Influence of Silane-Modified Coal Gangue Ceramsite on Properties of Ultra-High-Performance Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Grading Design

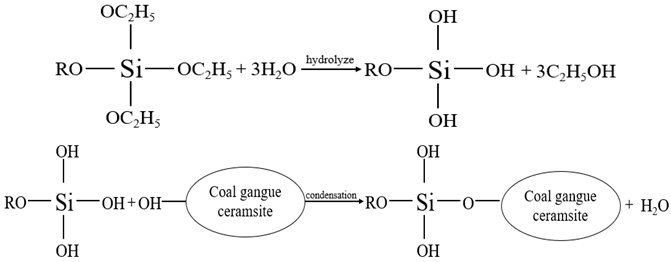

2.3. Hydrophobic Modification of Aggregate

2.4. Mixing Ratio

2.5. Contact Angle Experiment

2.6. Water Absorption

2.7. Fourier Infrared Exchange Spectrometer

2.8. Working Performance Experiment

2.9. Apparent Density

2.10. Mechanical Property Test

2.11. X-Ray Diffraction (XRD)

2.12. Thermogravimetric (TG) Analysis

2.13. Mercury Intrusion Porosimetry (MIP)

2.14. Scanning Electron Microscope (SEM)

3. Results and Discussion

3.1. Hydrophobic Modification

3.1.1. Contact Angle

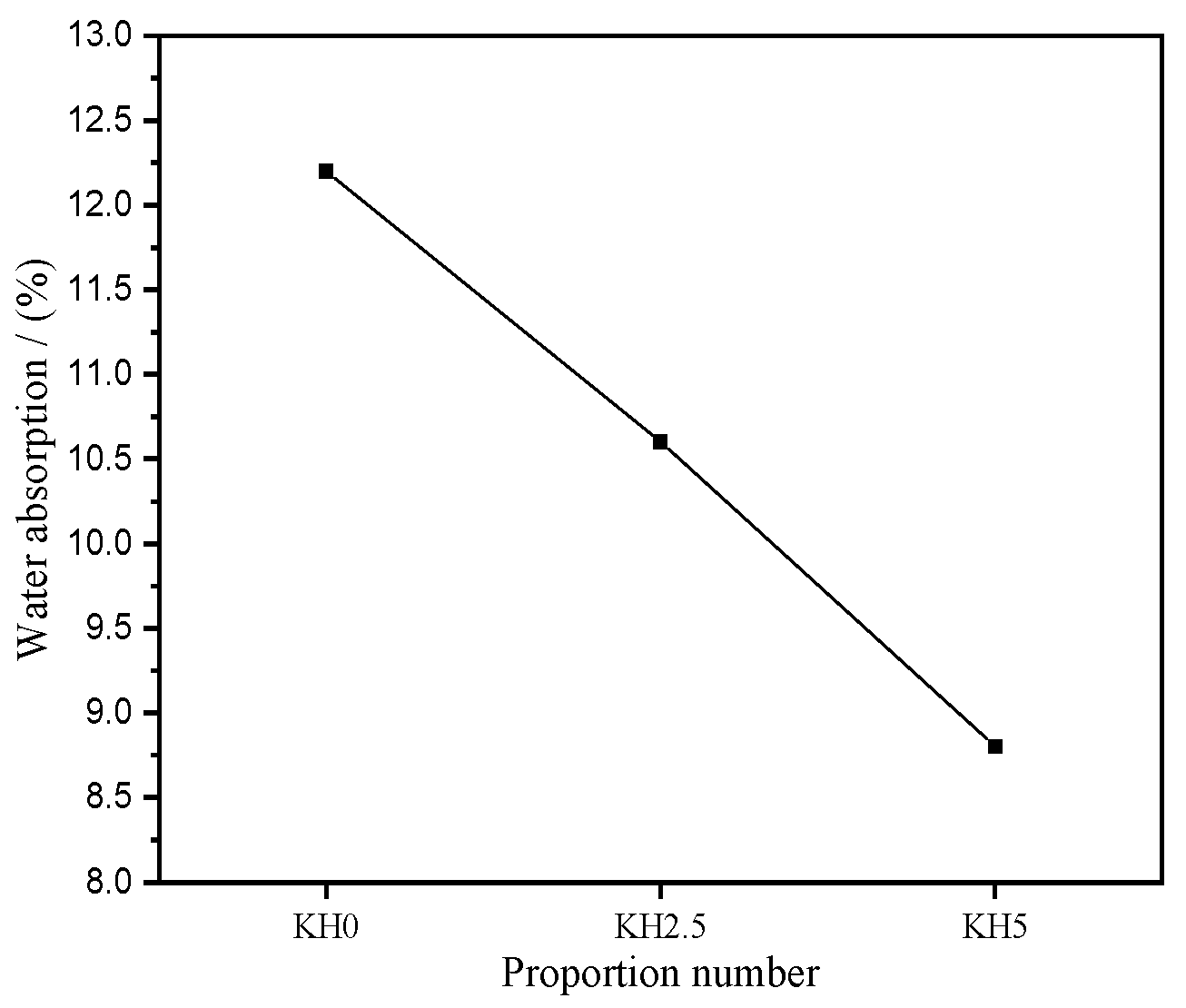

3.1.2. Water Absorption

3.1.3. FTIR Analysis

3.1.4. SEM

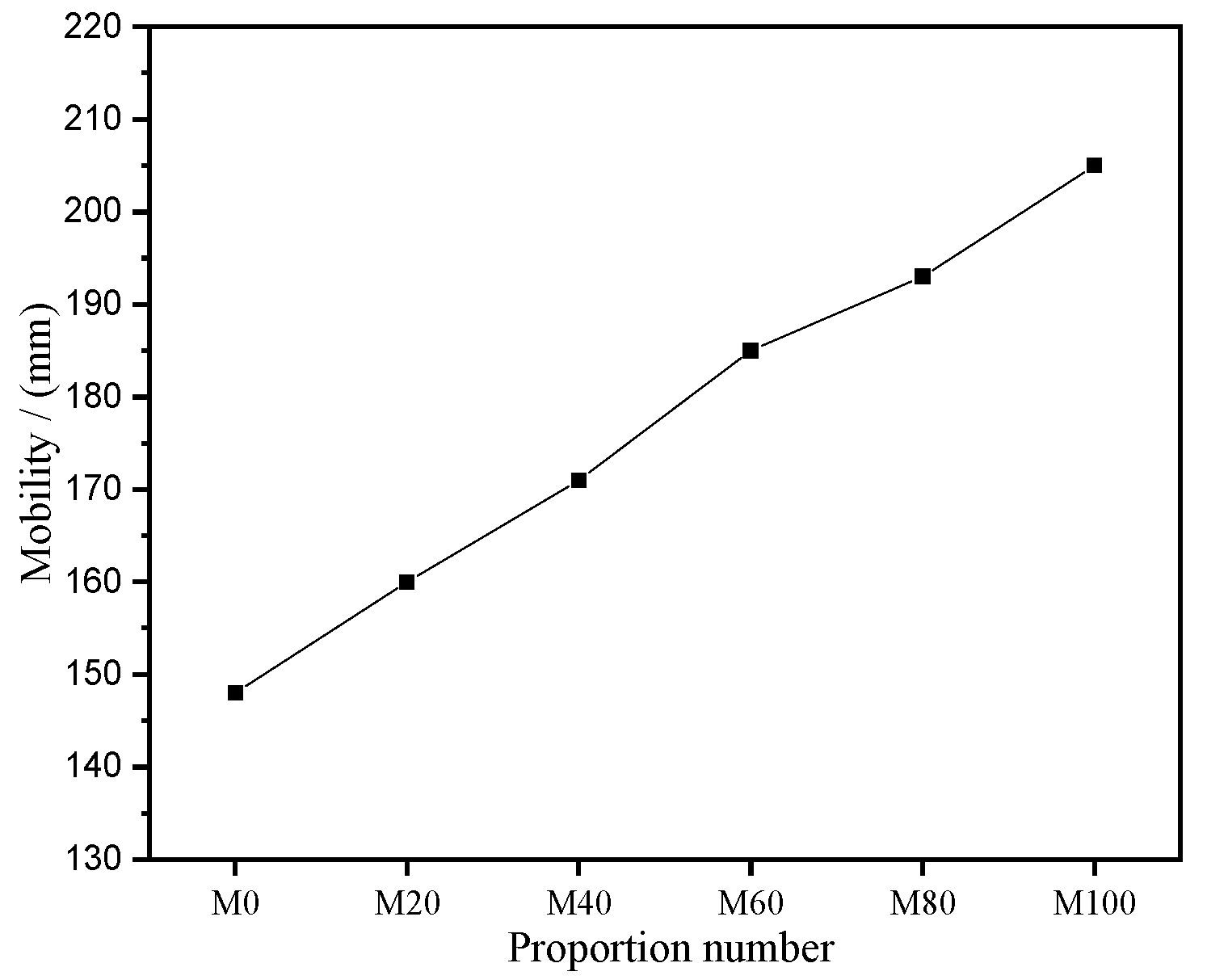

3.2. Working Performance

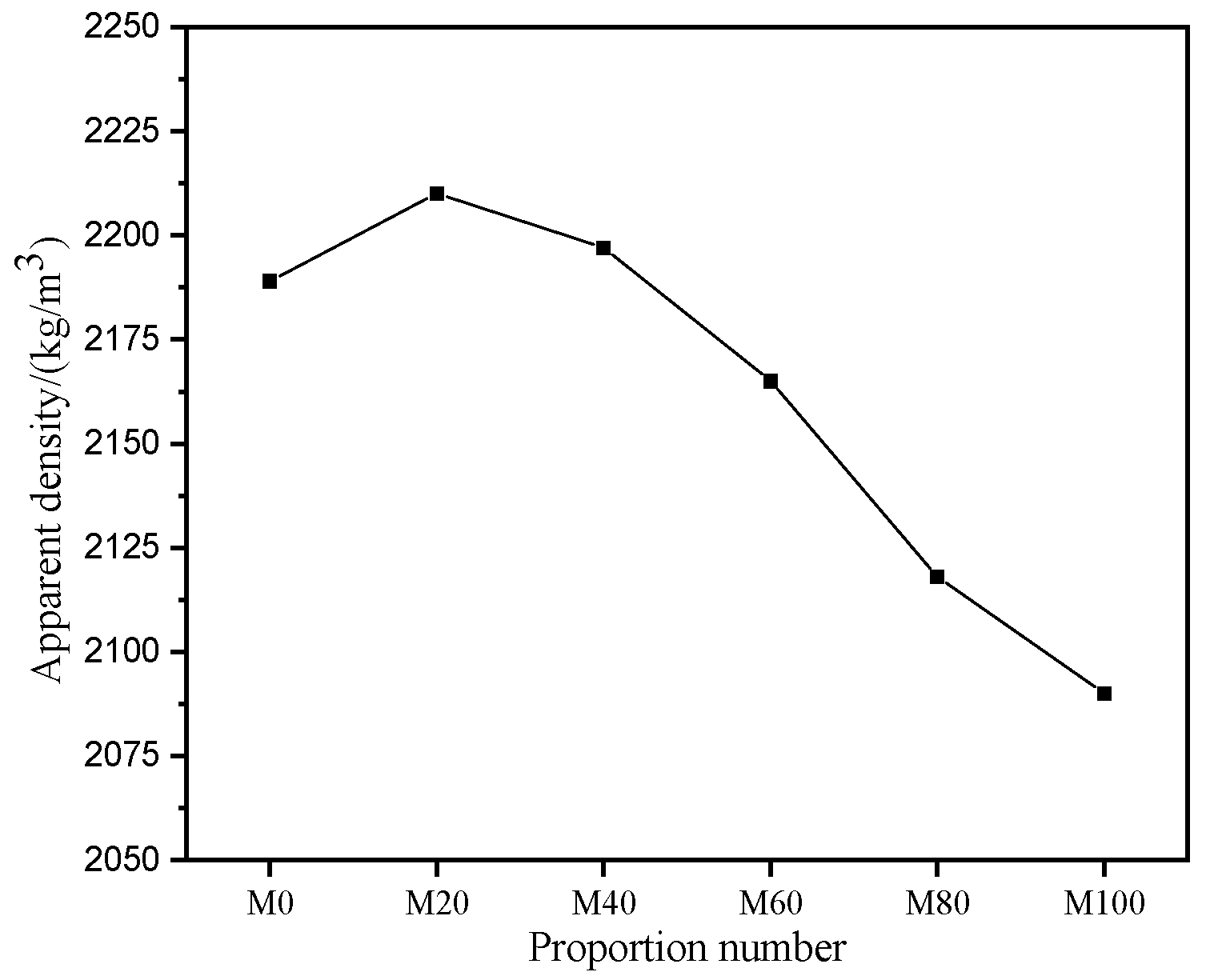

3.3. Apparent Density

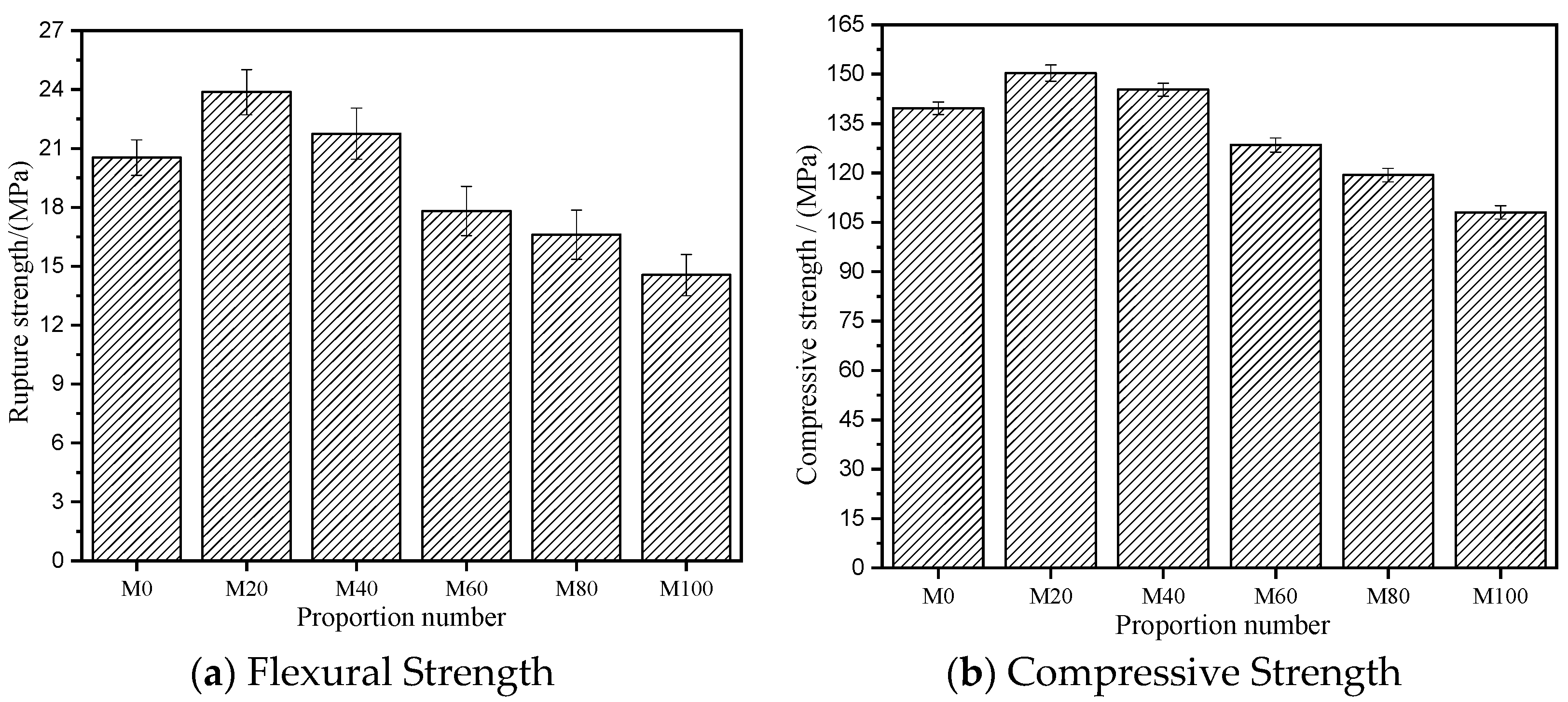

3.4. Mechanical Properties

3.5. Micro-Mechanism Analysis

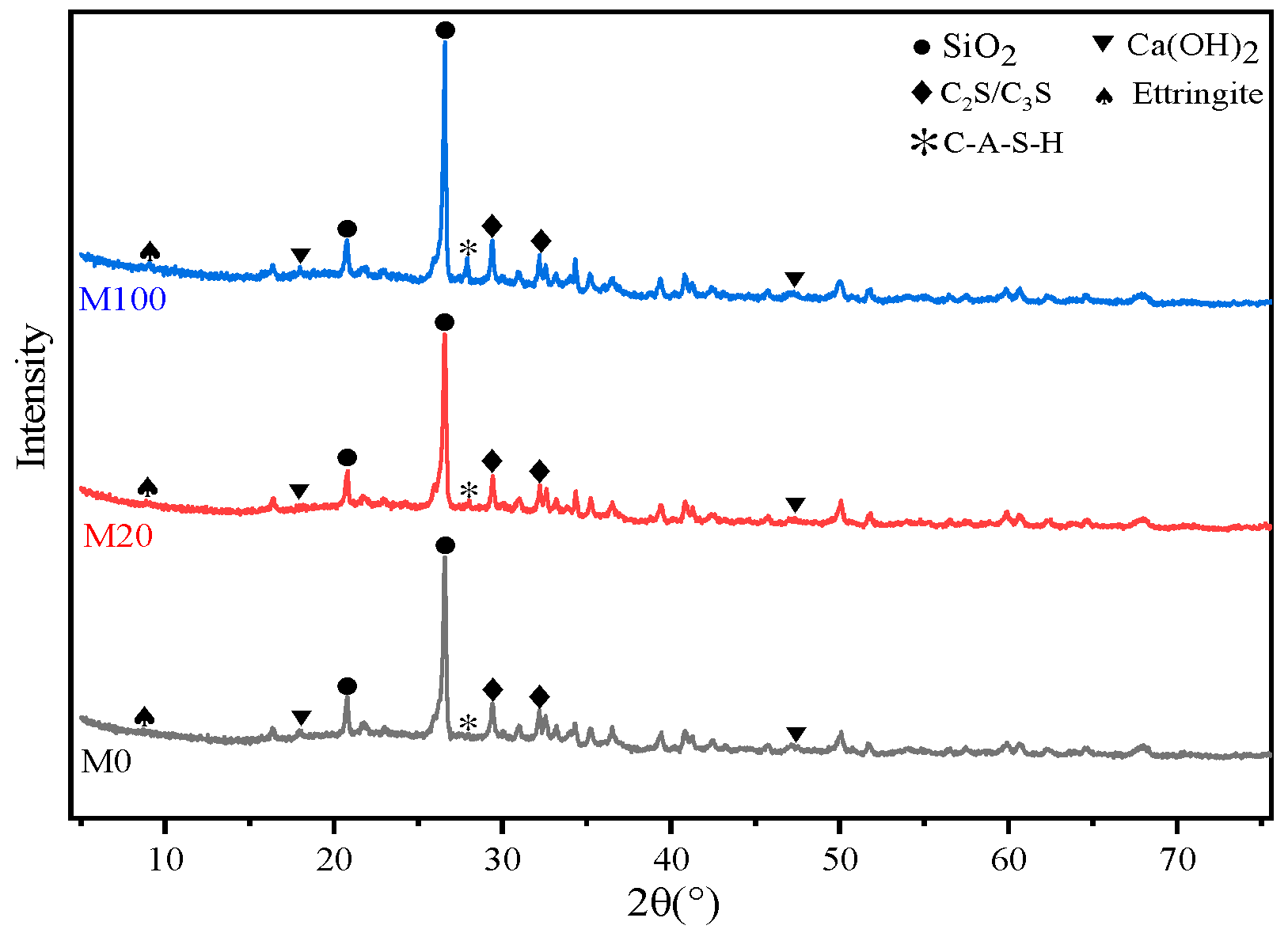

3.5.1. XRD Analysis

3.5.2. TG-DTG Analysis

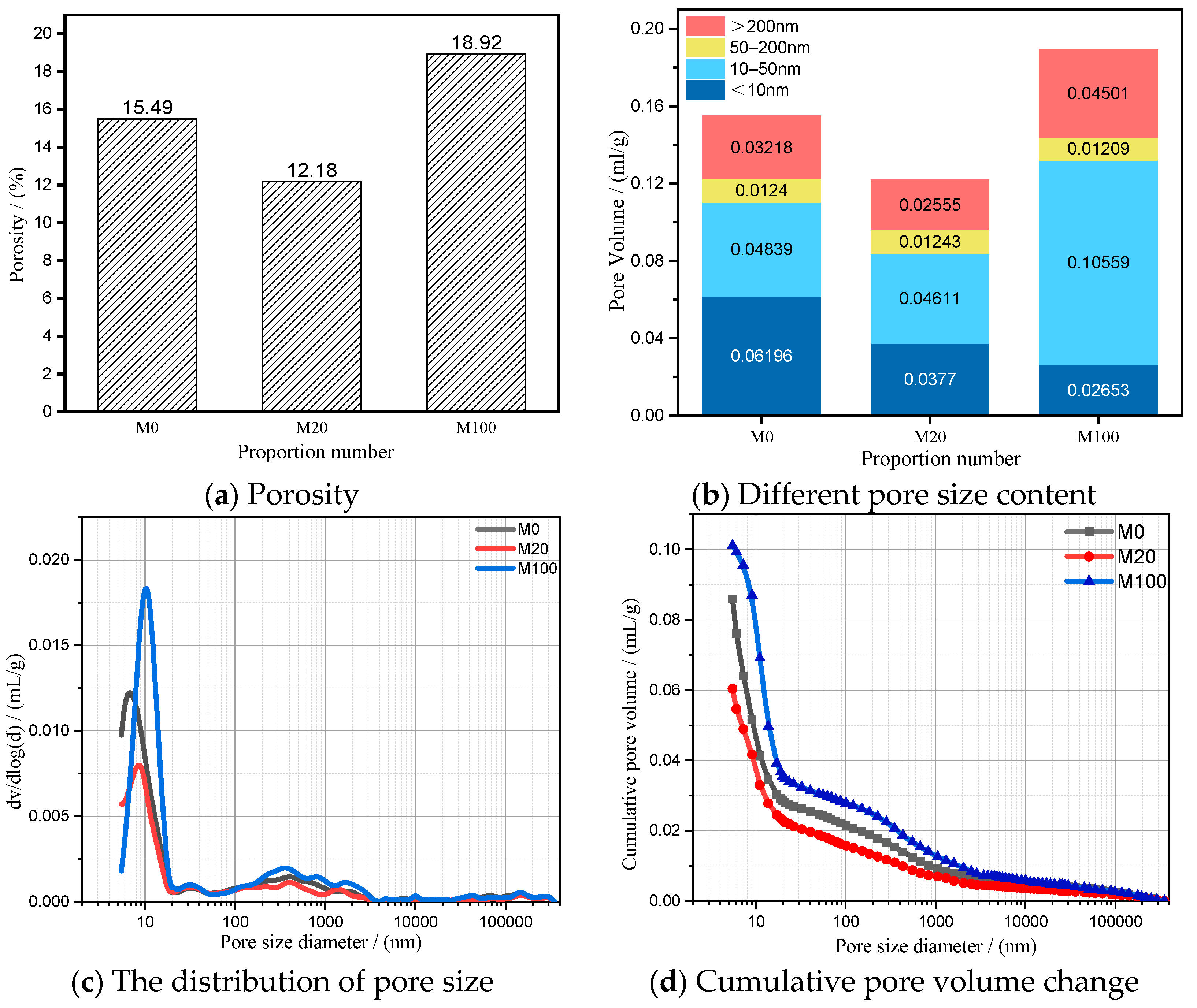

3.5.3. Pore Structure Analysis

3.5.4. SEM Analysis

4. Conclusions

- A 5% concentration of SCA solution can make CGC obviously hydrophobic. It is found that the water absorption of aggregate decreases by 27.9% and the contact angle reaches 111.32°. The changes of functional groups and morphology of the aggregate surface can be obviously observed by infrared analysis and scanning electron microscope.

- The working performance of UHPC was significantly improved with the increase of modified CGC content. When the substitution rate reached 100%, the fluidity increased by 38.51% compared with the reference group, which could effectively solve the influence of CGC super water absorption on the working performance of UHPC. However, the improvement of working performance is limited at low dosage, which shows that the effect of modified CGC on improving the fluidity of UHPC is more significant at a high substitution rate.

- When the substitution rate of modified CGC is less than 40%, the mechanical properties of UHPC 28d are improved. When the dosage is 20%, the flexural strength and compressive strength of UHPC are improved by 16% and 7%, respectively, compared with the M0 group without modified aggregate.

- Through XRD and TG-DTG experiments, it is found that the addition of modified aggregate is beneficial to improve the hydration degree of UHPC. The addition of hydrophobic aggregate can prevent too much free water from being absorbed by the aggregate and thus participate in the reaction of cement slurry to improve the degree of hydration. At the same time, MIP and SEM experiments show that adding 20% modified aggregate is beneficial in reducing the porosity of UHPC, optimizing the interfacial bonding performance, and improving its mechanical properties. However, when the content is further increased by more than 40%, the internal porosity of UHPC increases and the mechanical properties decrease. Although MIP and TG-DTG did not analyze the intermediate group, the trend showed that the porosity gradually increased from M20 to M100, and the interfacial bonding strength gradually decreased, which was consistent with the mechanical strength results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khayat, K.H.; Meng, W.N.; Vallurupalli, K.; Teng, L. Rheological properties of ultra-high-performance concrete—An overview. Cem. Concr. Res. 2019, 124, 16. [Google Scholar] [CrossRef]

- Wang, D.H.; Shi, C.J.; Wu, Z.M.; Xiao, J.F.; Huang, Z.Y.; Fang, Z. A review on ultra high performance concrete: Part II. Hydration, microstructure and properties. Constr. Build. Mater. 2015, 96, 368–377. [Google Scholar] [CrossRef]

- Tuan, N.V.; Ye, G.; van Breugel, K.; Copuroglu, O. Hydration and microstructure of ultra high performance concrete incorporating rice husk ash. Cem. Concr. Res. 2011, 41, 1104–1111. [Google Scholar] [CrossRef]

- Meng, W.N.; Khayat, K. Effects of saturated lightweight sand content on key characteristics of ultra-high-performance concrete. Cem. Concr. Res. 2017, 101, 46–54. [Google Scholar] [CrossRef]

- Guo, K.Z.; Zhang, G.Z.; Li, Y.; Yang, J.; Ding, Q.J. The mechanism of curing regimes on the macroscopic properties and microstructure of ultra-high performance concrete with lightweight aggregates. J. Build. Eng. 2024, 82, 20. [Google Scholar] [CrossRef]

- Lu, J.X.; Shen, P.L.; Zheng, H.B.; Ali, H.A.; Poon, C.S. Development and characteristics of ultra high-performance lightweight cementitious composites (UHP-LCCs). Cem. Concr. Res. 2021, 145, 17. [Google Scholar] [CrossRef]

- Dong, E.L.; Yu, R.; Fan, D.Q.; Chen, Z.; Ma, X.W. Absorption-desorption process of internal curing water in ultra-high performance concrete (UHPC) incorporating pumice: From relaxation theory to dynamic migration model. Cem. Concr. Compos. 2022, 133, 17. [Google Scholar] [CrossRef]

- Shi, J.Y.; Liu, B.J.; Zhou, F.; Shen, S.; Dai, J.D.; Ji, R.J.; Tan, J.X. Heat damage of concrete surfaces under steam curing and improvement measures. Constr. Build. Mater. 2020, 252, 16. [Google Scholar] [CrossRef]

- Sultan, H.K.; Alyaseri, I. Effects of elevated temperatures on mechanical properties of reactive powder concrete elements. Constr. Build. Mater. 2020, 261, 14. [Google Scholar] [CrossRef]

- Frías, M.; de Rojas, M.I.S.; García, R.; Valdés, A.J.; Medina, C. Effect of activated coal mining wastes on the properties of blended cement. Cem. Concr. Compos. 2012, 34, 678–683. [Google Scholar] [CrossRef]

- Qiu, J.S.; Zhu, M.Y.; Zhou, Y.X.; Guan, X. Effect and mechanism of coal gangue concrete modification by fly ash. Constr. Build. Mater. 2021, 294, 15. [Google Scholar] [CrossRef]

- Guan, H.B.; Yu, J.T.; Kibugenza, A.S.U.; Sun, Q.W. Preparation of coal gangue ceramsite high-strength concrete and investigation of its physico-mechanical properties. Sci. Rep. 2022, 12, 13. [Google Scholar] [CrossRef] [PubMed]

- Peng, C.; Dai, G.F.; Wang, Y.H.; Yang, J.H.; Wang, C.X.; Jiao, S.; Chen, L.; Duan, C.L.; Li, P. Preparation of high-strength ceramsite from coal gangue and printing and dyeing sludge: Design strategy and modelling mechanism. Ceram. Int. 2024, 50, 19963–19970. [Google Scholar] [CrossRef]

- Zhong, M.Y.; Meng, J.; Ning, B.K.; Na, F.X.; Cui, T.T.; Shi, X.X.; Cui, T. Preparation and alkali excitation mechanism of coal gangue-iron ore tailings non-sintering ceramsite. Constr. Build. Mater. 2024, 426, 12. [Google Scholar] [CrossRef]

- Yuan, P.; Zhu, Y.S.; Li, D.H.; Lu, X.F. Effect of Freeze-Thaw Cycle and Moisture Content on Compressive and Energy Properties of Alkali Slag Ceramsite Concrete. KSCE J. Civ. Eng. 2024, 28, 1980–1991. [Google Scholar] [CrossRef]

- Wang, C.Q.; Duan, D.Y.; Huang, D.M.; Chen, Q.; Tu, M.J.; Wu, K.; Wang, D. Lightweight ceramsite made of recycled waste coal gangue & municipal sludge: Particular heavy metals, physical performance and human health. J. Clean. Prod. 2022, 376, 16. [Google Scholar] [CrossRef]

- Aslam, M.; Shafigh, P.; Jumaat, M.Z.; Lachemi, M. Benefits of using blended waste coarse lightweight aggregates in structural lightweight aggregate concrete. J. Clean. Prod. 2016, 119, 108–117. [Google Scholar] [CrossRef]

- Sifan, M.; Nagaratnam, B.; Thamboo, J.; Poologanathan, K.; Corradi, M. Development and prospectives of lightweight high strength concrete using lightweight aggregates. Constr. Build. Mater. 2023, 362, 19. [Google Scholar] [CrossRef]

- Wang, Y.S.; Qiu, J.P.; Deng, W.; Xing, J.; Liang, J. Factors Affecting Brittleness Behavior of Coal-Gangue Ceramsite Lightweight Aggregate Concrete. Front. Mater. 2020, 7, 9. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, N. Influence of coal gangue aggregate grading on strength properties of concrete. Wuhan Univ. J. Nat. Sci. 2015, 20, 66–72. [Google Scholar] [CrossRef]

- Chen, D.D.; Ding, Q.J.; Zhang, G.Z.; Zhou, P.; Deng, Y.T.; Wan, C.Q.; Wang, X.P.; Xu, Q.Y. Development and characteristics of sustainable ultra-high performance concrete utilizing coal gangue ceramsite. Constr. Build. Mater. 2025, 459, 17. [Google Scholar] [CrossRef]

- Liu, J.M.; Ju, B.Y.; Yin, Q.; Xie, W.; Xiao, H.Y.; Dong, S.L.; Yang, W.S. Properties of Concrete Prepared with Silane Coupling Agent-Impregnated Coral Aggregate and Coral Concrete. Materials 2021, 14, 15. [Google Scholar] [CrossRef]

- Dong, Q.; Huang, B.S.; Shu, X. Rubber modified concrete improved by chemically active coating and silane coupling agent. Constr. Build. Mater. 2013, 48, 116–123. [Google Scholar] [CrossRef]

- Yiluo, Z.; Qijie, G.; Xiaoping, J.I. Experimental Research on Asphalt Treated Recycled Aggregate. J. Build. Mater. 2016, 9, 725–741. [Google Scholar]

- McBride, S.P.; Shukla, A.; Bose, A. Processing and characterization of a lightweight concrete using cenospheres. J. Mater. Sci. 2002, 37, 4217–4225. [Google Scholar] [CrossRef]

- Iorio, M.; Santarelli, M.L.; González-Gaitano, G.; González-Benito, J. Surface modification and characterization of basalt fibers as potential reinforcement of concretes. Appl. Surf. Sci. 2018, 427, 1248–1256. [Google Scholar] [CrossRef]

- Wang, Y.S.; Qiu, J.P.; Zeng, C. Shrinkage and Strength Properties of Coal Gangue Ceramsite Lightweight Aggregate Concrete. Adv. Mater. Sci. Eng. 2020, 2020, 10. [Google Scholar] [CrossRef]

- Makul, N.; Fediuk, R.; Amran, M.; Zeyad, A.M.; Klyuev, S.; Chulkova, I.; Ozbakkaloglu, T.; Vatin, N.; Karelina, M.; Azevedo, A. Design Strategy for Recycled Aggregate Concrete: A Review of Status and Future Perspectives. Crystals 2021, 11, 29. [Google Scholar] [CrossRef]

- Hüsken, G.; Brouwers, H.J.H. A new mix design concept for earth-moist concrete: A theoretical and experimental study. Cem. Concr. Res. 2008, 38, 1246–1259. [Google Scholar] [CrossRef]

- Gao, X.; Yu, Q.L.; Brouwers, H.J.H. Assessing the porosity and shrinkage of alkali activated slag-fly ash composites designed applying a packing model. Constr. Build. Mater. 2016, 119, 175–184. [Google Scholar] [CrossRef]

- Borges, P.H.R.; Fonseca, L.F.; Nunes, V.A.; Panzera, T.H.; Martuscelli, C.C. Andreasen Particle Packing Method on the Development of Geopolymer Concrete for Civil Engineering. J. Mater. Civ. Eng. 2014, 26, 692–697. [Google Scholar] [CrossRef]

- Ng, T.S.; Foster, S.J. Development of a mix design methodology for high-performance geopolymer mortars. Struct. Concr. 2013, 14, 148–156. [Google Scholar] [CrossRef]

- Wang, X.P.; Yu, R.; Shui, Z.H.; Song, Q.L.; Zhang, Z.H. Mix design and characteristics evaluation of an eco-friendly Ultra-High Performance Concrete incorporating recycled coral based materials. J. Clean. Prod. 2017, 165, 70–80. [Google Scholar] [CrossRef]

- Qian, D.; Yu, R.; Shui, Z.H.; Sun, Y.; Jiang, C.Y.; Zhou, F.J.; Ding, M.X.; Tong, X.S.; He, Y.J. A novel development of green ultra-high performance concrete (UHPC) based on appropriate application of recycled cementitious material. J. Clean. Prod. 2020, 261, 12. [Google Scholar] [CrossRef]

- Hüsken, G. A Multifunctional Design Approach for Sustainable Concrete: With Application to Concrete Mass Products. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2010. [Google Scholar]

- GB/T 50081-2019; Standard for Test Methods of Mechanical Properties of Ordinary Concrete. China Planning Press: Beijing, China, 2019.

- Zhang, D.R.; Zhu, H.J.; Wu, Q.S.; Yang, T.; Yin, Z.F.; Tian, L. Investigation of the hydrophobicity and microstructure of fly ash-slag geopolymer modified by polydimethylsiloxane. Constr. Build. Mater. 2023, 369, 8. [Google Scholar] [CrossRef]

- Prud’Homme, E.; Michaud, P.; Joussein, E.; Peyratout, C.; Smith, A.; Rossignol, S. In situ inorganic foams prepared from various clays at low temperature. Appl. Clay Sci. 2011, 51, 15–22. [Google Scholar] [CrossRef]

- Guo, X.; Dong, Y.; Di, J.; Li, Y. Modified Gangue for Coal Mine Wastewater’s Fe2+ and Mn2+ Adsorption. Non-Met. Mines 2017, 40. [Google Scholar] [CrossRef]

- Ma, Z.M.; Zhu, F.Z.; Zhao, T.J. Effects of surface modification of silane coupling agent on the properties of concrete with freeze-thaw damage. KSCE J. Civ. Eng. 2018, 22, 657–669. [Google Scholar] [CrossRef]

- GB/T 2419-2005; Test Method for Fluidity of Cement Mortar. China Standards Press: Beijing, China, 2005.

- Shan, R.; Han, T.; Zhao, W.; Wu, H.; Bai, Y.; Xu, Z.; Qiao, D.; Jing, G. Study on the performance of coal gangue ceramsite steel fiber high strength concrete. J. Build. Eng. 2024, 95, 110121. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, A.; Zhu, Y.; Dai, J.-G.; Xu, Q.; Liu, K.; Hao, F.; Sun, D. Manufacturing ultra-high performance geopolymer concrete (UHPGC) with activated coal gangue for both binder and aggregate. Compos. Part B Eng. 2024, 284, 111723. [Google Scholar] [CrossRef]

- Luo, B.Y.; Xiong, G.J.; Li, G.Y.; Li, Y.Q. Feature of silane coupling agent modified new to old concrete repair interfacial layer. J. Wuhan Univ. Technol. 2004, 26, 9–11. [Google Scholar] [CrossRef]

- Hou, C.Y.; Zhang, H.B. Effect of Silane Coupling Agent Treatment of Aggregates on Mortar Workability, Strength and Interfacial Microscopic Properties. Materials 2023, 16, 17. [Google Scholar] [CrossRef]

- Pan, Z.H.; Chen, J.M.; Zhan, Q.W.; Wang, S.G.; Jin, R.Y.; Shamass, R.; Rossi, F. Mechanical properties of PVC concrete and mortar modified with silane coupling agents. Constr. Build. Mater. 2022, 348, 11. [Google Scholar] [CrossRef]

- Kashani, A.; Ngo, T.D.; Hemachandra, P.; Hajimohammadi, A. Effects of surface treatments of recycled tyre crumb on cement-rubber bonding in concrete composite foam. Constr. Build. Mater. 2018, 171, 467–473. [Google Scholar] [CrossRef]

- He, Z.H.; Du, S.G.; Chen, D. Microstructure of ultra high performance concrete containing lithium slag. J. Hazard. Mater. 2018, 353, 35–43. [Google Scholar] [CrossRef]

- Xiong, G.J.; Luo, B.Y.; Wu, X.; Li, G.Y.; Chen, L.Q. Influence of silane coupling agent on quality of interfacial transition zone between concrete substrate and repair materials. Cem. Concr. Compos. 2006, 28, 97–101. [Google Scholar] [CrossRef]

- Dong, Y.; Yang, H.; Zhang, L.; Lin, Y. Effects of Aggregate Interface Characteristics on the Mechanical Property of Concrete. J. Build. Mater. 2014, 8, 598–605. [Google Scholar]

| Ingredient | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | K2O | TiO2 | LOI |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 57.03 | 21.35 | 6.45 | 3.69 | 4.01 | 3.10 | 0.75 | 0.28 | 2.51 |

| Silica fume | 0.54 | 90.45 | 0.56 | 0.44 | 0.87 | 0.27 | 1.57 | 0.01 | 3.58 |

| Fly ash(I) | 13.45 | 55.39 | 19.05 | 2.46 | 0.1 | 0.22 | 2.75 | 0.07 | 9.87 |

| CGC | 1.45 | 68.39 | 18.93 | 4.62 | 0.91 | 0.17 | 2.63 | 0.74 | 1.67 |

| Mixture | M0 | M20 | M40 | M60 | M80 | M100 |

|---|---|---|---|---|---|---|

| Cement | 310 | 310 | 310 | 310 | 310 | 310 |

| FA | 71 | 71 | 71 | 71 | 71 | 71 |

| SF | 95 | 95 | 95 | 95 | 95 | 95 |

| CGC | 395 | 316 | 237 | 158 | 79 | 0 |

| MCGC | 0 | 79 | 158 | 237 | 316 | 395 |

| Steel Fiber | 22 | 22 | 22 | 22 | 22 | 22 |

| PCE | 7 | 7 | 7 | 7 | 7 | 7 |

| Water | 100 | 100 | 100 | 100 | 100 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, Y.; Hua, S.; Zhang, D.; Yue, H. Influence of Silane-Modified Coal Gangue Ceramsite on Properties of Ultra-High-Performance Concrete. Appl. Sci. 2025, 15, 7968. https://doi.org/10.3390/app15147968

Qin Y, Hua S, Zhang D, Yue H. Influence of Silane-Modified Coal Gangue Ceramsite on Properties of Ultra-High-Performance Concrete. Applied Sciences. 2025; 15(14):7968. https://doi.org/10.3390/app15147968

Chicago/Turabian StyleQin, Yuanjie, Sudong Hua, Dongrui Zhang, and Hongfei Yue. 2025. "Influence of Silane-Modified Coal Gangue Ceramsite on Properties of Ultra-High-Performance Concrete" Applied Sciences 15, no. 14: 7968. https://doi.org/10.3390/app15147968

APA StyleQin, Y., Hua, S., Zhang, D., & Yue, H. (2025). Influence of Silane-Modified Coal Gangue Ceramsite on Properties of Ultra-High-Performance Concrete. Applied Sciences, 15(14), 7968. https://doi.org/10.3390/app15147968