Effect of Water Content and Cementation on the Shear Characteristics of Remolded Fault Gouge

Abstract

1. Introduction

2. Methods and Materials

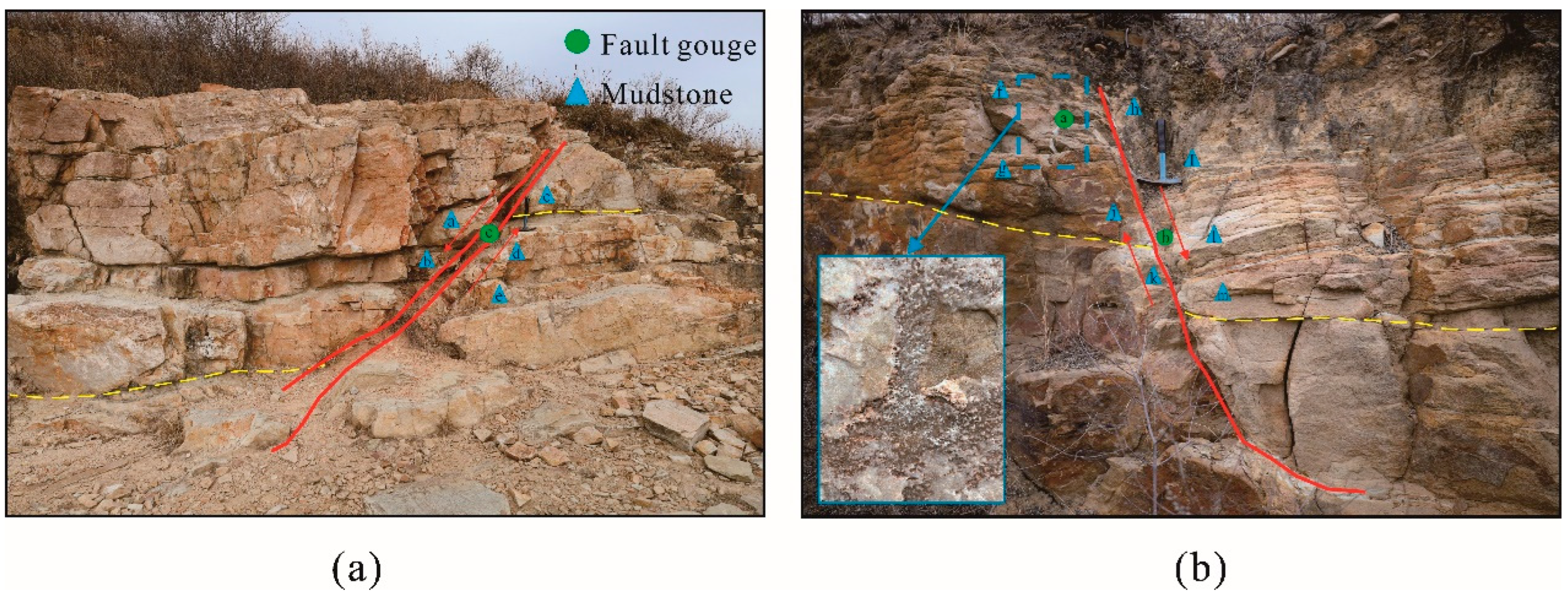

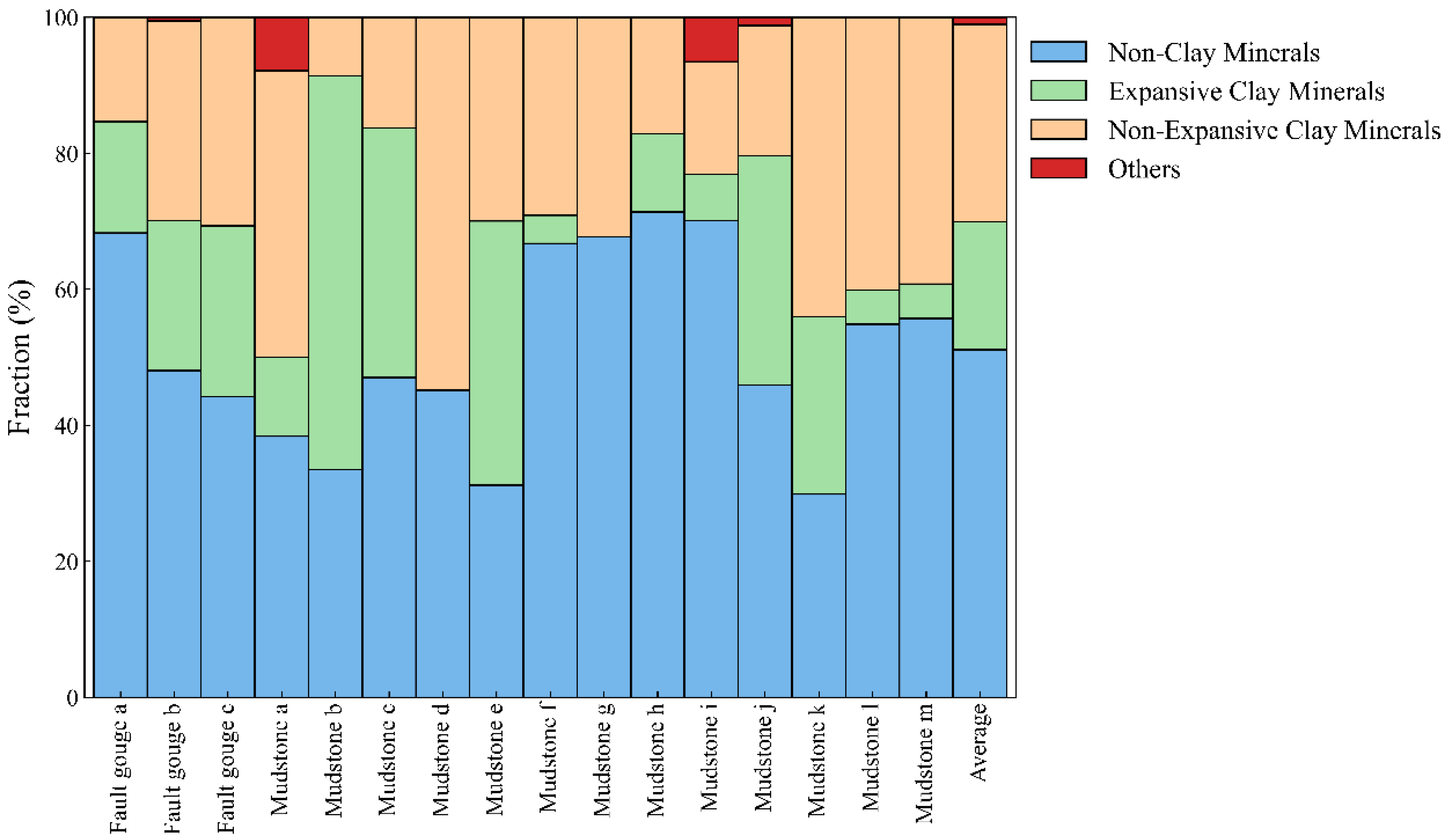

2.1. Field Investigation and Component Analysis of Natural Fault Gouge

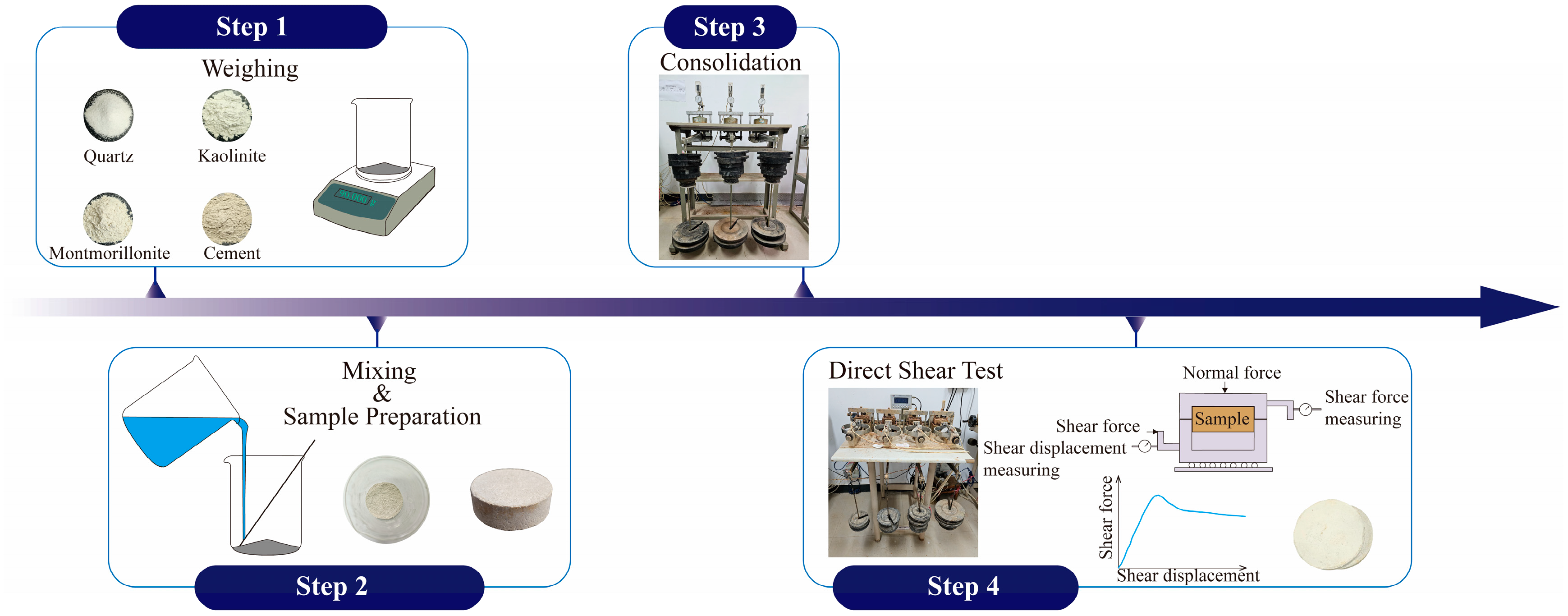

2.2. Experimental Materials

2.3. Experimental Design

2.4. Experimental Procedure

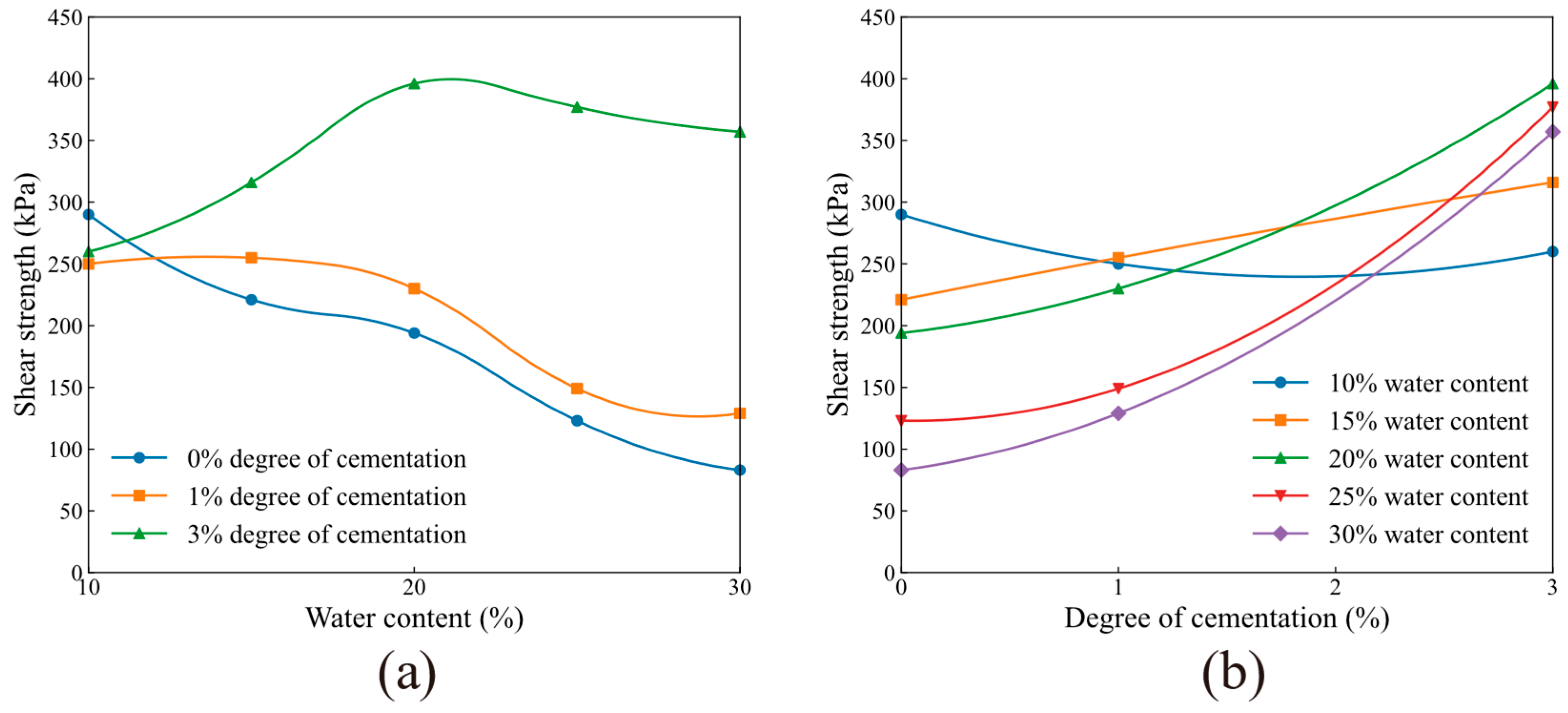

3. Results

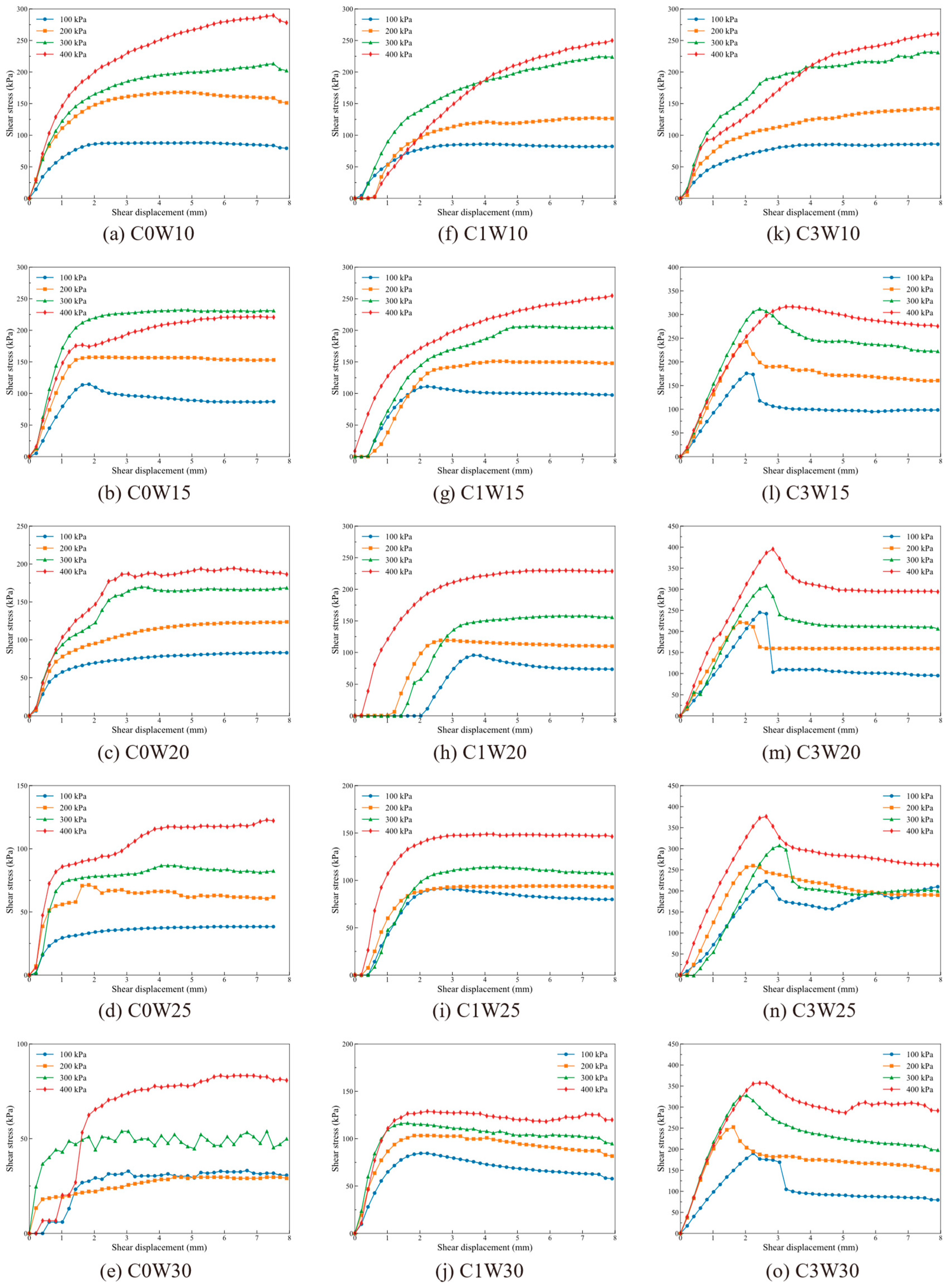

3.1. Shear Stress–Displacement Curves of Fault Gouge

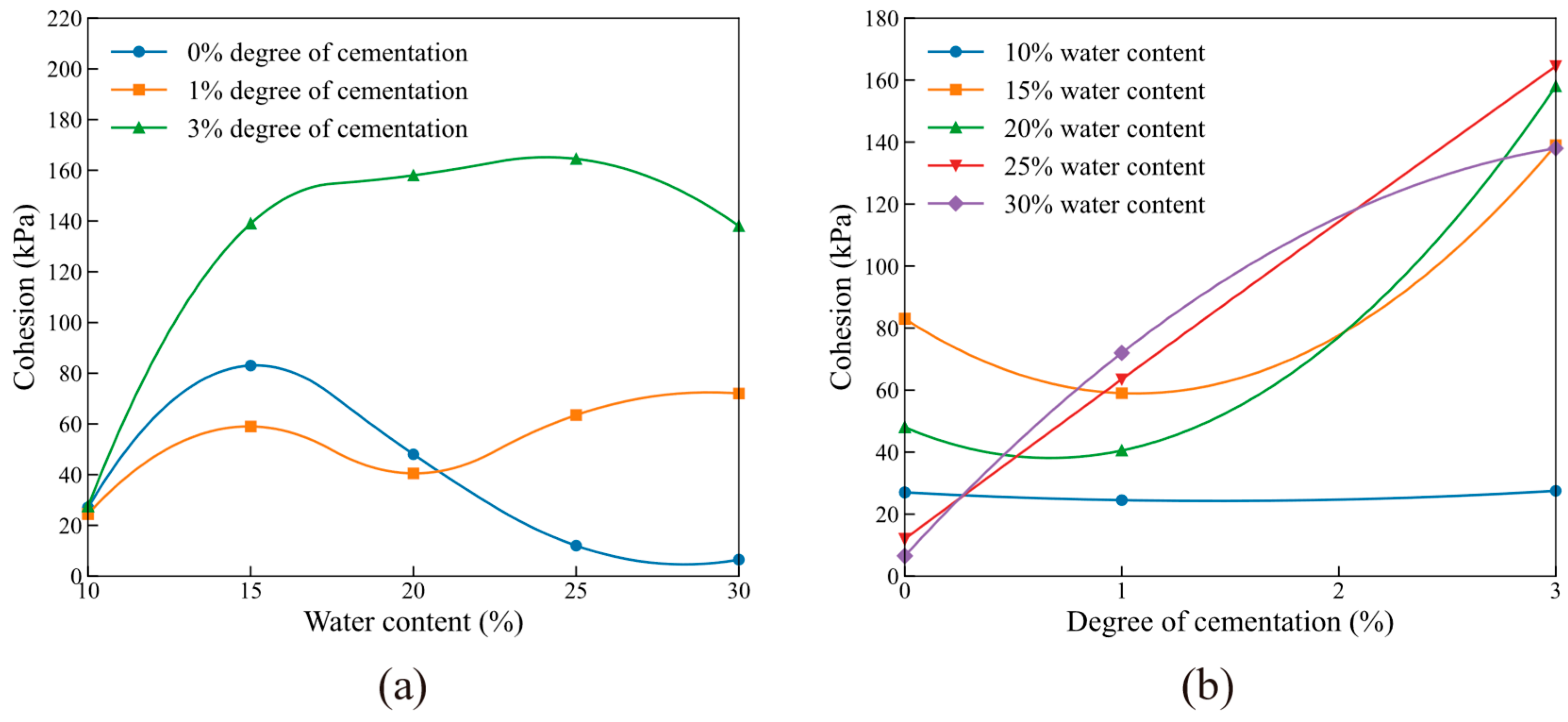

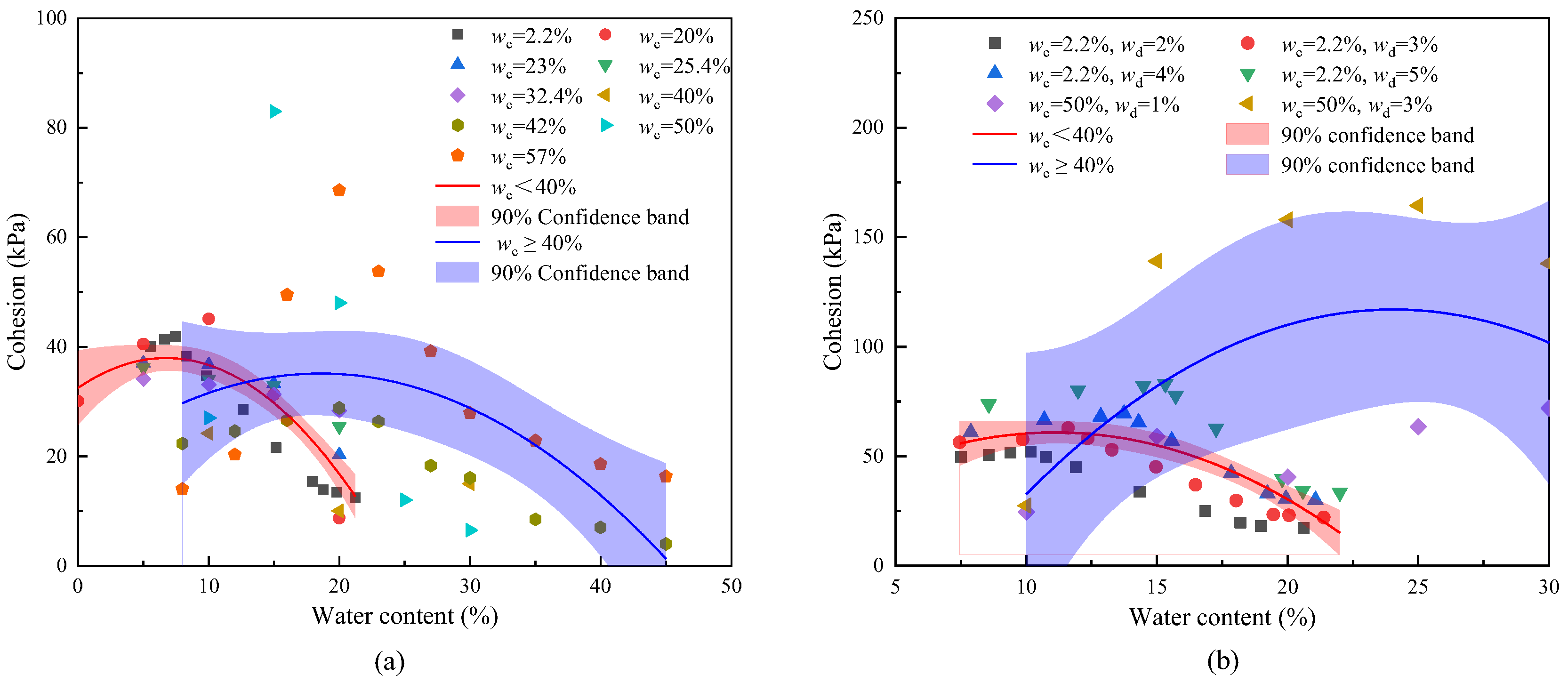

3.2. Cohesion

3.2.1. Relationship Between Cohesion and Water Content

3.2.2. Relationship Between Cohesion and Degree of Cementation

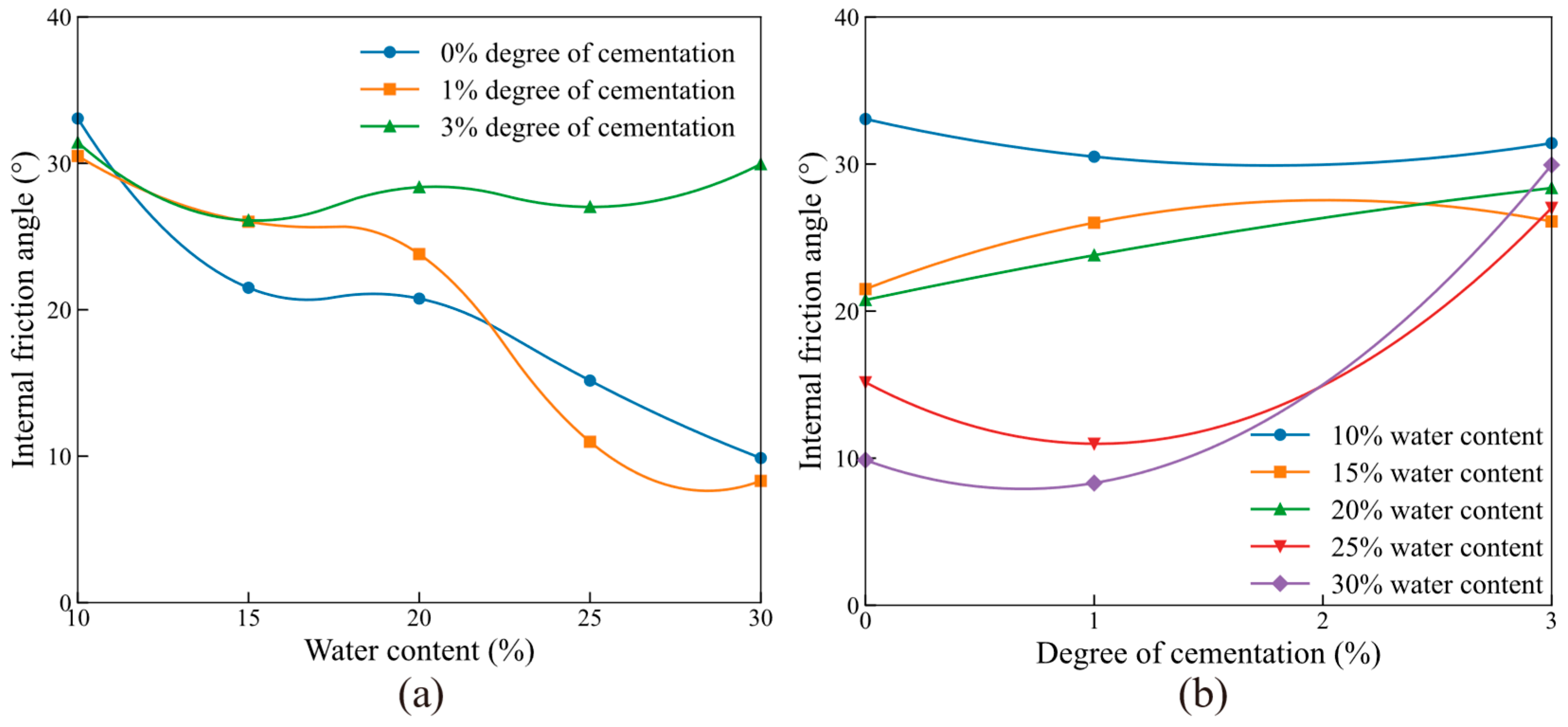

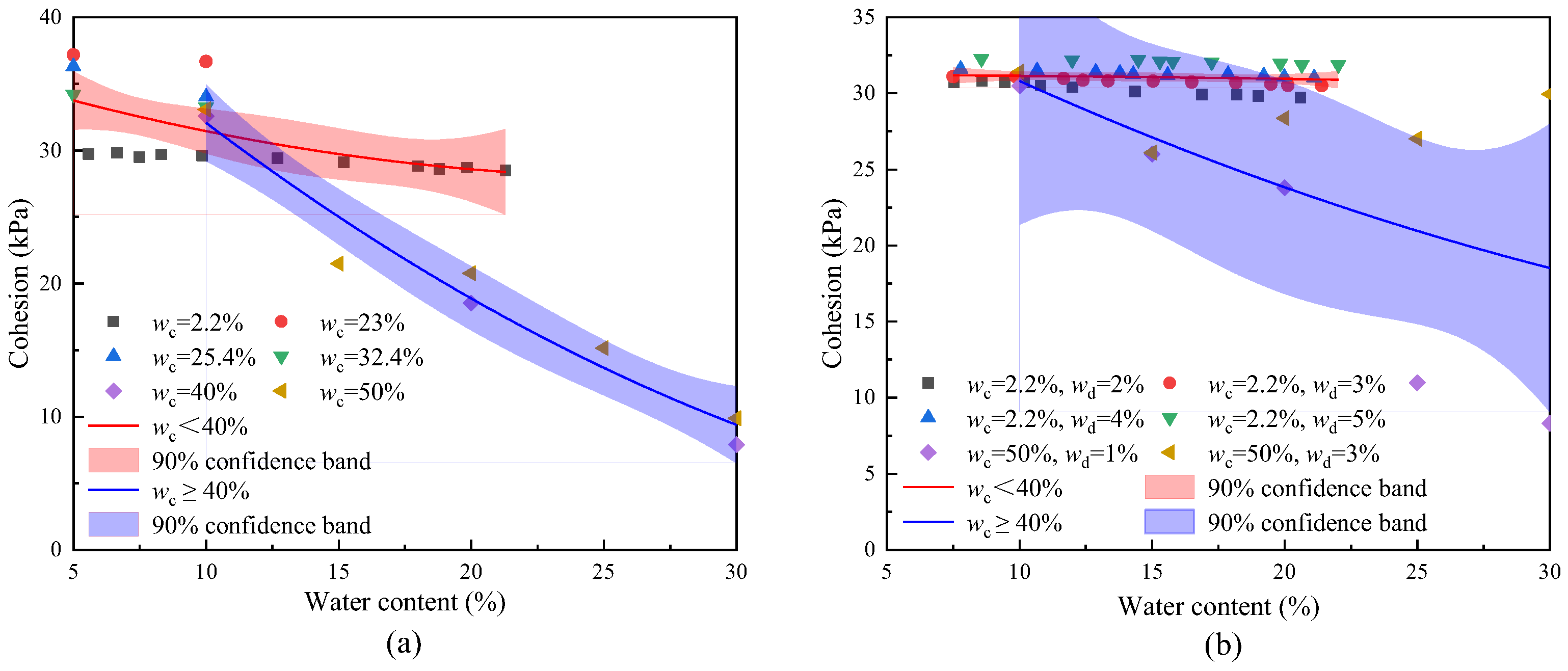

3.3. Internal Friction Angle

3.3.1. Relationship Between Internal Friction Angle and Water Content

3.3.2. Relationship Between Internal Friction Angle and Degree of Cementation

4. Discussion

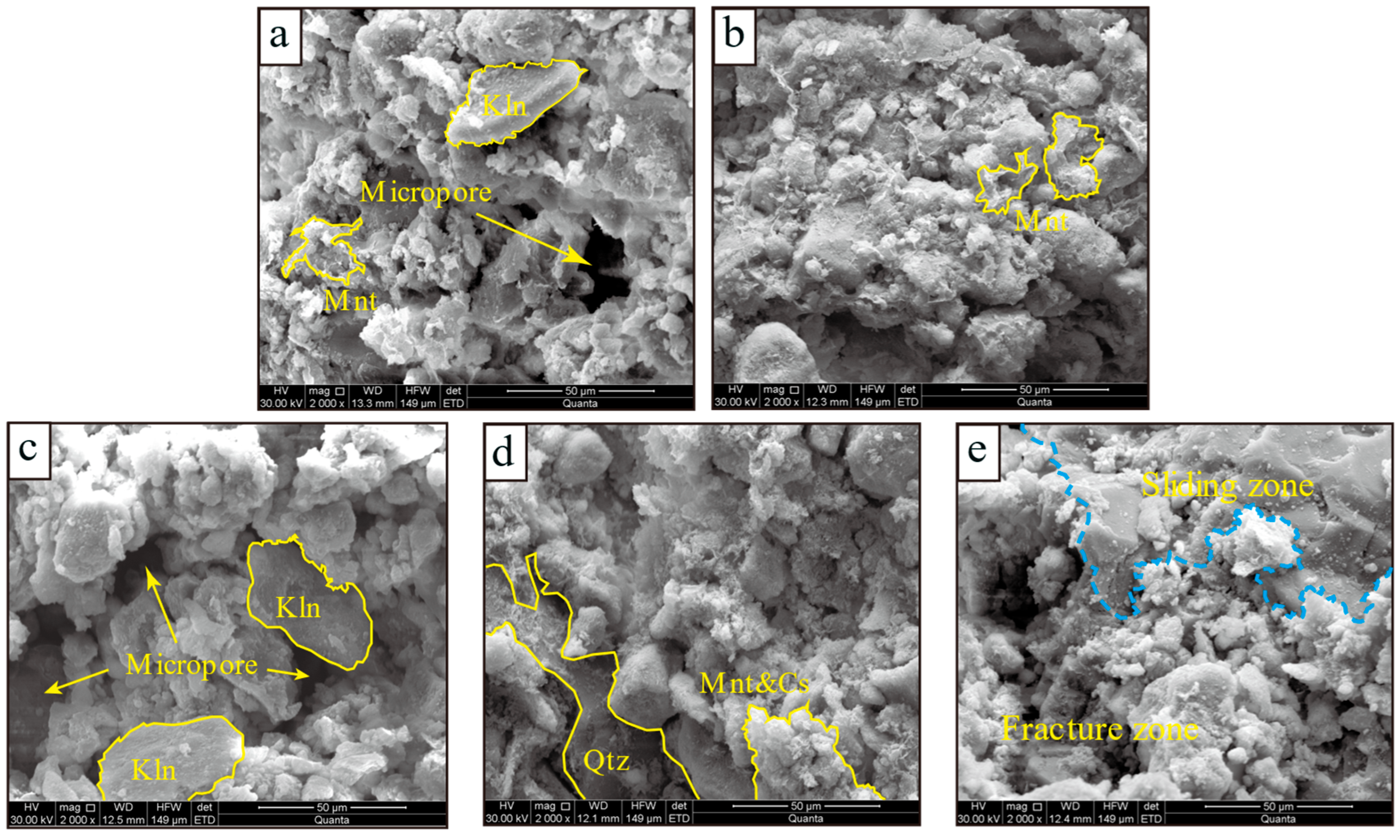

4.1. Microstructure Variation in Different Types of Remolded Fault Gouge

4.2. Influence of Clay Content, Water Content, and Cementation on Shear Strength Parameters

4.2.1. Cohesion with Variable Clay Content

4.2.2. Internal Friction Angle with Variable Clay Content

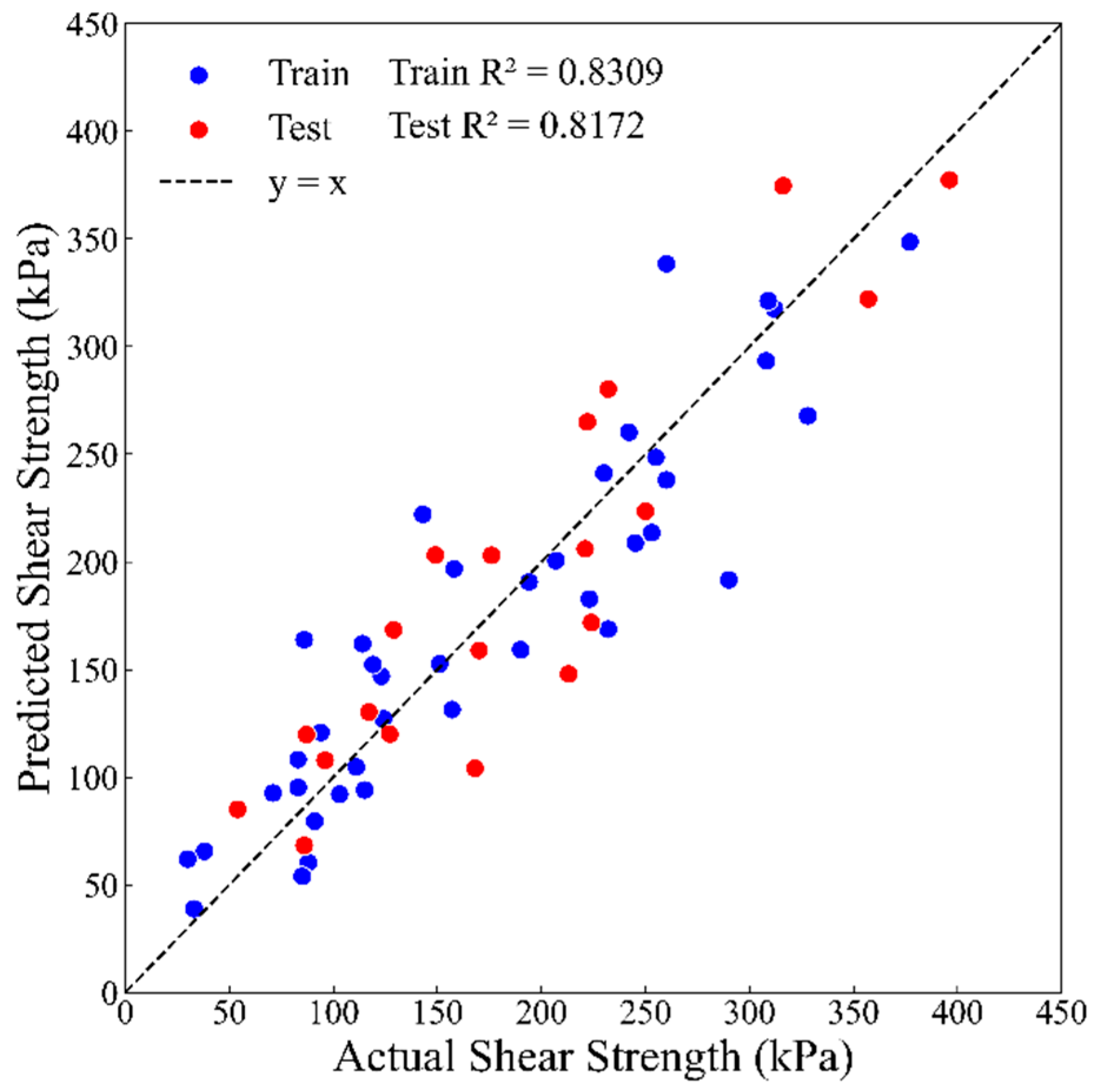

4.3. Shear Strength Model for High-Clay-Content Fault Gouge

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, S.; Hu, S.; Qi, Z.; Li, J.; Yan, W.; Huang, X.; Ao, X.; Yuan, Y. Stability evaluation of fault in hydrocarbon reservoir-based underground gas storage: A case study of W gas storage. Fuel 2024, 357, 129657. [Google Scholar] [CrossRef]

- Jing, J.; Yang, Y.; Tang, Z. Assessing the influence of injection temperature on CO2 storage efficiency and capacity in the sloping formation with fault. Energy 2021, 215, 119097. [Google Scholar] [CrossRef]

- Dong, D.-W.; Li, J.-Y.; Yang, Y.-H.; Wang, X.-L.; Liu, J. Improvements to the fuzzy mathematics comprehensive quantitative method for evaluating fault sealing. Pet. Sci. 2017, 14, 276–285. [Google Scholar] [CrossRef][Green Version]

- Zhou, X.; Wang, D.; Yu, H.; Yang, H.; Li, L. Major controlling factors and hydrocarbon accumulation models of large-scale lithologic reservoirs in shallow strata around the Bozhong sag, Bohai Bay Basin, China. Pet. Explor. Dev. 2022, 49, 758–769. [Google Scholar] [CrossRef]

- Zhong, Z.; Xu, C.; Hu, Y.; Zhang, F.; Wu, F.; Li, B. Frictional strength and sliding behaviors of an analogue rock-fault structure: A laboratory study. Int. J. Rock Mech. Min. Sci. 2024, 174, 105665. [Google Scholar] [CrossRef]

- Bense, V.F.; Gleeson, T.; Loveless, S.E.; Bour, O.; Scibek, J. Fault zone hydrogeology. Earth-Sci. Rev. 2013, 127, 171–192. [Google Scholar] [CrossRef]

- Fletcher, J.M.; Teran, O.J.; Rockwell, T.K.; Oskin, M.E.; Hudnut, K.W.; Spelz, R.M.; Lacan, P.; Dorsey, M.T.; Ostermeijer, G.; Mitchell, T.M.; et al. An analysis of the factors that control fault zone architecture and the importance of fault orientation relative to regional stress. GSA Bull. 2020, 132, 2084–2104. [Google Scholar] [CrossRef]

- Hattori, I.; Yamamoto, H. Rock Fragmentation and Particle Size in Crushed Zones by Faulting. J. Geol. 1999, 107, 209–222. [Google Scholar] [CrossRef]

- Faulkner, D.R.; Mitchell, T.M.; Healy, D.; Heap, M.J. Slip on “weak” faults by the rotation of regional stress in the fracture damage zone. Nature 2006, 444, 922–925. [Google Scholar] [CrossRef]

- Williams, R.T.; Mozley, P.S.; Sharp, W.D.; Goodwin, L.B. U-Th Dating of Syntectonic Calcite Veins Reveals the Dynamic Nature of Fracture Cementation and Healing in Faults. Geophys. Res. Lett. 2019, 46, 12900–12908. [Google Scholar] [CrossRef]

- Choi, J.-H.; Edwards, P.; Ko, K.; Kim, Y.-S. Definition and classification of fault damage zones: A review and a new methodological approach. Earth-Sci. Rev. 2016, 152, 70–87. [Google Scholar] [CrossRef]

- Viola, G.; Scheiber, T.; Fredin, O.; Zwingmann, H.; Margreth, A.; Knies, J. Deconvoluting complex structural histories archived in brittle fault zones. Nat. Commun. 2016, 7, 13448. [Google Scholar] [CrossRef]

- Hassanbeigi, E.; Solgi, A.; Arian, M.; Uromeihy, A. Impact of Brittle Faults with Varying Geometrical Structures on Rock Mass Engineering Properties in the North Tehran and Pourkan Verdij Fault Zones, Iran. Geotech. Geol. Eng. 2024, 42, 3063–3082. [Google Scholar] [CrossRef]

- Rutter, E.H.; Faulkner, D.R.; Brodie, K.H.; Phillips, R.J.; Searle, M.P. Rock deformation processes in the Karakoram fault zone, Eastern Karakoram, Ladakh, NW India. J. Struct. Geol. 2007, 29, 1315–1326. [Google Scholar] [CrossRef]

- Verberne, B.A.; Chen, J.; Niemeijer, A.R.; De Bresser, J.H.P.; Pennock, G.M.; Drury, M.R.; Spiers, C.J. Microscale cavitation as a mechanism for nucleating earthquakes at the base of the seismogenic zone. Nat. Commun. 2017, 8, 1645. [Google Scholar] [CrossRef] [PubMed]

- Salomon, E.; Rotevatn, A.; Kristensen, T.B.; Grundvåg, S.-A.; Henstra, G.A. Microstructure and fluid flow in the vicinity of basin bounding faults in rifts—The Dombjerg Fault, NE Greenland rift system. J. Struct. Geol. 2021, 153, 104463. [Google Scholar] [CrossRef]

- Williams, R.T.; Fagereng, Å. The Role of Quartz Cementation in the Seismic Cycle: A Critical Review. Rev. Geophys. 2022, 60, e2021RG000768. [Google Scholar] [CrossRef]

- Doglioni, C.; Barba, S.; Carminati, E.; Riguzzi, F. Fault on–off versus coseismic fluids reaction. Geosci. Front. 2014, 5, 767–780. [Google Scholar] [CrossRef]

- Rathnaweera, T.D.; Wu, W.; Ji, Y.; Gamage, R.P. Understanding injection-induced seismicity in enhanced geothermal systems: From the coupled thermo-hydro-mechanical-chemical process to anthropogenic earthquake prediction. Earth-Sci. Rev. 2020, 205, 103182. [Google Scholar] [CrossRef]

- Ban, S.; Liu, H.; Mao, H.; Shi, X.; Qiu, X.; Liu, M.; Min, Z.; Song, Y.; Wei, X. Numerical Tracking of Natural Gas Migration in Underground Gas Storage with Multilayered Sandstone and Fault-Bearing Caprocks. Energies 2023, 16, 4936. [Google Scholar] [CrossRef]

- Ikari, M.J.; Marone, C.; Saffer, D.M. On the relation between fault strength and frictional stability. Geology 2011, 39, 83–86. [Google Scholar] [CrossRef]

- Scuderi, M.M.; Collettini, C.; Marone, C. Frictional stability and earthquake triggering during fluid pressure stimulation of an experimental fault. Earth Planet. Sci. Lett. 2017, 477, 84–96. [Google Scholar] [CrossRef]

- An, M.; Zhang, F.; Min, K.; Elsworth, D.; Marone, C.; He, C. The Potential for Low-Grade Metamorphism to Facilitate Fault Instability in a Geothermal Reservoir. Geophys. Res. Lett. 2021, 48, e2021GL093552. [Google Scholar] [CrossRef]

- Geng, N.; Yao, X.; Chen, Y. Primary study on mechanical properties of the gouge for five large faults in China. Earthq. Res. China 1985, 4, 62–67. Available online: https://www.istis.sh.cn/metadata/resource/did:8f296240adff66c9c21e0f64420e0d85 (accessed on 10 July 2025). (In Chinese).

- Kenigsberg, A.R.; Rivière, J.; Marone, C.; Saffer, D.M. The Effects of Shear Strain, Fabric, and Porosity Evolution on Elastic and Mechanical Properties of Clay-Rich Fault Gouge. J. Geophys. Res. Solid Earth 2019, 124, 10968–10982. [Google Scholar] [CrossRef]

- Numelin, T.; Marone, C.; Kirby, E. Frictional properties of natural fault gouge from a low-angle normal fault, Panamint Valley, California. Tectonics 2007, 26, TC2004. [Google Scholar] [CrossRef]

- Ashman, I.R.; Faulkner, D.R. The Effect of Clay Content on the Dilatancy and Frictional Properties of Fault Gouge. J. Geophys. Res. Solid Earth 2023, 128, e2022JB025878. [Google Scholar] [CrossRef]

- Wang, P.; Tan, W.; Ma, X.; Li, Z.; Liu, J.; Wu, Y. Relationship between strength parameter and water content of fault gouge with different degrees of consolidation. Rock Soil Mech. 2019, 40, 1657–1662. (In Chinese) [Google Scholar] [CrossRef]

- Bao, H.; Qi, Q.; Lan, H.; Yan, C.; Xu, W.; Liu, X.; Li, L. Shear Mechanical Behaviours and Multistrength Parameter Characteristics of Fault Gouge. Adv. Civ. Eng. 2019, 2019, 4208032. [Google Scholar] [CrossRef]

- Morrow, C.A.; Moore, D.E.; Lockner, D.A. The effect of mineral bond strength and adsorbed water on fault gouge frictional strength. Geophys. Res. Lett. 2000, 27, 815–818. [Google Scholar] [CrossRef]

- Qi, Q.; Bao, H.; Lan, H.; Yan, C.; Zhang, K. Behavior of shearing mechanics and characteristics of strain softening of fault gouge. J. Eng. Geol. 2019, 27, 1101–1109. (In Chinese) [Google Scholar] [CrossRef]

- Saffer, D.M.; Marone, C. Comparison of smectite- and illite-rich gouge frictional properties: Application to the updip limit of the seismogenic zone along subduction megathrusts. Earth Planet. Sci. Lett. 2003, 215, 219–235. [Google Scholar] [CrossRef]

- Billi, A.; Smeraglia, L.; Aldega, L.; Balsamo, F.; Barberio, M.D.; Boschi, C.; Caracausi, A.; Carminati, E.; Iannace, A.; Mercuri, M.; et al. Dolostone pulverization induced by coseismic rapid decompression of CO2-rich gas in nature (Matese, Apennines, Italy). Earth Planet. Sci. Lett. 2023, 604, 117996. [Google Scholar] [CrossRef]

- Gbaguidi, S.V.; Odunlami, N.E.G.; Zevounou, C.; Agbodjan, C.P. Variability of cohesion and angle of friction as a function of water content in fine soils in the municipality of Lalo (Benin). World J. Adv. Res. Rev. 2023, 20, 142–152. [Google Scholar] [CrossRef]

- Fisher, Q.J.; Knipe, R.J. Fault sealing processes in siliciclastic sediments. Geol. Soc. Lond. Spec. Publ. 1998, 147, 117–134. [Google Scholar] [CrossRef]

- Pei, Y.; Paton, D.A.; Knipe, R.J.; Wu, K. A review of fault sealing behaviour and its evaluation in siliciclastic rocks. Earth-Sci. Rev. 2015, 150, 121–138. [Google Scholar] [CrossRef]

- Ottesen Ellevset, S.; Knipe, R.J.; Svava Olsen, T.; Fisher, Q.J.; Jones, G. Fault controlled communication in the Sleipner Vest Field, Norwegian Continental Shelf; detailed, quantitative input for reservoir simulation and well planning. Geol. Soc. Lond. Spec. Publ. 1998, 147, 283–297. [Google Scholar] [CrossRef]

- Sibson, R.H. Fault rocks and fault mechanisms. J. Geol. Soc. Lond. 1977, 133, 191–213. [Google Scholar] [CrossRef]

- Ismail, M.A.; Joer, H.A.; Sim, W.H.; Randolph, M.F. Effect of Cement Type on Shear Behavior of Cemented Calcareous Soil. J. Geotech. Geoenviron. Eng. 2002, 128, 520–529. [Google Scholar] [CrossRef]

- Kim, K.Y.; Suh, H.S.; Yun, T.S.; Moon, S.-W.; Seo, Y.-S. Effect of particle shape on the shear strength of fault gouge. Geosci. J. 2016, 20, 351–359. [Google Scholar] [CrossRef]

- Kong, D.; Wan, R.; Zhao, C.; Dai, J.; Dong, T.; Ni, W.; Gao, J.; Wang, T. Effect of conglomeration gradation on loess shear strength with different water content. Sci. Prog. 2021, 104, 368504211010581. [Google Scholar] [CrossRef]

- Kang, Y.; Hou, C.; Liu, B.; Bai, W. Influence of Water Content on the Shear Strength of Rock Joints with Clay-Rich Fillings. Rock Mech. Rock Eng. 2023, 56, 1437–1449. [Google Scholar] [CrossRef]

- Hattab, M.; Hammad, T.; Fleureau, J.-M. Internal friction angle variation in a kaolin/montmorillonite clay mix and microstructural identification. Géotechnique 2015, 65, 1–11. [Google Scholar] [CrossRef]

- Hammad, T.; Fleureau, J.-M.; Hattab, M. Kaolin/montmorillonite mixtures behaviour on oedometric path and microstructural variations. Eur. J. Environ. Civ. Eng. 2013, 17, 826–840. [Google Scholar] [CrossRef]

- Xie, L.; Liu, H.; Ban, S.; Mao, H. Experimental study on shear properties of fault gouge with different mineral compositions. Rock Soil Mech. 2023, 44, 2545–2554. (In Chinese) [Google Scholar] [CrossRef]

- Guo, P.; Wang, Y.; Zhang, X.; Ma, X.; Deng, S.; Zhu, X.; Qiu, Y. Investigation on elastic–plastic deformation and mechanical failure of varied-moisture expansive soil subjected to dry–wet cycles. Environ. Earth Sci. 2024, 83, 433. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Q.; Zhao, C.; Deng, L.; Fang, Q. Assessment of strength development of soil stabilized with cement and nano SiO2. Constr. Build. Mater. 2023, 409, 133889. [Google Scholar] [CrossRef]

- Liu, B.; Nie, D. Study on relation between strength parameter and water content of gouge. Chin. J. Geotech. Eng. 2006, 28, 2164–2167. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, Y.; Zhong, X.; Lin, J.; Zhao, D.; Jiang, F.; Wang, M.-K.; Ge, H.; Huang, Y. Effects of fractal dimension and water content on the shear strength of red soil in the hilly granitic region of southern China. Geomorphology 2020, 351, 106956. [Google Scholar] [CrossRef]

- Gong, W.; Quan, C.; Li, X.; Wang, L.; Zhao, C. Statistical analysis on the relationship between shear strength and water saturation of cohesive soils. Bull. Eng. Geol. Environ. 2022, 81, 337. [Google Scholar] [CrossRef]

- Siahkouhi, M.; Pletzer, C.; Marcher, T.; Schneider Muntau, B. Investigation on shear strength parameters of soil and soft rock material in the low stress range. Int. J. Geotech. Eng. 2024, 18, 66–74. [Google Scholar] [CrossRef]

- Wang, Q.; Qiu, S.; Zheng, H.; Zhang, R. Undrained shear strength prediction of clays using liquidity index. Acta Geotech. 2024, 19, 4325–4342. [Google Scholar] [CrossRef]

- Pham, T.A.; Sutman, M. An analytical model for predicting the shear strength of unsaturated soils. Proc. Inst. Civ. Eng. Geotech. Eng. 2022, 176, 369–387. [Google Scholar] [CrossRef]

- Pham, T.A.; Sutman, M.; Medero, G.M. Validation, reliability, and performance of shear strength models for unsaturated soils. Geotech. Geol. Eng. 2023, 41, 4271–4309. [Google Scholar] [CrossRef]

- Ravindran, S.; Gratchev, I. Effect of Water Content on Apparent Cohesion of Soils from Landslide Sites. Geotechnics 2022, 2, 385–394. [Google Scholar] [CrossRef]

- Chicco, D.; Warrens, M.J.; Jurman, G. The coefficient of determination R-squared is more informative than SMAPE, MAE, MAPE, MSE and RMSE in regression analysis evaluation. PeerJ Comput. Sci. 2021, 7, e623. [Google Scholar] [CrossRef]

| Sample | Cementation Degree (%) | Water Content (%) | Normal Pressure (kPa) |

|---|---|---|---|

| C0W10 | 0 | 10 | 100/200/300/400 |

| C0W15 | 15 | 100/200/300/400 | |

| C0W20 | 20 | 100/200/300/400 | |

| C0W25 | 25 | 100/200/300/400 | |

| C0W30 | 30 | 100/200/300/400 | |

| C1W10 | 1 | 10 | 100/200/300/400 |

| C1W15 | 15 | 100/200/300/400 | |

| C1W20 | 20 | 100/200/300/400 | |

| C1W25 | 25 | 100/200/300/400 | |

| C1W30 | 30 | 100/200/300/400 | |

| C3W10 | 3 | 10 | 100/200/300/400 |

| C3W15 | 15 | 100/200/300/400 | |

| C3W20 | 20 | 100/200/300/400 | |

| C3W25 | 25 | 100/200/300/400 | |

| C3W30 | 30 | 100/200/300/400 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Liu, H.; Pan, H.; Ban, S. Effect of Water Content and Cementation on the Shear Characteristics of Remolded Fault Gouge. Appl. Sci. 2025, 15, 7933. https://doi.org/10.3390/app15147933

Wang W, Liu H, Pan H, Ban S. Effect of Water Content and Cementation on the Shear Characteristics of Remolded Fault Gouge. Applied Sciences. 2025; 15(14):7933. https://doi.org/10.3390/app15147933

Chicago/Turabian StyleWang, Weimin, Hejuan Liu, Haizeng Pan, and Shengnan Ban. 2025. "Effect of Water Content and Cementation on the Shear Characteristics of Remolded Fault Gouge" Applied Sciences 15, no. 14: 7933. https://doi.org/10.3390/app15147933

APA StyleWang, W., Liu, H., Pan, H., & Ban, S. (2025). Effect of Water Content and Cementation on the Shear Characteristics of Remolded Fault Gouge. Applied Sciences, 15(14), 7933. https://doi.org/10.3390/app15147933