Bioinspired Kirigami Structure for Efficient Anchoring of Soft Robots via Optimization Analysis

Abstract

1. Introduction

2. Design, Composer, and Experimental Setup

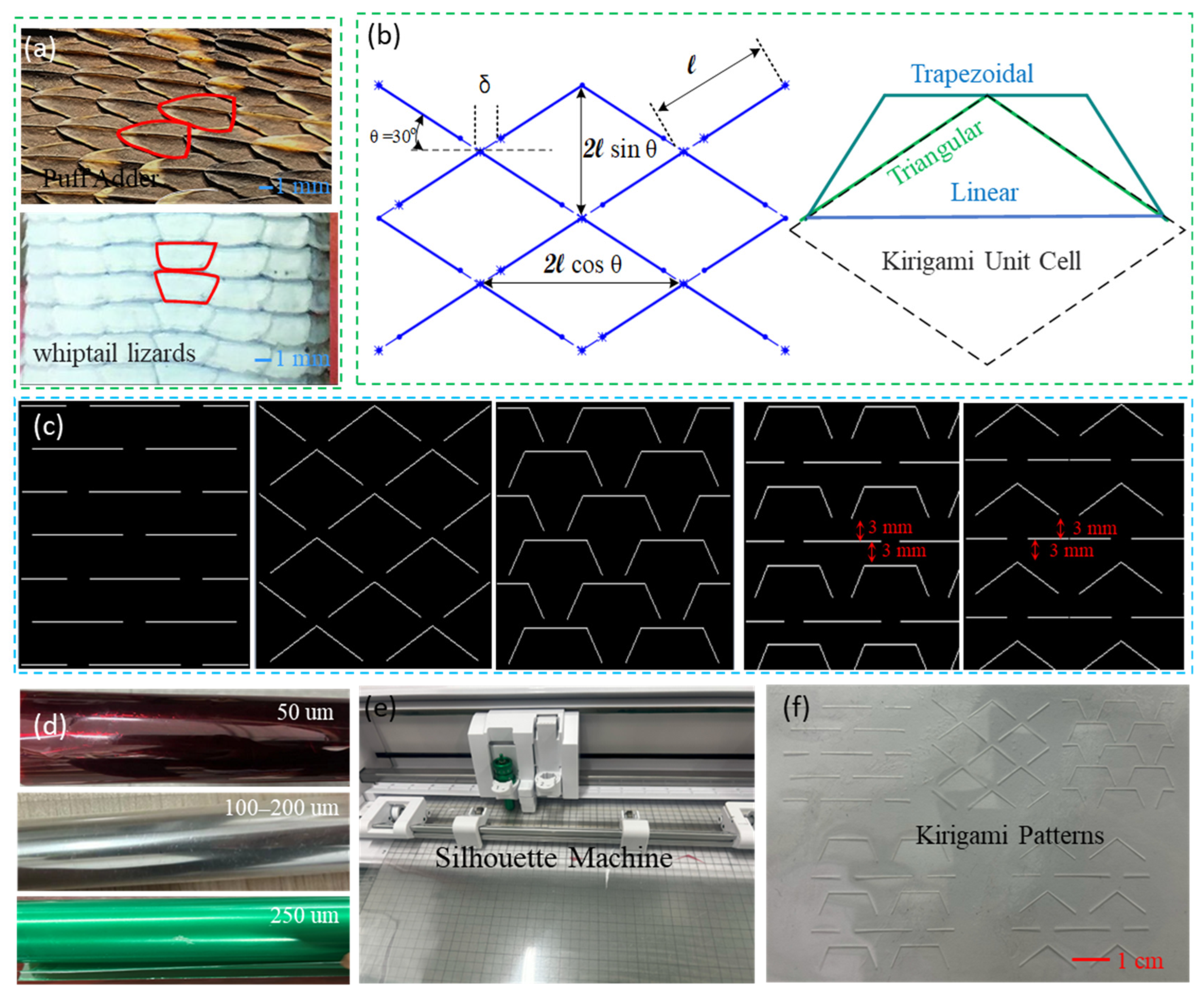

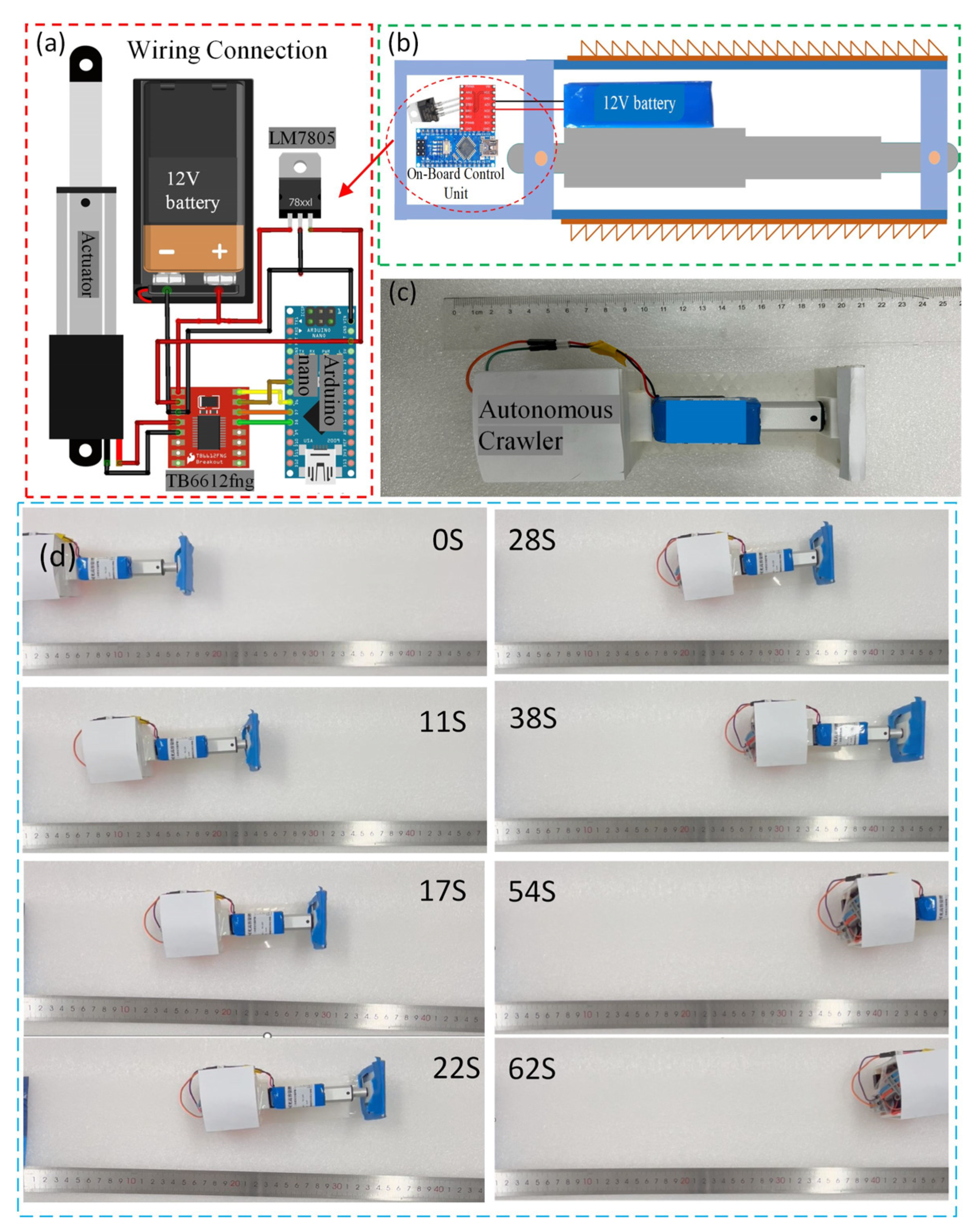

2.1. Kirigami Structure Design

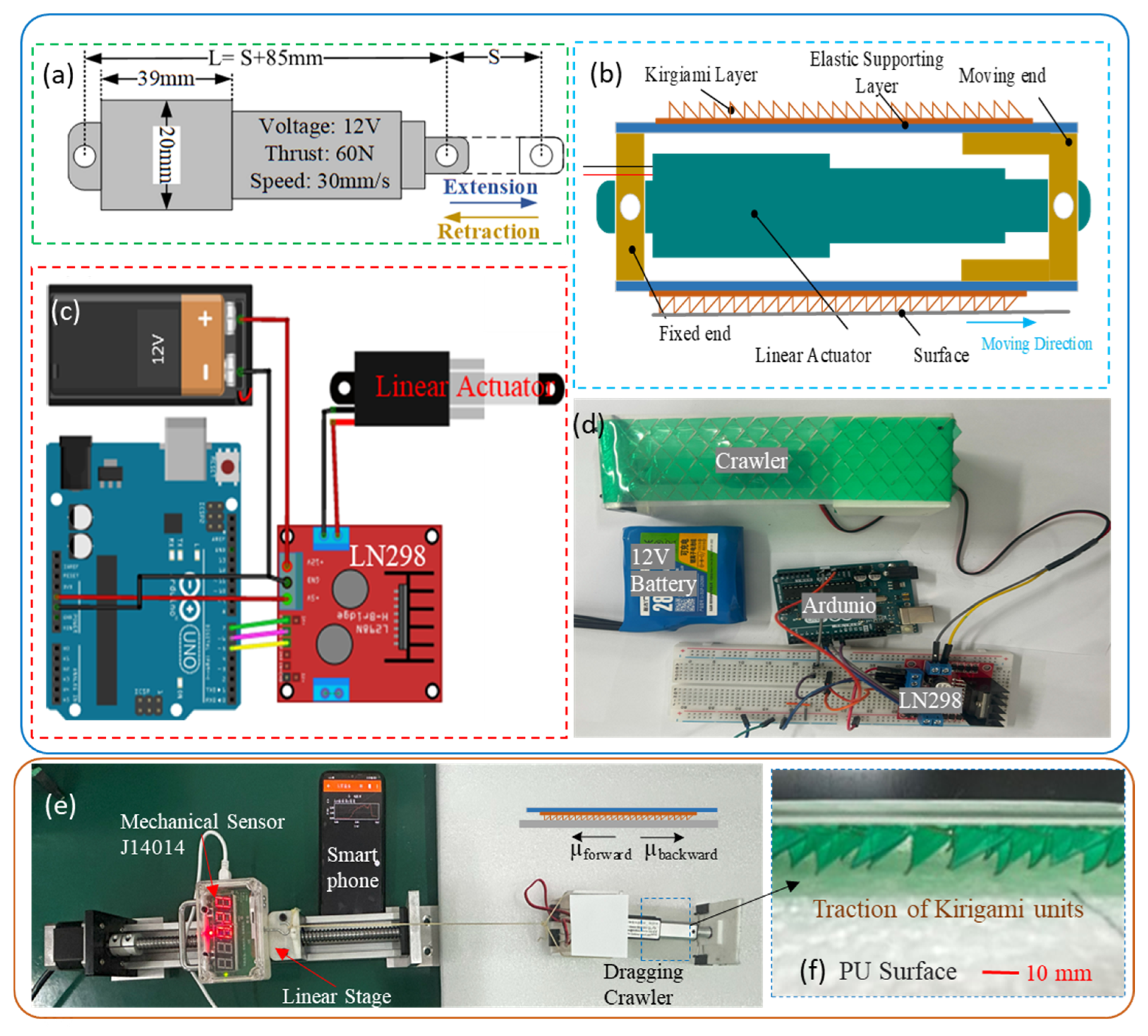

2.2. Composer of the Kirigami-Skinned Crawlers for Parameters Analysis

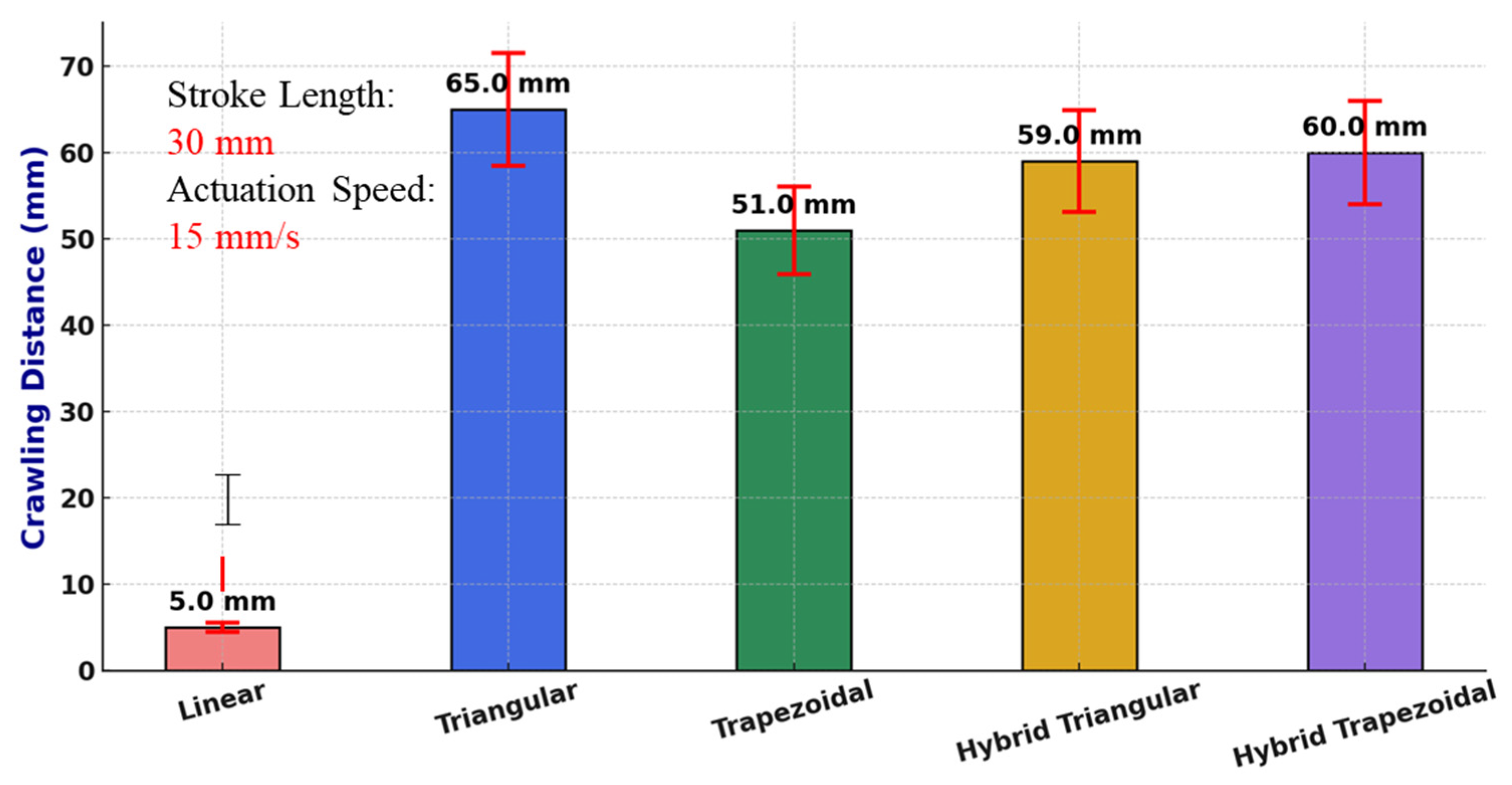

- Kirigami Structure Type vs. Crawling Distance: This experiment investigates how different kirigami geometries affect anisotropic friction and locomotion. Inspired by the morphological diversity of snake scales, five distinct patterns were tested: linear, trapezoidal, triangular, hybrid linear–triangular, and hybrid linear–trapezoidal. The primary aim was to analyze how each pattern’s deformation mechanics and surface contact profile contribute to directional friction and, thus, crawling performance. By comparing the average crawling distance over five actuation cycles, this study aims to identify the most efficient pattern for generating propulsive force (Figure 1c).

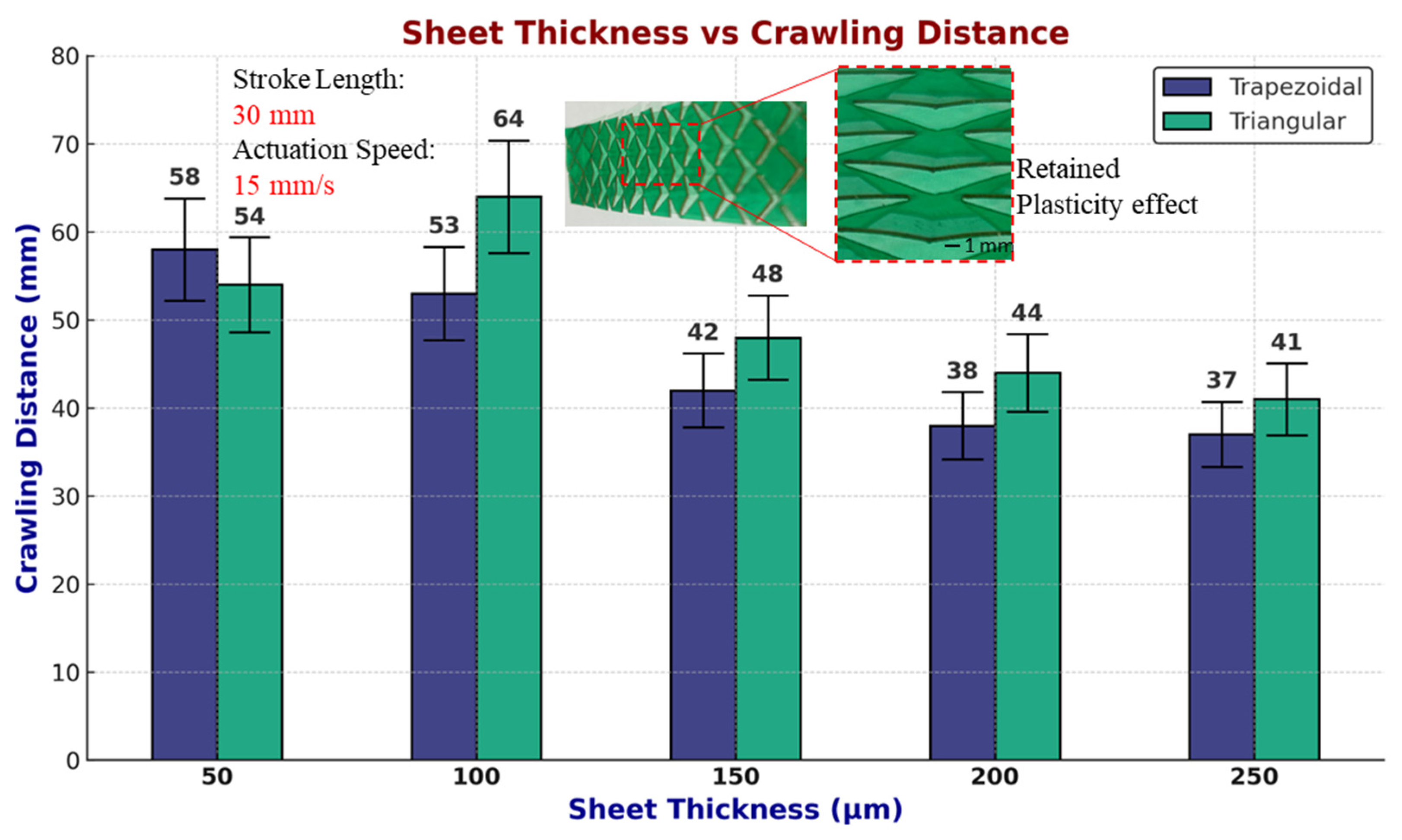

- PET Sheet Thickness vs. Crawling Distance: In this test, the effect of substrate flexibility and stiffness on locomotion was examined by using PET sheets of varying thicknesses: 50 μm (red), 100 μm, 150 μm, 200 μm (transparent), and 250 μm (green). The experiment evaluates the average crawling distance to determine the optimal balance between mechanical compliance and anchoring effectiveness, both of which are critical for reliable propulsion (Figure 1d).

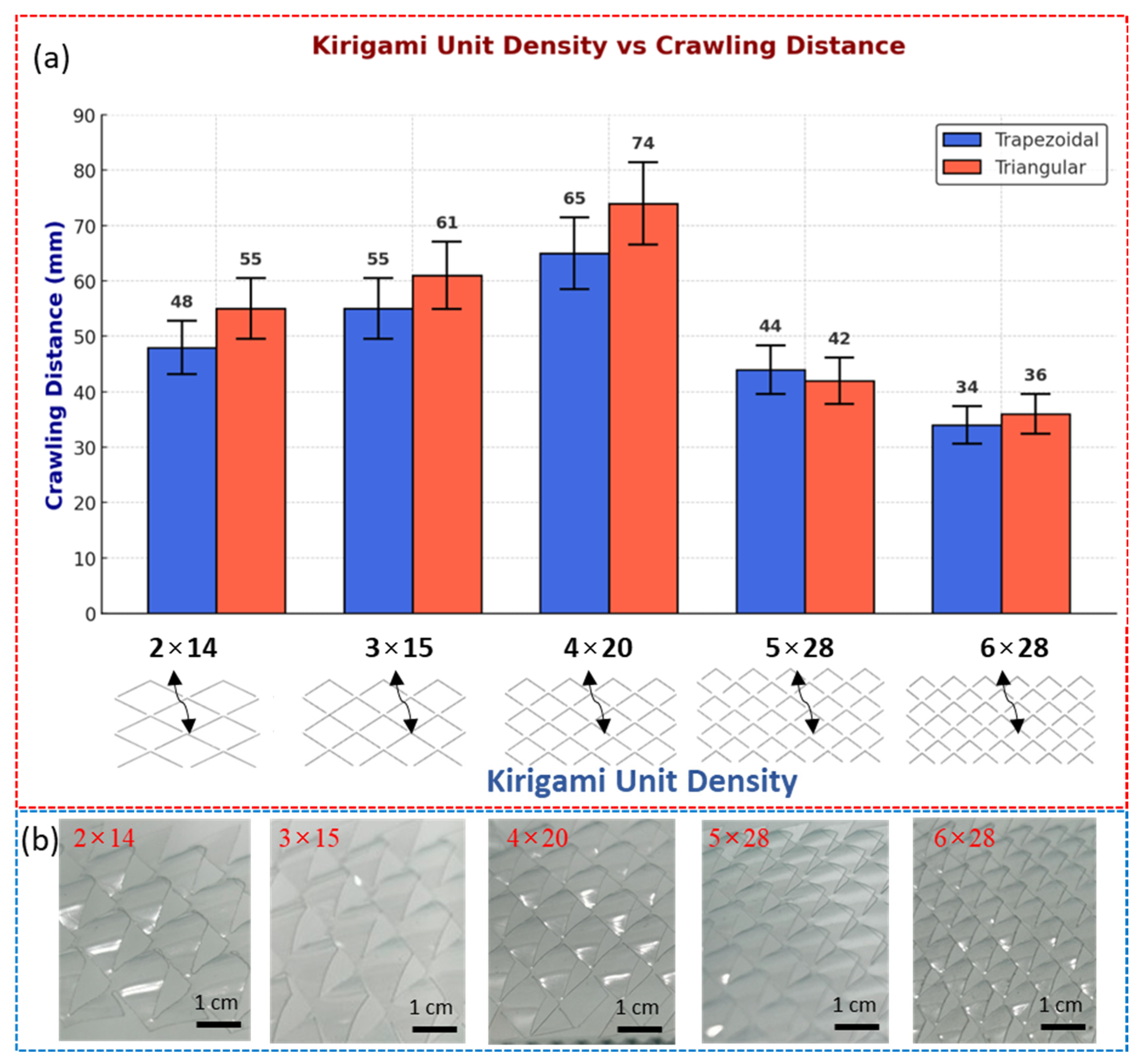

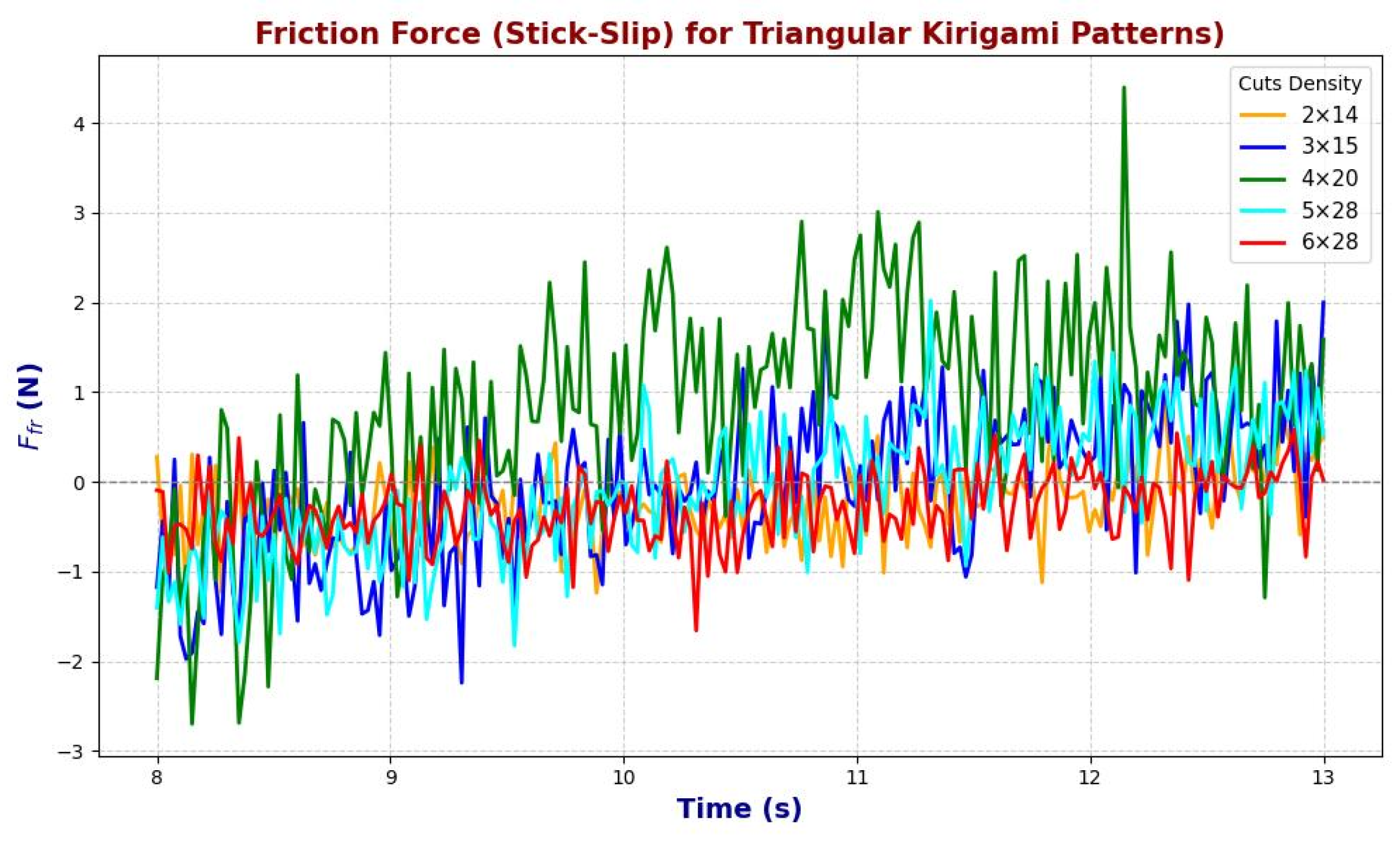

- Kirigami Cuts Density vs. Crawling Distance: To assess the impact of surface coverage and unit repetition on locomotion performance, we analyzed five different kirigami cut densities, i.e., 2 × 14, 3 × 15, 4 × 20, 5 × 28, and 6 × 28, implemented over a standardized contact area of 51 mm × 140 mm. In this notation, each density value M×N represents a grid of M cut units along the longitudinal (lengthwise) axis and N units along the transverse (widthwise) axis, covering the entire kirigami sheet. This structured arrangement modulates the number, spacing, and distribution of pop-up units, thereby influencing inter-unit mechanical interference, surface anchoring behavior, and crawling performance.

- By systematically varying the cut densities, we evaluated how increasing the number of units affects deformation dynamics and effective engagement with the ground surface. This approach enabled identification of an optimal density configuration that maximizes propulsion while minimizing performance losses due to structural interference.

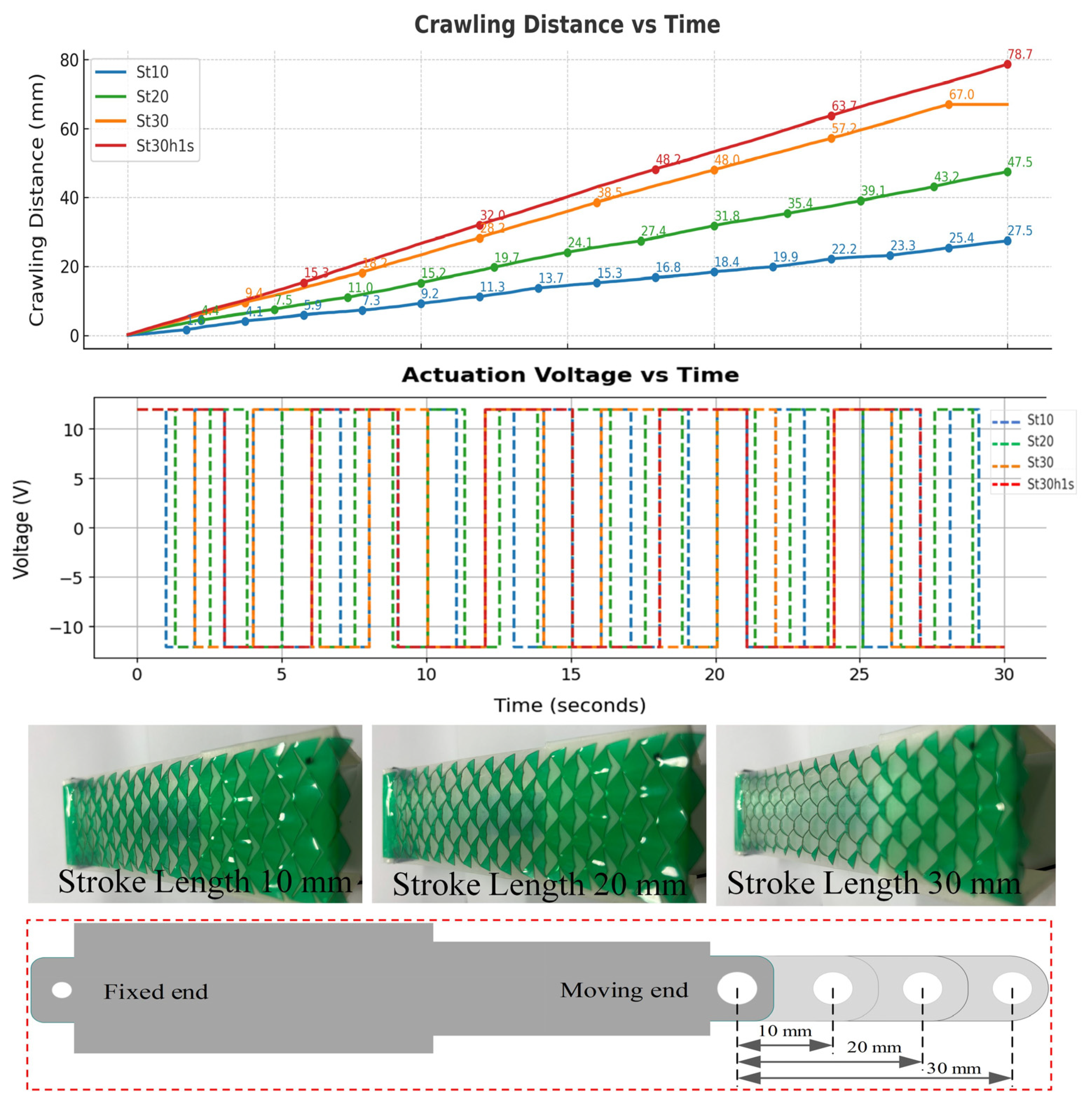

- Stroke Length vs. Crawling Distance: This test explores how actuator stroke amplitude influences the mechanical engagement of the kirigami skin with the substrate. The following four actuation protocols were examined: 10 mm (St10), 20 mm (St20), 30 mm (St30), and 30 mm with a 1-second hold before retraction (St30h1s). By measuring the crawling distance over five actuation cycles, the experiment evaluates how increased extension—combined with dwell time—affects unit deformation, surface interaction, and net displacement.

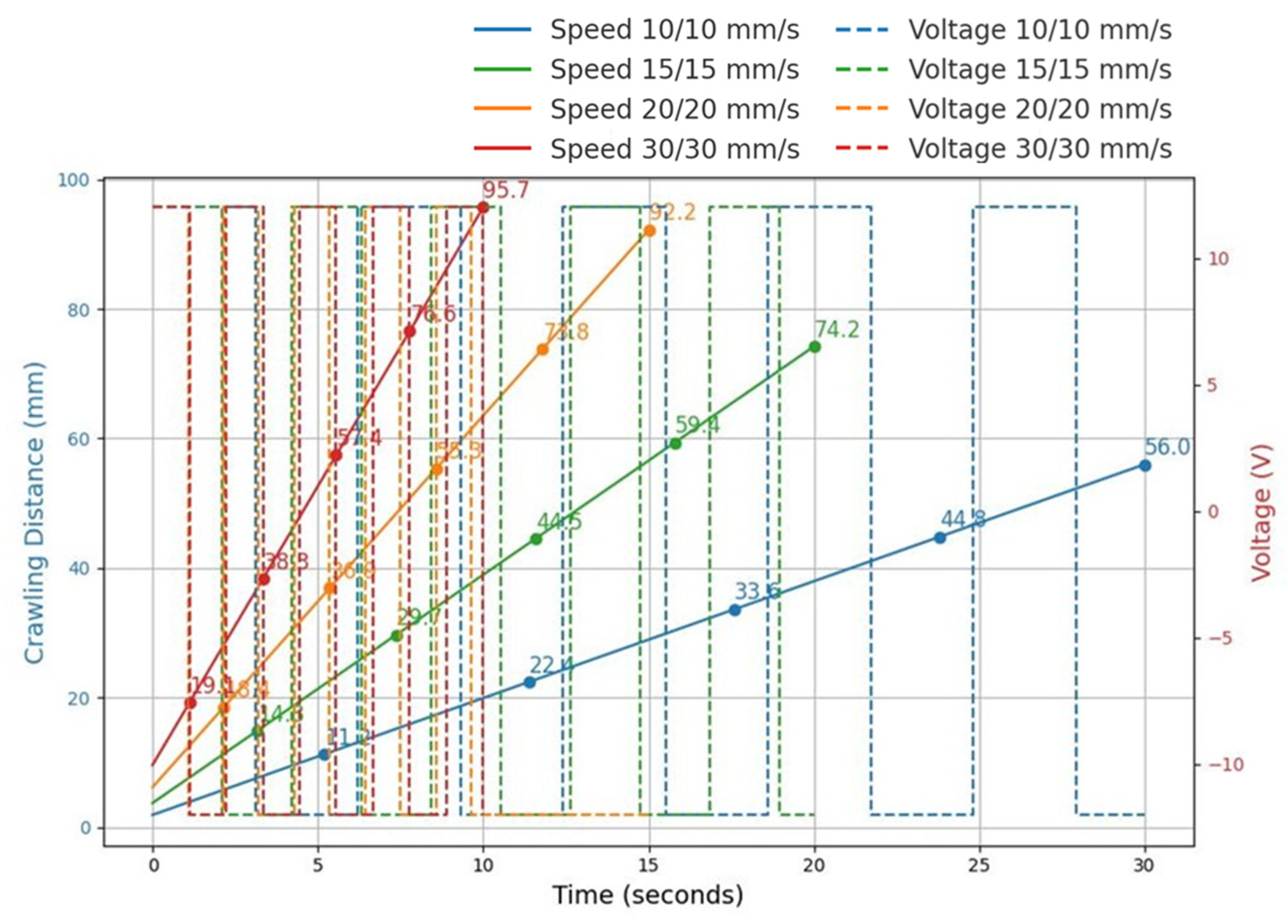

- Actuation Speed vs. Crawling Distance: This experiment evaluates how different extension/retraction speeds—10/10, 15/15, 20/20, and 30/30 mm/s—influence crawling performance. Actuation speed directly affects the contact time and engagement quality between kirigami structures and the surface. By comparing average crawling distances, the test aims to determine a speed regime that optimally balances actuation dynamics with surface interaction mechanics for efficient locomotion.

2.3. Theoretical and Analytical Design

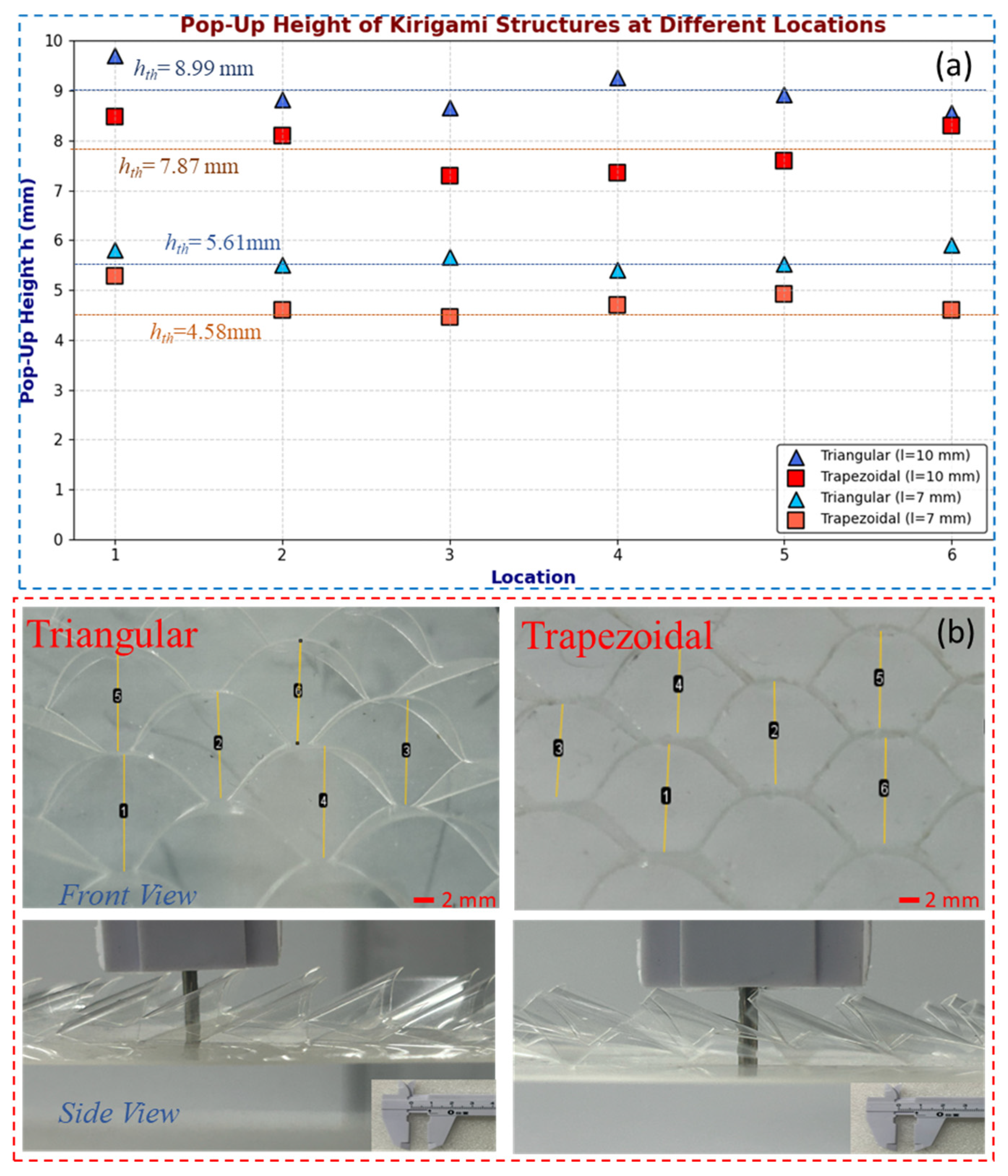

2.3.1. Pop-Up Height Analysis

2.3.2. Anisotropic Friction Analysis

3. Results and Analysis

3.1. Effect of Kirigami Structure on Crawling Efficiency

3.1.1. Experimental Conditions

3.1.2. Performance Analysis

3.2. Impact of Sheet Thickness

3.2.1. Experimental Conditions

3.2.2. Performance Analysis

3.3. Kirigami Cuts Density vs. Crawling Distance

3.3.1. Experimental Setup

3.3.2. Performance Analysis

3.4. Stroke Length Variation in Microcontroller-Controlled Experiments

3.4.1. Experimental Conditions

3.4.2. Performance Analysis

3.5. Optimization of Actuation Speed Parameters

3.5.1. Experimental Conditions

3.5.2. Performance Analysis

4. Autonomous Crawling of the Robot

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Laschi, C.; Trimmer, B. Soft robotics: A bioinspired evolution in robotics. Trends Biotechnol. 2013, 31, 287–294. [Google Scholar] [CrossRef] [PubMed]

- Verl, A.; Albu-Schäffer, A.; Brock, O.; Raatz, A. Soft Robotics: Transferring Theory to Application; Springer: Berlin/Heidelberg, Germany, 2015; pp. 1–291. [Google Scholar] [CrossRef]

- Hu, D.L.; Nirody, J.; Scott, T.; Shelley, M.J. The mechanics of slithering locomotion. Proc. Natl. Acad. Sci. USA 2009, 106, 10081–10085. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Aal, H.A.; El Mansori, M.; Zahouani, H. A comparative study of frictional response of shed snakeskin and human skin. Wear 2017, 376–377, 281–294. [Google Scholar] [CrossRef]

- Gray, J. The Mechanism of Locomotion in Snakes. J. Exp. Biol. 1946, 23, 101–120. Available online: https://journals.biologists.com/jeb/article-abstract/23/2/101/12102 (accessed on 20 April 2025). [CrossRef] [PubMed]

- Marvi, H.; Gong, C.; Gravish, N.; Astley, H.; Travers, M.; Hatton, R.L.; Mendelson, J.R.; Choset, H.; Hu, D.L.; Goldman, D.I. Sidewinding with minimal slip: Snake and robot ascent of sandy slopes. Science 2014, 346, 224–229. [Google Scholar] [CrossRef] [PubMed]

- Parvaresh, A.; Seyidoğlu, B.; Rafsanjani, A. Metamaterial Soft Snake Robot for Rectilinear Locomotion. In Proceedings of the 2024 IEEE 7th International Conference on Soft Robotics (RoboSoft), San Diego, CA, USA, 14–17 April 2024; pp. 519–524. [Google Scholar] [CrossRef]

- Lee, S.; Her, I.; Jung, W.; Hwang, Y. Snakeskin-Inspired 3D Printable Soft Robot Composed of Multi-Modular Vacuum-Powered Actuators. Actuators 2023, 12, 62. [Google Scholar] [CrossRef]

- Rafsanjani, A.; Zhang, Y.; Liu, B.; Rubinstein, S.M.; Bertoldi, K. Kirigami skins make a simple soft actuator crawl. Sci. Robot. 2018, 3, eaar7555. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Puranam, V.R.; Misra, S.; Venkiteswaran, V.K. A Snake-Inspired Multi-Segmented Magnetic Soft Robot Towards Medical Applications. IEEE Robot. Autom. Lett. 2022, 7, 5795–5802. [Google Scholar] [CrossRef]

- Grosso, B.F.; Mele, E.J. Bending Rules in Graphene Kirigami. Phys. Rev. Lett. 2015, 115, 195501. [Google Scholar] [CrossRef] [PubMed]

- Rafsanjani, A.; Bertoldi, K. Buckling-Induced Kirigami. Phys. Rev. Lett. 2017, 118, 084301. [Google Scholar] [CrossRef] [PubMed]

- Ganguly, S.; Margel, S. Fabrication and applications of magnetic polymer composites for soft robotics. Micromachines 2023, 14, 2173. [Google Scholar] [CrossRef] [PubMed]

- Differing Ectoparasite Loads, Sexual Modes, and Abundances of Whiptail Lizards from Native and Non-Native Habitats. Available online: https://www.researchgate.net/publication/325102493_Differing_ectoparasite_loads_sexual_modes_and_abundances_of_whiptail_lizards_from_native_and_non-native_habitats (accessed on 23 April 2025).

- Zheng, L.; Zhong, Y.; Gao, Y.; Li, J.; Zhang, Z.; Liu, Z.; Ren, L. Coupling Effect of Morphology and Mechanical Properties Contributes to the Tribological Behaviors of Snake Scales. J. Bionic Eng. 2018, 15, 481–493. [Google Scholar] [CrossRef]

- Gans, C. Biomechanics: An Approach to Vertebrate Biology; University of Michigan Press: Ann Arbor, MI, USA, 1980. [Google Scholar]

- Toro, A.; Abdel-Aal, H.; Zuluaga, E.; Cuervo, P.; Ballesteros, L.; Sánchez, J.; Rudas, J.; Isaza, C.; Misiolek, W. Influence of surface morphology and internal structure on the mechanical properties and tribological response of Boa Red Tail and Python Regius snake skin. J. Mech. Behav. Biomed. Mater. 2021, 119, 104497. [Google Scholar] [CrossRef] [PubMed]

- Marvi, H.; Hu, D.L. Friction enhancement in concertina locomotion of snakes. JRS Interface 2012, 9, 3067–3680. [Google Scholar] [CrossRef] [PubMed]

- Jayne, B.C. What Defines Different Modes of Snake Locomotion? Integr. Comp. Biol. 2020, 60, 156–170. [Google Scholar] [CrossRef] [PubMed]

- Rafsanjani, A.; Jin, L.; Deng, B.; Bertoldi, K. Propagation of pop ups in kirigami shells. Proc. Natl. Acad. Sci. USA 2019, 116, 8200–8205. [Google Scholar] [CrossRef] [PubMed]

- Mohammad, M.T.N.; Booth, C.N.; Hodgson, P.; Howlett, L.; Smith, P.J.; Sharkh, S.M. Design considerations and performance of a PM linear actuator in a radiation environment. In Proceedings of the 4th IET International Conference on Power Electronics, Machines and Drives (PEMD 2008), York, UK, 2–4 April 2008; pp. 757–761. [Google Scholar] [CrossRef]

- Hasanzadeh, S.; Besharatifard, H. Analysis, Modeling, and Simulation of a PM Linear Actuator with Surface Motion Ability. In Proceedings of the 2023 14th Power Electronics, Drive Systems, and Technologies Conference (PEDSTC), Babol, Iran, 31 January–2 February 2023. [Google Scholar] [CrossRef]

- Facebook. Available online: https://www.facebook.com/AfricanSnakebiteInstituteOfficial/photos/the-roughly-keeled-body-scales-of-a-puff-adder-bitis-arietans-arietans-snakes-sc/3730157157103687/?_rdr (accessed on 23 April 2025).

- Snakes. In Clinical Anatomy and Physiology of Exotic Species; Saunders Ltd.: Philadelphia, PA, USA, 2005; pp. 77–93. [CrossRef]

- Allam, A.A.; Abo-Eleneen, R.E.; Othman, S.I. Microstructure of scales in selected lizard species. Saudi J. Biol. Sci. 2019, 26, 129–136. [Google Scholar] [CrossRef] [PubMed]

- El-Atab, N.; Mishra, R.B.; Al-Modaf, F.; Joharji, L.; Alsharif, A.A.; Alamoudi, H.; Diaz, M.; Qaiser, N.; Hussain, M.M. Soft Actuators for Soft Robotic Applications: A Review. Adv. Intell. Syst. 2020, 2, 2000128. [Google Scholar] [CrossRef]

- 11.1: Compression Buckling of Thin Rectangular Plates—Engineering LibreTexts. Available online: https://eng.libretexts.org/Under_Construction/Aerospace_Structures_(Johnson)/11:_Buckling_of_columns_and_plates/11.01:_Compression_buckling_of_thin_rectangular_plates (accessed on 20 April 2025).

- Qu, J.; Cui, G.; Li, Z.; Fang, S.; Zhang, X.; Liu, A.; Wang, X. Advanced flexible sensing technologies for soft robots. Adv. Funct. Mater. 2024, 34, 2401311. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, M.N.; Huo, Y.; Shao, Z.; Yao, M.; Javaid, U. Bioinspired Kirigami Structure for Efficient Anchoring of Soft Robots via Optimization Analysis. Appl. Sci. 2025, 15, 7897. https://doi.org/10.3390/app15147897

Khan MN, Huo Y, Shao Z, Yao M, Javaid U. Bioinspired Kirigami Structure for Efficient Anchoring of Soft Robots via Optimization Analysis. Applied Sciences. 2025; 15(14):7897. https://doi.org/10.3390/app15147897

Chicago/Turabian StyleKhan, Muhammad Niaz, Ye Huo, Zhufeng Shao, Ming Yao, and Umair Javaid. 2025. "Bioinspired Kirigami Structure for Efficient Anchoring of Soft Robots via Optimization Analysis" Applied Sciences 15, no. 14: 7897. https://doi.org/10.3390/app15147897

APA StyleKhan, M. N., Huo, Y., Shao, Z., Yao, M., & Javaid, U. (2025). Bioinspired Kirigami Structure for Efficient Anchoring of Soft Robots via Optimization Analysis. Applied Sciences, 15(14), 7897. https://doi.org/10.3390/app15147897