Application of Dynamic Time Warping (DTW) in Comparing MRT Signals of Steel Ropes

Abstract

1. Introduction

- Corrosion;

- Premature rust and oxidation;

- Mechanical wear;

- Internal and external wire breaks;

- Fatigue in bends;

- Tension breaks;

- Core failure fatigue;

- Shear breaks;

- Heat damage;

- Type I errors (false positives)—premature rope discard and increased carbon footprint (up to 2300 kg CO2 per ton of steel),

- Type II errors (false negatives)—missed critical damage with safety risks.

2. Materials and Methods

2.1. MRT Methods

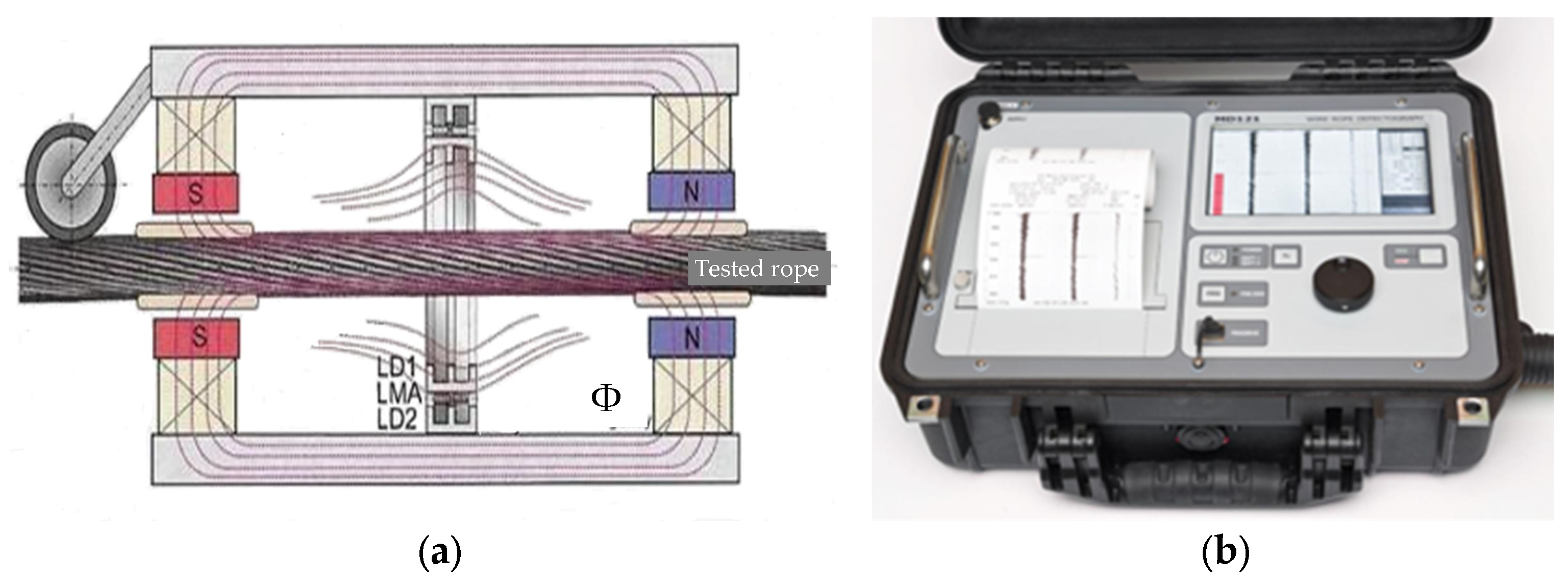

- A measuring head with

- the circuit of longitudinal magnetization of a fragment of a steel rope based on permanent magnets and magnetoguides;

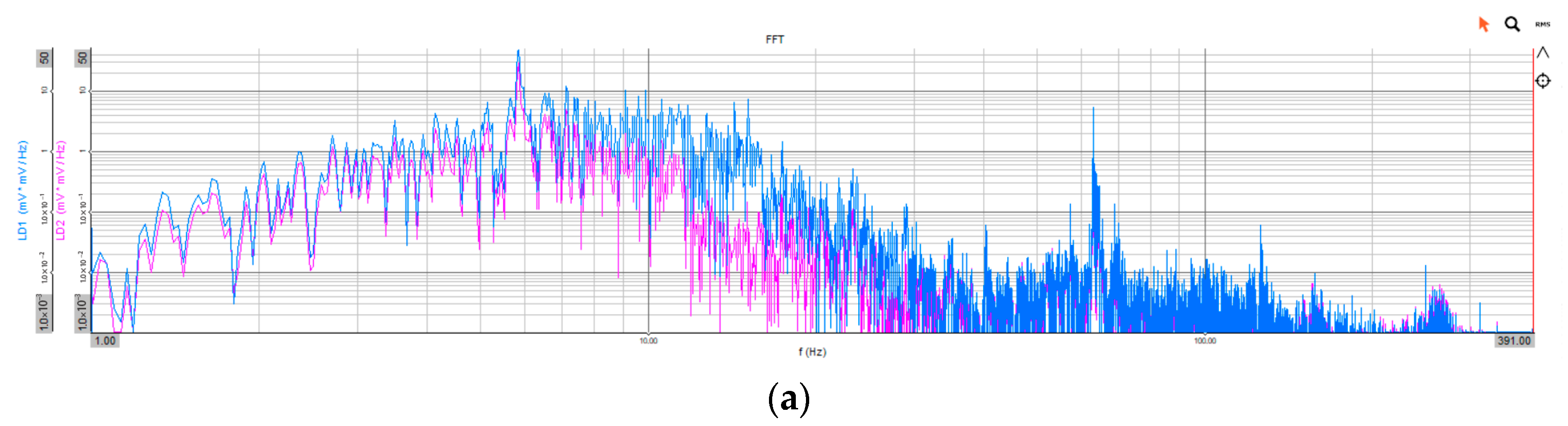

- two searching coils on the E-core, wrapping the tested rope in two different ways, which generate LF1 and LF2 signals (also marked in the literature as LD1 and LD2, local defect) proportional to the speed of changes in the magnetic flux (features of magnetic anomalies) and the location of the defect in the cross-section of the rope, taking into account the influence of the structural features of the E-core and the rope magnetization circuit on the signal spectrum;

- two Hall sensors with a magnetic field concentrator located between the coils, which record the scattering field around the rope and generate a resultant LMA signal proportional to the strength of the magnetic field.

- A defectograph in which

- the influence of changes in the speed of rope scanning (type from 0.15 m/s to 4 m/s) on the amplitude of LF1 and LF2 signals using the signal from the encoder is compensated;

- signals and recording time are sampled in parallel with a set frequency in the TIMER mode or the resolution of the rope displacement scan in the ENCODER mode;

- measurement data discrete in time are saved on a non-volatile memory carrier;

- the course of the recorded time series is illustrated on the screen;

- measurement data are pre-processed (filtration and calculation of additional variables—rope scanning speed in ENCODER mode, LF1 integrals, defined diagnostic estimates);

- a simplified analysis of measurement data is carried out according to preset criteria in the time domain or order, including visual comparison of the results with the previous recording (reference result);

- the function of printing test results on a thermal printer or an external printer is available;

- data transfer to an external computer (for extended data analysis and data archiving) is carried out using a standard RS-232 or USB 2.0 port.

2.1.1. Numerical Model of Search Coils

- The structural features of the rope—each outer strand generates a clear cyclic change in the magnetic field. Internal and medullary convolutions are also a source of weak cyclic magnetic anomalies.

- The technical condition of the rope.

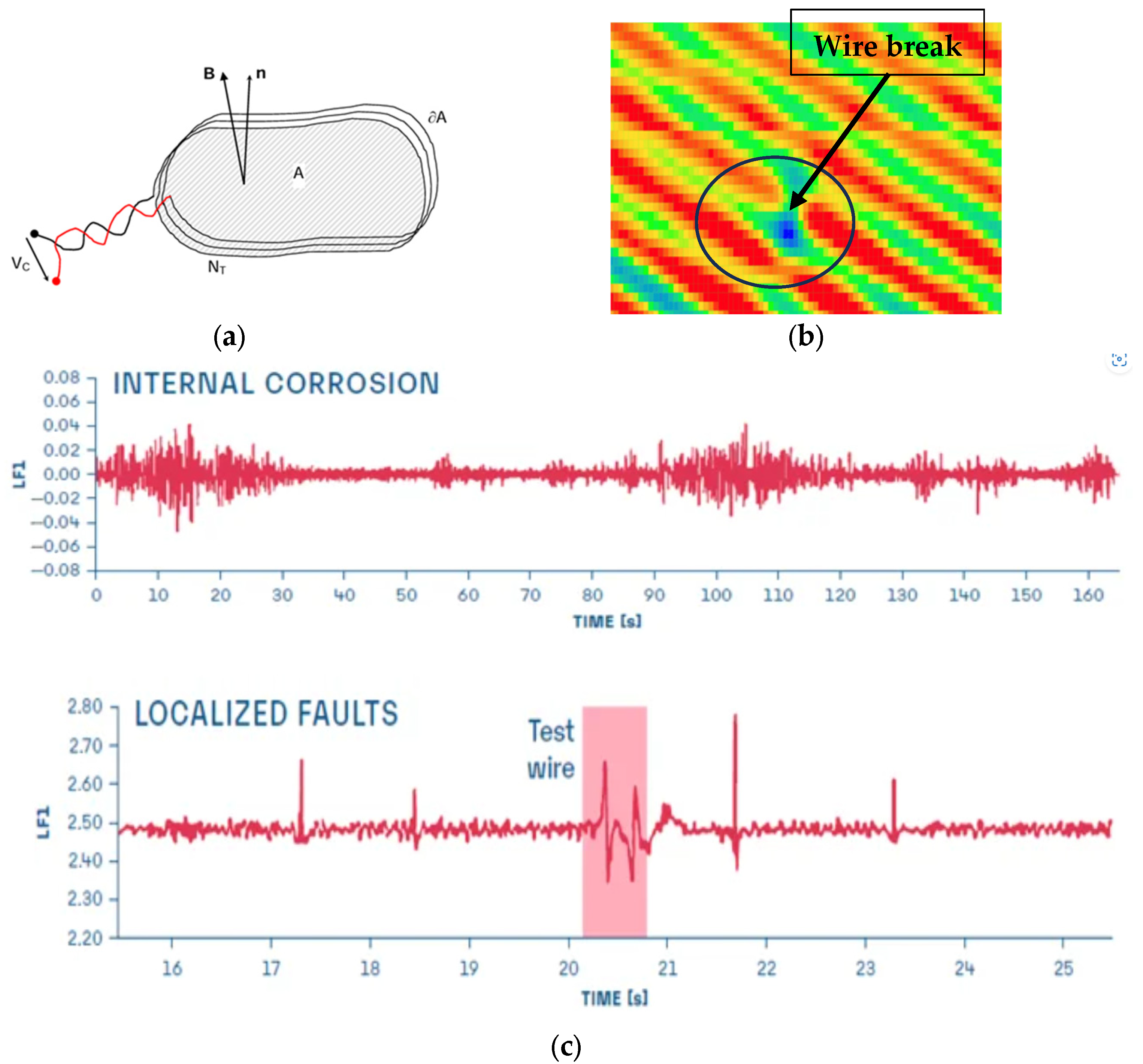

- Vc is the induced voltage across the coil,

- Φ is the magnetic flux through the surface A,

- Lc denotes the inductance of the coil, and di is the electric current flowing through it,

- B is the magnetic flux density,

- n is the unit normal vector to the surface,

- v is the velocity of the conductor.

- Ac is the effective cross-sectional area of the coil,

- ω is the angular velocity of rotation,

- ∇B represents the spatial gradient of the magnetic field.

- e is the base of the Natural Logarithm = 2.71828,

- is the actual part of the coil impedance,

- is the imaginary part of the coil impedance (reactance),

- is the inductive reactance of the coil,

- is the capacitive reactance of the coil related to the winding-to-turn capacitance,

- is the circular frequency of a signal (magnetic field) with a frequency of ,

- is an impedance module,

- is the phase angle between the voltage and electric current.

- Reduce inter-turn capacitances,

- Increase the inductance of the coil and the amplitude of the induced voltage, ,

- Differentiate the induced signal on the basis of known core design features.

- Coil nonlinearity resulting from the influence of the magnetization characteristics of the ferromagnetic core on the instantaneous values of current in the coil winding and hysteresis and eddy current losses in the core. For low-magnetic-field frequencies, the unit power of the losses in the ferromagnetic and hysteresis cores is proportional to the frequency (12), and the unit power of eddy current losses is proportional to the square of the frequency (13);

- Local heterogeneity of the magnetic permeability of rope wires (influence of different degrees of their degradation and current material strain, abrasion, and cracking of wires);

- Actual characteristics of the point sensitivity of the LF1 and LF2 coils, taking into account the heterogeneity of their sensitivity along the circuit, depending on the number of cylindrical coils distributed along the circuit on a given radius and the parameters of the magnetic field concentrator;

- E-core parameters;

- The impact of transmission line parameters;

- Parameters of the defectograph input circuit;

- The impact of the scanning speed compensation system;

- Continuous quantization parameters in Analog-to-Digital convectors (ADCs).

- is the coefficient depending on the grade of core material;

- is the coefficient depending on the grade of core material, its geometry and construction;

- is the frequency;

- is the amplitude of magnetic induction in the core;

- is the power exponent equal to 1.6 for and 2.0 for .

- is the discrete time;

- is the voltage component at the coil output generated by the technical condition of the wire rope ;

- is the voltage component at the coil output generated by other sources of magnetic field heterogeneity .

- Signal harmonics that reproduce the structural features of the rope and the measuring head, and in the current data analysis algorithms, MRT methods are considered structural noise;

- Color noise being the resultant of quantization noise, thermal noise of the measurement path, and external low-frequency electromagnetic interference.

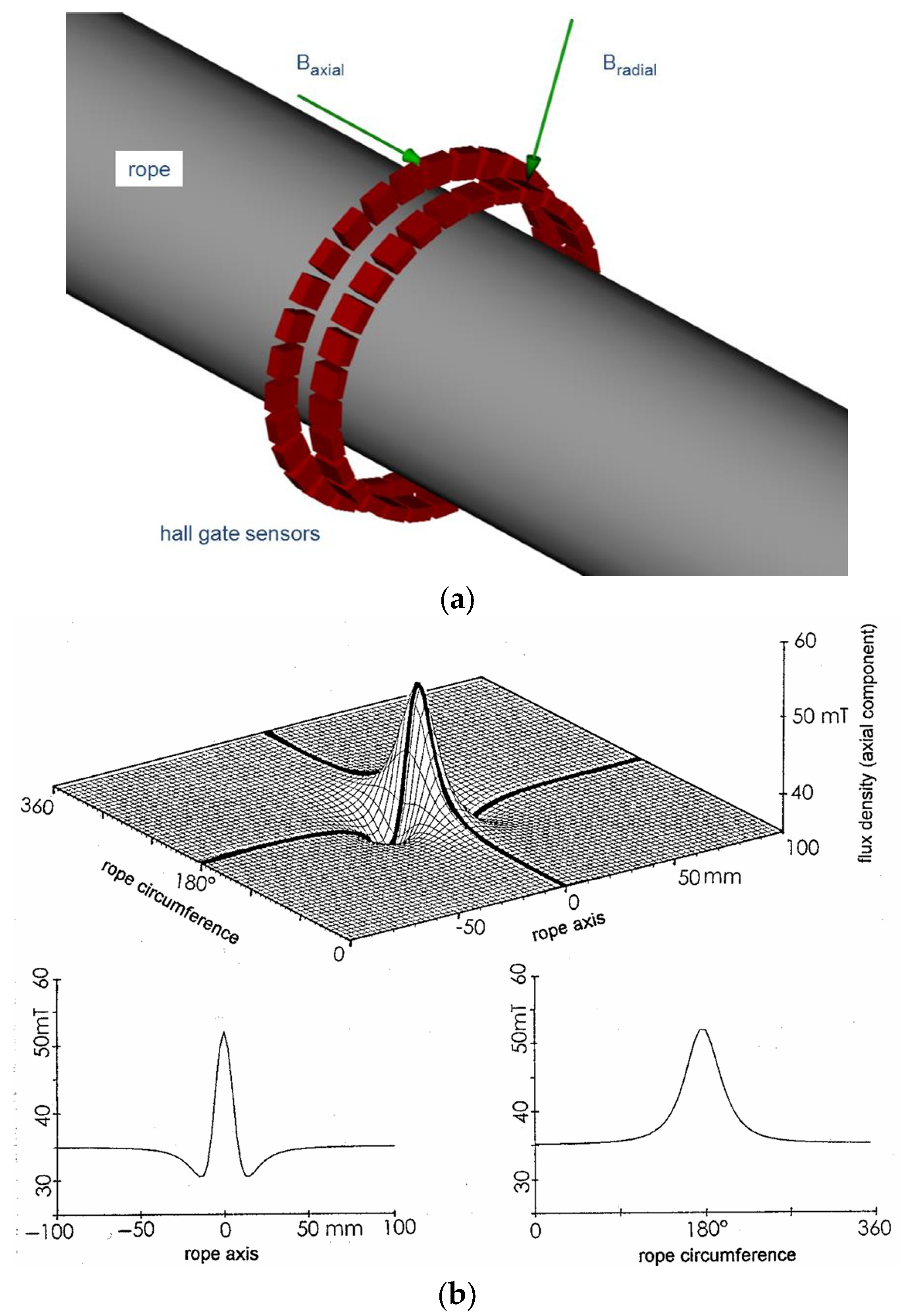

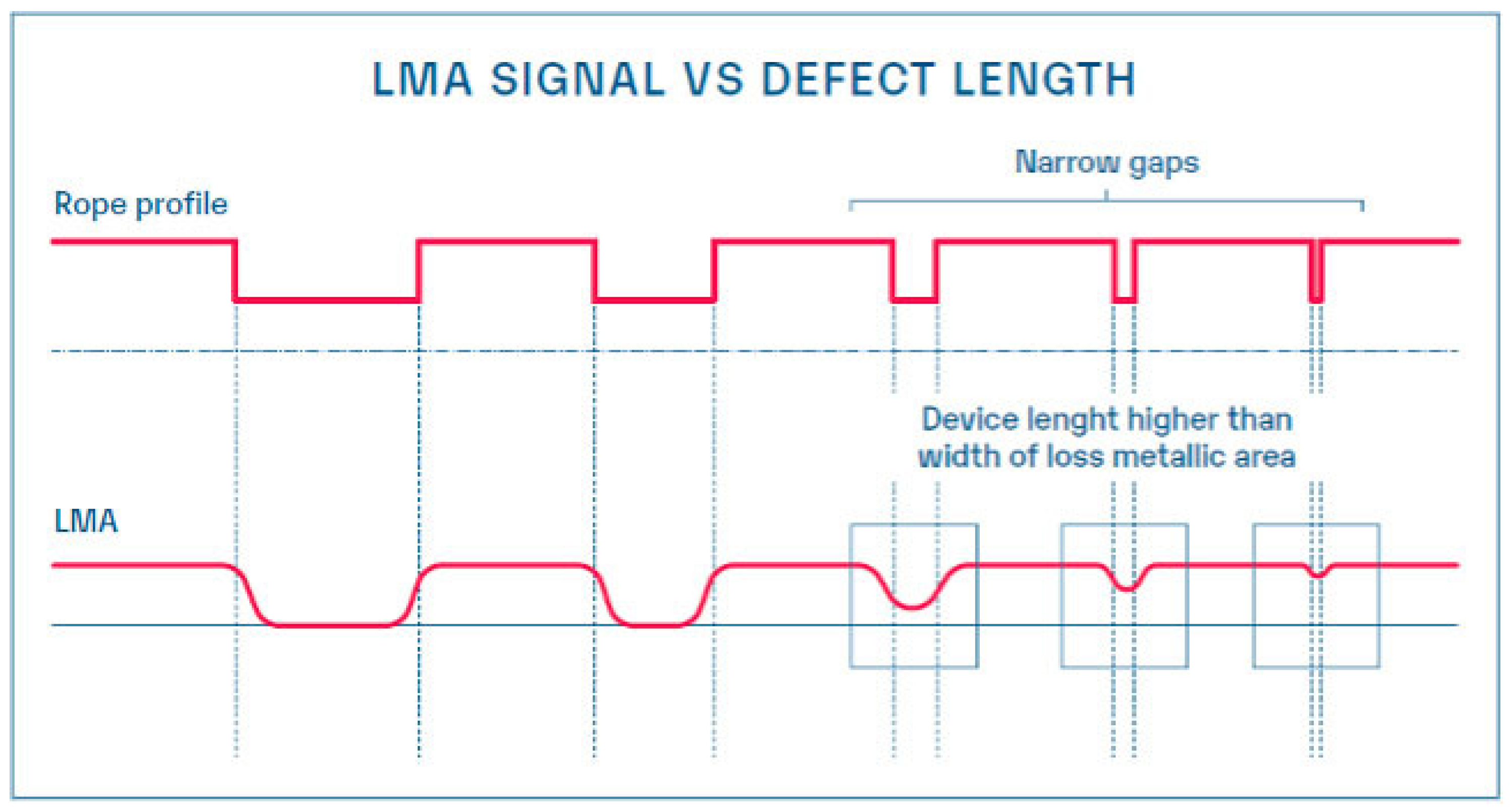

2.1.2. Numerical Model of the LMA Signal

- In the air gap under the pole piece of the magnetization circuit in order to record the induction of the magnetizing field of the rope . With the known parameters of the magnetizing circuit (geometry, magnetomotive force, and magnetic flux ), the signal indirectly reflects the magnetic reluctance of a fragment of the tested rope with a cross-section of the ferromagnetic part (the rope fragment is a component of the main magnetic circuit) and the existing state of magnetization of the rope.

- Inside the measuring head, in which the rope is fully demagnetized , in order to record the scattered magnetic field inside the head , depending on the existing magnetization of the rope, the magnetic parameters prevailing in the air gaps of both pole pieces of the measuring head, local magnetic anomalies of the rope, and broadband Barkhausen noise.

- Outside near the probe in order to record the external scattered magnetic field of the probe and the level of magnetization of the rope when magnetizing the rope along the “original” magnetization curve, taking into account the position of the Hall sensors relative to the external magnetic neutral axis.

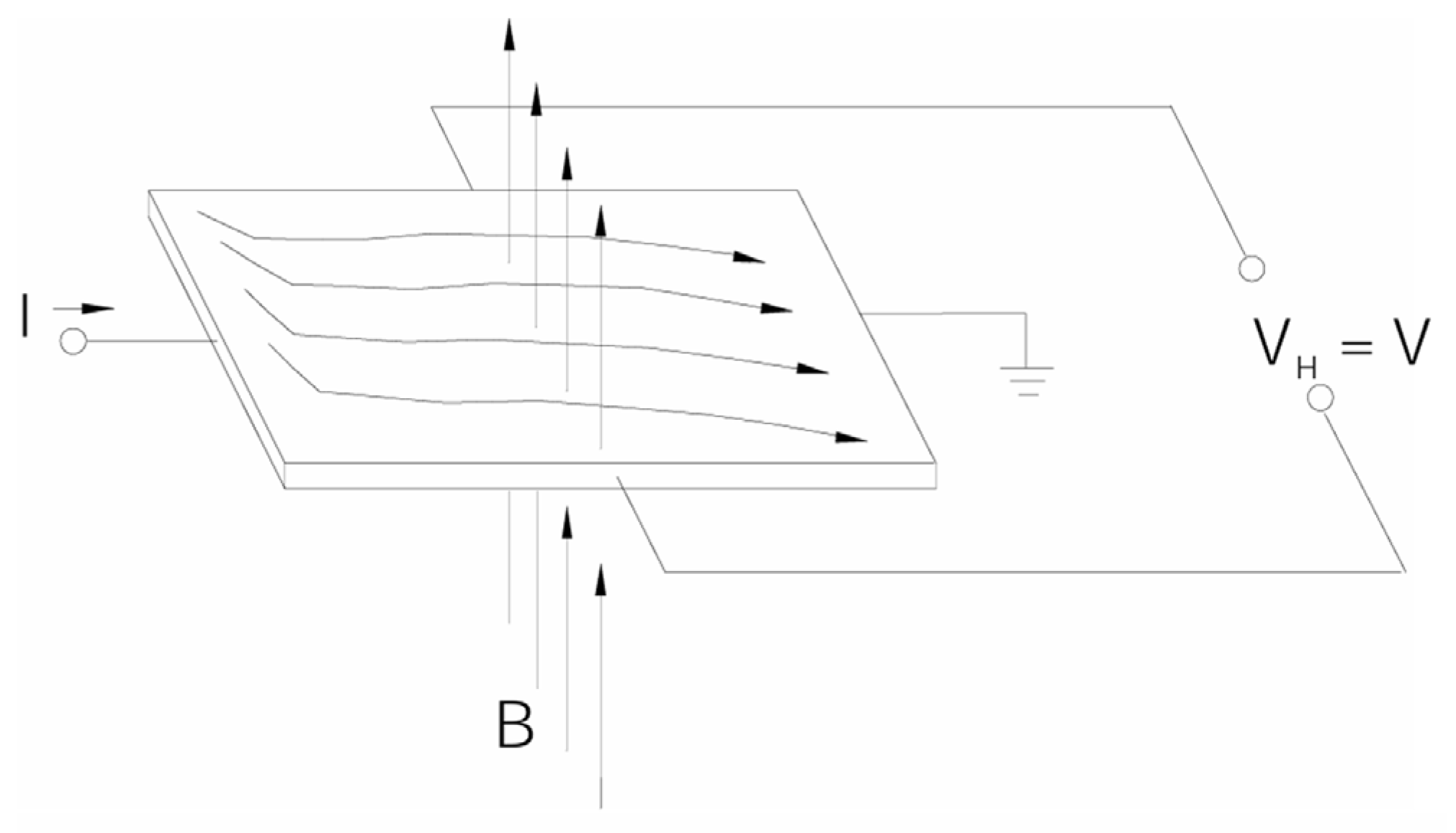

- is the output voltage of the Hall sensor;

- is the resistance of the Hall sensor;

- i is the electric current;

- is the thickness of the conductor;

- is the magnetic flux density (the only changing parameter in the input).

- The location around the rope circumference (e.g., upper or lower side of a track rope),

- The shape of the defect,

- The arrangement of clusters of wire breaks,

- The depth within the rope (for stranded ropes) and the distribution of wire breaks, e.g., in a single strand.

- is the axial component of magnetic flux density of the defect field;

- is the radial component of magnetic flux density of the defect field;

- is the distance from a measuring point on the surface to the rope axis;

- is the wire diameter;

- is the current;

- is the longitudinal coordinate in relation to the wire break end;

- is the angle;

- is the difference in flux density.

- is discrete time;

- is the LMA voltage component at the output of the Hall sensor generated by the technical condition of the wire rope;

- is the LMA voltage component at the output of the Hall sensor generated by other sources of magnetic field heterogeneity.

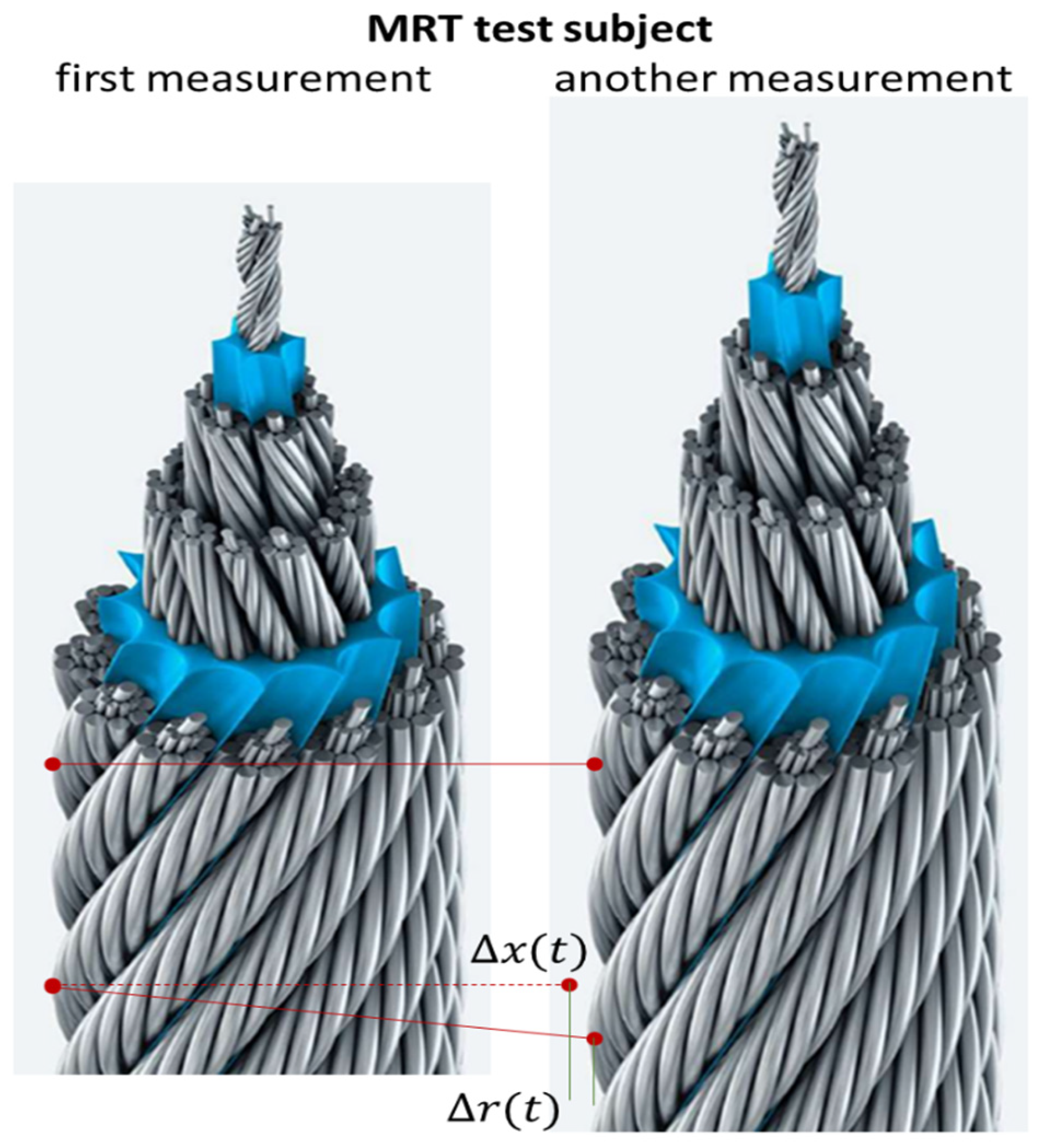

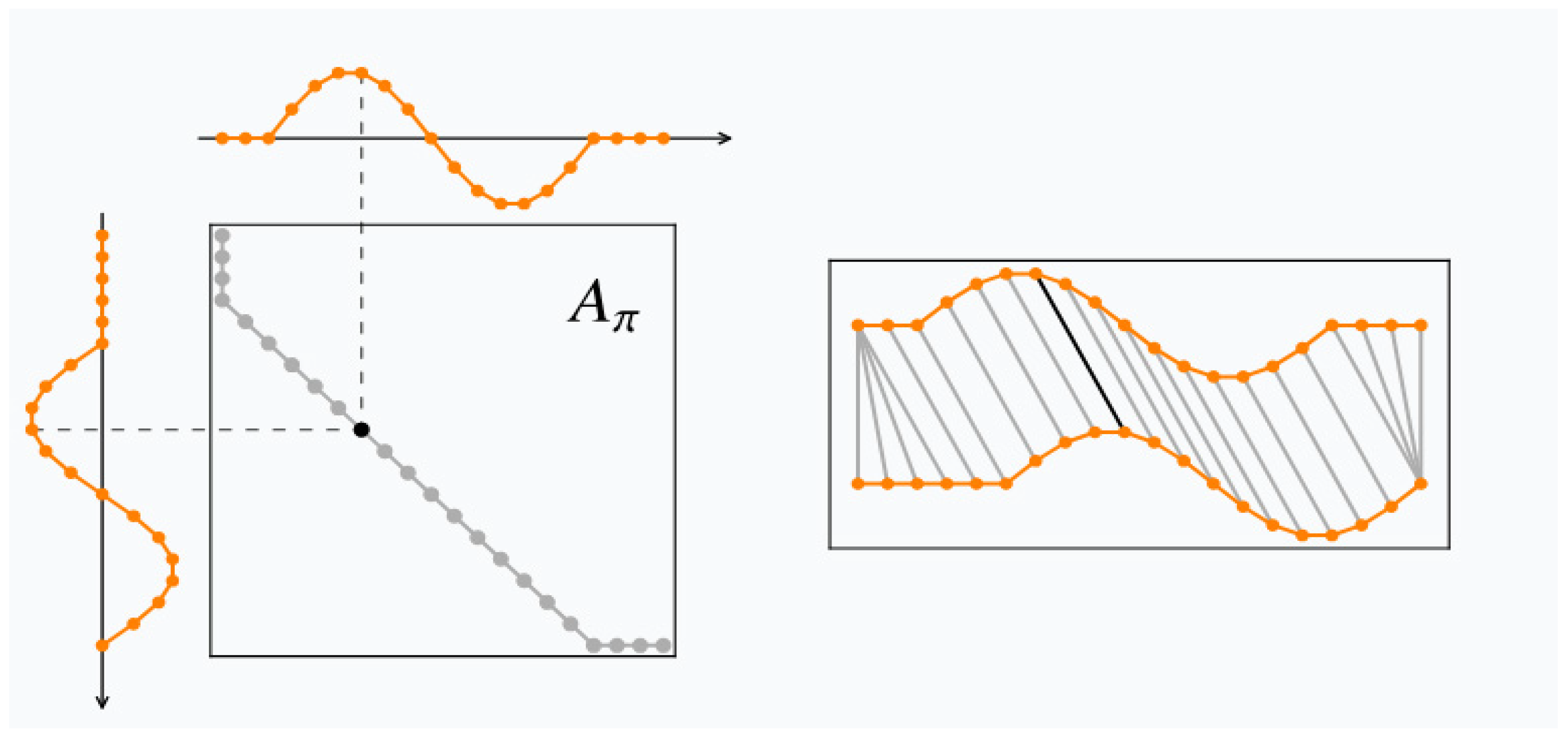

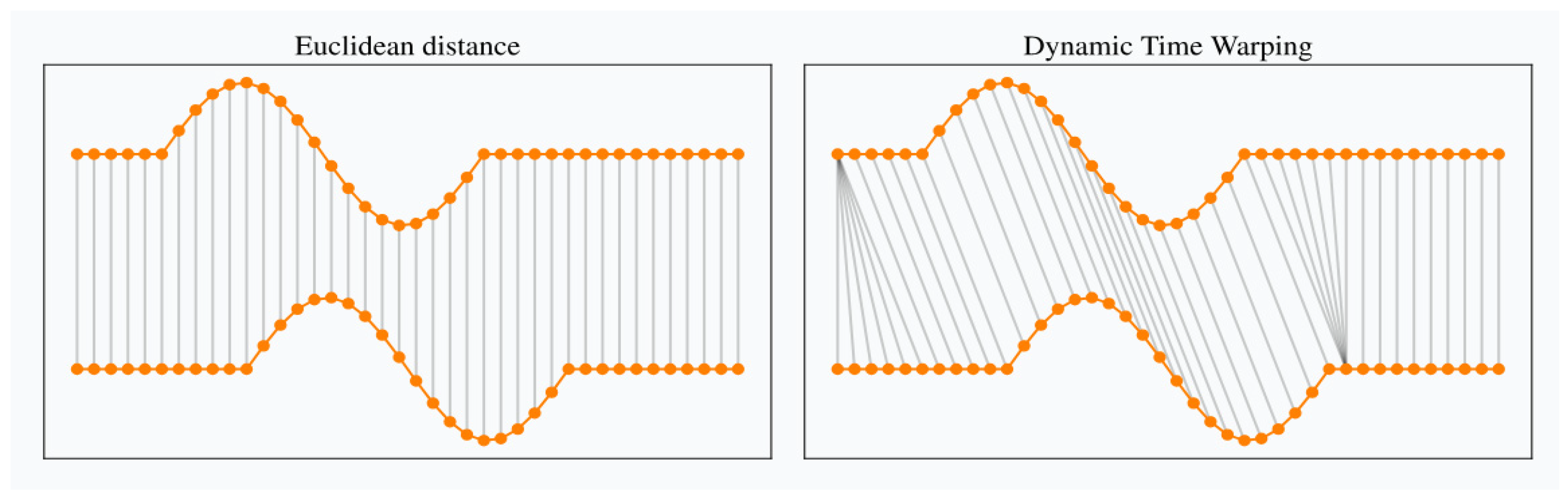

2.2. Algorithm DTW

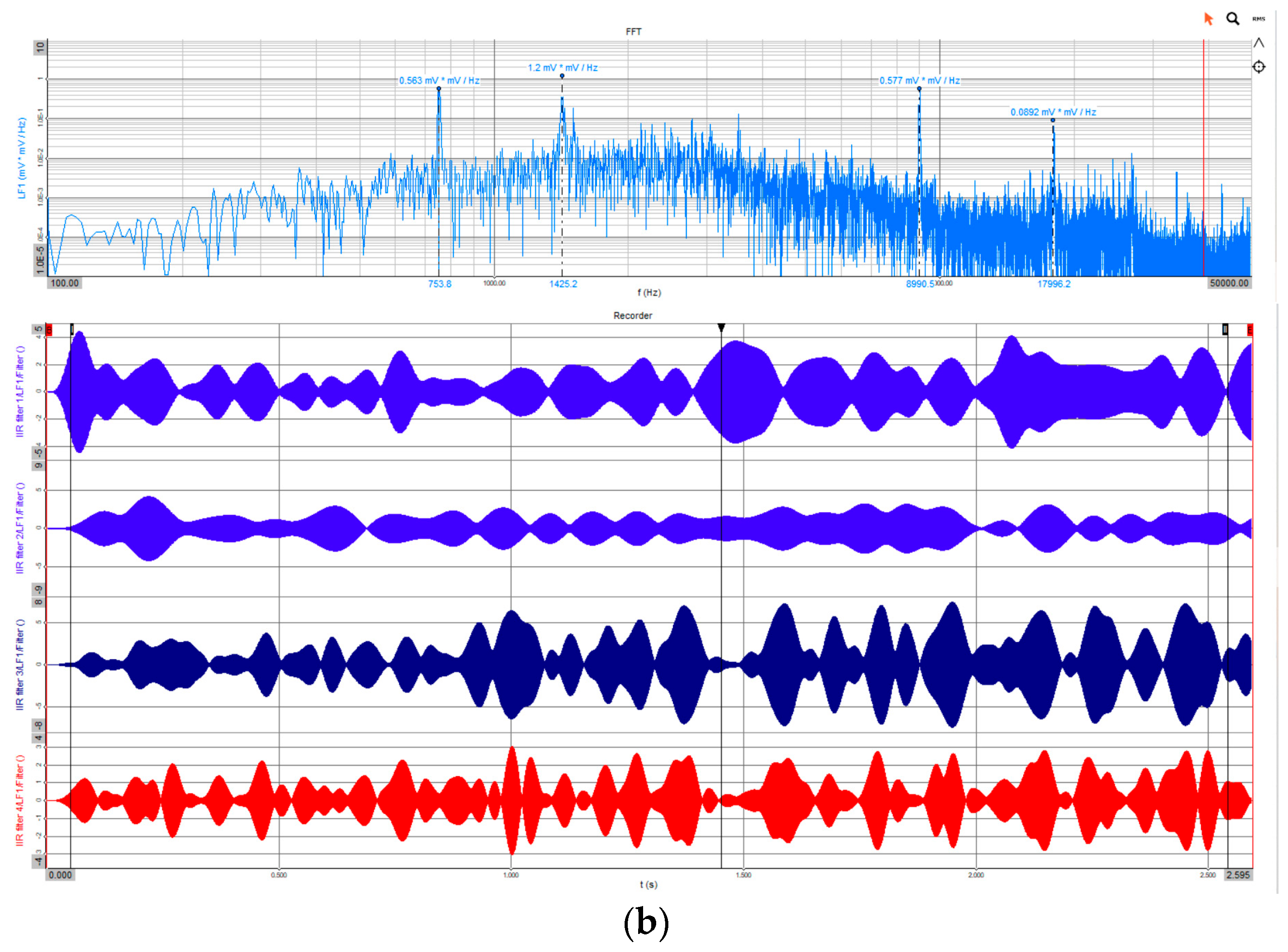

- The proportions between characteristic frequencies resulting from the rope’s pitch and its structural features (such as the number of outer, inner, and core strands);

- The main component of the colored noise, which reflects dynamic phenomena in the rope system, the noise of the measurement channel, and the level of electromagnetic interference near the measurement head.

- Periodic shortening by the user to equalize the stresses in the multi-rope system and maintain the skip stop parameters at a given level;

- Automatic shortening under the influence of torsional torsion.

- Rope dynamics—transverse and longitudinal vibrations and level of material effort related to the actual operating conditions of the rope system changing between successive MRT tests;

- Modal properties of the rope, which change under the influence of unknown load history, current loads, temperature, and the technical condition of the rope.

- C++ [60];

- R—package dtw described in [61];

- Python—dtw-python package [62], which is a clone of the dtw package from R. Python also includes the fastdtw [63,64] package (installation: pip install fastdtw), which is time-optimized and, for a window of 10,000 data points, is over 200 times faster than the classic DTW, with no information about the quality of time series fitting.

- is an alignment path of length , which is a sequence of pairs of indices ;

- is the set of all acceptable paths.

- ;

- .

- ;

- .

- ;

- .

- Detrending and z-score normalization of the time series—a preprocessing step that addresses DTW’s sensitivity to trend differences. Detrending removes any increasing or decreasing trends in the time series, while z-score normalization scales the values to a mean of zero and a standard deviation of one.

- Computation of the distance matrix between all pairs of samples—the matrix contains pairwise distances between all combinations of samples in the two time series. Although Euclidean distance works well in many cases, other metrics may be more appropriate, depending on the data.

- Computation of a cost matrix from the distance matrix—the cost matrix is derived from the distance matrix by recursively accumulating distances from neighbor to neighbor, starting from the initial corner (bottom left) to the final corner (top right). Different neighborhood rules define how these costs are propagated, e.g.,

- ▪

- Orthogonal only: accumulation occurs in x and y directions only, ignoring diagonals.

- ▪

- Orthogonal and diagonal moves: diagonal movements are also considered, typically weighted by a factor of √2 (1.414) to balance with orthogonal steps. The value of each cell in the matrix represents the slope or effort required to pass through it.

- ▪

- Finding the least-cost path within the cost matrix is the step where time warping occurs. The least-cost path minimizes the total cost from start to end of the cost matrix, optimally aligning the two time series.

- ▪

- Computation of a similarity metric based on the least-cost path—the simplest approach is to sum the distances of all points along the path. When comparing time series of different lengths, additional normalization is performed.

2.3. Subject of Research

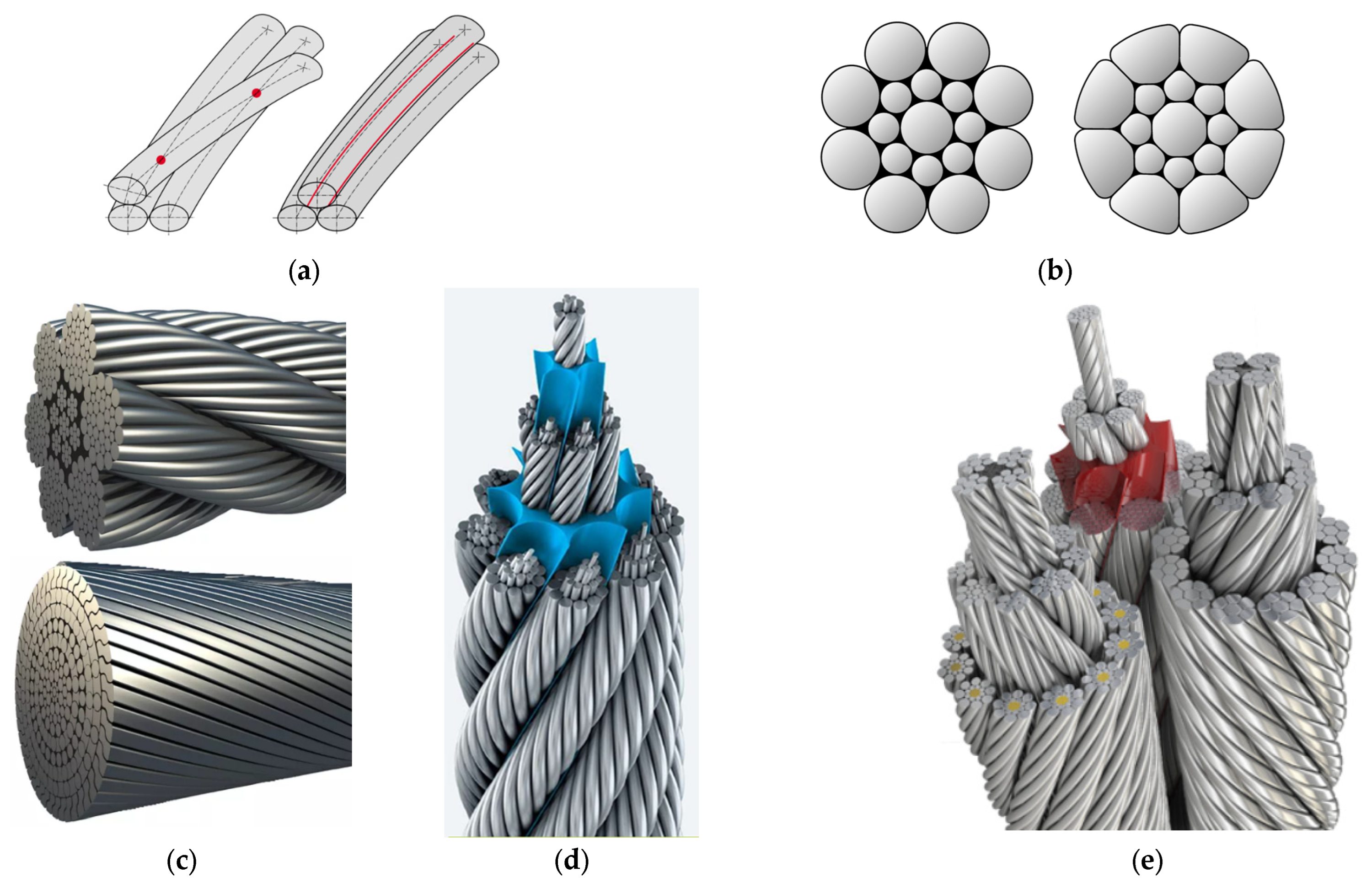

- During an active experiment in the AGH UST laboratory carried out on a looped (endless) single-layer six-strand Seale 6x19+NF steel rope with a Drumet natural Figure 12a. At the stage of production and braiding, artificial defects in the structure of various types were modeled into the lines and introduced at different depths of the rope cross-section [68]. The rope was located in a dry room and was not exposed to corrosion and fatigue. It was subject to demagnetization during classes with students mastering the technology of MRT testing and verification of new measurement paths and algorithms for steel rope diagnostics. The analyzed measurement data came from a recording in which the rope was not loaded with longitudinal force and was set in translational motion at a set stabilized forward speed through a wheel driven by an electric motor controlled from an inverter. The laboratory stand ensured long-term reproducibility of the diagnostic symptoms of rope damage.

- During passive experiments based on archival results from periodic tests of the technical condition of steel ropes using the MRT method in the Polish hard coal and copper mining industry, including the following:

- Two-layer round-strand steel rope 22.0 17x7+Ao Z/s-n-I-N-g-1570-WT-75/TT-2 containing 119 wires in 11 external strands and 6 internal strands on a natural fiber core (Figure 12b), used since 6.12.2004 in the “Guido” shaft of the Coal Mining Museum in Zabrze as a carrying rope for a cage hoist. Rope diameter 22 mm, rope coil stroke 180 mm, total rope length 190 m, safety factor when applied 9.84, min. safety factor 7.5. There is one stable wire break in the rope, which has so far been used for the initial synchronization of time series by the visual method. The symptom of wire breakage was used in the DTW algorithm to optimize the width of the rope fragment analysis window. Characteristics of the mining shaft hoist are as follows: hoisting machine B 1200/AC; hoisting class II; type, felling machine; driving speed 2 m/s; environmental conditions in exhaust shaft, wet; pulling depth, 170 m; number of pulls, approx. 5/week. Corrosion processes dominate in the lines.

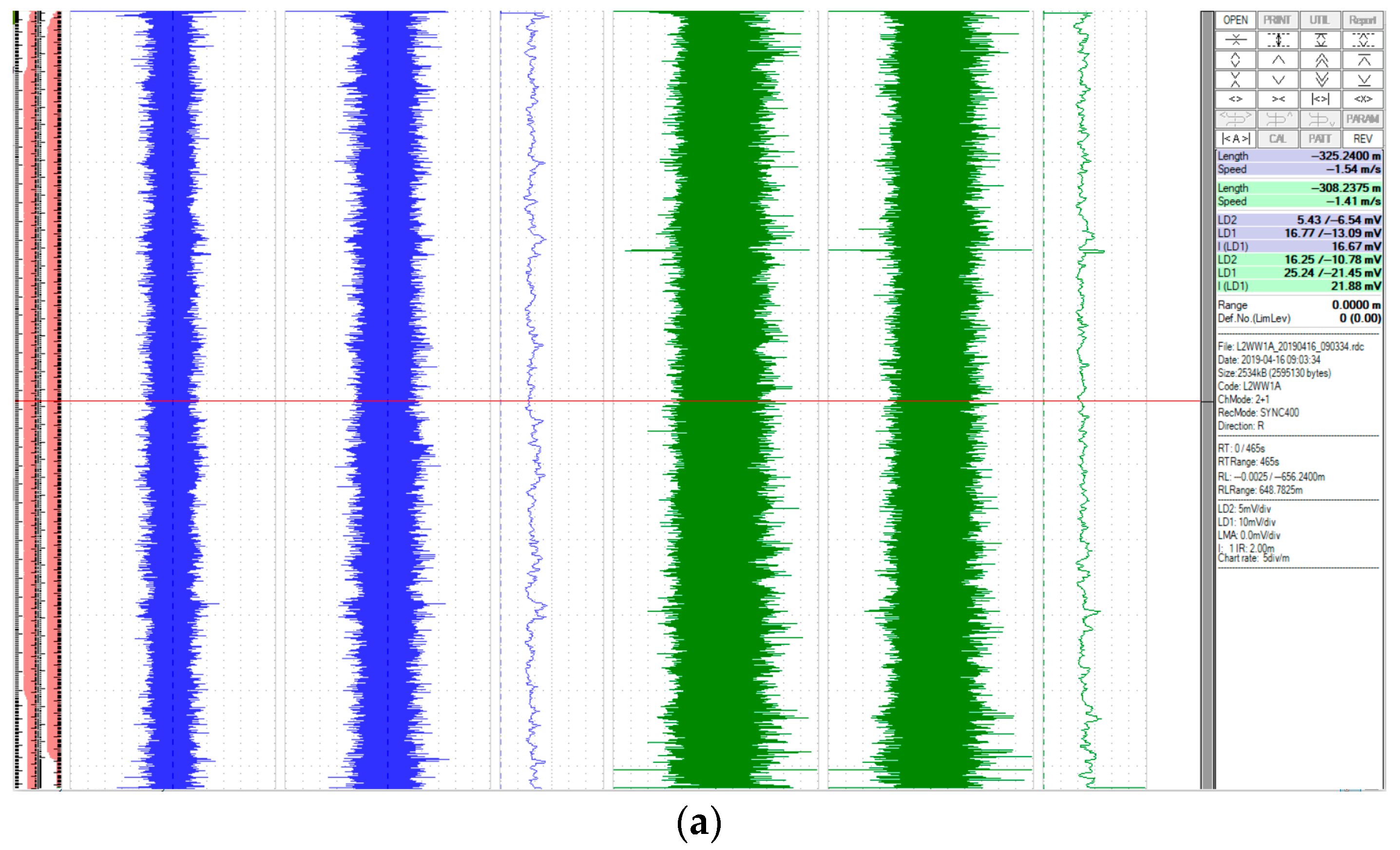

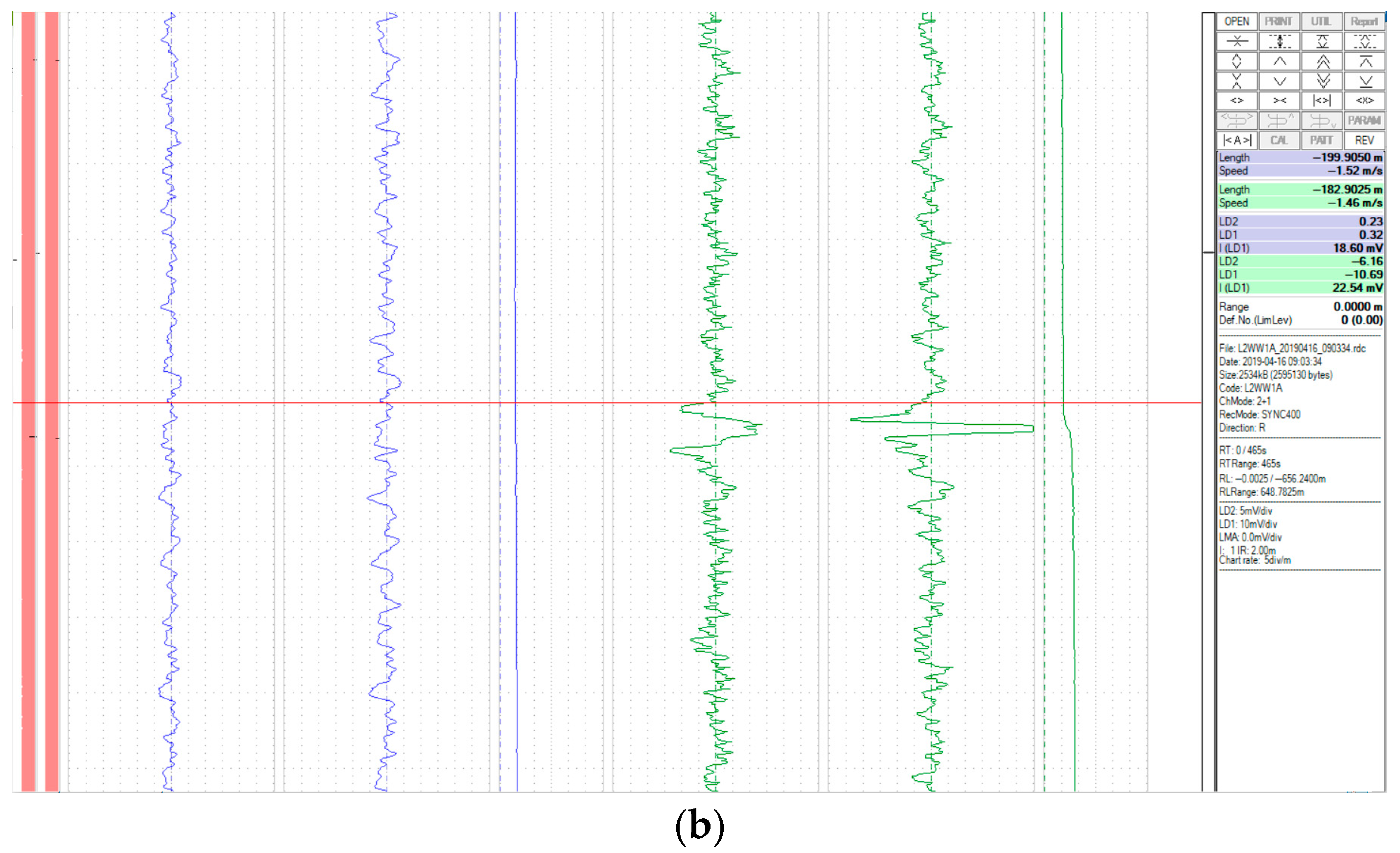

- (a)

- Single-layer wire rope NRHD24 by Arcelor Mittal containing 360 wires in 12 outer strands and 12 Warrington type core strands (Figure 12c). Rope used in a copper mine as an equalization rope is exposed to material fatigue and corrosion of external and core wires in places where the zinc-based protective layer is worn.

- (b)

- Double-layer steel line impregnated with STRATOPLAST MF 40.0 8x26WS+EPIWRC 1960 B/N(Zn/Al) z/Z (s/S) by CASAR containing wires in 8 outer strands, 6 inner strands, and 3 core strands. The strands are separated from each other by a polymer layer (Figure 12d). A rope mined in a hard coal mine in an exhaust shaft with aggressive shaft waters. Hoisting machine with KOEPA wheel; traveling speed 16 m/s; pulling number, more than 400/day. The line mainly involves fatigue processes in the presence of developing pitting corrosion of the outer wires in places where the protective layer of Bekaert BEZINAL® 3000 has been wiped off. The risk of corrosion of wires of the internal and core strands is very low until the polymer layer is damaged.

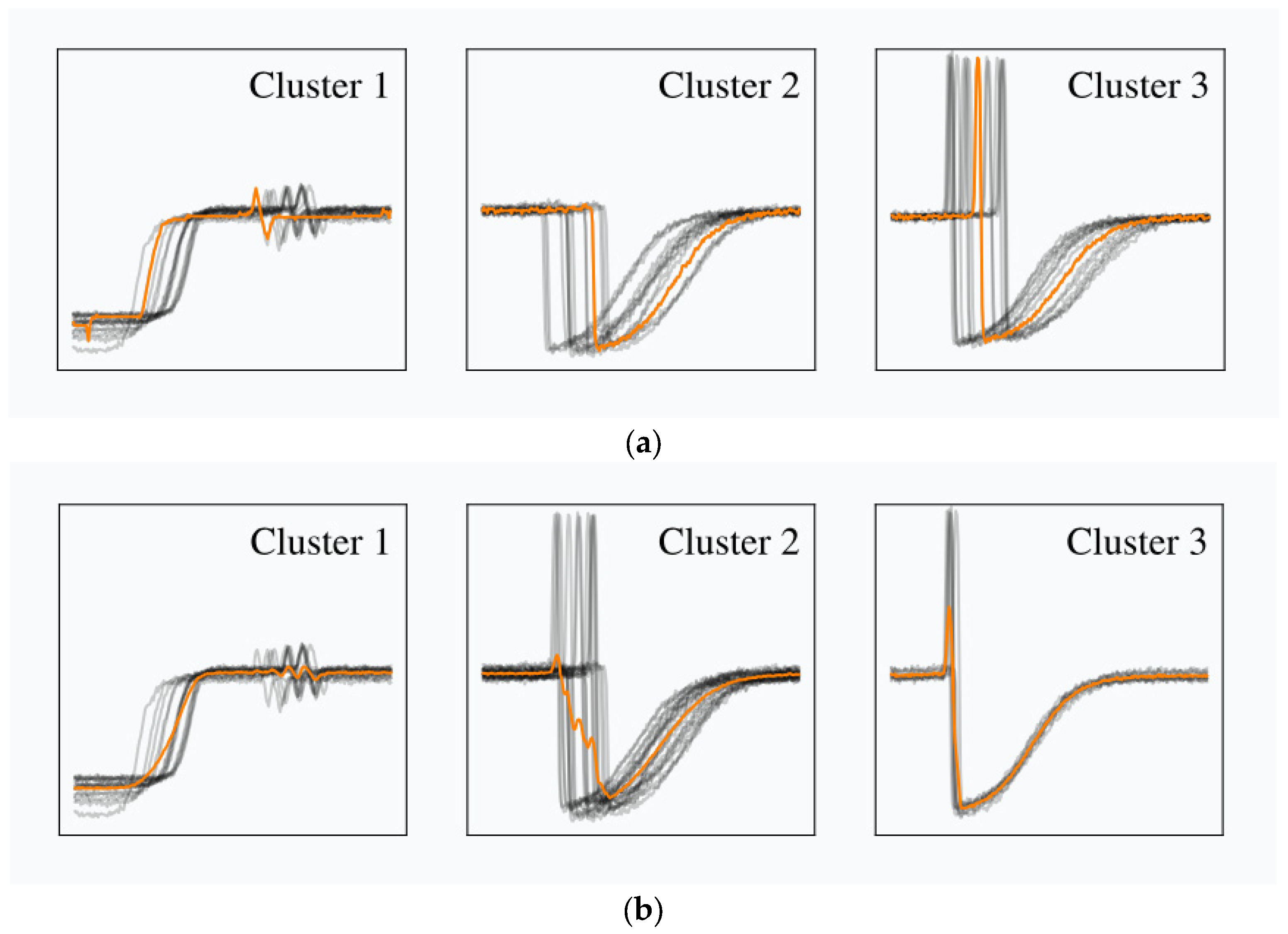

3. Results

3.1. Active Experiment

- Precision is the ratio of correctly predicted positive observations to the total number of correctly predicted positive observations;

- Recall is the ratio of correctly predicted positive observations to all observations in the wire rope patterns class;

- F1 measure is the weighted average of precision and recall.

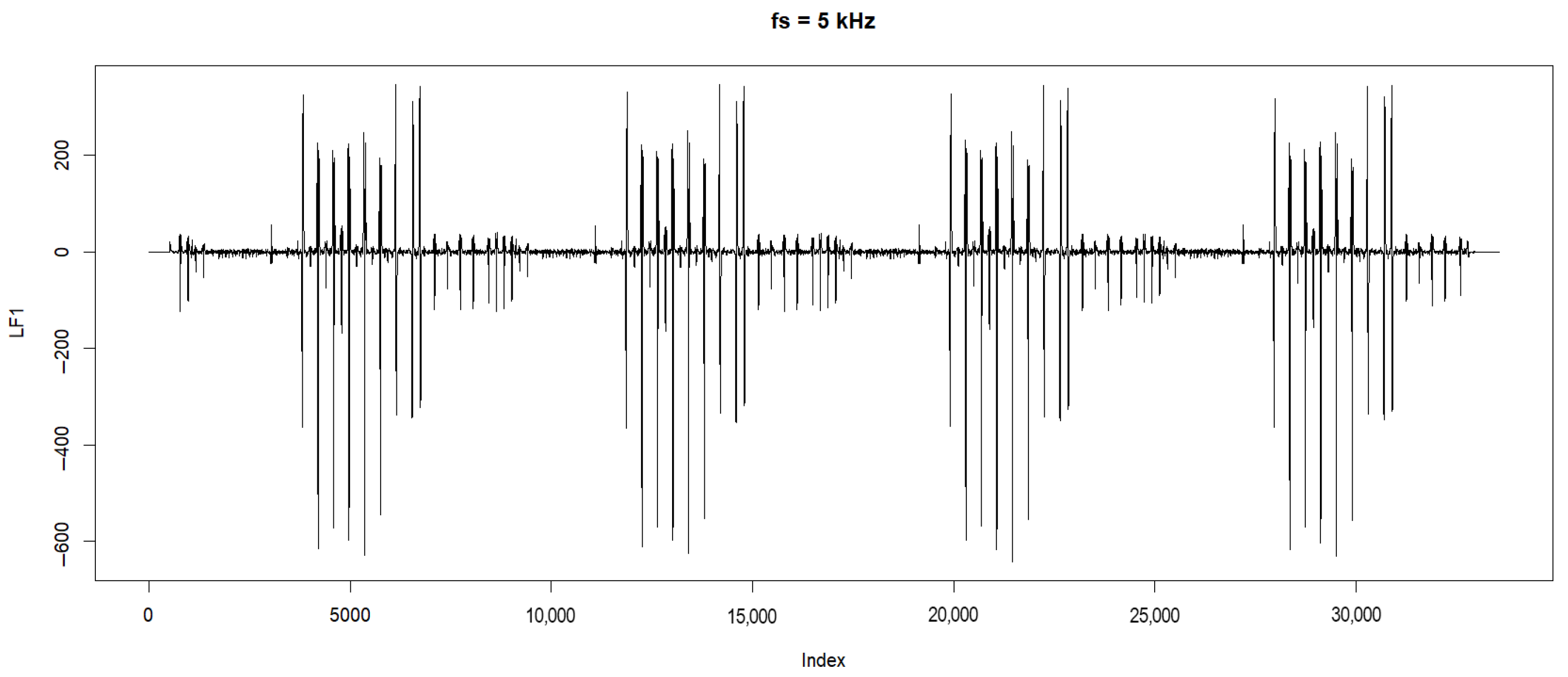

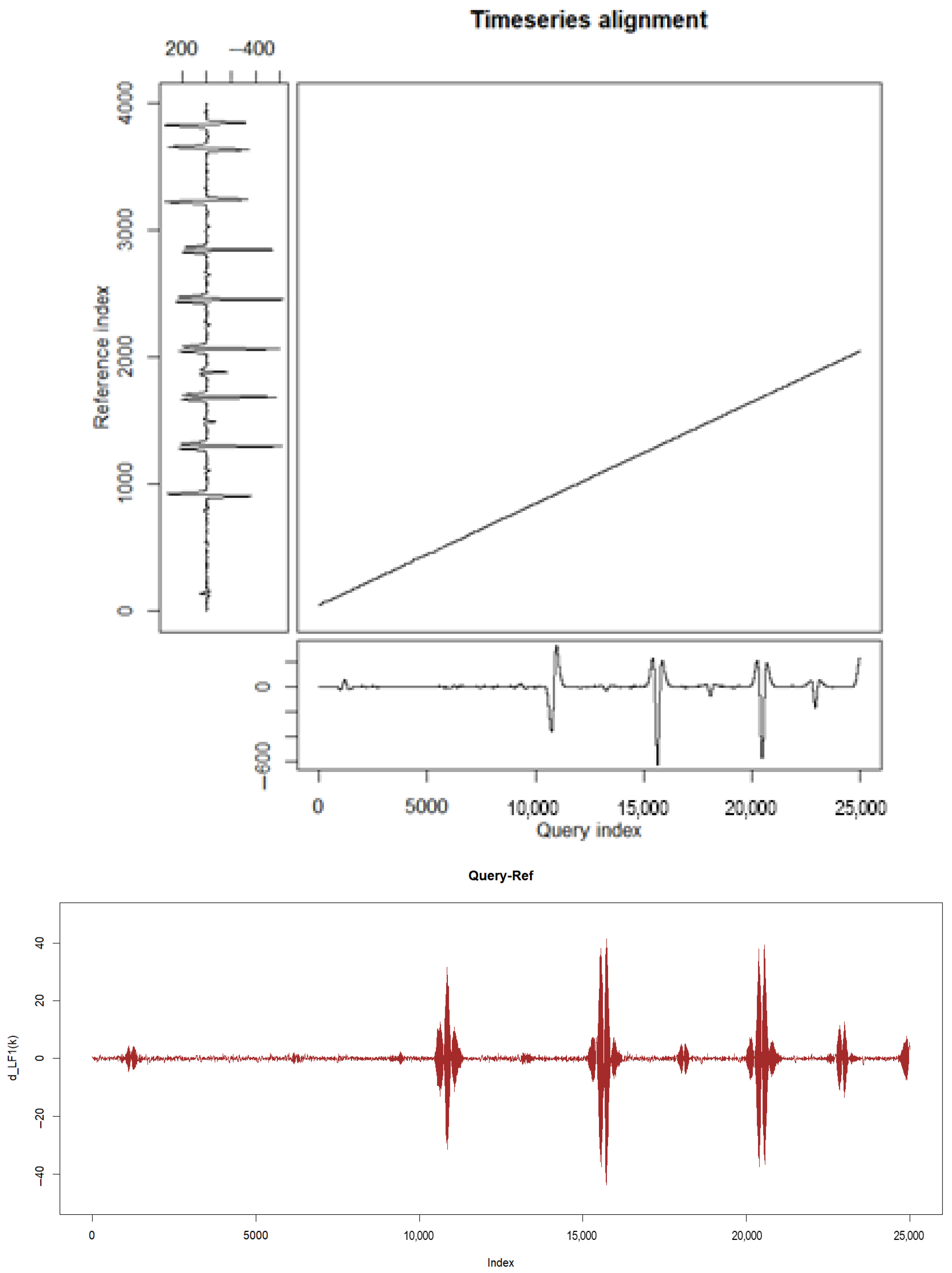

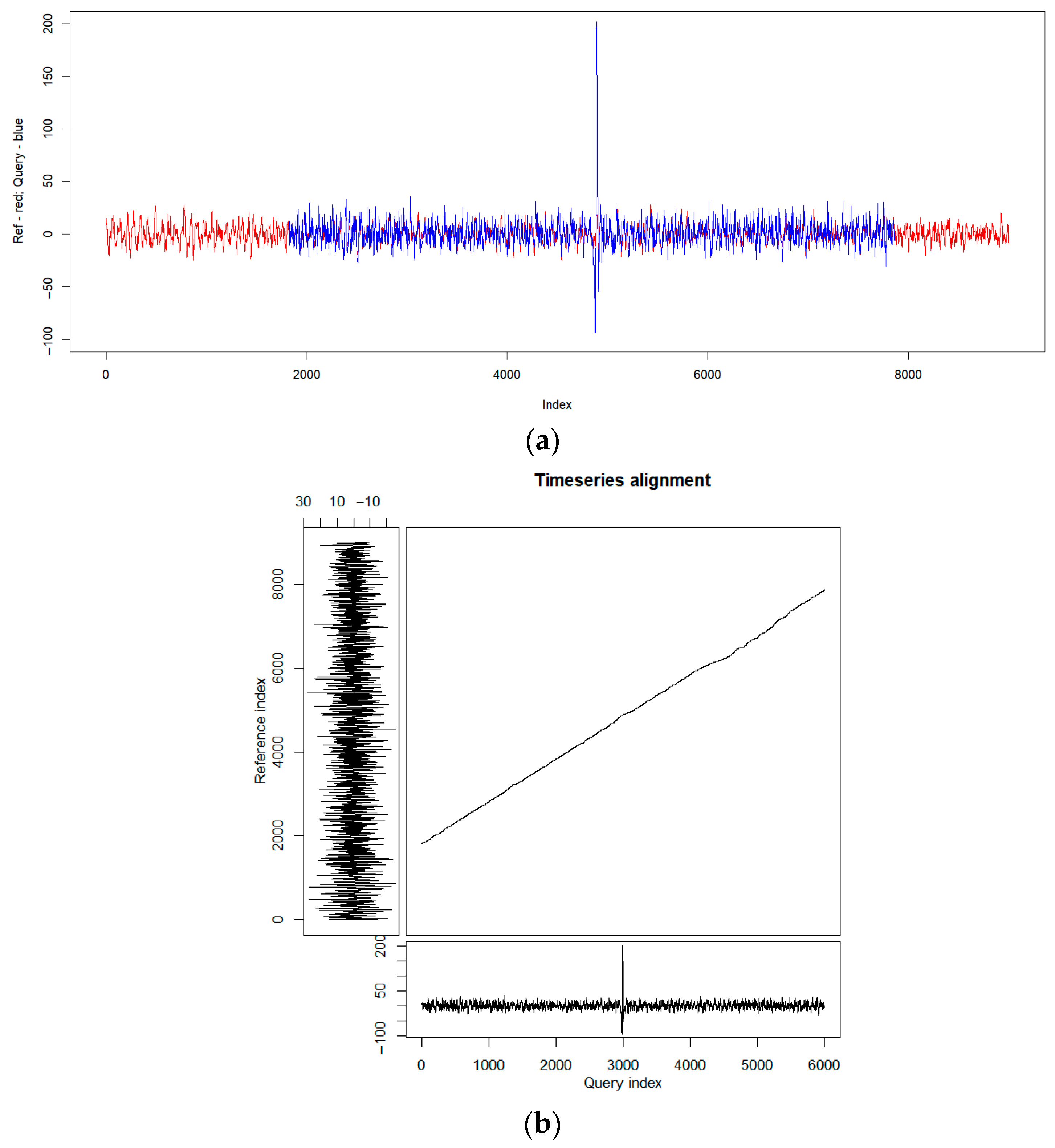

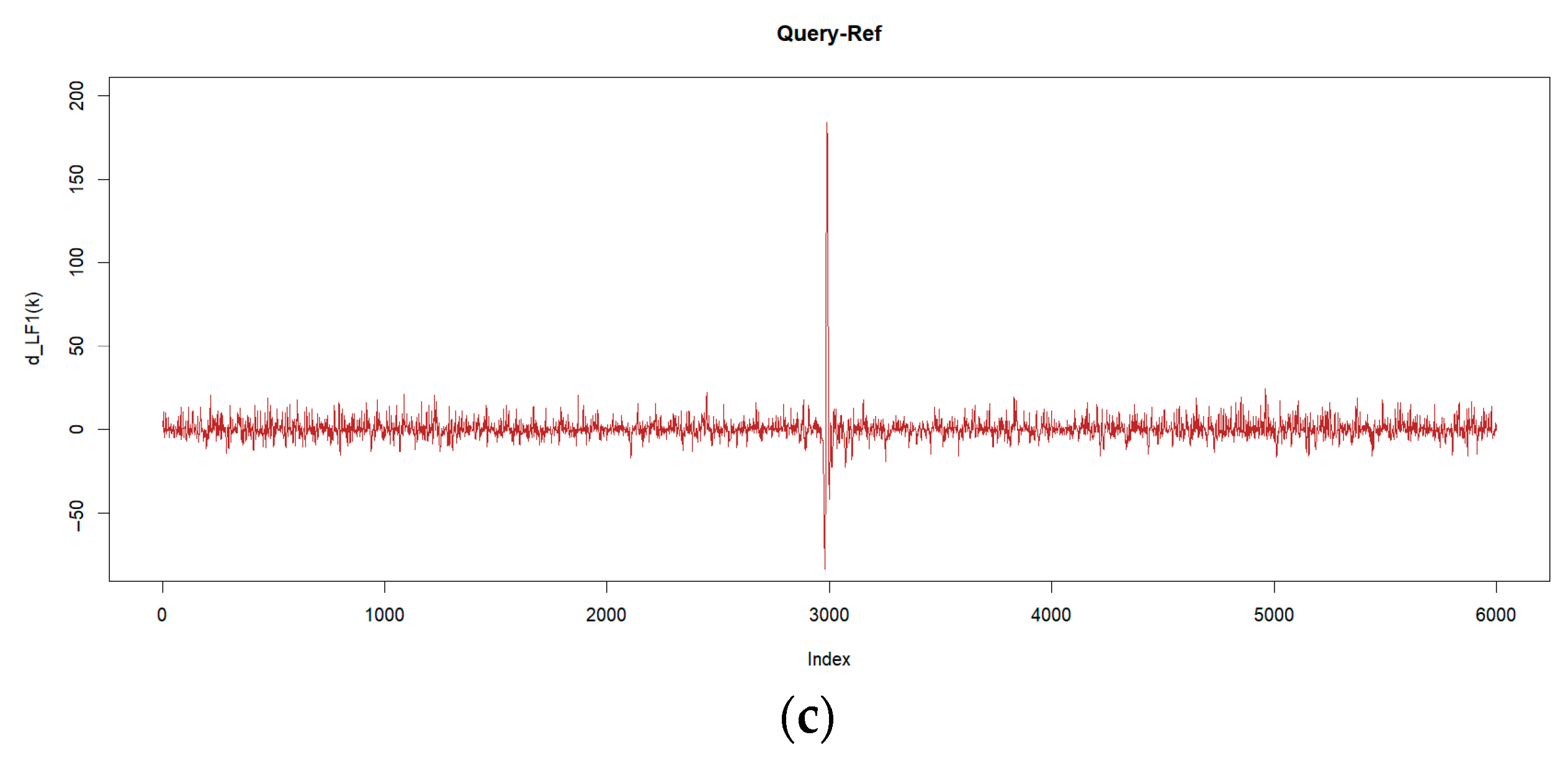

3.2. Passive Experiment

- Optimization of the analysis window width is necessary because, for time series x and x’ of length m and n, respectively, and the same ordering, there exist different paths in , which exponentially increases the required memory and data processing time. The length of the ropes tested in actual industrial installations was many times greater than that of the rope used in the active experiment, and due to the available computational power and data processing time, it was necessary to perform DTW analysis on successive segments of the current recording, taking into account the previous alignment results with the reference data.

- Verification of the effectiveness of the DTW algorithm in industrial conditions of MRT testing considering that the dynamics of rope operation and its degradation processes are impossible to reproduce in laboratory conditions.

- The research included data from long-term monitoring of wire ropes of various types and two resolutions of rope scanning in the ENCODER mode:

- Not less than 1.0 mm, required by ISO 4309:2017;

- Either 2.5 mm or 5.0 mm, used until the introduction of the amendment to the above-mentioned standard in 2017, and the MRT method still found in some users.

- The possibility of realizing LF time series matching using the Euclidean distance method in a window not exceeding 1.5 m of rope length and the DTW algorithm in a window of about 9 m;

- The need to perform DTW analysis with the use of a movable window (similar to the fast Fourier transform, SFFT) due to the limitation of the required memory volume needed to store the calculation results and the calculation time of a single rope fragment;

- Repeatability of the results of time-series synchronization obtained with the DTW algorithm for LF1 and LF2 signals, with a slight offset between the synchronized LF1 and LF2 signals increasing with the rope’s lifetime, probably resulting from the design features of the GP heads and differences in the magnetic field spectrum on the two rays of the search coils;

- The ability to monitor progressive corrosion of wires before reaching the ignition criterion of the current diagnostic rule and with a small impact of cyclic material fatigue (lack of broken wires) and abrasions;

- The desirability of analyzing harmonic components and noise in the LF signal in the aspect of rope system diagnostics, including longitudinal and transverse vibrations of the rope. After many years of operation, the rope shows repeatability of the frequency of harmonic signals, reflecting the rope’s pitch and the distance between the strands, which are amplitude-modulated along the tested rope—the influence of longitudinal, transverse, and torsional vibrations of the rope.

- The spectrum of the signal that can be visually seen in the time series imaged in the MD121 View software (Figure 19);

- Color noise, which increases in the subsequent years of operation of the NRHD24 rope as opposed to the noise of the round-strand rope (Figure 20);

- Amplitude modulation parameters of harmonic components of signals (Figure 20).

- the first break of the wire,

- excessive abrasion of the wire,

- developed corrosion

4. Discussion

5. Conclusions and Future Work

- DTW enables synchronization of LF signals with differing spectral content and sampling resolution, helping to detect subtle defects even when standard alignment fails.

- A differential analysis of DTW-aligned signals proved sensitive to changes in sampling resolution and scan speed, revealing the risk of diagnostic loss when encoder resolution drops below critical thresholds (e.g., 1000 pulses/meter at 1 m/s).

- Elongation-induced desynchronization and spectrum drift—particularly in polymer-impregnated ropes—can be mitigated through early and repeated MRT scans combined with adaptive DTW analysis.

- Integrating DTW-based alignment with real-time digital twin systems for predictive diagnostics.

- Developing hybrid models that combine MRT data with physical load parameters (e.g., tension, vibration) for condition-aware simulations.

- Applying wavelet and segmentation techniques for trend detection beyond hard thresholding.

- Exploring AI classifiers trained on DTW-aligned signal features to distinguish mechanical wear, corrosion, or fatigue.

- Enabling on-device DTW processing in embedded monitoring systems for continuous diagnostics in critical sectors like mining, offshore, and aviation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Feyrer, K. Wire Ropes: Tension, Endurance, Reliability, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 978-3-642-54995-3. [Google Scholar]

- ISO 4309:2017; Cranes—Wire Ropes—Care and Maintenance, Inspection and Discard. International Organization for Standardization: Geneva, Switzerland, 2017. Available online: https://www.standards.govt.nz/shop/iso-43092017 (accessed on 30 May 2025).

- EN 12927:2019; Safety Requirements for Cableway Installations Designed to Carry Persons—Ropes. European Committee for Standardization (CEN): Brussels, Belgium, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/392a2e7b-40c5-4aaa-97ba-b31653b7962e/en-12927-2019?srsltid=AfmBOooq-t6Oxldcw-wejLY-X8ilox3_KzvZgX8SkYBV39sQLKSdRmnz (accessed on 30 May 2025).

- Close, M. What is Wire Rope? Understanding the Specifications and Construction. Maz. Co. 2018. Available online: https://www.mazzellacompanies.com/learning-center/what-is-wire-rope-specifications-classifications-construction/ (accessed on 30 May 2025).

- Verreet, R. Technical-Documentation (Casar). 1997. Available online: https://www.casar.de/Portals/0/Documents/Brochures/technical-documentation.pdf (accessed on 30 May 2025).

- Kwasniewski, J.; Tobys, J.; Nocek, K.; Witos, M.; Krakowski, T.; Molski, S. Wyzwania badawcze w diagnostyce lin impregnowanych polimerem//Research challenges in the diagnosis of polymer impregnated steel wire ropes. In Proceedings of the Poprawa bezpieczeństwa, efektywności i ekonomiki pracy urządzeń szybowych dzięki zastosowaniu nowoczesnych rozwiązań i technologii, Szczyrk, Poland, 13–15 March 2025. [Google Scholar] [CrossRef]

- Yang, Y.; Yuan, X.; Li, Y.; He, Z.; Zhang, S.; Zheng, S. Effect of time-varying corrosion on the low-cycle fatigue mechanical properties of wire rope. Ocean. Eng. 2022, 250, 111027. [Google Scholar] [CrossRef]

- Ridge, I.M.L. Tension–torsion fatigue behaviour of wire ropes in offshore moorings. Ocean. Eng. 2009, 36, 650–660. [Google Scholar] [CrossRef]

- Witoś, M.; Zieja, M.; Tomaszewska, J.; Matlak, R. Assessment of the Probability Diagnosis of Non-Destructive Testing. In Proceedings of the International Conference on Safety Problems in the Mining Industry—Mechanization, Automation, Logistics and Transport, Wisła, Poland, 16–18 November 2022. [Google Scholar]

- CASAR Drahtseilwerk Saar GmbH CASAR Stratoplast M. 2019. Available online: https://www.casar.de/Portals/0/Stratoplast%20M.pdf (accessed on 30 May 2025).

- EN 10088-1:2005; Stainless Steels—Part 1: List of Stainless Steels. European Committee for Standardization (CEN): Brussels, Belgium, 2005. Available online: https://standards.iteh.ai/catalog/standards/cen/952db42f-8160-4518-8932-c51bc76f8715/en-10088-1-2005?srsltid=AfmBOoqbSewaBucBF7qv0gg-HmqJtTb2yJWA26nLyBGBAxYNc8gpnumB (accessed on 30 May 2025).

- EN 10088-5:2009; Stainless Steels—Part 5: Technical Delivery Conditions for Bars, Rods, Wire, Sections and Bright Products of Corrosion-Resisting Steels for Construction Purposes. European Committee for Standardization (CEN): Brussels, Belgium, 2009.

- Toth, G.L. Contribuţii la Studiul şi Cercetării Influenţei Construcţiei şi Condiţiilor de Utilizare Asupra Fiabilităţii Cablurilor Din Oţel. Ph.D. Thesis, Universitatea “Politehnica” din Timişoara, Facultatea de Mecanică, Catedra de Rezistenţa Materialelor, Timişoara, Romania, 2007. [Google Scholar]

- CASAR Drahtseilwerk Saar GmbH Compacting 2012. Available online: https://www.casar.de/Portals/0/Documents/Product-Information/compacting.pdf (accessed on 30 May 2025).

- Bekaert Bridon Dyform® 6. Available online: https://ropes.bekaert.com/gb/en/home/products/bridon-dyform6 (accessed on 30 May 2025).

- ArcelorMittal WireSolutions Wire Ropes. Available online: https://barsandrods.arcelormittal.com/wiresolutions/wireropes/home/EN (accessed on 30 May 2025).

- Yordanova, R.; Yankova, S. Evaluation of the Mechanical Properties of Steel Wire Rope During Its Operation in the Mining Industry. J. Chem. Technol. Metall. 2025, 60, 163–172. [Google Scholar] [CrossRef]

- Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on Machinery, and Amending Directive 95/16/EC (recast). 2006. Available online: https://eur-lex.europa.eu/eli/dir/2006/42/oj/eng (accessed on 30 May 2025).

- Rozporządzenie Ministra Energii z dnia 23 listopada 2016 r. w sprawie szczegółowych wymagań dotyczących prowadzenia ruchu podziemnych zakładów górniczych 2017. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20170001118 (accessed on 30 May 2025).

- Peake, A. The Role of Steel Wire Ropes in Mine Safety; CSIR Consulting and Analytical Services: New Delhi, India, 2006. [Google Scholar]

- BBC News Italy cable car fall: 14 dead after accident near Lake Maggiore. BBC News, 24 May 2021.

- Pandey, T. 141 Dead, Gujarat Bridge Was Disaster Waiting to Happen: 10 Points. NDTV. 31 October 2022. Available online: https://azertag.az/en/xeber/141_dead_gujarat_bridge_in_india_was_disaster_waiting_to_happen-2356496 (accessed on 30 May 2025).

- Langa, M. Morbi Bridge Collapse Tragedy: 141 Deaths Reported So Far. Hindu. 31 October 2022. Available online: https://www.thehindu.com/news/national/the-death-toll-in-morbi-bridge-collapse-tragedy-exceeds-130/article66076100.ece (accessed on 30 May 2025).

- Liu, S.; Sun, Y.; Jiang, X.; Kang, Y. A Review of Wire Rope Detection Methods, Sensors and Signal Processing Techniques. J. Nondestruct. Eval. 2020, 39, 85. [Google Scholar] [CrossRef]

- Rossteutscher, I.; Blaschke, O.; Dötzer, F.; Uphues, T.; Drese, K.S. Improved EMAT Sensor Design for Enhanced Ultrasonic Signal Detection in Steel Wire Ropes. Sensors 2024, 24, 7114. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Liu, G.; Zhong, Z.; Li, Q. Development of wire rope breakage monitoring sensor driven by FAST feeder module. Measurement 2025, 255, 118076. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, J.; Li, X.; Du, X.; Zhao, T.; Hou, Q.; Jin, X. Quantitative risk assessment of typhoon storm surge for multi-risk sources. J. Environ. Manag. 2022, 327, 116860. [Google Scholar] [CrossRef]

- Barsi, F.; Carboni, B.; Lacarbonara, W. A new mechanical model of short wire ropes: Theory and experimental validation. Eng. Struct. 2025, 323, 119217. [Google Scholar] [CrossRef]

- Wang, H.; Wang, H.; Liu, Q. TW-YOLO: High-precision Steel Wire Rope Detection Algorithm Based on Triplet Attention. Adv. Comput. Commun. 2025, 6, 48–54. [Google Scholar] [CrossRef]

- Shen, B.; Wang, X.; Sun, M.; Qian, W. Deformation Monitoring Model of Buried Pipeline Mechanical Parts Based on the Distributed Optical Fiber Monitoring System. J. Eng. 2024, 2024, 6621011. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, X.; Han, T.; Huang, H.; Huang, X.; Wang, L.; Wu, Z. Pipeline deformation monitoring based on long-gauge FBG sensing system: Missing data recovery and deformation calculation. J. Civ. Struct. Health Monit. 2025, 1–21. [Google Scholar] [CrossRef]

- MD121 Wire Rope Defectograph—Zawada NDT. Available online: http://www.z-ndt.com/MD121.pdf (accessed on 25 May 2025).

- Ellingson, S. Electromagnetics, 1st ed.; VT Publishing: Blacksburg, VA, USA, 2018; ISBN 978-0-9979201-9-2. [Google Scholar]

- Tumanski, S. Induction coil sensors—A review. Meas. Sci. Technol. 2007, 18, R31. [Google Scholar] [CrossRef]

- Buzio, M. Fabrication and calibration of search coils 2011. arXiv 2011, arXiv:1104.0803. [Google Scholar] [CrossRef]

- ROTEC GmbH ROTEC—Your Specialist in Rope and Cableway Technology. 2025. Available online: https://ro-tec.net/en/product-development/magnetic-rope-testing-devices/ (accessed on 30 May 2025).

- LF LMA Technology for Rope Testing|Mennens|Mennens Netherlands. Available online: https://www.mennens.nl/en/services/magnetic-rope-testing/lf-lma (accessed on 27 June 2025).

- Weischedel, H.R. Electromagnetic Inspection of Wire Ropes Using Sensor Arrays; University of Rhode Island: Kingston, RI, USA, 1982; Available online: https://apps.dtic.mil/sti/tr/pdf/ADA149016.pdf (accessed on 30 May 2025).

- Wang, H.; Zheng, H.; Tian, J.; He, H.; Ji, Z.; He, X. Research on quantitative identification method for wire rope wire breakage damage signals based on multi-decomposition information fusion. J. Saf. Sustain. 2024, 1, 89–97. [Google Scholar] [CrossRef]

- Debeleac, C.; Nastac, S.; Musca (Anghelache), G.D. Experimental Investigations Regarding the Structural Damage Monitoring of Strands Wire Rope within Mechanical Systems. Materials 2020, 13, 3439. [Google Scholar] [CrossRef]

- Canova, A.; Furno, E.; Buco, A.; Ressia, M.; Rossi, D.; Vusini, B. The wavelet analysis: Application to the magneto-inductive testing. E-J. Nondestruct. Test. 2014, 19. [Google Scholar]

- Tytko, A. Application of signal analysis in magnetic testing of wire ropes. In Proceedings of the AMAS Course–NTM 2, Warsaw, Poland, 20–22 May 2002. [Google Scholar]

- Martyna, R.; Martyna, M. Polish technology for testing wire ropes of the largest rope devices in the world. Nondestr Uctive Test. A Nd Diagn. 2017, 3, 11–16. [Google Scholar]

- Bozorth, R.M. Ferromagnetism; Wiley & Sons: Hoboken, NJ, USA, 1993; ISBN 978-0-470-54462-4. [Google Scholar]

- Honeywell Inc. Hall Effect_ Sensing and Application; Honeywell Inc.: Charlotte, NC, USA, 1998. [Google Scholar]

- Nussbaum, J.-M. High Resolution Magnetic Induction Wire Rope Test. Available online: https://repository.mines.edu/entities/publication/4a8eea39-5ccd-43df-a442-97f437dc1202 (accessed on 30 May 2025).

- OITAF Survey of Magnetic Rope Resting of Steel Wire Ropes. 2015. Available online: https://oitaf.org/wp-content/uploads/2023/12/525530_Book-3-1.pdf (accessed on 30 May 2025).

- AMC Instruments to LF or to LMA? That Is the Question! 2023. Available online: https://www.aemmeci.com/en/blog/media-article/41-to-lf-or-to-lma-that-is-the-question.html (accessed on 30 May 2025).

- Kreuz, T.; Mormann, F.; Andrzejak, R.G.; Kraskov, A.; Lehnertz, K.; Grassberger, P. Measuring synchronization in coupled model systems: A comparison of different approaches. Phys. D Nonlinear Phenom. 2007, 225, 29–42. [Google Scholar] [CrossRef]

- Stam, C.J.; Van Dijk, B.W. Synchronization likelihood: An unbiased measure of generalized synchronization in multivariate data sets. Phys. D Nonlinear Phenom. 2002, 163, 236–251. [Google Scholar] [CrossRef]

- Shang, D.; Shang, P. The Fisher-DisEn plane: A novel approach to distinguish different complex systems. Commun. Nonlinear Sci. Numer. Simul. 2020, 89, 105271. [Google Scholar] [CrossRef]

- Vintsyuk, T.K. Speech discrimination by dynamic programming. Cybern. Syst. Anal. 1972, 4, 52–57. [Google Scholar] [CrossRef]

- Itakura, F. Minimum Prediction Residual Principle to Speech Recognition. IEEE Trans. Acoust. Speech Signal Process. 1975, 23, 67–72. [Google Scholar] [CrossRef]

- Sakoe, H.; Chiba, S. Dynamic programming algorithm optimization for spoken word recognition. IEEE Trans. Acoust. Speech Signal Process. 1978, 26, 43–49. [Google Scholar] [CrossRef]

- Shearme, J.; Leach, P. Some experiments with a simple word recognition system. IEEE Trans. Audio Electroacoust. 1968, 16, 256–261. [Google Scholar] [CrossRef]

- Wang, Q. Dynamic Time Warping (DTW). 2025. Available online: https://www.mathworks.com/matlabcentral/fileexchange/43156-dynamic-time-warping-dtw (accessed on 30 May 2025).

- Micó, P. Continuous Dynamic Time Warping. 2025. Available online: https://www.mathworks.com/matlabcentral/fileexchange/16350-continuous-dynamic-time-warping (accessed on 30 May 2025).

- Cur, K.; Gołda, P.; Izdebski, M.; Świergolik, S.; Radomyski, A. Development of aviation infrastructure in selected European countries: Statistical analysis and implications. Aviat. Secur. Issues 2023, 4, 107–137. [Google Scholar] [CrossRef]

- Serantoni, C.; Riente, A.; Abeltino, A.; Bianchetti, G.; Maria De Giulio, M.; Salini, S.; Russo, A.; Landi, F.; De Spirito, M.; Maulucci, G. Integrating Dynamic Time Warping and K-means clustering for enhanced cardiovascular fitness assessment. Biomed. Signal Process. Control 2024, 97, 106677. [Google Scholar] [CrossRef]

- Kumtepeli, V.; Perriment, R.; Howey, D.A. DTW-C++: Fast dynamic time warping and clustering of time series data. J. Open Source Softw. 2024, 9, 6881. [Google Scholar] [CrossRef]

- Giorgino, T. Computing and Visualizing Dynamic Time Warping Alignments in R: The dtw Package. J. Stat. Softw. 2009, 31, 1–24. [Google Scholar] [CrossRef]

- DynamicTimeWarping Contributors Dtw-Python: Dynamic Time Warping in Python. 2024. Available online: https://pypi.org/project/dtw-python/ (accessed on 30 May 2025).

- Salvador, S.; Chan, P. FastDTW: Toward accurate dynamic time warping in linear time and space. Intell. Data Anal. 2007, 11, 561–580. [Google Scholar] [CrossRef]

- Tanida, K. fastdtw: Fast Dynamic Time Warping Implementation in Python. 2019. Available online: https://pypi.org/project/fastdtw/ (accessed on 30 May 2025).

- Maestre, R. FastDTW: A Python Implementation of the FastDTW Algorithm. Available online: https://github.com/rmaestre/FastDTW (accessed on 30 May 2025).

- Tavenard, R. An Introduction to Dynamic Time Warping. 2020. Available online: https://rtavenar.github.io/blog/dtw.html (accessed on 30 May 2025).

- Benito, B.M. A Gentle Intro to Dynamic Time Warping. 2025. Available online: https://www.blasbenito.com/post/dynamic-time-warping/ (accessed on 30 May 2025).

- Kwaśniewski, J. Personnel Certification System in the MTR Method; AGH: Kraków, Poland, 2010. [Google Scholar]

- Dewesoft Downloads. Available online: https://dewesoft.com/download (accessed on 25 May 2025).

- Powers, D.M.W. Evaluation: From precision, recall and F-measure to ROC, informedness, markedness and correlation 2020. arXiv 2020, arXiv:2010.16061. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomaszewska, J.; Witoś, M.; Kwaśniewski, J. Application of Dynamic Time Warping (DTW) in Comparing MRT Signals of Steel Ropes. Appl. Sci. 2025, 15, 7924. https://doi.org/10.3390/app15147924

Tomaszewska J, Witoś M, Kwaśniewski J. Application of Dynamic Time Warping (DTW) in Comparing MRT Signals of Steel Ropes. Applied Sciences. 2025; 15(14):7924. https://doi.org/10.3390/app15147924

Chicago/Turabian StyleTomaszewska, Justyna, Mirosław Witoś, and Jerzy Kwaśniewski. 2025. "Application of Dynamic Time Warping (DTW) in Comparing MRT Signals of Steel Ropes" Applied Sciences 15, no. 14: 7924. https://doi.org/10.3390/app15147924

APA StyleTomaszewska, J., Witoś, M., & Kwaśniewski, J. (2025). Application of Dynamic Time Warping (DTW) in Comparing MRT Signals of Steel Ropes. Applied Sciences, 15(14), 7924. https://doi.org/10.3390/app15147924