1. Introduction

Automatically repeating parameter-based tasks in models is a valuable asset in modern manufacturing and mechanical design environments [

1,

2]. Increasing product complexity with proportionate increases in design diversity, in turn, increases the need for scalability, traceability, and modularity in automation tools [

3]. Traditional CAD processes, specifically in environments that simulate assemblies/part families, typically rely on manual duplicate and edit, increasing the risk for error and inefficiency [

4]. This work proposes a systematic and modularity-based design automation approach implemented in VBA in CAD environments for streamlining repetitive tasks in design, imposing naming conventions and archive standards, and maintaining traceability in iterations.

In this context, internal combustion engines and turbochargers are critical components with various applications in industrial and manufacturing-related sectors, providing enhanced reliability and enhanced performance for industrial applications. Diesel engines especially offer durability and combustion efficiency, while turbochargers improve engine performance by increasing power density and efficiency, resulting in higher power output and reduced emissions [

5]. Mostly composed of cast iron, turbochargers account for 20% of sales in this industry and are a major source of greenhouse gas emissions, making them a prime target for reducing emissions [

6]. During the machining process, the crucial factor for manufacturing components is the precision of cutting tools meeting tolerance demands with energy-assisted subtracting technologies for avoiding efficiency reduction and surface integrity deterioration [

7].

Information comprised of a set of data is processed, analyzed, and organized in such a way that it is complete and solid [

8]. Currently, designers are forced to implement effective information organization techniques to be responsive and efficient, as the highly competitive, dynamic, and strongly regulated industrial sector faces a growing number of challenges. For industrial users in a wide range of sectors, including engineering, one challenge is to gain total control over processes through real-time management. For example, the workflow ranges from raw material purchasing to transformation via production, equipment, logistics, traceability, and distribution until it reaches the final consumer. According to questionnaires sent out to engineers, 20–30% of the time spent on information-based tasks is devoted to researching specific information and data [

9]. Furthermore, data organization is considered of paramount importance for a product’s traceability. The word “traceability”, derived from the word “trace”, refers to the ability to “track” and “trace” the history, location, and lifecycle of a product by utilizing data stored. To achieve this, data should be inseparable from a product and marked by a unique number. In addition, for the acquisition and organization of engineering data, the repeatability factor must be taken into consideration. Acceptable information retrieval times can be assessed not only when human error is eliminated, but also when the data storage process is carried out automatically.

CAD (computer-aided design) API, a set of programming interfaces that allows developers to interact with and extend the functionality of CAD software, enabling the automation of design tasks, customization of workflows, and integration with external systems, may be utilized across a wide range of industries and types of companies where automation and customization are significant factors for corporate development. Beyond engineering, some of them include manufacturing, construction, product design and consumer goods, renewable energy, supply chain, as well as research and academia for performing experimental design and analysis.

The objectives of this study are as follows: (a) improving the optimization of the design process using the example of engines’ parts and turbochargers; (b) guaranteeing the traceability of the documentation of each specific product; and (c) automating repetitive tasks for minimizing human error.

In view of all the elements described above, the aim of this paper is to propose and implement a fully modular optimization approach to streamline design workflows. The specific methodology is applied to mechanical engineering for the documentation of a newly designed product. To this end, our study will be based on the Application Programming Interface (API) of Autodesk Inventor (San Francisco, CA, USA), a computer-aided design (CAD) tool widely used and recognized in the world of mechanical engineering. Nevertheless, due to the wide area of CAD API’s implementation, the methodology may be generalized and be applicable to other sectors.

The present work aligns with the context of knowledge-based engineering (KBE), which represents a technology at the intersection of many fundamental disciplines, including computer programming, CAD, and artificial intelligence (AI) [

10,

11]. To the authors’ knowledge, the research gap that has been identified is the fact that there are no published literature works on the direct link between design applications and technical information. Therefore, the key objective is to build a multidisciplinary approach to information storage, including not only formal but also informal ones [

12]. In the end, in order to meet the aforementioned requirements dictated in automated processes, a script, created using Visual Basic for Applications (VBA), was developed and implemented using Autodesk Inventor API (V2022). This automated process interacts directly with the user, resolving human errors and archiving design data more efficiently.

Based on the challenges outlined above, this study addresses the following three key research questions: (RQ1) To what extent can a company’s design process be optimized using Autodesk Inventor’s API? (RQ2) Can documentation tasks be automated to both eliminate human error and ensure traceability? (RQ3) How many aspects of this process can be automated while accounting for practical limitations? The proposed methodology leverages the modular structure of CAD APIs in conjunction with a design intent-oriented approach, implemented through a Visual Basic for Applications (VBA) script in Autodesk Inventor. A practical case study from an industrial design workshop demonstrates the methodology’s application, focusing on repetitive design and documentation tasks. The motivation stems from widespread inefficiencies in file organization and data traceability, which often lead to delays and inconsistencies in documentation. By identifying and automating the most repetitive and error-prone tasks, this work aims to reduce time-to-market, enhance productivity, and minimize operational risk. The study’s main contribution lies in its practical deployment under real working conditions, ensuring that the automation solution is not only technically sound but also aligned with actual industrial needs. Finally, the potential for generalization to other CAD systems is discussed, highlighting the broader implications for CAD-based automation in engineering workflows.

The remainder of this article is structured as follows:

Section 2 (Related Work and Context) outlines relevant studies on design automation, optimization, and the use of CAD APIs.

Section 3 (Methodology and System Architecture) describes the proposed automation framework and its modular implementation using Autodesk Inventor’s API.

Section 4 (Case Studies) presents industrial applications of methodology in an industrial setting, highlighting recurring design challenges and automation outcomes.

Section 5 (Results and Discussion) analyzes the performance improvements and practical benefits of the proposed approach. Finally,

Section 6 (Conclusions and Future Work) summarizes the findings, answers the research questions, and discusses the broader potential of CAD-based automation across other engineering environments.

2. Related Work and Context

2.1. Historical Evolution of Automation

During the first Industrial Revolution, in the early 19th century [

13], innovations like the steam engine and the greater transition from manual labor to mechanized production were immense. The origin of the term “automation”, credited to D.S. Harder, then Director of Engineering at Ford Motor Company [

14], was gradually adopted in the context of manufacturing that was vastly modernized. Automation, the application of machines to tasks once performed by human beings or, increasingly, to tasks that would otherwise be impossible. These machines are concerned with performing a process by means of programmed commands combined with automatic feedback control to ensure proper execution of the instructions. Later on, in the mid-20th century, during the 1960s, CAD and computer-aided manufacturing (CAM) systems were introduced, enabling engineers to design and translate their designs directly into automated manufacturing instructions [

15], followed by the integration of programmable logic controllers (PLCs), enabling real-time control of machines and production lines [

16]. The rise of robotics and flexible manufacturing systems (FMSs) in the 1980s and 1990s broadened the scope of automation from repetitive tasks to more complex, adaptive processes [

17]. As an example, in [

18], the authors describe the transition to Industry 4.0, where the synergy of physical and digital systems creates “smart factories” able to actively adapt to production needs [

19], complemented with technologies like cyber–physical systems, the Internet of Things (IoT), and artificial intelligence (AI), which includes machine learning (ML) and deep learning (DL).

The introduction of Industry Revolution 5.0 emphasizes human–machine collaboration, sustainability, and value creation beyond efficiency and automation [

20]. Researchers in [

21] investigated the technologies, the challenges, and the opportunities related to this transition, revealing a growing interest in Industry 5.0, a strong link between them, as well as the creation of new business models requiring personnel with new advanced technological skills [

22].

2.2. Automation Systems and CAD API Integration

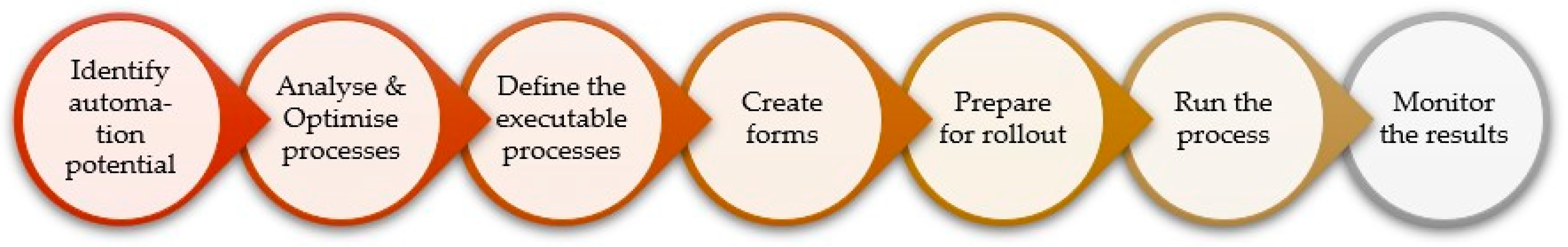

Automating a task or system, as shown in

Figure 1, involves the depicted steps. By following these steps, a structured approach to integrating automation into engineering processes becomes possible, ensuring both an effective and efficient transition from manual to automated workflows.

Knowledge-based engineering (KBE) refers to the integration of knowledge management into the design and manufacturing process. This enables engineering expertise and data to be reused to automate more complex tasks. Thus, KBE represents a powerful design approach that uses explicitly represented knowledge to automatically generate product variants [

23,

24]. In [

25], the authors consider that KBE is capable of drastically decreasing the time devoted to repetitive, labor-intensive tasks by automating the processes that traditionally involve manual intervention. According to [

10], KBE not only automates recurring tasks but also improves decision-making by drawing on past experiences and design rules. This helps to reduce iteration cycles and accelerate adaptation to new requirements. The authors of [

9] support this view by stating that shortening is of paramount importance in modern engineering, as it is imperative to be able to respond quickly to dynamic market demands. Moreover, as the authors of [

10] point out, the automated retrieval and application of previous design data enables KBE to minimize redundant tasks in alignment with Kugler’s assertion, as published in [

25]. The overall result is a leaner, more efficient workflow, where time and resources are optimized, thus meeting strict project deadlines and improving the overall quality of final products, allowing engineers to become more creative and innovative [

26].

Product design and engineering design are closely linked disciplines [

27], where the former defines user needs and vision, while the latter connects creativity with technical execution [

28]. Advances in manufacturing increasingly rely on the effective reuse of engineering knowledge [

29], data science integration, and flexible, modular automation systems—such as microservice-based industrial control architectures—to reduce information loss and enhance design efficiency [

30].

In the current study, an API (Application Programming Interface), which is the basis of a modern CAD system, will be utilized [

31]. Application Programming Interfaces (APIs) serve as intermediaries between software systems, facilitating seamless communication and interoperability among them [

32], automating repetitive tasks in CAD systems, and reducing the need for manual intervention [

33]. This makes APIs an essential tool for automating a wide range of engineering tasks, from routine operations to more complex processes such as parametric modeling and design validation. In [

34], the authors point out that these platforms guarantee greater interoperability. APIs can thus be exploited to extend the capabilities of CAD systems for better integration with other tools and data sources. The transition to cloud-based solutions facilitates enhanced computational performance, improved collaborative capabilities, and increased flexibility in design environments, thereby better addressing the evolving demands of diverse industrial sectors [

35].

Despite the considerable automation potential offered by Application Programming Interfaces (APIs) in CAD systems, their effective implementation often entails certain challenges, such as the requirement for programming proficiency and ongoing system maintenance. Nevertheless, those limitations are outweighed by the substantial advantages of API-driven automation, particularly in reducing repetitive manual input and enabling engineers to focus on higher-level design tasks. Various commercial CAD platforms provide API support to facilitate such automation. For instance, CATIA V5 [

36], developed by Dassault Systems, incorporates tools like PowerCopy, UserFeature, and macros to automate modeling through generic inputs, while SolidWorks utilizes both API and VBA functionalities for similar purposes [

37]. Autodesk Inventor represents another prominent example, where its dedicated API enables the automation of routine procedures through streamlined commands, thereby reducing the cognitive and operational load on engineers [

38,

39]. Beyond traditional automation, contemporary CAD systems are increasingly integrating artificial intelligence (AI), including machine learning (ML) and deep learning (DL), to further enhance adaptability and intelligence in design processes. Recent studies have introduced DL-based CAD/CAE frameworks capable of autonomously generating and analyzing 3D models during the conceptual design phase [

40]. These systems employ advanced techniques such as transfer learning, dimensionality reduction, and generative design, allowing real-time optimization and autonomous decision-making [

41]. The synergy between conventional API-based automation and AI-driven methodologies signifies a transformative evolution in CAD technologies, with future research expected to focus on developing robust and versatile knowledge models to support a broader range of design applications [

42].

3. Methodology and System Architecture

As part of this research, a structured methodology was developed and implemented with the objective of addressing inefficiencies and uncertainties in the technical documentation process through the use of the Autodesk Inventor API. The primary aim was to automate key aspects of the design and documentation workflow to improve operational efficiency, reduce manual workload, and minimize the likelihood of human error. The methodology was applied and evaluated within the context of a practical case study, drawing data from an actual manufacturing workshop. Initial analysis focused on identifying recurring bottlenecks and repetitive tasks—particularly those related to CAD file creation, documentation, and information management—that were prone to error and consumed substantial engineering time. Based on the frequency of these tasks, their criticality, and their potential for potential automation, specific processes were selected, including part file generation, folder structuring, manufacturing drawing creation, and centralized data archiving.

Following problem identification and process selection, automation development was carried out using the Autodesk Inventor API, employing a modular and scalable code structure written in VBA. A user-centric interface was designed through interactive forms to facilitate seamless data input and ensure completeness and consistency of user-provided information. The implementation adopted an iterative development model, utilizing turbocharger parts—chosen for their complexity and documentation demands—as test cases to improve and validate the approach. Early prototypes were compiled in the workshop environment, and iterative feedback was used to enhance the system’s robustness and functionality. As development progressed, advanced automation features, such as the automatic generation of manufacturing drawings, were incorporated. The final version of the code was deployed in the live production setting, offering a fully integrated, stable, and user-friendly solution within the CAD environment. The result was a significant cut-off in documentation time and an improvement in accuracy, aligning with the research goals of enhancing productivity and traceability in engineering workflows.

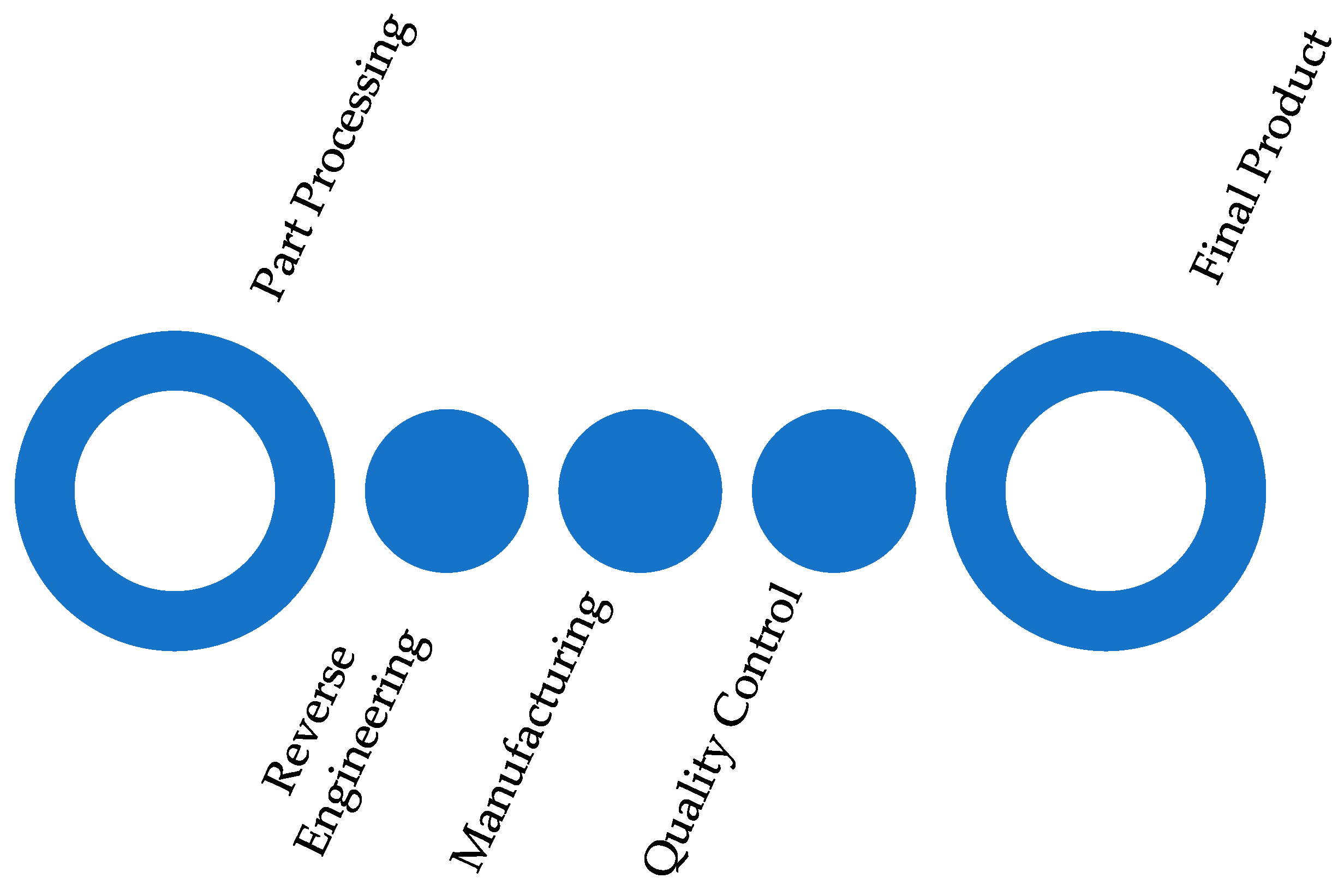

In this context, three main combined methodologies are proposed: reverse engineering, manufacturing, and quality control, following the specified order depicted in

Figure 2. The term ‘final product’ encompasses not only tangible items, such as a fully manufactured part, but also data-driven outputs, such as a manufacturing drawing from reverse engineering or a quality control inspection report.

In real-world workshop settings, engineers are frequently confronted with a high volume of quotation requests, each requiring prompt and accurate assessment. To manage each case effectively, engineers must address several fundamental questions: Has the customer provided a demonstrator of the part to be manufactured? Is a metrological inspection sufficient for the supplied item? Should reverse engineering be performed, or are manufacturing documents already available? Answering these questions necessitates a precise and comprehensive data acquisition process. The requirement for traceability and thorough documentation remains constant, whether dealing with a small component for basic inspection or a complex assembly for large-scale production. A CAD model inherently encapsulates a significant volume of information about a part or assembly, serving as the foundation for generating manufacturing drawings and bills of materials (BOMs), which subsequently initiate a series of downstream engineering procedures. The design engineer must either create or retrieve the appropriate CAD file, and if it does not exist, the prerequisite information must first be collected and securely stored. Once the design is completed, it becomes essential to organize and archive these data in a manner that ensures accessibility and traceability across teams. To streamline this process, the current approach leverages Autodesk Inventor’s API to automate the generation of 3D models, enabling rapid configuration of customizable designs and minimizing the downside need of repetitive documentation tasks [

43,

44]. An overview of the user interaction with the system and the primary input parameters handled by the automation code is illustrated in

Figure 3.

3.1. Software Environment

This study was conducted within the operational context of a specialized industrial company engaged in the maintenance and reconditioning of turbochargers, offering services that include health checks, intermediate and major overhauls, precision repairs, and the remanufacturing of critical components. Given the sector’s strong emphasis on operational efficiency and strict adherence to production schedules, the need for reliable, scalable, and time-saving design processes is paramount. The software environment selected for this research reflects the aforementioned practical demands. Autodesk Inventor was chosen as the main CAD platform due to its widespread use in this sector and its accessible API, which supports advanced automation through VBA scripting. The system was implemented and tested under real working conditions, addressing practical challenges in design data handling and part documentation. The customization options and modularity of the environment were tailored to fit the specific requirements of the turbocharger industry, ensuring relevance, applicability, and adaptability of the developed automation framework.

3.2. Automation Workflow Design

The automation framework developed in this work was designed to streamline repetitive tasks commonly encountered in mechanical engineering design and documentation workflows [

45]. Utilizing the Autodesk Inventor API, a quantitative and iterative approach was employed to implement a modular and scalable system capable of minimizing manual interventions and improving data traceability. The workflow was compiled using custom scripts developed in Visual Basic for Applications (VBA), enabling the automation of core design operations such as part file creation, folder generation, drawing documentation, and metadata management.

The core of the design focused on user-guided interactions through input forms, ensuring that essential information is collected consistently and accurately before model generation. This allowed for the seamless transition from raw input to structured output, reducing the risk of error and enforcing standardized documentation procedures. The automation logic was developed to be both hierarchical and reusable, facilitating the deployment of the system across a variety of design scenarios.

Three representative case studies were used to inform and validate the automation process, selected for their complexity, frequency, and the degree of task repetition involved. These cases, selected from daily operations within the collaborating industrial company, served both as testbeds for iterative code development and, at the same time, as validation scenarios evaluating the robustness and applicability of the proposed solution. The integration of this workflow within Autodesk Inventor not only enabled rapid and repeatable model creation but also ensured alignment with actual engineering demands.

For clarity and readability, detailed implementation aspects of the automation system have been relocated to

Appendix A. This includes the structure and logic of the VBA code, the design of user input forms, the directory and file-naming conventions, and the workflow for generating CAD files and manufacturing drawings. Additionally, screenshots, interface examples, and a breakdown of modular subroutines are provided to support reproducibility and facilitate potential adaptation to other engineering contexts.

4. Case Studies

To evaluate the practical effectiveness of the proposed automation workflow, three representative case studies were selected from the daily operations of a mechanical engineering company specializing in turbocharger servicing and reconditioning. These cases were chosen based on their frequency, complexity, and relevance to repetitive design and documentation tasks. Each case highlights a distinct engineering scenario in which the implemented automation system was applied to streamline workflow processes, reduce manual effort, and ensure traceability. For each case, the presentation follows a structured format, outlining the specific design objective, the automated workflow applied using Autodesk Inventor’s API, and the outcomes observed in terms of time savings, consistency, and error reduction. Detailed code structures, interface laments, and procedural walkthroughs related to these cases are provided in

Appendix A for reference and reproducibility.

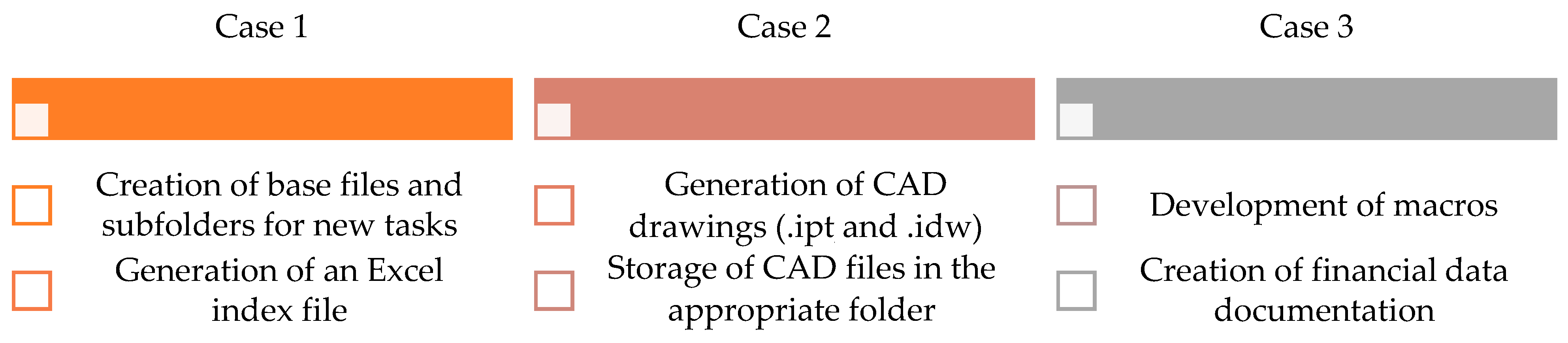

Figure 4 depicts the content of the three cases, which will be further elaborated.

4.1. Case Study 1: Automated Folder and Archiving Structure for Design Documentation

The objective in the first case study was to make data archiving related to reverse engineering tasks simpler by automating common folder hierarchies and index files. This is a mandatory step toward attaining traceability, consistency, and proper project-linked documentation organization, particularly for components such as those in this case in a turbocharger.

Using the user interface designed for this case (illustrated in

Figure 3), engineers begin by entering basic part-related information into a form. Upon clicking the “Next” button, the system automatically generates a predefined folder hierarchy tailored to the selected project type. This includes directories for part analysis, scan data, and reverse engineering outputs. A notification confirms the folder creation path, while additional prompts inform the user of archiving options. To support accessibility and future data analysis, an Excel index file is generated (

Figure 5), which contains hyperlinks to all relevant subdirectories and files. The automation logic ensures uniformity in folder naming and structure, eliminating variation between users and minimizing manual input errors. The specific directory naming structure and file system logic are detailed in

Appendix A.5.

The automation of folder generation and data archiving significantly improved documentation efficiency by removing the need for manual folder setup. It ensured that all project data followed a consistent structure, enhancing file retrieval and version control. The use of an automatically generated Excel spreadsheet as a centralized index allowed users to manage documentation through a single interface, with embedded hyperlinks enabling rapid navigation to any stored file. Apart from structural organization, the Excel index also offers potential as a statistical dashboard, supporting future data-driven evaluations of part characteristics or project metrics.

4.2. Case Study 2: Automated Drawing Generation from CAD Models

The objective for Case Study 2 was to extend automation processes with the generation of completely annotated mechanical drawings from part files in CAD. Integrating drawing generation into the same automated chain that generates folder hierarchies and metadata, the objective was to save time in manual drafting and ensure that drawing output is within pre-specified standards.

Building on the folder-generation routine of Case 1, the engineer first completes the initialization form (

Figure 3) and selects the CAD STEP option. This triggers the API script to open the existing .ipt part file and automatically invoke the drawing environment. The routine generates a new .idw (or .dwg) drawing file in the project’s “Engineering Drawings” folder, populating three standard views—left, top, and isometric—and inserting the title block information captured in the form. Basic dimensions are added to the primary view according to a template, and prompts notify the user of the drawing’s save location.

The automated drawing procedure reduced the time required to create and annotate a part drawing from over an hour to under five minutes while guaranteeing consistent formatting and eliminating transcription errors.

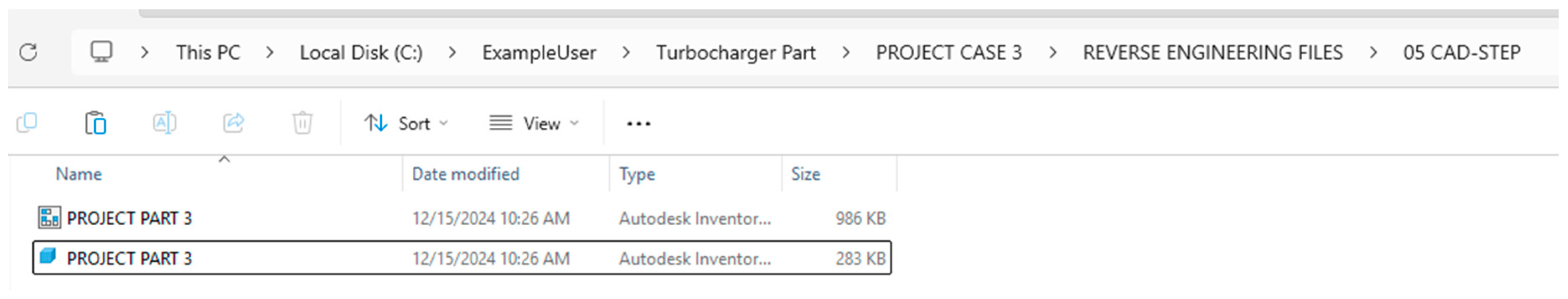

Figure 6 illustrates the resulting project folder containing both the .ipt model and .idw drawing files.

Figure 7 presents a representative output, showing the three views, populated title block, and template-driven dimensions. By integrating drawing generation into the broader automation framework, this case demonstrated both a substantial productivity gain and a robust mechanism for maintaining drawing quality and traceability.

4.3. Case Study 3: Full Workflow Automation with Cost Estimation and Reporting

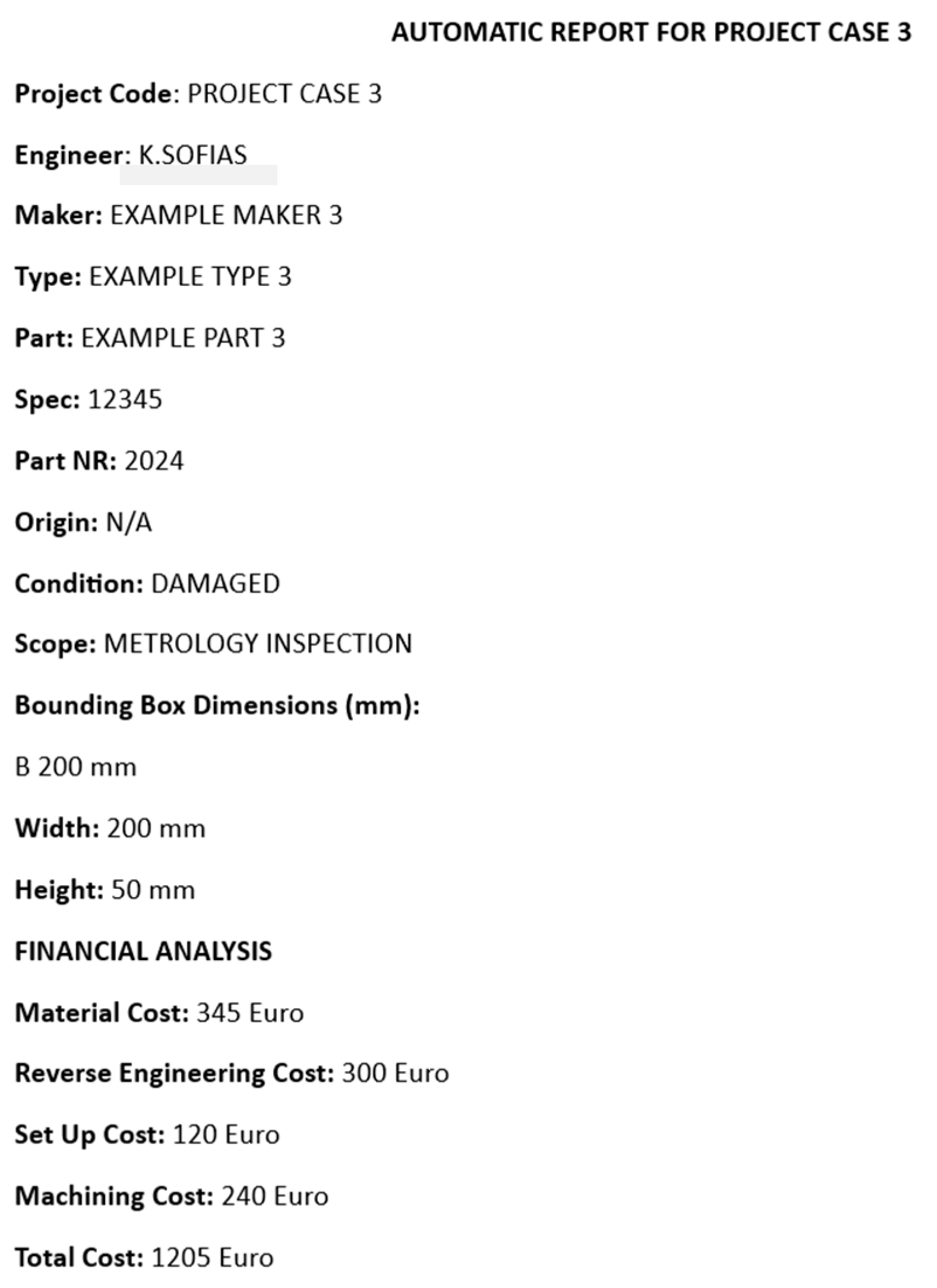

The third case study demonstrates the widespread potential of the automation system created by integrating higher-level features such as automated drawing generation, fiscal data processing, structured archiving, and report generation. The ultimate objective was to emulate an actual current-day workflow of an engineering environment in which technical deliverables such as CAD files and drawings, along with cost estimates and part documentation, are all automated, thus providing an integrated as well as component-level approach to reducing design time, human error, and inconsistency.

Building upon the procedures in Cases 1 and 2, Case 3 starts with the engineer filling in the required metadata and activating the “Financial Data” and “Reverse Engineering” tabs through the input interface. These options prompt the user to insert key cost-related variables like material price, process times, and consumable costs (see

Table 1. Upon submission, the system generates a CAD part file (.ipt) and its relevant drawing file (.idw), as shown in

Figure 8, that includes multiple standard views and an autocompleted title block.

The system then proceeds to automatically generate a structured directory of folders for engineering drawings, manufacturing data, quality control files, and reverse engineering outputs. An MS Word-based report file is also created (

Figure 9), containing a summary of user-provided data, a snapshot of the part drawing, a footprint box outlining the raw part dimensions, and the total calculated manufacturing cost. The footprint box supports the selection of the appropriate raw material dimensions, eliminating manual measurements. This reporting functionality enhances documentation accuracy and promotes communication among design, costing, and production teams.

All directory paths and coding logic used in this case are documented in

Appendix A.7, while

Figure 10 illustrates the automatically generated report with embedded drawing and financial summary.

Appendix A.7 outlines the key variables used in the financial analysis of the part production process. These include material costs, time required for reverse engineering and machine setup, and the cost of consumables. Each variable contributes to the accurate calculation of total production costs. Upon saving, the system automatically processes these data to support decision-making.

Implementation of Case 3 confirmed the modularity and scalability of the implemented system. The automation substituted folder development, drawing preparation, and preliminary cost estimates, reducing switching between tasks. The system processed finance data safely using embedded calculators with precalculated calculations (e.g., hourly rates and material markups) and could present an overall cost summary on request. Modularity in the code supports dynamic value updating and possible expansion of the costing model in the future. Word reporting offers accessibility, while graphical integration enhances interpretability. This case demonstrates the ability of the system to encapsulate complicated tasks of an engineer through integrating the processes of design, costing, and documentation within an automated process.

Together, the three case studies in this chapter collectively present the versatility, scalability, and practical applicability of the suggested automation system to varying levels of design complexity. Spanning from basic folder generation and metadata management to drawing automation and integration with cost estimation, the system proved it could solve common problems in actual engineering environments. Each case demonstrated an aspect of the system’s capability that justified the system’s assertion of reducing manual effort, maintaining standardized documentation, and enhancing traceability of the information. By matching the level of automation with the nature of the work at hand, the approach strikes an equilibrium between flexibility and control that supports rapid deployment as well as extended extensibility.

5. Results and Discussion

This section presents the main outcomes of the automation framework developed using Autodesk Inventor’s API, focusing on its impact on design efficiency, error reduction, and scalability in mechanical engineering workflows. By comparing automated processes with established manual methods across three representative case studies, the analysis exhibits tangible improvements in productivity and consistency, particularly in routine documentation and data archiving tasks.

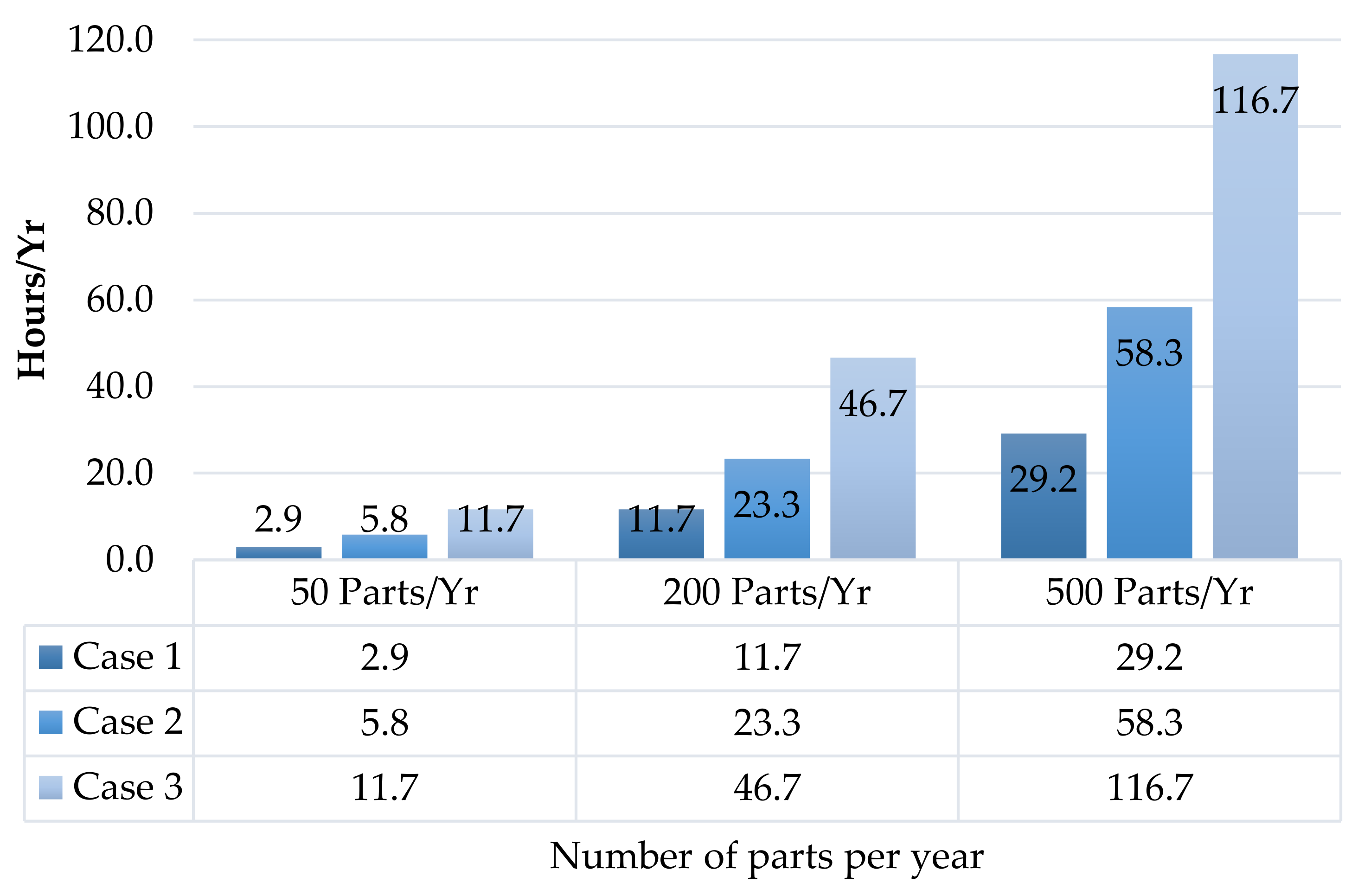

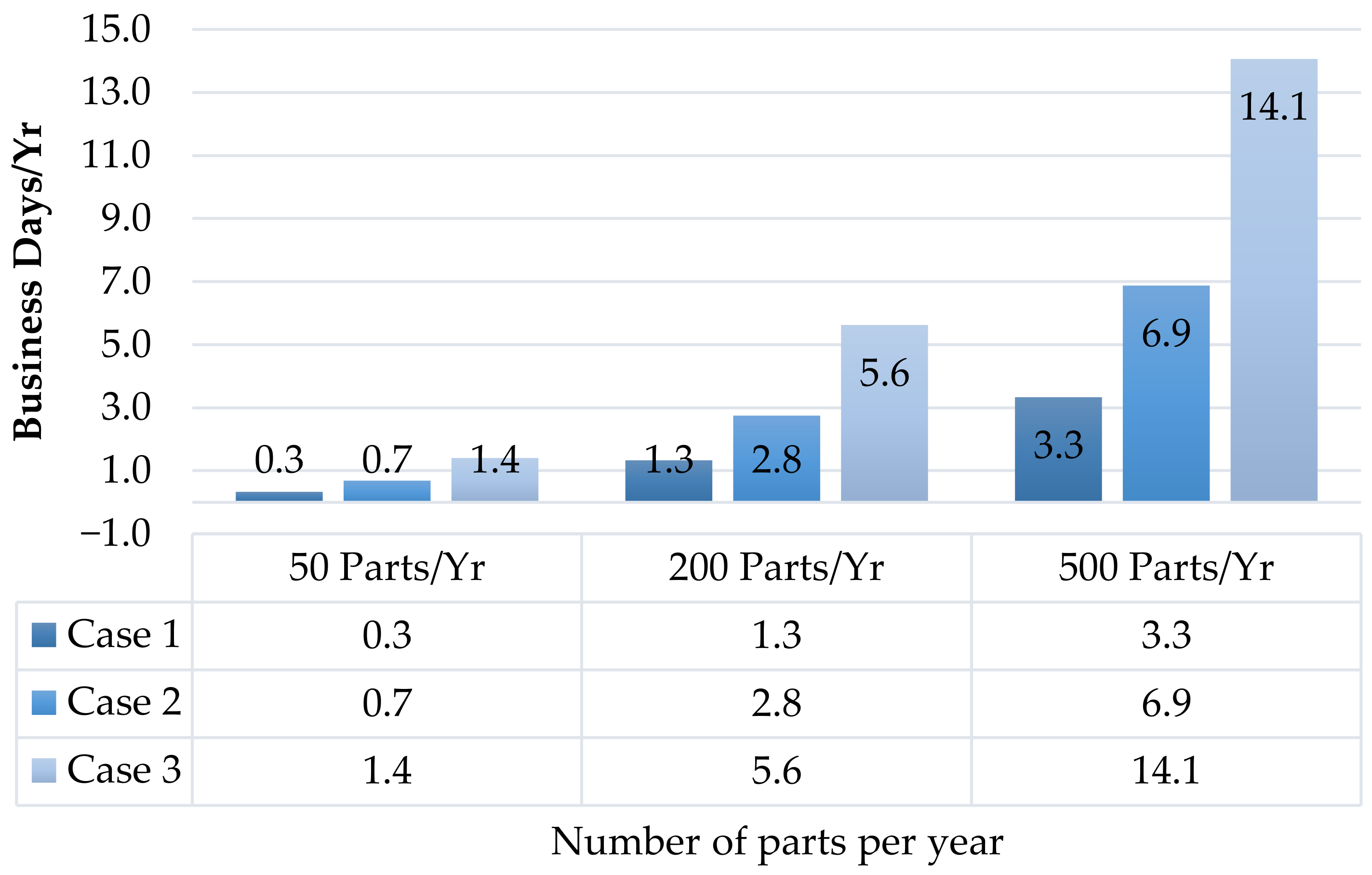

In Case 1, automation was applied to streamline folder creation and metadata organization through an MS Excel-based index system. While seemingly simple, these tasks consume considerable time in manual workflows and are prone to inconsistencies. As shown in

Figure 11, the manual documentation process required approximately 2.9 h for an annual batch of 50 parts. In contrast, the automated process reduced this to just 8 min (

Figure 12), highlighting an over 90% reduction in task time. The Excel file served as a centralized, hyperlink-driven archive, improving file accessibility and reducing the likelihood of misplacement or duplication.

Case 2 introduced drawing generation from CAD part files, expanding the automation framework to include visual and dimensional documentation. This feature eliminated the need for manual drawing setup, title block editing, and view placement. When scaled across multiple parts, the time savings and error reduction became more pronounced, especially in enforcing standardized drawing formats.

Figure 13 illustrates cumulative time savings as production volumes increase, clearly indicating the scalability of the approach and its growing benefits in high-throughput environments.

Case 3 showcased the full integration of automation features, combining drawing generation, structured archiving, report compilation, and cost estimation within a single workflow. This advanced use case demonstrated how modular code could address both technical and financial aspects of the design process. The automatically generated Word report included part metadata, dimensional previews, and calculated cost estimates, providing a comprehensive reference for design, production, and managerial teams. The modularity of the codebase allowed real-time updates to pricing parameters and logic, ensuring adaptability to future changes in cost structures or part specifications.

Overall, the results provide strong evidence of the system’s ability to reduce design lead time, minimize documentation errors, and standardize file management. The visualizations in

Figure 10,

Figure 11 and

Figure 12 confirm that automation gains compound with production scale, making the framework particularly advantageous in industrial contexts requiring frequent design iterations or part customization.

A key contribution of this work lies in its non-commercial, in-house development model. Unlike proprietary automation platforms with rigid workflows and high subscription costs, the proposed system offers full code transparency and modification capabilities. Engineers with basic programming knowledge can adapt the tool to evolving project needs, enabling organizations to avoid vendor lock-in and reduce long-term maintenance expenses. This agility allows teams to extend functionality, integrate additional modules, or respond to operational feedback more quickly than would be feasible with commercial systems.

Moreover, the cost-effectiveness of the proposed approach is significant. Many commercial automation solutions are financially inaccessible to small companies or startups. In contrast, the use of VBA within Autodesk Inventor, a platform already present in many engineering firms, enables the creation of powerful automation tools without incurring additional licensing costs. The system’s self-sufficiency fosters internal expertise development, reducing dependence on external software providers and promoting continuous process improvement.

In summary, this study demonstrates that a modular, customizable automation framework can deliver measurable efficiency gains and operational flexibility in mechanical design environments. The solution is particularly well suited to organizations seeking scalable, cost-efficient alternatives to commercial automation packages, including those with limited technical or financial resources. The following chapter outlines the broader conclusions of this work and proposes directions for further development and optimization.

To provide a concise overview of the performance gains observed across the three case studies,

Table 2 presents a comparative summary of the key outcomes. This table highlights the specific automation objectives addressed in each case, the primary features implemented, and the resulting benefits in terms of time savings, error reduction, and scalability.

6. Conclusions and Future Work

This study set out to investigate the potential of CAD-based automation to improve efficiency, traceability, and error minimization in mechanical design documentation workflows. Through the development and deployment of a modular automation framework using Autodesk Inventor’s API, the research addressed three primary questions concerning optimization (RQ1), traceability and error reduction (RQ2), and the extent and limitations of automation in practice (RQ3). The results from three structured case studies clearly demonstrate that automating repetitive engineering tasks significantly reduces documentation time and enhances consistency, particularly in high-volume or high-variation production environments.

Regarding RQ1, the framework proved highly effective in optimizing core design processes, especially in tasks such as CAD file creation, drawing generation, and directory structuring. Time savings were consistently demonstrated, with automated processes requiring a fraction of the time needed for their manual equivalents. In response to RQ2, the methodology ensured improved traceability through standardized documentation and archiving routines. The integration of metadata into both CAD models and linked Excel/Word outputs significantly lowered the risk of incomplete or inconsistent records, supporting regulatory compliance and downstream process reliability. For RQ3, while the automation system achieved substantial coverage of routine operations, certain limitations persist. Complex design tasks such as advanced geometric modeling or engineering judgment in drawing comprehension still require human intervention, stressing the ongoing importance of human oversight in design engineering.

While the proposed framework delivered substantial time and error reduction benefits, its current implementation is limited to the Autodesk Inventor platform and relies on VBA scripting, which may constrain portability and extensibility. Additionally, the impact of automation on reducing human error could not be quantitatively measured due to the subjective nature of manual processes. These limitations dictate the need for broader validation and structured error analysis in future work.

Regarding broader implications, this study contributes to the body of knowledge pertaining to sustainable engineering practices. By eliminating unnecessary manual labor and reducing errors, the automation process results in greater resource effectiveness combined with a reduced need for costly rework. These advantages not only enhance operational excellence but also aid in the attainment of sustainability goals in terms of minimizing material waste and energy consumption.

For this purpose, several future research directions are proposed. First, extension of the framework to accommodate other CAD systems or integrated Product Lifecycle Management (PLM) systems would enhance its value considerably. Second, envisioning the integration of machine learning (ML) or artificial intelligence (AI) technologies into the automation logic could provide adaptive capabilities, i.e., proactive prediction of errors, smart parameter recommendation, or process adaptation automatically based on usage feedback. Machine learning (ML) has become a valuable asset in materials science due to its ability to capture nonlinear relationships and identify patterns within complex, high-dimensional data [

46]. The rational design of photoanode materials is pivotal for advancing photoelectrochemical (PEC) water splitting toward sustainable hydrogen production. This review highlights recent progress in the machine learning (ML)-assisted development of nanostructured metal oxide photoanodes, focusing on bridging materials discovery and device-level performance optimization. We first delineate the fundamental physicochemical criteria for efficient photoanodes, including suitable band alignment, visible-light absorption, charge carrier mobility, and electrochemical stability. Conventional strategies such as nanostructuring, elemental doping, and surface/interface engineering are critically evaluated. We then discuss the integration of ML techniques—ranging from high-throughput density functional theory (DFT)-based screening to experimental data-driven modeling—for accelerating the identification of promising oxides (e.g., BiVO

4, Fe

2O

3, and WO

3) and optimizing key parameters such as dopant selection, morphology, and catalyst interfaces. Particular attention is given to surrogate modeling, Bayesian optimization, convolutional neural networks, and explainable AI approaches that enable closed-loop synthesis–experiment–ML frameworks. ML-assisted performance prediction and tandem device design are also addressed. Finally, current challenges in data standardization, model generalizability, and experimental validation are outlined, and future perspectives are proposed for integrating ML with automated platforms and physics-informed modeling to facilitate scalable PEC material development for clean energy applications. While cutting-edge AI and VR tools offer transformative potential in advanced sectors like aerospace or automotive design, cost and complexity often limit their applicability in traditional mechanical workshops. Thus, the approach advocated in this study favors accessible, scalable, and internally manageable automation solutions—especially suited for small-to-medium-sized enterprises seeking cost-effective digital transformation.

Furthermore, security and IT infrastructure would need to be addressed for long-term system development, particularly as automated workflows are handling more sensitive design information and collaborative access. Version control procedures would prevent inadvertent overwrites and make it easier to track design revisions. In addition, the integration of secure data storage, encryption, and role-based user access would further strengthen the architecture for networked or multi-user setups. These features become increasingly critical as the system is scaled up or integrated with more comprehensive enterprise systems such as PLM or cloud-based CAD systems.

Lastly, future work could explore the use of simulation tools or open-source platforms (e.g., FreeCAD (San Francisco, CA, USA), Autodesk Generative Design (San Francisco, CA, USA)) for constraint-driven optimization. However, the methodology developed here remains intentionally grounded in practical, low-barrier technologies, making it particularly relevant for industries where customization, traceability, and process control are key priorities, yet advanced digital infrastructure may be limited.