Effect of Apple, Chestnut, and Acorn Flours on the Technological and Sensory Properties of Wheat Bread

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Materials

2.2. Preparation of Flour from Acorns, Chestnuts, and Apples

2.3. Colour Measurement

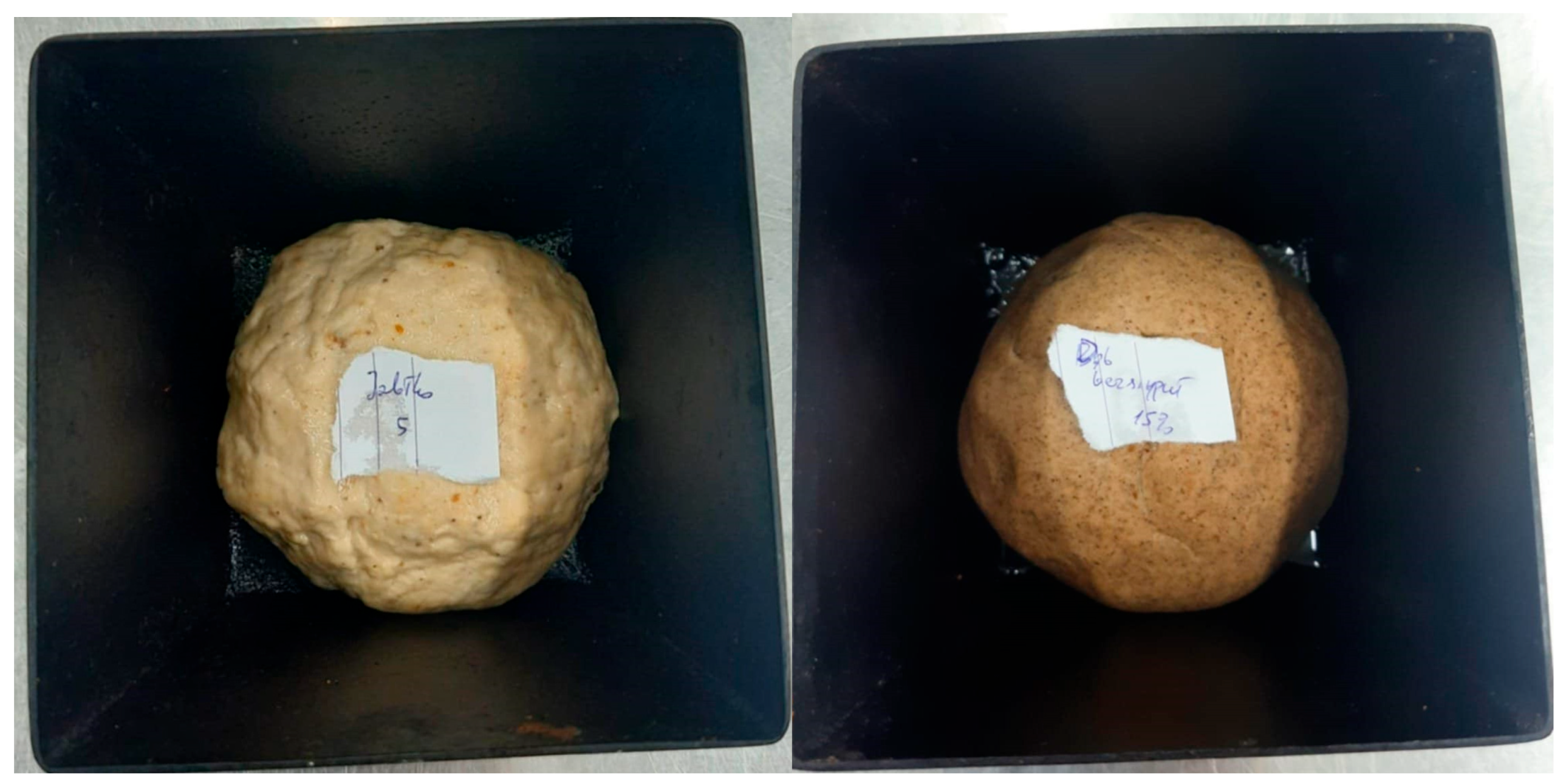

2.4. Laboratory Bread Baking

- -

- Red oak (Quercus rubra);

- -

- Pedunculate oak (Q. robur);

- -

- Sessile oak (Q. petraea);

- -

- Horse chestnut (Aesculus hippocastanum);

- -

- Sweet chestnut (Castanea sativa);

- -

- A traditional apple cultivar (Malus domestica cv. Oberländer Himbeerapfel).

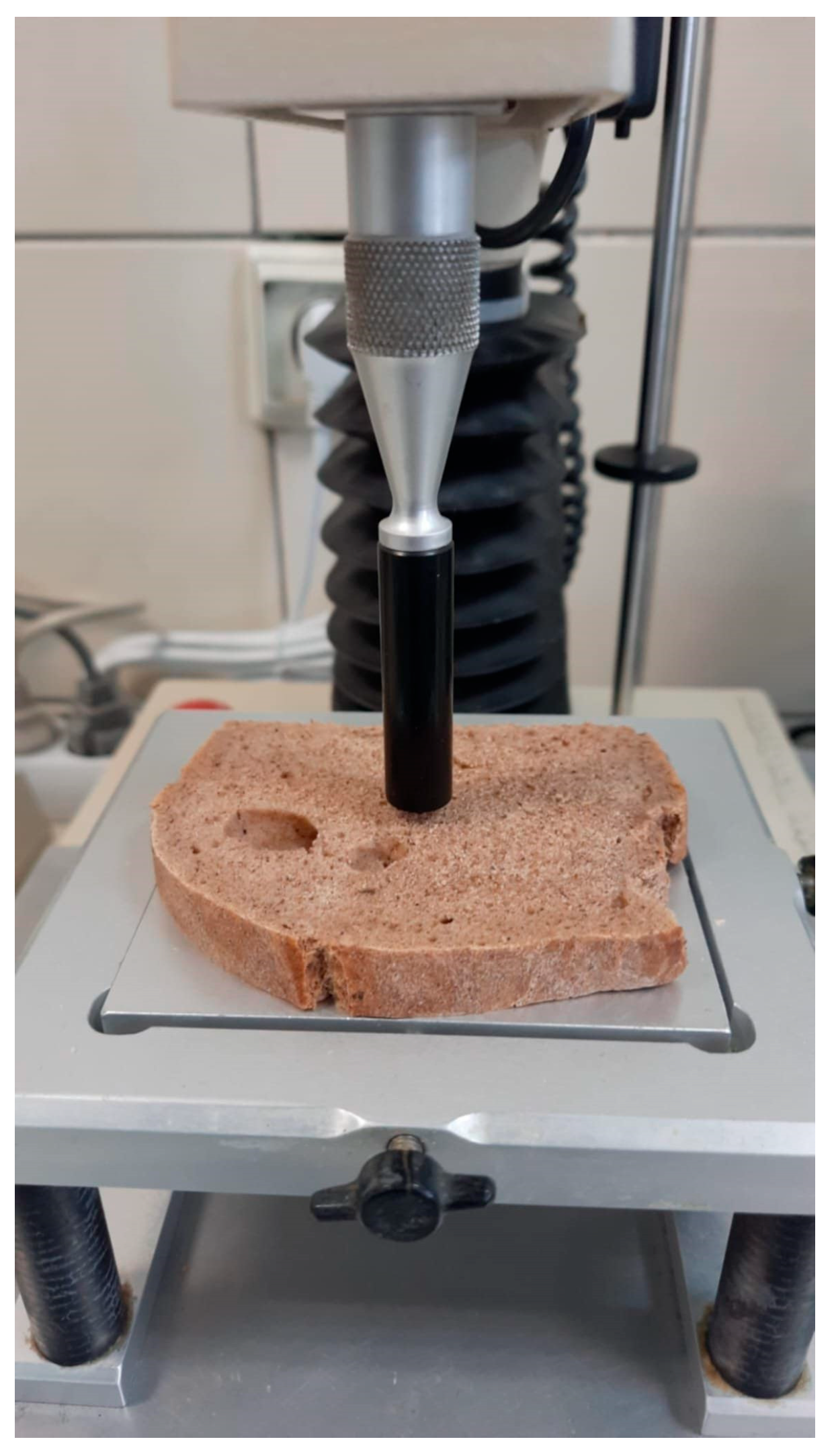

2.5. Instrumental Texture Analysis of Bread

2.6. Sensory Evaluation

- 1 = very poor;

- 2 = poor;

- 3 = acceptable;

- 4 = good;

- 5 = very good.

2.7. Statistical Analysis

3. Results and Discussion

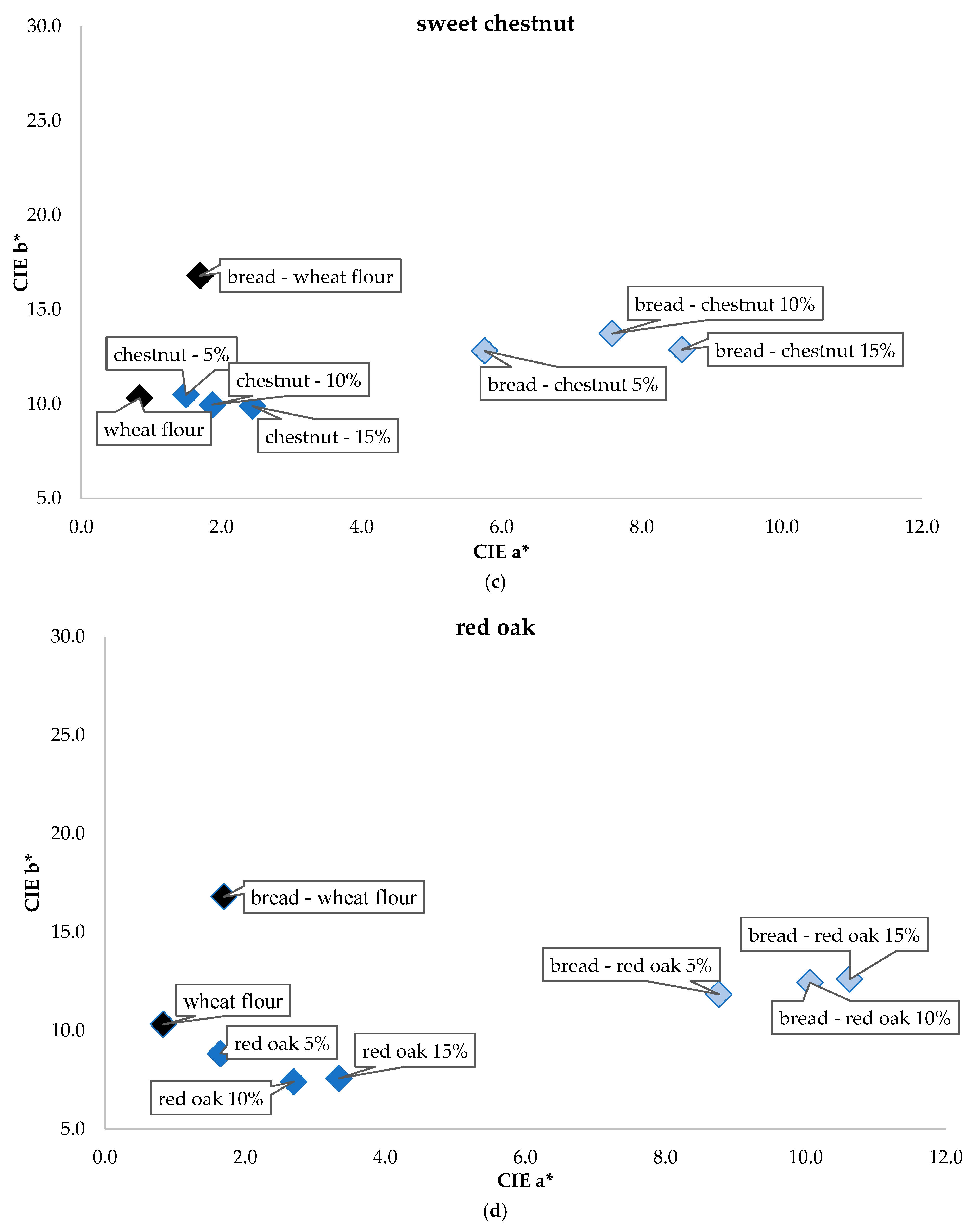

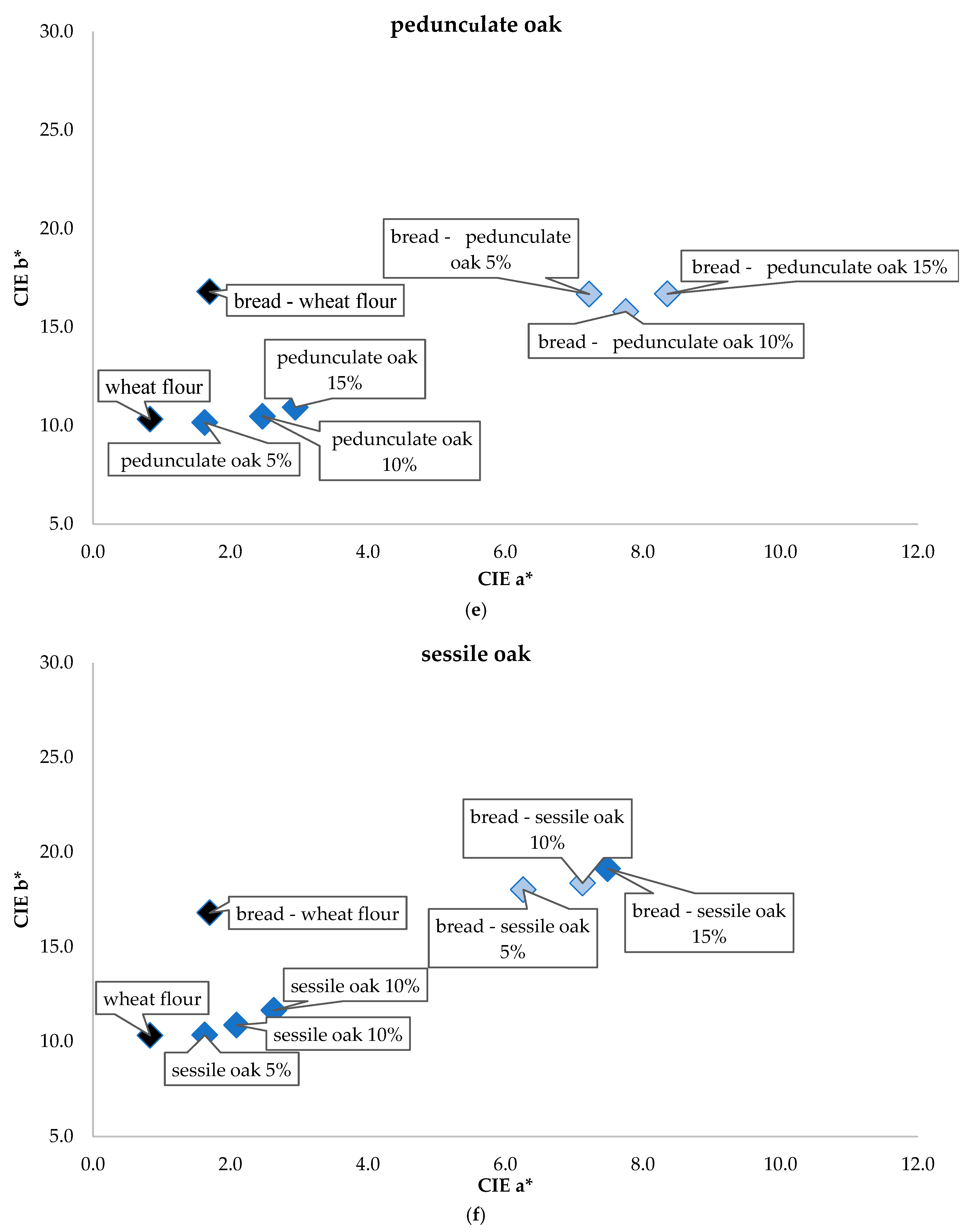

3.1. Changes in the Colour of Flour and Baked Product Crumb as Affected by Additives

3.2. Effect of Fruit- and Tree-Based Flours on the Textural Properties of Wheat Bread

3.2.1. Hardness (N)

3.2.2. Adhesiveness

3.2.3. Springiness

3.3. Sensory Evaluation of Bread

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ditlevsen, K.; Sandøe, P.; Lassen, J. Healthy Food Is Nutritious, but Organic Food Is Healthy Because It Is Pure: The Negotiation of Healthy Food Choices by Danish Consumers of Organic Food. Food Qual. Prefer. 2019, 71, 46–53. [Google Scholar] [CrossRef]

- Liang, X.; Feng, L.; Ran, J.; Sun, J.; Chen, X.; Jiao, Z.; Jiao, L. Influence of Adding Steam-Exploded Apple Pomace on Wheat Flour Characteristics and Biscuit Quality. J. Food Sci. Technol. 2020, 57, 3031–3039. [Google Scholar] [CrossRef] [PubMed]

- Beltrão Martins, R.; Nunes, M.C.; Gouvinhas, I.; Ferreira, L.M.M.; Peres, J.A.; Barros, A.I.R.N.A.; Raymundo, A. Apple Flour in a Sweet Gluten-Free Bread Formulation: Impact on Nutritional Value, Glycemic Index, Structure and Sensory Profile. Foods 2022, 11, 3172. [Google Scholar] [CrossRef] [PubMed]

- Bainbridge, D.A. Use of Acorns for Food in California: Past, Present, Future. In Proceedings of the Symposium on Multiple-Use Management of California’s Hardwoods; Plumb, T.R., Pillsbury, N.H., Eds.; PSFRES: Berkeley, SC, USA, 1987; Volume 100, pp. 453–458. [Google Scholar] [CrossRef]

- Łuczaj, Ł. Dziko Rosnące Rośliny Jadalne Użytkowane w Polsce od Połowy XIX w. do Czasów Współczesnych. Etnobiol. Pol. 2011, 1, 57–125. (In Polish) [Google Scholar]

- Pinna, C. Acorn Bread: A Traditional Food of the Past in Sardinia (Italy). J. Cult. Herit. 2013, 14, S71–S74. [Google Scholar] [CrossRef]

- Silva, S.; Costa, E.M.; Borges, A.; Carvalho, A.P.; Monteiro, M.J.; Pintado, M.M.E. Nutritional Characterization of Acorn Flour (a Traditional Component of the Mediterranean Gastronomical Folklore). J. Food Meas. Charact. 2016, 10, 584–588. [Google Scholar] [CrossRef]

- Tantray, Y.R.; Wani, M.S.; Hussain, A. Genus Quercus: An Overview. Int. J. Adv. Res. Sci. Eng. 2017, 6, 1880–1886. [Google Scholar]

- Kammerer, D.R.; Kammerer, J.; Valet, R.; Carle, R. Recovery of Polyphenols from the By-Products of Plant Food Processing and Application as Valuable Food Ingredients. Food Res. Int. 2014, 65, 2–12. [Google Scholar] [CrossRef]

- Lyu, F.; Luiz, S.F.; Azeredo, D.R.P.; Cruz, G.A.; Ajlouni, S.; Ranadheera, S.C. Apple Pomace as a Functional and Healthy Ingredient in Food Products: A Review. Processes 2020, 8, 319. [Google Scholar] [CrossRef]

- Szabłowska, E.; Tańska, M. Acorns as a Source of Valuable Compounds for Food and Medical Applications: A Review of Quercus Species Diversity and Laboratory Studies. Appl. Sci. 2024, 14, 2799. [Google Scholar] [CrossRef]

- Sikora, F.; Ochmian, I.; Sobolewska, M. OK. Acta Univ. Cibiniensis. Ser. E Food Technol. 2022, 26, 43–54. [Google Scholar] [CrossRef]

- Bchir, B.; Rabetafika, H.N.; Paquot, M.; Blecker, C. Effect of Pear, Apple and Date Fibres from Cooked Fruit By-Products on Dough Performance and Bread Quality. Food Bioprocess Technol. 2014, 7, 1114–1127. [Google Scholar] [CrossRef]

- Wani, I.A.; Hamid, H.; Hamdani, A.M.; Gani, A.; Ashwar, B.A. Physico-Chemical, Rheological and Antioxidant Properties of Sweet Chestnut (Castanea sativa Mill.) as Affected by Pan and Microwave Roasting. J. Adv. Res. 2017, 8, 399–405. [Google Scholar] [CrossRef] [PubMed]

- Pasqualone, A.; Vurro, F.; Summo, C.; Abd-El-Khalek, M.H.; Al-Dmoor, H.H.; Grgic, T.; Le-Bail, P. The large and diverse family of Mediterranean flat breads: A database. Foods 2022, 11, 2326. [Google Scholar] [CrossRef] [PubMed]

- Sikora, F.; Ochmian, I.; Sobolewska, M. Acorn Flour as a Functional Ingredient: Impacts on Health and Baking Properties in Wheat-Based Products. Acta Univ. Cibiniensis. Ser. E Food Technol. 2024, 28, 171–182. [Google Scholar] [CrossRef]

- Amina, M.; Djamel, F.; Djamel, H. Influence of Fermentation and Germination Treatments on Physicochemical and Functional Properties of Acorn Flour. Bulg. J. Agric. Sci. 2018, 24, 719–726. [Google Scholar]

- Correia, P.R.; Beirão-da-Costa, M.L. Effect of Drying Temperatures on Starch-Related Functional and Thermal Properties of Acorn Flours. J. Food Sci. 2011, 76, E196–E202. [Google Scholar] [CrossRef] [PubMed]

- Polimac, M.; Komlenić, D.K. Acorn Flour–Naturally Gluten Free. In Proceedings of the 8th International Congress Flour-Bread’15, 10th Croatian Congress of Cereal Technologists, Opatija, Croatia, 29–30 October 2015; pp. 177–181. [Google Scholar]

- Szabłowska, E.; Tańska, M. Acorn Flour Properties Depending on the Production Method and Laboratory Baking Test Results: A Review. Compr. Rev. Food Sci. Food Saf. 2021, 20, 980–1008. [Google Scholar] [CrossRef] [PubMed]

- Savarino, P.; Colson, E.; André, J.; Gerbaux, P. Horse Chestnut Saponins–Escins, Isoescins, Transescins, and Desacylescins. Molecules 2023, 28, 2087. [Google Scholar] [CrossRef] [PubMed]

- Foca, G.; Ulrici, A.; Cocchi, M.; Durante, C.; Vigni, M.L.; Marchetti, A.; Tassi, L. Seeds of Horse Chestnut (Aesculus hippocastanum L.) and Their Possible Utilization for Human Consumption. In Nuts and Seeds in Health and Disease Prevention; Academic Press: Camp Hill, PA, USA, 2011; pp. 653–661. [Google Scholar]

- Molavi, H.; Keramat, J.; Raisee, B. Evaluation of the Cake Quality Made from Acorn–Wheat Flour Blends as a Functional Food. J. Food Biosci. Technol. 2015, 5, 53–60. [Google Scholar]

- Kaya, E.; Kamalak, A. Potential Nutritive Value and Condensed Tannin Contents of Acorns from Different Oak Species. J. Fac. Vet. Med. Kafkas Univ. 2012, 18, 1061–1066. Available online: https://d1wqtxts1xzle7.cloudfront.net/35908038/1061-1066-libre.pdf?1418293603=&response-content-disposition=inline%3B+filename%3DPotential_Nutritive_Value_and_Condensed.pdf&Expires=1752945689&Signature=HzwHdc7yZmirn8OmQ-LoY9JO9rBY0PkhP-j~imBPJ0OKdL0Iz40Z-3e1pzLIuGXqUWnmBosBJHSJDchxHVceeoUQ~FOQJnlhqC2w-BUmu49Us9ALLd7ExUNcnczTjyoInpj6RCpCbLgZVdP5~CLpBbCSMxWGf5gD3QvGOKNRfdBmu-WspEOMvnszb~Msw5Ko36cXk9nrIrSwMQP7fSxn3yaJxmFmpNbOLk5CDSYGZ7UUcF~fbr4Nb5DUzxQwOBPM87VCTjIT-5M9pyYeMWEJnomoBpPiqQrVUdgPT0xxG~1YSRhZ7tgOyl1MoBjRo753HvPTAONeIhNHGM5hhJXjvA__&Key-Pair-Id=APKAJLOHF5GGSLRBV4ZA (accessed on 16 July 2025). [CrossRef]

- Zhu, F. Properties and Food Uses of Chestnut Flour and Starch. Food Bioprocess Technol. 2017, 10, 1173–1191. [Google Scholar] [CrossRef]

- Masoodi, F.A.; Chauhan, G.S. Use of Apple Pomace as a Source of Dietary Fiber in Wheat Bread. J. Food Process Preserv. 1998, 22, 255–263. [Google Scholar] [CrossRef]

- Ajo, R.Y. Effect of Acorn Flour Substitution on Arabic Bread Properties. Pak. J. Agric. Sci. 2018, 55, 913–919. [Google Scholar]

- Korus, J.; Witczak, M.; Ziobro, R.; Juszczak, L. The Influence of Acorn Flour on Rheological Properties of Gluten-Free Dough and Physical Characteristics of the Bread. Eur. Food Res. Technol. 2015, 240, 1135–1143. [Google Scholar] [CrossRef]

- Beltrão Martins, R.; Nunes, M.C.; Ferreira, L.M.M.; Peres, J.A.; Barros, A.I.R.N.A.; Raymundo, A. Impact of Acorn Flour on Gluten-Free Dough Rheology Properties. Foods 2020, 9, 560. [Google Scholar] [CrossRef] [PubMed]

- Švec, I.; Hrušková, M.; Kadlčíková, I. Features of Flour Composites Based on the Wheat or Wheat-Barley Flour Combined with Acorn and Chestnut. Croat. J. Food Sci. Technol. 2018, 10, 89–97. [Google Scholar] [CrossRef]

- Sikora, F.; Lachowicz, S.; Kapusta, I.; Dylawerski, M.; Zyska, W.; Ochmian, I. Changes in the Quality of Old Apple Cultivars After Freeze-Drying. Acta Univ. Cibiniensis. Ser. E Food Technol. 2020, 24, 175–185. [Google Scholar] [CrossRef]

- Ochmian, I.; Sikora, F.; Gałczyńska, M.; Lachowicz-Wiśniewska, S. Eight Old Cultivars of Apple Trees–An Evaluation of Their Potential for Use by the Processing Industry. Żywność 2023, 30, 160–177. [Google Scholar] [CrossRef]

- Dall’Asta, C.; Cirlini, M.; Morini, E.; Rinaldi, M.; Ganino, T.; Chiavaro, E. Effect of Chestnut Flour Supplementation on Physico-Chemical Properties and Volatiles in Bread Making. LWT-Food Sci. Technol. 2013, 53, 233–239. [Google Scholar] [CrossRef]

- Błaszak, M.; Lachowicz-Wiśniewska, S.; Kapusta, I.; Szewczuk, M.; Ochmian, I. Enhanced Extraction of Polyphenols, Physicochemical Properties, and Microbial Control in Vitis vinifera L. Juice Using Ultrasound-Assisted Maceration. Molecules 2025, 30, 587. [Google Scholar] [CrossRef] [PubMed]

- PN-A-74108; Bread–Test Methods (Pieczywo—Metody Badań). Polski Komitet Normalizacyjny, Wydawnictwa Normalizacyjne ALFA-WERO: Warszawa, Poland, 1996.

- ICC Standard No. 131; Method for Test Baking of Wheat Flours. ICC: Paris, France, 1980.

- Rocha Parra, A.F.; Ribotta, P.D.; Ferrero, C. Apple Pomace in Gluten-Free Formulations: Effect on Rheology and Product Quality. Int. J. Food Sci. Technol. 2015, 50, 682–690. [Google Scholar] [CrossRef]

- Skendi, A.; Mouselemidou, P.; Papageorgiou, M.; Papastergiadis, E. Effect of Acorn Meal–Water Combinations on Technological Properties and Fine Structure of Gluten-Free Bread. Food Chem. 2018, 253, 119–126. [Google Scholar] [CrossRef] [PubMed]

- Rocha Parra, A.F.; Sahagún, M.; Ribotta, P.D.; Ferrero, C.; Gómez, M. Particle Size and Hydration Properties of Dried Apple Pomace: Effect on Dough Viscoelasticity and Quality of Sugar-Snap Cookies. Food Bioprocess Technol. 2019, 12, 1083–1092. [Google Scholar] [CrossRef]

- Demirkesen, I.; Mert, B.; Sumnu, G.; Sahin, S. Utilization of Chestnut Flour in Gluten-Free Bread Formulations. J. Food Eng. 2010, 101, 329–336. [Google Scholar] [CrossRef]

- Zhang, L.; Cheng, L.; Jiang, L.; Wang, Y.; Yang, G.; He, G. Effects of Tannic Acid on Gluten Protein Structure, Dough Properties and Bread Quality of Chinese Wheat. J. Sci. Food Agric. 2010, 90, 2462–2468. [Google Scholar] [CrossRef] [PubMed]

- Shafi, M.; Baba, W.N.; Masoodi, F.A.; Bazaz, R. Wheat–Water Chestnut Flour Blends: Effect of Baking on Antioxidant Properties of Cookies. J. Food Sci. Technol. 2016, 53, 4278–4288. [Google Scholar] [CrossRef] [PubMed]

- Marciniak-Lukasiak, K.; Lesniewska, P.; Zielińska, D.; Sowinski, M.; Zbikowska, K.; Lukasiak, P.; Zbikowska, A. The Influence of Chestnut Flour on the Quality of Gluten-Free Bread. Appl. Sci. 2022, 12, 8340. [Google Scholar] [CrossRef]

- Raczyk, M.; Kruszewski, B.; Michałowska, D. Effect of Coconut and Chestnut Flour Supplementations on Texture, Nutritional and Sensory Properties of Baked Wheat-Based Bread. Molecules 2021, 26, 4641. [Google Scholar] [CrossRef] [PubMed]

- Rao, Z.; Kou, F.; Wang, Q.; Lei, X.; Zhao, J.; Ming, J. Effect of Superfine Grinding Chestnut Powder on the Structural and Physicochemical Properties of Wheat Dough. Int. J. Biol. Macromol. 2024, 259, 129257. [Google Scholar] [CrossRef] [PubMed]

- Cantero, L.; Salmerón, J.; Miranda, J.; Larretxi, I.; Fernández-Gil, M.D.P.; Bustamante, M.Á.; Martínez, O. Performance of Apple Pomace for Gluten-Free Bread Manufacture: Effect on Physicochemical Characteristics and Nutritional Value. Appl. Sci. 2022, 12, 5934. [Google Scholar] [CrossRef]

- Park, J.Y.; Joo, J.I.; Kim, J.M. Changes in the Quality of Bread Added with Acorn Flour During the Storage Periods. J. East Asian Soc. Diet. Life 2017, 27, 529–539. [Google Scholar] [CrossRef]

- Beltrão Martins, R.; Garzón, R.; Peres, J.A.; Barros, A.I.; Raymundo, A.; Rosell, C.M. Acorn Flour and Sourdough: An Innovative Combination to Improve Gluten-Free Bread Characteristics. Eur. Food Res. Technol. 2022, 248, 1691–1702. [Google Scholar] [CrossRef]

- Man, S.; Păucean, A.; Muste, S.; Mureşan, C.; Frâncu, A.V. Chestnut flour addition influence on bread quality. J. Agroaliment. Process. Technol. 2012, 18, 150–154. [Google Scholar]

- Nisar, R.; Baba, W.N.; Masoodi, F.A. Effect of Chemical and Thermal Treatments on Quality Parameters and Antioxidant Activity of Apple (Pulp) Grown in High Himalayan Regions. Cogent Food Agric. 2015, 1, 1063797. [Google Scholar] [CrossRef]

- Jannati, N.; Hojjatoleslamy, M.; Hosseini, E.; Mozafari, H.R.; Siavoshi, M. Effect of apple pomace powder on rheological properties of dough and sangak bread texture. Carpathian J. Food Sci. Technol. 2018, 10, 77–84. [Google Scholar]

- Pyanikova, E.A.; Kovaleva, A.E.; Ovchinnikova, E.V.; Afanasieva, L.A. Researching the possibility of using recycled apple raw materials to create functional food products. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 677, p. 032030. [Google Scholar]

- Usman, M.; Ahmed, S.; Mehmood, A.; Bilal, M.; Patil, P.J.; Akram, K.; Farooq, U. Effect of apple pomace on nutrition, rheology of dough and cookies quality. J. Food Sci. Technol. 2020, 57, 3244–3251. [Google Scholar] [CrossRef] [PubMed]

- Shafi, S.; Wani, I.A.; Gani, A.; Sharma, P.; Wani, H.M.; Masoodi, F.A.; Hamdani, A.M. Effect of Water and Ether Extraction on Functional and Antioxidant Properties of Indian Horse Chestnut (Aesculus indica Colebr) Flour. J. Food Meas. Charact. 2016, 10, 387–395. [Google Scholar] [CrossRef]

- Pasqualone, A.; Makhlouf, F.Z.; Barkat, M.; Difonzo, G.; Summo, C.; Squeo, G.; Caponio, F. Effect of Acorn Flour on the Physico-Chemical and Sensory Properties of Biscuits. Heliyon 2019, 5, e02242. [Google Scholar] [CrossRef] [PubMed]

- Vinha, A.F.; Costa, A.S.G.; Barreira, J.C.; Pacheco, R.; Oliveira, M.B.P. Chemical and Antioxidant Profiles of Acorn Tissues from Quercus spp.: Potential as New Industrial Raw Materials. Ind. Crops Prod. 2016, 94, 143–151. [Google Scholar] [CrossRef]

- Beltrão Martins, R.; Gouvinhas, I.; Nunes, M.C.; Peres, J.A.; Raymundo, A.; Barros, A.I. Acorn flour as a source of bioactive compounds in gluten-free bread. Molecules 2020, 25, 3568. [Google Scholar] [CrossRef] [PubMed]

- Capriles, V.D.; Dos Santos, F.G.; Arêas, J.A.G. Gluten-free breadmaking: Improving nutritional and bioactive compounds. J. Cereal Sci. 2016, 67, 83–91. [Google Scholar] [CrossRef]

- Gonzaga, M.; Batista, M.; Guiné, R.; Correia, P. Development and characterization of wheat breads with acorn flour. In Proceedings of the ICEUBI2015—International Conference of Engineering: Engineering for Society, Covilhã, Portugal, 2–4 December 2015; pp. 1–6. Available online: https://repositorio.ipv.pt/entities/publication/61e0c3d1-f7f9-4ab7-b254-de9673030c03 (accessed on 14 July 2025).

- Mousavi, B.; Ghaderi, S.; Hesarinejad, M.A.; Pourmahmoudi, A. Effect of varying levels of acorn flour on antioxidant, staling and sensory properties of Iranian toast. Int. J. Food Stud. 2021, 10, 145–160. [Google Scholar] [CrossRef]

- Shiri, R.; Sargazi, M.; Azizi, M.H. Quality attributes of gluten-free rice breads enriched with acorn flour and inulin using different fermentation types. Food Sci. Nutr. 2021, 9, 3074–3083. [Google Scholar] [CrossRef] [PubMed]

- Szabłowska, E.; Tańska, M. Effects of acorn flour addition on baking characteristics of wheat flour. Foods 2025, 14, 190. [Google Scholar] [CrossRef] [PubMed]

| Type of Flour | Proportion | Flour (L*) | Crumb of the Baked Product (L*) |

|---|---|---|---|

| Wheat flour | 100% | 91.9 h * | 72.8 k |

| 5% | 88.4 fgh | 51.0 fg | |

| Wheat flour + red oak | 10% | 78.4 b | 48.3 def |

| 15% | 73.4 a | 43.2 ab | |

| 5% | 87.0 efg | 55.4 h | |

| Wheat flour + pedunculate oak | 10% | 82.5 cd | 49.7 efg |

| 15% | 79.6 bc | 43.7 bc | |

| 5% | 85.4 def | 55.5 h | |

| Wheat flour + sessile oak | 10% | 82.3 cd | 47.2 de |

| 15% | 78.1 b | 46.0 bcd | |

| 5% | 87.2 efg | 58.8 i | |

| Wheat flour + horse chestnut | 10% | 85.2 def | 52.5 g |

| 15% | 82.5 cd | 40.6 a | |

| 5% | 90.1 gh | 59.4 i | |

| Wheat flour + sweet chestnut | 10% | 88.5 fgh | 56.5 hi |

| 15% | 86.8 efg | 46.4 cd | |

| 5% | 90.9 h | 68.4 j | |

| Wheat flour + apple | 10% | 89.6 gh | 58.7 i |

| 15% | 84.7 de | 50.6 fg |

| Type of Flour | Proportion | Hardness (N) | Adhesiveness | Springiness |

|---|---|---|---|---|

| Wheat flour | 100% | 12.01 hi * | 0.469 b | 0.974 f |

| Wheat flour + red oak | 5% | 8.44 c | −0.722 de | 0.981 fg |

| 10% | 13.75 jk | −0.490 d | 0.952 c | |

| 15% | 13.01 ij | 0.042 bc | 0.944 b | |

| Wheat flour + pedunculate oak | 5% | 11.72 gh | −0.064 c | 0.961 d |

| 10% | 11.71 gh | −0.426 d | 0.955 cd | |

| 15% | 14.95 k | −0.935 e | 0.939 b | |

| Wheat flour + sessile oak | 5% | 8.78 cd | −0.387 d | 0.964 d |

| 10% | 9.94 ef | −0.831 e | 0.971 f | |

| 15% | 10.16 ef | −0.405 d | 0.969 e | |

| Wheat flour + sweet chestnut | 5% | 5.85 a | −0.396 d | 0.987 g |

| 10% | 7.41 b | −1.308 f | 0.969 e | |

| 15% | 5.91 a | −0.467 d | 0.987gh | |

| Wheat flour + horse chestnut | 5% | 10.77 fg | −0.222 cd | 0.967e |

| 10% | 12.81 ij | −0.996 ef | 0.966 de | |

| 15% | 5.38 a | 1.029 a | 0.999 h | |

| Wheat flour + apple | 5% | 11.65 gh | 0.379 b | 0.949 bc |

| 10% | 9.70 de | −0.789 e | 0.972 f | |

| 15% | 9.70 de | −1.462 f | 0.919 a |

| Crust | Crumb | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Type of Flour | Proportion | Appearance | Colour | Thickness | Other Attributes | Elasticity | Porosity | Flavour and Aroma | Other Attributes | Total Score |

| Wheat flour | 100% | 3.76 | 3.62 | 3.43 | 3.51 | 3.29 | 3.48 | 3.43 | 3.87 | 28.39 |

| Wheat flour + red oak | 5% | 3.95 | 3.76 | 3.14 | 3.30 | 3.33 | 3.33 | 3.05 | 3.58 | 27.44 |

| 10% | 3.81 | 3.90 | 3.00 | 3.27 | 3.05 | 3.33 | 3.05 | 3.48 | 26.89 | |

| 15% | 3.57 | 4.10 | 2.95 | 3.19 | 2.67 | 3.33 | 3.14 | 3.32 | 26.27 | |

| Wheat flour + pedunculate oak | 5% | 3.76 | 3.52 | 3.33 | 3.28 | 3.00 | 3.14 | 3.10 | 3.35 | 26.48 |

| 10% | 3.67 | 3.62 | 2.90 | 3.13 | 2.67 | 2.86 | 2.95 | 3.13 | 24.93 | |

| 15% | 3.71 | 3.76 | 3.10 | 3.16 | 2.67 | 3.14 | 2.81 | 3.09 | 25.44 | |

| Wheat flour + sessile oak | 5% | 3.86 | 3.81 | 3.19 | 3.57 | 3.29 | 3.29 | 3.33 | 3.43 | 27.77 |

| 10% | 3.71 | 3.76 | 3.24 | 3.35 | 3.10 | 3.10 | 2.71 | 3.15 | 26.12 | |

| 15% | 3.52 | 3.76 | 3.05 | 3.32 | 3.05 | 3.05 | 2.43 | 3.06 | 25.24 | |

| Wheat flour + sweet chestnut | 5% | 3.95 | 3.62 | 3.62 | 4.33 | 3.76 | 3.62 | 3.95 | 3.92 | 30.77 |

| 10% | 4.00 | 3.86 | 3.81 | 3.98 | 3.71 | 3.90 | 4.10 | 4.40 | 31.76 | |

| 15% | 4.29 | 4.14 | 3.95 | 4.02 | 3.90 | 4.10 | 4.14 | 4.36 | 32.9 | |

| Wheat flour + horse chestnut | 5% | 3.52 | 3.33 | 3.14 | 2.55 | 2.76 | 2.76 | 1.95 | 2.70 | 22.71 |

| 10% | - | - | - | - | - | - | - | - | 0 | |

| 15% | - | - | - | - | - | - | - | - | 0 | |

| Wheat flour + apple | 5% | 3.76 | 3.76 | 3.57 | 3.68 | 3.48 | 3.33 | 3.71 | 3.83 | 29.12 |

| 10% | 4.10 | 3.86 | 3.81 | 3.77 | 3.48 | 3.52 | 3.90 | 3.85 | 30.29 | |

| 15% | 4.05 | 4.10 | 3.86 | 3.81 | 3.57 | 3.52 | 4.05 | 3.81 | 30.77 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sikora, F.; Ochmian, I.; Sobolewska, M.; Iwański, R. Effect of Apple, Chestnut, and Acorn Flours on the Technological and Sensory Properties of Wheat Bread. Appl. Sci. 2025, 15, 8067. https://doi.org/10.3390/app15148067

Sikora F, Ochmian I, Sobolewska M, Iwański R. Effect of Apple, Chestnut, and Acorn Flours on the Technological and Sensory Properties of Wheat Bread. Applied Sciences. 2025; 15(14):8067. https://doi.org/10.3390/app15148067

Chicago/Turabian StyleSikora, Fryderyk, Ireneusz Ochmian, Magdalena Sobolewska, and Robert Iwański. 2025. "Effect of Apple, Chestnut, and Acorn Flours on the Technological and Sensory Properties of Wheat Bread" Applied Sciences 15, no. 14: 8067. https://doi.org/10.3390/app15148067

APA StyleSikora, F., Ochmian, I., Sobolewska, M., & Iwański, R. (2025). Effect of Apple, Chestnut, and Acorn Flours on the Technological and Sensory Properties of Wheat Bread. Applied Sciences, 15(14), 8067. https://doi.org/10.3390/app15148067