1. Introduction

Studying nonideal oscillating systems wherein the excitation source is affected by the dynamic behavior of the subordinate nonlinear system is considered a challenging task in theoretical and practical research in engineering sciences. When this behavior has no effect on excitation, such systems are known as ideal systems or ideal-powered systems. The behavior of ideal systems is very well known in the modern literature, but there are fewer findings on nonideal systems. Reviews of nonideal problems have been published in the papers [

1,

2,

3,

4]. The theory of nonideal mechanical system (NIS) was developed in [

5,

6]. For this kind of nonideal dynamic system, it is necessary to add a member (equation) describing the interaction between the power supply and the subordinate system. Compared to an ideal system, the differential equations of a nonideal system are significantly nonlinear.

The nonideal source effect is known to be manifested in actual machines and mechanisms. Let us consider the response of the dynamics of nonideal vibrating systems based on some lever mechanisms.

More generalized dynamic and mathematical models of the nonideal flat lever orthogonal vibration table mechanism were created in the article [

7]. In the paper [

8], the responses of rotational motion dynamics and oscillatory damped motion of the mechanism were studied. As a result of the influence of the lever mechanism on the excitation source during stable modes of the motor shaft rotation, it was shown that its rotational speed fluctuates relative to its average value. The frequency of variation in rotational speed was equal to its mean value, and its amplitude was inversely proportional to this value. This means that the smaller the rotational speed of the motor, the larger the amplitude and smaller the frequency of variation in the rotational speed of the driving member. The actuated rotational speed depends on the length of the crank and the engine torque. The conditions imposed on the amplitude of oscillations, regularities of change in the amplitude of the damped oscillatory motion of the crank, as well as the dependence of the frequency of the oscillatory motion on its amplitude and the parameters of the energy source and mechanism are established. Stability conditions of rotational motion and oscillatory damped motion are found. The studies in [

9] focused on the oscillatory motion of the mechanism at slow engine speeds. The characteristics of the change in the amplitude of the motor rotational speed depending on the length of the driving member and on the mass of the load on the operating member were determined. In the papers [

7,

10], the influence of friction in kinematic pairs on the dynamics of the orthogonal vibration table mechanism with a low-speed engine at a constant stationary load in the operating member was studied.

One of the simplest lever mechanisms is the crank-slider mechanism, which converts the rotational movement of the driving element into translational movement, and therefore it is the base for many devices. This mechanism has been extensively analyzed and applied in internal combustion and Stirling engines, compressors [

11,

12,

13,

14,

15,

16], robotics and mechatronic devices [

17,

18,

19,

20,

21], excavation, tunneling, and construction machinery [

22,

23,

24], power equipment [

25,

26,

27], forging and stamping machines [

28,

29], and various other applications [

30,

31,

32]. There is a significant amount of research carried out on the simple crank-driven mechanism, since it is the main element of the devices. Most of the studies relate to rigid member mechanisms with the crank (crankshaft) being rigidly supported and rotating at a constant rotational speed. Most of these studies are either analytical or numerical and examine various mechanical aspects of the dynamic response and stability of crank-driven mechanism of devices [

33].

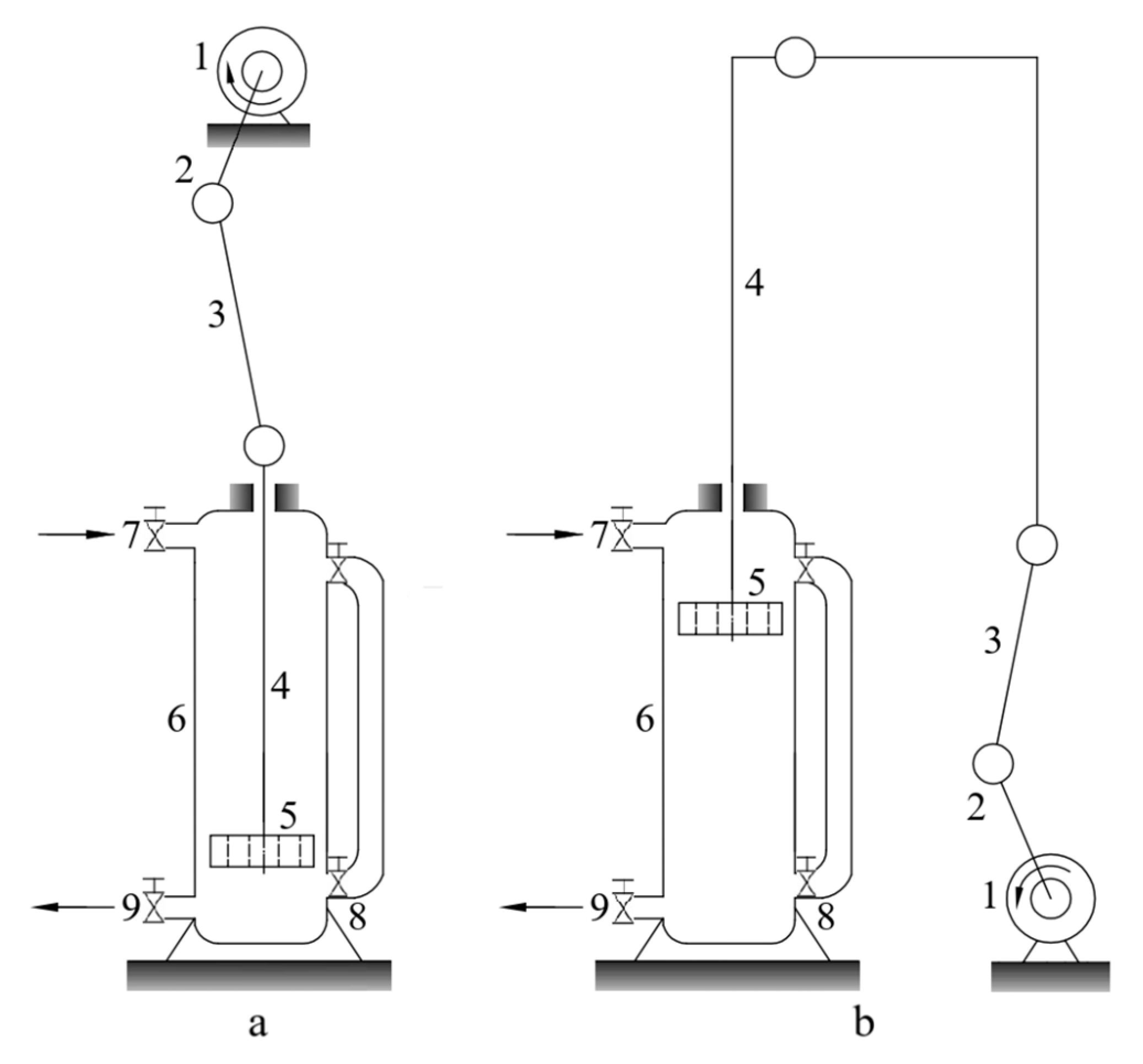

By connecting two crank-slider mechanisms, it is possible to obtain a corresponding device that also converts the rotational motion of the driving member into translational motion of the slider connected to the mixing piston. The idea of combining two crank-slider mechanisms is not new. Crank-slider mechanisms with dual sliders and combined systems are already used in instruments, devices, machines, and robots for various purposes [

34,

35,

36,

37,

38]. In papers [

33,

39], the problem is extended by incorporating a nonideal force and flexible support for the crank (crankshaft). These two factors in combination with the nonlinearity of the kinematics give rise to a model that closely resembles the actual mechanism. The slide-crank mechanism, due to its simplicity, is adopted as the basic mechanism for the cutting device. In the paper [

40], a more realistic system is considered: the mechanism is mounted on an elastic support and the effect of nonideal force on the system and the cutting process is analyzed. In the paper [

6], different designs of mechanisms are compared: simple, eccentric and slide-crank mechanism. Kinematic and dynamic analysis of ideal and nonideal force systems resting on rigid and spring supports is given. The advantages and disadvantages of the systems are outlined.

In articles [

41,

42], a new model of the effect of the movement of a single-action crank-driven pump on the modes of a nonideal energy source, i.e., a damless hydraulic turbine, and vice versa, was developed and studied. Consequently, the rotation of the hydraulic turbine becomes nonuniform, and the coefficient of nonuniformity of motion depends on the parameters of the piston pump and the hydraulic turbine itself. The average value of the hydraulic turbine angular velocity depends only on the parameters of the nonideal force source and the velocity of the watercourse flow.

To date, although there are patents and hand-made unsophisticated slide-crank mixing mechanisms (see, for example, [

43,

44,

45,

46]), there has been no mathematical modeling of the dynamics of these mechanisms, taking into account the technological processes carried out by different modes of motion of the driving member, the interaction with the source of energy. For this reason, this paper aims to study the dynamics of the oscillation-damped mode of the driving member motion, focusing on the application of slide-crank mechanism for mixing–whipping and shaking the slurry with appropriate technological characteristics, thus making a significant contribution to the theory of nonideal mechanical systems.

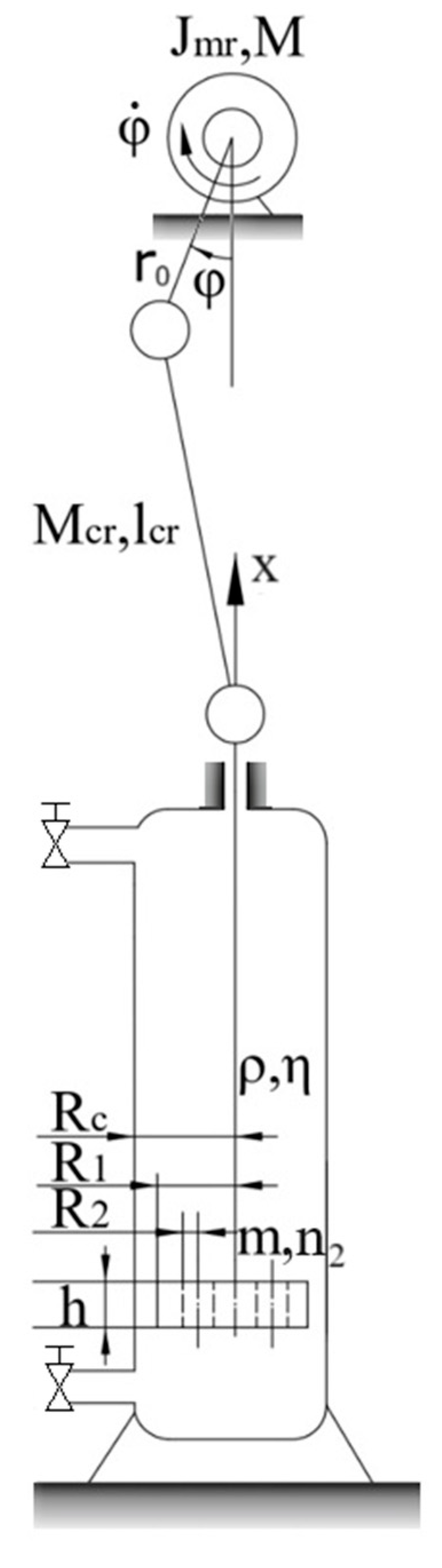

3. Results and Discussion

The results of solving the equations of motion (25) and (26) and calculating the mixing and whipping force power (27), as graphs of dependencies

φ =

φ(

t),

,

and

at different parameters of the system, are shown in

Figure 2,

Figure 3,

Figure 4,

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12,

Figure 13,

Figure 14,

Figure 15,

Figure 16,

Figure 17,

Figure 18,

Figure 19,

Figure 20,

Figure 21,

Figure 22,

Figure 23,

Figure 24 and

Figure 25.

If the engine power (torque a) is insufficient for the rotary motion of the crank, then the crank will perform a damped oscillation process. The crank, under the action of torque a, initially rotates upwards by some angle and then falls downwards, before reaching the neutral equilibrium position under the action of torque; it rises again, etc., until the oscillations are completely damped out.

The greater the engine torque

a, the greater the initial maximum crank angle (

Figure 2). The crank deflection angle

φ tends to a limit of constant value

φ1 as time elapses after completing the oscillating process. The greater the engine torque

a, the greater the value of the crank angle

. This means that the crank makes damped oscillations not around the neutral equilibrium position, but around a certain value

of angle

φ. This is caused by the fact that, at the rotational speed of the crank

, its angle of rotation is

. With constant magnitude of

and coefficient

the limiting angle of rotation of the crank

~

(where

). Considering that the maximum crank angle is 1.57 rad, the larger the engine torque

a, the larger the limiting crank angle

φl and the oscillation period.

Figure 2.

Dependence φ = φ(t) for different values of a.

Figure 2.

Dependence φ = φ(t) for different values of a.

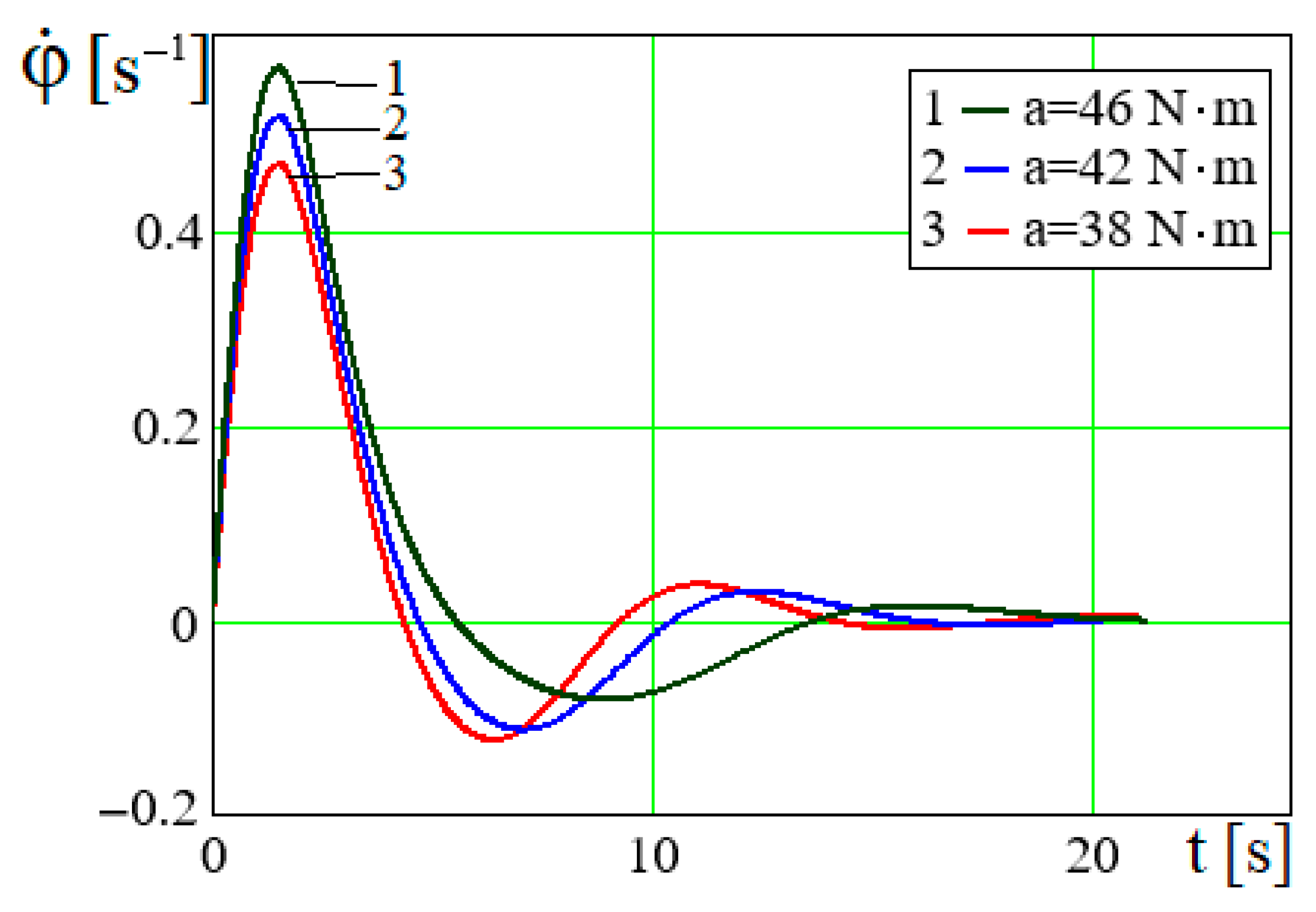

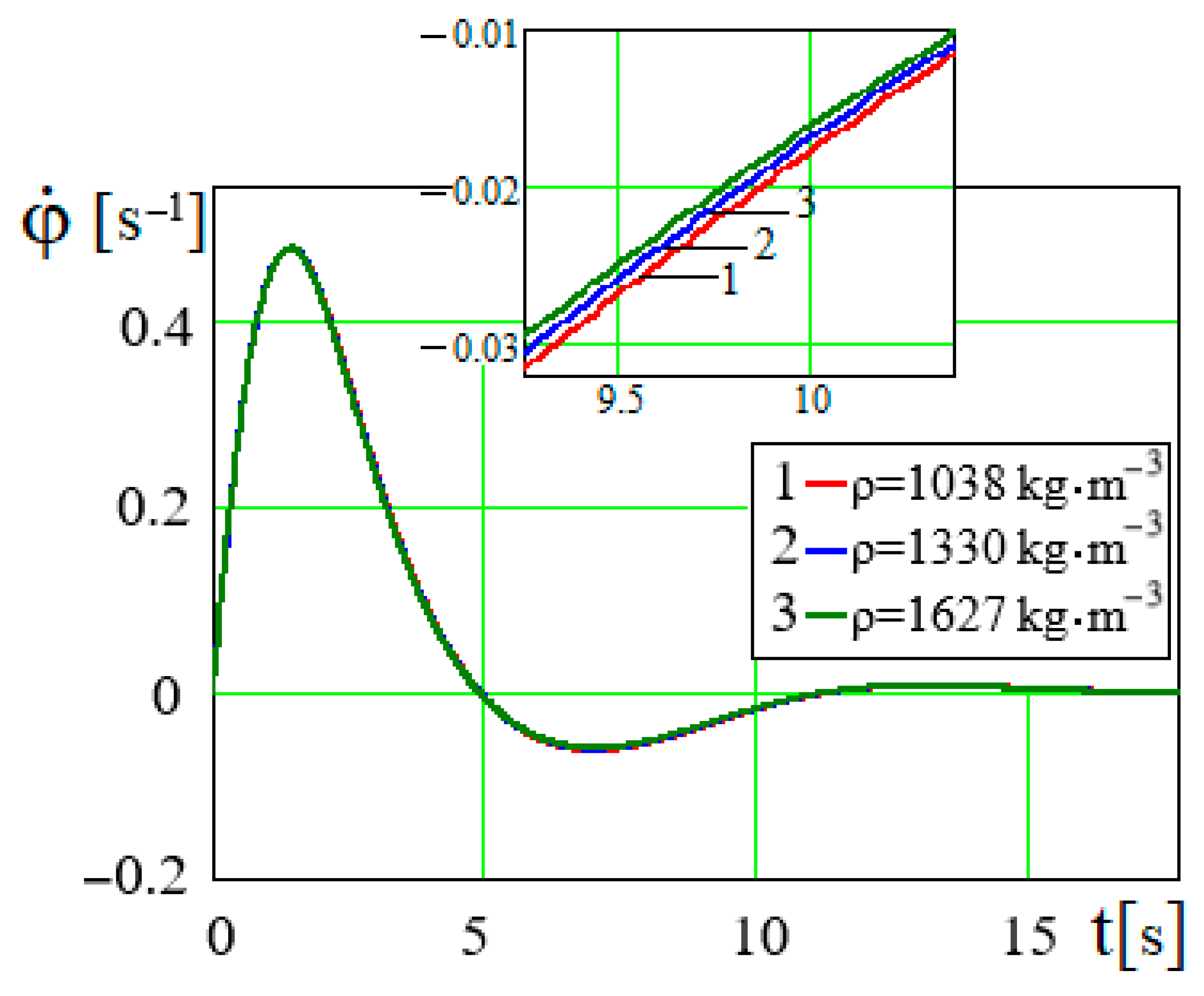

The rotational speed of the crank

also makes damped oscillations around the zero value with initial and subsequent amplitudes; the less the rotational speed, the less the corresponding torque value with decreased period (

Figure 3).

Dependency graphs

P =

P(

φ) and

in

Figure 4 and

Figure 5 show that during the upward rotation of the crank, the pressure force on the piston from above increases, and, accordingly, the power of the mixing–whipping force decreases and the value of

P reaches its maximum in further increasing the crank angle (

Figure 4). In this case, the rate of increase in the rotational speed of the excitation source shaft will be greatly attenuated and the motor shaft rotational speed will decrease by the end of the cycle (

Figure 5). From the relations (27),

~

. The general character of dependence

P =

P(

φ) (

Figure 4) is determined by the relation

~

, but the amplitude and periodicity of the function

are influenced by the value

, to be more precise, by the value

a. Since

and

(

Figure 3),

(

Figure 2). The smaller the value of the

a engine torque, the smaller is the amplitude and period of oscillation of the mixing–whipping force power

P depending on the angle of rotation φ of the crank according to the graphical relationships

φ =

φ(

t) and

in

Figure 2 and

Figure 3. Maximum magnitudes of the values

φ and

in the graphical dependencies

φ(

t) and

(

Figure 2 and

Figure 3) determine the right boundaries of the dependencies

P =

P(

φ) and

(

Figure 4 and

Figure 5); the minimum values

φl and

(

) (

Figure 2 and

Figure 3) determine the left boundaries of the power graphical dependencies.

Thus, the graphs in

Figure 2,

Figure 3,

Figure 4 and

Figure 5 show the results of the action of the power parameters of the excitation source on the kinematic parameters of the driving member of the device and on the energy characteristic of the dynamics of the operating member.

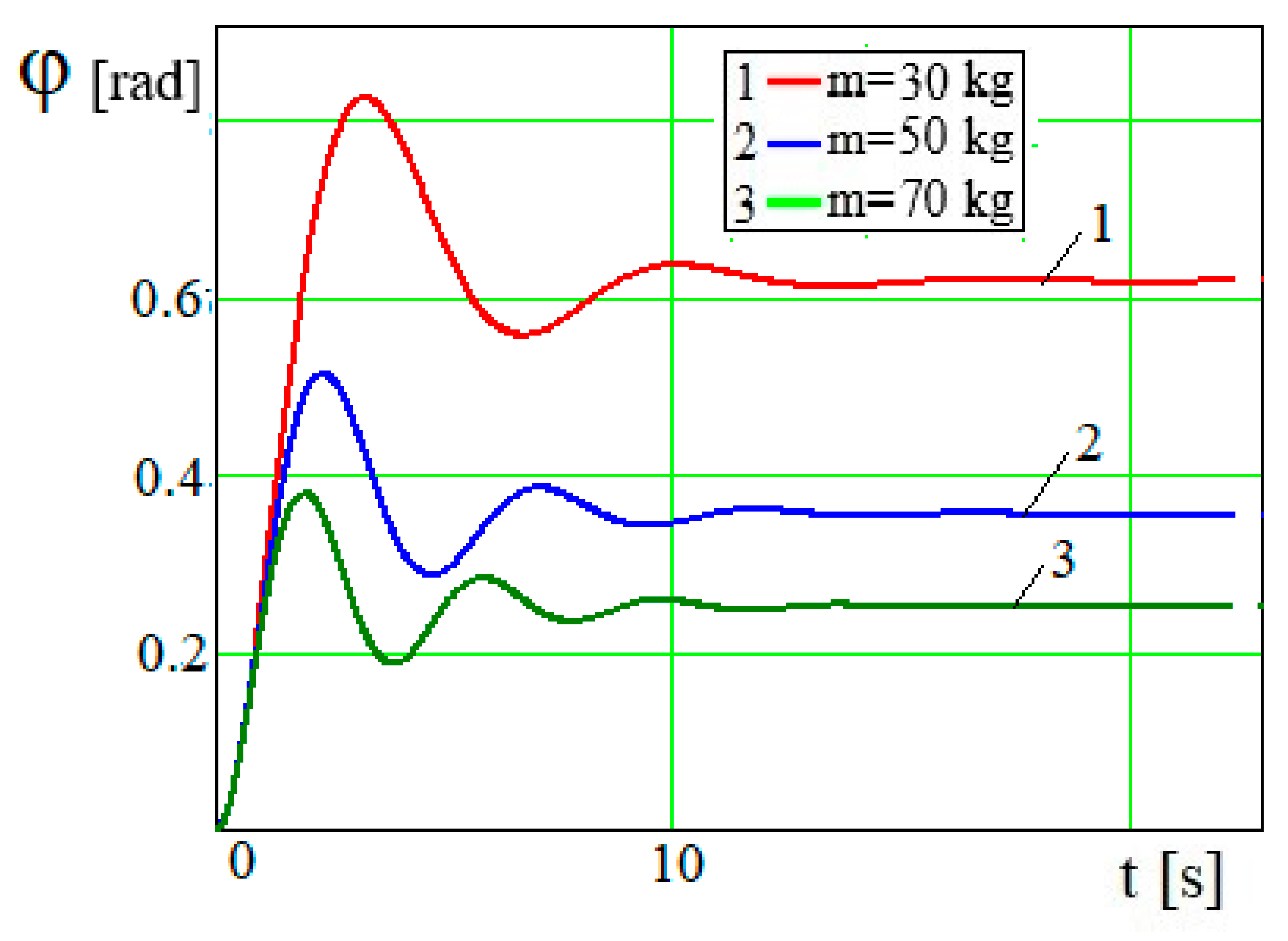

In

Figure 6 and

Figure 7, lines 1, 2 and 3, which are oscillatory characteristics of the vibrational mode of engine shaft motion, depend on the piston mass. The values of the mass of the piston

m are taken in relation to the rotating torque of the motor

a for the effect of an oscillatorily and aperiodically damped mode of crank movement. As the piston mass increases, the amplitude of oscillations of the angle

and the period of its damped oscillations decrease. After a lapse of time, the lines practically straighten out, and the angle of rotation

tends to the limit values. The limiting value of the rotation angle

~

(where

); in turn,

~

. As the mass of the piston increases, the value

of the angle

φ decreases (

Figure 6).

Figure 3.

Dependence for different values of a.

Figure 3.

Dependence for different values of a.

Figure 4.

Dependence P = P(φ) for different values of a.

Figure 4.

Dependence P = P(φ) for different values of a.

Figure 5.

Dependence for different values of a.

Figure 5.

Dependence for different values of a.

Figure 6.

Dependence φ = φ(t) for different values of m.

Figure 6.

Dependence φ = φ(t) for different values of m.

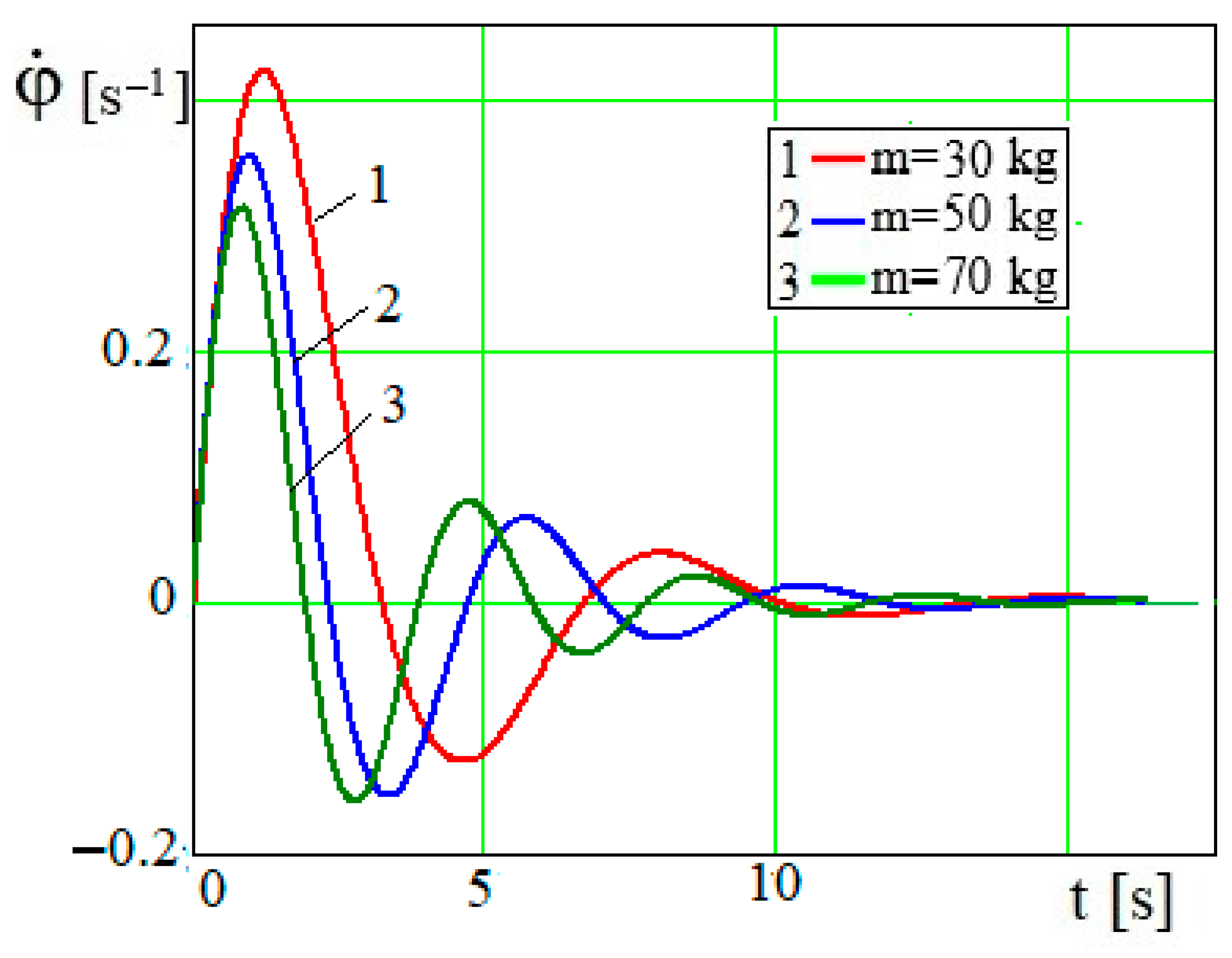

Figure 7.

Dependence for different values of m.

Figure 7.

Dependence for different values of m.

The vibrational characteristics of the motor shaft rotation depend on the parameters of the device members. At relatively small piston masses, the engine shaft performs a rotational motion. In

Figure 7, at sufficiently large piston masses, the shaft of the force source makes a damped oscillation of the engine shaft speed

. As the piston mass increases, the initial and subsequent amplitudes and period of oscillation

decrease, and the line around which the oscillation process occurs is defined by the zero magnitude value

. The greater the magnitude of the force moment resulting from the piston gravity (or piston mass) directed opposite to the

a engine torque, the smaller the maximum magnitudes of the oscillations

and

, and the smaller the repeatability of their oscillations.

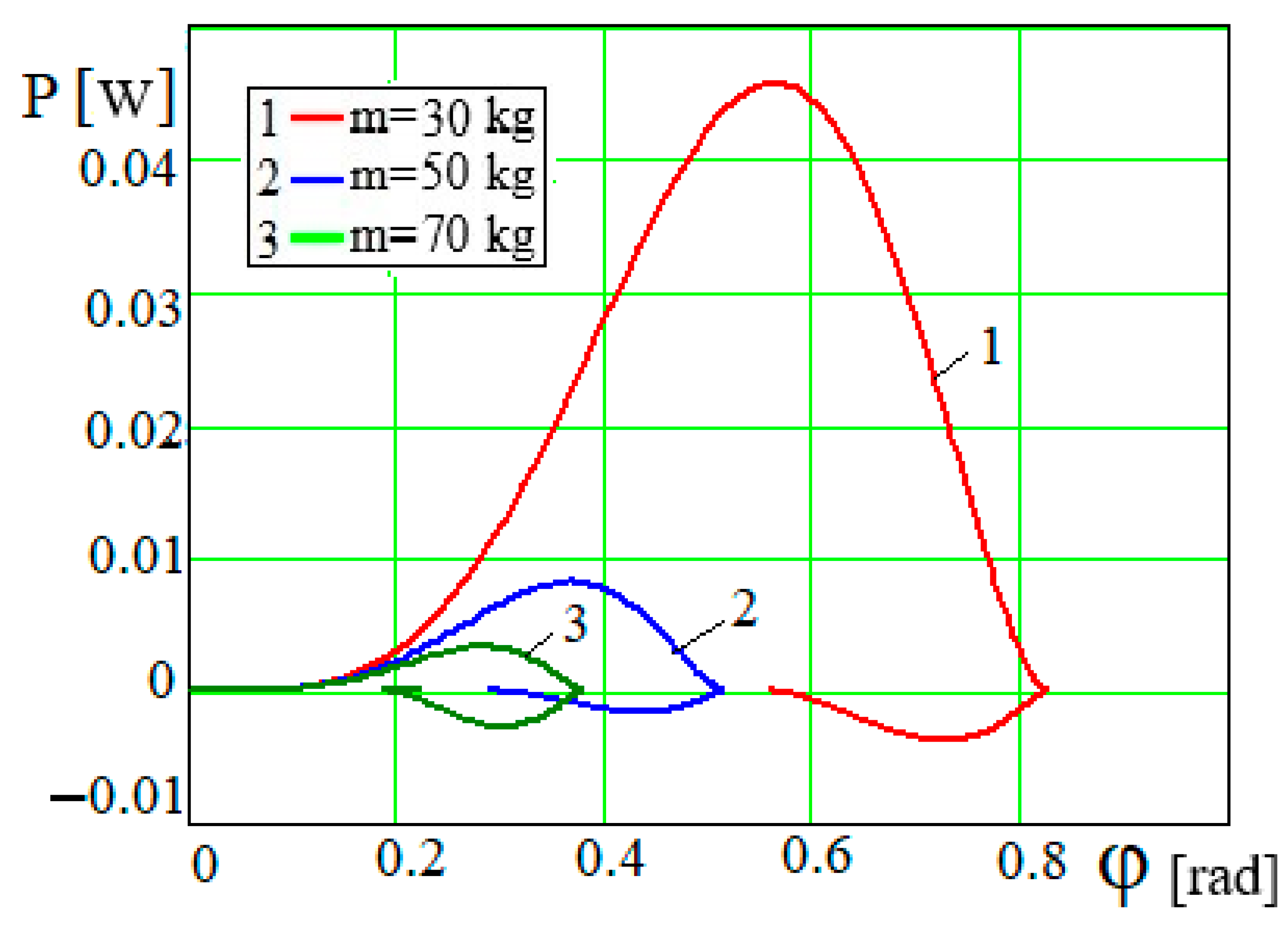

It follows from Formula (27) that the power of the mixing and whipping force is ~.

Then, in turn, the limit value of the excitation source shaft rotation angle based on Equation (25) or (26) is as follows:

~

. At

(

—engine shaft rotational speed limit value) limit, the magnitude value is

~

, taking into account

~

. The limit values of the rotation angle corresponding to the power value

coincide with the values of this angle in the dependencies

φ =

φ(

t) in

Figure 6. Dependency graphs

and

in

Figure 8 and

Figure 9 show that the larger the mass of the piston, the smaller the maximum power values of the mixing and whipping forces

. The decrease in the maximum value of

P with increasing mass

m is accompanied by a shift in the corresponding magnitudes of the values

and

to the beginning of the abscissa. The graphs in

Figure 9 show that, when approaching the end of the oscillating damping process, the technological process of whipping intensifies, which is demonstrated by a sharp increase in the force of mixing and whipping and its power and at some of their values and a sharp drop in their values. At

,

(

Figure 9). The rightmost limits of the graphs

P =

P(

φ) and

are limited by the maximum values of

φ and

. The leftmost limits of the graphs

P =

P(

φ) and

are defined by the minimum values of

φ and

.

Figure 8.

Dependence P = P(φ) for different values of m.

Figure 8.

Dependence P = P(φ) for different values of m.

Figure 9.

Dependence for different values of m.

Figure 9.

Dependence for different values of m.

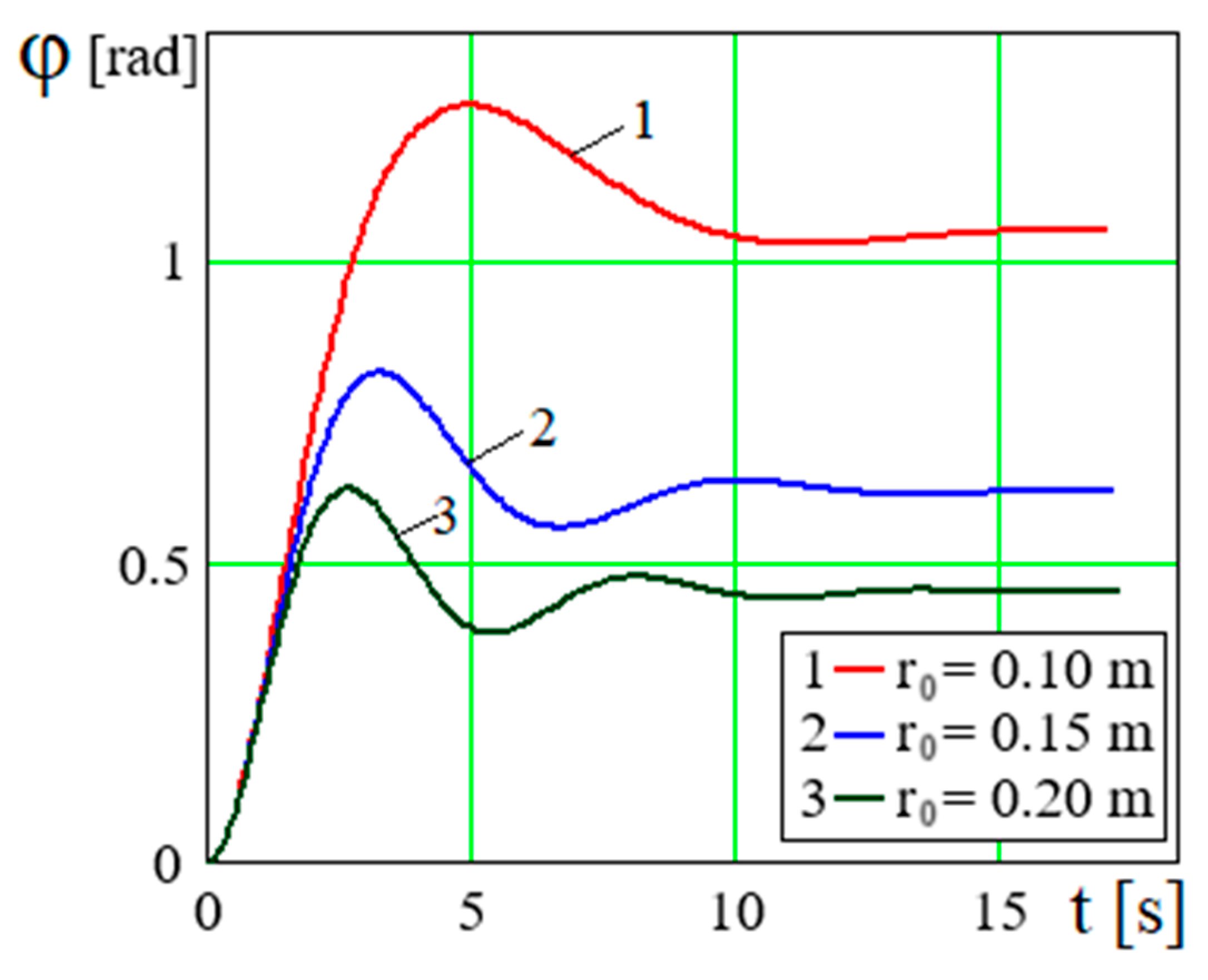

The device parameters, including the crank length, influence the kinematic oscillation parameters of the engine shaft motion (

Figure 10 and

Figure 11). After a lapse of time, the rotation angle of the driven engine shaft oscillates around the values to which it tends to oscillate, with an amplitude and period of oscillation smaller the longer the length of the driving member, as it is known that the limiting value of the rotation angle

φ:

~

while

~

.

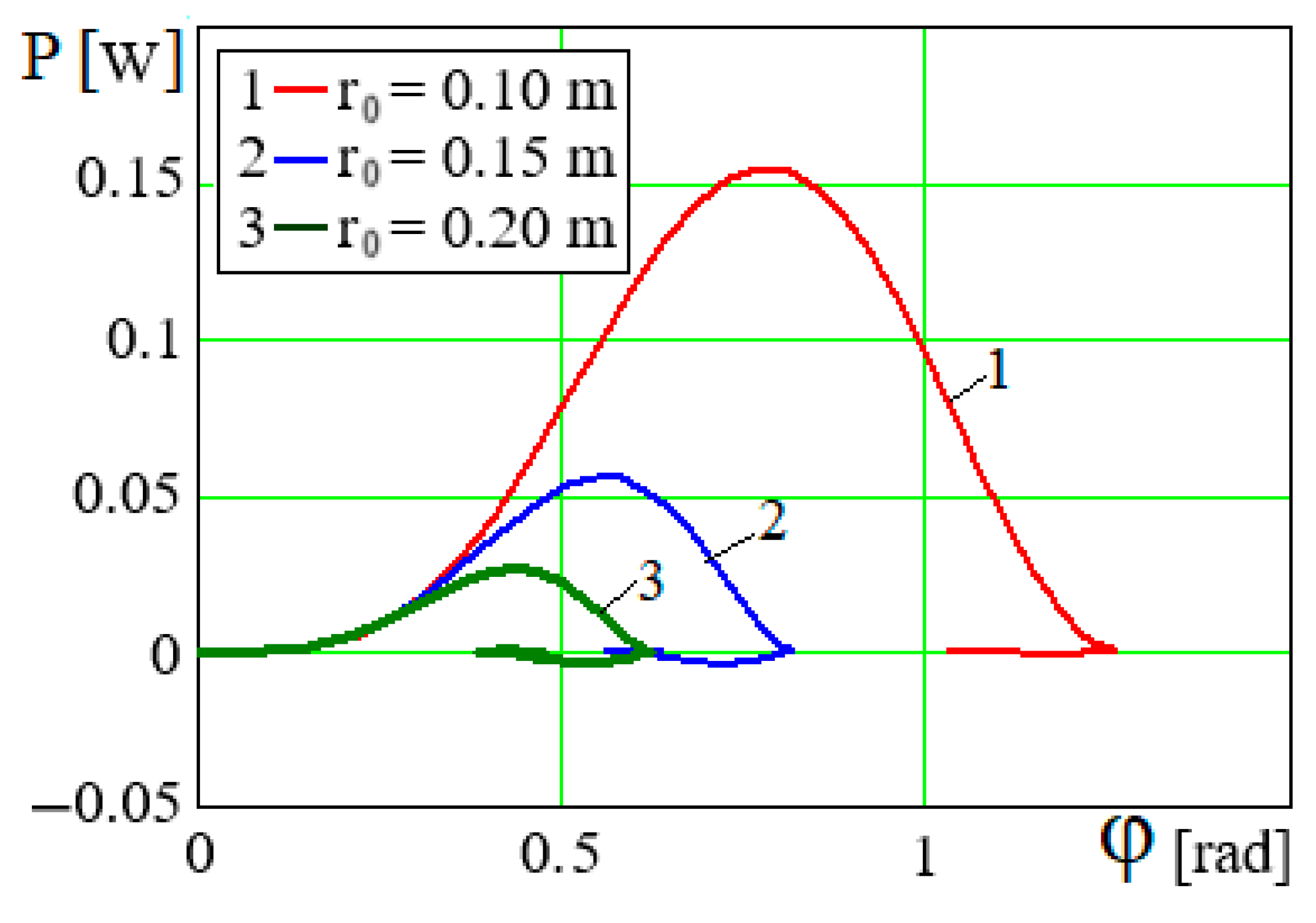

From Formula (27), we obtain

~

. From this dependence, the first thing to note is the proportionality

~

. Despite this dependence, based on the graphical relationships in

Figure 12 and

Figure 13, the predominant relationship is

~

, i.e., the value

is proportional to the minus

n-th degree of

, the value

is proportional to the minus

m-th degree of

, and the total should be

n +

m > 3.

Figure 10.

Dependence φ = φ(t) for different values of r.

Figure 10.

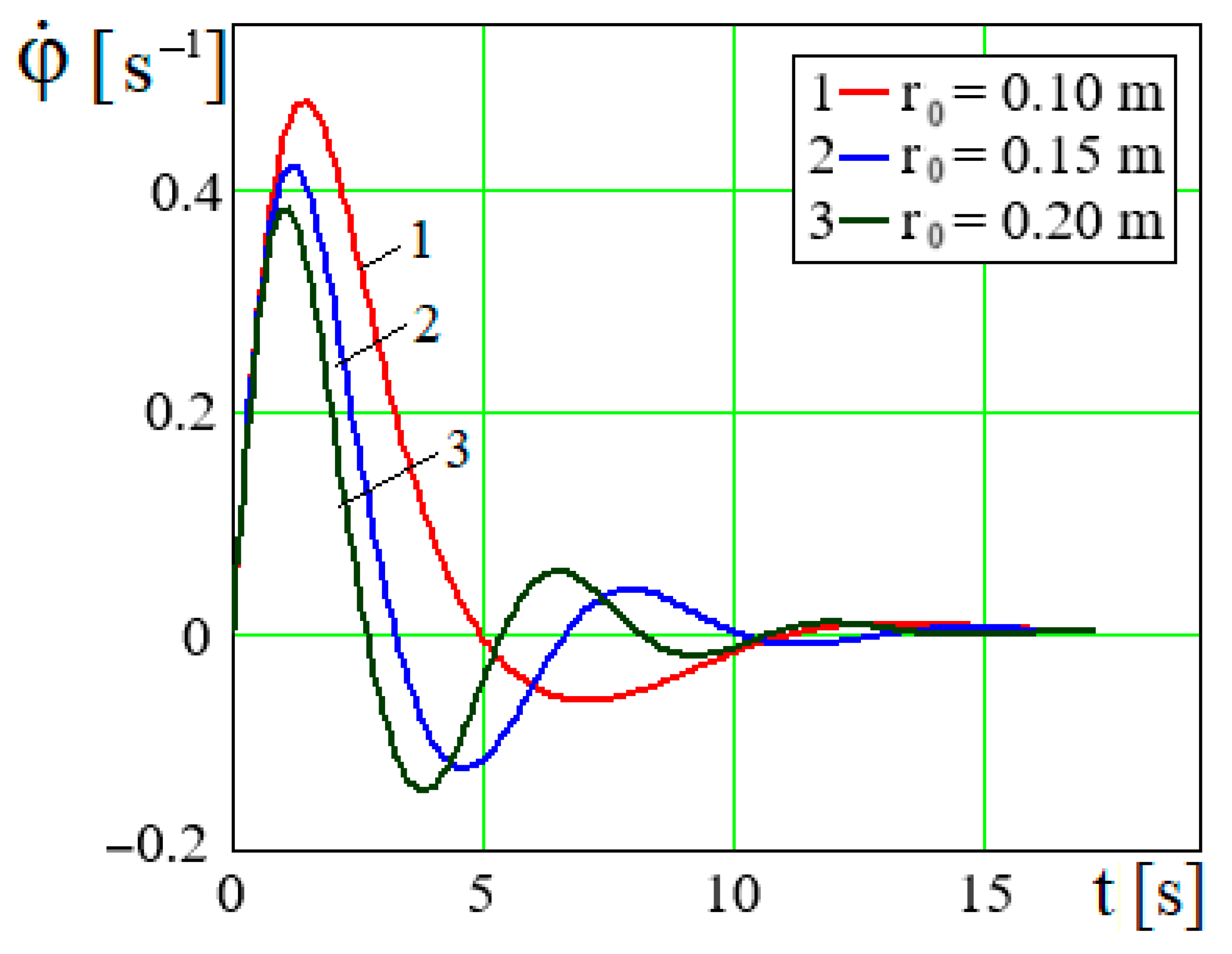

Dependence φ = φ(t) for different values of r.

Figure 11.

Dependence for different values of r.

Figure 11.

Dependence for different values of r.

Figure 12.

Dependence P = P(φ) at a = 23 N·m, m = 20 kg and various values of r.

Figure 12.

Dependence P = P(φ) at a = 23 N·m, m = 20 kg and various values of r.

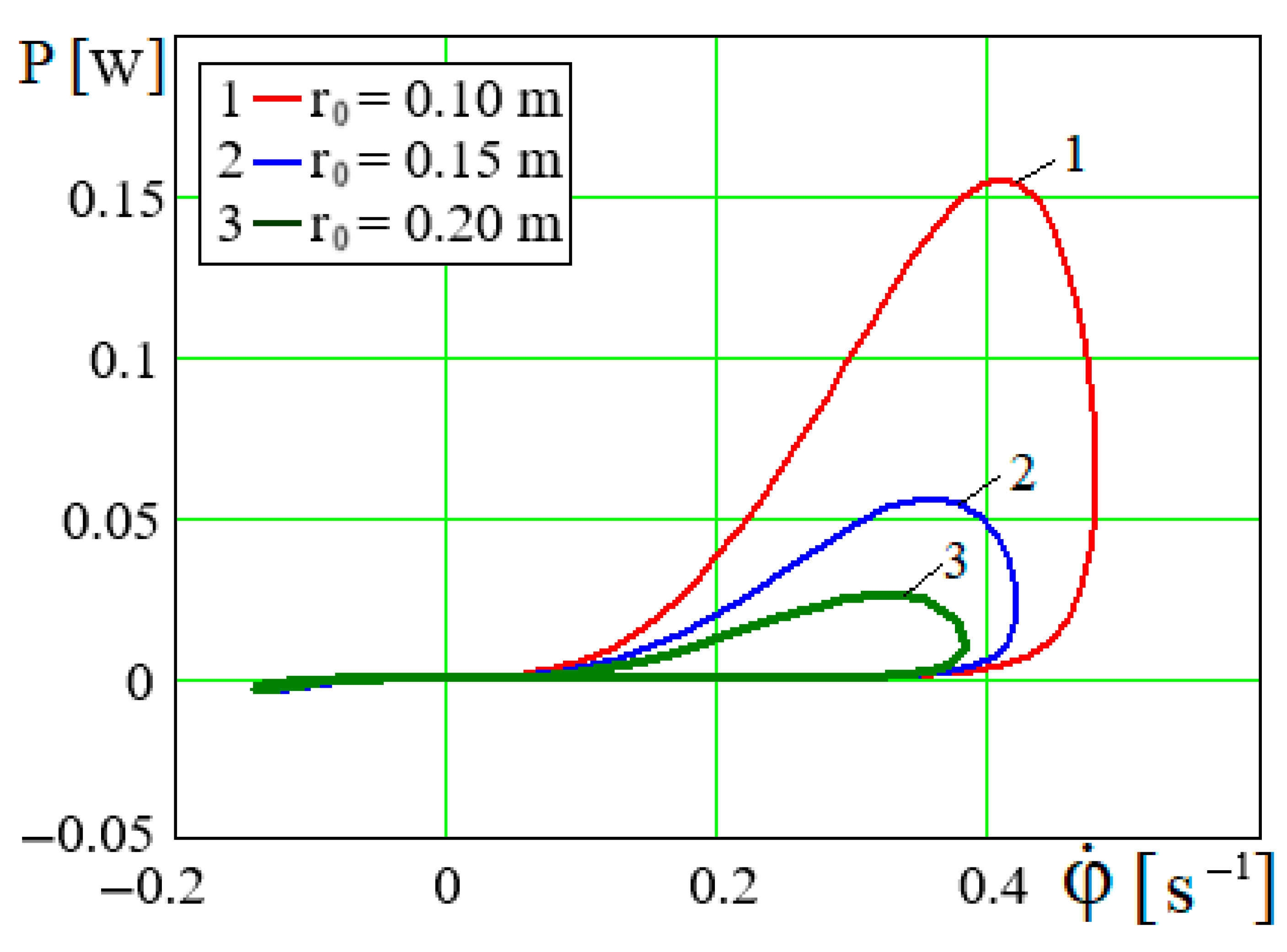

Figure 13.

Dependence for different values of r.

Figure 13.

Dependence for different values of r.

On the other hand, the limit values of the excitation source shaft angle

~

for different values of

r, to which the value of

φ at the end of the oscillating damping process will tend, are the same in

Figure 10 and

Figure 12. The rightmost limits of the curves

P =

P(

φ) along the axis

φ at various values of

r in

Figure 12 are determined by the maximum values of

φ in the graphical patterns

φ =

φ(

t) in

Figure 10. The curves

P =

P(

φ) end at those points that correspond to the limit values

~

of the rotation angle

. Likewise, the right borders of the curves

in

Figure 13 are determined by the maximum values of rotational speed

, and the left borders by the minimum values

in

Figure 11. The sections

P =

P(

φ) in

Figure 12, where there is a “decrease” of

φ along the abscissa axis, correspond to the sections of the dependences

φ =

φ(

t) in

Figure 10 after the maximum values of

φmax.

The limit value of the shaft angle of a nonideal engine is

~

. The value is

~

. Therefore, the lines

φ(

t) that correspond to the values of

ρ are positioned so densely (

Figure 14), that, at the end of the oscillating and aperiodic damped oscillation, they merge into a single line and

. Dense placement of lines of dependence of

at various values of fluid density

ρ is also observed in

Figure 15. It follows from Formula (27) that

~

. The general character of the dependence

P =

P(

φ) in

Figure 16 is determined by the graph of the periodic function

, and its amplitude is affected by

. Regardless of the fact that there are dependencies

and

, the density of the fluid

ρ slightly affects the oscillation period of

P =

P(

φ). This effect has been well observed in the graphical relationships

φ =

φ(

t) and

in

Figure 14 and

Figure 15.

Figure 14.

Dependence φ = φ(t) for different values of ρ.

Figure 14.

Dependence φ = φ(t) for different values of ρ.

Figure 15.

Dependence for different values of ρ.

Figure 15.

Dependence for different values of ρ.

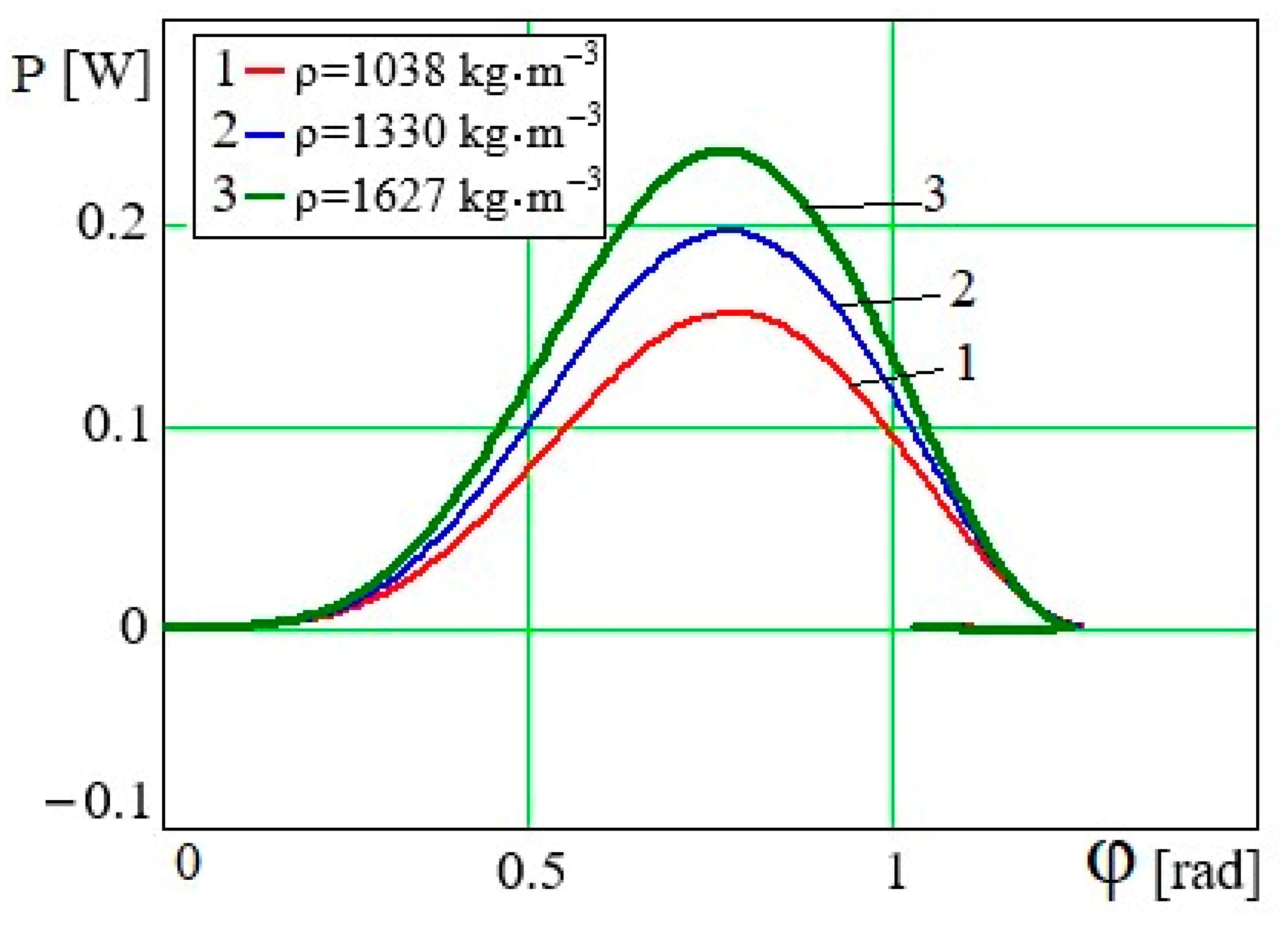

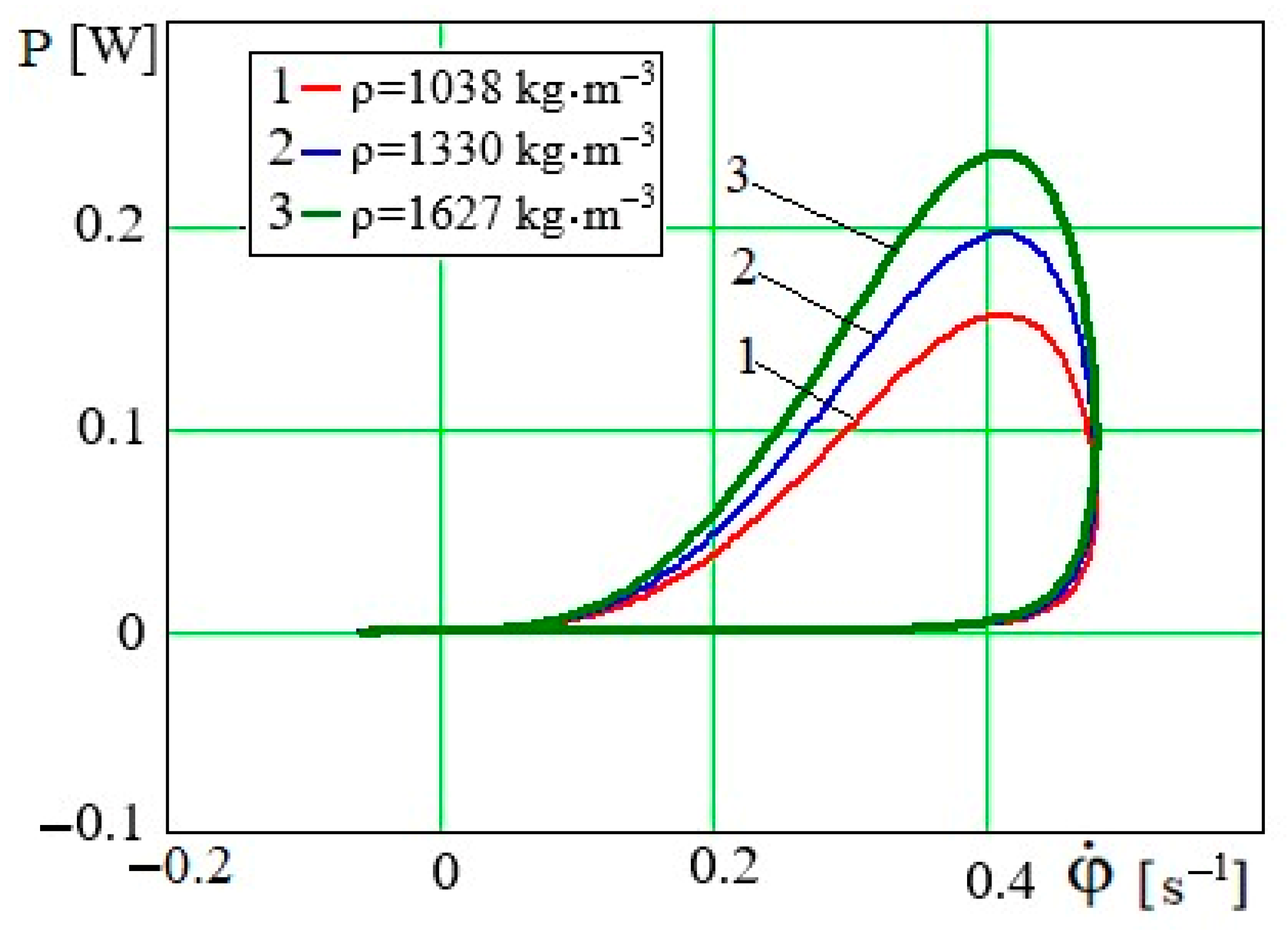

It is obvious from graphical dependences

P =

P(

φ) and

in

Figure 16 and

Figure 17, that the more the density of fluid, the more force and power will be required for the implementation of technological processes of mixing and whipping. In contrast to similar graphical dependences

P =

P(

φ) and

, the values of abscissas

φ and

, corresponding to the maximum values of power, with increasing density of fluid remain almost unchanged. This is approximately the same for all curves

φ =

φ(

t) and

at various values of density of fluid in

Figure 14 and

Figure 15. The maximum values

φmax = 1.25 rad and

determine the rightmost limits of graphical dependences

P =

P(

φ) and

in

Figure 16 and

Figure 17, and the limit value of

rad and value

(

Figure 14 and

Figure 15) for the endpoint graphs.

Figure 16.

Dependence P = P(φ) for different values of ρ.

Figure 16.

Dependence P = P(φ) for different values of ρ.

Figure 17.

Dependence for different values of ρ.

Figure 17.

Dependence for different values of ρ.

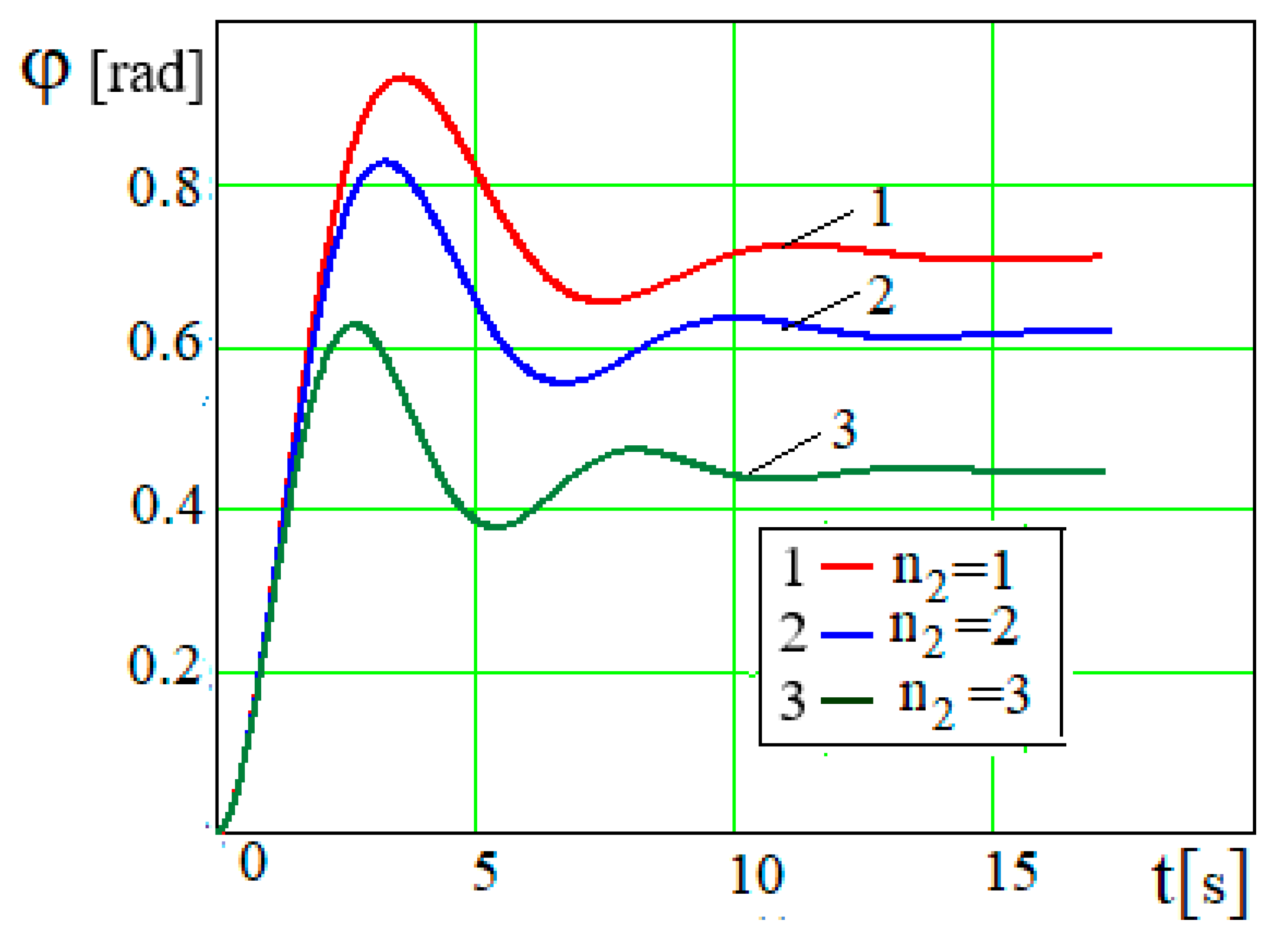

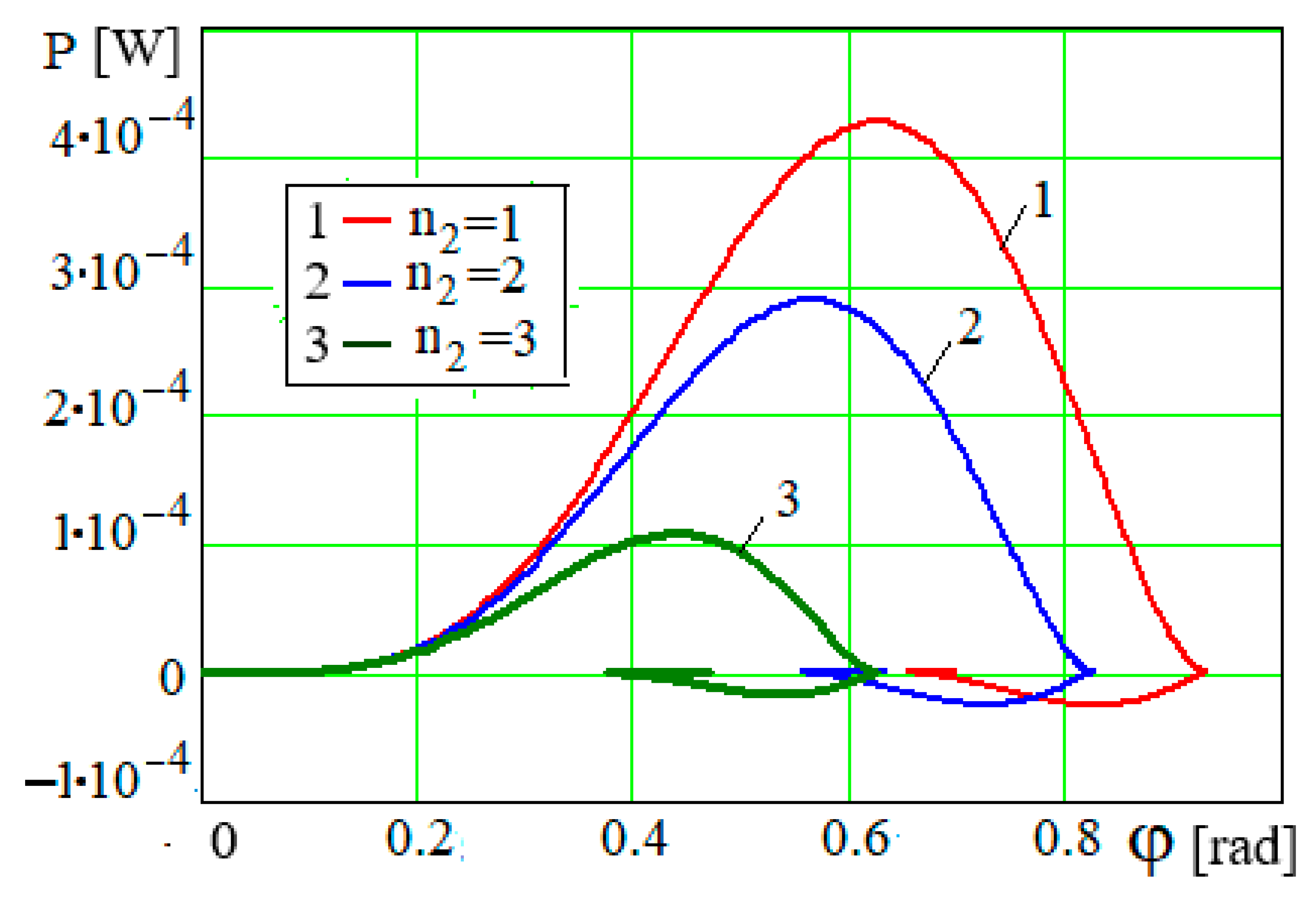

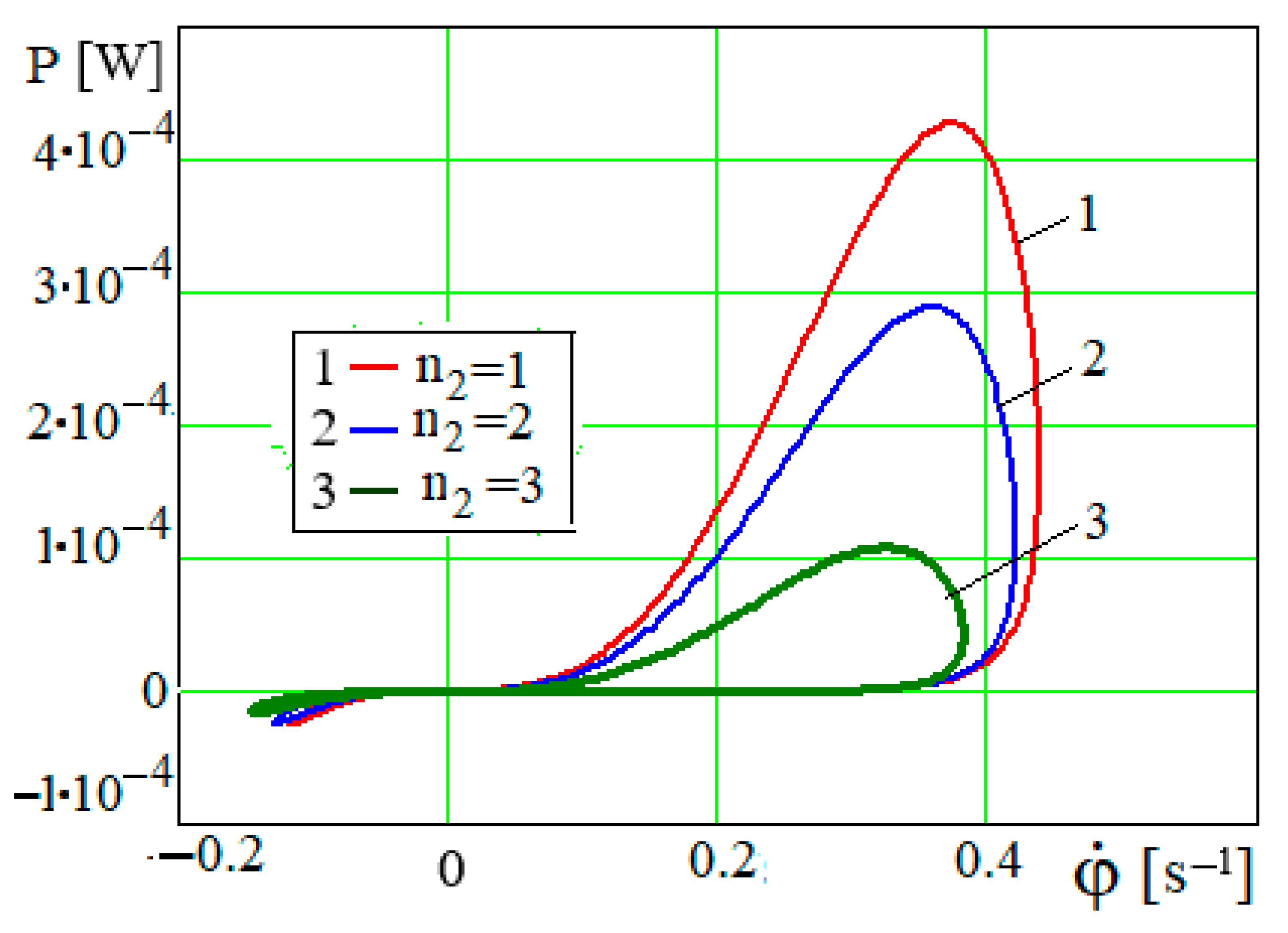

The effect of the number of

piston holes on

and the dependencies

is graphically presented in

Figure 18 and

Figure 19. The greater the number of holes

, the less the resistance to the movement of the piston and, accordingly, the less the stirring–beating force (27.1) and the initial maximum angle of deflection of the motor shaft. At the rotational speed of the crank

, its angle of rotation

(where

), and, in turn, the value

depends on

according to Formula (24.2) or (24.3). The limit values of

, to which the angle

φ tends during the damped oscillatory process, are different from zero (

Figure 18).

At the force source shaft angle of , the engine shaft rotational speed is .

Figure 18.

Dependence φ = φ(t) at m = 25 kg and various values of .

Figure 18.

Dependence φ = φ(t) at m = 25 kg and various values of .

Figure 19.

Dependence at m = 25 kg and various values of .

Figure 19.

Dependence at m = 25 kg and various values of .

As seen in

Figure 20, the greater the number of holes

, the less the maximum power of the upward lifting force of the piston required. This is obvious from the dependence of the power of the stirring–beating force on the number of holes

n2 of the piston (27.2). The maximum deflection angles of

φ in

Figure 18 define the right limits of the dependence

P =

P(

φ) at various values of

, and the limit values of

the left end limits. The value

affects the rotation angle

φ in the relation of

~

, since

and

(

Figure 19), and therefore the periodicity of the function is

. The larger the

, the larger is the period of the function

(

Figure 20).

Figure 20.

Dependence P = P(φ) at m = 25 kg and various values of .

Figure 20.

Dependence P = P(φ) at m = 25 kg and various values of .

Figure 21.

Dependence at m = 25 kg and various values of .

Figure 21.

Dependence at m = 25 kg and various values of .

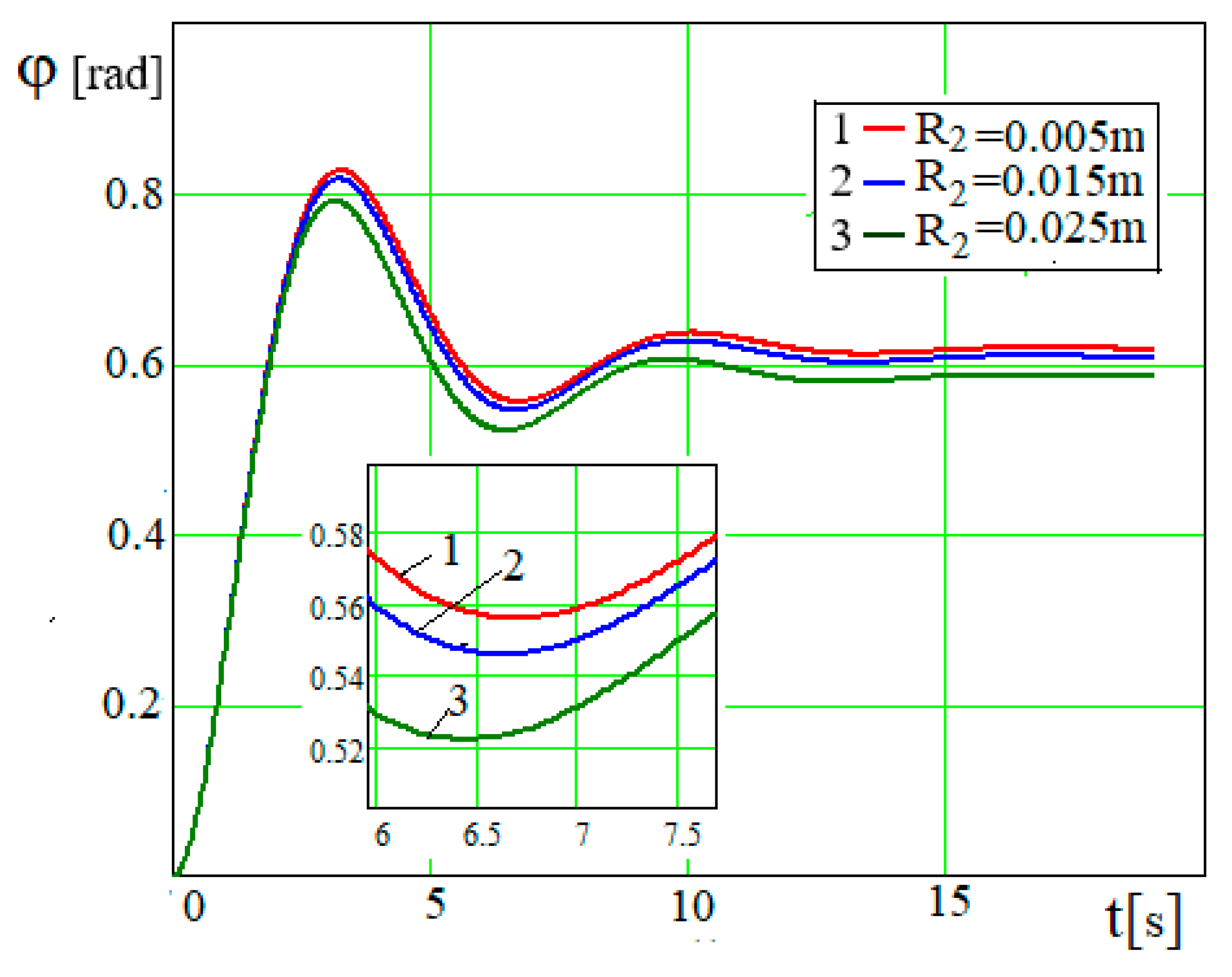

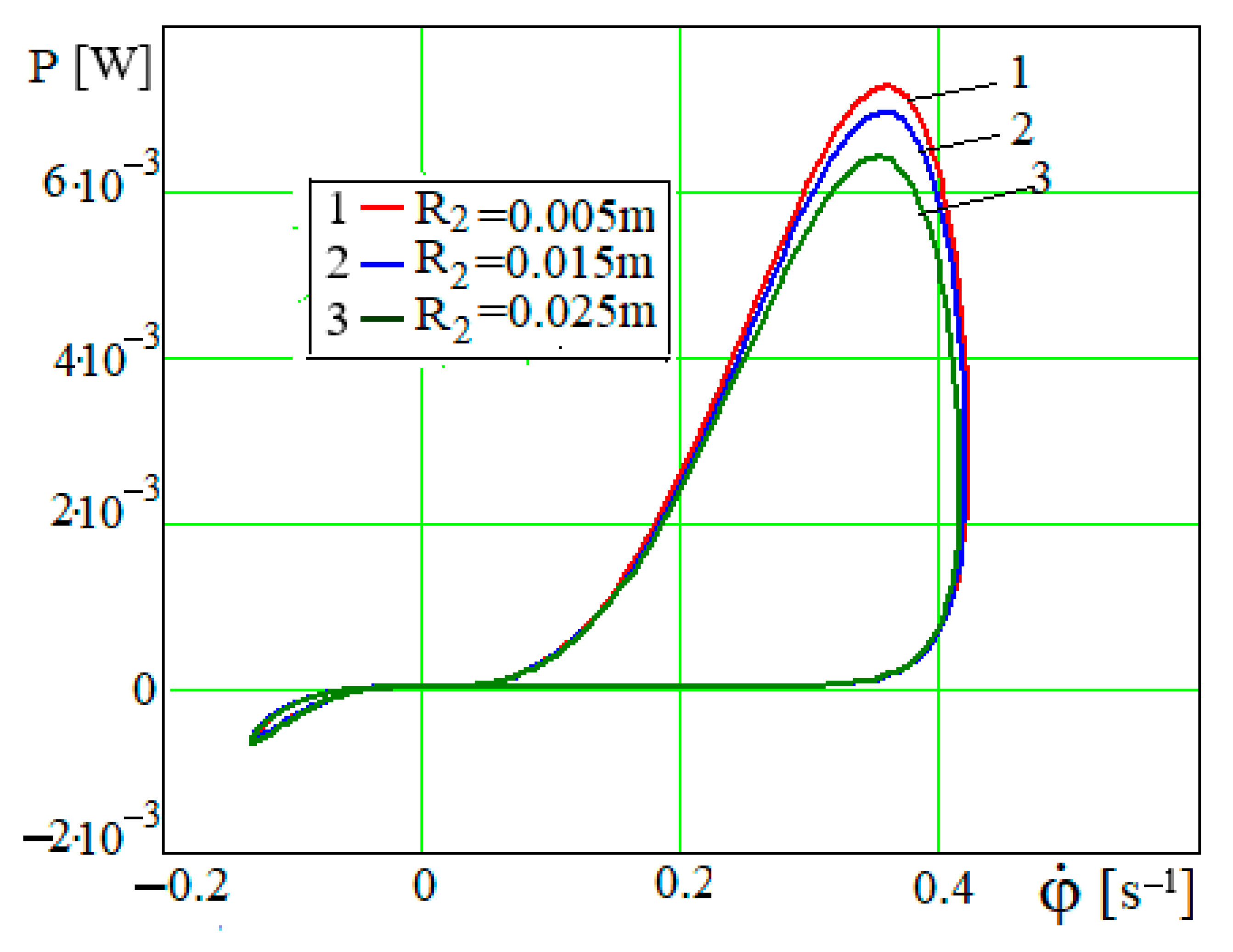

The radius of the holes on the piston

has little effect on the dependences

φ =

φ(

t) and

(

Figure 22 and

Figure 23). Therefore, the

values are taken to obtain more visual graphs. These graphical dependences have almost the same period of oscillation, but the initial and subsequent amplitudes are larger. The angle of rotation

φ over time tends to the limits, which are determined by the relation

, where

. Obviously,

at

(

Figure 23).

Figure 22.

Dependence φ = φ(t) at m = 30 kg and various values of .

Figure 22.

Dependence φ = φ(t) at m = 30 kg and various values of .

Figure 23.

Dependence at m = 30 kg and various values of .

Figure 23.

Dependence at m = 30 kg and various values of .

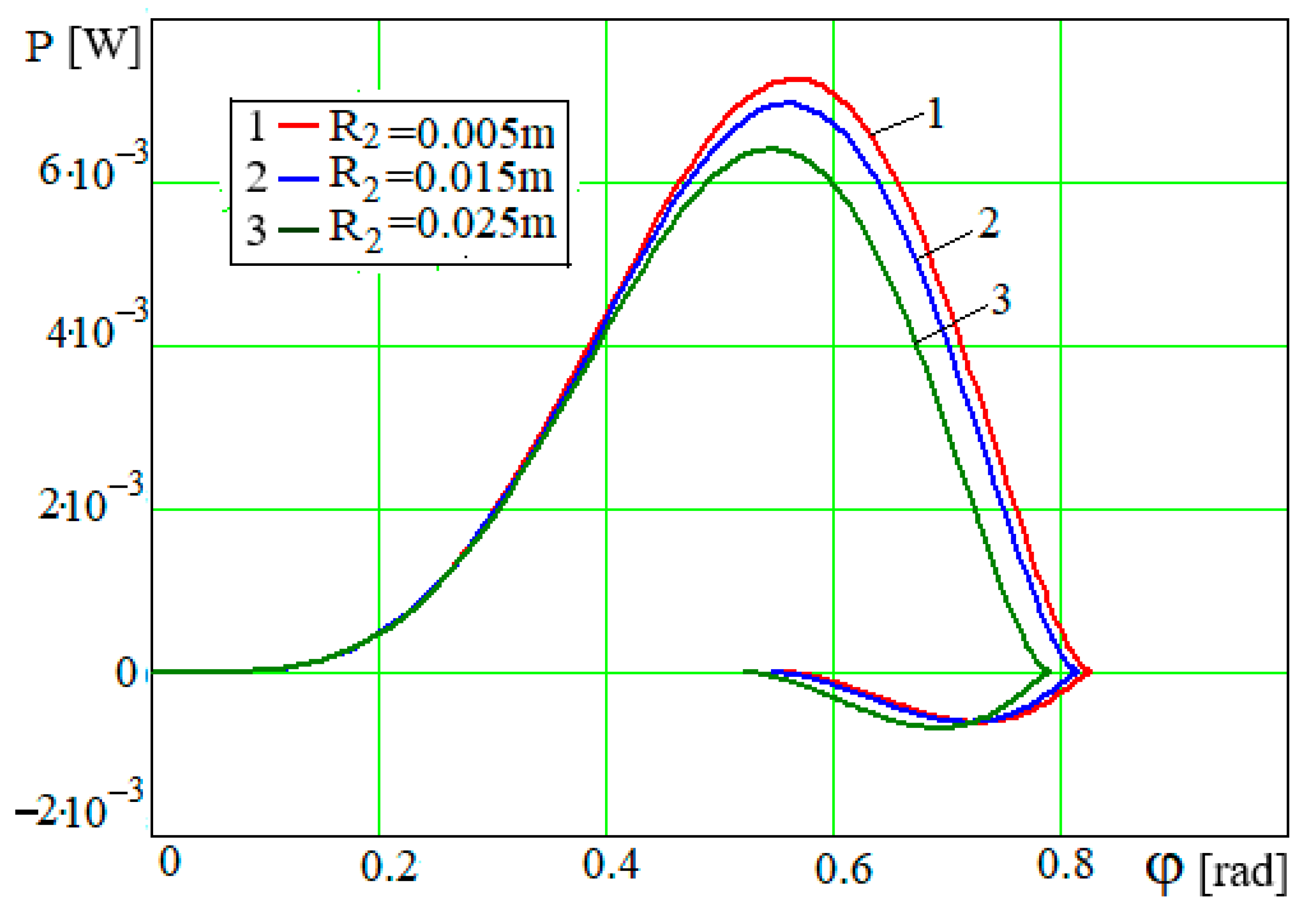

When the piston hole expands, less power of the mixing–whipping force is utilized, because the resistance of the fluid to the piston motion will be reduced (

Figure 24 and

Figure 25). The higher the amplitudes of oscillations of

(

Figure 22), the wider the right boundary and larger the left final boundary of the dependence

P =

P(

φ) and larger the period of oscillations (

Figure 24). The appearance of the negative parts of the dependence

P =

P(

φ) and

is associated with a decrease in the value of

after the initial maximum (

Figure 22) and the negative part of the dependence

(

Figure 23). Obviously, the right boundary of the dependence

(

Figure 25) is determined by the maximum value of

(

Figure 23).

Figure 24.

Dependence P = P(φ) at m = 30 kg and various values of .

Figure 24.

Dependence P = P(φ) at m = 30 kg and various values of .

Figure 25.

Dependence at m = 30 kg and various values of .

Figure 25.

Dependence at m = 30 kg and various values of .

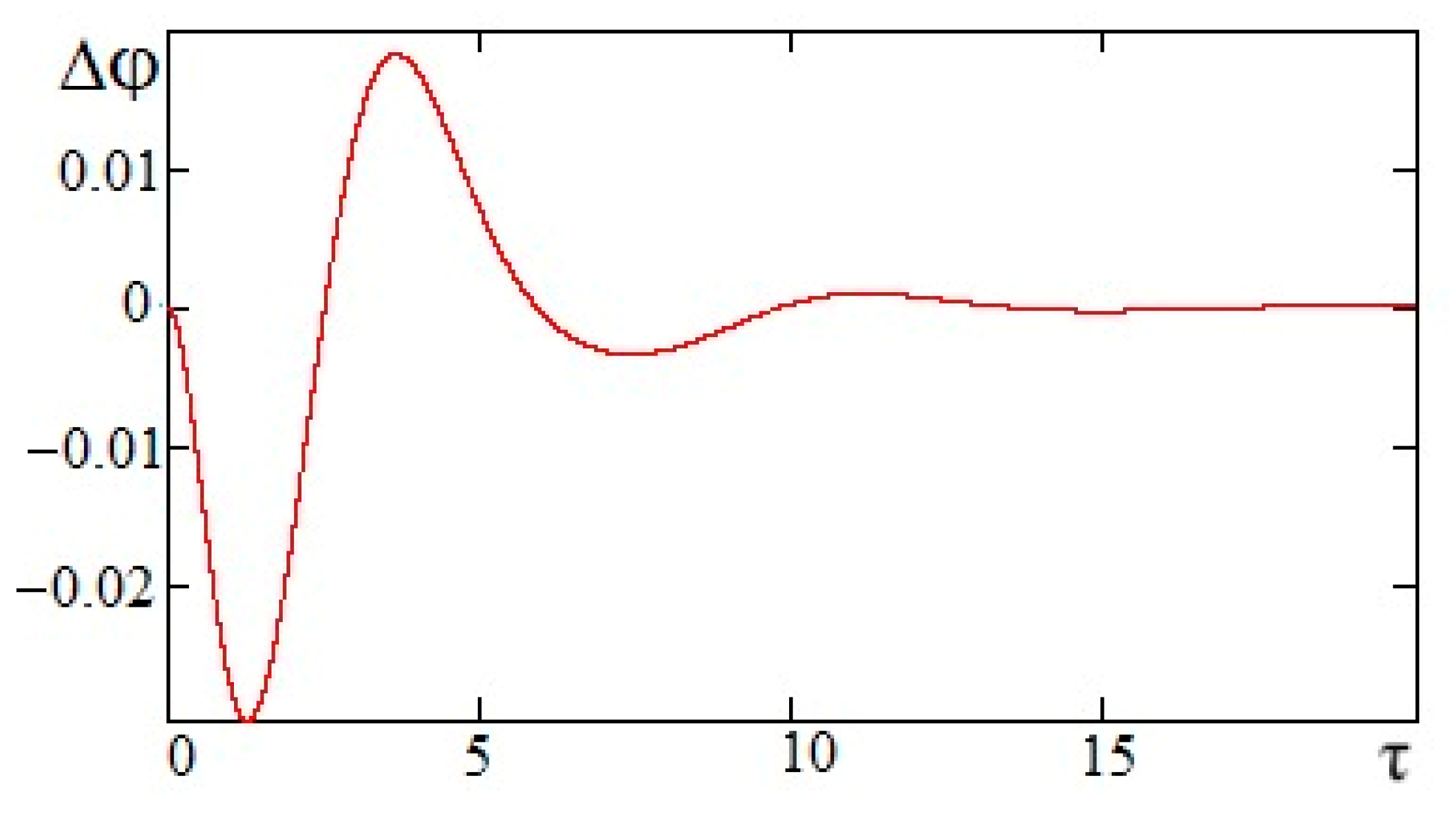

Summarizing all dependencies

φ =

φ(

t =

τ/ω0), an assessment can be made regarding the applicability of the Runge–Kutta method quartic for the numerical solution of the equation of motion Equation (25) or (26). When solving the equation of motion Equation (25), the mesh step was selected in such a way as to ensure the required calculation accuracy. If numerical solutions are available on two meshes

y(

τ,

h) and

y(

τ,

rh), where

r > 1, then the error of the solution on the mesh with the smaller step is given by

where

p is the order of the Runge–Kutta scheme,

r is the ratio of the steps, and

h is the increment step of the variable

τ.

The dependence of the solution error of Equation (25) on the dimensionless time at

r = 2,

h = 2 × 10

−3,

p = 4 is shown in

Figure 26.

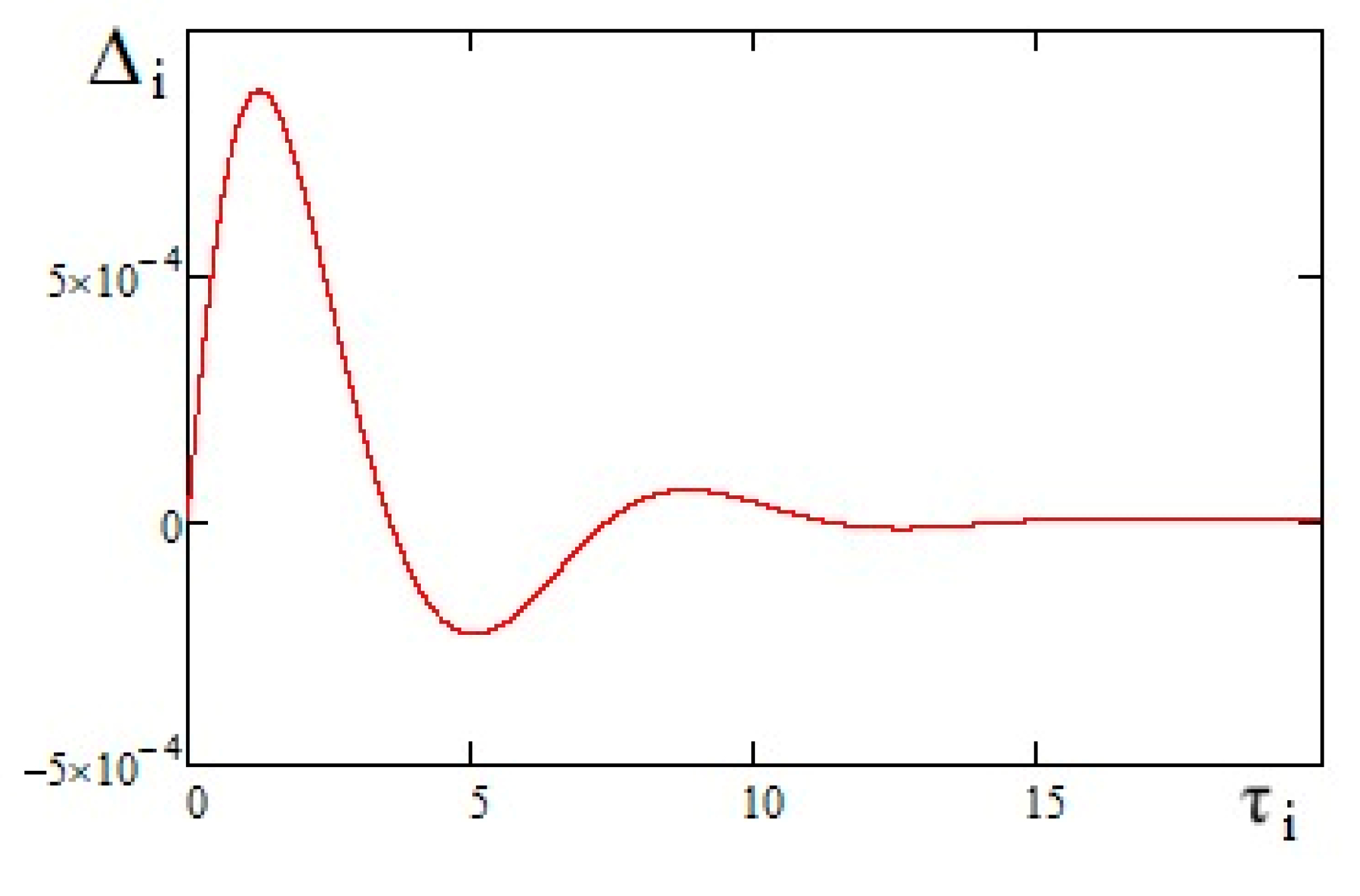

The dependence of the solution increment Δ

i =

φ i+1 −

φi (

i = 1, 2, 3,

n) of Equation (25) on dimensionless time is shown in

Figure 27. The graph in

Figure 27 shows that the increment between values of the solution of Equation (25) tends to zero as time increases. Therefore, the solution of Equation (25) is convergent.

As is known, the results of solving the equations of motion Equations (25) and (26) are presented in

Figure 2,

Figure 6,

Figure 10,

Figure 14,

Figure 18, and

Figure 22 as graphical dependencies

φ =

φ(

t), for various system parameters. The solution curves of Equation (25) shown in these figures vary slowly and do not exhibit a rapid “transient phase.” When developing the mathematical model of the mixing and whipping system for low-viscosity suspensions (for example, kumys viscosity averages η = 1.75·10

−3 Pa·s), it was assumed that the whipping effect is negligible. The very soft, small-sized particles of the suspension, in the form of protein flakes, easily break apart under low forces. Therefore, the resulting equations of motion do not include terms describing the whipping effect. These equations are easily solved numerically using the Runge–Kutta method quartic with a moderate integration step that ensures the required accuracy. Therefore, the equations of motion (25) and (26) are non-stiff. No signs related to stiffness were observed while solving Equation (25).

The phase trajectories of the vibrational motion of the driving member are represented as twisted spirals [

8,

50,

51]. These spirals become more pronounced with increasing crank length, number and radius of piston holes, and piston mass, and decrease with higher fluid density. As the system transitions to rotational motion [

7,

8,

9,

10,

41,

42], the spirals straighten out and transform into curves with periodically varying amplitude

around lines defined by the driven angular velocity of the engine shaft [

7,

8,

9,

10,

50].

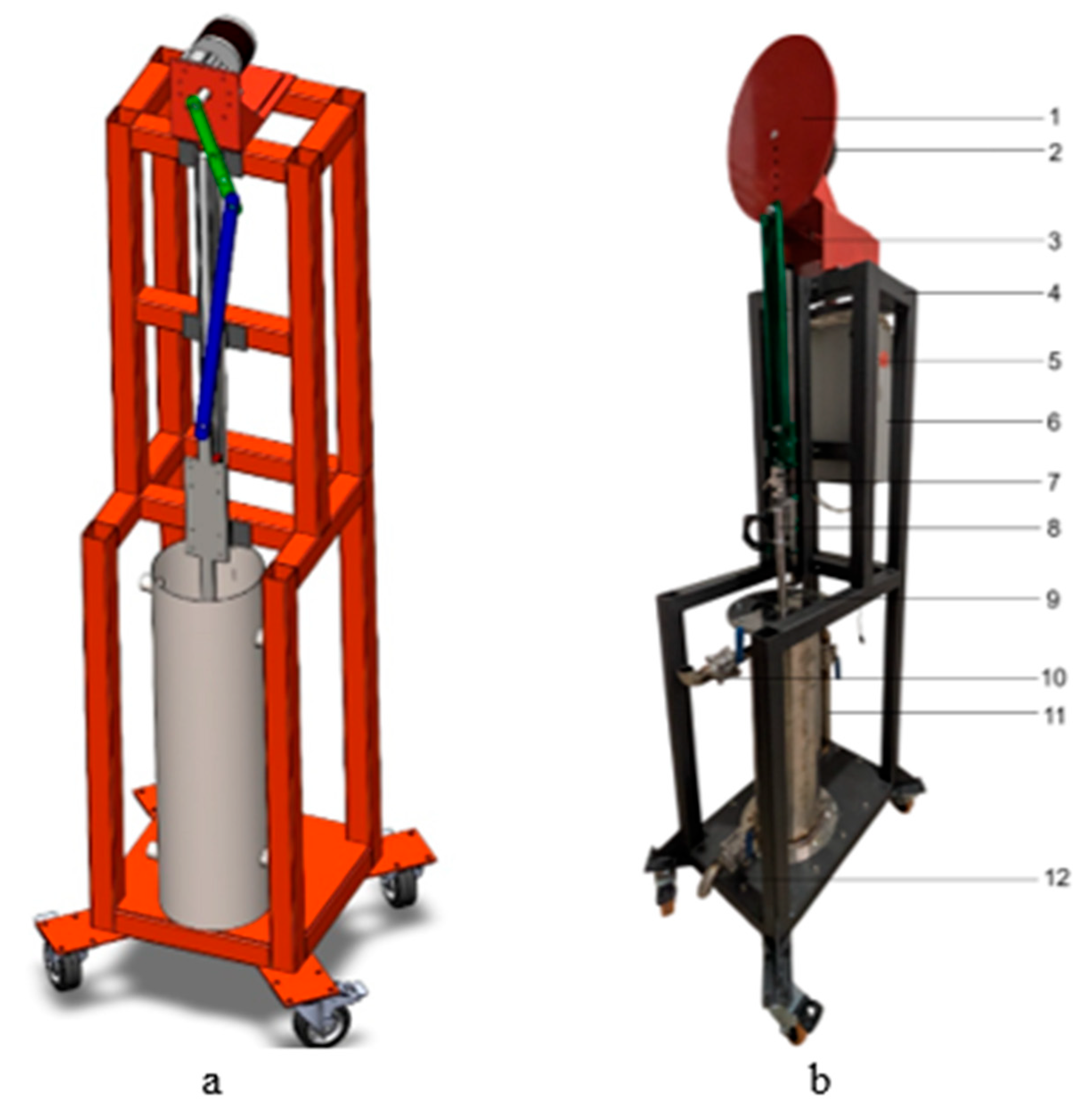

5. Experimental Study of the Dynamics of the Stirring–Beating and Shaking Up Device

An experimental study of the dynamics of the stirring–beating and shaking (

Figure 30) up device under the oscillatory- and aperiodic-damping mode of the disk-crank movement was carried out according to the following methodology. The voltage and the motor power were selected at a constant current in the motor circuit, at which the disk-crank rises up, slowing down the movement, stops before reaching 90° of the rotation angle and then descends downward, slowing down the movement, and stops before reaching a static zero equilibrium. This oscillatory- and aperiodic-damping process occurs in the interval of the disk-crank rotation angle

φ (0,

π/2), as expected, following the results of numerical studies of the dependence

φ =

φ (

t) (

Figure 2,

Figure 6,

Figure 10,

Figure 14,

Figure 18 and

Figure 22) and, after a while, the process repeats again.

In order to determine experimentally the power of the piston and liquid interaction force, it is necessary to measure the force of the piston and liquid interaction and the corresponding piston (slide) speed. The experimental studies in this work were carried out following the methodology proposed by ZETLAB [

52]. Calibration of the strain gauge and accelerometer was performed according to the ZETLAB procedure [

52]. When using strain gauges, it is necessary to complete a calibration table [

52], which will be used in the experimental research. Quantitative comparisons were made with strain gauge calibration tables provided by ZETLAB [

52], which showed no significant errors. Based on experience of ZETLAB [

52] in measuring normal stresses in rods using a strain gauge, when properly calibrated, deviations in repeated measurements are minimal.

The piston and liquid interaction force was measured by the strain gauge CALT DYLY-103 built into the slide, which was connected to the strain gauge station ZET058 [

52] and then to the computer. Using the ZETLAB software [

52], an oscillogram of the force acting on the slide was obtained for various cases of oscillatory and aperiodically damped operation of the disk-crank of the prototype stirring–beating device. According to the obtained force oscillogram, the maximum force of interaction of the piston with the liquid was estimated for various cases of the motion mode. To determine the linear acceleration of the slider, the intelligent digital sensor ZET 7052-N by ZETLAB [

52] was used. The intelligent digital sensor ZET 7052-N is a vibration sensor equipped with a built-in three-axis sensitive element, which converts the constant component of acceleration into a digital code along three mutually perpendicular axes: X, Y, and Z. The ZET 7052-N digital sensor by ZETLAB [

52] is supplied pre-calibrated and accompanied with a calibration certificate. The intelligent digital sensor ZET 7052-N is connected to a computer via the ZET 7076 interface [

52]. Using a filtering program [

52], the linear velocity of the slider was obtained and then converted into the crank’s angular velocity through the system’s transfer function. The experimental data were processed using ZETLAB software [

52] and MATLAB.

The prototype stirring–beating device in combination with the measuring equipment during the experimental studies is shown in

Figure 30 and the video material and stored data showing the oscillatory and aperiodically damped mode of motion of the stirring–beating and shaking up device are presented in the appendices [

53]. For experimental studies, a disk-crank with holes located at different distances from the center, a piston in the form of a disk with different mass and holes of different numbers and different radii have been prepared. The shape and parameters of the holes can influence flow losses through them and, consequently, affect the pressure difference between the upper and lower surfaces of the piston. Therefore, to minimize flow losses, the piston holes were manufactured using laser technology [

54].

The standard parameter values of the mixing–whipping device prototype and the fluid are given in

Table 2.

The oscillogram of the periodic variation in the force of the piston and liquid interaction, minus the values of the buoyancy force and the force of gravity of the piston, represents the oscillogram of the variation in the force of stirring and beating by the piston. The power of the stirring–beating force is determined by the product of the stirring–beating force with the corresponding speed of the piston (slide). The results of experimental studies are presented in

Figure 31,

Figure 32,

Figure 33 and

Figure 34. They show a good agreement between the results of experimental and numerical studies.

As the mass of the piston increases, the torque created by the gravity action with the initial torque remaining unchanged increases, the difference between the engine torque and the torque created by the gravity action, the buoyancy and the friction forces between the piston and the liquid decreases, as do the values of the disk-crank rotation angle and its angular velocity. As a result, the power of the stirring–beating force and its maximum value are reduced (

Figure 31).

When the crank is elongated, the torque created by the gravity action increases, as in the previous case, but by increasing the throw of the crank, with the engine torque initially unchanged, the torque created by the action of the stirring–beating force and its power, including its maximum value, decreases (

Figure 32), as do the values of the disk-crank rotation angle and its angular velocity.

Both with increasing the number of piston holes (

Figure 33), and with the expansion of the piston holes (

Figure 34), the resistance to the movement of the piston decreases, the force of the pressure difference on the piston and its power, including its maximum value, decrease, and the values of the rotation angle of the driving link and its angular velocity decrease (see Formula (27)).