Research on the Diaphragm Movement Characteristics and Cavity Profile Optimization of a Dual-Stage Diaphragm Compressor for Hydrogen Refueling Applications

Abstract

1. Introduction

- A DSDC test rig was constructed to evaluate its pressure and volumetric efficiency performance under varying pressure and rotational speed conditions.

- An integrated investigation framework was established, combining finite element method (FEM) simulations with theoretical stress models, to characterize diaphragm stress distributions and movement behavior in the DSDC test rig.

- A novel double-arc profile (DAP) cavity geometry was proposed for the DSDC, and comparative optimizations across different cavity profiles were further discussed.

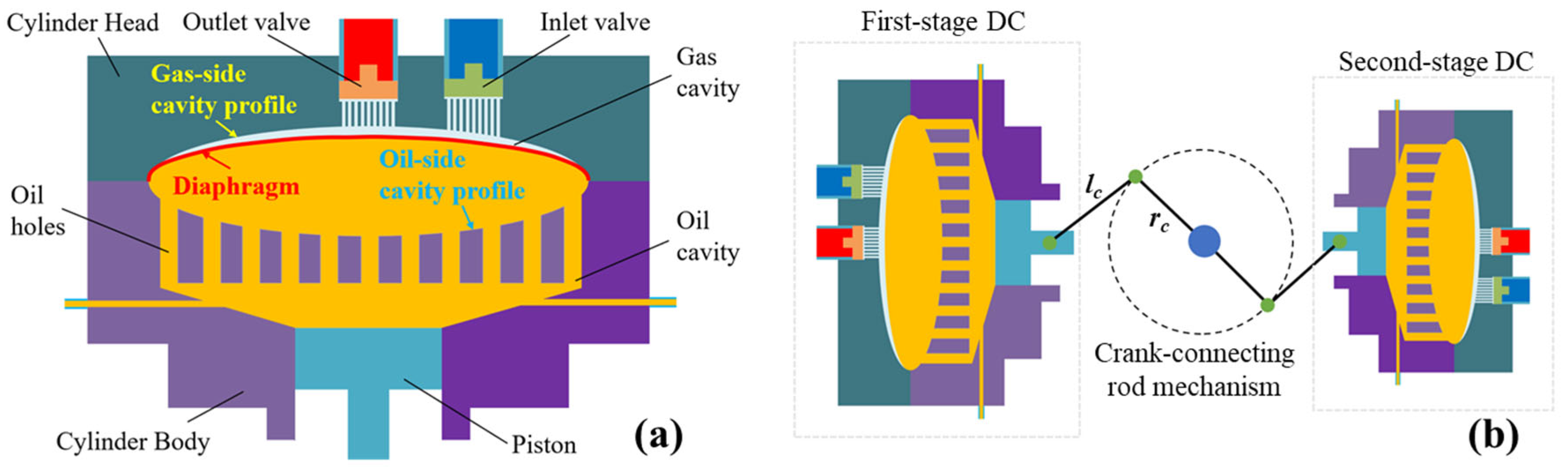

2. Descriptions of the DSDC

2.1. Working Principle

2.2. Experimental Setup

3. Method

3.1. Volumetric Efficiency

3.2. Gas and Oil Pressure Model

- (1)

- Gas expansion stage

- (2)

- Gas suction stage

- (3)

- Gas compression stage

- (4)

- Gas discharge stage

- (1)

- Oil expansion stage

- (2)

- Oil compression stage

- (3)

- Oil discharge stage

3.3. Cavity Profile Design

3.4. FEM Simulation Setup

3.5. Diaphragm Stress Model

- (1)

- Force equilibrium equation in the radial direction (r)

- (2)

- Force equilibrium equation in the axial direction (h)

- (3)

- Moment equilibrium equation for the circumferential section st

3.6. Diaphragm Motion Model

3.7. Cavity Profile Optimization

3.8. Complete Simulation Procedure

4. Results and Discussion

4.1. Model Validation and Experimental Results

4.1.1. Mesh Independence Analysis

4.1.2. Validation of the FEM and Theoretical Stress Models

4.1.3. ANN-Fitting Model

4.1.4. Experimental Results and Pressure Variations

4.2. Diaphragm Movement and Stress Characteristics of the DSDC

4.2.1. Diaphragm Deformation Under Different Pressure Conditions

4.2.2. Diaphragm Movement Under Different Experimental Conditions

4.2.3. Diaphragm Stress Distribution Under the Specific Case #3 Condition

4.3. Further Discussion on the Cavity Profile Optimization

4.3.1. SEP-Type Cavity Profile

4.3.2. DEP-Type Cavity Profile

4.3.3. DAP-Type Cavity Profile

4.3.4. Optimization Comparison

5. Conclusions

- (1)

- The DSDC experimental results indicated that under operating conditions of 1.6 MPa suction pressure, 8 MPa second-stage discharge pressure, and 200 rpm rotational speed, the volumetric efficiencies reached 74.02% and 87.63% for the first-stage and second-stage diaphragm compressors, respectively.

- (2)

- The theoretical stress analysis results indicated that for the DSDC test rig, the driving pressure differences at the TDC position reached 85.58 kPa for the first-stage diaphragm and 75.49 kPa for the second-stage diaphragm.

- (3)

- The diaphragm movement analysis results indicated that under operating conditions of 1.6 MPa suction pressure, 8 MPa second-stage discharge pressure, and 200 rpm rotational speed, the first-stage and second-stage diaphragms reached the maximum center deflections of 4.14 mm and 2.53 mm, respectively, at the BDC position.

- (4)

- The optimized first-stage SEP, DEP, and DAP diaphragm cavity profiles reached cavity volumes of 1.005, 1.015, and 1.017 times that of the experimental SEP profile, respectively, while the maximum principal stresses were reduced to 0.999, 0.993, and 0.965 times the baseline value. The optimized second-stage SEP, DEP, and DAP diaphragm cavity profiles reached cavity volumes of 1.104, 1.111, and 1.171 times the experimental SEP baseline, accompanied by maximum principal stress reductions to 0.947, 0.944, and 0.930 times the baseline value.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Abbreviations | |

| BDC | Bottom Dead Center |

| DAP | Double-Arc Profile |

| DC | Diaphragm Compressor |

| DEP | Double Exponential Profile |

| DSDC | Dual-Stage Diaphragm Compressor |

| FEM | Finite Element Method |

| FSI | Fluid–Structure Interaction |

| SEP | Single Exponential Profile |

| TDC | Top Dead Center |

| Symbols | |

| b | Diaphragm thickness (m) |

| D | Diameter (m) |

| E | Elastic modulus (Pa) |

| h | Cavity deflection curve (m) |

| H | Maximum diaphragm deflection (m) |

| km, kn | Expansion and compression indexes (-) |

| lc | Connecting rod length (m) |

| L | Length (m) |

| Mb, Nb | Design parameters of the DEP profile (-) |

| n | Rotational speed (rpm) |

| NMG | Mesh grid number (-) |

| p | Gas pressure (Pa) |

| Qmg | Experimental gas mass flowrate (kg·h−1) |

| Qth | Theoretical gas mass flowrate (kg·h−1) |

| r | Radius (m) |

| rc | Crank radius (m) |

| R | Diaphragm cavity radius (m) |

| RNa, RNb | Segment radii of the DAP profile (m) |

| s | Characteristic diaphragm length (m) |

| V | Volume (m3) |

| Vc | Residual volume (m3) |

| Vin | Inlet gas volume (m3) |

| Vloss | Suction volume loss (m3) |

| Vmo | Diaphragm swept volume (m3) |

| Voc | Total oil cavity volume (m3) |

| Za | Design parameter of the SEP profile (-) |

| α | Crank angle (rad) |

| β | Oil bulk modulus (Pa) |

| p | Diaphragm pressure difference (Pa) |

| δ | Diaphragm stress (MPa) |

| θ | Deflection angle (rad) |

| λd | Volumetric efficiency (-) |

| λN | Design parameter of the DAP profile (-) |

| μ | Poisson’s ratio (-) |

| ρr | Specific radius (-) |

| φ | Radial angle (rad) |

| Subscripts | |

| 1s, 2s | First-stage and second-stage |

| a, b, N | SEP, DEP, DAP profiles |

| at | Atmosphere |

| A, B, C | Three-layer diaphragms |

| Exp, Opt | Experimental and optimized results |

| g, o | Gas and oil |

| hs | Moving piston |

| op | Oil pump |

| P, M, Q | Tensile, bending, and shear stresses |

| r, t | Radial and circumferential directions |

| st | Stroke |

| s, d | Suction and discharge |

| u, d, c | Upper, lower, and circumferential surfaces |

| z | Crank-connecting rod mechanism |

References

- Khademi, M.M.; Kasaeian, A. Hydrogen production using solar heliostat fields: A review. Energy 2025, 314, 134259. [Google Scholar] [CrossRef]

- Woon, K.S.; Phuang, Z.X.; Taler, J.; Varbanov, P.S.; Chong, C.T.; Klemes, J.J.; Lee, C.T. Recent advances in urban green energy development towards carbon emissions neutrality. Energy 2023, 267, 126502. [Google Scholar] [CrossRef]

- Huang, J.Z.; Lu, D.N.; Huang, X.A.; Hu, Z.D.; Liu, L.; Lin, C.Z.; Jing, R.; Xie, C.P.; Brandon, N.; Zheng, X.Y. Is China ready for a hydrogen economy? Feasibility analysis of hydrogen energy in the Chinese transportation sector. Renew Energ. 2024, 223, 119964. [Google Scholar] [CrossRef]

- Otsubo, Y. Hydrogen compression and long-distance transportation: Emerging technologies and applications in the oil and gas industry-A technical review. Energ. Convers. Manag. X 2025, 25, 100836. [Google Scholar] [CrossRef]

- Rasul, M.G.; Hazrat, M.A.; Sattar, M.A.; Jahirul, M.I.; Shearer, M.J. The future of hydrogen: Challenges on production, storage and applications. Energ Convers. Manag. 2022, 272, 11632. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, Q.; Cao, J.H.; Wang, Y.L.; Peng, X.Y. Performance assessment and optimisation of a concentric two-piston compressor system for hydrogen storage. Energ. Convers. Manag. 2024, 310, 118470. [Google Scholar] [CrossRef]

- Tahan, M.R. Recent advances in hydrogen compressors for use in large-scale renewable energy integration. Int. J. Hydrog. Energy 2022, 47, 35275–35292. [Google Scholar] [CrossRef]

- Giuffrida, A.; Colbertaldo, P. Overview of diaphragm compressors for hydrogen service: Capacity, discharge pressure and operational challenges. J. Energy Storage 2025, 129, 117286. [Google Scholar] [CrossRef]

- Sun, C.Z.; He, Z.L.; Chen, X.Q.; Li, D.T.; Ma, K.; Chen, M.Y.; Wang, T.; Wang, X.L. Thermodynamic, sensitivity analyses and optimization of a dual-stage diaphragm compressor system: A model-based and experimental study. Energy 2025, 330, 136848. [Google Scholar] [CrossRef]

- Li, J.Y.; Jia, X.H.; Wu, Z.M.; Peng, X.Y. The cavity profile of a diaphragm compressor for a hydrogen refueling station. Int. J. Hydrog. Energy 2014, 39, 3926–3935. [Google Scholar] [CrossRef]

- Li, J.Y.; Liang, L.; Jia, X.H.; Peng, X.Y. A new generatrix of the cavity profile of a diaphragm compressor. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 228, 1754–1766. [Google Scholar] [CrossRef]

- Jia, X.H.; Zhao, Y.; Chen, J.H.; Peng, X.Y. Research on the flowrate and diaphragm movement in a diaphragm compressor for a hydrogen refueling station. Int. J. Hydrog. Energy 2016, 41, 14842–14851. [Google Scholar] [CrossRef]

- Hu, Y.L.; Xu, X.Y.; Wang, W. A new cavity profile for a diaphragm compressor used in hydrogen fueling stations. Int. J. Hydrog. Energy 2017, 42, 24458–24469. [Google Scholar] [CrossRef]

- Wang, T.; Tang, Z.; Jia, X.H. Study on the stress and deformation of a diaphragm compressor cylinder head under extreme conditions. Int. Conf. Compress. Their Syst. 2019, 604, 012029. [Google Scholar] [CrossRef]

- Wang, T.; Jia, X.H.; Li, X.Y.; Ren, S.D.; Peng, X.Y. Thermal-structural coupled analysis and improvement of the diaphragm compressor cylinder head for a hydrogen refueling station. Int. J. Hydrog. Energy 2020, 45, 809–821. [Google Scholar] [CrossRef]

- Wang, Q.S.; He, G.L.; Zhao, W.J.; Han, Z.H.; Wei, L.L. Design of GH4169 diaphragm for combined improvements of yield strength and surface roughness. Clean Energy 2023, 7, 53–58. [Google Scholar] [CrossRef]

- Lei, J.G.; Lin, Z.J.; Zhu, Q.; Han, G.Y.; Li, P. Analysis of diaphragm compressor exhausts volume decrease. Int. Conf. Meas. 2013, 233–235. [Google Scholar] [CrossRef]

- Ren, S.D.; Jia, X.H.; Jiang, J.C.; Zhang, S.T.; Zhao, B.; Peng, X.Y. Effect of hydraulic oil compressibility on the volumetric efficiency of a diaphragm compressor for hydrogen refueling stations. Int. J. Hydrog. Energy 2022, 47, 15224–15235. [Google Scholar] [CrossRef]

- Ren, S.D.; Jia, X.H.; Shi, L.; Li, K.; Peng, X.Y. Theoretical and experimental study on improving diaphragm compressor design for hydrogen refueling stations through use of a free moving oil piston concept. J. Energy Storage 2023, 74, 109397. [Google Scholar] [CrossRef]

- Ren, S.D.; Jia, X.H.; Li, K.; Chen, F.; Zhang, S.T.; Shi, P.; Peng, X. Enhancement performance of a diaphragm compressor in hydrogen refueling stations by managing hydraulic oil temperature. Case Stud. Therm. Eng. 2024, 53, 103905. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Guo, Y.; Diao, A.N.; Zhang, J.T.; Peng, X.Y. Thermodynamic analysis of diaphragm compressor in hydrogen refuelling stations by using fluid-structure interaction method. Appl. Therm. Eng. 2024, 242, 122394. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Zhao, B.; Yao, Y.C.; Jia, X.H.; Peng, X.Y. Experimental study and sensitivity analysis of performance for a hydrogen diaphragm compressor. Renew Energ. 2024, 237, 121871. [Google Scholar] [CrossRef]

- Zhao, Z.R.; Wang, G.F.; Zhang, J.Y.; Tian, Y.F. Study on the characteristics of a novel wrap-around cooled diaphragm compressor for hydrogen refueling station. Case Stud. Therm. Eng. 2024, 56, 104242. [Google Scholar] [CrossRef]

- Qu, Z.C. Reciprocating Compressor Principle, 2nd ed.; Xi’an Jiaotong University Press: Xi’an, China, 2018. [Google Scholar]

- Reddy, J.N. Theory and Analysis of Elastic Plates and Shells, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Mittelstedt, C. Theory of Plates and Shells; Springer Vieweg: Berlin, Germany, 2023. [Google Scholar]

- Sapsathiarn, Y.; Rajapakse, R.K.N.D. Finite-element modeling of circular nanoplates. J. Nanomech. Micromech. 2013, 3, 59–66. [Google Scholar] [CrossRef]

- Mcculloch, W.S.; Pitts, W. A logical calculus of the ideas immanent in nervous activity. Bull. Math. Biol. 1990, 52, 99–115. [Google Scholar] [CrossRef]

- Xu, G.P.; Yu, Z.T.; Xia, L.; Wang, C.J.; Ji, S.B. Performance improvement of solid oxide fuel cells by combining three-dimensional CFD modeling, artificial neural network and genetic algorithm. Energ. Convers. Manage. 2022, 268, 116026. [Google Scholar] [CrossRef]

| Profile | Depth H (mm) | Radius R (mm) | Exponential Za (-) | Piston Diameter Dz (mm) | Stroke Length Lz (mm) | |

|---|---|---|---|---|---|---|

| 1s-DC | SEP | 9 | 315 | 6.6 | 110 | 180 |

| 2s-DC | 6.1 | 223 | 3.4 | 60 | 180 |

| Surfaces and Blocks (“::” Means Contact Faces) | Contact Type/Load |

|---|---|

| (1) Meshing blocks of each component 1::2::3::4::5 | Bonded |

| (2) Edge blocks of diaphragms Ad4::Bu4, Bd4::Cu4, Cd4::Du4, Ad5::Bu5, Bd5::Cu5, Cd5::Du5 | Bonded |

| (3) Center blocks of diaphragms Ad1::Bu1, Ad2::Bu2, Ad3::Bu3, Bd1::Cu1, Bd2::Cu2, Bd3::Cu3 | No separation |

| (4) Surfaces between diaphragms and cylinder body Cd1::Du1, Cd2::Du2, Cd3::Du3 | Frictional |

| (5) Load surface: Au1, Au2, Au3 | Pressure difference (p) |

| (6) Fixed surface: Dd1, Dd2, Dd3, Dd4, Dd5 | Fixed |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, C.; He, Z.; Li, D.; Chen, X.; Tang, J.; Yan, M.; Kang, X. Research on the Diaphragm Movement Characteristics and Cavity Profile Optimization of a Dual-Stage Diaphragm Compressor for Hydrogen Refueling Applications. Appl. Sci. 2025, 15, 8353. https://doi.org/10.3390/app15158353

Sun C, He Z, Li D, Chen X, Tang J, Yan M, Kang X. Research on the Diaphragm Movement Characteristics and Cavity Profile Optimization of a Dual-Stage Diaphragm Compressor for Hydrogen Refueling Applications. Applied Sciences. 2025; 15(15):8353. https://doi.org/10.3390/app15158353

Chicago/Turabian StyleSun, Chongzhou, Zhilong He, Dantong Li, Xiaoqian Chen, Jie Tang, Manguo Yan, and Xiangjie Kang. 2025. "Research on the Diaphragm Movement Characteristics and Cavity Profile Optimization of a Dual-Stage Diaphragm Compressor for Hydrogen Refueling Applications" Applied Sciences 15, no. 15: 8353. https://doi.org/10.3390/app15158353

APA StyleSun, C., He, Z., Li, D., Chen, X., Tang, J., Yan, M., & Kang, X. (2025). Research on the Diaphragm Movement Characteristics and Cavity Profile Optimization of a Dual-Stage Diaphragm Compressor for Hydrogen Refueling Applications. Applied Sciences, 15(15), 8353. https://doi.org/10.3390/app15158353