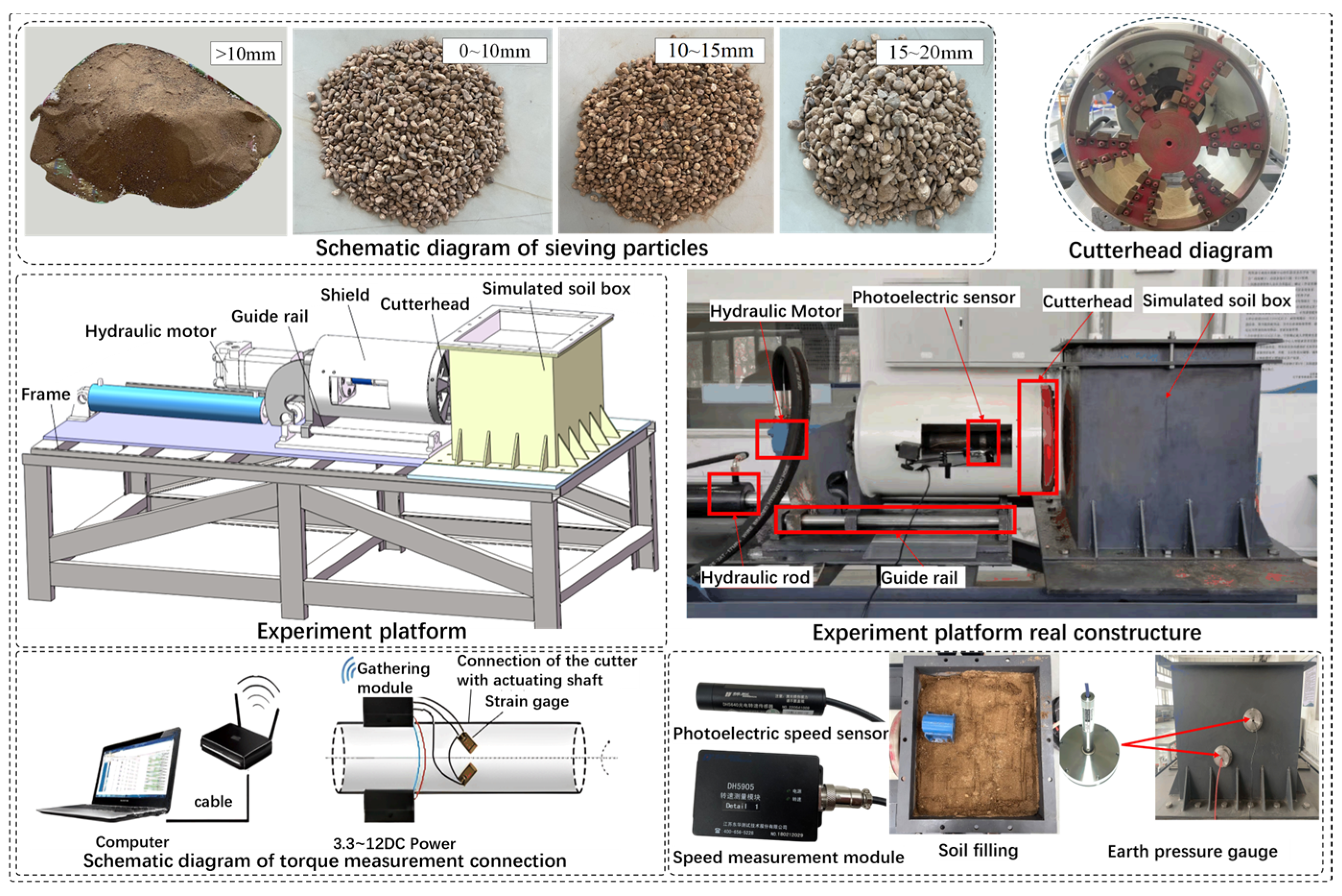

The working formation of the earth pressure balance shield machine studied in this paper is the sandy pebble formation, whose main components are sandy soil, gravel sand, and pebbles. The pebbles exhibit uneven particle sizes, strong abrasiveness, and poor fluidity. Due to the discontinuity of the formation, the torque and thrust of the cutterhead of the earth pressure balance shield machine fluctuate greatly during excavation, and wear of the cutterhead and cutting tools often occurs. In this section, the discrete element method is utilized to simulate the movement of the cutterhead system of the earth pressure balance shield machine in the sandy pebble formation and the influence of formation changes on the operating parameters of the cutterhead system is studied.

Discrete Element Simulation

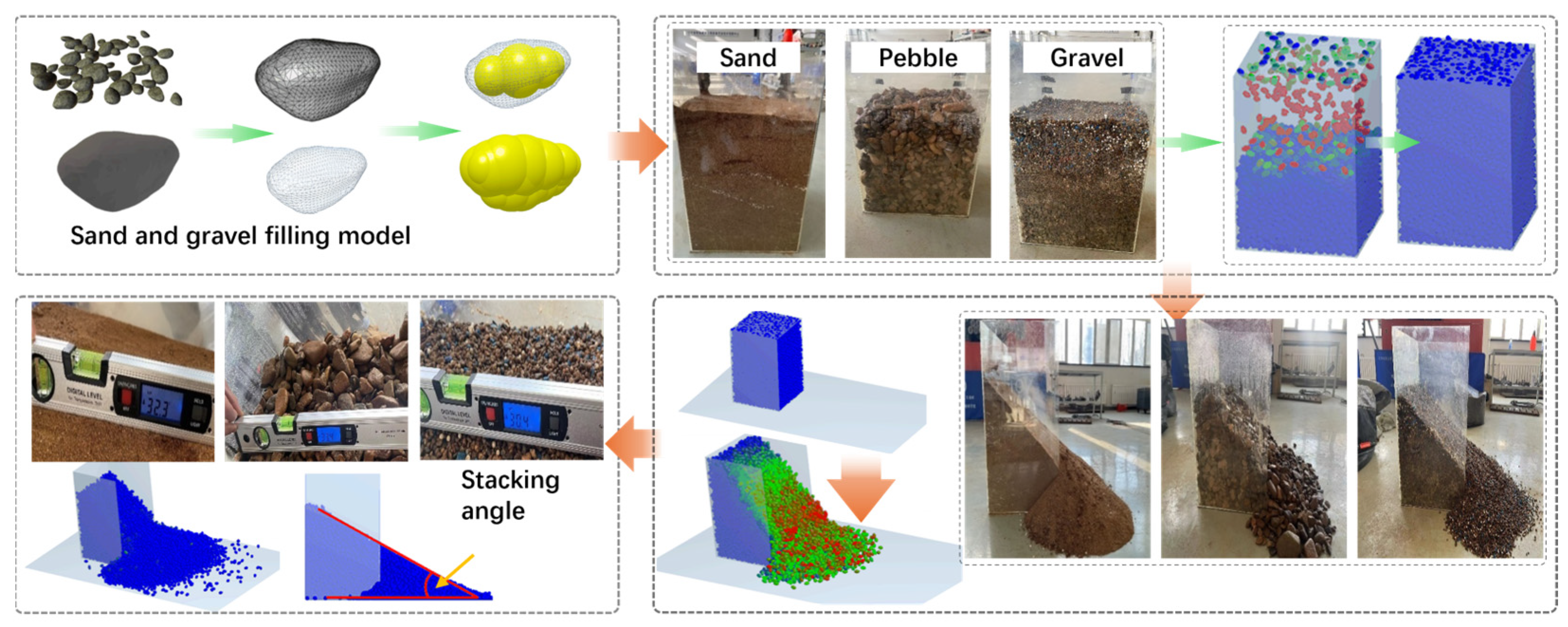

The DEM is utilized to calibrate the stacking angle. The stacking angle is known as the repose angle, which is maintained by the conical material pile when granular materials are freely stacked on a plane. The maximum angle between the slope surface of the material and the plane is called the maximum stacking angle. For loose granular materials, the natural repose angle is approximately equal to the peak friction angle of the soil. Therefore, the internal friction angle of the particles can be estimated through the accumulation angle experiment. The process of staking angle measurement is shown in

Figure 1.

In order to reduce the errors caused by manual operation, when conducting the stacking angle experiments of the three types of particles above, the stacking angle experiments of each type of particle were repeated in three groups, and the average value of the measured stacking angles was taken as the stacking angles of each type of particle, as shown in

Table 1. By consulting the geological exploration report and relevant materials, intrinsic parameters such as density, Poisson’s ratio, and shear modulus of the three types of particles can be obtained, as shown in

Table 2.

The simulated experiments on the stacking angles of three types of particles involved sand, pebbles, and gravel. To eliminate the randomness of the simulation, after comparison and multiple simulation exercises, the stacking angles, recovery coefficients, static friction coefficients, and rolling friction coefficients of the three particle materials were finally determined, as shown in

Table 3.

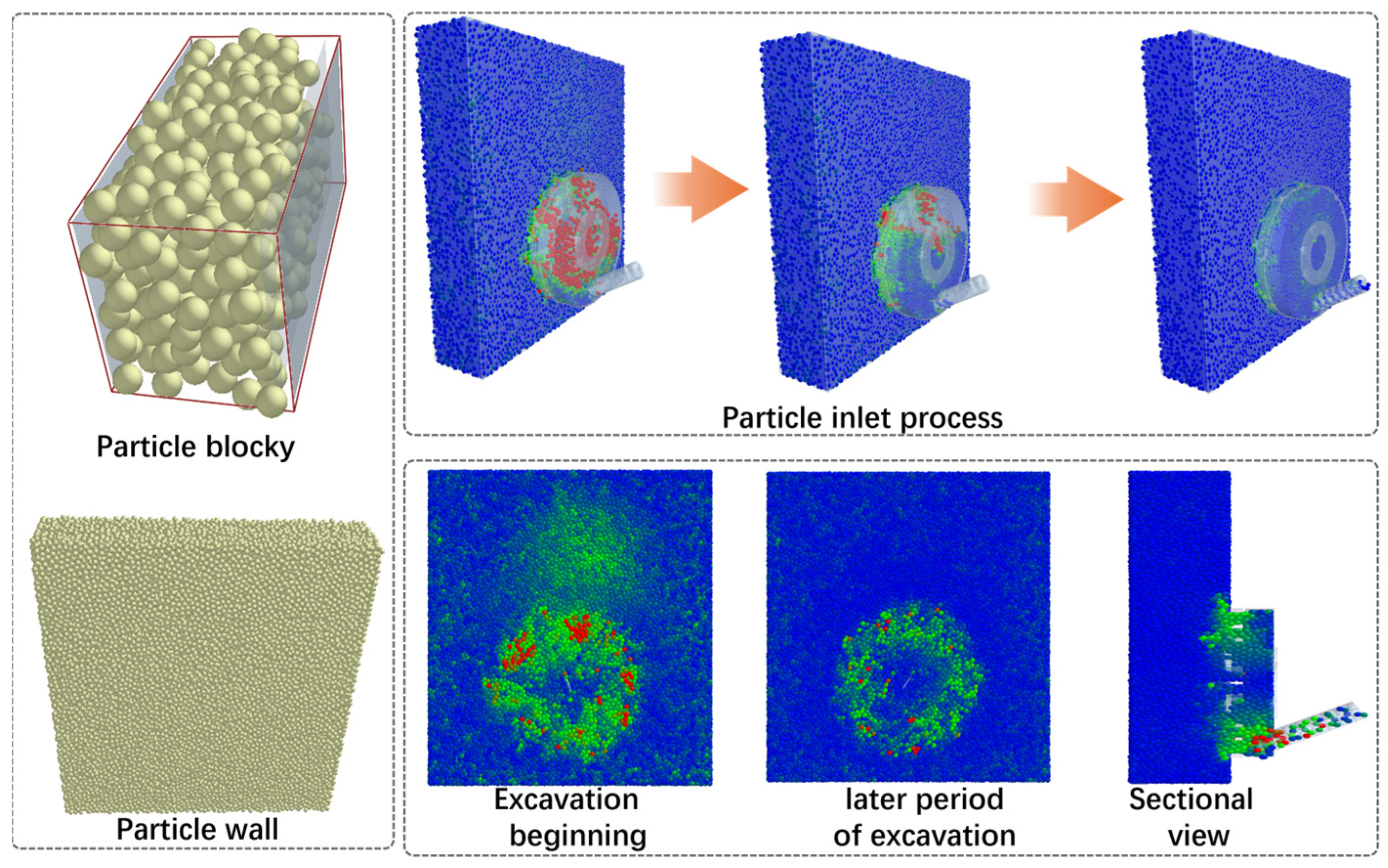

Figure 2 is a schematic diagram of the speed of particles entering the soil chamber and the tunneling face of the cutterhead. The color changes in the figure reflect the speed changes in particles entering the soil chamber.

When the cutter head system is being excavated, the particle movement at the face is relatively intense. In the later stage of the simulation, the particle movement is stable. It can be observed that the particle velocity is large in the part where the screw conveyor extends into the soil bunker.

Combining the simulation effect and calculation time, after adjustment, the selected particle diameter was 60 mm. The particle shape was circular particles. After the filling of each particle was completed, the particle wall was left to stand for 20 s. The tunneling speed of the cutter head system was set to 60 mm/min, the rotational speed of the cutter head to 1.6 r/min, and the rotational speed of the screw conveyor to 9 r/min; the step size was set to 20%. The simulation time for each group was set to 400 s, the data storage interval was set to 1 s, and the mesh particle size was set to 3R. Tunneling simulations were conducted in single-particle formation for three types of particles (sandy soil, gravel, and pebbles). Due to the discontinuous distribution of pebble layers in the formation, it was also necessary to conduct tunneling simulation of composite particle formation. The formations of sand—gravel, sand—pebbles, gravel—pebbles, and sand—gravel—pebbles were set up. The proportion of particles in the two types of formations was 50% each, and the proportion of particles in the three types of formations was 33.3% each.

The above simulation was conducted in a formation with a soil cover ratio of 1. The excavation simulation of the cutterhead system was then carried out in a formation with a soil cover ratio of 2. The formation setting scheme is shown in

Table 4. The rotational speed of the cutter head, the tunneling speed, and the rotational speed of the screw conveyor were preset parameters, while the torque and thrust of the cutter head were feedback parameters. Formation type five was selected, and the influence relationship of each parameter was analyzed. The simulation schemes for setting different rotational speeds and different tunneling speeds are shown in

Table 5.

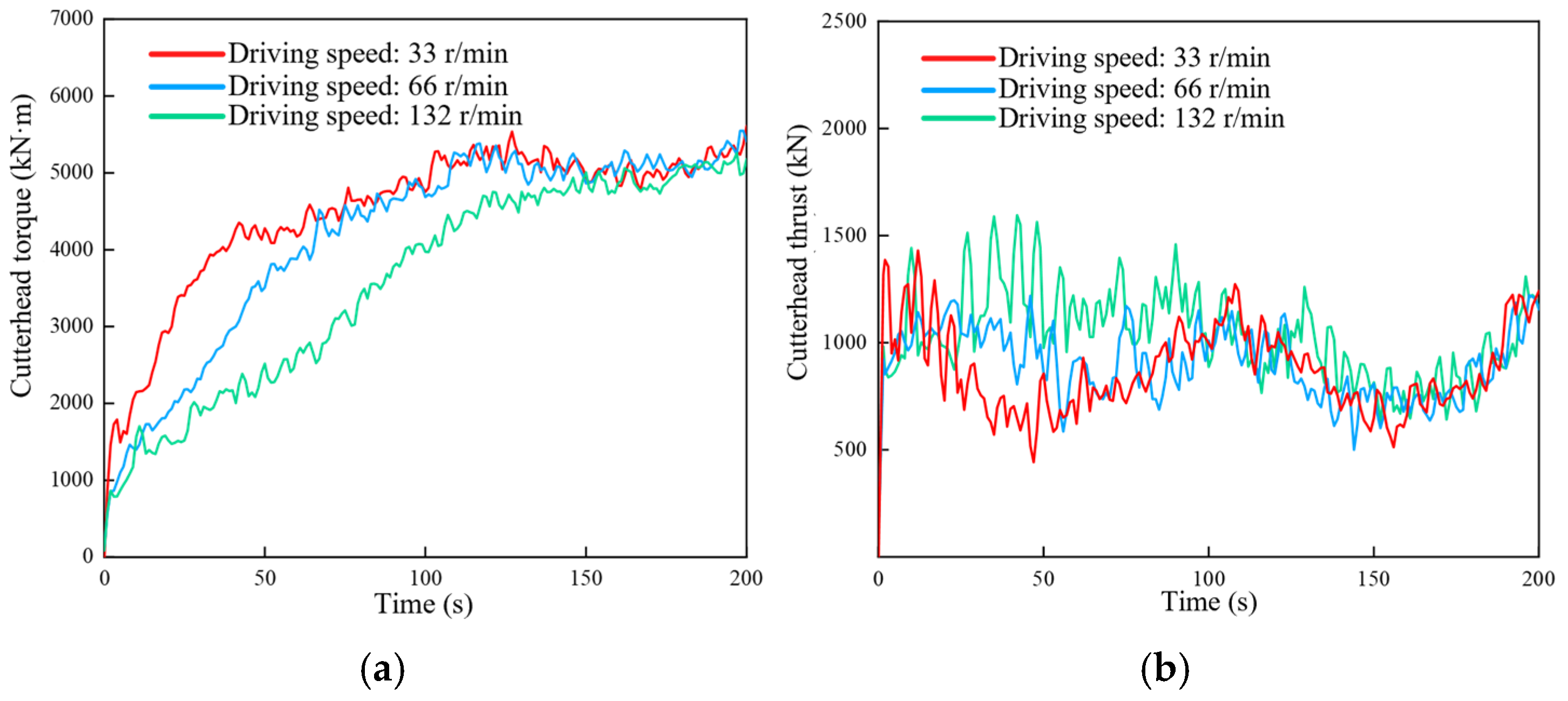

The torque of the cutterhead was analyzed through simulation of earth pressure balance shield machine tunneling.

Figure 3a,b show the torque and thrust of the cutterhead system when tunneling in a single granular formation. It can be seen from

Figure 3a that at the beginning of the tunneling, the torque of the cutterhead increases rapidly. In the middle stage of the simulation, as the tunneling enters the stable period, the increase in the torque of the cutterhead decreases and tends to be stable. The maximum torque of the cutter head in the sandy soil formation, the gravel and sand formation, and the pebble formation is 2430 kN·m, 4915 kN·m, and 5115 kN·m, respectively.

The formation depth and particle contact parameters were set the same as single formation tunneling. The simulation results of the composite formation were analyzed.

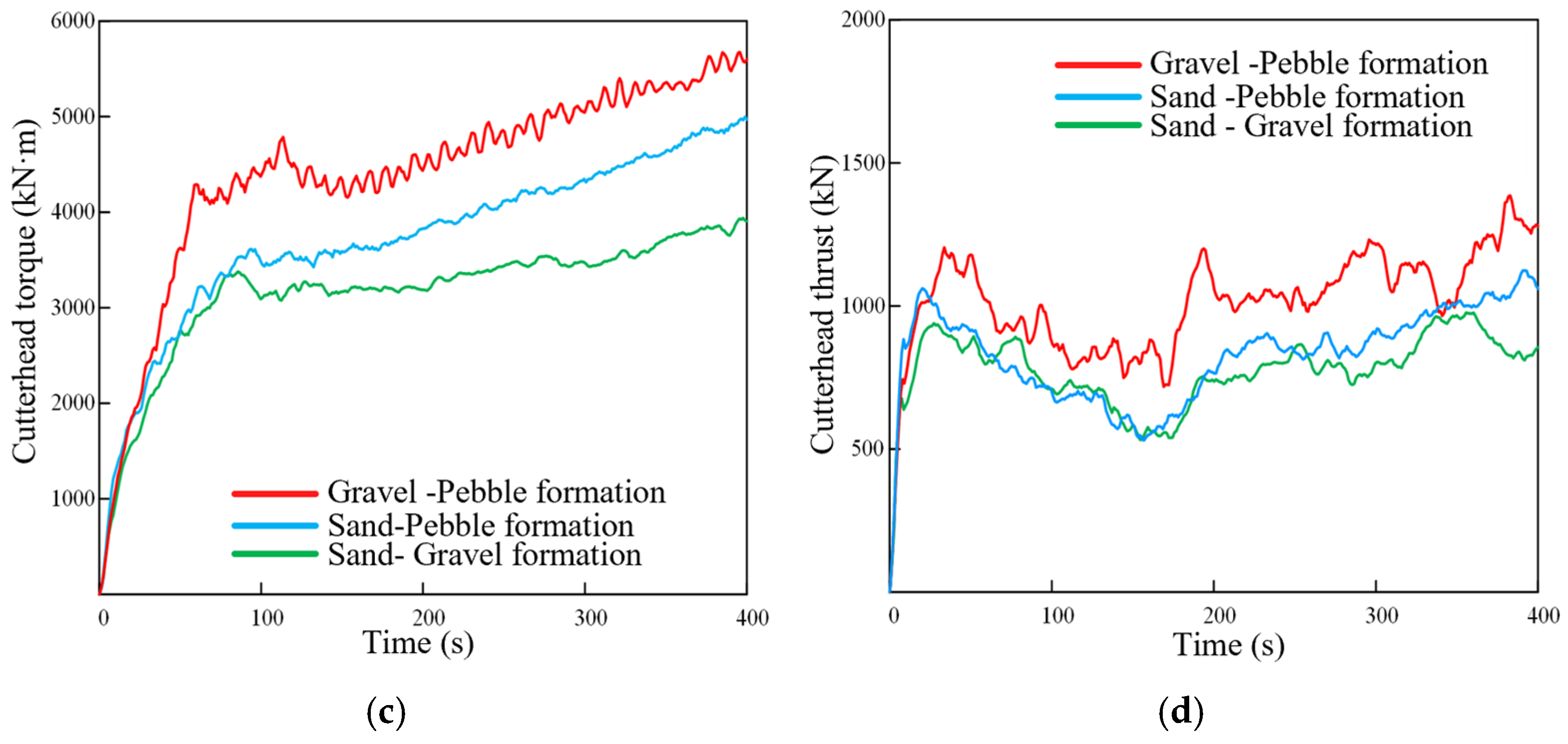

Figure 3c,d show the cutterhead torque and thrust of the cutterhead system for tunneling in the double-particle formation.

Figure 3c shows the torque of the cutter head in the double-particle formation. It can be seen that the torque of the cutter head increases with the increase in the content of gravel and pebble particles. The maximum torque of the cutter head in the sand–gravel formation is 4452 kN·m, the sand–pebble formation is 5615 kN·m, and the gravel–pebble formation is 5874 kN·m.

Figure 3d shows the thrust of the cutter head in the double-particle formation. In the sandy soil–gravel formation, the maximum thrust of the cutter head is 1256 kN. The maximum thrust of the cutter head in the sandy soil–pebble formation is 1204 kN, and in the gravel–pebble formation it is 1462 kN. When the content of gravel and pebbles increases, the excavation thrust of the cutter head system in the formation will increase accordingly.

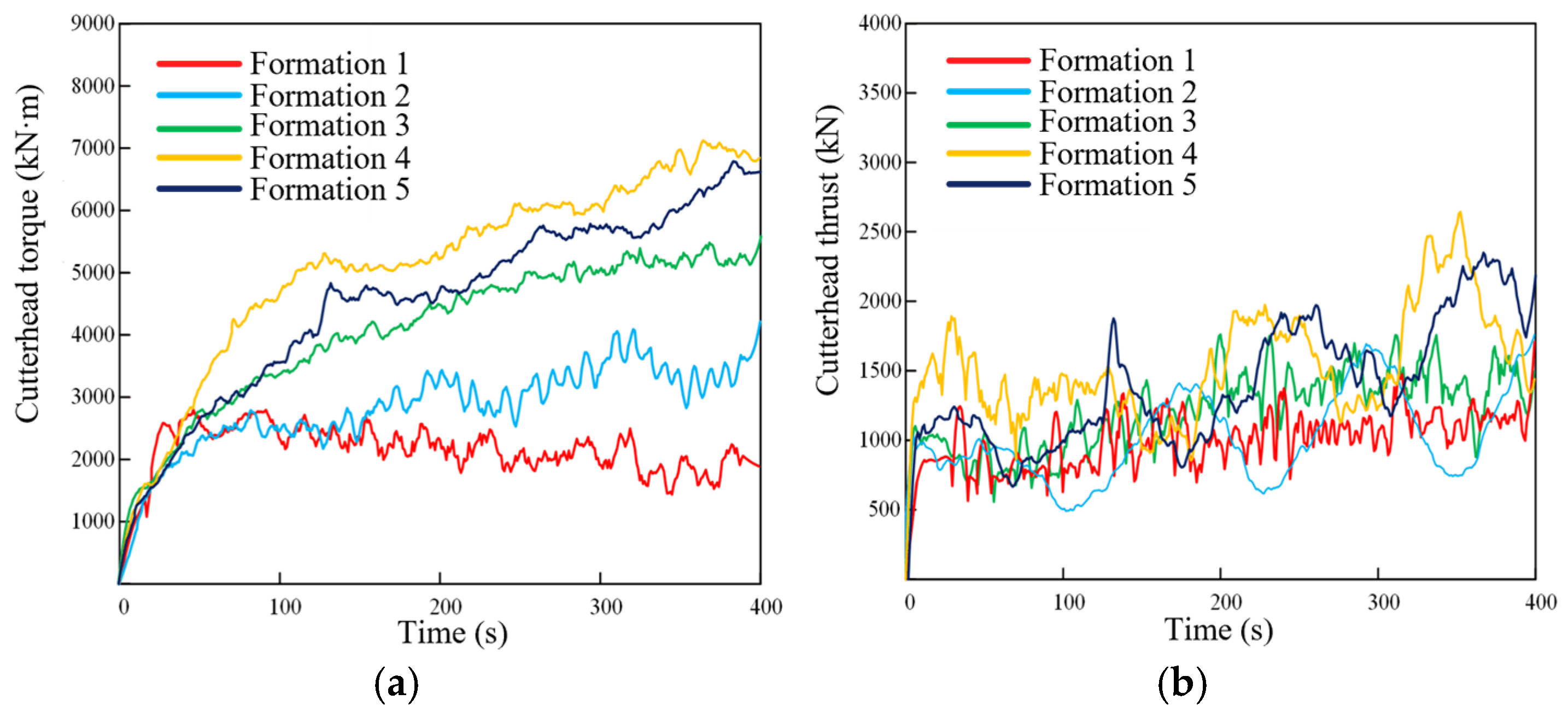

The torque and thrust of the cutter head with a soil cover ratio of 2 are shown in

Figure 4. The torque of the cutter head gradually increases and then tends to be stable. It can be observed from

Figure 4a that the torque of the cutter head increases with the increase in the contents of gravel-sand and pebble particle formation. The maximum torques of the cutter heads of formations 1, 2, 3, 4, and 5 are 2956 kN·m, 3756 kN·m, 5712 kN·m, and 6523 kN·m, respectively. In formation 1, there are sand particles. In the later stage of the simulation, the torque of the cutter head shows a downward trend. Among the four formations, the torque of the cutter head is the greatest, and the proportion of gravel, sand, and pebbles in the formation is the largest. It can be seen from

Figure 4b that the thrust of the cutter head fluctuates in the formation, with smaller amplitudes in formation 1 and formation 3 and larger amplitudes emerging in formation 2, formation 4, and formation 5.

In the research that follows, formation 5 is selected as the research object, and the simulation results in

Table 5 are analyzed to study the influence of tunneling parameters.

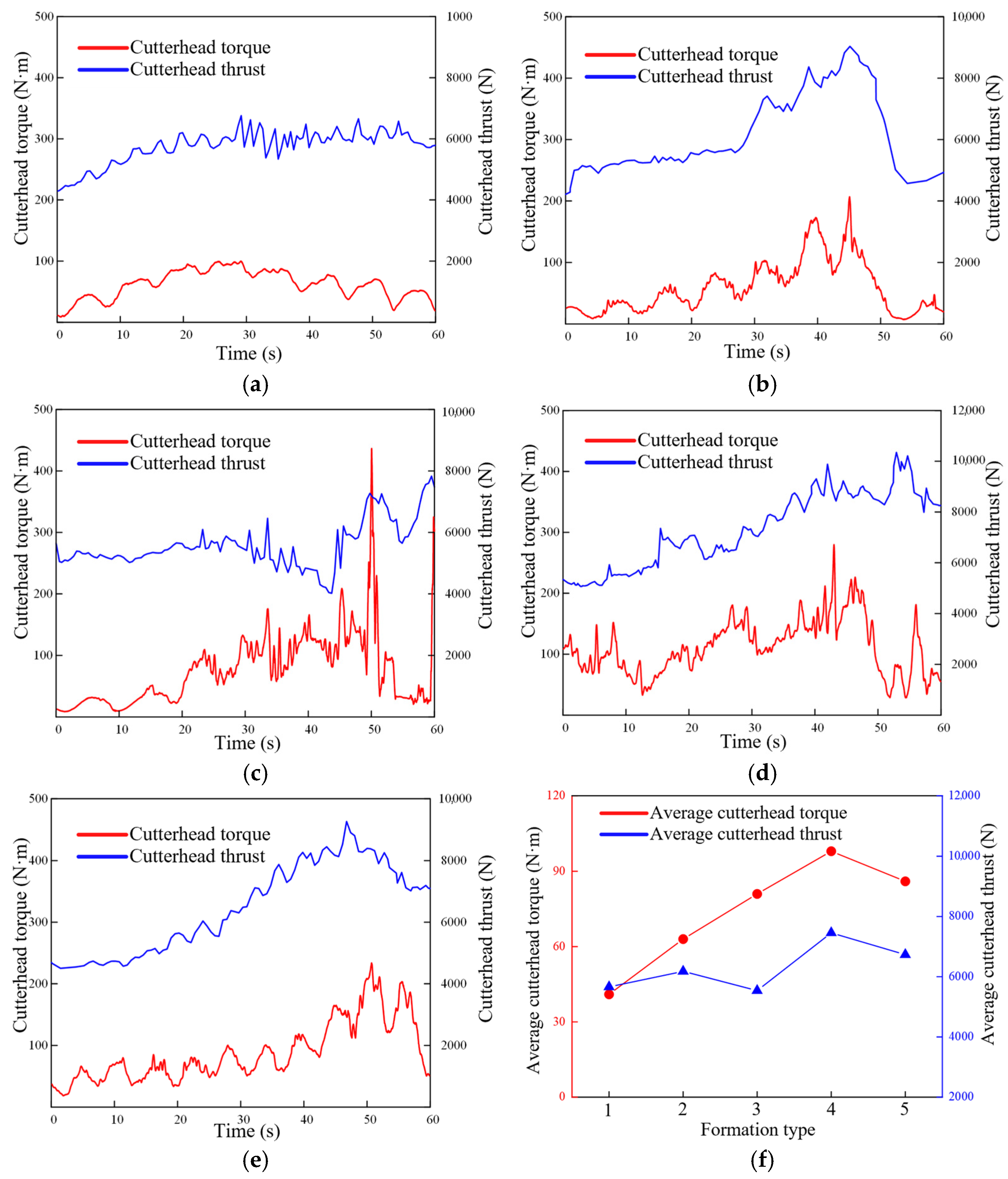

Figure 5 shows the torque and thrust of the screw conveyor at different cutter head speeds when the tunneling speed is 66 mm/min and the rotational speed is 10 r/min.

Figure 5a shows that the cutterhead torque increases with the rotational speed, whereas

Figure 5b shows that the cutterhead thrust decreases with the rotational speed of the cutterhead.

Figure 6 shows the torque and thrust of the cutter head at different tunneling speeds; the cutter head speed is 2 r/min and the screw conveyor speed is 10 r/min. It can be seen from

Figure 6a that the faster the tunneling speed, the slower the increase in the torque of the cutter head. When the cutter head enters a stable tunneling process, the torque value stabilizes at about 5000 kN·m. The thrust and torque of the cutterhead fluctuate at the beginning of tunneling. During stable tunneling, the thrust at each tunneling speed is within the same range.

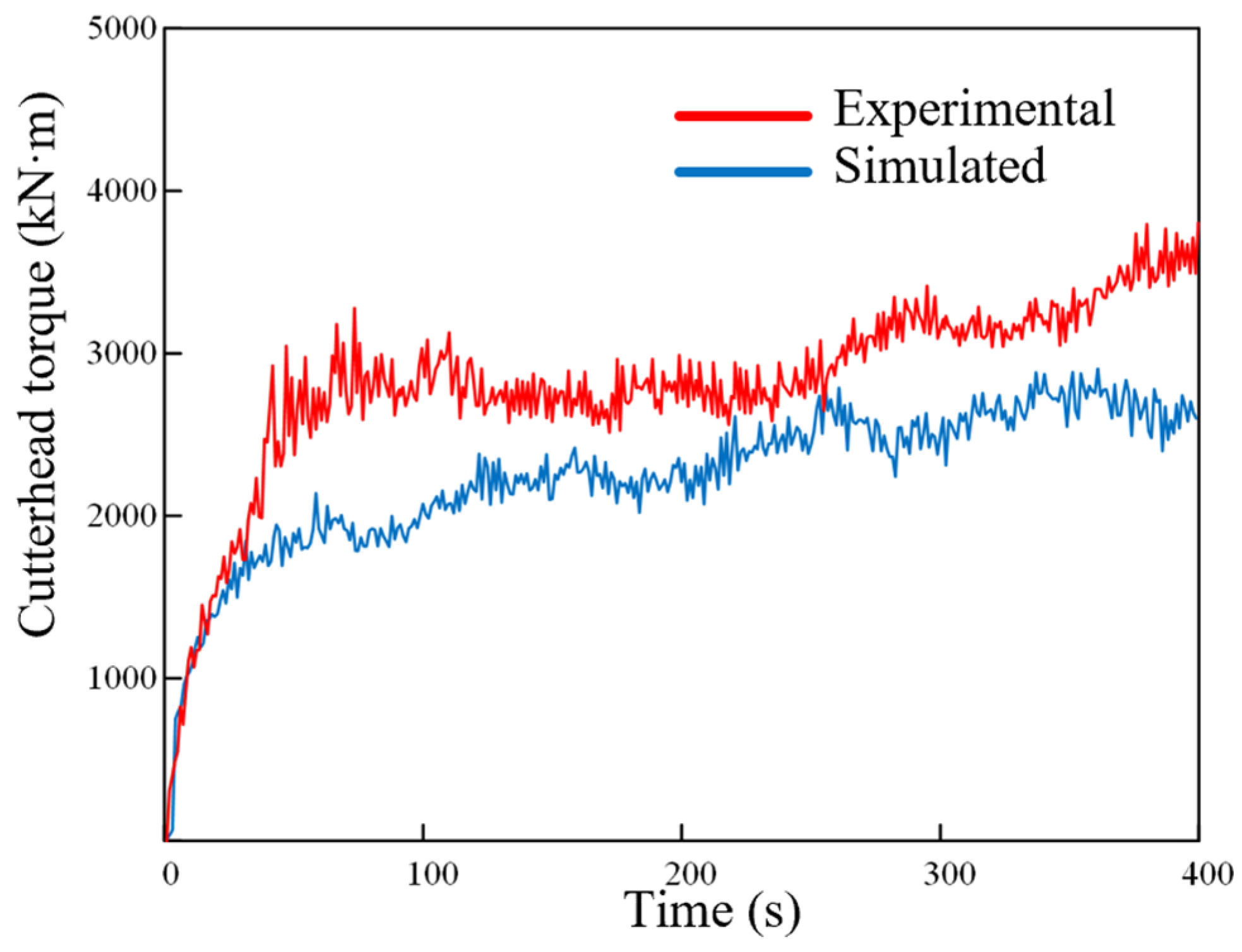

The actual cutterhead torque and the simulated cutterhead torque in one loop selected from this range are compared as shown in

Figure 7. It was found that the actual torque and the simulated torque increase instantaneously when the cutterhead starts tunneling, but the cutterhead torque gradually approaches stability at around 200 s.