Optimization of Vertical Ultrasonic Attenuator Parameters for Reducing Exhaust Gas Smoke of Compression–Ignition Engines: Efficient Selection of Emitter Power, Number, and Spacing

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

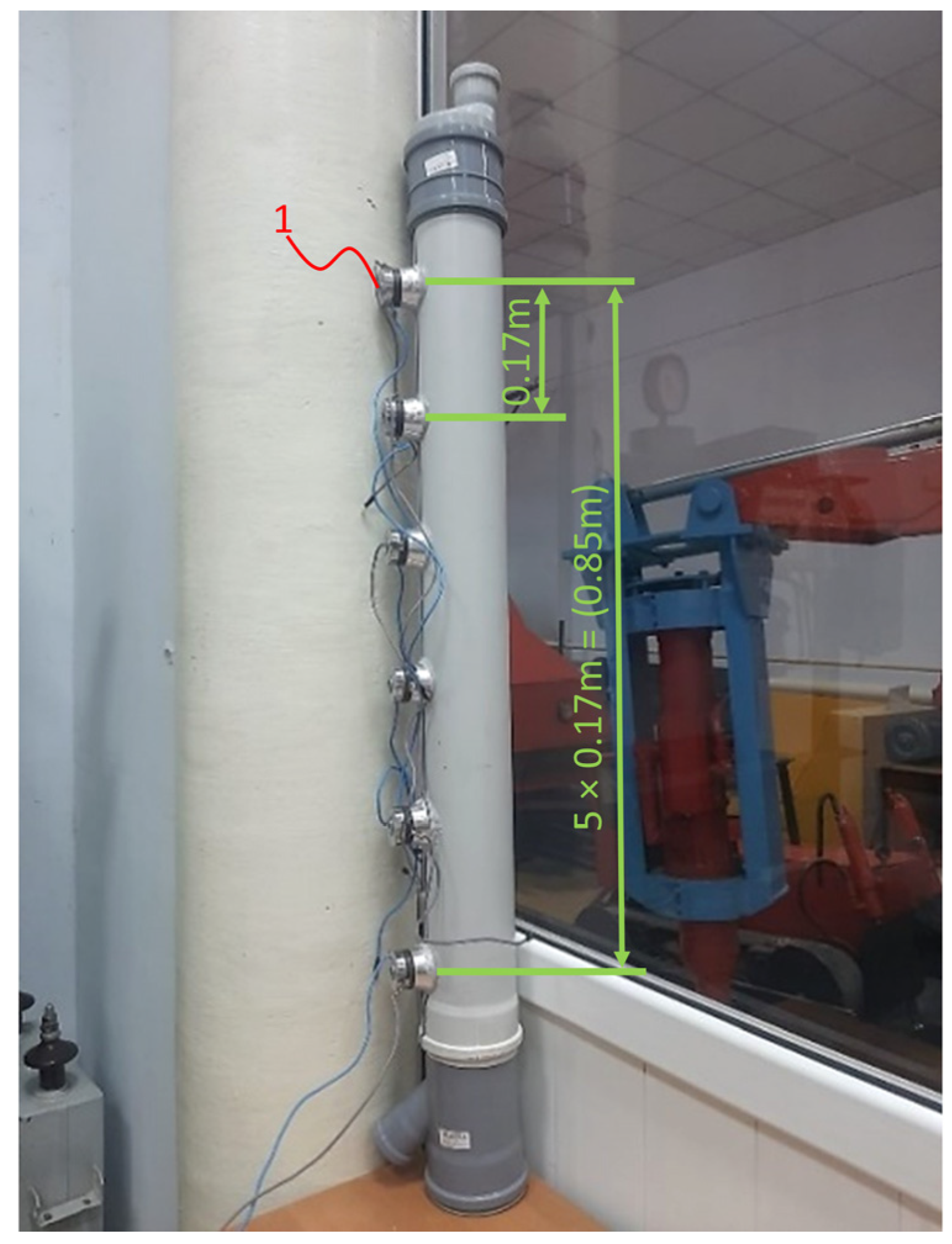

2.1. Exhaust Gas Cleaning System

2.2. Research Object

2.3. Research Stand, Plan, and Procedure for Conducting the Experiments

- -

- The first stage involved determining the baseline values of the exhaust gas smoke without ultrasonic influence, establishing the initial level of pollutant emissions.

- -

- The second stage involved conducting measurements with activated ultrasonic emitters, varying their configurations and connection order to identify the most effective operating mode.

- Baseline stage (control measurement): Initially, the exhaust gas smoke levels were measured without ultrasonic exposure (experiment 1). This allowed for the determination of the baseline level of pollutant emissions, which was used as a reference for comparison.

- Individual emitter activation stage: At this stage, individual emitters were activated one by one (experiments 2–4) to evaluate the specific contribution of the effect of each emitter on particle coagulation and the reduction in exhaust gas smoke levels.

- Combined connection stage: Next, experiments were conducted in which various combinations of two or more emitters were activated (experiments 5–8). The goal of this stage was to identify the most effective emitter configurations for maximizing the reduction in PM in the exhaust gas flow.

- Maximum power stage: In the final stage of the experiment (experiment 9), all six ultrasonic emitters were activated simultaneously. This mode allowed for the assessment of the maximum acoustic effect on PM particles and determined whether the optimal reduction in exhaust gas smoke levels was achieved with this configuration.

3. Results and Discussion

3.1. Results of Experimental Studies

3.2. Results of the Conducted Regression–Correlation Analysis

3.3. Results of the Mathematical Analysis of the Regression Equation

3.4. Recommendations for Adjusting the Parameters of the Ultrasonic Muffler

3.5. Discussion of the Results in the Context of Previous Studies

3.6. Limitations of the Study

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| DOC | Diesel oxidation catalysts |

| DPF | Diesel particulate filters |

| EGR | Exhaust gas recirculation |

| HC | Hydrocarbons |

| H2S | Hydrogen sulfide |

| NOx | Nitrogen oxides |

| PM | Particulate matter |

| SCR | Selective catalytic reduction |

References

- Tucki, K.; Orynycz, O.A.; Świć, A.; Wasiak, A.; Mruk, R.; Gola, A. Analysis of the Possibility of Using Neural Networks to Monitor the Technical Efficiency of Diesel Engines During Operation. Adv. Sci. Technol. Res. J. 2023, 17, 1–15. [Google Scholar] [CrossRef]

- Smigins, R.; Skrzek, T.; Górska, M.; Pawlak, G. Investigation of Harmful Chemical Compounds from Dual-Fuelled Diesel Engine. Adv. Sci. Technol. Res. J. 2020, 14, 21–29. [Google Scholar] [CrossRef]

- Chwist, M.; Gruca, M.; Pyrc, M.; Szwaja, M. By-Products from Thermal Processing of Rubber Waste as Fuel for the Internal Combustion Piston Engine. Combust. Engines 2020, 181, 11–18. [Google Scholar] [CrossRef]

- Feng, R.; Yu, J.; Shu, X.; Deng, B.; Hua, Z. Can the World Harmonized Steady Cycle (WHSC) Accurately Reflect Real-World Driving Conditions for Heavy-Duty Diesel Engine Emission Valuations? A Comprehensive Experimental Study. Therm. Sci. Eng. Prog. 2025, 59, 103321. [Google Scholar] [CrossRef]

- Mohankumar, S.; Senthilkumar, P. Particulate Matter Formation and Its Control Methodologies for Diesel Engine: A Comprehensive Review. Renew. Sustain. Energy Rev. 2017, 80, 1227–1238. [Google Scholar] [CrossRef]

- Joshi, A. Review of Vehicle Engine Efficiency and Emissions. SAE Int. J. Adv. Curr. Prac. Mobil. 2020, 2, 2479–2507. [Google Scholar] [CrossRef]

- Rymaniak, Ł.; Lijewski, P.; Kamińska, M.; Fuć, P.; Kurc, B.; Siedlecki, M.; Kalociński, T.; Jagielski, A. The Role of Real Power Output from Farm Tractor Engines in Determining Their Environmental Performance in Actual Operating Conditions. Comput. Electron. Agric. 2020, 173, 105405. [Google Scholar] [CrossRef]

- Warguła, Ł.; Lijewski, P.; Kukla, M. Effects of Changing Drive Control Method of Idling Wood Size Reduction Machines on Fuel Consumption and Exhaust Emissions. Croat. J. For. Eng. (Online) 2023, 44, 137–151. [Google Scholar] [CrossRef]

- Sobczak, J.; Kamińska, M.; Ziółkowski, A.; Rymaniak, Ł.; Szymlet, N. Analysis of Pollutant Emissions of a Railbus Based on Real Train Emissions Measurements. Combust. Engines 2025, 201, 22–33. [Google Scholar] [CrossRef]

- Puzdrowska, P. Comparison of Methods for Diagnosing Marine IC Engines Based on Working Medium Parameters Including Exhaust Gas Specific Enthalpy. Combust. Engines 2024, 201, 3–13. [Google Scholar] [CrossRef]

- Sassykova, L.; Nalibayeva, A.; Aubakirov, Y.; Tashmukhambetova, Z.; Otzhan, U.; Zhakirova, N.; Faizullaeva, M. Preparation and Study of Catalysts on Metal Blocks for Neutralization of Exhaust Gases of the Stationary Diesel Generator. Orient. J. Chem. 2017, 33, 1941–1948. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Z.; Wang, J.; He, X. Improvement of Emission Characteristics and Thermal Efficiency in Diesel Engines by Fueling Gasoline/Diesel/PODEn Blends. Energy 2016, 97, 105–112. [Google Scholar] [CrossRef]

- Zimakowska-Laskowska, M.; Kozłowski, E.; Laskowski, P.; Wiśniowski, P.; Świderski, A.; Orynycz, O. Vehicle Exhaust Emissions in the Light of Modern Research Tools: Synergy of Chassis Dynamometers and Computational Models. Combust. Engines 2025, 200, 145–154. [Google Scholar] [CrossRef]

- Rimkus, A.; Kozłowski, E.; Vipartas, T.; Pukalskas, S.; Wiśniowski, P.; Matijošius, J. Emission Characteristics of Hydrogen-Enriched Gasoline Under Dynamic Driving Conditions. Energies 2025, 18, 1190. [Google Scholar] [CrossRef]

- Sharma, R.; Kurmi, O.P.; Hariprasad, P.; Tyagi, S.K. Health Implications Due to Exposure to Fine and Ultra-Fine Particulate Matters: A Short Review. Int. J. Ambient. Energy 2024, 45, 2314256. [Google Scholar] [CrossRef]

- Fiordelisi, A.; Piscitelli, P.; Trimarco, B.; Coscioni, E.; Iaccarino, G.; Sorriento, D. The Mechanisms of Air Pollution and Particulate Matter in Cardiovascular Diseases. Heart Fail. Rev. 2017, 22, 337–347. [Google Scholar] [CrossRef] [PubMed]

- Dasadhikari, K. Attribution of PM2.5 Health Impacts in Asia-Pacific. Master’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2018. [Google Scholar]

- Hassan, N.E.; Rashid, H.A. Review of Toxic Gases and Their Impact on Human Health. Jabirian J. Biointerface Res. Pharmaceut. Appl. Chem. 2024, 1, 7–12. [Google Scholar] [CrossRef]

- Chen, C.; Yao, A.; Yao, C.; Wang, B.; Lu, H.; Feng, J.; Feng, L. Study of the Characteristics of PM and the Correlation of Soot and Smoke Opacity on the Diesel Methanol Dual Fuel Engine. Appl. Therm. Eng. 2019, 148, 391–403. [Google Scholar] [CrossRef]

- Duvvuri, P.P.; Sukumaran, S.; Shrivastava, R.K.; Sreedhara, S. Modeling Soot Particle Size Distribution in Diesel Engines. Fuel 2019, 243, 70–78. [Google Scholar] [CrossRef]

- DeMarini, D.M.; Linak, W.P. Mutagenicity and Carcinogenicity of Combustion Emissions Are Impacted More by Combustor Technology than by Fuel Composition: A Brief Review. Environ. Mol. Mutagen. 2022, 63, 135–150. [Google Scholar] [CrossRef]

- World Health Organization. WHO Global Air Quality Guidelines: Particulate Matter (PM2.5 and PM10), Ozone, Nitrogen Dioxide, Sulfur Dioxide and Carbon Monoxide; World Health Organization: Geneva, Switzerland, 2021; ISBN 978-92-4-003422-8. [Google Scholar]

- Alozie, N.S.I. Issues of Particulate Matter Emission from Diesel Engine and Its Control. Ph.D. Thesis, Brunel University, London, UK, 2016. [Google Scholar]

- Valeika, G.; Matijošius, J.; Rimkus, A. Research of the Impact of EGR Rate on Energy and Environmental Parameters of Compression Ignition Internal Combustion Engine Fuelled by Hydrogenated Vegetable Oil (HVO) and Biobutanol—Castor Oil Fuel Mixtures. Energy Convers. Manag. 2022, 270, 116198. [Google Scholar] [CrossRef]

- Tucki, K.; Mruk, R.; Orynycz, O.; Botwińska, K.; Gola, A.; Bączyk, A. Toxicity of Exhaust Fumes (CO, NOx) of the Compression-Ignition (Diesel) Engine with the Use of Simulation. Sustainability 2019, 11, 2188. [Google Scholar] [CrossRef]

- Lee, K.; Cho, H. Comparative Analysis of Performance and Emission Characteristics of Biodiesels from Animal Fats and Vegetable Oils as Fuel for Common Rail Engines. Energies 2024, 17, 1711. [Google Scholar] [CrossRef]

- Gao, J.; Chen, H.; Tian, G.; Ma, C.; Zhu, F. An Analysis of Energy Flow in a Turbocharged Diesel Engine of a Heavy Truck and Potentials of Improving Fuel Economy and Reducing Exhaust Emissions. Energy Convers. Manag. 2019, 184, 456–465. [Google Scholar] [CrossRef]

- Biswas, S.; Verma, V.; Schauer, J.J.; Sioutas, C. Chemical Speciation of PM Emissions from Heavy-Duty Diesel Vehicles Equipped with Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) Retrofits. Atmos. Environ. 2009, 43, 1917–1925. [Google Scholar] [CrossRef]

- Li, J.; Li, G.; Sun, H.; Li, L.; Zheng, Z.; Yao, M. Development of the Two-Stage SCR Control Strategy to Satisfy Ultra-Low NOx Emission Regulation for Heavy-Duty Diesel Engine. J. Environ. Sci. 2025, 156, 360–370. [Google Scholar] [CrossRef] [PubMed]

- Thangaraja, J.; Kannan, C. Effect of Exhaust Gas Recirculation on Advanced Diesel Combustion and Alternate Fuels—A Review. Appl. Energy 2016, 180, 169–184. [Google Scholar] [CrossRef]

- Deng, B.; Cai, W.; Zhang, W.; Bian, L.; Che, X.; Xiang, Y.; Wu, D. A Comprehensive Investigation of EGR (Exhaust Gas Recirculation) Effects on Energy Distribution and Emissions of a Turbo-Charging Diesel Engine under World Harmonized Transient Cycle. Energy 2025, 316, 134506. [Google Scholar] [CrossRef]

- Stoeck, T. Problems of Regeneration of Modern Piezoelectric Fuel Injectors. Combust. Engines 2022, 61, 3–8. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, Y. Research on the Integrated Intercooler Intake System of Turbocharged Diesel Engine. Int. J. Automot. Technol. 2020, 21, 339–349. [Google Scholar] [CrossRef]

- Naser, L.; Ilir, D.; Shpetim, L. Modelling and Simulation of the Turbocharged Diesel Engine with Intercooler. IFAC-PapersOnLine 2016, 49, 237–242. [Google Scholar] [CrossRef]

- Calam, A.; Solmaz, H.; Yılmaz, E.; İçingür, Y. Investigation of Effect of Compression Ratio on Combustion and Exhaust Emissions in A HCCI Engine. Energy 2019, 168, 1208–1216. [Google Scholar] [CrossRef]

- Feng, R.; Hu, X.; Li, G.; Sun, Z.; Deng, B. A Comparative Investigation between Particle Oxidation Catalyst (POC) and Diesel Particulate Filter (DPF) Coupling Aftertreatment System on Emission Reduction of a Non-Road Diesel Engine. Ecotoxicol. Environ. Saf. 2022, 238, 113576. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Dong, R.; Lan, G.; Yuan, T.; Tan, D. Diesel Particulate Filter Regeneration Mechanism of Modern Automobile Engines and Methods of Reducing PM Emissions: A Review. Env. Sci. Pollut. Res. 2023, 30, 39338–39376. [Google Scholar] [CrossRef]

- Lin, D.; Zhang, L.; Liu, Z.; Wang, B.; Han, Y. Progress of Selective Catalytic Reduction Denitrification Catalysts at Wide Temperature in Carbon Neutralization. Front. Chem. 2022, 10, 946133. [Google Scholar] [CrossRef]

- Ferella, F. A Review on Management and Recycling of Spent Selective Catalytic Reduction Catalysts. J. Clean. Prod. 2020, 246, 118990. [Google Scholar] [CrossRef]

- Karre, A.V.; Garlapalli, R.K.; Jena, A.; Tripathi, N. State of the Art Developments in Oxidation Performance and Deactivation of Diesel Oxidation Catalyst (DOC). Catal. Commun. 2023, 179, 106682. [Google Scholar] [CrossRef]

- Caliskan, H.; Mori, K. Environmental, Enviroeconomic and Enhanced Thermodynamic Analyses of a Diesel Engine with Diesel Oxidation Catalyst (DOC) and Diesel Particulate Filter (DPF) after Treatment Systems. Energy 2017, 128, 128–144. [Google Scholar] [CrossRef]

- Kleinhenz, M.; Fiedler, A.; Lauer, P.; Döring, A. SCR Coated DPF for Marine Engine Applications. Top. Catal. 2019, 62, 282–287. [Google Scholar] [CrossRef]

- Kadyrov, A.S.; Sarsembekov, B.K.; Ganyukov, A.A.; Zhunusbekova, Z.Z.; Alikarimov, K.N. Experimental Research of the Coagulation Process of Exhaust Gases under the Influence of Ultrasound. Komunikácie 2021, 23, B288–B298. [Google Scholar] [CrossRef]

- Kadyrov, A.; Bembenek, M.; Sarsembekov, B.; Kukesheva, A.; Nurkusheva, S. The Influence of the Frequency of Ultrasound on the Exhaust Gas Purification Process in a Diesel Car Muffler. Appl. Sci. 2024, 14, 5027. [Google Scholar] [CrossRef]

- Pak, I.; Kadyrov, A.; Askarov, B.; Suleyev, B.; Karsakova, A. Developing and Studying the Method of Ultrasonic Purification and Utilization of Internal Combustion Engine Exhaust Gases. Komunikácie 2023, 25, B245–B258. [Google Scholar] [CrossRef]

- Kadyrov, A.; Ganyukov, A.; Pak, I.; Suleyev, B.; Balabekova, K. Theoretical and Experimental Study of Operation of the Tank Equipment for Ultrasonic Purification of the Internal Combustion Engine Exhaust Gases. Komunikácie 2021, 23, B219–B226. [Google Scholar] [CrossRef]

- Kadyrov, A.; Sarsembekov, B.; Ganyukov, A.; Suyunbaev, S.; Sinelnikov, K. Ultrasonic Unit for Reducing the Toxicity of Diesel Vehicle Exhaust Gases. Komunikácie 2022, 24, B189–B198. [Google Scholar] [CrossRef]

- Shalunov, A.V.; Bochenkov, A.S. Method for Increasing Efficiency of Ultrasonic Coagulation Due to Secondary Acoustic Effects. In Proceedings of the III International Conference on Advances in Science, Engineering, and Digital Education: Asedu-III 2022, Krasnoyarsk, Russian, 8–10 December 2022; AIP Publishing: Melville, NY, USA, 2024; Volume 2969. [Google Scholar]

- He, B.; Wang, J.; Yan, X.; Chen, H.; Tian, X. Combustion and Emission Characteristics of Engines Using Ethanol-Diesel Fuels Blended on Line. Qinghua Daxue Xuebao/J. Tsinghua Univ. 2003, 43, 1523–1525+1541. [Google Scholar]

| Parameter | Value |

|---|---|

| Operating (resonant) frequency | 40 kHz |

| Output power | 100 W |

| Static capacitance | 5200 ± 10% pF |

| Impedance at resonance | ≤20 Ω |

| Insulation resistance (at 2500 V DC) | ≥100 MΩ |

| Waveguide diameter (maximum) | 55 m |

| Waveguide diameter (minimum) | 45 mm |

| Piezo element diameter | 45 mm |

| Waveguide length | 24 mm |

| Total length of the transmitter | 46 mm |

| Female thread | M10 |

| Thread depth | 10 mm |

| Reflector thickness | 12 mm |

| Bandwidth | ~38–42 kHz |

| Radiation angle (beam width) | approx. 45–60° |

| Parameter | Value |

|---|---|

| Engine make and model | D-243, Minsk Motor Plant (MMZ) |

| Manufacturer city and country | Minsk, Belarus (then part of the Union of Soviet Socialist Republics (USSR)) |

| Installed in | MTZ-80 tractor |

| Year of manufacture | 1986 (test sample) |

| Engine type | Diesel, 4-stroke, naturally aspirated |

| Configuration | Inline, 4 cylinders |

| Displacement | 4750 cm3 |

| Bore × stroke | 110 × 125 mm |

| Power output | 59 kW (80 hp) at 2200 rpm |

| Torque | Up to 290 Nm at 1400–1600 rpm |

| Cooling system | Liquid-cooled |

| Fuel | Diesel |

| Emission standard | Non-compliant with modern standards (no DPF, EGR, etc.) |

| Parameter | Value |

|---|---|

| Base machine | MTZ-80 (Minsk Tractor Works) |

| Manufacturer city and country | Minsk, Belarus (then part of the USSR) |

| Model of backhoe loader | Self-propelled machine based on MTZ-80 with front loader equipment |

| Year of manufacture | Approximately 1986–1990 |

| Type of machine | Multifunctional backhoe loader |

| Purpose | Earthworks, material handling, laboratory testing |

| Operating weight | ~6500–7500 kg (depending on attachments) |

| Transmission type | Manual transmission with low-speed gears |

| Maximum speed | ~30 km/h |

| Loader equipment | Front bucket (width ~1.9 m, capacity ~0.8 m3) |

| Additional equipment | Capability for rear excavator arm installation |

| Measurement equipment installed | Gas analyzer, power supply units, ultrasonic emitters, data acquisition units |

| Design features | Modified into a laboratory stand for exhaust gas treatment experiments |

| Experiment | Engine Speed, rpm | Smoke (by Experiment) (D), % | Power of UE (N), W | Distance Between Ultrasonic Emitters | Smoke Density (According to the Regression Equation) (D), % | Deviation, (%) |

|---|---|---|---|---|---|---|

| 1 | 1000 | 79 | − | − | 79.68 | 0.86 |

| 2 | 73 | 100 | 0.17 | 73.69 | 0.95 | |

| 3 | 77 | 100 | 0.34 | 76.27 | 0.94 | |

| 4 | 79 | 100 | 0.85 | 76.88 | 2.67 | |

| 5 | 69 | 200 | 0.34 | 69.16 | 0.23 | |

| 6 | 70 | 200 | 0.85 | 71.78 | 2.54 | |

| 7 | 71 | 200 | 0.51 | 71.22 | 0.31 | |

| 8 | 67 | 300 | 0.85 | 67.97 | 1.45 | |

| 9 | 66 | 600 | 0.85 | 64.314 | 2.55 | |

| 1 | 1500 | 87 | − | − | 84.3 | 3.1 |

| 2 | 78 | 100 | 0.17 | 78.86 | 1.1 | |

| 3 | 80 | 100 | 0.34 | 81.29 | 1.62 | |

| 4 | 81 | 100 | 0.85 | 81.5 | 0.62 | |

| 5 | 74 | 200 | 0.34 | 74.86 | 1.17 | |

| 6 | 78 | 200 | 0.85 | 77.08 | 1.17 | |

| 7 | 80 | 200 | 0.51 | 76.79 | 4.01 | |

| 8 | 72 | 300 | 0.85 | 73.95 | 2.71 | |

| 9 | 71 | 600 | 0.85 | 72.32 | 1.87 | |

| 1 | 2000 | 96 | − | − | 96.03 | 0.03 |

| 2 | 90 | 100 | 0.17 | 91.13 | 1.25 | |

| 3 | 91 | 100 | 0.34 | 93.43 | 2.67 | |

| 4 | 92 | 100 | 0.85 | 93.24 | 1.35 | |

| 5 | 89 | 200 | 0.34 | 87.68 | 1.48 | |

| 6 | 90 | 200 | 0.85 | 89.49 | 0.55 | |

| 7 | 91 | 200 | 0.51 | 89.47 | 1.67 | |

| 8 | 89 | 300 | 0.85 | 87.04 | 2.19 | |

| 9 | 87 | 600 | 0.85 | 87.45 | 0.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kadyrov, A.; Warguła, Ł.; Kukesheva, A.; Dyssenbaev, Y.; Kaczmarzyk, P.; Klapsa, W.; Wieczorek, B. Optimization of Vertical Ultrasonic Attenuator Parameters for Reducing Exhaust Gas Smoke of Compression–Ignition Engines: Efficient Selection of Emitter Power, Number, and Spacing. Appl. Sci. 2025, 15, 7870. https://doi.org/10.3390/app15147870

Kadyrov A, Warguła Ł, Kukesheva A, Dyssenbaev Y, Kaczmarzyk P, Klapsa W, Wieczorek B. Optimization of Vertical Ultrasonic Attenuator Parameters for Reducing Exhaust Gas Smoke of Compression–Ignition Engines: Efficient Selection of Emitter Power, Number, and Spacing. Applied Sciences. 2025; 15(14):7870. https://doi.org/10.3390/app15147870

Chicago/Turabian StyleKadyrov, Adil, Łukasz Warguła, Aliya Kukesheva, Yermek Dyssenbaev, Piotr Kaczmarzyk, Wojciech Klapsa, and Bartosz Wieczorek. 2025. "Optimization of Vertical Ultrasonic Attenuator Parameters for Reducing Exhaust Gas Smoke of Compression–Ignition Engines: Efficient Selection of Emitter Power, Number, and Spacing" Applied Sciences 15, no. 14: 7870. https://doi.org/10.3390/app15147870

APA StyleKadyrov, A., Warguła, Ł., Kukesheva, A., Dyssenbaev, Y., Kaczmarzyk, P., Klapsa, W., & Wieczorek, B. (2025). Optimization of Vertical Ultrasonic Attenuator Parameters for Reducing Exhaust Gas Smoke of Compression–Ignition Engines: Efficient Selection of Emitter Power, Number, and Spacing. Applied Sciences, 15(14), 7870. https://doi.org/10.3390/app15147870