Research on the Use of Hydro-Pneumatic Shock Absorbers for the Rear Suspension of a Vehicle Cabin

Abstract

1. Introduction

2. Materials and Methods

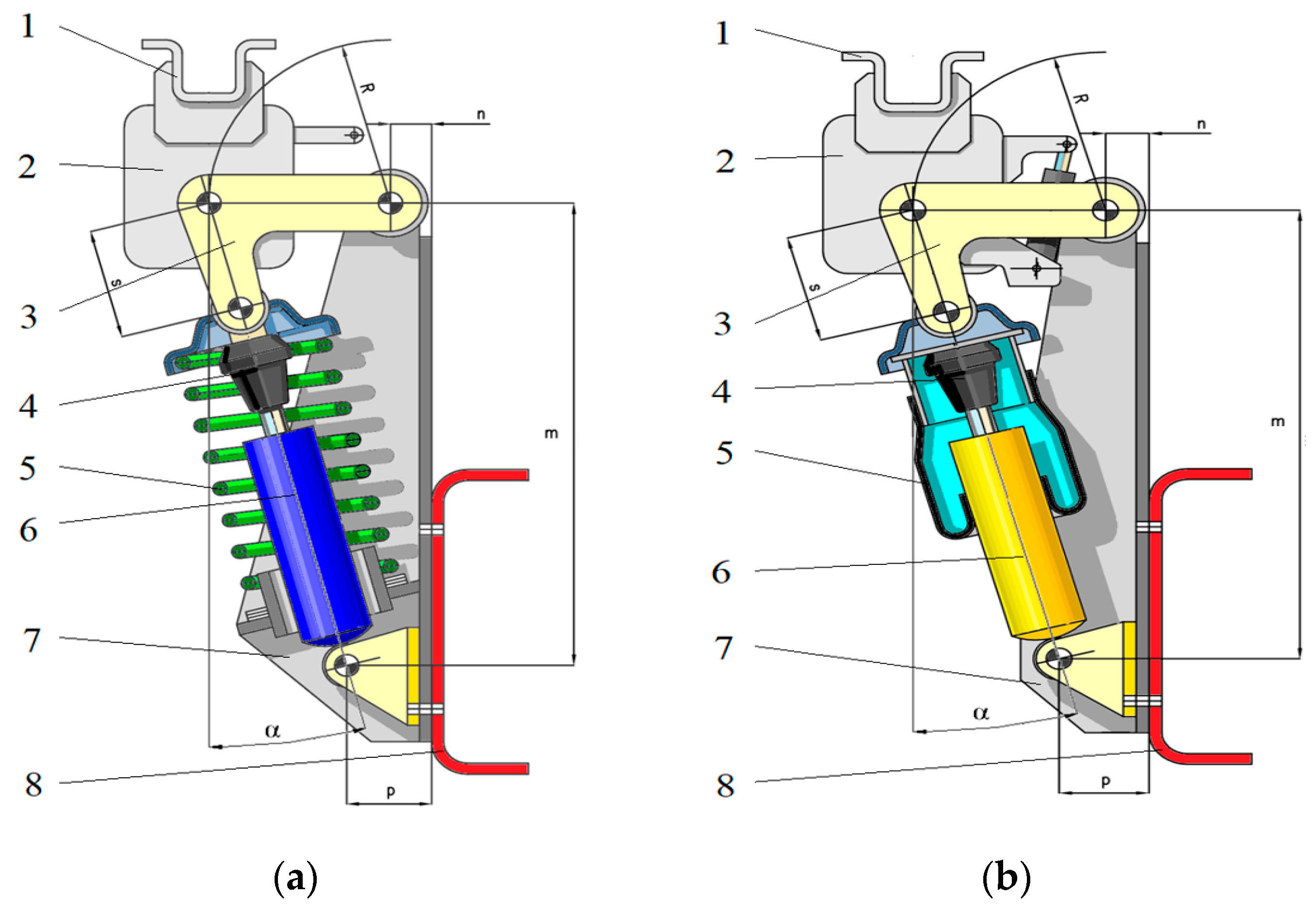

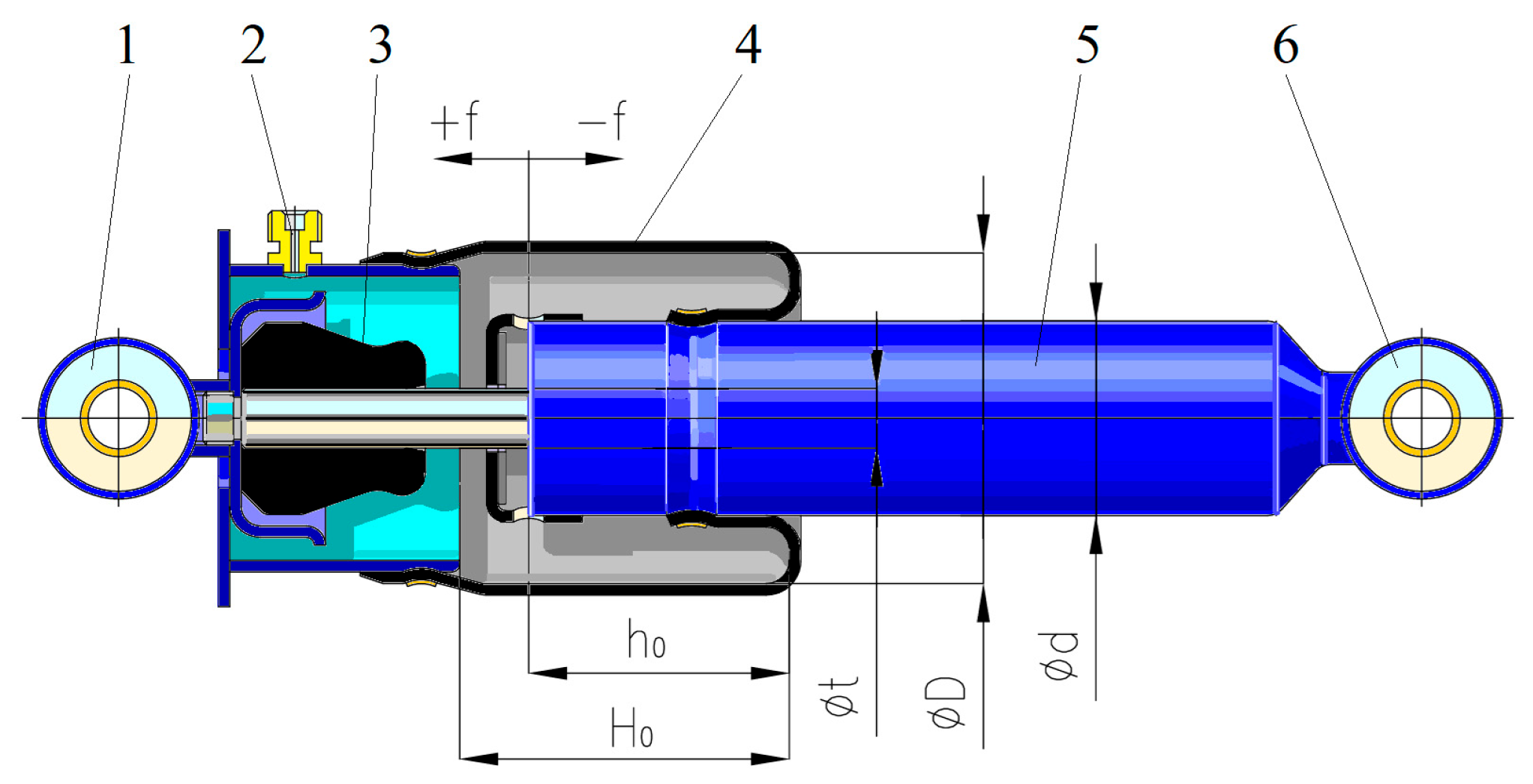

2.1. Geometrical Aspects of the Studied Shock Absorbers

2.2. Schematic Diagram of the Loading on an Elastic Element

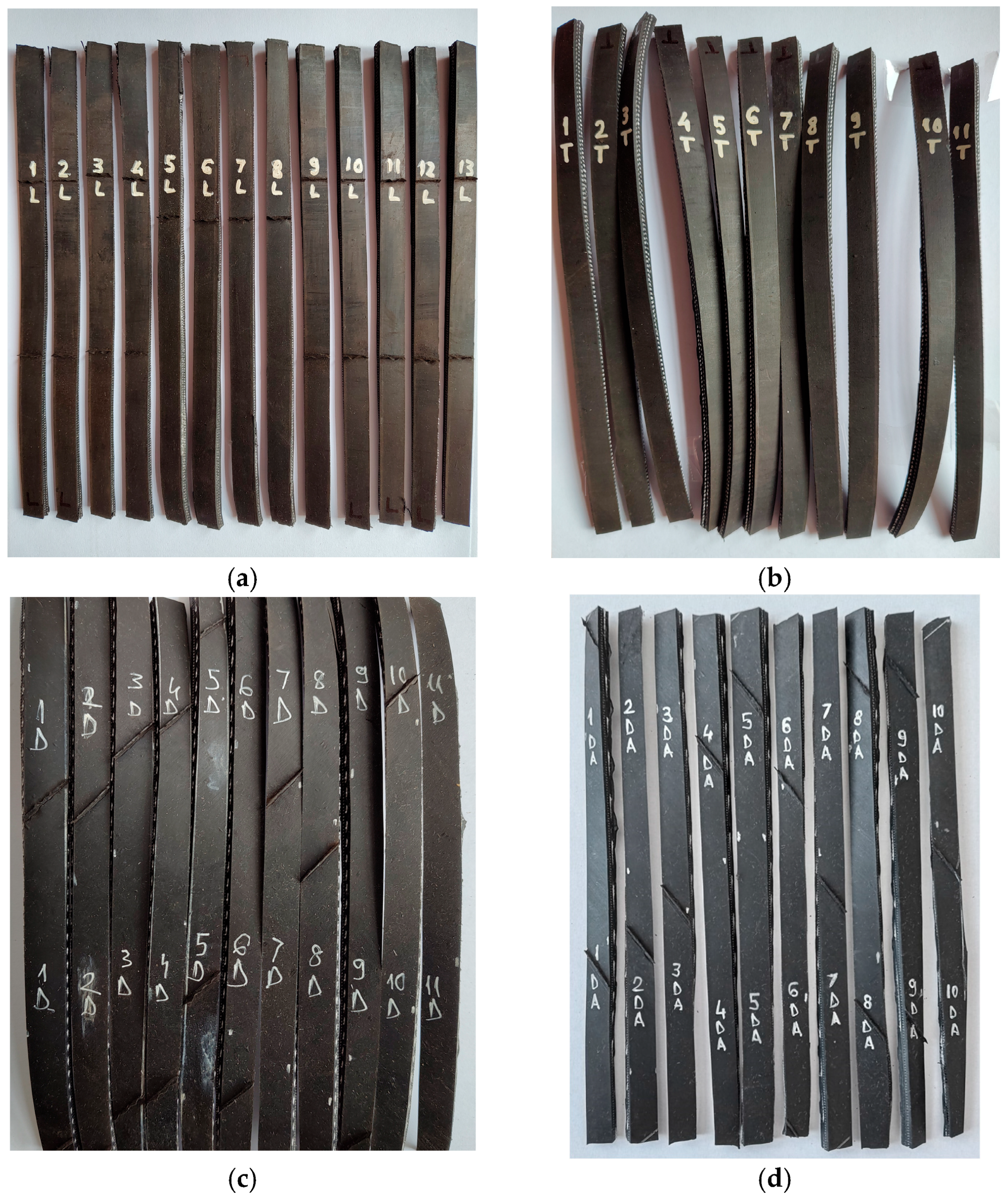

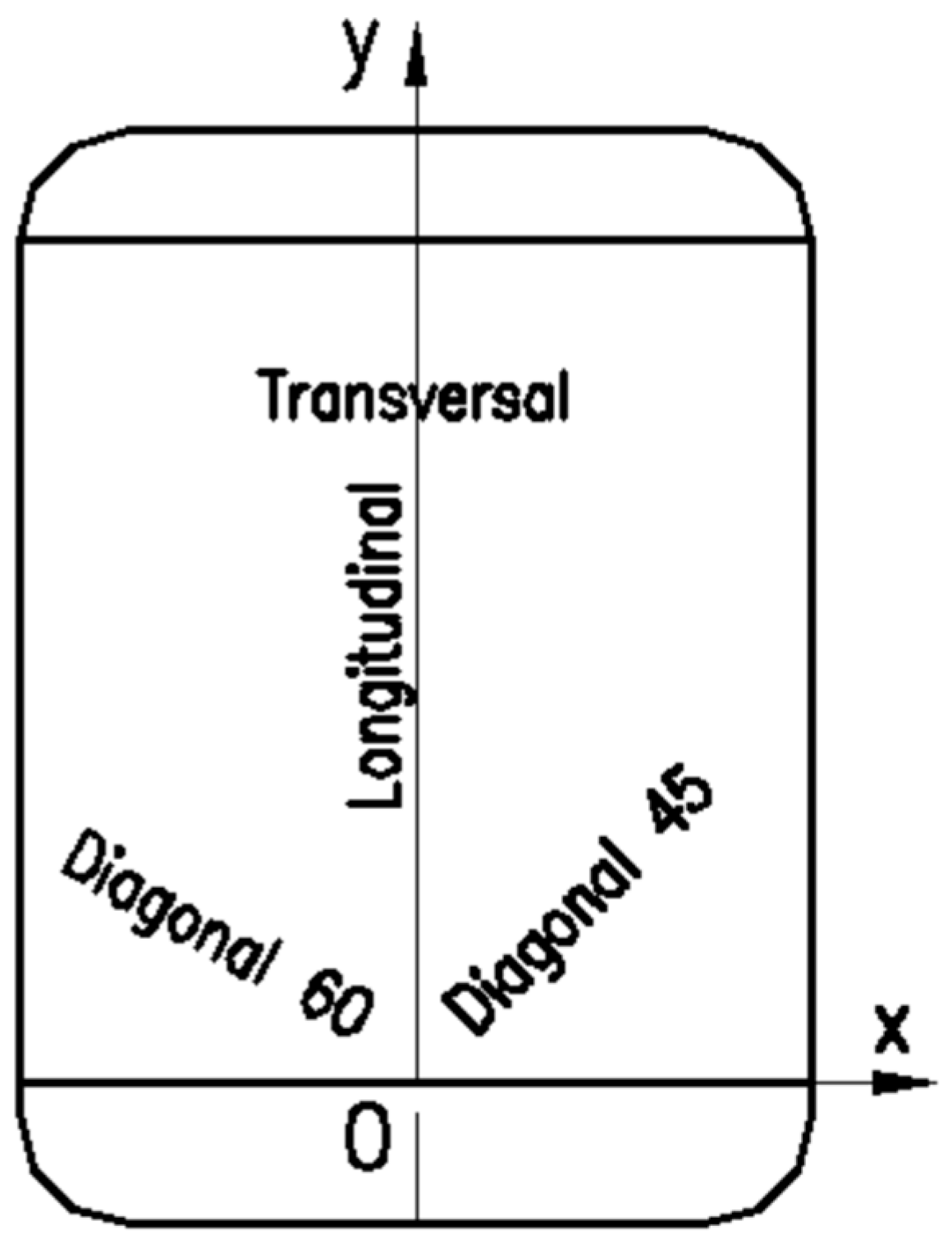

2.3. Materials Used for Air Sockets

3. Methods

3.1. Numerical Considerations for the Hydro-Pneumatic Shock Absorber

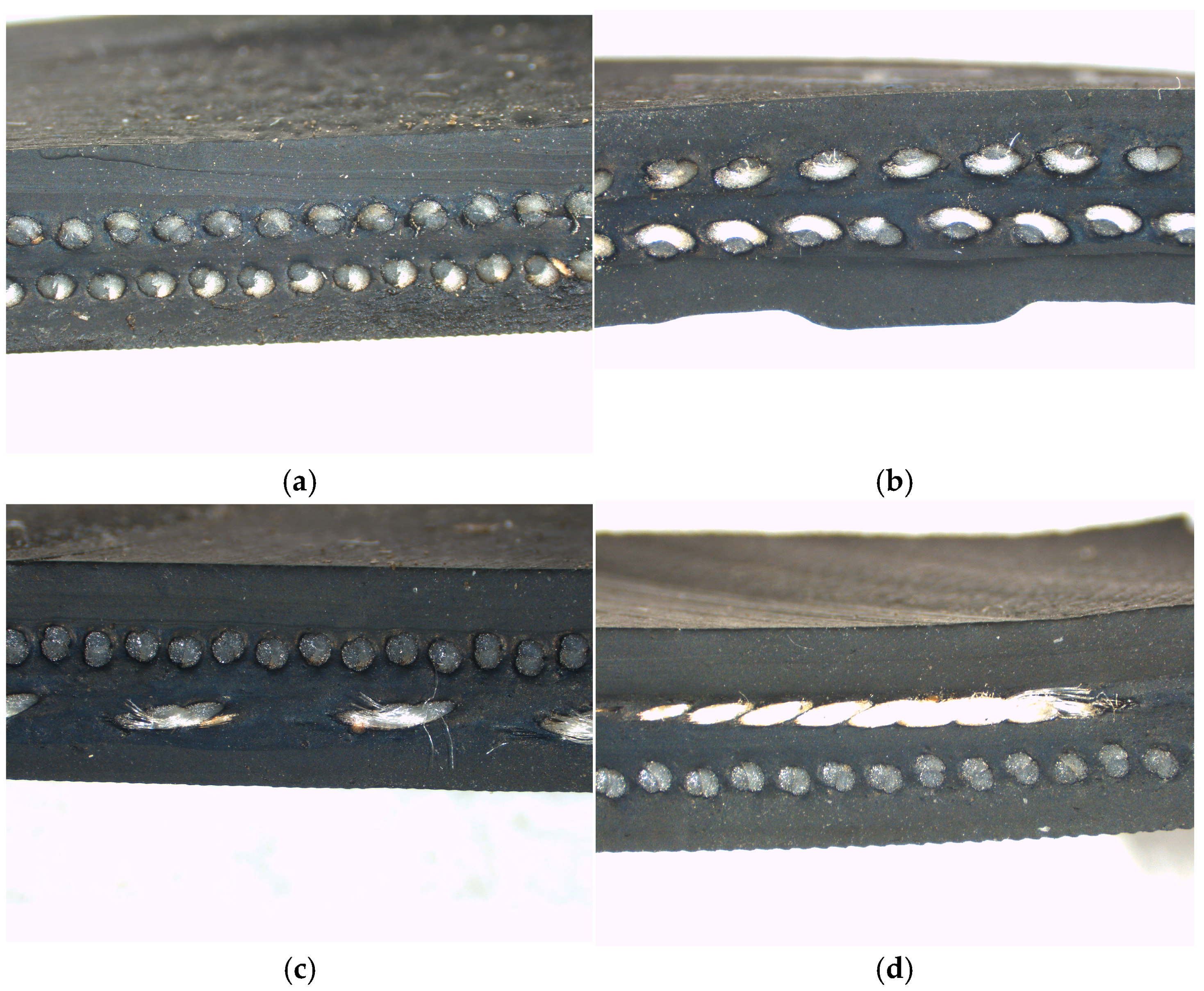

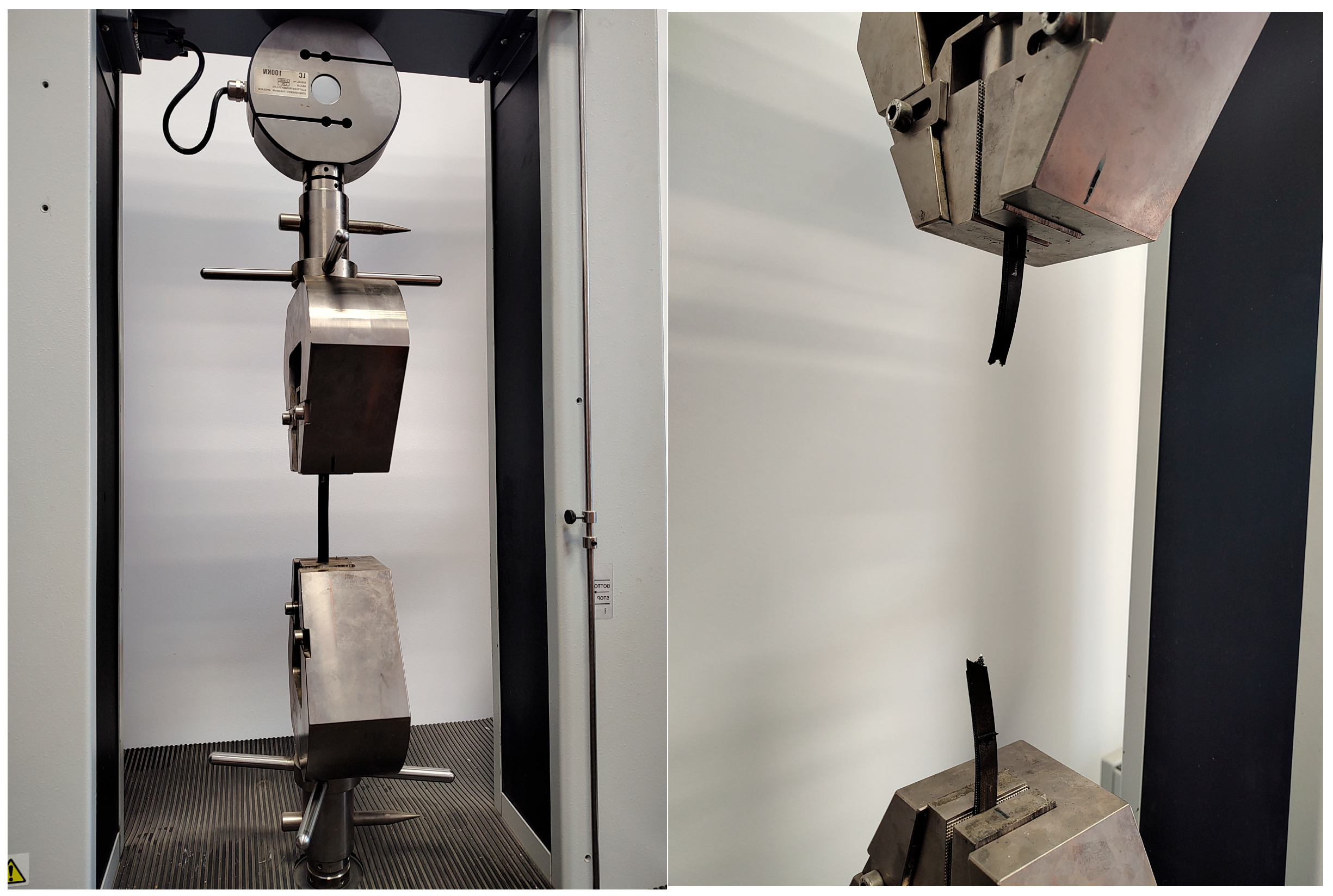

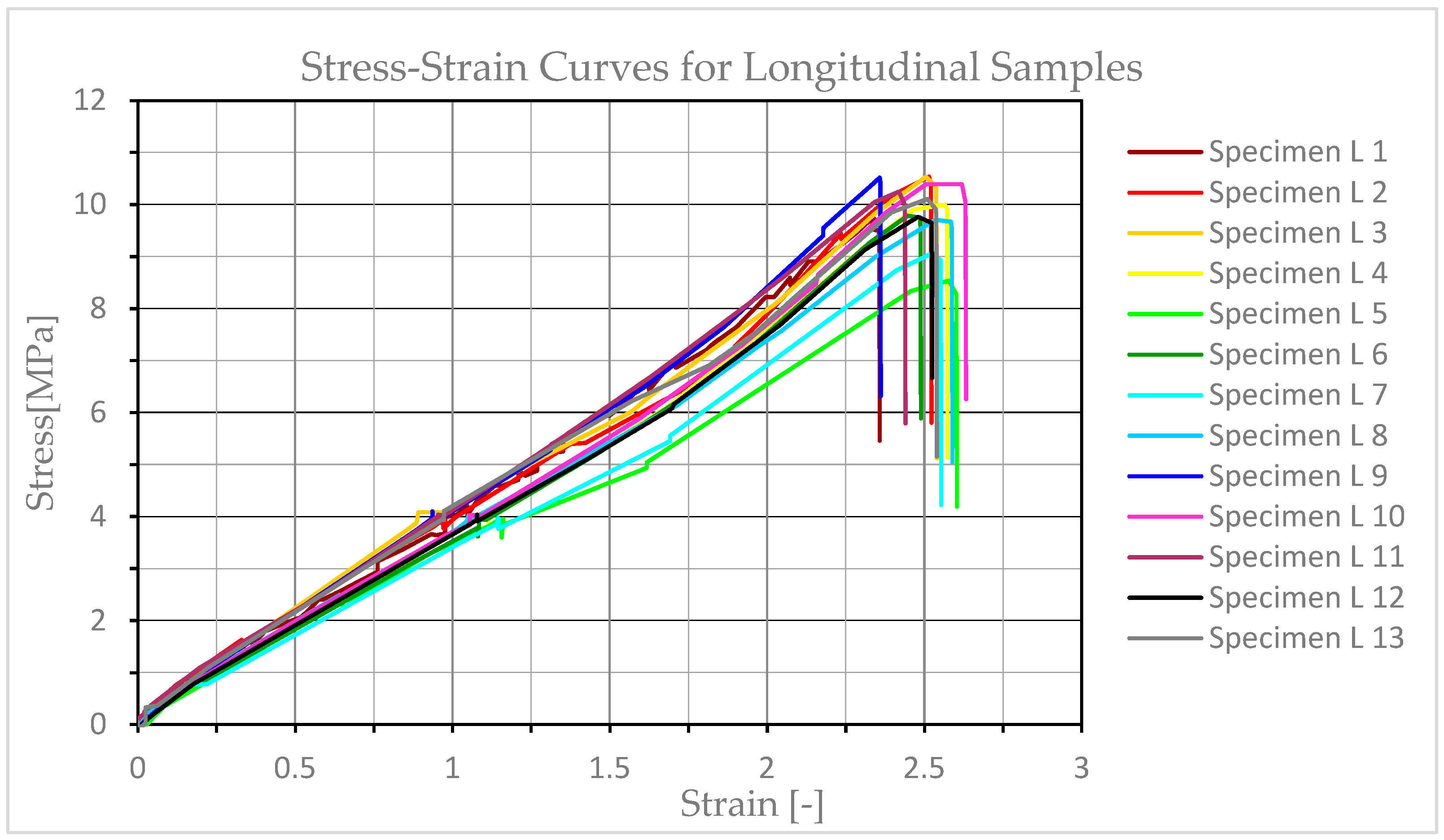

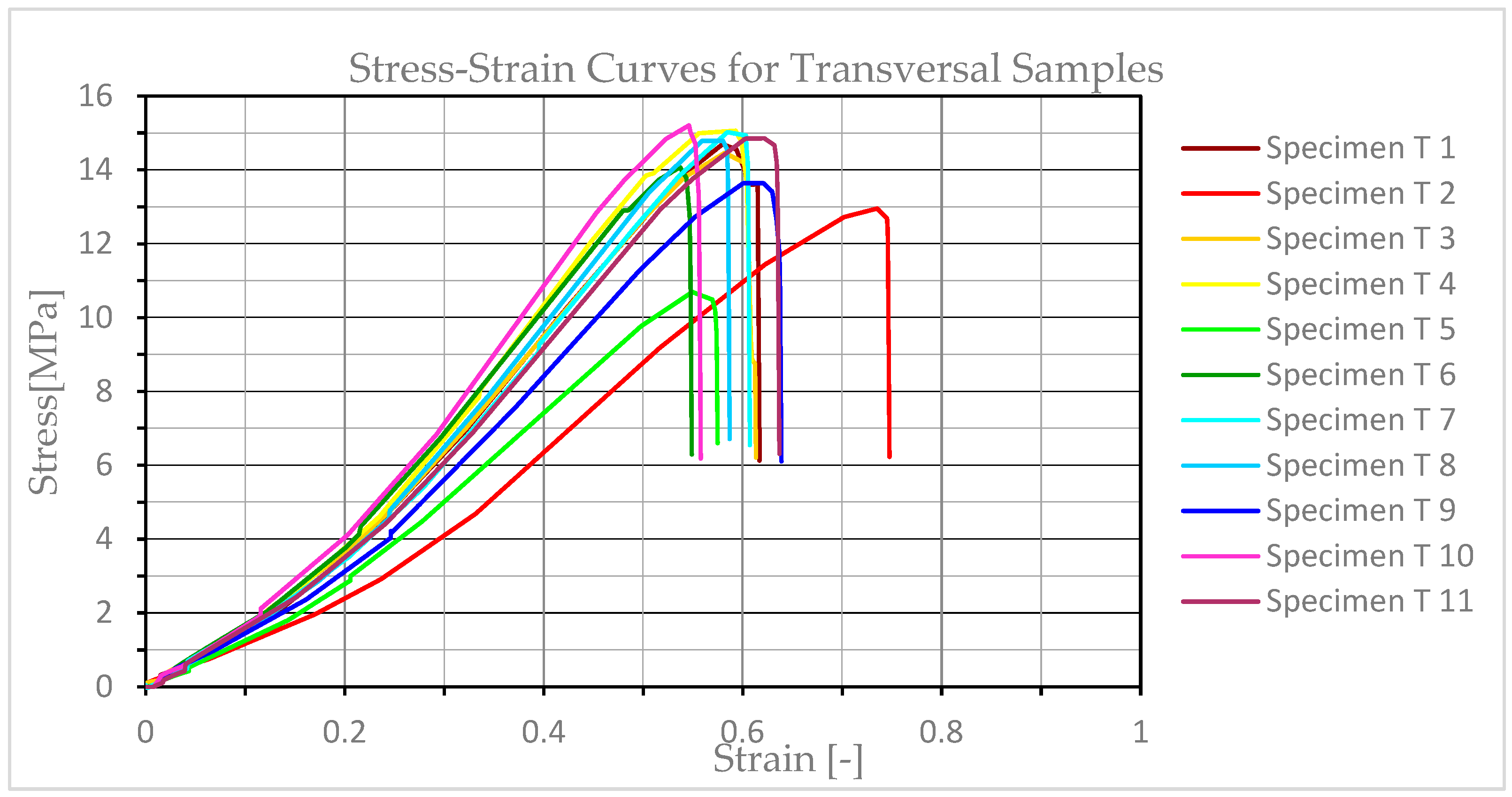

3.2. Experimental Analysis on the Proposed Materials of the Air Socket

4. Results and Discussion

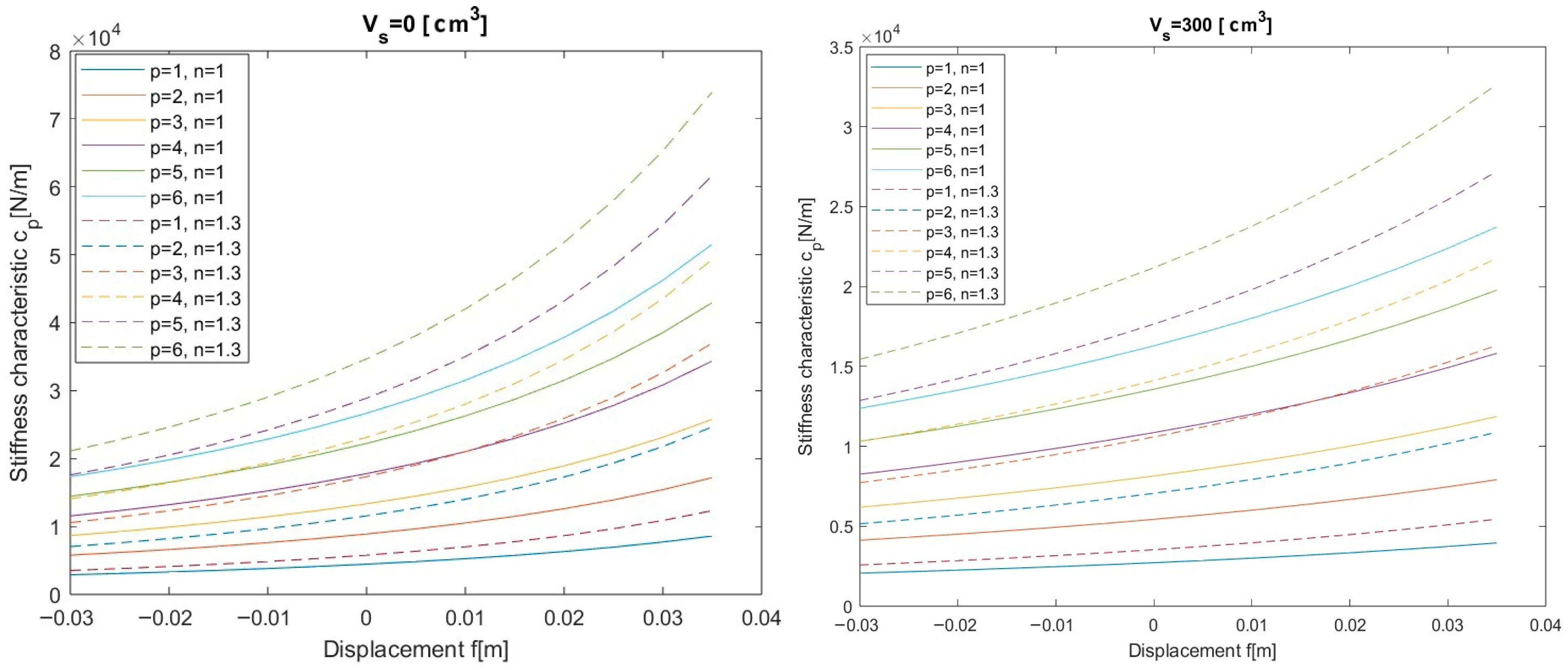

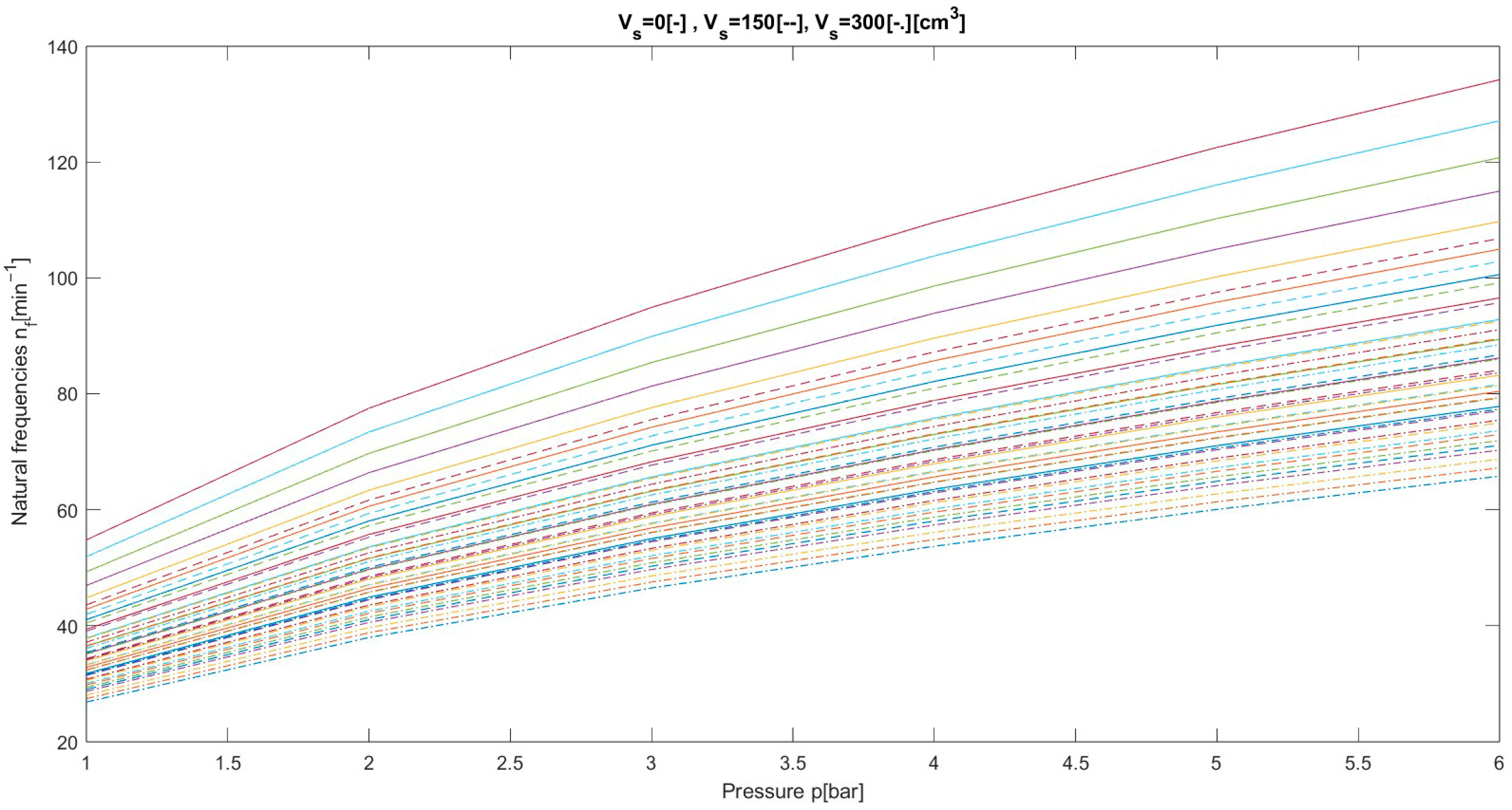

4.1. Numerical Analysis Results of the Hydro-Pneumatic Shock Absorber

4.2. Experimental Analysis Results on the Proposed Materials of the Air Socket

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Timbó, R.; Ritto, T.G. Impact of damper seal coefficients uncertainties in rotor dynamics. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 165. [Google Scholar] [CrossRef]

- Yue, S.; Titurus, B.; Li, Z.; Wu, C.; Du, Z. Analysis of liquid spring damper for vertical landing reusable launch vehicle with network-based methodology. Nonlinear Dyn. 2023, 111, 2135–2160. [Google Scholar] [CrossRef]

- Knap, L.; Makowski, M.; Siczek, K.; Kubiak, P.; Mrowicki, A. Hydraulic Vehicle Damper Controlled by Piezoelectric Valve. Sensors 2023, 23, 2007. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Shen, Y.; Du, F.; Li, M.; Yang, X. Topology Optimization Design and Dynamic Performance Analysis of Inerter-Spring-Damper Suspension Based on PowerDriven-Damper Control Strategy. World Electr. Veh. J. 2024, 15, 8. [Google Scholar] [CrossRef]

- Yang, X.; Yan, L.; Shen, Y.; Li, H.; Liu, Y. Dynamic performance analysis and parameters perturbation study of inerter–spring–damper suspension for heavy vehicle. J. Low Freq. Noise Vib. Act. Control. 2020, 40, 1335–1350. [Google Scholar] [CrossRef]

- Franczyk, B.; Gołdasz, J. Modelling and Experimental Study of a Passive Frequency-Dependent Vehicle Suspension Damper. Acta Mech. Automatica. Sciendo 2024, 18, 409–418. [Google Scholar] [CrossRef]

- Hryciów, Z. An Investigation of the Influence of Temperature and Technical Condition on the Hydraulic Shock Absorber Characteristics. Appl. Sci. 2022, 12, 12765. [Google Scholar] [CrossRef]

- Schickhofer, L.; Antonopoulos, C.G. Cause–effect relationship between model parameters and damping performance of hydraulic shock absorbers. Int. J. Non–Linear Mech. 2024, 159, 104627. [Google Scholar] [CrossRef]

- Stembalski, M.; Czarnuch, A.; Szydłowski, T.; Batory, D. Assessment of the Possibility of Validating the Durability Testing Method for Large-Sized Vehicles Based on Changes in Shock Absorber Characteristics—Preliminary Tests. Appl. Sci. 2024, 14, 127. [Google Scholar] [CrossRef]

- Liu, Z.; Jiang, C.; Wen, J. Research on new shock absorber with variable piston volume for automotive. J. Adv. Mech. Des. Syst. Manuf. 2023, 17, JAMDSM0055. [Google Scholar] [CrossRef]

- Grzesikiewicz, W.; Makowski, M. Semi-Active System of Vehicle Vibration Damping. Appl. Sci. 2021, 11, 4577. [Google Scholar] [CrossRef]

- Makowski, M.; Knap, L. Investigation of an off-road vehicle equipped with magnetorheological dampers. Adv. Mech. Engineering. 2018, 10, 1687814018778222. [Google Scholar] [CrossRef]

- Sun, X.; Cai, Y.; Yuan, C.; Chen, L.; Wang, R. Hybrid model predictive control of damping multi-mode switching damper for vehicle suspensions. J. Vibroengineering. 2017, 19, 2910–2930. [Google Scholar] [CrossRef]

- Kayabekir, A.E.; Bekda, G.; Nigdeli, S.M.; Geem, Z.W. Optimum Design of PID Controlled Active Tuned Mass Damper via Modified Harmony Search. Appl. Sci. 2020, 10, 2976. [Google Scholar] [CrossRef]

- Wu, Z.; Xu, G.; Yang, H.; Li, M.; Wallaschek, J. Analysis of Damping Characteristics of a Hydraulic Shock Absorber. Shock. Vib. 2021, 2021, 8883024. [Google Scholar] [CrossRef]

- Lozoya-Santos, J.D.-J.; Tudon-Martinez, J.C.; Morales-Menendez, R.; Sename, O.; Spaggiari, A.; Ramírez-Mendoza, R. A General Modeling Approach for Shock Absorbers: 2 DoF MR Damper Case Study. Front. Mater. 2021, 7, 590328. [Google Scholar] [CrossRef]

- Jamolov, U.; Peccini, F.; Maizza, G. Multiphysics Design of an Automotive Regenerative Eddy Current Damper. Energies 2022, 15, 5044. [Google Scholar] [CrossRef]

- Yaghoubi, S.; Ghanbarzadeh, A. Modeling and optimization of car suspension system in the presence of magnetorheological damper using Simulink-PSO hybrid technique. Results Eng. 2024, 22, 102065. [Google Scholar] [CrossRef]

- Fleps-Dezasse, M.; Brembeck, J. LPV Control of Full-Vehicle Vertical Dynamics using Semi-Active Dampers. IFAC-Pap. 2016, 49, 432–439. [Google Scholar] [CrossRef]

- Suciu, B. Experimental investigation on a controllable colloidal damper for vehicle suspension. Mech. Eng. J. 2015, 2, 14-00512. [Google Scholar] [CrossRef]

- Bai, Y.; Liu, R.; Wu, J.; Che, J.; Wu, M.; Zhou, R.; Chen, X.; Zeng, L.; Jiang, W. Stiffness model for pneumatic spring with air-diaphragm coupling effect. Precis. Eng. 2024, 91, 728–738. [Google Scholar] [CrossRef]

- Shatskyi, I.; Velychkovych, A. Analytical Model of Structural Damping in Friction Module of Shell Shock Absorber Connected to Spring. Shock. Vib. 2023, 2023, 1–17. [Google Scholar] [CrossRef]

- Velychkovych, A.; Mykhailiuk, V.; Andrusyak, A. Numerical Model for Studying the Properties of a New Friction Damper Developed Based on the Shell with a Helical Cut. Appl. Mech. 2025, 6, 1. [Google Scholar] [CrossRef]

- Korneev, S.A.; Korneev, V.S.; Penkov, I.A. Defining relationships for reinforcing shell elements of a rubber cord composite. Procedia Eng. 2016, 152, 309–313. [Google Scholar] [CrossRef]

- Goncaa, V.; Polukoshkob, S.; Boykoc, A. Analytical and Experimental Research of Compressive Stiffness for Laminated Elastomeric Structures. Procedia Eng. 2014, 69, 1388–1396. [Google Scholar] [CrossRef]

- Wong, D.; Fabito, G.; Debnath, S.; Anwar, M.; Davies, I.J. A critical review: Recent developments of natural fiber/rubber reinforced polymer composites. Clean. Mater. 2024, 13, 100261. [Google Scholar] [CrossRef]

- Kabakçi, G.C.; Aslan, O.; Bayraktar, E. A Review on Analysis of Reinforced Recycled Rubber Composites. J. Compos. Sci. 2022, 6, 225. [Google Scholar] [CrossRef]

- Anizah, M.A.N.; Nadras, O.; Hazwan, H.M.; Kannika, S.; Nabil, H. Lignin as Alternative Reinforcing Filler in the Rubber Industry: A Review. Front. Mater. 2020, 6, 329. [Google Scholar] [CrossRef]

- Ren, T.; Song, P.; Yang, W.; Formela, K.; Wang, S. Reinforcing and plasticizing effects of reclaimed rubber on the vulcanization and properties of natural rubber. J. Appl. Polym. Sci. 2022, 140, e53580. [Google Scholar] [CrossRef]

- Pan, S.; Zhao, M.; Andrawes, B.; Zhao, H.; Li, L. Compressive behavior of cylindrical rubber buffer confined with fiber reinforced polymer. J. Low Freq. Noise Vib. Act. Control. 2020, 39, 470–484. [Google Scholar] [CrossRef]

- Tian, X.; Zhu, L.; Li, K.; Wang, K.; Bian, H.; Li, L.; Li, S.; Wang, C. Effect of Gear Pump Extrusion Processing on the Properties of Fiber Reinforced Rubber Composites. Polymers 2020, 12, 985. [Google Scholar] [CrossRef]

- ISO 5893:2019; Rubber and Plastics Test Equipment—Tensile, Flexural and Compression Types (Constant Rate of Traverse)—Specification. ISO: Geneva, Switzerland, 2019.

| Element | Value [mm] |

|---|---|

| H0 | 84 |

| h0 | 65 |

| d | 51 |

| D | 84 |

| t | 15.5 |

| F [N] | m [kg] | |

|---|---|---|

| Empty cabin | 2400 | 244.648318 |

| Loaded cabin | 8500 | 866.4627931 |

| Sample L | Sample T | Sample D_45 | Sample D_60 | |

|---|---|---|---|---|

| Median Width | 10.100 mm | 10.182 mm | 10.100 mm | 10.410 mm |

| Median Thickness | 4.4100 mm | 4.2400 mm | 4.4100 mm | 4.4100 mm |

| Median Area | 44.541 mm2 | 43.172 mm2 | 44.541 mm2 | 45.908 mm2 |

| m1 | m2 | m3 | m4 | m5 | m6 | m7 | m8 |

|---|---|---|---|---|---|---|---|

| 197.75 | 203.87 | 214.06 | 224.26 | 234.45 | 244.64 | 254.84 | 260.95 |

| Empty Cabin Maximum Mass | Loaded Cabin Minimum Mass | |

|---|---|---|

| Pressure on the elastic element p [N/m2] | 3.5 × 105 | 4.62 × 105 |

| Stiffness of the elastic element c [N/m] | 15,550 | 20,530 |

| Natural oscillations n [min−1] | 84.67 | 84.7 |

| Value | |

|---|---|

| Outer diameter [mm] | 80 |

| Thickness [mm] | 11.5 |

| Length [mm] | 270 |

| Coil number | 10 |

| Active coils | 8 |

| Empty Cabin Maximum Mass | Loaded Cabin Minimum Mass | |

|---|---|---|

| Pressure on the elastic element p [N/m2] | 3.5 × 105 | 4.62 × 105 |

| Stiffness of the helical spring c [N/m] | 31,012.113 | |

| Natural oscillations n [min−1] | 119.57 | 103.57 |

| Sample L | Sample T | Sample D_45 | Sample D_60 | |

|---|---|---|---|---|

| Stress at Break [MPa] | 9.821 | 9.453 | 19.054 | 30.483 |

| Strain at Break [-] | 2.508 | 0.613 | 0.764 | 0.375 |

| Stiffness [N/m] | 2489.9 | 2456.1 | 8800.4 | 4402.3 |

| Young’s Modulus [kN] | 4.192 | 4.266 | 14.818 | 7.192 |

| Load at Maximum Load [MPa] | 0.441 | 0.610 | 0.959 | 1.542 |

| Stress at Maximum Load [MPa] | 9.915 | 14.131 | 21.547 | 33.589 |

| Machine Extension at Maximum Load [mm] | 186.9 | 44.567 | 56.990 | 28.108 |

| Strain at Maximum Load [-] | 2.491 | 0.593 | 0.759 | 0.374 |

| Tensile Strength [MPa] | 9.915 | 14.131 | 21.547 | 33.589 |

| Elongation at Fracture [mm] | 188.17 | 45.994 | 57.307 | 28.140 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gheorghe, V.; Chircan, E.; Teodorescu Draghicescu, H. Research on the Use of Hydro-Pneumatic Shock Absorbers for the Rear Suspension of a Vehicle Cabin. Appl. Sci. 2025, 15, 7759. https://doi.org/10.3390/app15147759

Gheorghe V, Chircan E, Teodorescu Draghicescu H. Research on the Use of Hydro-Pneumatic Shock Absorbers for the Rear Suspension of a Vehicle Cabin. Applied Sciences. 2025; 15(14):7759. https://doi.org/10.3390/app15147759

Chicago/Turabian StyleGheorghe, Vasile, Eliza Chircan, and Horatiu Teodorescu Draghicescu. 2025. "Research on the Use of Hydro-Pneumatic Shock Absorbers for the Rear Suspension of a Vehicle Cabin" Applied Sciences 15, no. 14: 7759. https://doi.org/10.3390/app15147759

APA StyleGheorghe, V., Chircan, E., & Teodorescu Draghicescu, H. (2025). Research on the Use of Hydro-Pneumatic Shock Absorbers for the Rear Suspension of a Vehicle Cabin. Applied Sciences, 15(14), 7759. https://doi.org/10.3390/app15147759