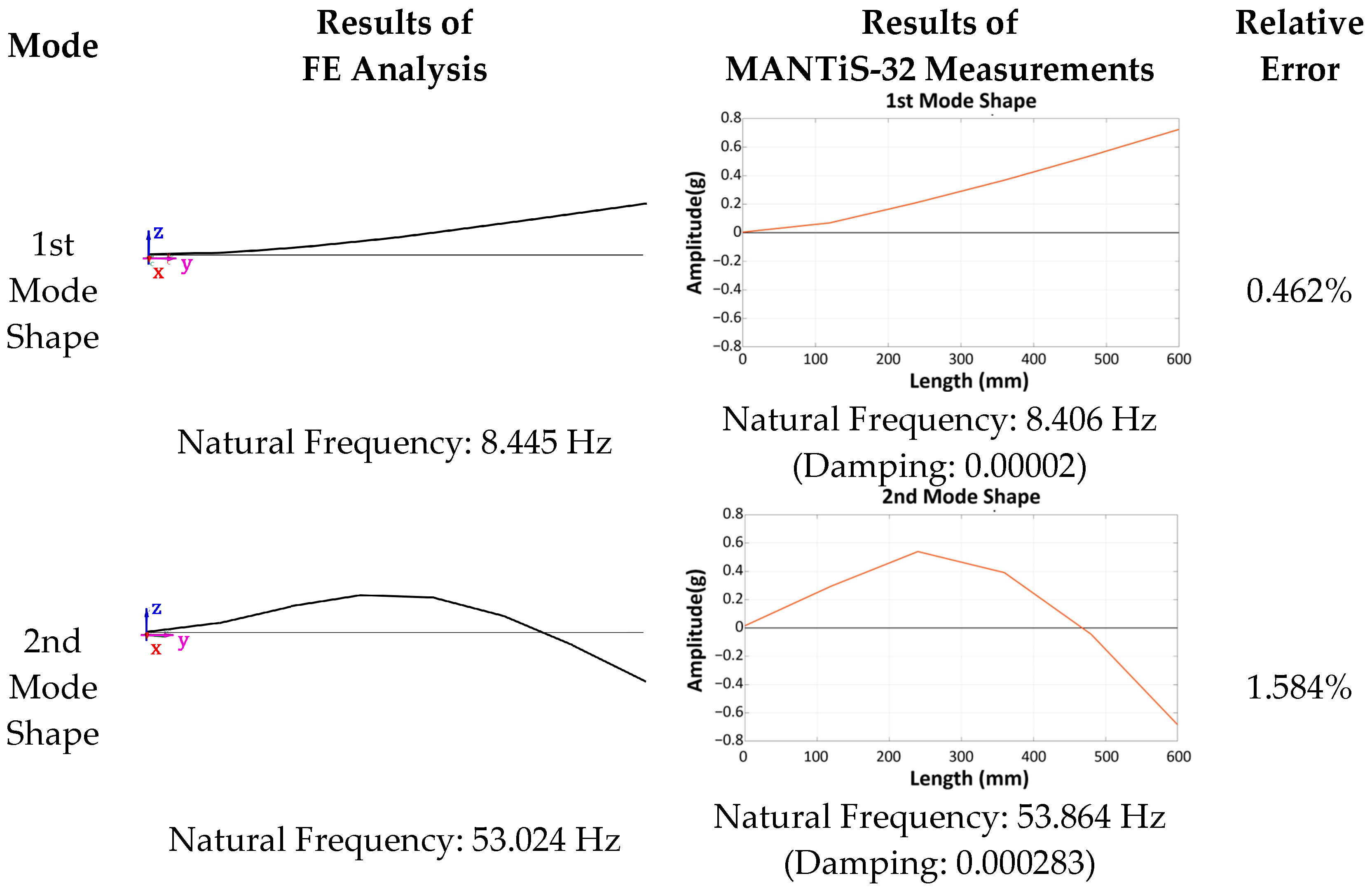

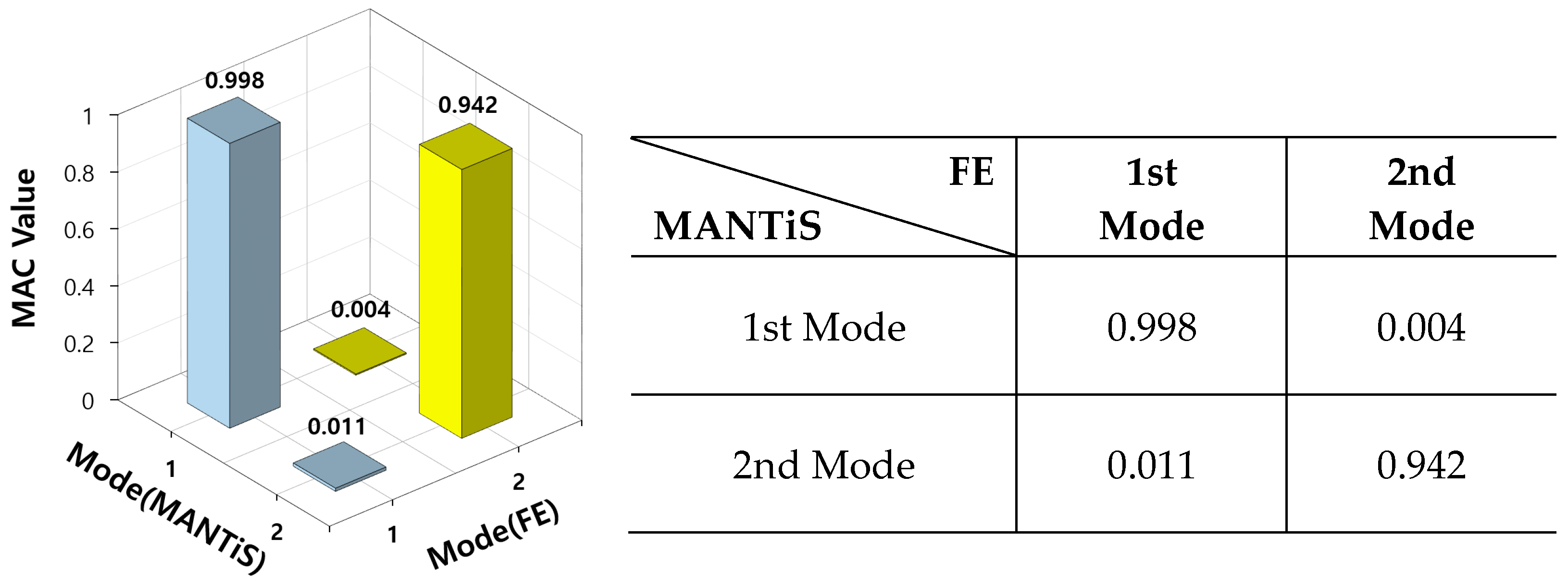

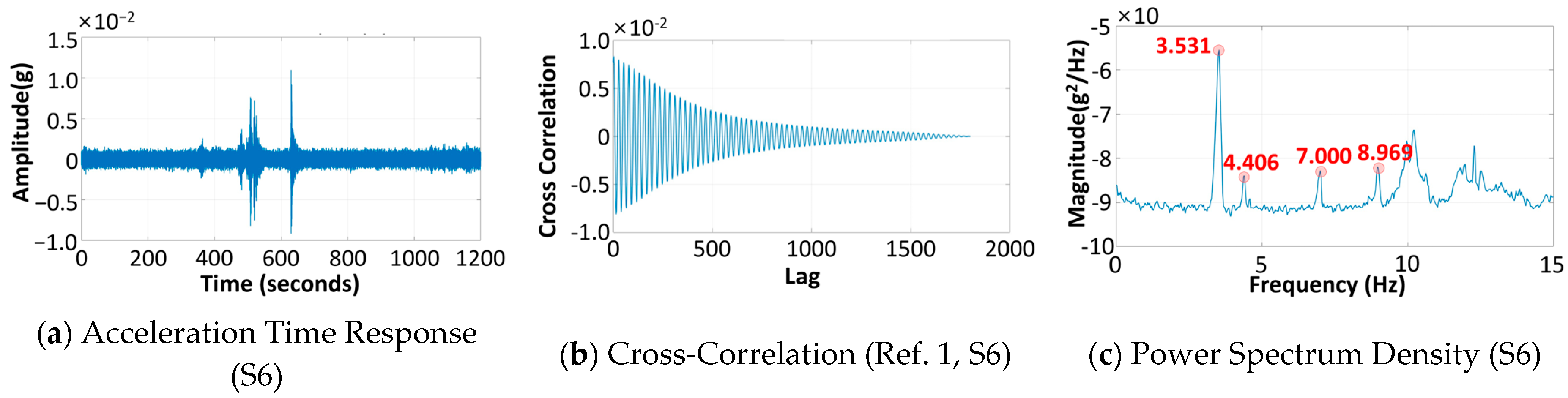

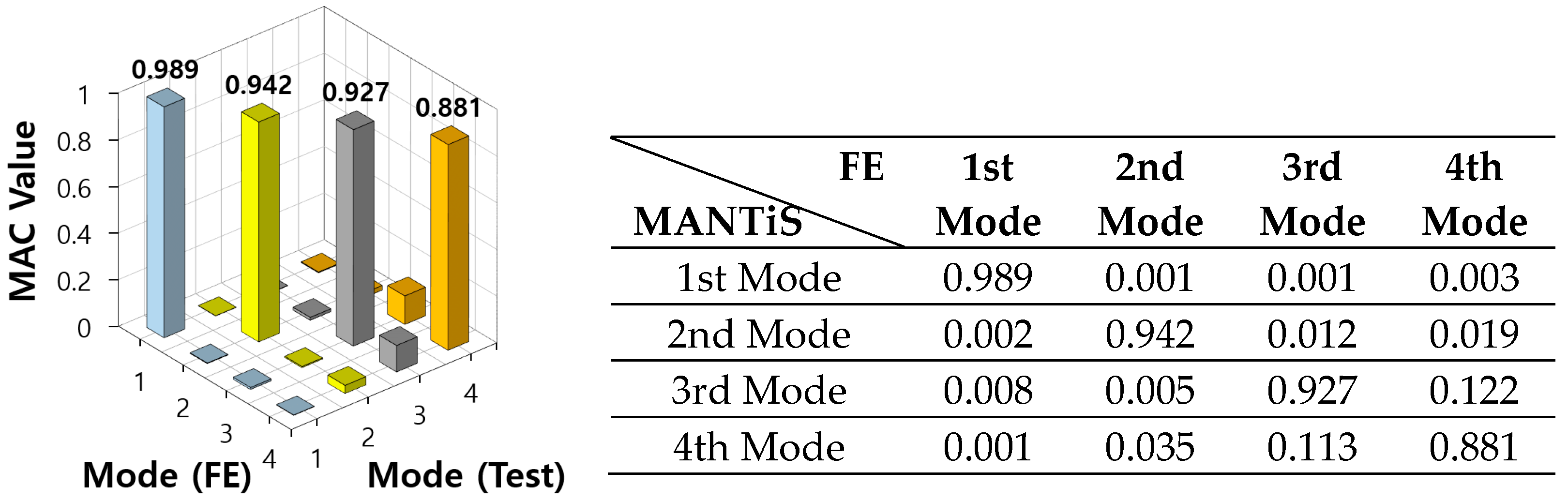

To assess the system’s capability in real-world applications, a 1:30-scale model of a cable-stayed bridge was instrumented with 26 sensors for real-time ambient modal analysis. The modal parameters—natural frequencies and mode shapes—were successfully extracted. Comparison with finite element analysis revealed frequency discrepancies within 1.6%, and mode shape correlation using the Modal Assurance Criterion (MAC) showed a high level of agreement (90–98%).

In conclusion, the MANTiS-32 system demonstrates strong potential as a robust, energy-efficient wireless SHM solution for small- to medium-scale bridges. Its ability to acquire synchronized, high-fidelity data and support real-time modal analysis validates its effectiveness for deployment in structural performance monitoring and condition-based maintenance strategies. However, the MANTiS-32 system may be limited in its ability to accurately capture the dynamic responses of long-span bridges, particularly those characterized by low-frequency (0.1~1 Hz) and low-amplitude vibrations.

6. Further Research Plan

First, long-term performance verification of the MANTiS-32 system will be conducted on an actual bridge structure. In particular, short- and long-term field tests will be carried out under outdoor environmental conditions—including temperature fluctuations, humidity, ambient noise, and wireless interference—to evaluate the system’s durability and operational stability.

Second, by integrating the MANTiS-32 system with a Performance-Based Monitoring (PBM) framework, a long-term condition assessment of an in-service bridge—focusing especially on fatigue-related performance degradation—will be performed. Through this, the applicability of the MANTiS-32 system to performance-based structural health monitoring will be validated.

Third, to ensure the long-term field operability of the MANTiS-32 system, a power supply system using a solar panel and lithium–polymer battery will be applied. The energy efficiency, battery lifespan, average current consumption during active and sleep modes, and expected maintenance intervals will be assessed to evaluate the feasibility of sustained autonomous operation in the field.