Comparative Life Cycle Assessment of Solar Thermal, Solar PV, and Biogas Energy Systems: Insights from Case Studies

Abstract

1. Introduction

2. Methodology

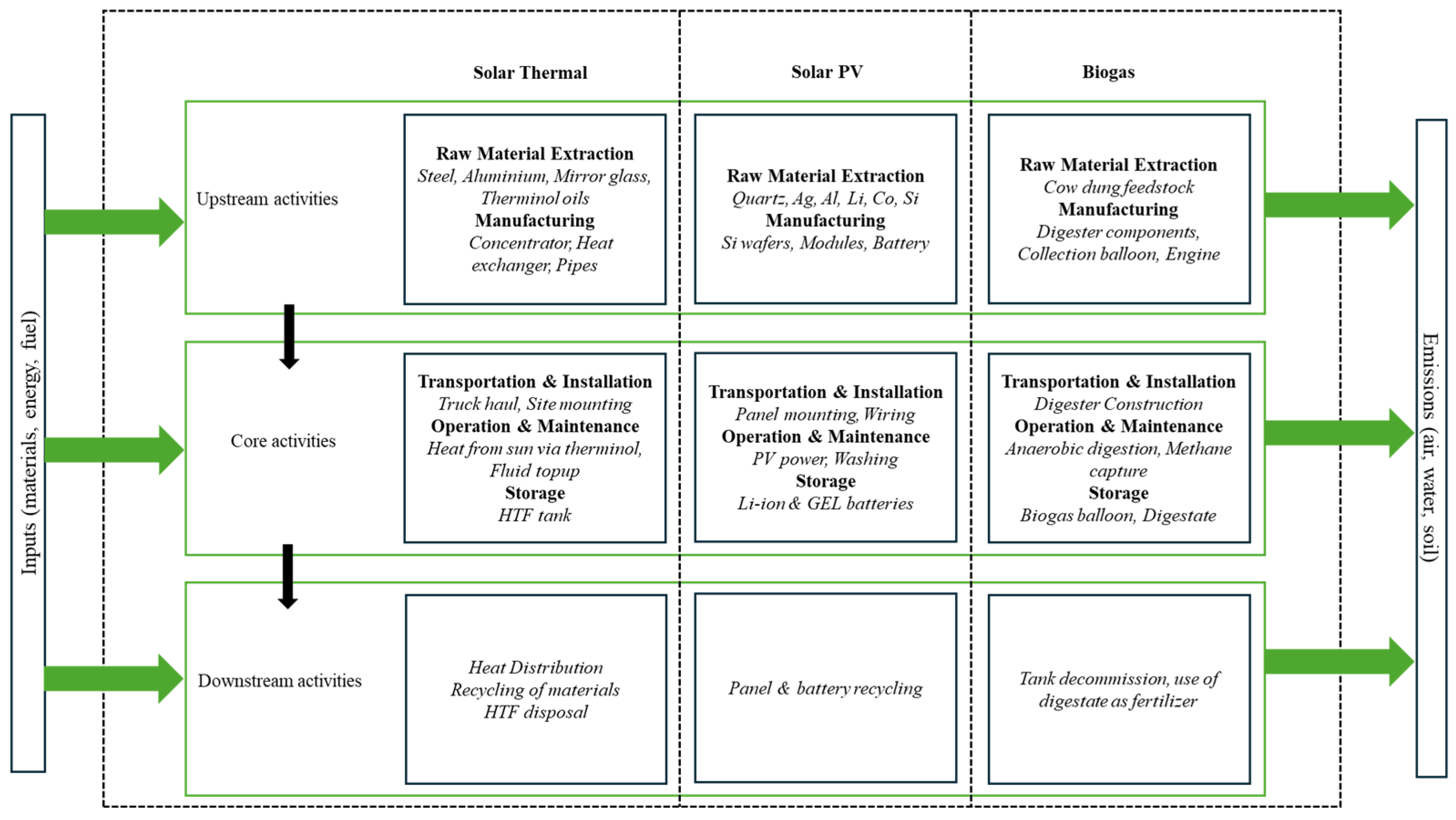

2.1. System Boundaries and Modeling

2.2. Data Sources

2.3. LCA Framework

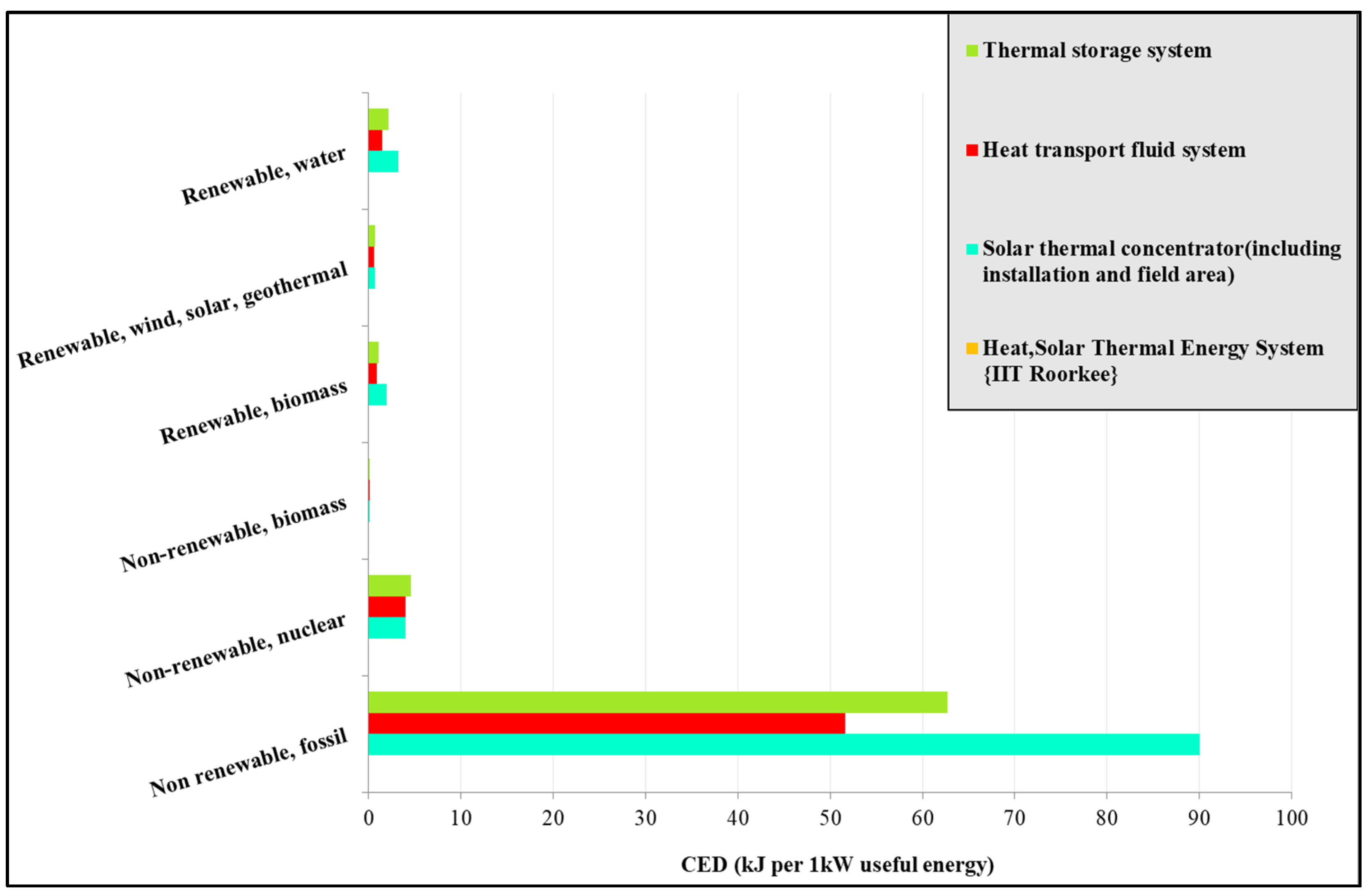

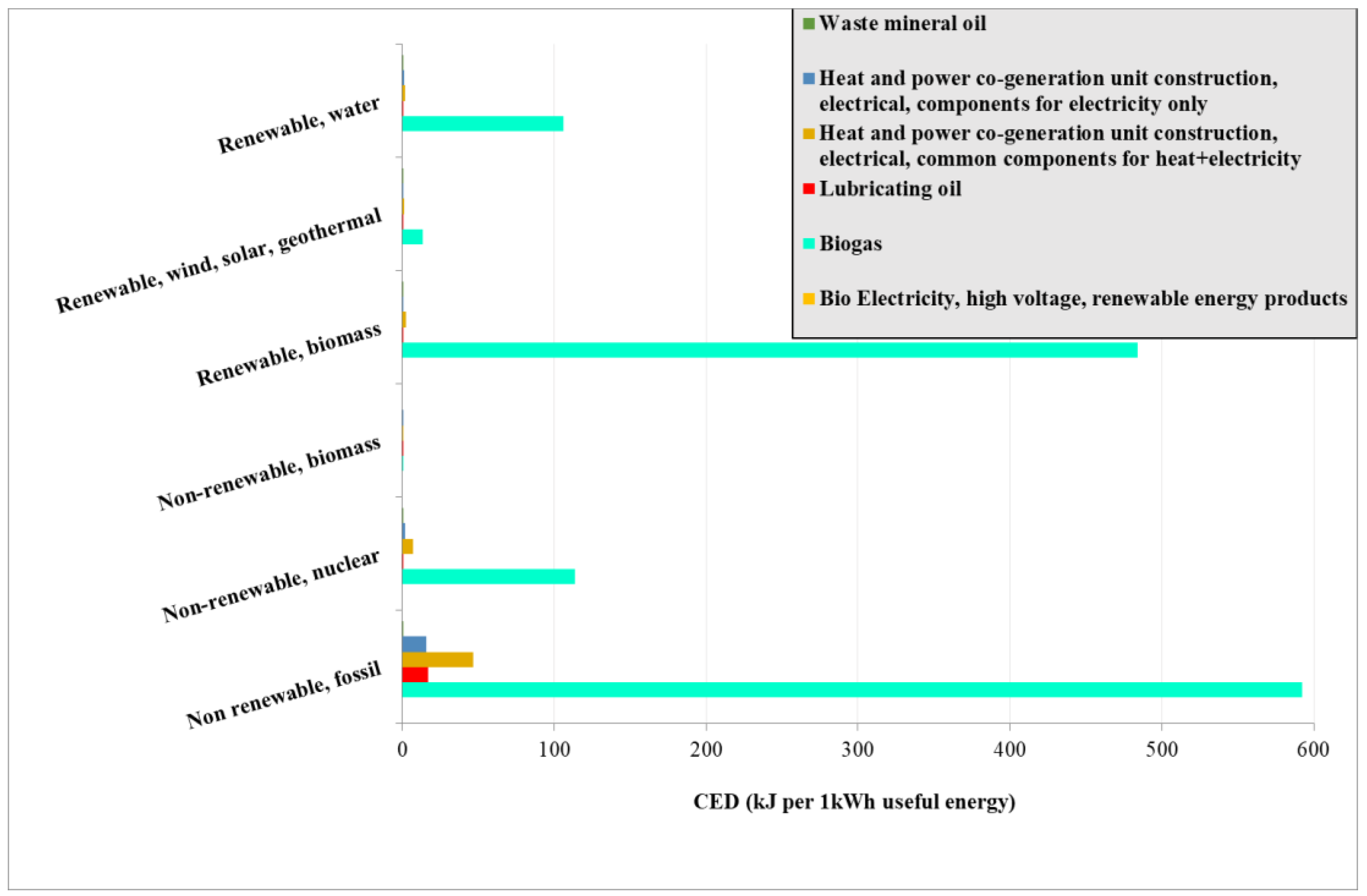

2.4. Cumulative Energy Demand (CED)

2.5. End-of-Life Modeling

3. Case Studies

3.1. Overview of Installation Sites

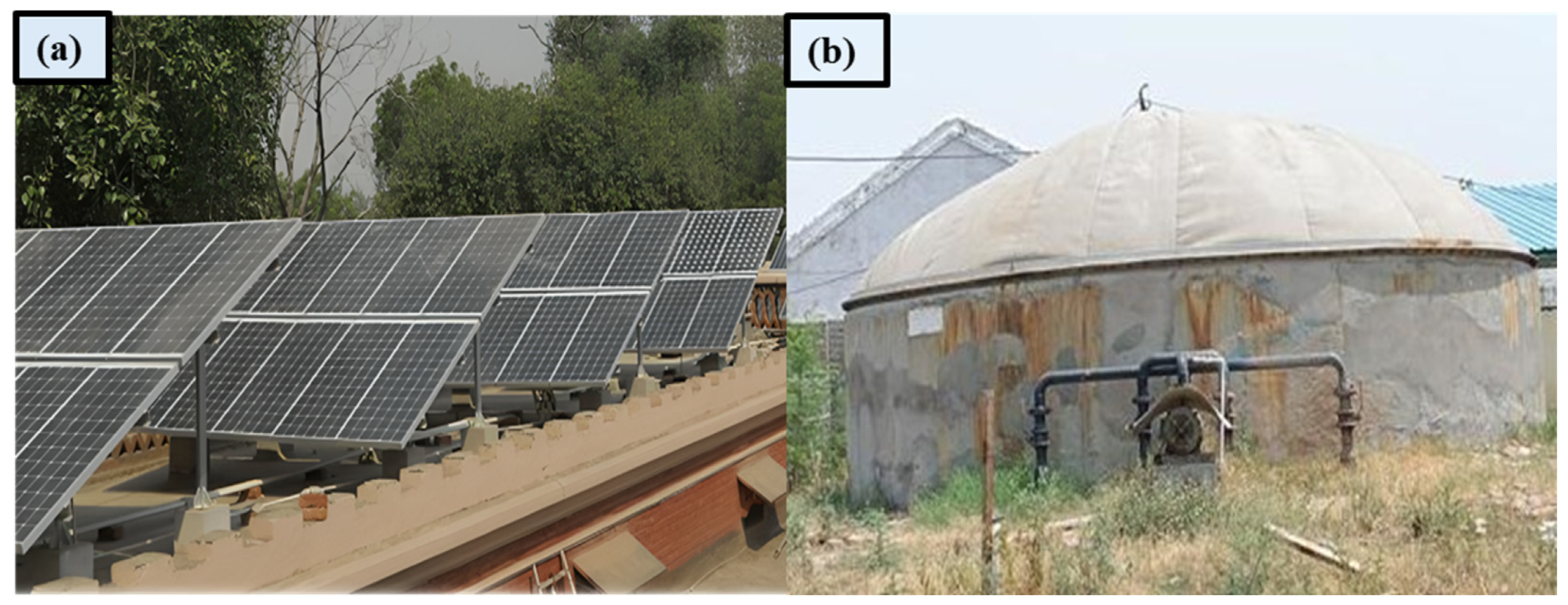

3.1.1. Solar Thermal System at IIT Roorkee

3.1.2. Solar PV and Biogas Power Plant at DEI Agra

3.2. System Specifications

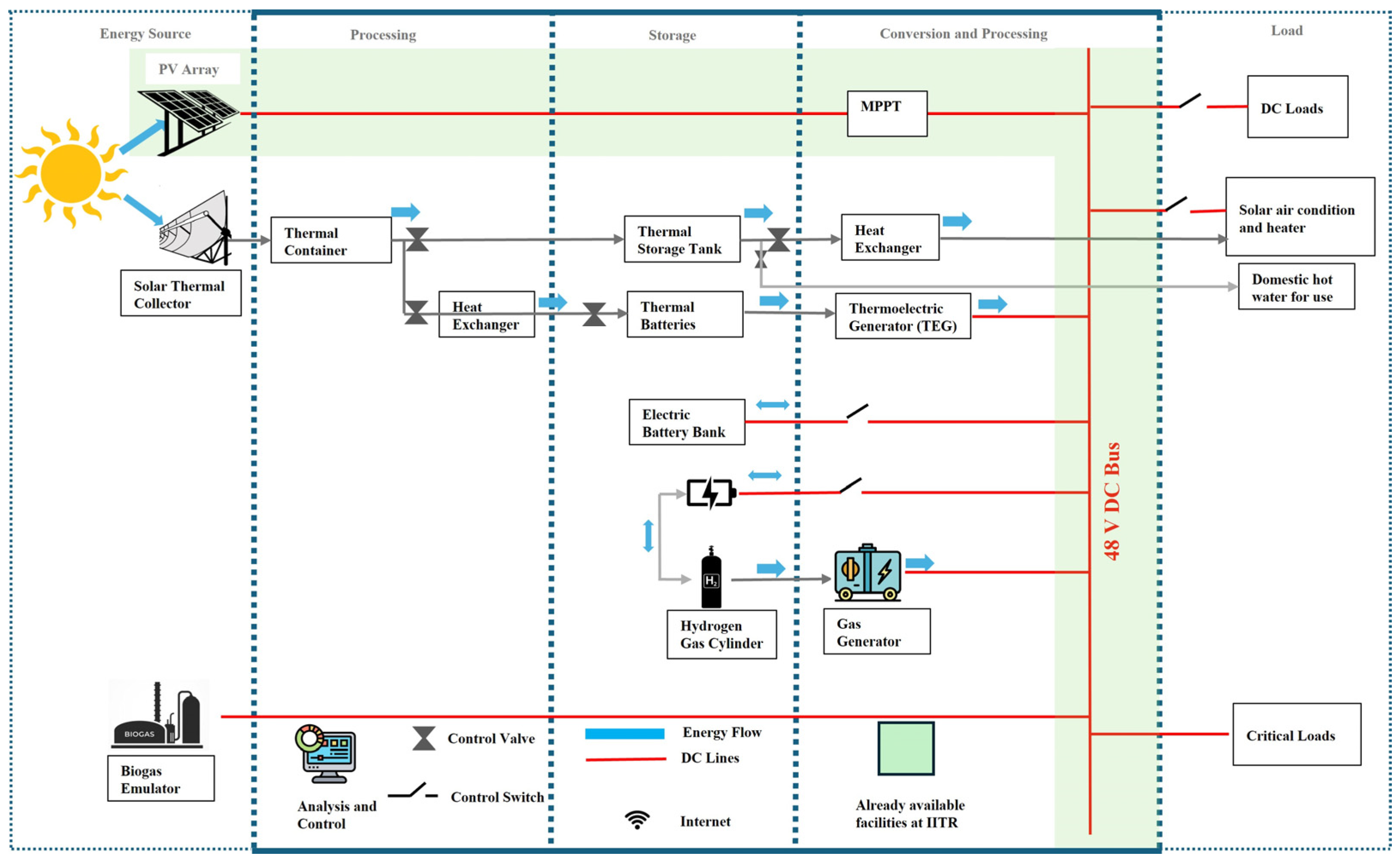

3.3. Integrated Energy Vectors

3.4. Economic Indicators

4. Results and Discussion

4.1. Thermal Energy System

4.1.1. System Advantages and Environmental Benefits

4.1.2. Challenges and Limitations

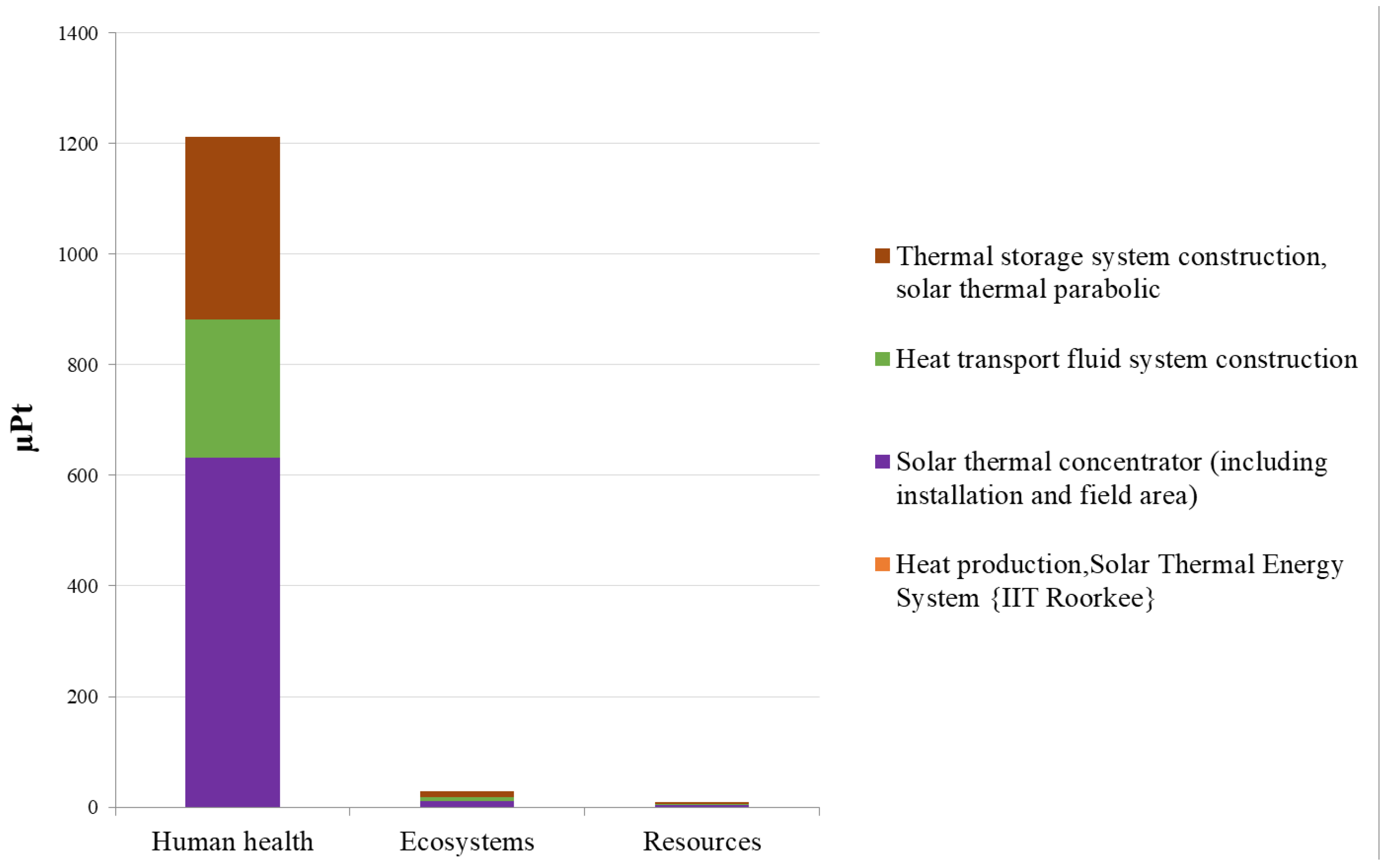

4.1.3. Environmental Impact Analysis

4.2. Electricity Energy System

4.2.1. System Advantages and Environmental Benefits

4.2.2. Challenges and Limitations

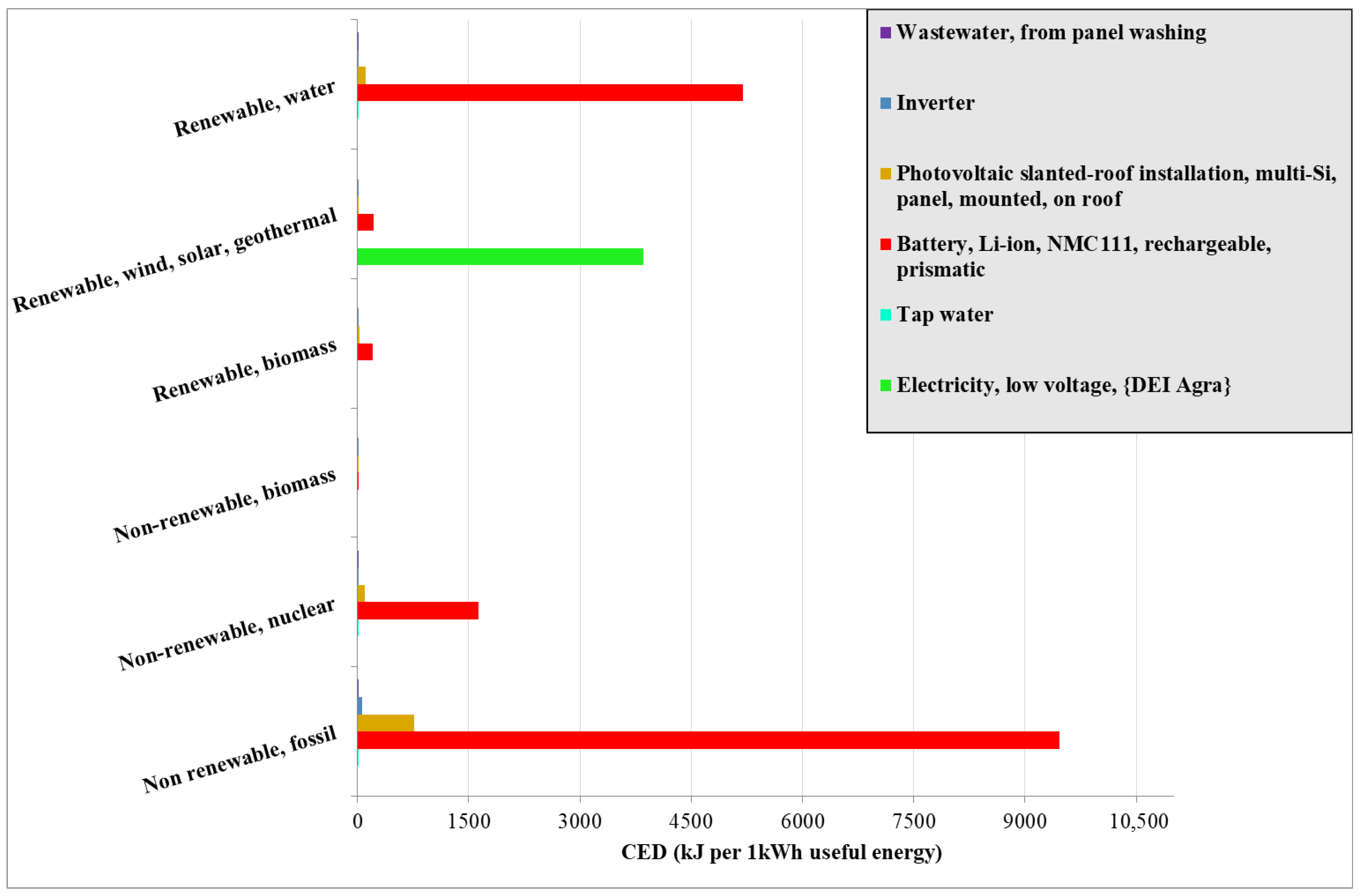

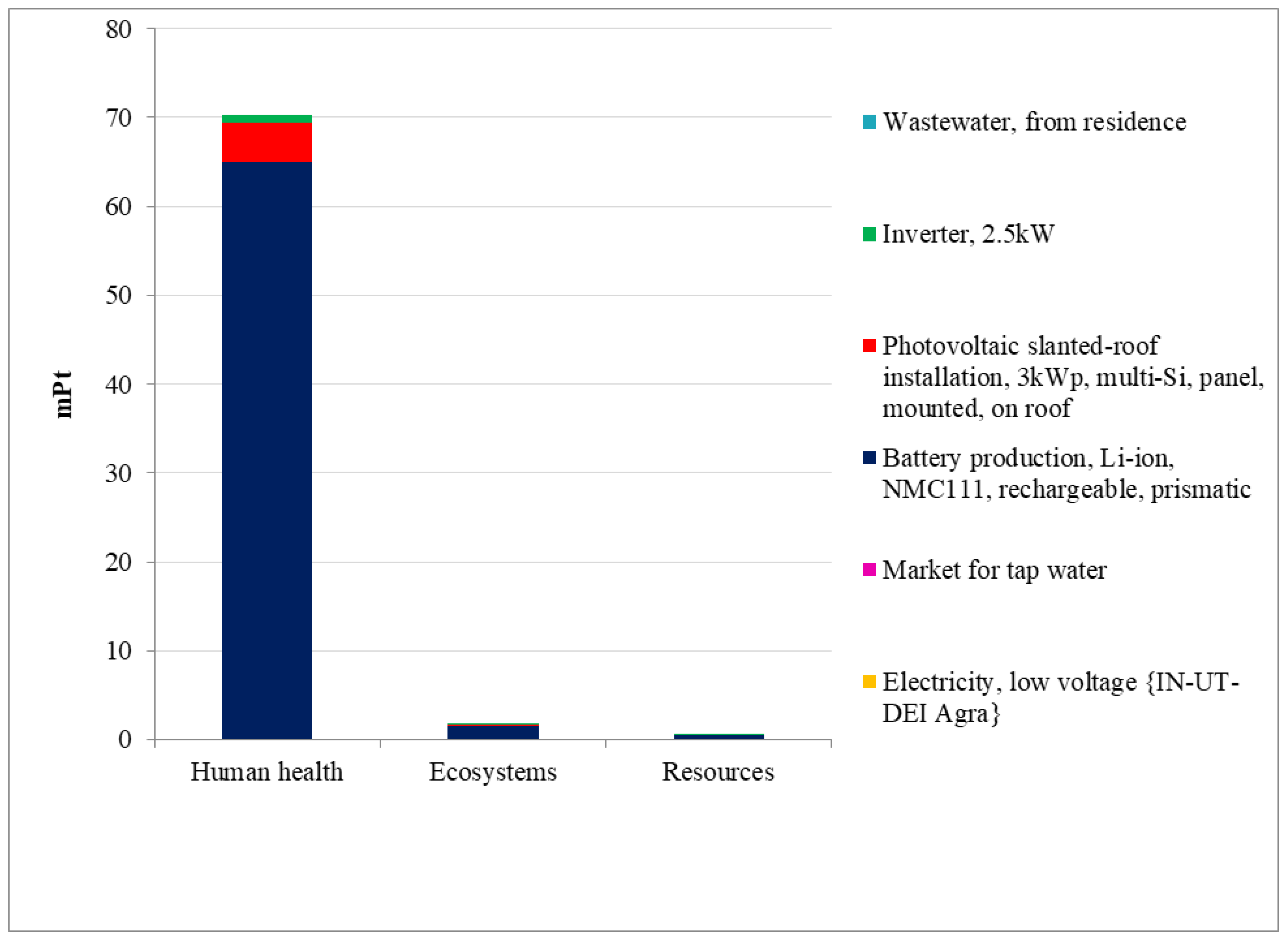

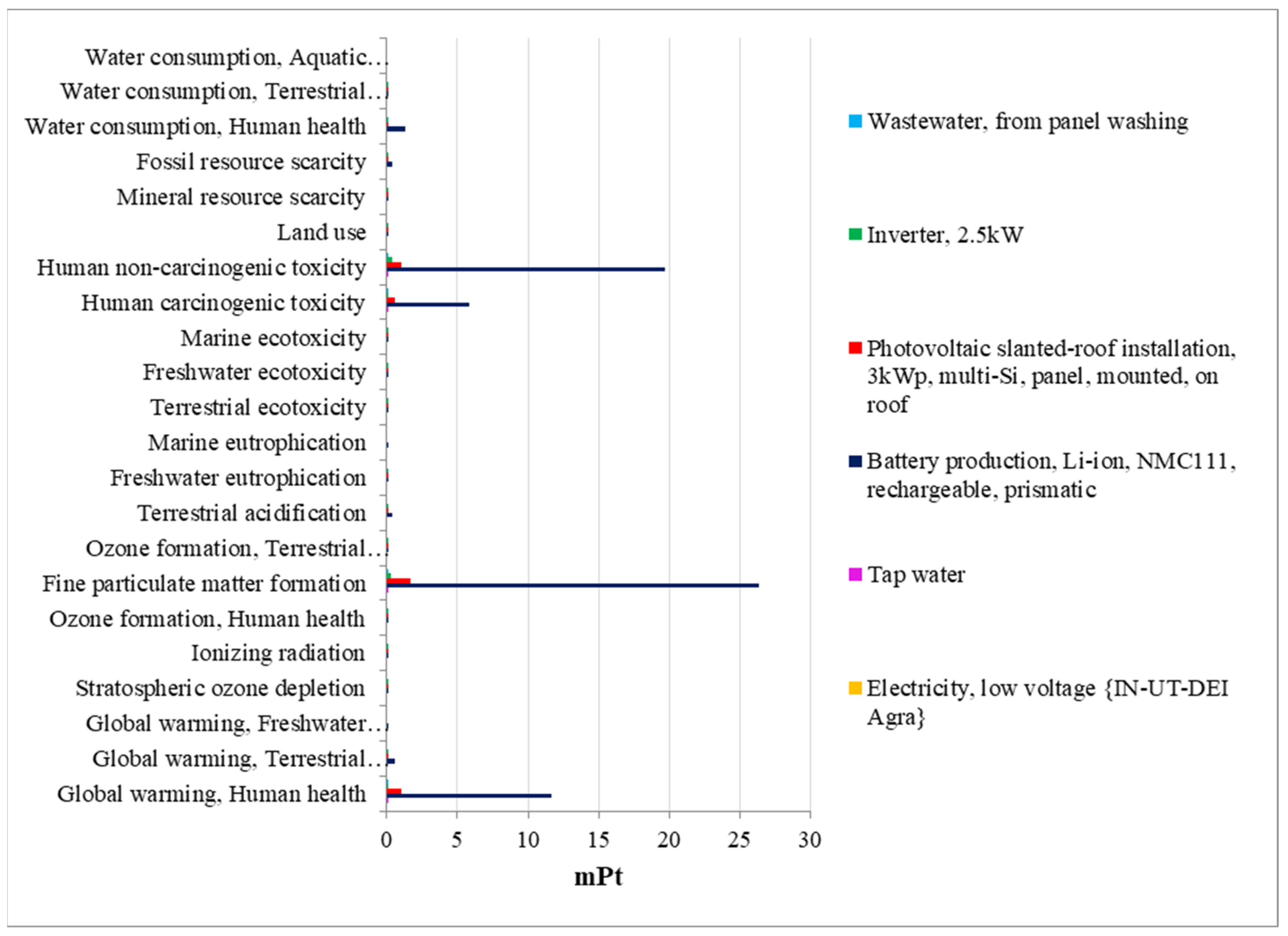

4.2.3. Environmental Impact Analysis

4.3. Bio-Based Electricity Energy System

4.3.1. System Advantages and Environmental Benefits

4.3.2. Challenges and Limitations

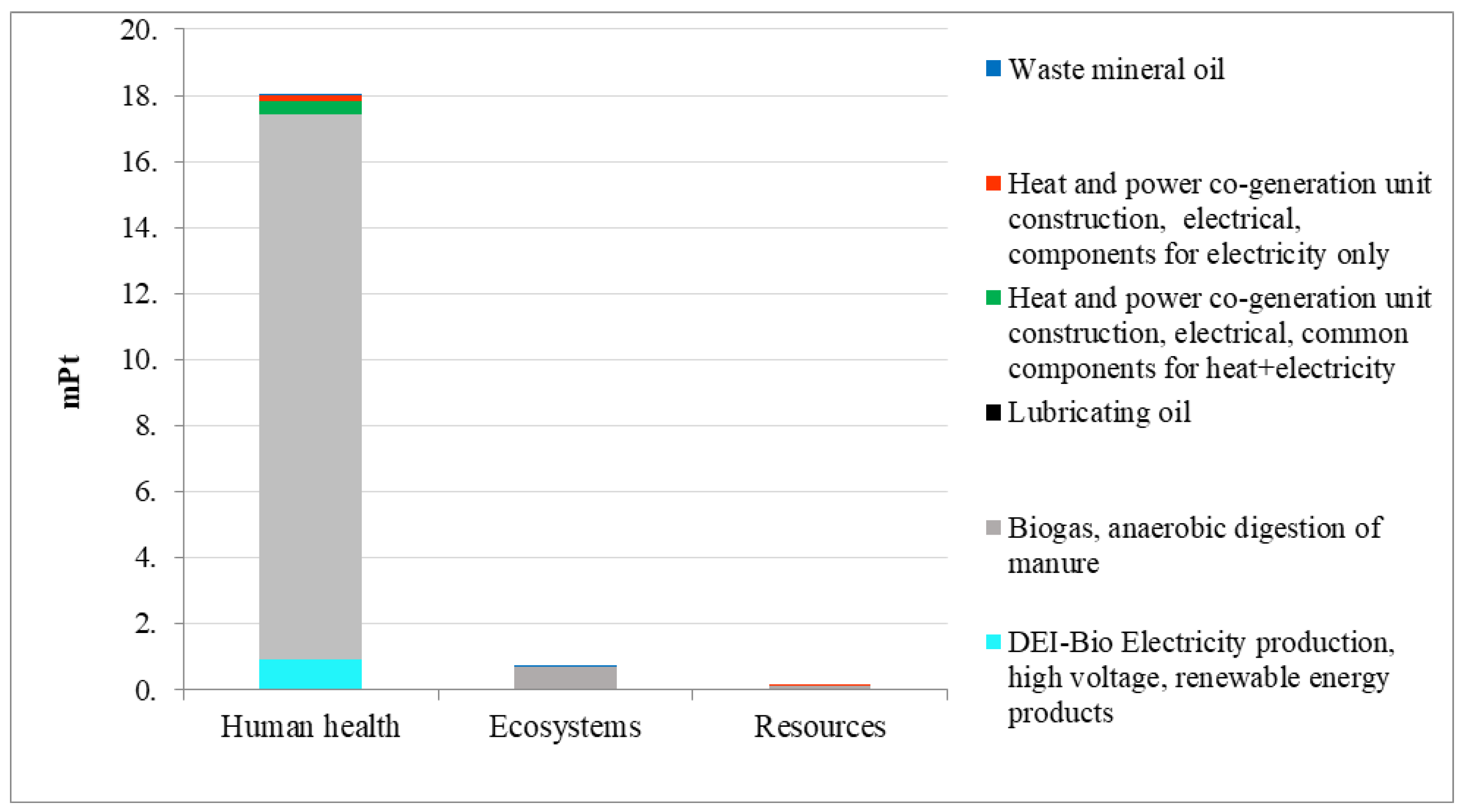

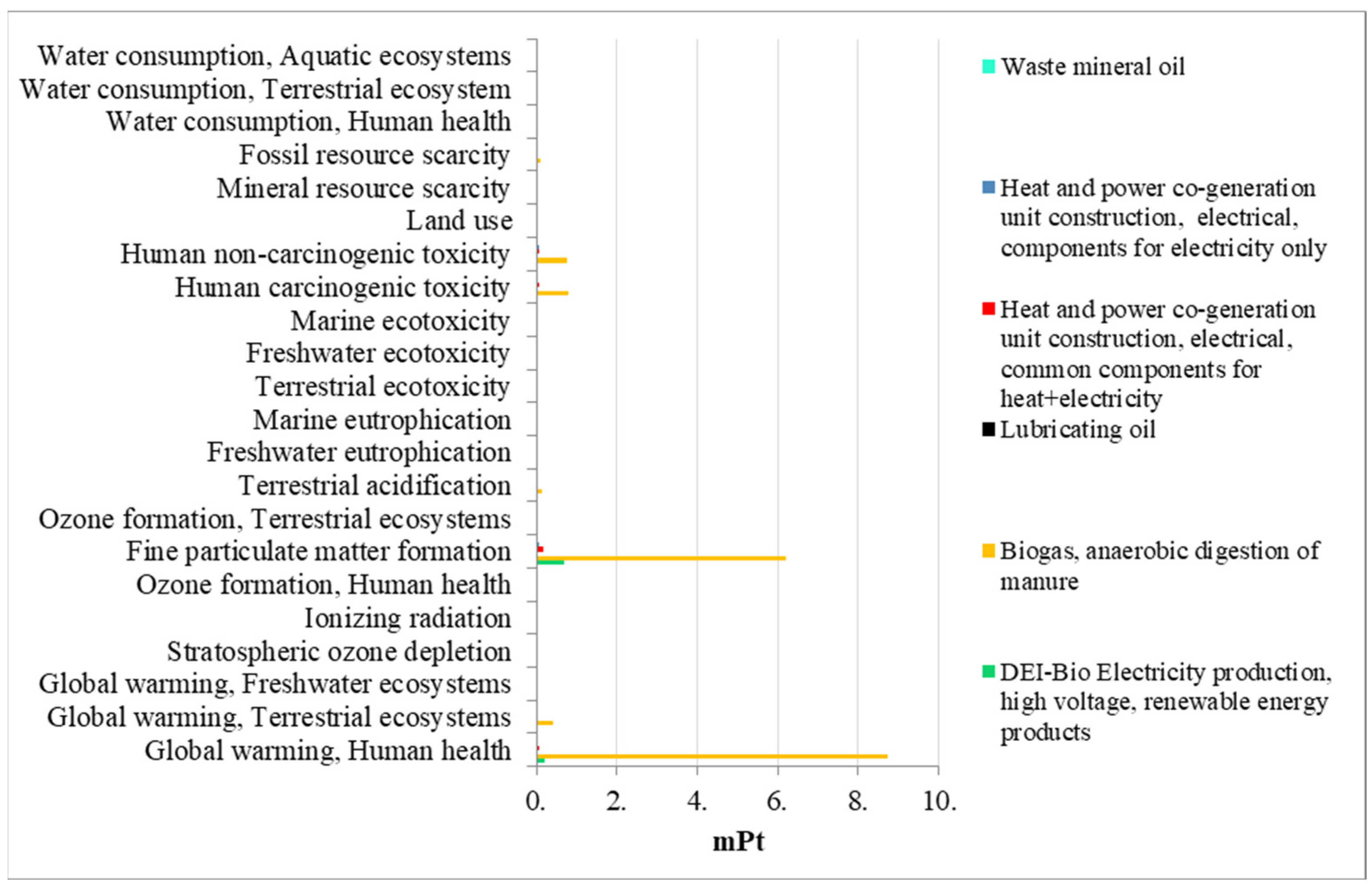

4.3.3. Environmental Impact Analysis

4.4. Comparative Summary and Suitability

Impact of End-of-Life Options on Endpoint Score

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CED | Cumulative Energy Demand |

| LCA | Life Cycle Assessment |

| GHG | Greenhouse Gas |

| CHP | Combined Heat and Power |

| PV | Photovoltaic |

Appendix A

| Impact Categories/Indicators | Relevance |

|---|---|

| Global-warming potential—human health, freshwater, terrestrial (kg CO2-eq) | Dominant climate-forcing emissions from component manufacture and biogas combustion. |

| Stratospheric ozone depletion (kg CFC-11-eq) | Halocarbon use in inverter/BOS cooling and battery-pack HVAC. |

| Ionizing radiation (kBq Co-60-eq) | Nuclear share in background electricity used for upstream silicon, steel and battery production. |

| Ozone formation—human health, terrestrial ecosystems (kg NOX-eq) | NOX/VOC releases from high-temperature glass, steel and silicon processing. |

| Fine particulate-matter formation (kg PM2.5-eq) | Combustion-related PM2.5 from metallurgical energy inputs; key driver of health damage scores. |

| Terrestrial acidification (kg SO2-eq) | SO2 from coal- and oil-fired power that supplies metal smelting and module manufacture. |

| Freshwater eutrophication (kg P-eq) | Phosphorus releases in mining tailings and potential digestate runoff. |

| Marine eutrophication (kg N-eq) | Nitrogen emissions from upstream ammonia production and fertilizer manufacturing chains. |

| Terrestrial, freshwater, marine ecotoxicity (kg 1,4-DCB-eq) | Metal leaching and solvent use in PV, battery and digester construction. |

| Human carcinogenic/non-carcinogenic toxicity (kg 1,4-DCB-eq) | Exposure risks from Co, Ni, Pb and solvent residues in batteries and electronics. |

| Land use (m2·yr crop-eq) | Ground-mount PV area and biomass cropping for digester feedstock. |

| Mineral resource scarcity (kg Cu-eq) | Depletion of Al, Si, Li, Co, Ni, Cu and rare metals in concentrators, modules and batteries. |

| Fossil resource scarcity (kg oil-eq) | Non-renewable primary energy still required for all upstream manufacturing stages. |

| Water consumption—human health, aquatic, terrestrial (m3) | Cooling water for silicon/steel production and periodic panel-washing. |

References

- Saleh, H.M.; Hassan, A.I. The Challenges of Sustainable Energy Transition: A Focus on Renewable Energy. Appl. Chem. Eng. 2024, 7, 2084. [Google Scholar] [CrossRef]

- Yasmeen, H.; Zameer, H. Dynamics of Energy Transition and Climate Actions on Sustainable Cities: A Cross Country Comparison of East Asia and Pacific. Rev. Dev. Econ. 2024, 28, 1319–1344. [Google Scholar] [CrossRef]

- Doļģe, K.; Blumberga, D. From Targets to Action: Analyzing the Viability of REPowerEU in Achieving Energy Sustainability. E3S Web Conf. 2023, 433, 03003. [Google Scholar] [CrossRef]

- Kodirov, D.; Muratov, K.; Tursunov, O.; Ugwu, E.I.; Durmanov, A. The Use of Renewable Energy Sources in Integrated Energy Supply Systems for Agriculture. Iop Conf. Ser. Earth Environ. Sci. 2020, 614, 012007. [Google Scholar] [CrossRef]

- Pappas, C.; Karakosta, C.; Marinakis, V.; Psarras, J. A comparison of electricity production technologies in terms of sustainable development. Energy Convers. Manag. 2012, 64, 626–632. [Google Scholar] [CrossRef]

- Sharma, V.K.; Singh, R.; Gehlot, A.; Buddhi, D.; Braccio, S.; Priyadarshi, N.; Khan, B. Imperative Role of Photovoltaic and Concentrating Solar Power Technologies Towards Renewable Energy Generation. Int. J. Photoenergy 2022, 2022, 3852484. [Google Scholar] [CrossRef]

- Islam, S.M.; Ferdous, S.A.; Bhuyan, A.; Sultana, S.M.; Sarker, S.; Jamal, T. A Techno-Economic Investigation on Hydrogen Utilization as a Long-Term Energy Storage Solution for Microgrids. In Proceedings of the 2021 6th International Conference on Development in Renewable Energy Technology (ICDRET), Dhaka, Bangladesh, 28–30 December 2021. [Google Scholar] [CrossRef]

- Dawood, F.; Shafiullah, G.M.; Anda, M. Stand-Alone Microgrid With 100% Renewable Energy: A Case Study with Hybrid Solar PV-Battery-Hydrogen. Sustainability 2020, 12, 2047. [Google Scholar] [CrossRef]

- Saad, N.M.; Sujod, M.Z.; Ming, L.H.; Abas, M.F.; Jadin, M.S.; Ishak, M.R.; Abdullah, N.R.H. Impacts of Photovoltaic Distributed Generation Location and Size on Distribution Power System Network. Int. J. Power Electron. Drive Syst. 2018, 9, 905. [Google Scholar] [CrossRef]

- Lim, S.-C.; Huh, J.H.; Hong, S.-H.; Park, C.-Y.; Kim, J.-C. Solar Power Forecasting Using CNN-LSTM Hybrid Model. Energies 2022, 15, 8233. [Google Scholar] [CrossRef]

- Kabeyi, M.J.B.; Olanrewaju, O.A. Biogas Production and Applications in the Sustainable Energy Transition. J. Energy 2022, 2022, 1–43. [Google Scholar] [CrossRef]

- Kurşun, B. Production and Utilization Stage Analysis of Biogas: Case of IZAYDAS Plant. Marmara Fen Bilim. Derg. 2018, 30, 111–118. [Google Scholar] [CrossRef]

- Zhou, B.; Xu, D.; Li, C.; Chung, C.Y.; Cao, Y.; Chan, K.W.; Wu, Q. Optimal Scheduling of Biogas–Solar–Wind Renewable Portfolio for Multicarrier Energy Supplies. IEEE Trans. Power Syst. 2018, 33, 6229–6239. [Google Scholar] [CrossRef]

- Chang, C.C.; Do, M.V.; Hsu, W.L.; Liu, B.-L.; Chang, C.Y.; Chen, Y.H.; Yuan, M.-H.; Lin, C.F.; Yu, C.-P.; Chen, Y.H.; et al. A Case Study on the Electricity Generation Using a Micro Gas Turbine Fuelled by Biogas from a Sewage Treatment Plant. Energies 2019, 12, 2424. [Google Scholar] [CrossRef]

- IEA-PVPS. Life-Cycle Assessment of Photovoltaic Systems: 2024 Update; IEA-PVPS Secretariat: Paris, France, 2024. [Google Scholar]

- International Renewable Energy Agency. Solar Thermal Energy—Technology Brief 2023; IRENA: Abu Dhabi, United Arab Emirates, 2023.

- MNRE. Biogas Power Generation and Thermal Application Programme—Revised Guidelines 2024; Government of India: New Delhi, India, 2024.

- Philipps, S.; Warmuth, W. Photovoltaics Report; Fraunhofer-Institut für Solare Energiesysteme ISE & PSE Projects GmbH: Freiburg, Germany, 2024. [Google Scholar]

- Cummins, I. QSK19G Series Biogas Generator Set—Technical Datasheet; Cummins Inc.: Columbus, IN, USA, 2023. [Google Scholar]

- ISO 14044: 2006 + A1:2020; Environmental Management—Life-Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2020.

- Fraunhofer ISE. Battery Lifetime Analysis Under Real-World Cycling: 2024 Update; Fraunhofer ISE: Freiburg, Germany, 2024. [Google Scholar]

- BYD. B-Box LV Battery System—Installation and User Manual, Rev. 2024-03; BYD: Shenzhen, China, 2024. [Google Scholar]

- ISO 14044: 2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- SimaPro. SimaPro Database Manual—Methods Library; PRé Sustainability: Amersfoort, The Netherlands, 2020. [Google Scholar]

- Ecoinvent, A. Ecoinvent Database, version 3.9.1; Ecoinvent Association: Zurich, Switzerland, 2022. [Google Scholar]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.D.M.; Hollander, A.; Zijp, M.; van Zelm, R. ReCiPe 2016 v1.08: A Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level; RIVM Report 2016-0104a; National Institute for Public Health and the Environment (RIVM): Bilthoven, The Netherlands, 2016.

- RenewSys India Pvt. Ltd. PV-Glass Recycling Plant: Press Release and Technical Overview; RenewSys: Hyderabad, India, 2023. [Google Scholar]

- Attero CleanTech Pvt. Ltd. Li-Ion Battery Hydrometallurgical Recycling Facility—Capacity Statement; Attero CleanTech: Noida, India, 2024. [Google Scholar]

- MoEfcc. Draft E-Waste (Management) Rules, 2024; MoEfcc: New Delhi, India, 2024.

- Kalidoss, P.; Venkatachalapathy, S.; Suresh, S. Optical and Thermal Properties of Therminol 55-TiO2 Nanofluids for Solar Energy Storage. Int. J. Photoenergy 2020, 2020, 7085497. [Google Scholar] [CrossRef]

- Attar, I.; Naïli, N.; Farhat, A. A Heating System Using Flat Plate Collectors to Control the Inside Greenhouse Microclimate in Tunisia. J. Renew. Energ. 2023, 15, 547–559. [Google Scholar] [CrossRef]

- Crespo, B.; Cavanaugh, C.; Potter, A.; Yaniger, S.; Gaustad, G.; Wilkinson, C.J. Technoeconomic Feasibility of Photovoltaic Recycling. Int. J. Appl. Glass Sci. 2024, 15, 381–390. [Google Scholar] [CrossRef]

- Zeng, Q.; Lai, Y.; Jiang, L.; Liu, F.; Hao, X.; Wang, L.; Green, M.A. Integrated Photorechargeable Energy Storage System: Next-Generation Power Source Driving the Future. Adv. Energy Mater. 2020, 10, 1903930. [Google Scholar] [CrossRef]

- Essak, L.; Ghosh, A. Floating Photovoltaics: A Review. Clean Technol. 2022, 4, 752–769. [Google Scholar] [CrossRef]

- Urbina, A. Sustainability of Photovoltaic Technologies in Future Net-zero Emissions Scenarios. Prog. Photovolt. Res. Appl. 2022, 31, 1255–1269. [Google Scholar] [CrossRef]

- Lennon, A.; Lunardi, M.M.; Hallam, B.; Dias, P. The Aluminium Demand Risk of Terawatt Photovoltaics for Net Zero Emissions by 2050. Nat. Sustain. 2022, 5, 357–363. [Google Scholar] [CrossRef]

- Shrestha, N.; Zaman, A. Decommissioning and Recycling of End-of-Life Photovoltaic Solar Panels in Western Australia. Sustainability 2024, 16, 526. [Google Scholar] [CrossRef]

- Aichberger, C.; Jungmeier, G. Environmental Life Cycle Impacts of Automotive Batteries Based on a Literature Review. Energies 2020, 13, 6345. [Google Scholar] [CrossRef]

- Boussaa, S.A.; Benkrid, A.; Boutarek, N.; Ayachi, M. End of Life Silicon Based Photovoltaic Panels: A Review. J. Renew. Energ. 2020, 23, 201–216. [Google Scholar] [CrossRef]

- Akhter, M.S.; Mansur, A.A.; Islam, M.I.; Lipu, M.S.H.; Karim, T.F.; Abdolrasol, M.G.M.; Alghamdi, T.A.H. Sustainable Strategies for Crystalline Solar Cell Recycling: A Review on Recycling Techniques, Companies, and Environmental Impact Analysis. Sustainability 2024, 16, 5785. [Google Scholar] [CrossRef]

- Omar, A.; Seilkhan, Z.; Bissembayeva, G.; González-Rodríguez, O.; Rojas–Solórzano, L. The Circular Economy Approach to Evaluating End-of-life Cost Alternatives of Solar PV Panels: The Case of Burnoye-1, Kazakhstan. Environ. Prog. Sustain. Energy 2022, 42, e13948. [Google Scholar] [CrossRef]

- Madrigal, A.N.; Iyer-Raniga, U.; Yang, R.L. Exploring Design Thinking Processes in Circular Economy Strategies for PV Waste Management in Australia. Iop Conf. Ser. Earth Environ. Sci. 2024, 1363, 012051. [Google Scholar] [CrossRef]

- Lunardi, M.M.; Alvarez–Gaitan, J.P.; Bilbao, J.I.; Corkish, R. Comparative Life Cycle Assessment of End-of-Life Silicon Solar Photovoltaic Modules. Appl. Sci. 2018, 8, 1396. [Google Scholar] [CrossRef]

- Farghali, M.; Osman, A.I.; Umetsu, K.; Rooney, D.W. Integration of biogas systems into a carbon zero and hydrogen economy: A review. Environ. Chem. Lett. 2022, 20, 2853–2927. [Google Scholar] [CrossRef]

- Kamiluddin, M.M.; Budianto, E.; Frimawaty, E. The Financial Analysis for the Advisability of the Biogas Project from Cattle Manure in Household Scale. E3S Web Conf. 2018, 74, 03004. [Google Scholar] [CrossRef]

- Barbosa, D.B.P.; Nabel, M.; Jablonowski, N.D. Biogas-Digestate as Nutrient Source for Biomass Production of Sida Hermaphrodita, Zea mays L. and Medicago sativa L. Energy Procedia 2014, 59, 120–126. [Google Scholar] [CrossRef]

- Dasí-Crespo, D.; Carcerller-Toselli, A.; Blay, C.R.; Escrivá-Escrivà, G.; Porta, C.R. Design and Implementation of a Biogas Pilot Plant for Bioaugmentation Strategies in a Rural Municipality. Renew. Energy Power Qual. J. 2024, 22, 17–22. [Google Scholar] [CrossRef] [PubMed]

- Porta, C.R.; Blay, C.R.; Dasí-Crespo, D.; Escrivá-Escrivà, G. Optimising a Biogas and Photovoltaic Hybrid System for Sustainable Power Supply in Rural Areas. Appl. Sci. 2023, 13, 2155. [Google Scholar] [CrossRef]

- Li, Y.; Alaimo, C.P.; Kim, M.; Kado, N.Y.; Peppers, J.; Xue, J.; Wan, C.; Green, P.G.; Zhang, R.; Jenkins, B.M.; et al. Composition and Toxicity of Biogas Produced from Different Feedstocks in California. Environ. Sci. Technol. 2019, 53, 11569–11579. [Google Scholar] [CrossRef] [PubMed]

- Paolini, V.; Petracchini, F.; Segreto, M.; Tomassetti, L.; Naja, N.; Cecinato, A. Environmental Impact of Biogas: A Short Review of Current Knowledge. J. Environ. Sci. Health Part A 2018, 53, 899–906. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Cao, X.; Jiao, L. PEM Water Electrolysis for Hydrogen Production: Fundamentals, Advances, and Prospects. Carbon Neutrality 2022, 1, 21. [Google Scholar] [CrossRef]

- Gantenbein, A.; Kröcher, O.; Biollaz, S.M.; Schildhauer, T.J. Techno-Economic Evaluation of Biological and Fluidised-Bed Based Methanation Process Chains for Grid-Ready Biomethane Production. Front. Energy Res. 2022, 9, 775259. [Google Scholar] [CrossRef]

- Uday, V.; Jogwar, S.S. Optimal Design of an Integrated Biogas-Based Fuel Cell System. Ind. Eng. Chem. Res. 2024, 63, 4496–4508. [Google Scholar] [CrossRef]

- Liu, J.; Huang, L.; Leveneur, J.; Fiedler, H.; Clarke, S.; Larsen, T.; Kennedy, J.; Taylor, M.P. Experimental Investigation of PEM Water Electrolyser Stack Performance Under Dynamic Operation Conditions. J. Electrochem. Soc. 2024, 171, 054521. [Google Scholar] [CrossRef]

| Parameter | Solar PV (150 kWp, BHEL 300 W) | Solar-Thermal CPC (3.5 kW Dish) | Biogas CHP (4 kWe) | Data Source |

|---|---|---|---|---|

| Component lifetime (yr) | 25 | 20 | 15 | O&M logs; [15,16,17] |

| Conversion efficiency | 17% | 42% | 32% | On-site; [18,19] |

| Emission factor (g CO2-eq/kWh) | 600 | 50 | 200 | SimaPro Model Output |

| Allocation method | Mass-based (mounting steel) | Energy content | Energy content | [20] |

| Battery depth-of-discharge | 80% | – | – | [21,22] |

| Metric | Electrical | Thermal Storage System | Biogas |

|---|---|---|---|

| Source | Solar Panel (300 W rated (BHEL)) A total of 150 kW generation is achieved according to operating conditions. | One Solar thermal Concentrator: 3.5 kW per Dish @1000 W/m2 Irradiation and 25 °C Ambient, Dish area: 4.4 m2 Base material: Steel Receiver material: Aluminum (90 mm dia) | Cow dung 25 ton |

| Intermediate systems |

Input Grid—190–270v at 50 Hz Solar maximum PV voltage (VOC)—600 v Output 230 v @ 50 Hz

Input 3 phase 415 AC volts at 50 Hz DC 240 volts, PV charger of 100 kW capacity, Output Peak load capacity—200 kW | Heat Exchanger: Liquid evaporator Type: Plate heat exchanger Fluid 1: Water Fluid 2: Therminol Efficiency: 90% Insulated Intermediate pipe: Cast iron Pressure drop: 1.25 kPa The total weight (no connections): 4 kg | Biogas digester 150 m3 capacity |

| Storage | Battery— (i) Lithium-ion battery bank- Rated power—20 kW Rated voltage—240 VDC Rated energy—48 kWh + 3% (ii) Exide SG500 LM Tubular GEL Batteries of 2 Volts 250 AH | Thermal Energy storage Type: Sensible thermalstorage system Size: 2 m3 (200 L) MOC: SS Insulation material: glass wool Capacity:32 MJ or 8.8 kWh (max storage temperature 200 °C Min storage temp 110 °C Storage media: Thermic Fluid Therminol 55 Portable Thermal Energy storage Size: 04 m3 (40 L) Insulation material: Aerogel (max storage temperature 180 °C Min storage temp 40 °C Storage media: Thermic Fluid Therminol 55 | Biogas balloon Max Volume—100 m3 Plan capacity of 50 m3 Total storage is 150 m3 |

| Load | 100 kW for all classrooms | Steam Cooking: Total steam required for cooking 8.5 kg (100 people per meal) 1 kwh = 1 kg steam Approx Space heating: 3 kWh | 5 kVA (4 kW) biogas generator Rated current/phase at 100% load—18.50 Amp 1 m3 Biogas generates around 1.4 kWh |

| System | CAPEX Items | Amount (INR) | LCOE (INR/kWh) |

|---|---|---|---|

| Solar PV (rooftop, 150 kWp, 300 W BHEL modules) | 500 × 300 W modules—3 × 50 kVA DSP Grid-Support Conditioners (inverters/UPS)—3 × 240 V, 150 Ah OPzS battery strings | ≈44.1 million (≈2.94 lakh/kWp) | 2.4 |

| Solar-thermal CPC dish (3.5 kW, 4.4 m2 aperture) | Steel paraboloid structure, aluminum receiver tube Ø 90 mm single-axis tracker and mount | 37,400 per dish (MNRE benchmark) to ≈2.8 lakh (hostel cooking system analogue) | 3.3 |

| Biogas CHP set (pilot, 4 kWe) | 5 kVA biogas genset (Indo Engineering Works) | 90,000 | 4.1 |

| Digester balloon replacement (Ø: 7 m, H: 2 m) | Thermoplastic membrane + fittings | 179,000 |

| Metric | Solar Thermal | Solar PV | Biogas |

|---|---|---|---|

| GHG Emissions | Moderate (0.6 kg CO2-eq/kWh) | Very low (0.05 kg CO2-eq/kWh) | Low-to-moderate (0.2 kg CO2-eq/kWh) |

| CED | 230 kJ primary/kWh | 21,700 kJ primary/kWh | 1406 kJ primary/kWh |

| Life cycle damage | 1.25 mPt/kWh | 72.45 mPt/kWh | 18.8 mPt/kWh |

| Reliability | Dependent on solar irradiance, Storage needed for night or low sun. | Weather-dependent, Battery backup helps, but adds cost. | Feedstock-dependent, Consistent supply of organic waste required. |

| Pollutants and Waste | Minimal direct emissions in operation, Used Therminol fluid disposal. | Minimal direct emissions, E-waste from panel disposal. | Methane leakage (high global warming potential), H2S, NH3 in digestate; digestate reuse. |

| Scenario | Treatment Route | PV Modules (mPt/kWh) | Li-Ion Batteries (mPt/kWh) |

|---|---|---|---|

| BAS | Engineered landfill | 0.031 | 0.012 |

| OLR | Glass- and aluminum-only recovery | 0.018 (−41%) | — |

| CLR | Full hydrometallurgical recycling | 0.014 (−55%) | 0.005 (−58%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thakur, S.; Singh, D.; Mughal, U.N.; Kumar, V.; Calay, R.K. Comparative Life Cycle Assessment of Solar Thermal, Solar PV, and Biogas Energy Systems: Insights from Case Studies. Appl. Sci. 2025, 15, 8082. https://doi.org/10.3390/app15148082

Thakur S, Singh D, Mughal UN, Kumar V, Calay RK. Comparative Life Cycle Assessment of Solar Thermal, Solar PV, and Biogas Energy Systems: Insights from Case Studies. Applied Sciences. 2025; 15(14):8082. https://doi.org/10.3390/app15148082

Chicago/Turabian StyleThakur, Somil, Deepak Singh, Umair Najeeb Mughal, Vishal Kumar, and Rajnish Kaur Calay. 2025. "Comparative Life Cycle Assessment of Solar Thermal, Solar PV, and Biogas Energy Systems: Insights from Case Studies" Applied Sciences 15, no. 14: 8082. https://doi.org/10.3390/app15148082

APA StyleThakur, S., Singh, D., Mughal, U. N., Kumar, V., & Calay, R. K. (2025). Comparative Life Cycle Assessment of Solar Thermal, Solar PV, and Biogas Energy Systems: Insights from Case Studies. Applied Sciences, 15(14), 8082. https://doi.org/10.3390/app15148082