Dynamic Analysis of an Offshore Knuckle-Boom Crane Under Different Load Applications Laws

Abstract

1. Introduction

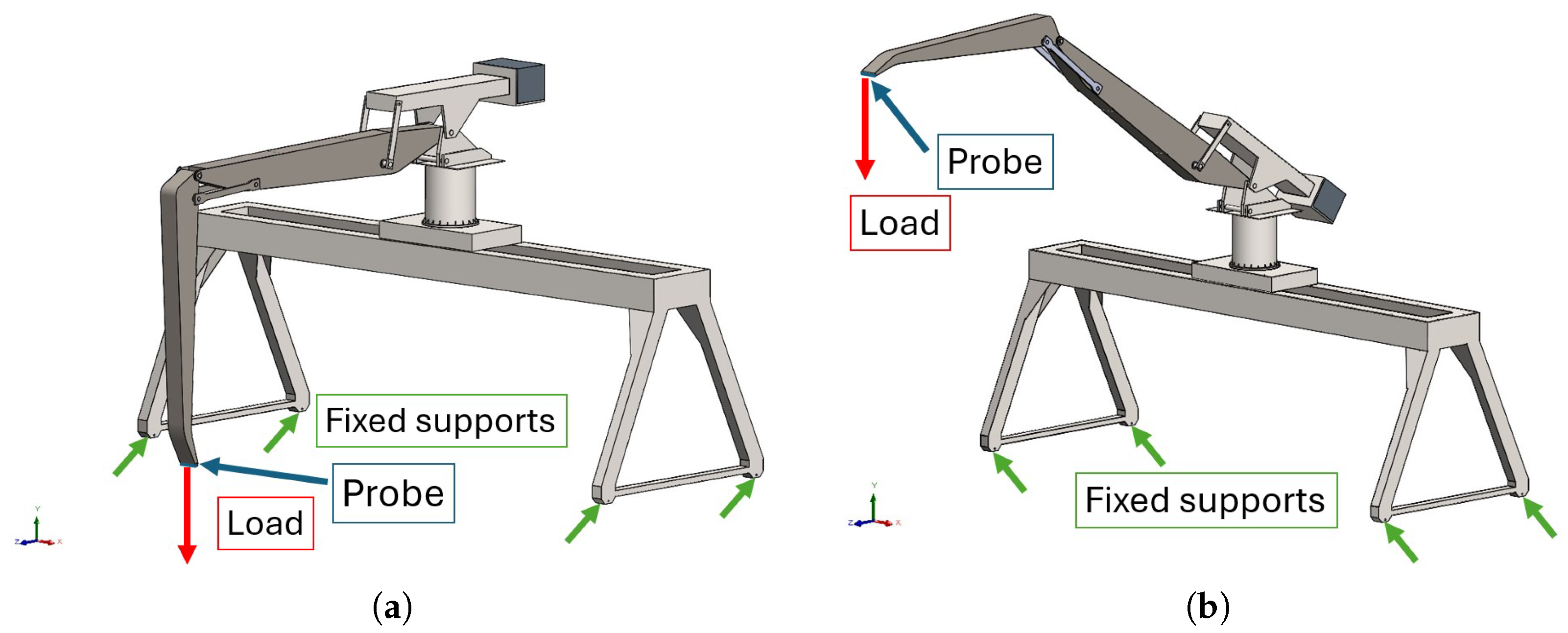

2. Materials and Methods

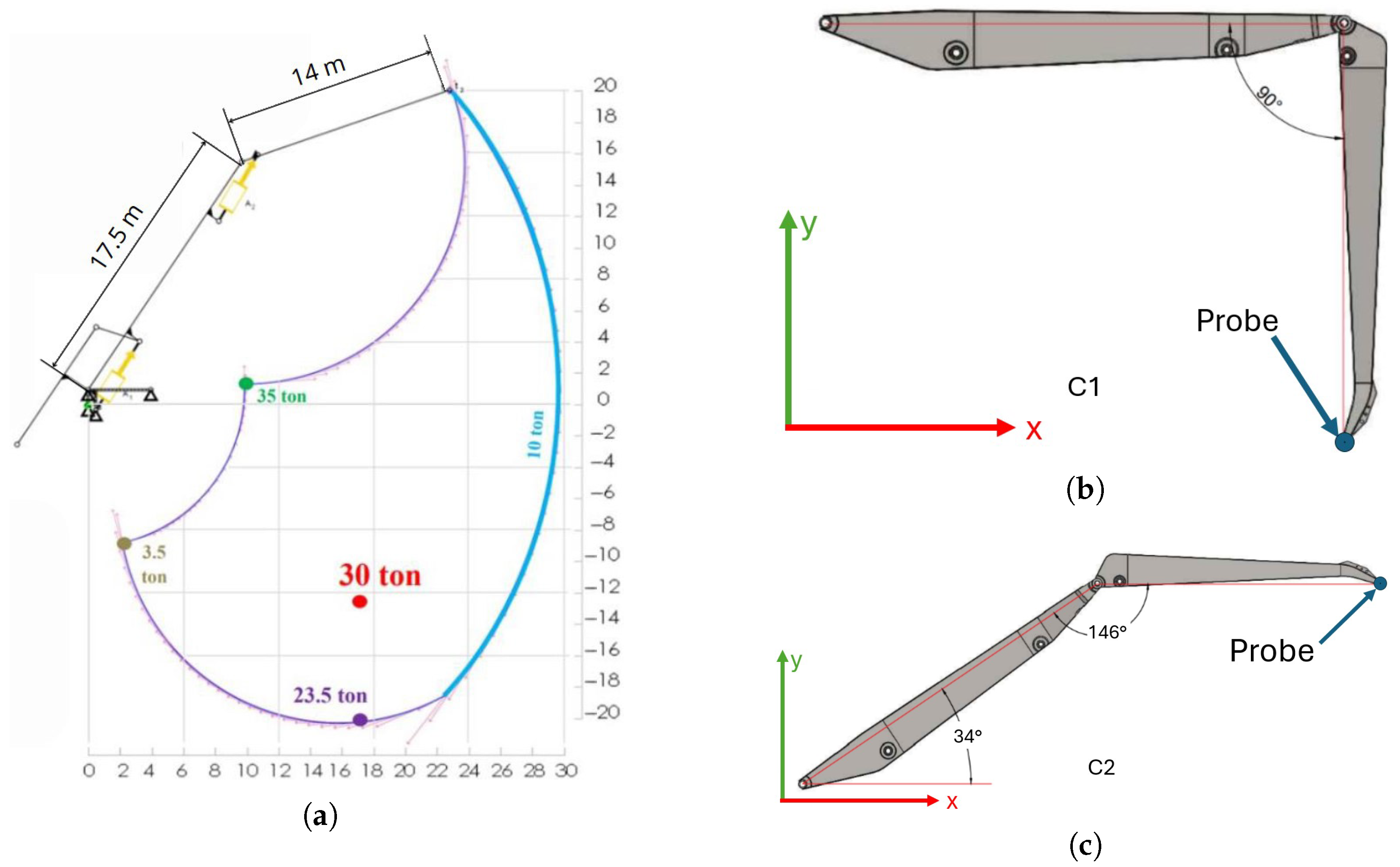

2.1. Description of the Analyzed Crane

- loading section, composed of the movable parts that allow the uplift;

- translation and rotation module, which are the moving parts that allow relative movement between the loading and handling module;

- movement module, composed of the moving parts that allow relative motion between the ground and the structure.

- the translation cart (needed for the translation movement);

- the cylinder;

- the fifth wheel (needed for the rotation movement, an example [34]);

- the anti-tilting system.

- liftable load with the boom in horizontal position: 300,000 N;

- spreader weight: 100,000 N;

- maximum outreach: 30 m;

- maximum height to take the container: 20 m;

- maximum depth reached below the ground level: 20 m.

2.2. Simplified Model

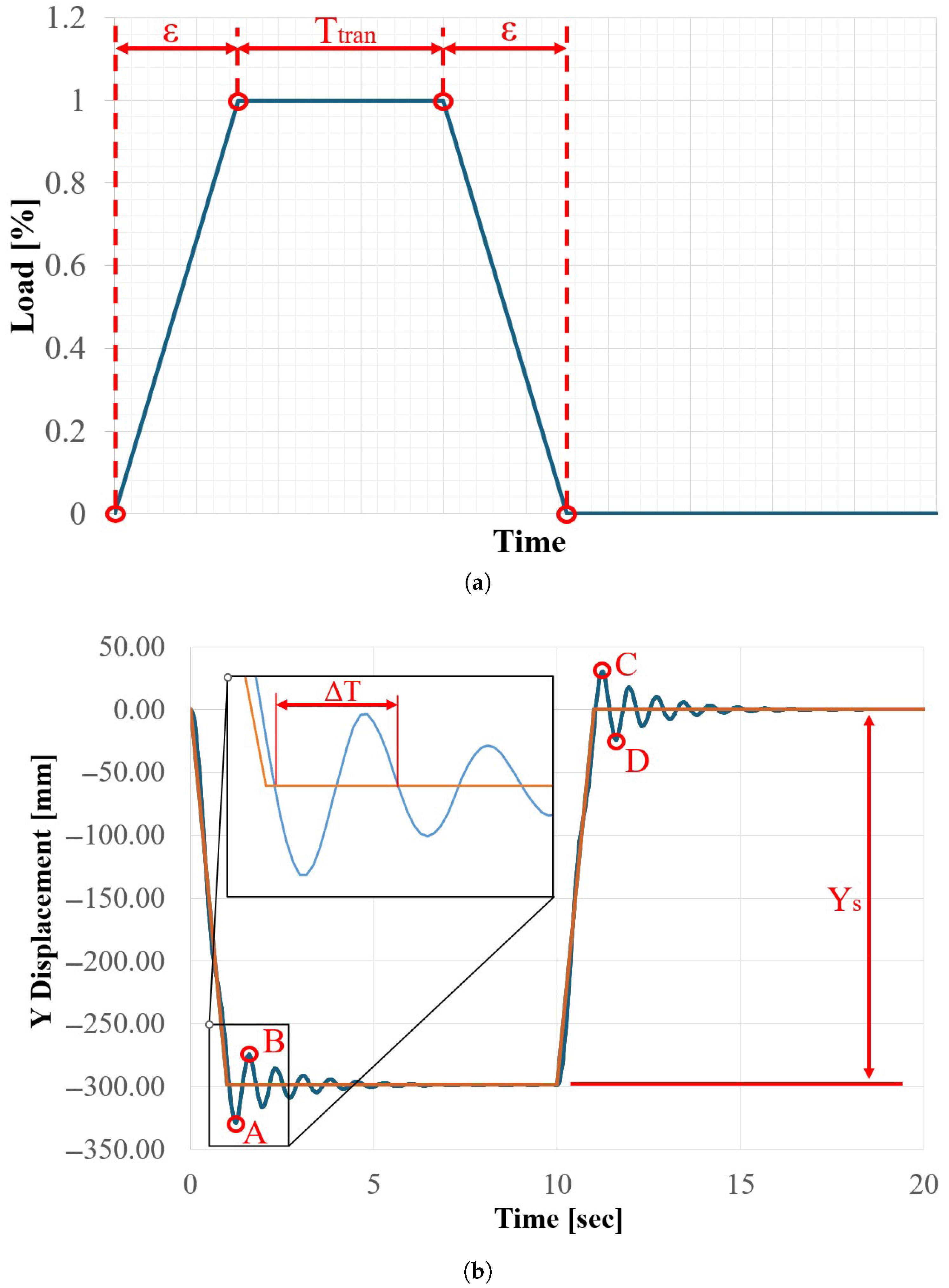

3. Results

- point A, which is the lowest peak of the load step;

- point B, which is the highest peak of the application of the load;

- point C, which is the highest peak of the load step;

- point D, which is the lowest peak after the release of the load;

- the settling value after the application of the load .

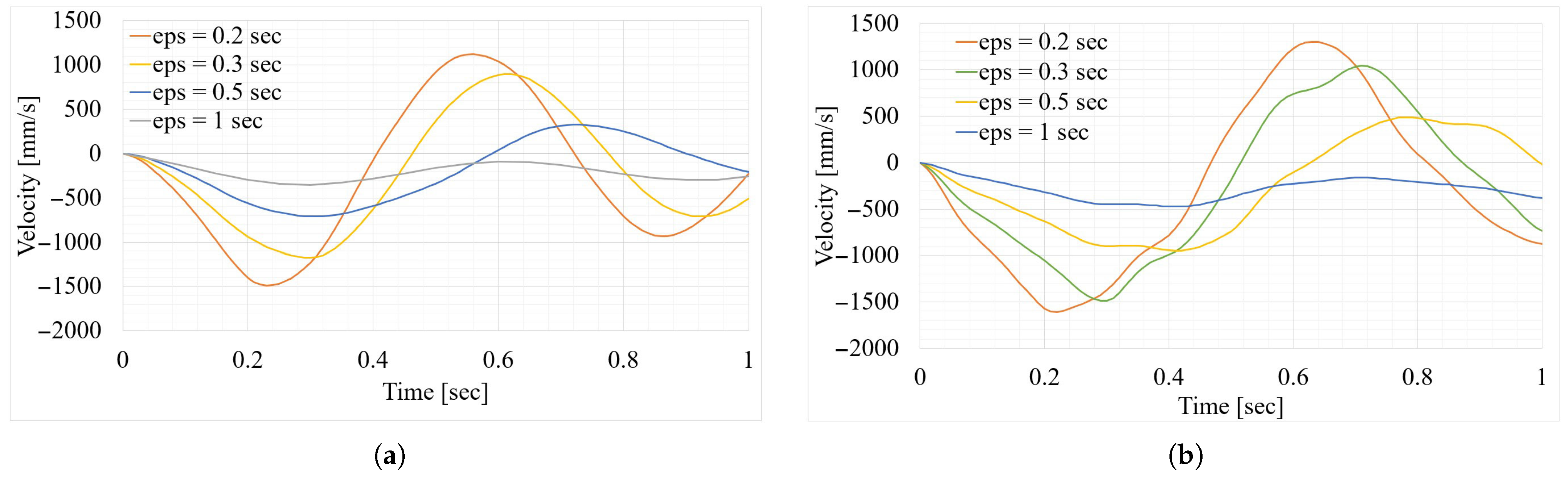

4. Discussion

5. Conclusions

- Regarding the Y-axis displacement, the decrease of the value of implies an increase of the overshoot related to the settling value, following a power trend line. Both the analyzed configurations display the same curve.

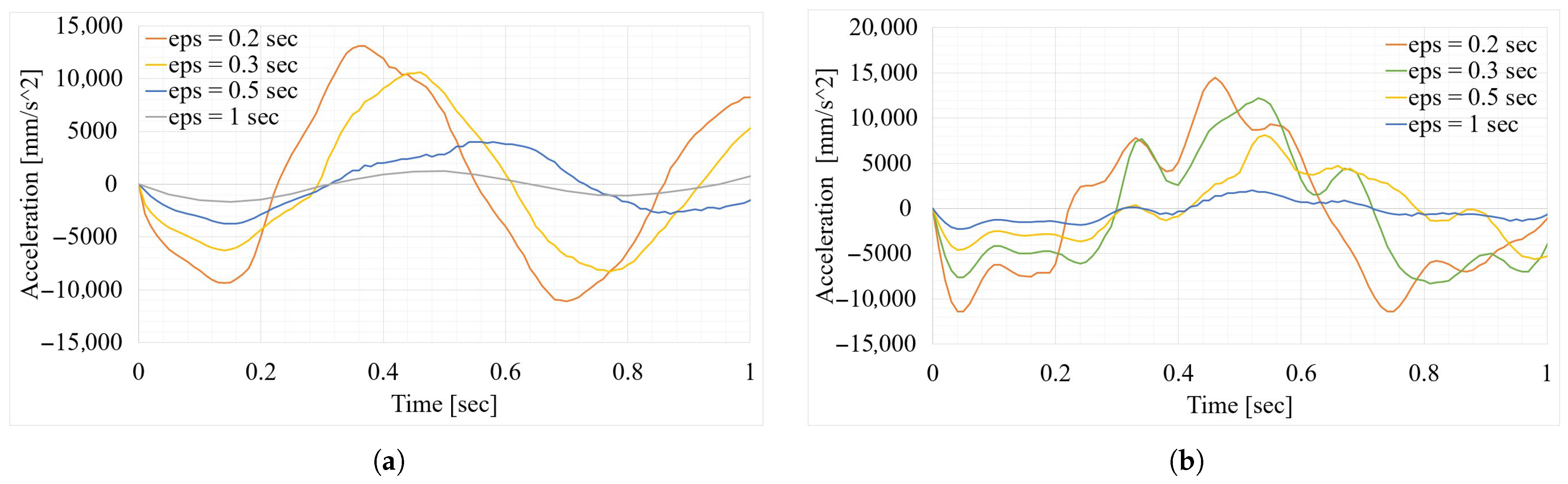

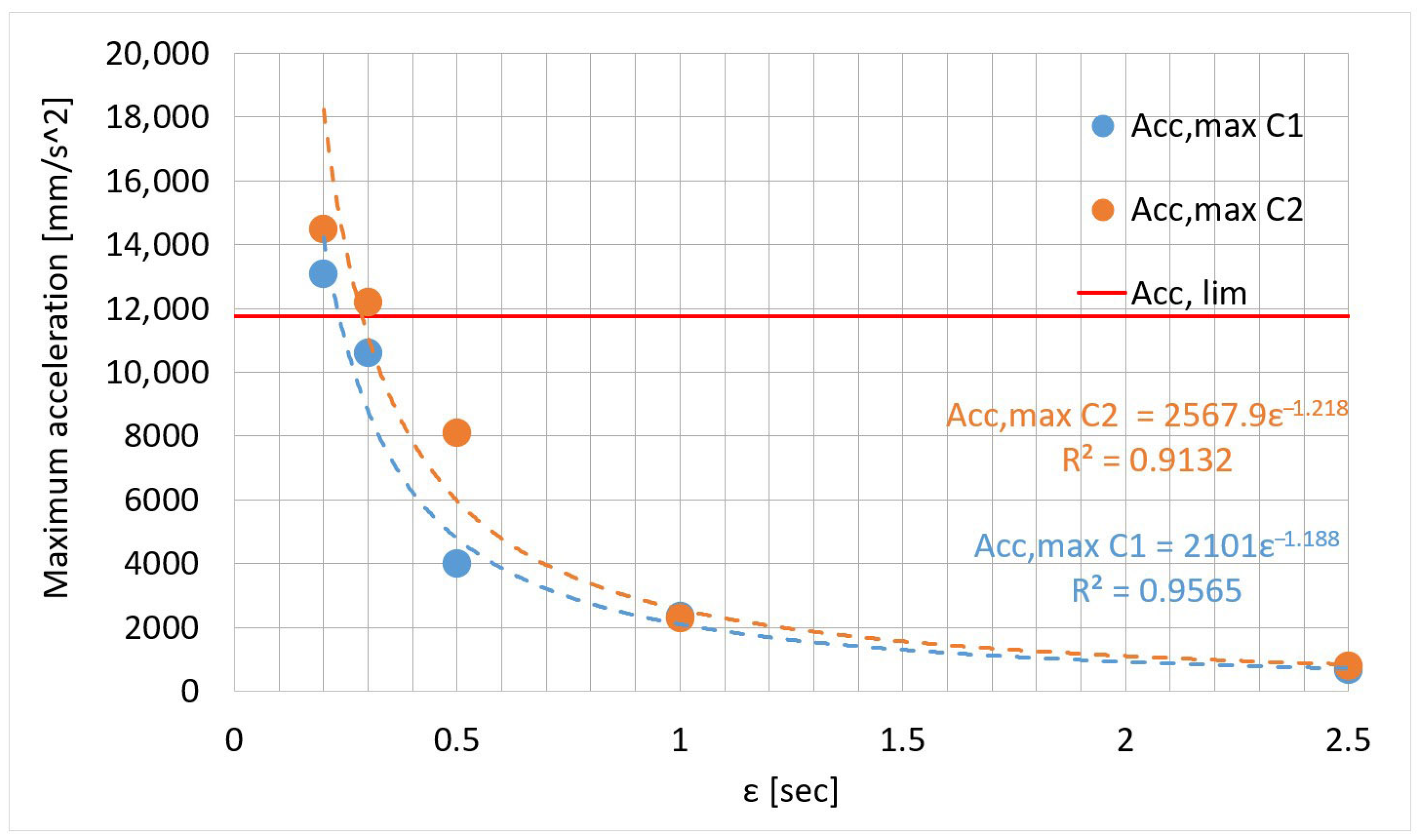

- Regarding the accelerations along the Y-axis, even here the decrease of the value of implies an increase of the maximum accelerations evaluated on the structure, following a power trend line.

- Taking into consideration also the acceleration limit related to the gravity acceleration, it is possible to suggest a boundary condition on the so-called time to avoid possible critical effects caused by inertial forces.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, W.; Qin, X.; Yang, Z. Effects of installation location on the in-service wind load of a tower crane. Proc. Inst. Civ. Eng. Struct. Build. 2020, 173, 141–156. [Google Scholar] [CrossRef]

- Wu, X.; Sun, Y.; Wu, Y.; Su, N.; Peng, S. The interference effects of wind load and wind-induced dynamic response of quayside container cranes. Appl. Sci. 2022, 12, 10969. [Google Scholar] [CrossRef]

- Nguyen, V.B.; Huh, J.; Meisuh, B.K. Evaluation of the effect of the vertical component of an earthquake on the seismic response of container cranes using the shake table test. Structures 2023, 58, 105590. [Google Scholar] [CrossRef]

- Li, S.; Brun, M.; Gravouil, A.; Fekak, F.E. Explicit/implicit multi-time step simulation of bridge crane under earthquake with frictional contacts and high-frequency Rayleigh damping. Finite Elem. Anal. Des. 2023, 220, 103946. [Google Scholar] [CrossRef]

- Nyezhentsev, O.; Kravchenko, O.; Gerlici, J.; Lovska, A. Mathematical modeling energy losses and dynamic loads during operation of the crane lifting mechanism. Transp. Res. Procedia 2023, 74, 791–798. [Google Scholar] [CrossRef]

- Shahnavaz, F.; Taghaddos, H.; Najafabadi, R.S.; Hermann, U. Multi crane lift simulation using Building Information Modeling. Autom. Constr. 2020, 118, 103305. [Google Scholar] [CrossRef]

- EN 13001; Cranes–General Design. CEN: Brussels, Belgium, 2021.

- EN 15001; Gas infrastructure—Gas Installation Pipework with an Operating Pressure Greater than 0.5 bar. CEN: Brussels, Belgium, 2021.

- European Parliament and Council. Directive 2006/42/EC on machinery, and amending Directive 95/16/EC (recast). Off. J. Eur. Union 2006, L 157, 24–86. [Google Scholar]

- Antipas, I.R. Modeling the Dynamic Loads Affecting a Bridge Crane during Start-Up. Adv. Eng. Res. 2024, 24, 190–197. [Google Scholar] [CrossRef]

- Haniszewski, T. Preliminary modeling studies of sudden release of a part of the hoist load with using experimental miniature test crane. Vibroeng. Procedia 2017, 13, 193–198. [Google Scholar] [CrossRef][Green Version]

- Yang, S.; Fang, X.; Zhang, J.; Wang, D. Dynamic behavior of bridge-erecting machine subjected to moving mass suspended by wire ropes. Appl. Math. Mech. 2016, 37, 741–748. [Google Scholar] [CrossRef]

- Yıldırım, Ş.; Esim, E. Investigation of dynamic response of multi-carriages double bridge overhead type crane system subjected to the moving load. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 108. [Google Scholar] [CrossRef]

- Buczkowski, R.; Żyliński, B. Finite Element Fatigue Analysis of Unsupported Crane; Polish Maritime Research: Gdańsk, Poland, 2021. [Google Scholar]

- Guo, H.; Chen, K. Modal and fatigue characteristics analysis of key components of tower crane. Vibroeng. Procedia 2024, 54, 72–77. [Google Scholar] [CrossRef]

- Georgiev, C. Enhancing Tower Crane Stability through Mast Bracing and Finite Element Analysis. Proc. Tech. Univ. Sofia 2024, 74, 8–14. [Google Scholar] [CrossRef]

- Gu, J.; Qin, Y.; Gao, H.; Yan, Y.; Yang, J.; Yang, K.; Mi, C. Nonlinear buckling analysis of tower crane structure based on movable boundaries. Adv. Mech. Eng. 2022, 14, 16878132221138308. [Google Scholar] [CrossRef]

- Guan, B.; Cheng, K.; Zhao, E. Experimental and Numerical Study of the Jib Connection Frame of a Wheeled Crane. Appl. Sci. 2025, 15, 4872. [Google Scholar] [CrossRef]

- Dipu, M.N.H.; Apu, M.H.; Chowdhury, P.P. Identification of the effective crane hook’s cross-section by incorporating finite element method and programming language. Heliyon 2024, 10, e29918. [Google Scholar] [CrossRef]

- Bing, L.; Xidong, H.; Jianguo, L.; Yulan, W.; Xing, L.; Siqi, L.; Yongli, W. Finite element analysis of the chassis in telescopic crawler crane. J. Phys. Conf. Ser. 2021, 1939, 012034. [Google Scholar] [CrossRef]

- Bak, M.K.; Hansen, M.R. Analysis of offshore knuckle boom crane-part one: Modeling and parameter identification. Model. Identication Control 2013, 34, 157–174. [Google Scholar] [CrossRef]

- Adamiec-Wójcik, I.; Drąg, Ł.; Metelski, M.; Nadratowski, K.; Wojciech, S. A 3D model for static and dynamic analysis of an offshore knuckle boom crane. Appl. Math. Model. 2019, 66, 256–274. [Google Scholar] [CrossRef]

- Moi, T.; Cibicik, A.; Rølvåg, T. Digital twin based condition monitoring of a knuckle boom crane: An experimental study. Eng. Fail. Anal. 2020, 112, 104517. [Google Scholar] [CrossRef]

- Landsverk, R.; Zhou, J.; Hagen, D. Antiswing control and trajectory planning for offshore cranes. In Proceedings of the IECON 2023—49th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 16–19 October 2023; IEEE: Piscataway, NJ, USA, 2023. [Google Scholar]

- Cibicik, A.; Pedersen, E.; Egeland, O. Dynamics of luffing motion of a flexible knuckle boom crane actuated by hydraulic cylinders. Mech. Mach. Theory 2020, 143, 103616. [Google Scholar] [CrossRef]

- Ling, Q.; He, Y.; He, Y.; Pang, C. Dynamic response of multibody structure subjected to blast loading. Eur. J. Mech. A Solids 2017, 64, 46–57. [Google Scholar] [CrossRef]

- Kulka, J.; Mantic, M.; Fedorko, G.; Molnar, V. Analysis of crane track degradation due to operation. Eng. Fail. Anal. 2016, 59, 384–395. [Google Scholar] [CrossRef]

- Augustyn, M.; Barski, M. Estimation of the wind load required to cause the overturning of a gantry crane, comparing different structures of the main horizontal girder. Appl. Sci. 2024, 14, 1092. [Google Scholar] [CrossRef]

- Huh, J.; Nguyen, V.B.; Tran, Q.H.; Ahn, J.H.; Kang, C. Effects of boundary condition models on the seismic responses of a container crane. Appl. Sci. 2019, 9, 241. [Google Scholar] [CrossRef]

- Wang, Z.; Li, S.; Yu, S. Numerical Analysis for Earthquake Response of Polar Crane. IOP Conf. Ser. Earth Environ. Sci. 2021, 719, 042001. [Google Scholar] [CrossRef]

- Solazzi, L.; Tomasi, I. Design of an Overhead Crane in Steel, Aluminium and Composite Material Using the Prestress Method. J. Compos. Sci. 2024, 8, 380. [Google Scholar] [CrossRef]

- Suvorov, V.; Vasilyev, R.; Melnikov, B.; Kuznetsov, I.; Bahrami, M.R. Weight Reduction of a Ship Crane Truss Structure Made of Composites. Appl. Sci. 2023, 13, 8916. [Google Scholar] [CrossRef]

- Gąska, D.; Haniszewski, T. Modelling studies on the use of aluminium alloys in lightweight load-carrying crane structures. Transp. Probl. 2016, 11, 13–20. [Google Scholar] [CrossRef]

- Xiao, J.; Wu, Y.; Long, W.; Xu, C. Failure Analysis of Gantry Crane Slewing Bearing Based on Gear Position Accuracy Error. Appl. Sci. 2022, 12, 11907. [Google Scholar] [CrossRef]

- EN 10025-2; Hot Rolled Products of Structural Steels—Part 2: Technical Delivery Conditions for Non-Alloy Structural Steels. CEN: Brussels, Belgium, 2004.

- Petrović, A.; Ignjatović, D.; Sedmak, S.; Milošević-Mitić, V.; Momčilović, N.; Trišović, N.; Jeremić, L. Model analysis of bucket wheel excavator SchRs 630 strength. Eng. Fail. Anal. 2021, 126, 105451. [Google Scholar] [CrossRef]

- Petrović, A.; Momčilović, N.; Sedmak, A.; Đorđević, B.; Radu, D.; Milošević-Mitić, V.; Bogojević, A. Reliability-based approach for structural integrity assessment of a bucket wheel excavator. Theor. Appl. Fract. Mech. 2025, 136, 104849. [Google Scholar] [CrossRef]

- Popescu, A.M.; Demidenko, O.; Yanushkevich, K.; Donath, C.; Neacsu, E.I.; Constantin, V. Influence of seawater corrosion on structure and magnetic properties of the SR355JR and S355J2 carbon steels. J. Mex. Chem. Soc. 2022, 66, 300–311. [Google Scholar] [CrossRef]

- Solazzi, L.; Zrnić, N. Modal Analysis of Gantry Crane and Superstrucutre Made by Steel and Alluminium Alloy. FME Trans. 2025, 53, 225–232. [Google Scholar] [CrossRef]

- Géradin, M.; Rixen, D.J. Mechanical Vibrations: Theory and Application to Structural Dynamics; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Girard, A.; Roy, N. Structural Dynamics in Industry; John Wiley & Sons: Hoboken, NJ, USA, 2010; Volume 7. [Google Scholar]

- Solazzi, L.; Danzi, N. Dynamic effects on the lattice boom crane due to the wind, moving load and earthquake events. U. Porto J. Eng. 2023, 9, 109–124. [Google Scholar] [CrossRef]

- Solazzi, L. Experimental and analytical study on elevating working platform. Procedia Eng. 2017, 199, 2597–2602. [Google Scholar] [CrossRef]

- Solazzi, L.; Incerti, G.; Petrogalli, C. Estimation of the Dynamic Effect in the Lifting Operations of a Boom Crane. In Proceedings of the 28th European Conference on Modelling and Simulation ©ECMS, Brescia, Italy, 27–30 May 2014. [Google Scholar]

- Solazzi, L.; Zrnic, N. Design of a high capacity derrick crane considering the effects induced by the application and the release of the load. J. Appl. Eng. Sci. 2017, 15, 15–24. [Google Scholar] [CrossRef]

- Hu, S.C.; Zou, N.B.; Ouyang, S.; Zhang, W.Y. Simulation Analysis about Dynamic Characteristics of Crane’s Jib System Based on the Lifting Loads. Adv. Mater. Res. 2014, 910, 304–307. [Google Scholar] [CrossRef]

- Solazzi, L.; Cima, M. Structural dynamics of big gantry crane subjected to different trolley move laws. J. Phys. Conf. Ser. 2019, 1264, 012046. [Google Scholar] [CrossRef]

- Yoon, B.-J.; Lee, K.-S.; Lee, J.-H. Study on overturn proof monitoring system of mobile crane. Appl. Sci. 2021, 11, 6819. [Google Scholar] [CrossRef]

- Toma, S.; Chen, W.F. A Study on Safety Criteria for Toppling of Pile Drivers and Cranes Based on Structural Stability. Arch. Adv. Eng. Sci. 2025, 3, 93–99. [Google Scholar] [CrossRef]

- Solazzi, L.; Assi, A.; Ceresoli, F. Excavator arms: Numerical, experimental and new concept design. Compos. Struct. 2019, 217, 60–74. [Google Scholar] [CrossRef]

| Configuration C1 | |||

| Point | Y [mm] | [mm] | [%] |

| A | −231.44 | 24.73 | 11.96 |

| B | −187.44 | 18.97 | 9.18 |

| C | 24.71 | 24.71 | 11.97 |

| D | −18.96 | 18.96 | 9.17 |

| Configuration C2 | |||

| Point | Y [mm] | [mm] | [%] |

| A | −329.11 | 30.56 | 10.24 |

| B | −274.03 | 24.52 | 8.21 |

| C | 30.56 | 30.56 | 10.24 |

| D | −24.54 | 24.54 | 8.22 |

| Configuration | [Hz] | [Hz] | |

|---|---|---|---|

| C1 | 0.72 | 1.39 | 1.38 |

| C2 | 0.62 | 1.61 | 1.61 |

| Configuration | Without Value of s | With Value of s |

|---|---|---|

| C1 | ||

| C2 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomasi, I.; Solazzi, L. Dynamic Analysis of an Offshore Knuckle-Boom Crane Under Different Load Applications Laws. Appl. Sci. 2025, 15, 8100. https://doi.org/10.3390/app15148100

Tomasi I, Solazzi L. Dynamic Analysis of an Offshore Knuckle-Boom Crane Under Different Load Applications Laws. Applied Sciences. 2025; 15(14):8100. https://doi.org/10.3390/app15148100

Chicago/Turabian StyleTomasi, Ivan, and Luigi Solazzi. 2025. "Dynamic Analysis of an Offshore Knuckle-Boom Crane Under Different Load Applications Laws" Applied Sciences 15, no. 14: 8100. https://doi.org/10.3390/app15148100

APA StyleTomasi, I., & Solazzi, L. (2025). Dynamic Analysis of an Offshore Knuckle-Boom Crane Under Different Load Applications Laws. Applied Sciences, 15(14), 8100. https://doi.org/10.3390/app15148100