Visualization of Distributed Plasticity in Concrete Piles Using OpenSeesPy

Abstract

1. Introduction and Background

1.1. Motivation: Limitations of Lumped Hinges in Practice

1.2. State of the Art in Fiber Modeling and Visualization

1.3. Contribution of This Work

- Using OpenSeesPy to integrate full 3D soil–pile interaction with distributed plasticity;

- Automating result visualization so that fiber strain and curvature demand along the pile length can be plotted;

- Enables engineers to generate automated sequences for modifying model parameters and instantly obtaining updated stress–strain visualizations, thereby streamlining parametric studies, and design optimization;

- Benchmarking the OpenSeesPy fiber model against the commercial SAP2000 frame-hinge model of the same pile.

2. Modeling Methodology

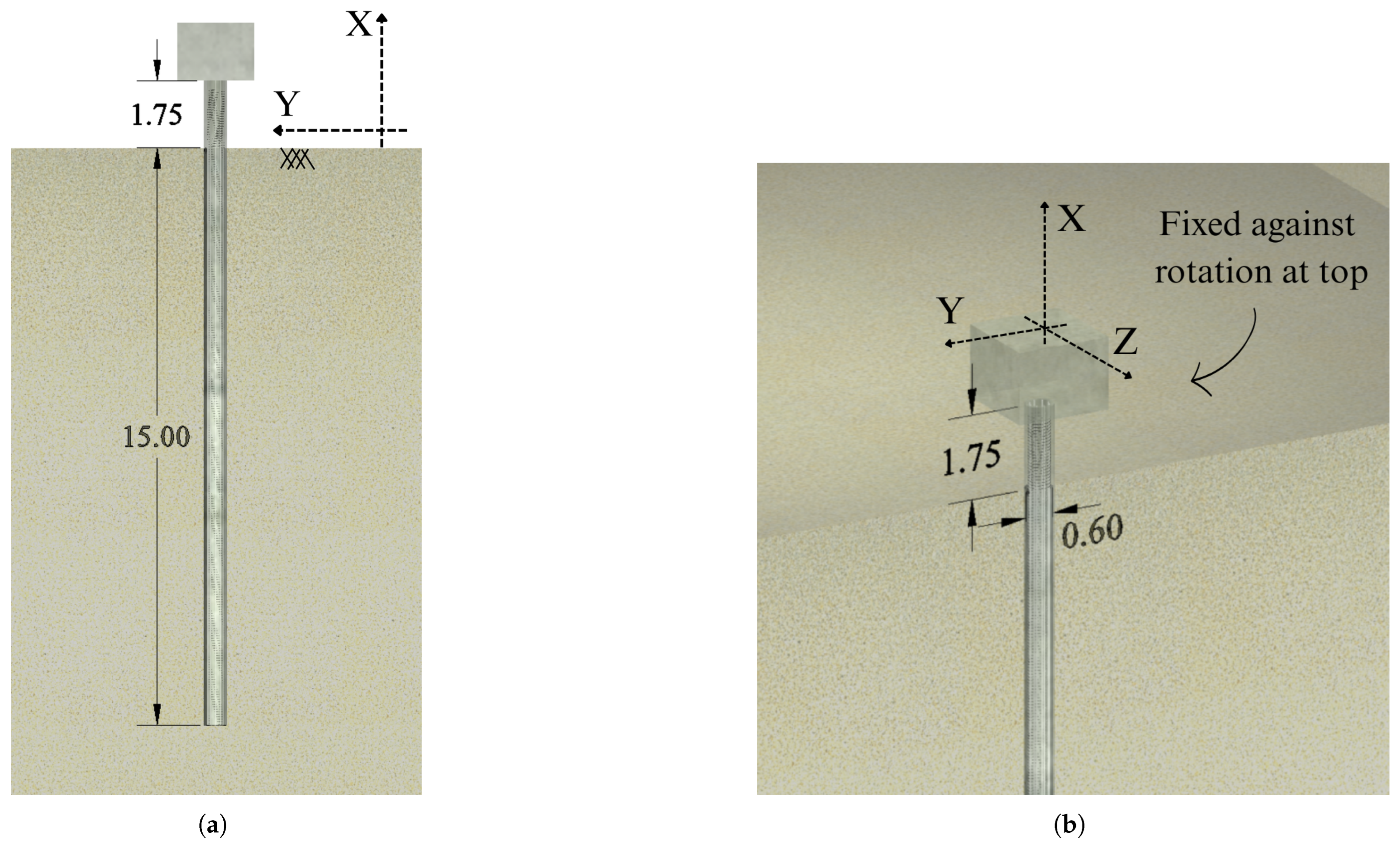

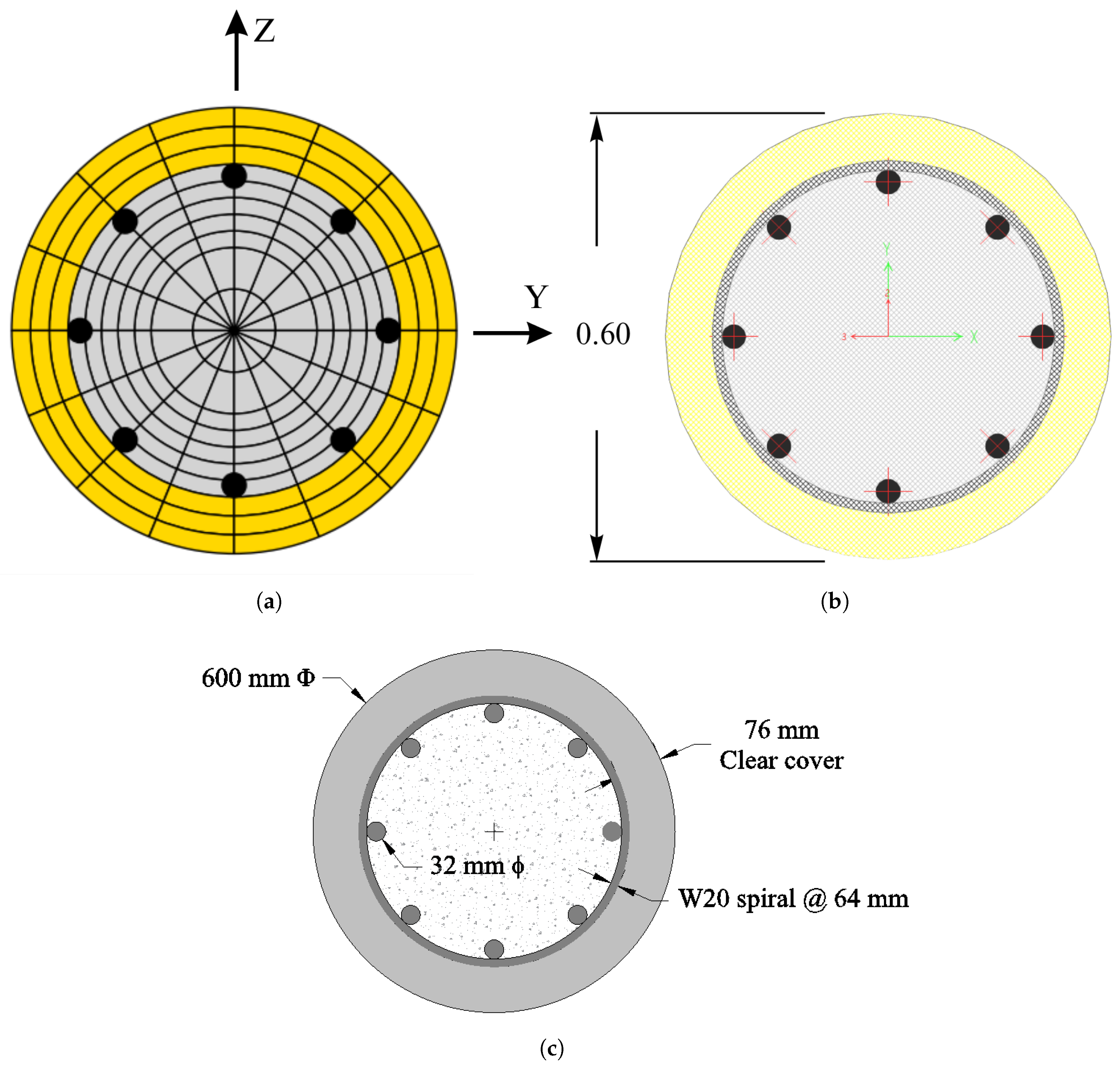

2.1. Fiber-Based Model of an RC Pile in OpenSeesPy

2.2. Nonlinear Soil–Structure Interaction Springs

- PySimple1 for lateral resistance (p–y behavior);

- TzSimple1 for axial shaft friction (t–z behavior);

- QzSimple1 for end-bearing resistance (q–z behavior).

2.3. Pile Geometry, Material Properties, and Loading

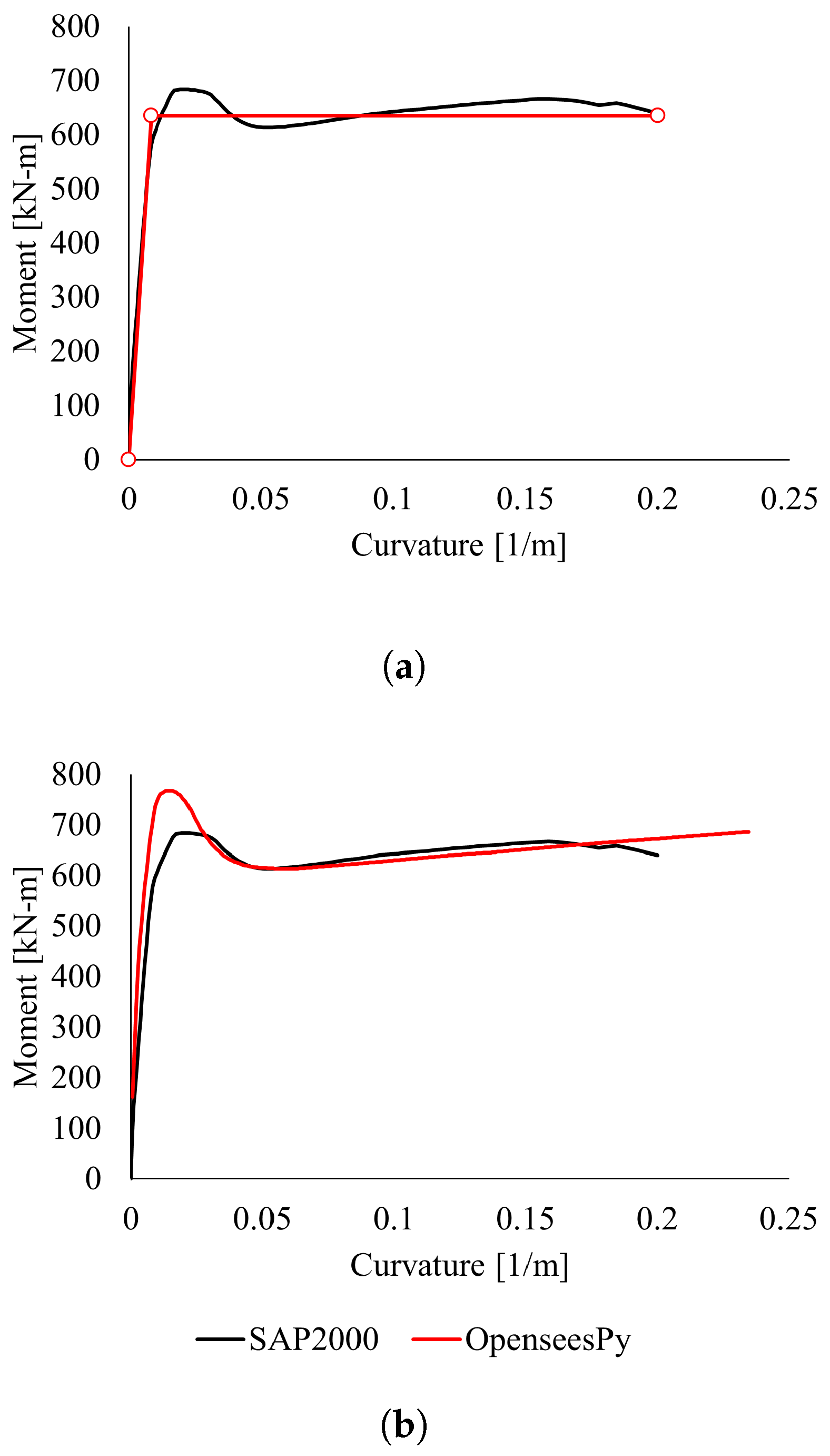

2.4. SAP2000 Plastic Hinge Model for Comparison

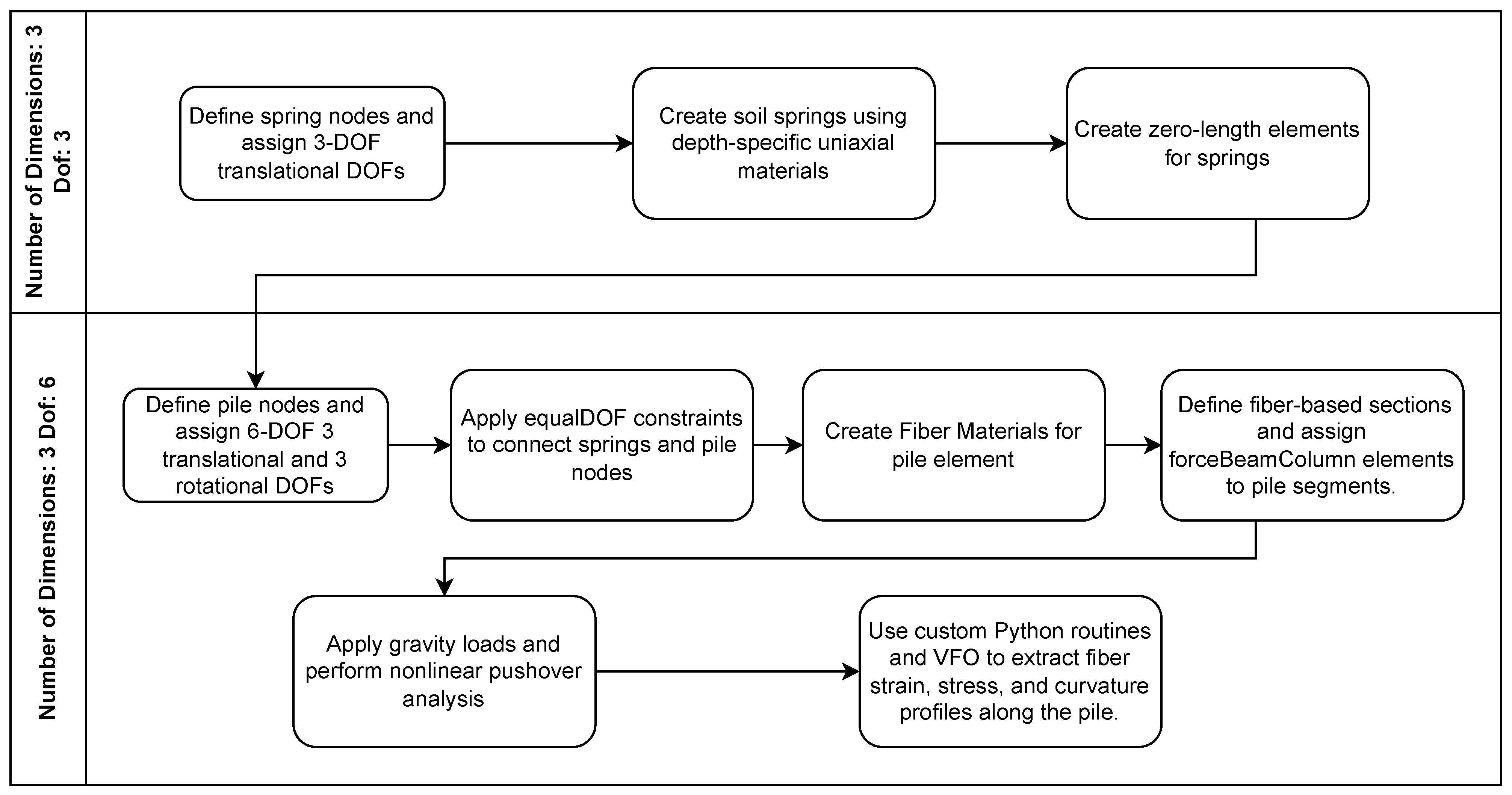

2.5. OpenseesPy Analysis Workflow and Post-Processing

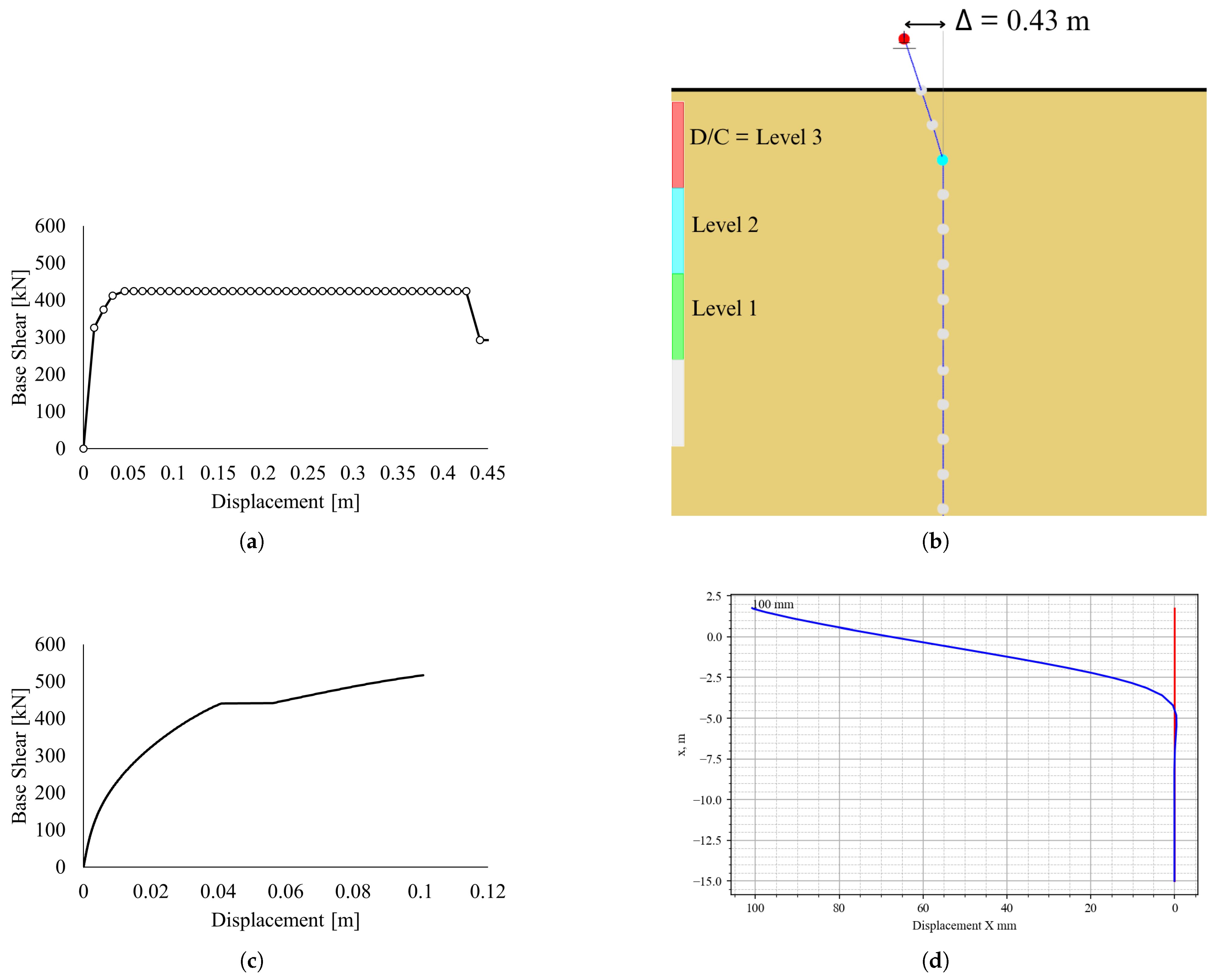

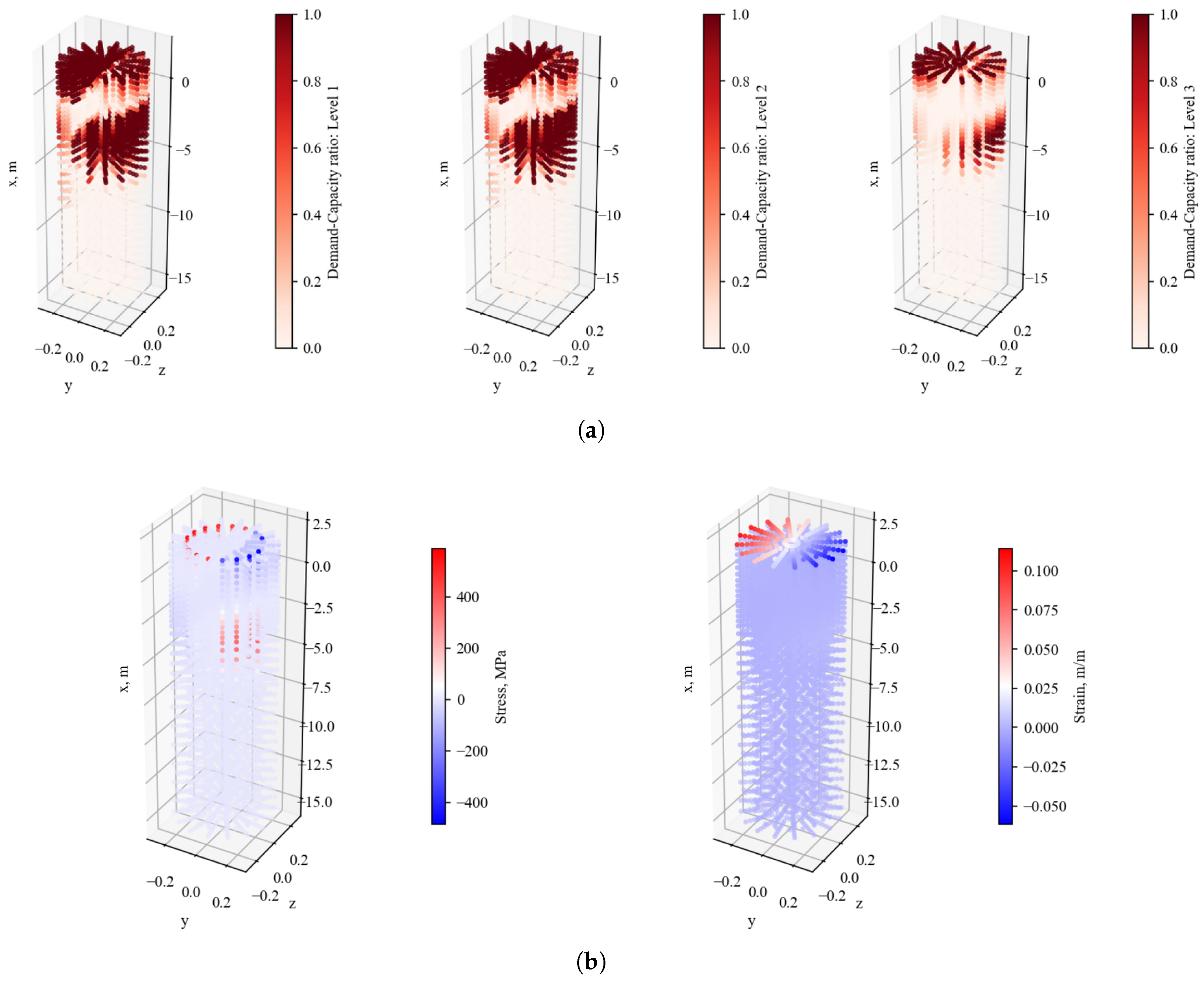

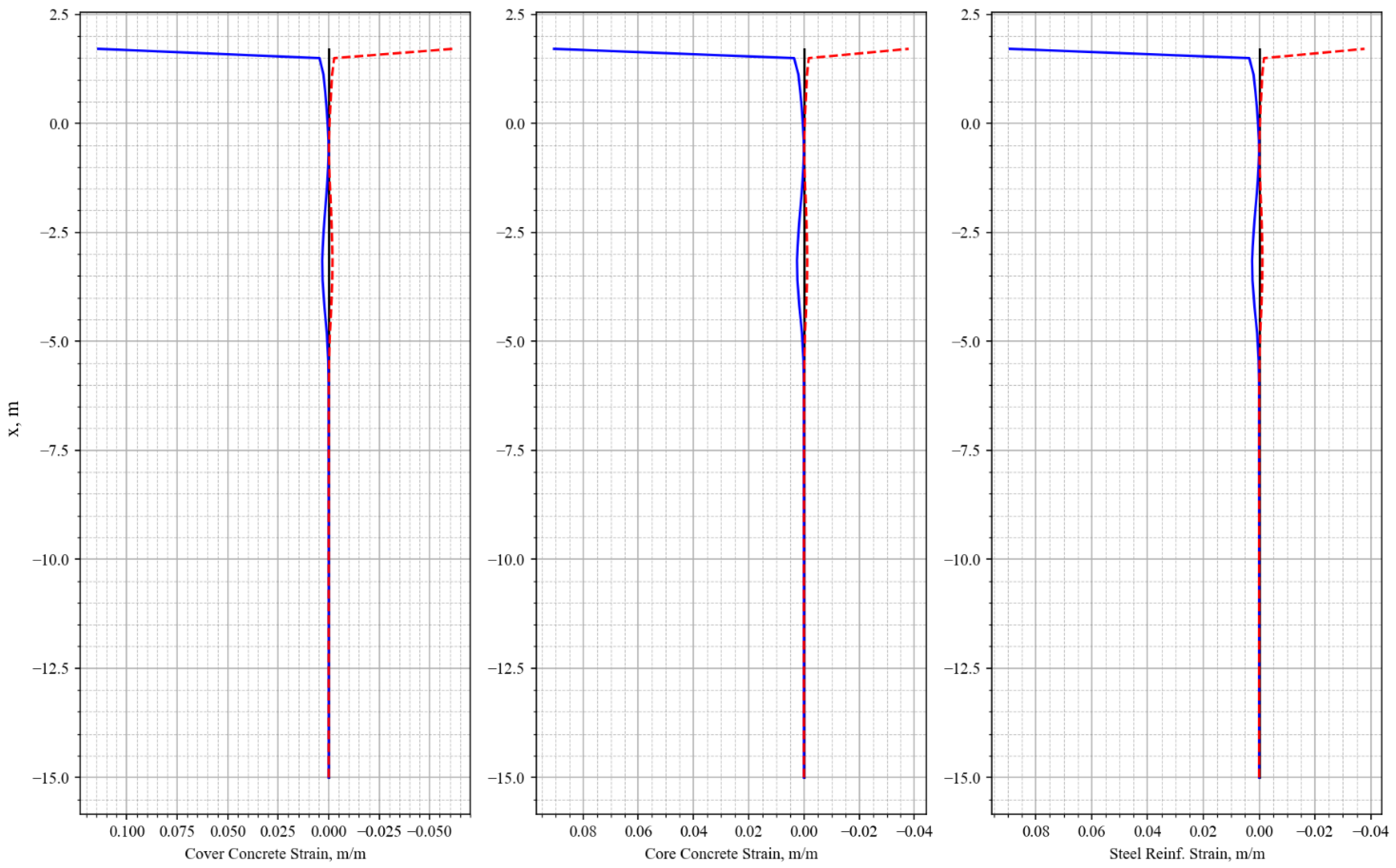

3. Results and Discussion

4. Conclusions

- The fiber-element formulation enables distributed plasticity and axial–flexural interaction, which lumped hinge models inherently miss.

- The enhanced nonlinear spring model captures realistic p–y, t–z, and q–z behavior, improving accuracy in structural member demands.

- Post-processing tools allow for detailed extraction and visualization of strain and stress in each individual fiber, demand/capacity ratios (DCRs) at the material level, and curvature and strain profiles along the pile length.

- Visualization capabilities make it possible to directly identify plastic hinge formation, reinforcement yielding, and core concrete crushing with spatial resolution and without reliance on interpretations.

5. Data and Code Availability

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ASCE | American Society of Civil Engineers |

| DOF | Degree of Freedom |

| DP | Diameters of Pile |

| FE | Finite Element |

| FEA | Finite Element Analysis |

| ML | Machine Learning |

| RC | Reinforced Concrete |

| SSI | Soil–Structure Interaction |

| STKO | Scientific ToolKit for OpenSees |

| VFO | Visualization for OpenSees |

References

- ASCE/COPRI 61-14; Seismic Design of Piers and Wharves. American Society of Civil Engineers: Reston, VA, USA, 2014.

- ASCE 41-17; Seismic Evaluation and Retrofit of Existing Buildings. American Society of Civil Engineers: Reston, VA, USA, 2017. [CrossRef]

- EN 1998-1-1:2024; Eurocode 8: Design of Structures for Earthquake Resistance—Part 1-1: General Rules and Seismic Action. European Committee for Standardization (CEN): Brussels, Belgium, 2024.

- ACI CODE-318-19(22); Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2019; Reapproved 2022.

- POLB. Port of Long Beach Wharf Design Criteria; Port of Long Beach: Long Beach, CA, USA, 2021. [Google Scholar]

- POLA. The Port of Los Angeles Code for Seismic Design, Upgrade and Repair of Container Wharves; Port of Los Angeles: Los Angeles, CA, USA, 2010. [Google Scholar]

- OCDI. Technical Standards and Commentaries for Port and Harbour Facilities in Japan; The Overseas Coastal Area Development Institute of Japan: Tokyo, Japan, 2025. [Google Scholar]

- Deierlein, G.G.; Reinhorn, A.M.; Willford, M.R. Nonlinear structural analysis for seismic design. NEHRP Seism. Des. Tech. Brief 2010, 4, 1–36. [Google Scholar]

- Vafaei, M.; Alih, S.C.; Fallah, A. The accuracy of the lumped plasticity model for estimating nonlinear behavior of reinforced concrete frames under gradually increasing vertical loads. Struct. Concr. 2020, 21, 65–80. [Google Scholar] [CrossRef]

- Ilyas, M.; Ahmad, A.; Riaz, A.; Khan, F.A.; Sher, S.; Waseem, M.; Ali, S.Z.; Badrashi, Y.I.; Waqas, H.A.; Seitz, H.; et al. Review of modeling techniques for analysis and assessment of RC beam–column joints subjected to seismic loads. Materials 2022, 15, 7448. [Google Scholar] [CrossRef] [PubMed]

- Refani, A.N.; Nagao, T. Simplified Method for Nonlinear Seismic Response Analysis of Corroded Pile-Supported Wharf. Appl. Sci. 2023, 13, 10936. [Google Scholar] [CrossRef]

- Izadpanah, M.; Habibi, A.R. New spread plasticity model for reinforced concrete structural elements accounting for both gravity and lateral load effects. J. Struct. Eng. 2018, 144, 04018028. [Google Scholar] [CrossRef]

- Cook, D.; Sen, A.; Liel, A.; Basnet, T.; Creagh, A.; Koodiani, H.K.; Berkowitz, R.; Ghannoum, W.; Hortacsu, A.; Kim, I.; et al. ASCE/SEI 41 assessment of reinforced concrete buildings: Benchmarking nonlinear dynamic procedures with empirical damage observations. Earthq. Spectra 2023, 39, 1721–1754. [Google Scholar] [CrossRef]

- Abuduweili, Y.; Ma, L.; Shi, K.; Zhu, X. Bearing Capacity and Deformation of Micropiles Considering Plastic Hinge. Buildings 2025, 15, 1168. [Google Scholar] [CrossRef]

- Heidary-Torkamani, H.; Bargi, K.; Amirabadi, R. Seismic vulnerability assessment of pile-supported wharves using fragility curves. Struct. Infrastruct. Eng. 2014, 10, 1417–1431. [Google Scholar] [CrossRef]

- Deghoul, L.; Gabi, S.; Hamrouni, A. The influence of the soil constitutive models on the seismic analysis of pile-supported wharf structures with batter piles in cut-slope rock dike. Stud. Geotech. Mech. 2020, 42, 191–209. [Google Scholar] [CrossRef]

- Boyke, C.; Nagao, T. Seismic Performance Assessment of Pile-Supported Wharfs: 2D Frame Analysis Method Considering Both Inertial and Kinematic Forces. Appl. Sci. 2023, 13, 3629. [Google Scholar] [CrossRef]

- Zhao, J.; Cui, C.; Zhang, P.; Wang, K.; Zhao, M. Parameter sensitivity analysis of the seismic response of a piled wharf structure. Buildings 2023, 13, 349. [Google Scholar] [CrossRef]

- Plata, R.R.; Lai, C.G.; Cubrinovski, M. Dynamic non-linear soil-structure interaction analyses of a large diameter pile-supported wharf founded on liquefiable soils. Jpn. Geotech. Soc. Spec. Publ. 2024, 10, 495–500. [Google Scholar]

- Roth, W.; Dawson, E. Analyzing the seismic performance of wharves, part 2: SSI analysis with non-linear, effective-stress soil models. In Advancing Mitigation Technologies and Disaster Response for Lifeline Systems; American Society of Civil Engineers: Reston, VA, USA, 2003; pp. 395–404. [Google Scholar]

- Donahue, M.J.; Dickenson, S.E.; Miller, T.H.; Yim, S.C. Implications of the observed seismic performance of a pile-supported wharf for numerical modeling. Earthq. Spectra 2005, 21, 617–634. [Google Scholar] [CrossRef]

- Zacchei, E.; Lyra, P.H.; Stucchi, F.R. Pushover analysis for flexible and semi-flexible pile-supported wharf structures accounting the dynamic magnification factors due to torsional effects. Struct. Concr. 2020, 21, 2669–2688. [Google Scholar] [CrossRef]

- Soltani, M.; Amirabadi, R. Seismic vulnerability assessment of pile-supported wharves using fragility surfaces. J. Earthq. Eng. 2022, 26, 7140–7155. [Google Scholar] [CrossRef]

- Neuenhofer, A.; Filippou, F.C. Geometrically nonlinear flexibility-based frame finite element. J. Struct. Eng. 1998, 124, 704–711. [Google Scholar] [CrossRef]

- Alemdar, B.N.; White, D.W. Displacement, flexibility, and mixed beam–column finite element formulations for distributed plasticity analysis. J. Struct. Eng. 2005, 131, 1811–1819. [Google Scholar] [CrossRef]

- Zeng, X.G.; Jiang, S.F.; Xu, X.C.; Huang, H.S. Numerical modeling of earthquake-damaged circular bridge columns repaired using combination of near-surface-mounted BFRP bars with external BFRP sheets jacketing. Materials 2019, 12, 258. [Google Scholar] [CrossRef]

- Darmawan, M.F.; Fajar, A.; Satyarno, I.; Awaludin, A.; Yogatama, B.A. Seismic Performance Comparison of Pile Supported Slab Viaduct with PHC Pile and RC Bored Pile in South Part of Java Island. In Proceedings of the 5th International Conference on Sustainable Civil Engineering Structures and Construction Materials; Springer: Singapore, 2020; pp. 719–734. [Google Scholar]

- Narinder; Goswami, K.; Bose, S.; Banerjee, A.; Chakraborty, S. ML-Based Surrogate Model for RC Bridge Pier Collapse Fragility Prediction. In Proceedings of 17th Symposium on Earthquake Engineering; Springer: Singapore, 2022; pp. 661–671. [Google Scholar]

- Liang, W.; Leng, L.; Tian, H.; Tian, X. Nonlinear numerical simulation of dynamic response of pile site and pile foundation under earthquake. Nonlinear Eng. 2022, 11, 485–493. [Google Scholar] [CrossRef]

- Setiawan, A.F.; Santoso, A.K.; Darmawan, M.F.; Adi, A.D.; Ismanti, S. Nonlinear analysis for investigating seismic performance of a spun pile-column of viaduct structure. Civ. Eng. J. 2023, 9, 1561–1578. [Google Scholar] [CrossRef]

- Tipsunavee, T.; Arangjelovski, G.; Jongpradist, P. Numerical analysis on effects of soil improvement on pile forces on existing high-rise building. Buildings 2023, 13, 1523. [Google Scholar] [CrossRef]

- Çetindemir, O.; Zülfikar, A.C. Numerical validation of fully coupled nonlinear seismic soil–pile–structure interaction. Buildings 2024, 14, 1502. [Google Scholar] [CrossRef]

- Chiaramonte, M.M.; Arduino, P.; Lehman, D.E.; Roeder, C.W. Seismic analyses of conventional and improved marginal wharves. Earthq. Eng. Struct. Dyn. 2013, 42, 1435–1450. [Google Scholar] [CrossRef]

- Goel, R.K. Evaluation of in-ground plastic-hinge length and depth for piles in marine oil terminals. Earthq. Spectra 2015, 31, 2397–2417. [Google Scholar] [CrossRef]

- Su, L.; Lu, J.; Elgamal, A.; Arulmoli, A.K. Seismic performance of a pile-supported wharf: Three-dimensional finite element simulation. Soil Dyn. Earthq. Eng. 2017, 95, 167–179. [Google Scholar] [CrossRef]

- Su, L.; Wan, H.P.; Lu, J.; Ling, X.; Elgamal, A.; Arulmoli, A.K. Seismic performance evaluation of a pile-supported wharf system at two seismic hazard levels. Ocean Eng. 2021, 219, 108333. [Google Scholar] [CrossRef]

- Su, L.; Zhang, X.; Xie, L.; Zhang, P.; Zhang, A.; Qiu, Z.; Ling, X. Response characteristic of crane-wharf interaction system: Numerical simulation and global sensitivity analysis. Ocean Eng. 2022, 266, 113011. [Google Scholar] [CrossRef]

- ASDEA Software Technology. STKO—Scientific ToolKit for OpenSees. Version 4.0.0. 2025. Available online: https://asdea.eu/software/ (accessed on 5 July 2025).

- vfo—Visualization for OpenSees. Available online: https://vfo.readthedocs.io/en/latest/ (accessed on 5 February 2025).

- Zhu, M.; McKenna, F.; Scott, M.H. OpenSeesPy: Python library for the OpenSees finite element framework. SoftwareX 2018, 7, 6–11. [Google Scholar] [CrossRef]

- McKenna, F. OpenSees: A framework for earthquake engineering simulation. Comput. Sci. Eng. 2011, 13, 58–66. [Google Scholar] [CrossRef]

- Arroyo, O.; Feliciano, D.; Novoa, D.; Valcárcel, J. opseestools: A Python library to streamline OpenSeesPy workflows. SoftwareX 2024, 27, 101832. [Google Scholar] [CrossRef]

- Yan, Y.; Xie, Y. opstool: A Python library for OpenSeesPy analysis automation, streamlined pre-and post-processing, and enhanced data visualization. SoftwareX 2025, 30, 102126. [Google Scholar] [CrossRef]

- Solorzano, G.; Plevris, V. An Open-Source Framework for Modeling RC Shear Walls Using Deep Neural Networks. Adv. Civ. Eng. 2023, 2023, 7953869. [Google Scholar] [CrossRef]

- Smyl, D. OpenPyStruct: Open-Source Toolkit for Machine Learning-Driven Structural Optimization. engrxiv 2025. [Google Scholar] [CrossRef]

- McGann, C.; Arduino, P. Laterally-Loaded Pile Foundation. Available online: https://opensees.berkeley.edu/wiki/index.php/Laterally-Loaded_Pile_Foundation (accessed on 5 February 2025).

- Sunil, J.; Kamatchi, P. Nonlinear modelling strategies for seismic performance evaluation of reinforced concrete structures. Mater. Today: Proc. 2022, 65, 503–510. [Google Scholar] [CrossRef]

- Segura Jr, C.L.; Sattar, S.; Hariri-Ardebili, M.A. Quantifying material uncertainty in seismic evaluations of reinforced concrete bridge column structures. ACI Struct. J. 2022, 119. [Google Scholar] [CrossRef]

- Koronides, M.; Michailides, C.; Onoufriou, T. Nonlinear Soil–Pile–Structure Interaction Behaviour of Marine Jetty Structures. J. Mar. Sci. Eng. 2024, 12, 1153. [Google Scholar] [CrossRef]

- Koronides, M.; Michailides, C.; Stylianidis, P.; Onoufriou, T. Numerical Study of the Nonlinear Soil–Pile–Structure Interaction Effects on the Lateral Response of Marine Jetties. J. Mar. Sci. Eng. 2024, 12, 2075. [Google Scholar] [CrossRef]

- API. API Recommended Practice 2A-LRFD: Planning, Designing, and Constructing Fixed Offshore Platforms—Load and Resistance Factor Design, 2nd ed.; American Petroleum Institute: Washington, DC, USA, 2019. [Google Scholar]

- Mosher, R.L. Load-Transfer Criteria for Numerical Analysis of Axially Loaded Piles in Sand. Part 1: Load-Transfer Criteria; Final Report; US Army Engineer Waterways Experiment Station: Vicksburg, MS, USA, 1984. [Google Scholar]

- Kulhawy, F.H. Drilled Shaft Foundations; Springer: Boston, MA, USA, 1991; pp. 537–552. [Google Scholar]

- Meyerhof, G.G. Bearing capacity and settlement of pile foundations. J. Geotech. Eng. Div. 1976, 102, 197–228. [Google Scholar] [CrossRef]

- Vijivergiya, V. Load-movement characteristics of piles. In Proceedings of the 4th Symp. of Waterway, Port, Coastal and Occean Div., ASCE, Long Beach, CA, USA, 9–11 March 1977; Volume 2, pp. 269–284. [Google Scholar]

- Kulhawy, F.H.; Mayne, P.W. Manual on Estimating Soil Properties for Foundation Design; Technical Report; Electric Power Research Institute: Palo Alto, CA, USA; Cornell University: Ithaca, NY, USA, 1990. [Google Scholar]

- Mander, J.B.; Priestley, M.J.; Park, R. Theoretical stress-strain model for confined concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef]

- Park, R.; Paulay, T. Reinforced Concrete Structures; John Wiley & Sons: New York, NY, USA, 1991. [Google Scholar]

| Step | SAP2000 (min) | OpenSeesPy (min) | Comments |

|---|---|---|---|

| Geometry and Section Definition | 90–120 | 120–180 | GUI-based input in SAP2000; scripted coordinates and section definitions in OpenSeesPy. |

| Material and Spring Assignment | 60–90 | 90–120 | Materials and springs assigned via dialogs in SAP2000; manually defined in Python. |

| Load Application and Analysis Setup | 10–20 | 15–25 | SAP2000 uses graphical interfaces; OpenSeesPy requires command-based scripting. |

| Analysis Execution and Post-Processing | 15–20 | 35–45 | SAP2000 offers built-in plots; OpenSeesPy requires exporting recorders and plotting via Matplotlib. |

| Total (approx.) | 175–250 | 260–370 | OpenSeesPy takes longer initially but allows automation and full reproducibility. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pantoja, J.-C.; Tinoco, J.; Smith-Pardo, J.P.; Boada-Parra, G.; Matos, J. Visualization of Distributed Plasticity in Concrete Piles Using OpenSeesPy. Appl. Sci. 2025, 15, 8004. https://doi.org/10.3390/app15148004

Pantoja J-C, Tinoco J, Smith-Pardo JP, Boada-Parra G, Matos J. Visualization of Distributed Plasticity in Concrete Piles Using OpenSeesPy. Applied Sciences. 2025; 15(14):8004. https://doi.org/10.3390/app15148004

Chicago/Turabian StylePantoja, Juan-Carlos, Joaquim Tinoco, Jhon Paul Smith-Pardo, Gustavo Boada-Parra, and José Matos. 2025. "Visualization of Distributed Plasticity in Concrete Piles Using OpenSeesPy" Applied Sciences 15, no. 14: 8004. https://doi.org/10.3390/app15148004

APA StylePantoja, J.-C., Tinoco, J., Smith-Pardo, J. P., Boada-Parra, G., & Matos, J. (2025). Visualization of Distributed Plasticity in Concrete Piles Using OpenSeesPy. Applied Sciences, 15(14), 8004. https://doi.org/10.3390/app15148004