Sustainable Packaging Design: Packaging Optimization and Material Reduction for Environmental Protection and Economic Benefits to Industry and Society

Abstract

1. Introduction

2. Literature Review

2.1. CO2 Emissions

2.2. The Role of Plastics

2.3. Packaging Redesign and Sustainability

- Is beneficial, safe, and healthy for individuals and communities throughout its life cycle;

- Meets market criteria for both performance and cost;

- Is sourced, manufactured, transported, and recycled using renewable energy;

- Optimizes the use of renewable or recycled source materials;

- Is manufactured using clean production technologies and best practices;

- Is made from materials that are healthy throughout the life cycle;

- Is physically designed to optimize materials and energy;

- Is effectively recovered and utilized in biological and/or industrial closed-loop cycles.

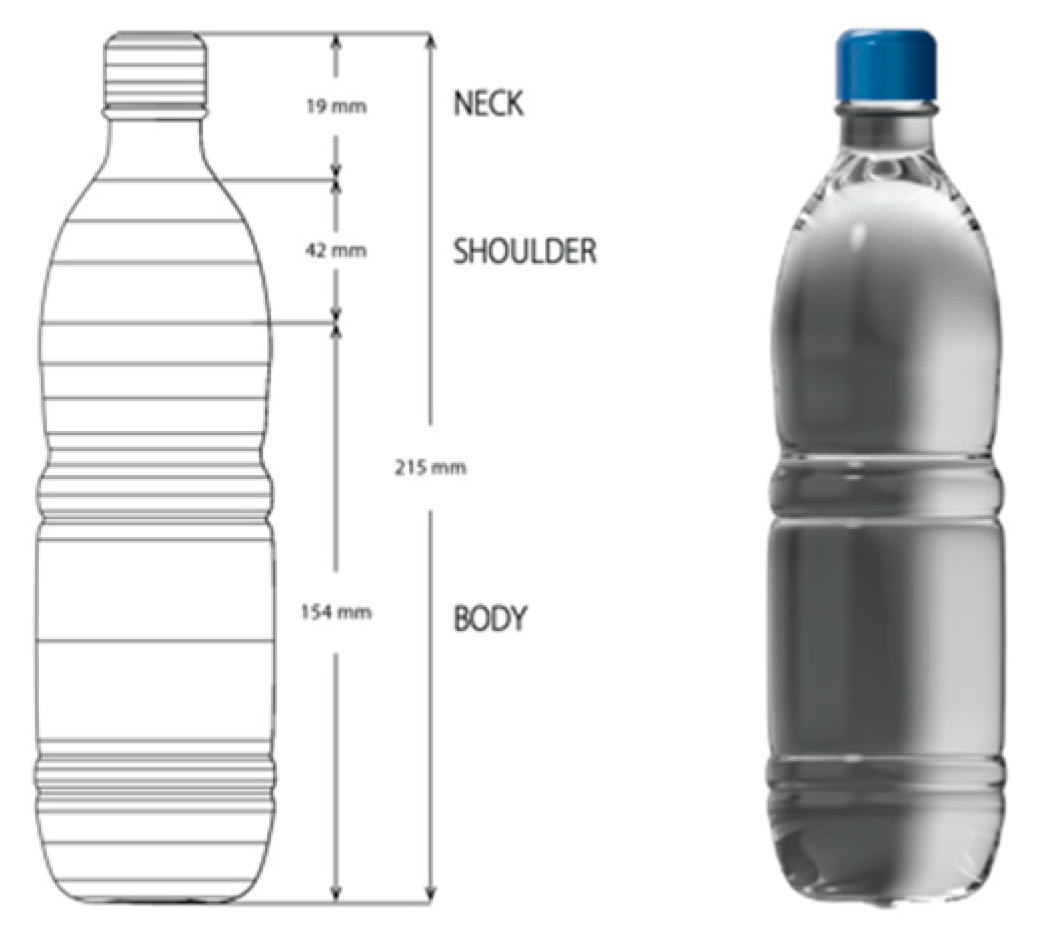

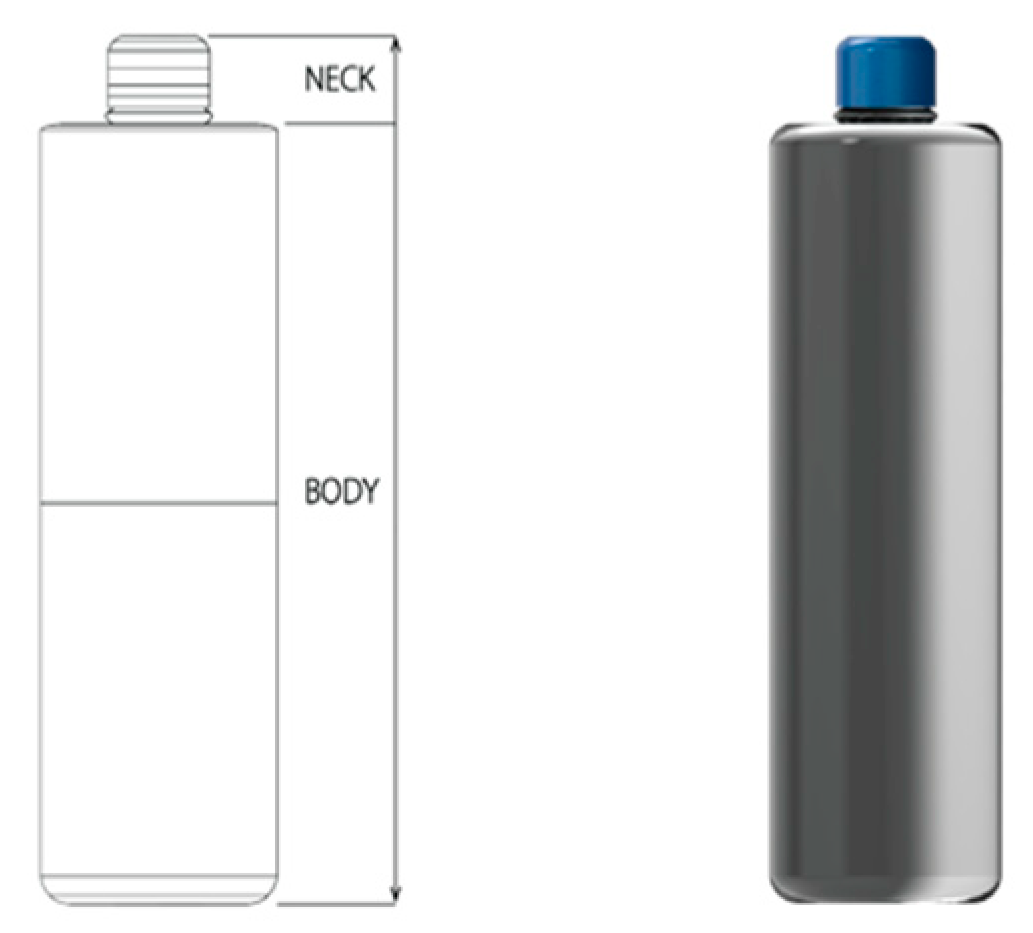

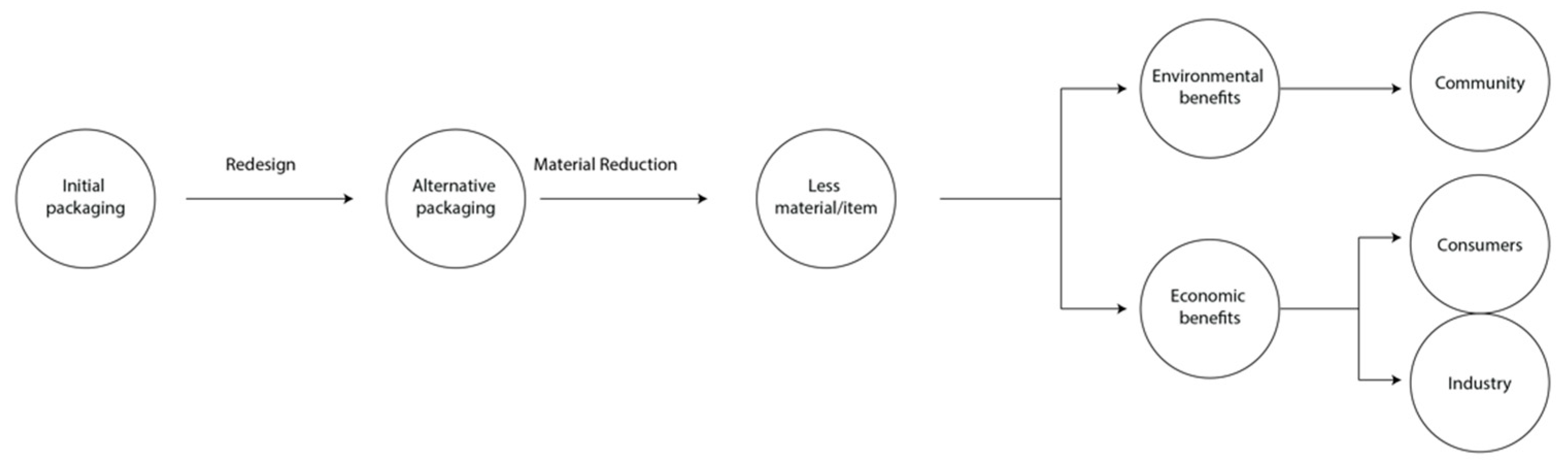

3. The Case Study

Mathematical Modeling—Relations

- a.

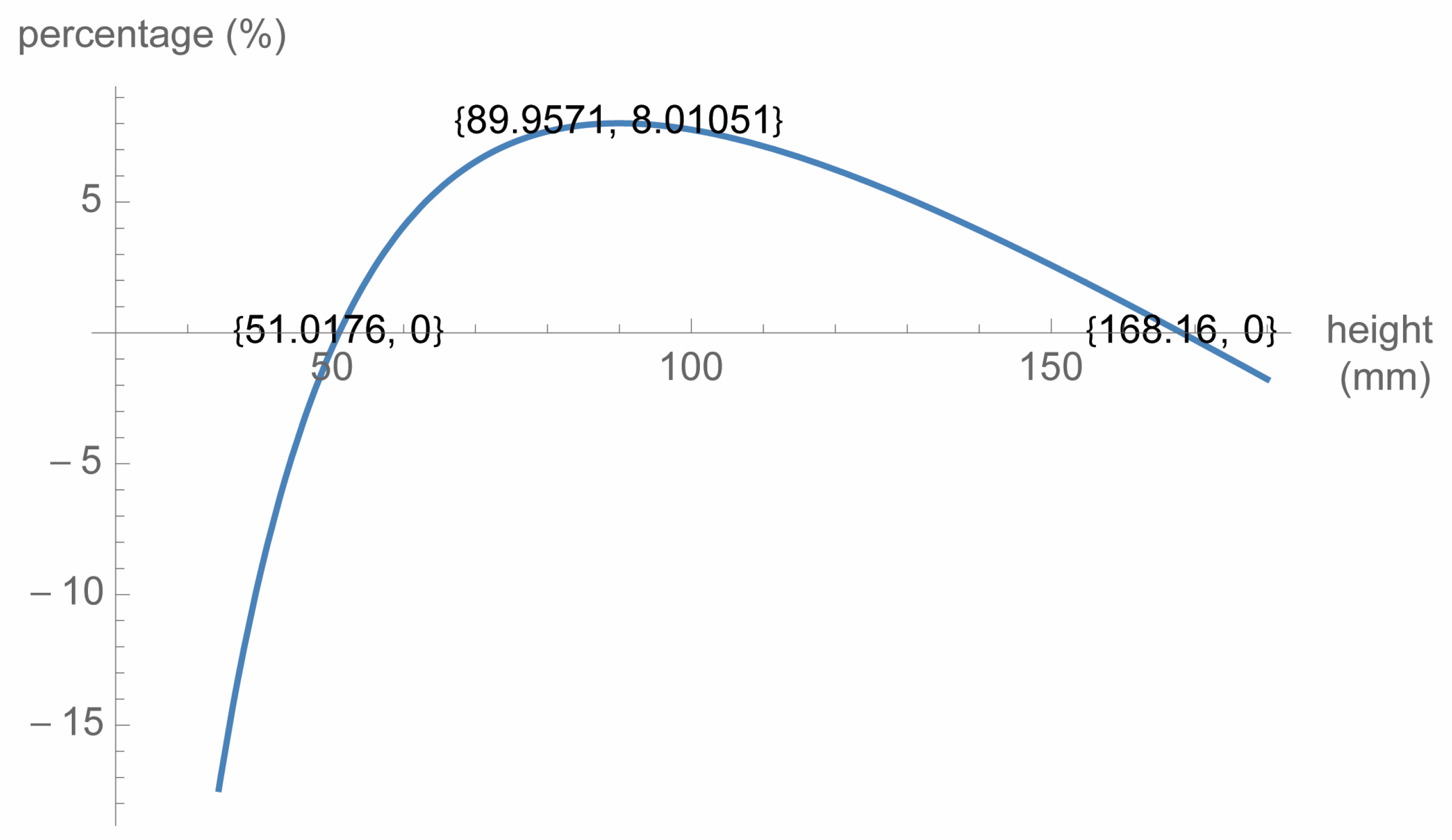

- When the functions are calculated by considering the total height () of the new bottle as the variable, and the radius is calculated in relation to this height, in order to reduce the quantity of material (see Figure 3):

- b.

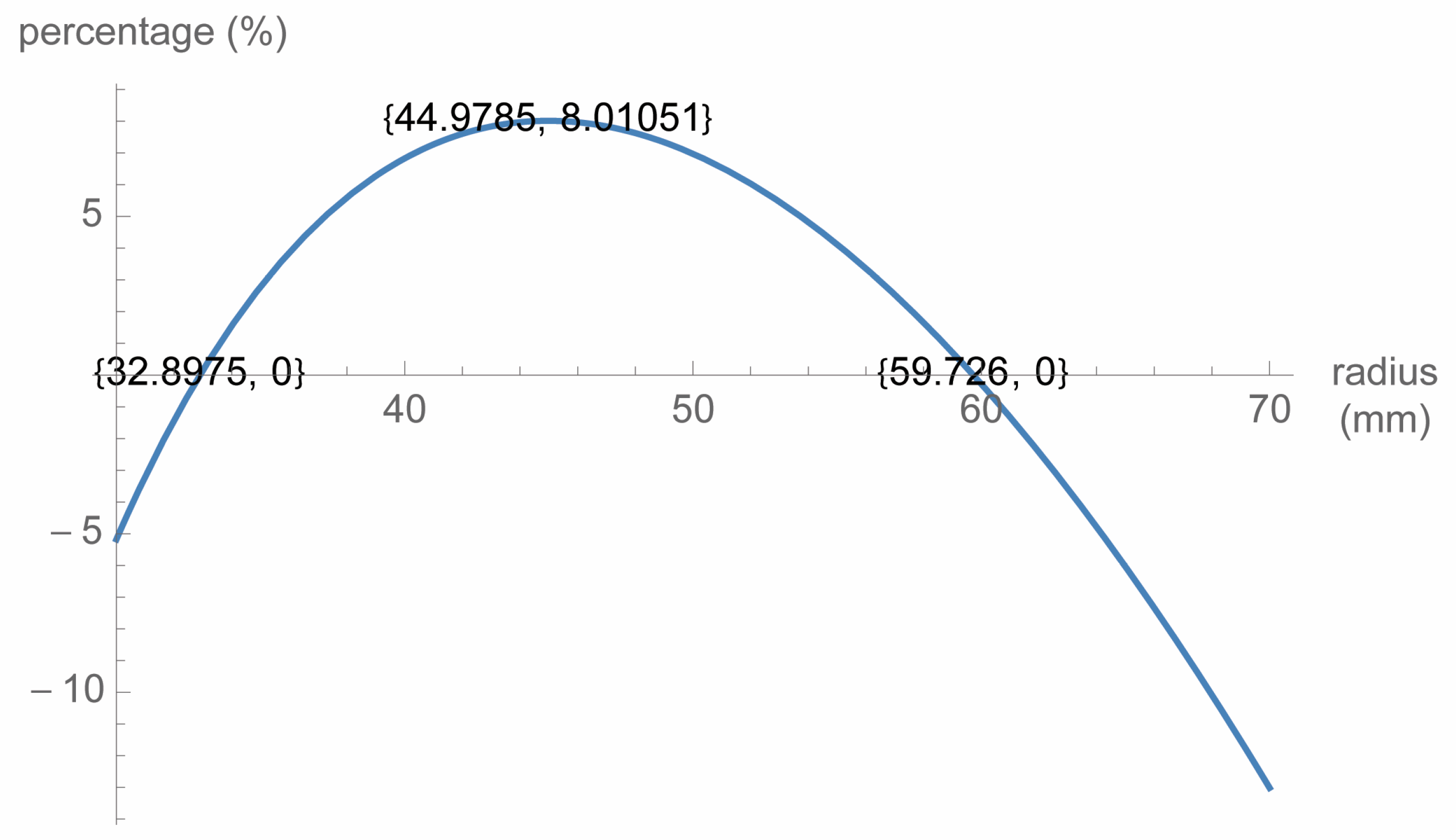

- When the functions are calculated by considering the radius () of the new bottle as the variable, and the height of the new bottle is calculated with respect to this radius, in order to reduce the quantity of material (see Figure 4):

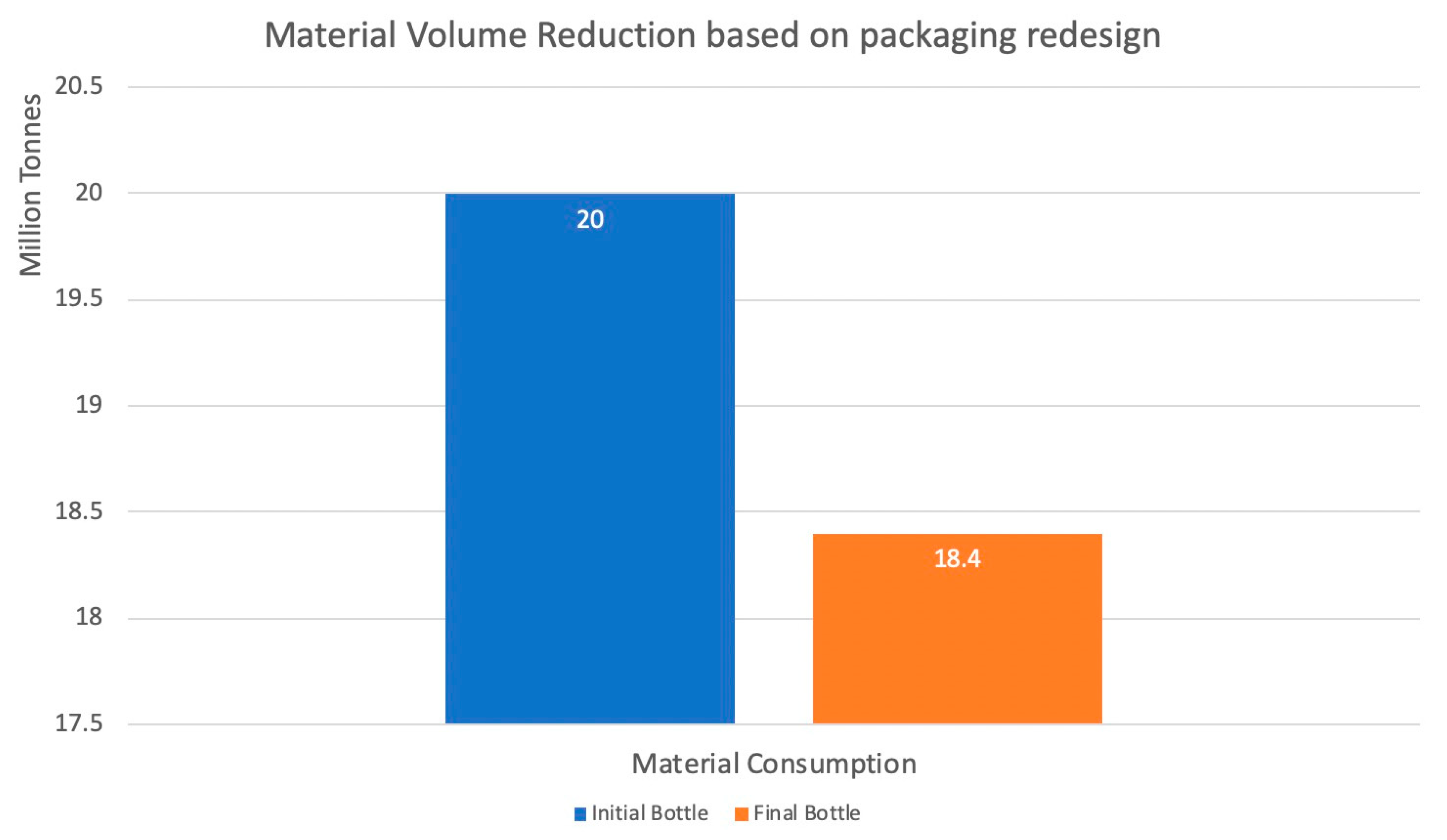

4. Discussion

5. Conclusion and Policy Implications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dulambayeva, R.; Jumabayev, S.; Marmontova, T.; Zhunussova, A. COVID–19 in transport industry: The case of Kazakhstan: Government measures and public reaction. Transp. Res. Procedia 2022, 63, 1377–1388. [Google Scholar] [CrossRef]

- Gulseven, O.; Al Harmoodi, F.; Al Falasi, M.; Alshomali, I. How the COVID-19 pandemic will affect the UN Sustainable Development Goals? SSRN Electron. J. 2020, 3592933. [Google Scholar] [CrossRef]

- Chmielarz, W.; Zborowski, M.; Xuetao, J.; Atasever, M.; Szpakowska, J. COVID-19 pandemic as sustainability determinant of e-commerce in the creation of information society. Procedia Comput. Sci. 2022, 207, 4378–4389. [Google Scholar] [CrossRef]

- National Oceanic and Atmospheric Administration. Climate Change Impacts. Available online: https://www.noaa.gov/education/resource-collections/climate/climate-change-impacts (accessed on 13 August 2021).

- Alexander, L.V.; Allen, S.K.; Bindoff, N.L.; Bréon, F.-M.; Church, J.A.; Cubasch, U.; Emori, S.; Forster, P.; Friedlingstein, P.; Gillett, N.P.; et al. Climate change 2013: The physical science basis. In Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change (IPCC); Cambridge University Press: Cambridge, UK, 2013. [Google Scholar]

- Intergovernmental Panel on Climate Change. Summary for Policymakers. In Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Masson-Delmotte, V., Zhai, P., Pirani, A., Connors, S.L., Péan, C., Berger, S., Caud, N., Chen, Y., Goldfarb, L., Gomis, M.I., et al., Eds.; Cambridge University Press: Cambridge, UK, 2021. [Google Scholar]

- Foster, G.; Rahmstorf, S. Global temperature evolution 1979–2010. Environ. Res. Lett. 2011, 6, 044022. [Google Scholar] [CrossRef]

- Okereke, C.; Wittneben, B.; Bowen, F. Climate change: Challenging business, transforming politics. Bus. Soc. 2011, 51, 7–30. [Google Scholar] [CrossRef]

- Allen, M.; Barros, V.; Broome, J. IPCC Fifth Assessment Synthesis Report—Climate Change 2014 Synthesis Report; IPCC: Geneva, Switzerland, 2014; p. 116. [Google Scholar]

- Palinkas, L.A.; Wong, M. Global climate change and mental health. Curr. Opin. Psychol. 2020, 32, 12–16. [Google Scholar] [CrossRef] [PubMed]

- Cevik, S.; Jalles, J.T. For whom the bell tolls: Climate change and income inequality. Energy Policy 2023, 174, 113475. [Google Scholar] [CrossRef]

- Tubiello, F.N.; Karl, K.; Flammini, A.; Gütschow, J.; Obli-Laryea, G.; Conchedda, G.; Pan, X.Y.; Sally, Y.Q.; Heiðarsdóttir, H.H.; Wanner, N.; et al. Pre- and post-production processes increasingly dominate greenhouse gas emissions from agri-food systems. Earth Syst. Sci. Data 2022, 14, 1795–1809. [Google Scholar] [CrossRef]

- Busby, J.W.; Cook, K.H.; Vizy, E.K.; Smith, T.G.; Bekalo, M. Identifying hot spots of security vulnerability associated with climate change in Africa. Clim. Change 2014, 124, 717–731. [Google Scholar] [CrossRef]

- Brundtland, G.H. Our Common Future; Oxford University Press: Oxford, UK, 1987. [Google Scholar]

- Baarsch, F.; Granadillos, J.R.; Hare, W.; Knaus, M.; Krapp, M.; Schaeffer, M.; Lotze-Campen, H. The impact of climate change on incomes and convergence in Africa. World Dev. 2020, 126, 104699. [Google Scholar] [CrossRef]

- Guest, R. The economics of sustainability in the context of climate change: An overview. J. World Bus. 2010, 45, 326–335. [Google Scholar] [CrossRef]

- Abdelzaher, D.M.; Martynov, A.; Abdel Zaher, A.M. Vulnerability to climate change: Are innovative countries in a better position? Res. Int. Bus. Financ. 2020, 51, 101098. [Google Scholar] [CrossRef]

- Flaherty, M.; Gevorkyan, A.; Radpour, S.; Semmler, W. Financing climate policies through climate bonds—A three stage model and empirics. Res. Int. Bus. Financ. 2017, 42, 468–479. [Google Scholar] [CrossRef]

- Winn, M.; Kirchgeorg, M.; Griffiths, A.; Linnenluecke, M.K.; Günther, E. Impacts from climate change on organizations: A conceptual foundation. Bus. Strategy Environ. 2011, 20, 157–173. [Google Scholar] [CrossRef]

- Shuai, C.; Chen, X.; Wu, Y.; Zhang, Y.; Tan, Y. A three-step strategy for decoupling economic growth from carbon emission: Empirical evidences from 133 countries. Sci. Total Environ. 2019, 646, 524–543. [Google Scholar] [CrossRef]

- Wu, Y.; Tam, V.W.Y.; Shuai, C.; Shen, L.; Zhang, Y.; Liao, S. Decoupling China’s economic growth from carbon emissions: Empirical studies from 30 Chinese provinces (2001–2015). Sci. Total Environ. 2019, 656, 576–588. [Google Scholar] [CrossRef]

- Lai, S.; Lu, J.; Luo, X.; Ge, J. Carbon emission evaluation model and carbon reduction strategies for newly urbanized areas. Sustain. Prod. Consum. 2022, 31, 13–25. [Google Scholar] [CrossRef]

- United Nations. Paris Agreement. 2015. Available online: https://unfccc.int/sites/default/files/english_paris_agreement.pdf (accessed on 17 September 2024).

- Rogelj, J.; den Elzen, M.; Höhne, N.; Fransen, T.; Fekete, H.; Winkler, H.; Schaeffer, R.; Rocha, M.; Oberthür, S.; Meinshausen, M. Paris Agreement climate proposals need a boost to keep warming well below 2 °C. Nature 2016, 534, 631–639. [Google Scholar] [CrossRef]

- Twerefou, D.K.; Danso-Mensah, K.; Bokpin, G.A. The environmental effects of economic growth and globalization in Sub-Saharan Africa: A panel general method of moments approach. Res. Int. Bus. Financ. 2017, 42, 939–949. [Google Scholar] [CrossRef]

- Offermann-van Heek, J.; Arning, K.; Linzenich, A.; Ziefle, M. Trust and distrust in carbon capture and utilization industry as relevant factors for the acceptance of carbon-based products. Front. Energy Res. 2018, 6, 73. [Google Scholar] [CrossRef]

- Georgakoudis, E.D. Packaging Operations Within the Greek Logistic Industry: Evaluating and Redesigning Paper Packaging in Compliance with Environmental Regulations. Ph.D. Thesis, The University of Huddersfield, Huddersfield, UK, 2014. [Google Scholar]

- Parboteeah, K.P.; Addae, H.M.; Cullen, J.B. Propensity to support sustainability initiatives: A cross-national model. J. Bus. Ethics 2011, 105, 403–413. [Google Scholar] [CrossRef]

- Husted, B.W. Culture and ecology: A cross-national study of the determinants of environmental sustainability. Manag. Int. Rev. 2005, 45, 349–371. [Google Scholar]

- Galbreath, J.; Charles, D.; Klass, D. Knowledge and the climate change issue: An exploratory study of cluster and extra-cluster effects. J. Bus. Ethics 2013, 125, 11–25. [Google Scholar] [CrossRef]

- da Guarda, E.L.A.; Domingos, R.M.A.; Jorge, S.H.M.; Durante, L.C.; Sanches, J.C.M.; Leão, M.; Callejas, I.J.A. The influence of climate change on renewable energy systems designed to achieve zero energy buildings in the present: A case study in the Brazilian savannah. Sustain. Cities Soc. 2020, 52, 101843. [Google Scholar] [CrossRef]

- Kim, M.H.; Kim, D.; Heo, J.; Lee, D.W. Energy performance investigation of net plus energy town: Energy balance of the Jincheon Eco-Friendly Energy Town. Renew. Energy 2020, 147, 1784–1800. [Google Scholar] [CrossRef]

- Fuxman, L.; Mohr, I.; Mahmoud, A.B.; Grigoriou, N. The new 3Ps of sustainability marketing: The case of fashion. Sustain. Prod. Consum. 2022, 31, 384–396. [Google Scholar] [CrossRef]

- Tipi, N.; Georgakoudis, E.D. Packaging Design and Sustainability—The Case of Paper Packaging Supply Chain. In Sustainable and Green Supply Chains and Logistics: Case Study Collection; Bak, Ö., Ed.; Kogan Page: London, UK, 2021; pp. 147–161. [Google Scholar]

- Georgakoudis, E.D.; Pechlivanidou, G.G.; Tipi, N.S. The packaging redesign issue—Space exploitation and environmental benefits. Manag. Environ. Qual. Int. J. 2022, 34, 1–20. [Google Scholar] [CrossRef]

- Craighill, A.L.; Powell, J.C. Lifecycle assessment and economic evaluation of recycling: A case study. Resour. Conserv. Recycl. 1996, 17, 75–96. [Google Scholar] [CrossRef]

- da Cruz, N.F.; Simões, P.; Marques, R.C. Economic cost recovery in the recycling of packaging waste: The case of Portugal. J. Clean. Prod. 2012, 37, 8–18. [Google Scholar] [CrossRef]

- Fraser, D. The Effect of War on Food Prices. BBC News. Available online: https://www.bbc.com/news/uk-scotland-60644376 (accessed on 7 March 2022).

- Simchi-Levi, D.; Haren, P. How the War in Ukraine is Further Disrupting Global Supply Chains. Harvard Business Review. Available online: https://hbr.org/2022/03/how-the-war-in-ukraine-is-further-disrupting-global-supply-chains (accessed on 19 March 2025).

- Risch, B.W.K. The raw material supply of the European Community: The importance of secondary raw materials. Resour. Policy 1978, 4, 181–188. [Google Scholar] [CrossRef]

- Dussaux, D.; Glachant, M. How much does recycling reduce imports? Evidence from metallic raw materials. J. Environ. Econ. Policy 2018, 8, 128–146. [Google Scholar] [CrossRef]

- Muhammad, B. Energy consumption, CO2 emissions and economic growth in developed, emerging and Middle East and North Africa countries. Energy 2019, 179, 232–245. [Google Scholar] [CrossRef]

- Al-Mulali, U.; Che Sab, C.N.B. Electricity consumption, CO2 emission, and economic growth in the Middle East. Energy Sources Part B Econ. Plan. Policy 2018, 13, 257–263. [Google Scholar] [CrossRef]

- Saidi, K.; Hammami, S. The impact of energy consumption and CO2 emissions on economic growth: Fresh evidence from dynamic simultaneous-equations models. Sustain. Cities Soc. 2015, 14, 178–186. [Google Scholar] [CrossRef]

- Coondoo, D.; Dinda, S. Causality between income and emission: A country group-specific econometric analysis. Ecol. Econ. 2002, 40, 351–367. [Google Scholar] [CrossRef]

- Richmond, A.K.; Kaufmann, R.K. Is there a turning point in the relationship between income and energy use and/or carbon emissions? Ecol. Econ. 2006, 56, 176–189. [Google Scholar] [CrossRef]

- Guan, D.; Hubacek, K.; Weber, C.L.; Peters, G.P.; Reiner, D.M. The drivers of Chinese CO2 emissions from 1980 to 2030. Glob. Environ. Change 2008, 18, 626–634. [Google Scholar] [CrossRef]

- Shen, L.; Wu, Y.; Lou, Y.; Zeng, D.; Shuai, C.; Song, X. What drives the carbon emission in the Chinese cities?—A case of pilot low carbon city of Beijing. J. Clean. Prod. 2018, 174, 343–354. [Google Scholar] [CrossRef]

- Xu, G.; Schwarz, P.; Yang, H. Determining China’s CO2 emissions peak with a dynamic nonlinear artificial neural network approach and scenario analysis. Energy Policy 2019, 128, 752–762. [Google Scholar] [CrossRef]

- Oliveira, T.; Varum, C.; Botelho, A. Econometric modeling of CO2 emissions abatement: Comparing alternative approaches. Renew. Sustain. Energy Rev. 2019, 105, 310–322. [Google Scholar] [CrossRef]

- Zhang, C.; Luo, H.; Wang, Z. An economic analysis of waste heat recovery and utilization in data centers considering environmental benefits. Sustain. Prod. Consum. 2022, 31, 127–138. [Google Scholar] [CrossRef]

- Fridell, E.; Bäckström, S.; Stripple, H. Considering infrastructure when calculating emissions for freight transportation. Transp. Res. Part D Transp. Environ. 2019, 69, 346–363. [Google Scholar] [CrossRef]

- Abokyi, E.; Appiah-Konadu, P.; Abokyi, F.; Oteng-Abayie, E.F. Industrial growth and emissions of CO2 in Ghana: The role of financial development and fossil fuel consumption. Energy Rep. 2019, 5, 1339–1353. [Google Scholar] [CrossRef]

- Mikayilov, J.I.; Galeotti, M.; Hasanov, F.J. The impact of economic growth on CO2 emissions in Azerbaijan. J. Clean. Prod. 2018, 197, 1558–1572. [Google Scholar] [CrossRef]

- Winkler, H.; Spalding-Fecher, R.; Tyani, L. Comparing developing countries under potential carbon allocation schemes. Clim. Policy 2002, 2, 303–318. [Google Scholar] [CrossRef]

- Du, H.; Chen, Z.; Peng, B.; Southworth, F.; Ma, S.; Wang, Y. What drives CO2 emissions from the transport sector? A linkage analysis. Energy 2019, 175, 195–204. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Ozkan-Ozen, Y.D.; Ozbiltekin, M. Minimizing losses in milk supply chain with sustainability: An example from an emerging economy. Resour. Conserv. Recycl. 2018, 139, 270–279. [Google Scholar] [CrossRef]

- Stern, D.I.; Common, M.S.; Barbier, E.B. Economic growth and environmental degradation: The environmental Kuznets curve and sustainable development. World Dev. 1996, 24, 1151–1160. [Google Scholar] [CrossRef]

- Stern, D.I.; Common, M.S. Is there an environmental Kuznets curve for sulfur? J. Environ. Econ. Manag. 2001, 41, 162–178. [Google Scholar] [CrossRef]

- Dinda, S. Environmental Kuznets curve hypothesis: A survey. Ecol. Econ. 2004, 49, 431–455. [Google Scholar] [CrossRef]

- Matthews, C.; Moran, F.; Jaiswal, A.K. A review on European Union’s strategy for plastics in a circular economy and its impact on food safety. J. Clean. Prod. 2021, 283, 125263. [Google Scholar] [CrossRef]

- Marsh, K.; Bugusu, B. Food packaging—Roles, materials, and environmental issues. J. Food Sci. 2007, 72, R39–R55. [Google Scholar] [CrossRef]

- Leal Filho, W.; Saari, U.; Fedoruk, M.; Iital, A.; Moora, H.; Klöga, M.; Voronova, V. An overview of the problems posed by plastic products and the role of extended producer responsibility in Europe. J. Clean. Prod. 2019, 214, 550–558. [Google Scholar] [CrossRef]

- Laville, S.; Taylor, M. A Million Bottles a Minute: World’s Plastic Binge “As Dangerous as Climate Change”. The Guardian. Available online: https://www.theguardian.com/environment/2017/jun/28/a-million-a-minute-worlds-plastic-bottle-binge-as-dangerous-as-climate-change (accessed on 28 June 2017).

- Etale, A.; Jobin, M.; Siegrist, M. Tap versus bottled water consumption: The influence of social norms, affect and image on consumer choice. Appetite 2018, 121, 138–146. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Rambonnet, L.; Vink, S.C.; Land-Zandstra, A.M.; Bosker, T. Making citizen science count: Best practices and challenges of citizen science projects on plastics in aquatic environments. Mar. Pollut. Bull. 2019, 145, 271–277. [Google Scholar] [CrossRef] [PubMed]

- Drzyzga, O.; Prieto, A. Plastic waste management, a matter for the “community”. Microb. Biotechnol. 2018, 12, 66–68. [Google Scholar] [CrossRef]

- Meng, Q.J.; Ji, Q.; Zhang, Y.G.; Liu, D.; Grossnickle, D.M.; Luo, Z.X. An arboreal docodont from the Jurassic and mammaliaform ecological diversification. Science 2015, 347, 764–768. [Google Scholar] [CrossRef]

- Cózar, A.; Sanz-Martín, M.; Martí, E.; González-Gordillo, J.I.; Ubeda, B.; Gálvez, J.Á.; Irigoien, X.; Duarte, C.M. Plastic accumulation in the Mediterranean Sea. PLoS ONE 2015, 10, e0121762. [Google Scholar] [CrossRef]

- Dilkes-Hoffman, L.S.; Lane, J.L.; Grant, T.; Pratt, S.; Lant, P.A.; Laycock, B. Environmental impact of biodegradable food packaging when considering food waste. J. Clean. Prod. 2018, 180, 325–334. [Google Scholar] [CrossRef]

- Faraca, G.; Astrup, T. Plastic waste from recycling centres: Characterisation and evaluation of plastic recyclability. Waste Manag. 2019, 95, 388–398. [Google Scholar] [CrossRef]

- De Marchi, E.; Pigliafreddo, S.; Banterle, A.; Parolini, M.; Cavaliere, A. Plastic packaging goes sustainable: An analysis of consumer preferences for plastic water bottles. Environ. Sci. Policy 2020, 114, 305–311. [Google Scholar] [CrossRef]

- Calver, G. What Is Packaging Design? RotoVision: Leinfelden-Echterdingen, Germany, 2004. [Google Scholar]

- Sustainability|Meaning in the Cambridge English Dictionary. Cambridge Dictionary; Cambridge University Press: Cambridge, UK, 2019. Available online: https://dictionary.cambridge.org/dictionary/english/sustainability (accessed on 16 April 2025).

- Sustainable Packaging Coalition. About Us—Sustainable Packaging Coalition. Available online: https://sustainablepackaging.org/about-us (accessed on 12 May 2025).

- Bumbudsanpharoke, N.; Ko, S. Packaging technology for home meal replacement: Innovations and future prospective. Food Control 2022, 132, 108470. [Google Scholar] [CrossRef]

- Georgakoudis, E.D.; Tipi, N.S.; Bamford, C.G. Packaging redesign—Benefits for the environment and the community. Int. J. Sustain. Eng. 2018, 11, 307–320. [Google Scholar] [CrossRef]

- Wever, R.; Vogtländer, J. Eco-efficient value creation: An alternative perspective on packaging and sustainability. Packag. Technol. Sci. 2012, 26, 229–248. [Google Scholar] [CrossRef]

- Bjørn, A.; Hauschild, M.Z. Absolute versus relative environmental sustainability. J. Ind. Ecol. 2012, 17, 321–332. [Google Scholar] [CrossRef]

- Niero, M.; Hauschild, M.Z.; Hoffmeyer, S.B.; Olsen, S.I. Combining eco-efficiency and eco-effectiveness for continuous loop beverage packaging systems: Lessons from the Carlsberg Circular Community. J. Ind. Ecol. 2017, 21, 742–753. [Google Scholar] [CrossRef]

- Yokokawa, N.; Amasawa, E.; Hirao, M. Design assessment framework for food packaging integrating consumer preferences and environmental impact. Sustain. Prod. Consum. 2021, 27, 1514–1525. [Google Scholar] [CrossRef]

- Keller, J.; Scagnetti, C.; Albrecht, S. The relevance of recyclability for the life cycle assessment of packaging based on design for life cycle. Sustainability 2022, 14, 4076. [Google Scholar] [CrossRef]

- Svanes, E.; Vold, M.; Møller, H.; Pettersen, M.K.; Larsen, H.; Hanssen, O.J. Sustainable packaging design: A holistic methodology for packaging design. Packag. Technol. Sci. 2010, 23, e887. [Google Scholar] [CrossRef]

- Vazquez, Y.V.; Dutari, T.; Castillo, L.A.; Barbosa, S.E. Ecodesign approach for plastic minimization in shampoo bottles. Packag. Technol. Sci. 2023, 36, 823–831. [Google Scholar] [CrossRef]

- Gavazzi, P.; Dobrucka, R.; Przekop, R. Current trends in the German packaging industry. Logforum 2022, 18, 27–33. [Google Scholar] [CrossRef]

- Jagoda, S.U.M.; Gamage, J.R.; Karunathilake, H.P. Environmentally sustainable plastic food packaging: A holistic life cycle thinking approach for design decisions. J. Clean. Prod. 2023, 400, 136680. [Google Scholar] [CrossRef]

- Thakker, V.; Bakshi, B.R. Ranking eco-innovations to enable a sustainable circular economy with net-zero emissions. ACS Sustain. Chem. Eng. 2023, 11, 1363–1374. [Google Scholar] [CrossRef]

- Landi, D.; Cicconi, P.; Germani, M. Analyzing the environmental sustainability of packaging for household appliances: A test case. Procedia CIRP 2020, 90, 355–360. [Google Scholar] [CrossRef]

- Tiseo, I. PET Global Bottle Production 2021. Statista. Available online: https://www.statista.com/statistics/723191/production-of-polyethylene-terephthalate-bottles-worldwide (accessed on 12 September 2023).

- Patel, U. Aluminium vs. Plastic: Who’ll Win the Water Bottle War? Wood Mackenzie. Available online: https://www.woodmac.com/news/feature/aluminium-vs-plastic-who-will-win-the-water-bottle-war (accessed on 3 September 2019).

- Plastics Information Europe. Polymer Prices—Plastics Information Europe. PIE Web. Available online: https://pieweb.plasteurope.com/Default.aspx?pageid=199&docid=24983 (accessed on 4 May 2023).

- Ellen MacArthur Foundation; McKinsey Company; World Economic Forum. The New Plastics Economy: Rethinking the Future of Plastics. Available online: https://ellenmacarthurfoundation.org/the-new-plastics-economy-rethinking-the-future-of-plastics (accessed on 3 December 2016).

- Yun, B.; Bisquert, P.; Buche, P.; Croitoru, M.; Guillard, V.; Thomopoulos, R. Choice of environment-friendly food packagings through argumentation systems and preferences. Ecol. Inform. 2018, 48, 24–36. [Google Scholar] [CrossRef]

- European Environment Agency. Special Report: The Polluter Pays Principle. Available online: https://www.eca.europa.eu/Lists/ECADocuments/SR21_12/SR_polluter_pays_principle_EN.pdf (accessed on 6 June 2021).

| Total Height (mm) | Radius (mm) | Bottle Shoulder (mm) | Neck (mm) | Area (m2) | ||||

|---|---|---|---|---|---|---|---|---|

| Initial Bottle | Final Bottle | Initial Bottle | Final Bottle | Initial Bottle | Final Bottle | Initial Bottle | Final Bottle | |

| 215 | 80 | 31.5 | 47.6956 | 42 | 0 | 19 | 0.0427525 | 0.0394616 |

| 215 1 | 89.9571 | 31.5 | 44.9785 | 42 | 0 | 19 | 0.0427525 | 0.0393278 |

| 215 | 90 | 31.5 | 44.9678 | 42 | 0 | 19 | 0.0427525 | 0.0393278 |

| 215 | 100 | 31.5 | 42.6602 | 42 | 0 | 19 | 0.0427525 | 0.0394328 |

| 215 | 110 | 31.5 | 40.6749 | 42 | 0 | 19 | 0.0427525 | 0.0397015 |

| 215 | 120 | 31.5 | 38.9433 | 42 | 0 | 19 | 0.0427525 | 0.0400853 |

| 215 | 130 | 31.5 | 37.4155 | 42 | 0 | 19 | 0.0427525 | 0.0405513 |

| 215 | 140 | 31.5 | 36.0545 | 42 | 0 | 19 | 0.0427525 | 0.0410766 |

| 215 | 150 | 31.5 | 34.8319 | 42 | 0 | 19 | 0.0427525 | 0.0416453 |

| 215 | 160 | 31.5 | 33.7259 | 42 | 0 | 19 | 0.0427525 | 0.0422455 |

| 215 2 | 168.16 | 31.5 | 32.8975 | 42 | 0 | 19 | 0.0427525 | 0.0427525 |

| 215 | 170 | 31.5 | 32.7189 | 42 | 0 | 19 | 0.0427525 | 0.0428685 |

| 215 | 180 | 31.5 | 31.7971 | 42 | 0 | 19 | 0.0427525 | 0.0435081 |

| 215 | 190 | 31.5 | 30.949 | 42 | 0 | 19 | 0.0427525 | 0.0441591 |

| 215 | 200 | 31.5 | 30.1653 | 42 | 0 | 19 | 0.0427525 | 0.0448181 |

| 215 | 210 | 31.5 | 29.4384 | 42 | 0 | 19 | 0.0427525 | 0.0454819 |

| 215 | 220 | 31.5 | 28.7615 | 42 | 0 | 19 | 0.0427525 | 0.0461485 |

| 215 | 230 | 31.5 | 28.1293 | 42 | 0 | 19 | 0.0427525 | 0.046816 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Georgakoudis, E.D.; Pechlivanidou, G.G.; Tipi, N.S. Sustainable Packaging Design: Packaging Optimization and Material Reduction for Environmental Protection and Economic Benefits to Industry and Society. Appl. Sci. 2025, 15, 8289. https://doi.org/10.3390/app15158289

Georgakoudis ED, Pechlivanidou GG, Tipi NS. Sustainable Packaging Design: Packaging Optimization and Material Reduction for Environmental Protection and Economic Benefits to Industry and Society. Applied Sciences. 2025; 15(15):8289. https://doi.org/10.3390/app15158289

Chicago/Turabian StyleGeorgakoudis, Elias D., Georgia G. Pechlivanidou, and Nicoleta S. Tipi. 2025. "Sustainable Packaging Design: Packaging Optimization and Material Reduction for Environmental Protection and Economic Benefits to Industry and Society" Applied Sciences 15, no. 15: 8289. https://doi.org/10.3390/app15158289

APA StyleGeorgakoudis, E. D., Pechlivanidou, G. G., & Tipi, N. S. (2025). Sustainable Packaging Design: Packaging Optimization and Material Reduction for Environmental Protection and Economic Benefits to Industry and Society. Applied Sciences, 15(15), 8289. https://doi.org/10.3390/app15158289