Study on Optimization of Downward Mining Schemes of Sanshandao Gold Mine

Abstract

1. Introduction

2. Engineering Background

3. Numerical Simulation of Downward Mining Schemes

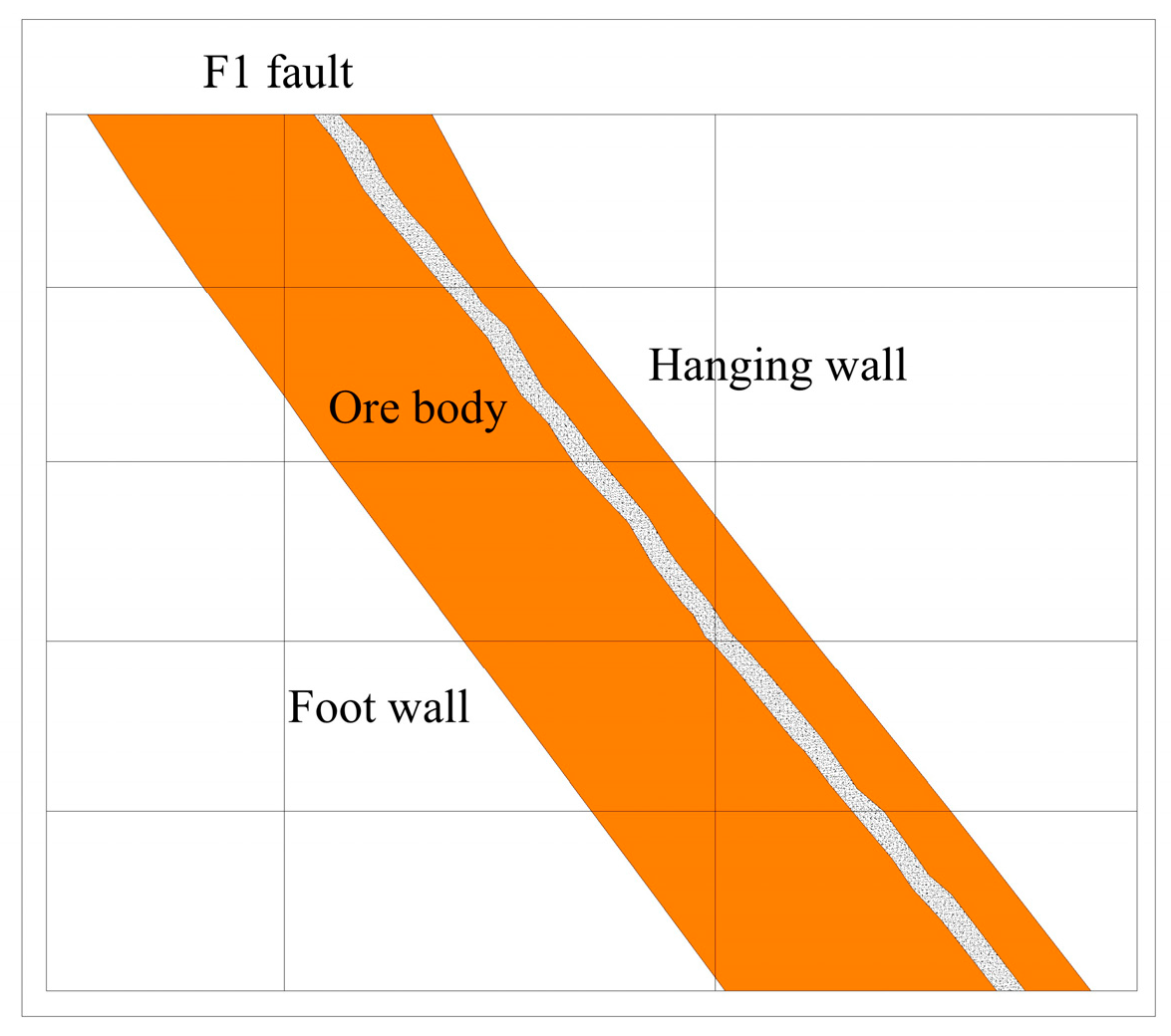

3.1. Computational Model Establishment

3.2. Determination of Rock Mass In Situ Stress

3.3. Design of Downward Mining Schemes

4. Analysis of Numerical Simulation Results

4.1. Comparative Analysis of Vertical Stress Changes of Different Mining Schemes

4.2. Comparative Analysis of Horizontal Stress Changes of Different Mining Schemes

4.3. Analysis and Comparison of Vertical Displacement Changes of Different Mining Schemes

4.4. Analysis and Comparison of Horizontal Displacement Changes of Different Mining Schemes

4.5. Evolution Analysis of Maximum and Minimum Principal Stress in Stope

4.6. Stress Analysis After All Stopes Are Mined and Filled

4.7. The Plastic Zone Analysis After All Stopes Are Mined and Filled

5. Optimization of Schemes for Deep Mining of Sanshandao Gold Mine

5.1. Comprehensive Evaluation Indicators

5.2. Membership Degree of Quantitative Indicators

5.3. Analytic Hierarchy Process

5.4. Optimization of Mining Schemes in Sanshandao Gold Mine

6. Engineering Application and Limitations

7. Conclusions

- (1)

- According to the characteristics of the mining method of the deep ore body of the Sanshandao gold mine, three different downward mining schemes were designed, namely, the staggered downward mining from the horizontal wing to the other wing, the vertical interval six, and the oblique interval two; the horizontal center to the two wings separated by five mining one, the vertical interval six, and the oblique interval two; and the horizontal two wings to the center of the staggered downward mining scheme.

- (2)

- A numerical simulation analysis was conducted on three distinct mining phases, with the objective of elucidating the evolution rules governing the maximum principal stress, minimum principal stress, equivalent strain, vertical displacement, horizontal displacement, and the distribution of the plastic zone in different mining schemes across varying mining phases. The change in vertical displacement is between 4.42 and 22.73 mm, while the change in horizontal displacement is between 1.72 and 3.69 mm. These values demonstrate that vertical displacement has a more significant impact on the stability of the stope than horizontal displacement.

- (3)

- As the mining range is extended, the mechanical effect of the filling body is becoming increasingly pronounced. The downward mining scheme is conducive to the effective management of deep ground pressure at the Sanshandao gold mine. Scheme 2 is conducive to the control of stress concentration, the reduction in tensile stress in the mining area, the prevention of large plastic zones and large displacements in the mining area, and the realization of ground pressure control at the Sanshandao gold mine.

- (4)

- Based on the characteristics of three mining technology schemes, the evolution laws of stress-strain distribution and other data for three different schemes were analyzed. The AHP and FCE method was used to optimize different mining schemes in the deep deposit of Sanshandao gold mine. Six indicators (maximum compressive stress of surrounding rock, average vertical displacement of top pillar monitoring points, average vertical stress of top pillar monitoring points, maximum compressive stress in the mining area, maximum tensile stress in the mining area, and degree of plastic failure) were selected to establish an evaluation index system, and Scheme 2 was determined as the optimal scheme. Finally, the rationality and reliability of Scheme 2 were validated through on-site industrial trials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Z.X.; Dang, W.G.; He, X.G. Undersea safety mining of the large gold deposit in Xinli District of Sanshandao Gold Mine. Int. J. Miner. Metall. Mater. 2012, 19, 574–583. [Google Scholar] [CrossRef]

- Peng, K.; Li, X.B.; Wan, C.C.; Peng, S.Q.; Zhao, G.Y. Safe mining technology of undersea metal mine. Trans. Nonferrous Met. Soc. China 2012, 22, 740–746. [Google Scholar] [CrossRef]

- Peng, K.; Liu, Z.P.; Zhang, Y.L.; Fan, X.; Chen, Q.F. Determination of isolation layer thickness for undersea mine based on differential cubature solution to irregular Mindlin plate. J. Cent. South Univ. 2017, 24, 708–719. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, G.Y.; Wang, S.F.; Li, X. Investigations of the height of fractured zones in overburden induced by undersea mining. Arab. J. Geosci. 2019, 12, 618. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, G.Y.; Wang, S.F.; Wu, H.; Wang, S.W. A case study on the height of a water-flow fracture zone above undersea mining: Sanshandao Gold Mine, China. Environ. Earth Sci. 2019, 78, 122. [Google Scholar] [CrossRef]

- Li, D.; Zhang, J.F.; Wang, C.W.; Chen, Y.; Ge, D.C. Assessing Rockburst Hazards Using a Self-Developed Real-Time Microseismic Monitoring System in a Deep-Sea Goldmine. IEEE Access 2019, 7, 134360–134371. [Google Scholar] [CrossRef]

- Liu, Z.X.; Han, K.W.; Yang, S.; Liu, Y.X. Fractal evolution mechanism of rock fracture in undersea metal mining. J. Cent. South Univ. 2020, 27, 1320–1333. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, Y.X.; Han, P.H.; Bai, Q.S. Coal pillar failure analysis and instability evaluation methods: A short review and prospect. Eng. Fail. Anal. 2022, 138, 106344. [Google Scholar] [CrossRef]

- Chen, X.H.; Yang, S.H.; Hu, D.B.; Li, X.H. Sustainable mining method selection by a multi-stakeholder collaborative multi-attribute group decision-making method. Resour. Policy 2024, 92, 105043. [Google Scholar] [CrossRef]

- Jahanbani, Z.; Mortazavi, A.; Ataee-pour, M. A Causal Analysis of the Influential Criteria in Underground Mining Method Selection. Rock Mech. Rock Eng. 2024, 57, 8581–8603. [Google Scholar] [CrossRef]

- Liu, B.; Wang, Y.J.; Zhang, J.; Hou, S.L.; He, M.C.; Wu, X.; Li, H.C. Comparative Analysis on the Safety Characteristics of N00 Mining Method with Conventional 121 Mining Method. Geotech. Geol. Eng. 2024, 42, 321–338. [Google Scholar] [CrossRef]

- Xia, W.H.; Li, Y.; Song, W.D.; Fu, J.X.; Zhang, C.; Yu, L. Stability Analysis of Secondary Mining of Submarine Mine Under the Clamping Control of Fault and Fracture Zone. Min. Metall. Explor. 2024, 41, 909–924. [Google Scholar] [CrossRef]

- Li, S.; Yu, L.F.; Dan, Z.Y.; Yin, T.B.; Chen, J.Y. The Recent Progress China Has Made in Mining Method Transformation, Part I: Shrinkage Method Transformed into Backfilling Method. Appl. Sci. 2024, 14, 10033. [Google Scholar] [CrossRef]

- Liu, Z.-x.; Luo, T.; Li, X.; Li, X.-b.; Huai, Z.; Wang, S.-f. Construction of reasonable pillar group for undersea mining in metal mine. Trans. Nonferrous Met. Soc. China 2018, 28, 757–765. [Google Scholar] [CrossRef]

- Tan, B.H.; Ren, F.Y.; Ning, Y.J.; He, R.X.; Zhu, Q. A New Mining Scheme for Hanging-Wall Ore-Body during the Transition from Open Pit to Underground Mining: A Numerical Study. Adv. Civ. Eng. 2018, 2018, 1465672. [Google Scholar] [CrossRef]

- Wang, F.F.; Ren, Q.Y.; Chen, B.; Zou, P.; Peng, Z.J.; Hu, W.J.; Ma, Z. Numerical Investigation on Safe Mining of Residual Pillar in Goaf: A Case Study of Panlong Lead-Zinc Mine. Geotech. Geol. Eng. 2020, 38, 4269–4287. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhou, J.L.; Lai, L.; Xu, M.T.; Xu, Y.L. Determination of optimal mining width for coal mining under the slope by of using numerical simulation. Sci. Rep. 2024, 14, 1124. [Google Scholar] [CrossRef]

- Zhao, K.; Liang, N.; Zeng, P.; Wang, W.; Gong, C.; Xiong, L.; Liu, H. Research on Optimization and Numerical Simulation of Layout Scheme of Mining Approach in Downward Slicing and Filling Method. Appl. Sci. 2023, 13, 8688. [Google Scholar] [CrossRef]

- Shi, J.; Feng, J. Simulate on Support Technology of Deep Mining. Geotech. Geol. Eng. 2021, 39, 4663–4668. [Google Scholar] [CrossRef]

- Liang, W.-z.; Zhao, G.-y.; Wu, H.; Chen, Y. Optimization of mining method in subsea deep gold mines: A case study. Trans. Nonferrous Met. Soc. China 2019, 29, 2160–2169. [Google Scholar] [CrossRef]

- Mijalkovski, S.; Peltechki, D.; Despodov, Z.; Mirakovski, D.; Adjiski, V.; Doneva, N. Application of the FUZZY TOPSIS method for selecting an underground mining method. Acta Montan. Slovaca 2023, 28, 465–478. [Google Scholar] [CrossRef]

- Yavuz, M. The application of the analytic hierarchy process (AHP) and Yager’s method in underground mining method selection problem. Int. J. Min. Reclam. Environ. 2015, 29, 453–475. [Google Scholar] [CrossRef]

- Bajić, S.; Bajić, D.; Gluščević, B.; Ristić Vakanjac, V. Application of Fuzzy Analytic Hierarchy Process to Underground Mining Method Selection. Symmetry 2020, 12, 192. [Google Scholar] [CrossRef]

- Hu, B.Y.; Zhang, Q.L.; Li, S.; Yu, H.X.; Wang, X.M.; Wang, H. Application of Numerical Simulation Methods in Solving Complex Mining Engineering Problems in Dingxi Mine, China. Minerals 2022, 12, 123. [Google Scholar] [CrossRef]

- Hou, D.; Xu, M.; Li, X.; Wang, J.; Wang, M.; Li, S. Optimization of mining methods for deep orebody of large phosphate mines. Front. Built Environ. 2023, 9, 1282684. [Google Scholar] [CrossRef]

- Alpay, S.; Yavuz, M. Underground mining method selection by decision making tools. Tunn. Undergr. Space Technol. 2009, 24, 173–184. [Google Scholar] [CrossRef]

- Sadiq, R.; Husain, T.; Veitch, B.; Bose, N. Risk-based decision-making for drilling waste discharges using a fuzzy synthetic evaluation technique. Ocean Eng. 2004, 31, 1929–1953. [Google Scholar] [CrossRef]

- Ataei, M.; Jamshidi, M.; Sereshki, F.; Jalali, S.M.E. Mining method selection by AHP approach. J. South. Afr. Inst. Min. Metall. 2008, 108, 743–751. [Google Scholar]

- Wen, K.-L. A Matlab toolbox for grey clustering and fuzzy comprehensive evaluation. Adv. Eng. Softw. 2008, 39, 137–145. [Google Scholar] [CrossRef]

- Lin, Q.; Zhang, S.; Lin, H.; Zhang, K.; Fan, W.; Huang, C.; Shao, Z.; Lan, M. Failure behavior of jointed rock masses containing a circular hole under compressive-shear load: Insights from DIC technique. Theor. Appl. Fract. Mech. 2025, 139, 105089. [Google Scholar] [CrossRef]

- Liu, W.J.; Liu, Z.X.; Wang, M.; Zhang, S.X. A comparative performance study on the development of hybrid extreme gradient boosting models for predicting rock layer subsidence in subsea gold mine. Geomech. Geophys. Geo-Energy Geo-Resour. 2025, 11, 39. [Google Scholar] [CrossRef]

- Liu, W.J.; Liu, Z.X.; Xiong, S.; Wang, M. Comparative prediction performance of the strength of a new type of Ti tailings cemented backfilling body using PSO-RF, SSA-RF, and WOA-RF models. Case Stud. Constr. Mater. 2024, 20, e02766. [Google Scholar] [CrossRef]

- Li, C. Application of Fuzzy Comprehensive Evaluation in Selecting Large Sports Venues. Agro Food Ind. Hi-Tech 2017, 28, 22–26. [Google Scholar]

- Ma, W.; Wang, Y. Fuzzy comprehensive evaluation model of interuniversity collaborative learning based on network. Open Phys. 2017, 15, 427–432. [Google Scholar] [CrossRef]

- He, R.X.; Liu, H.; Ren, F.Y.; Li, G.H.; Zhang, J.; Zhou, Y.J. Comprehensive Evaluation and Decision for Goaf Based on Fuzzy Theory in Underground Metal Mine. Adv. Civ. Eng. 2022, 2022, 3104961. [Google Scholar] [CrossRef]

- Fu, Z.G.; Wu, X.L.; Liao, H.C.; Herrera, F. Underground Mining Method Selection With the Hesitant Fuzzy Linguistic Gained and Lost Dominance Score Method. IEEE Access 2018, 6, 66442–66458. [Google Scholar] [CrossRef]

- Lin, Y.; Lin, C.; Qiu, X. Fuzzy Comprehensive Evaluation Method of Masonry Structure Safety Based on Grey Clustering Theory. Math. Probl. Eng. 2018, 2018, 8710192. [Google Scholar] [CrossRef]

- Wang, Z. Fuzzy comprehensive evaluation of physical education based on high dimensional data mining. J. Intell. Fuzzy Syst. 2018, 35, 3065–3076. [Google Scholar] [CrossRef]

- Wu, Z.; Li, Q.; Kong, D.; Chen, G.; Luo, D. The ANP-Fuzzy-TOPSIS model for the optimization of the scheme of large-section blasting. Arab. J. Geosci. 2020, 13, 47. [Google Scholar] [CrossRef]

- Ali, M.A.M.; Kim, J.G. Selection mining methods via multiple criteria decision analysis using TOPSIS and modification of the UBC method. J. Sustain. Min. 2021, 20, 49–55. [Google Scholar] [CrossRef]

- Zhu, L. Research and application of AHP-fuzzy comprehensive evaluation model. Evol. Intell. 2022, 15, 2403–2409. [Google Scholar] [CrossRef]

| Rock Mass | Elastic Modulus (Pa) | Shear Modulus (Pa) | Density (g/cm3) | Internal Friction Angle (°) | Cohesion (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|

| Wall rock | 1.096 × 1010 | 6.895 × 109 | 2.7 | 36.94 | 42.78 | 8.54 |

| Ore body | 32.18 × 109 | 2.024 × 109 | 2.7 | 32.60 | 21.45 | 4.91 |

| 1:4 backfill body | 2.894 × 107 | 2.449 × 107 | 2.2 | 43.50 | 3.10 | 1.51 |

| 1:8 backfill body | 1.234 × 107 | 9.71 × 106 | 2.1 | 38.70 | 1.71 | 0.42 |

| Non-cemented backfills | 6.32 × 106 | 3.68 × 106 | 1.6 | 32.00 | 0.17 | 0.03 |

| Index Factor | Scheme 1 | Scheme 2 | Scheme 3 |

|---|---|---|---|

| Maximum compressive stress of surrounding rock/MPa | 52.16 | 52.21 | 53.06 |

| Average vertical displacement of top column monitoring point/cm | 19.10 | 19.10 | 19.07 |

| Average vertical stress at top column monitoring point/MPa | 11.32 | 11.27 | 11.12 |

| Maximum compressive stress of backfill/MPa | 39.73 | 39.78 | 41.03 |

| Maximum tensile stress of backfill/MPa | 3.85 | 3.74 | 3.92 |

| Plastic failure degree/% | 12.35 | 12.40 | 11.83 |

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RI | 0 | 0 | 0.52 | 0.89 | 1.12 | 1.24 | 1.36 | 1.41 | 1.46 | 1.49 | 1.52 | 1.54 | 1.56 | 1.58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.; Liu, Z.; Li, Z. Study on Optimization of Downward Mining Schemes of Sanshandao Gold Mine. Appl. Sci. 2025, 15, 8296. https://doi.org/10.3390/app15158296

Liu W, Liu Z, Li Z. Study on Optimization of Downward Mining Schemes of Sanshandao Gold Mine. Applied Sciences. 2025; 15(15):8296. https://doi.org/10.3390/app15158296

Chicago/Turabian StyleLiu, Weijun, Zhixiang Liu, and Zaiyong Li. 2025. "Study on Optimization of Downward Mining Schemes of Sanshandao Gold Mine" Applied Sciences 15, no. 15: 8296. https://doi.org/10.3390/app15158296

APA StyleLiu, W., Liu, Z., & Li, Z. (2025). Study on Optimization of Downward Mining Schemes of Sanshandao Gold Mine. Applied Sciences, 15(15), 8296. https://doi.org/10.3390/app15158296