Abstract

This paper presents the results of testing the insulation performance of geopolymers based on fly ashes with the addition of waste broken glass. The waste glass was dried and ground to a maximum of 1 mm grain size. The proportions of broken glass in the total binder’s mass were 0%, 10%, 20%, and 30%. Sodium hydroxide and sodium silicate were the activators of the alkaline reaction. The obtained geopolymer materials were characterised by determining the basic physico-mechanical properties. The chemical composition, density, and thermal conductivity coefficient were determined. The mechanical performance, including compressive and flexural strength, was investigated after 28 days of curing. The morphological analysis was also carried out using microphotographs obtained from optical and scanning microscopes. A significant effect of the waste glass on the tested geopolymers’ mechanical performance was observed. Proportions of 10% and 20% broken glass in the binder led to more than a four-fold increase in the compressive strength and a two-fold increase in the flexural strength compared to the geopolymer without the waste glass. All tested geopolymers had excellent insulation ability compared to the reference mortar (more than 80% higher than cement mortar). However, the problem is potential alkali–silica reaction, which can occur when the waste glass content is high.

1. Introduction

Considering the climatic changes caused, among others, by the greenhouse effect, limiting the greenhouse gas emissions, including CO2, is a priority. The total world production of Portland cement accounts for about 8% of anthropogenic CO2 emissions [1]. This has led to scientists expressing increasing interest in developing sustainable binding materials that can replace Portland cement as a binder for concrete. A potential alternative is geopolymers [2], which demonstrate higher impact resistance [3,4], sulphate aggression resistance [5], and thermal resistance [6,7] compared to ordinary concrete.

Ground granulated blast furnace slag (GGBFS) and fly ash (FA), which are industrial by-products, are often used as precursors for aluminosilicates in the alkali-activated reaction of geopolymers production. In this reaction, GGBFS and FA dissolve under the action of alkaline hydroxides and/or silicates; then polycondensation takes place [8]. The alkaline activation by GGBFS and FA causes the creation of calcium–aluminium–silicate gel (C-A-S-H) [9] and sodium–oxide–silicate gel (N-A-S-H) [10], respectively. It has been found that the mixed GGBFS and FA geopolymer, due to the high cross-linking of the reaction products, surpasses the one-phase geopolymer in terms of workability [11], compressive strength, drying shrinkage [12] and resistance to chloride penetration [13].

Despite the everyday use of polyvinyl chloride for package manufacturing, large amounts of waste glass are still produced worldwide. Most of this glass comes from beverage bottles and food packaging [14]. Additional waste glass is produced during building demolitions and renovations. In 2021, 250,000 tons of waste glass were produced monthly in the European Union [15]. Broken glass is at present a significant component of municipal solid waste. Waste glass consists not only of glass packaging but also of flat glass, laboratory glass, bulb glass, and decorative glass. The rising demand for chemically strengthened glass products, like monitors, tablets, and smartphone screens, has also caused an increase in the volume of waste glass, making it challenging to utilise and process [16]. In 2018, broken glass comprised more than 5% of the municipal solid waste stored at landfill sites in the USA [17]. Glass that is stored in landfills or calcined does not decompose, but it increases the total volume of the waste produced by these waste management methods. Additionally, this glass cannot be used for energy recovery [18,19]. However, recycling waste glass using selective waste segregation makes it possible to save basic material resources, energy, and water [20]. Such an approach helps to diminish the volume of waste in landfills. According to [21], one ton of stored glass waste occupies about 1.5 m3 of the landfill.

Strict requirements for the quality of the input raw material for utility glass production contribute to the low level of glass recycling. Coloured glass waste often fails to satisfy the criteria for a range of properties after decolourising. An additional obstacle in the process of glass waste re-use is contamination, including heavy metals contamination [22]. Therefore, in recent years, scientists have searched for sustainable solutions to increase the efficiency of activities in the circular economy related to waste glass utilisation [23,24,25]. Among other changes, there is a demand for more efficient production of high-quality glass, including chemically strengthened glass (used, e.g., in smartphone screens) [26]. However, producing such glass requires an expensive final processing [27].

Significant differences in the melting temperature of various types of waste glass and the high costs of its recycling cause technological difficulties and low motivation to re-use these wastes to produce new glass [28]. Moreover, glassworks that directly use glass waste are unavailable in some countries or city agglomerations, such as Hong Kong. Thus, much of the waste glass is sent to refuse sites. Such treatment harms the environment due to the non-biodegradable character of the glass, and it occupies valuable land. Therefore, an alternative use of waste glass is increasingly sought after. In the production of cement-based building materials, the leading direction is using recycled waste glass (WG) as a fine aggregate [29].

The use of WG improves the fluidity of geopolymer mortars because of the low water absorption and smooth surface of WG grains [30,31]. Numerous previous investigations [32,33,34,35] have demonstrated that the smooth surface of WG particles worsens the mechanical performance of cement–geopolymer mortar and concrete. Using WG as a fine aggregate diminished the geopolymer mortar’s sorption [36] and improved the chloride resistance [28,31]. Additionally, including WG decreased the high drying shrinkage of the cement mortar [37]. The thermal conductivity of geopolymer mortar has been decreased by using WG as an aggregate due to its own low thermal conductivity [36]. However, because most waste glass from the food industry contains a three-component sodium–calcium–silicate system, harmful alkali–silica reactions (ASRs) can occur in alkaline environments, like geopolymer or cement [38]. It was found in [39] that the geopolymer binder is less exposed to ASR degradation than the cement binder due to calcium deficiency. As demonstrated in [40], a finely ground WG can act as an alternative for the fine aggregate in geopolymers based on FA or GGBFS, because fine glass particles increase the matrix alkalinity, which leads to a broader range of dissolution and reactions close to the aggregate grains. The research presented in [41] has shown that the mixture’s fluidity improved with growing WG content when using WG as a partial substituent for the fine aggregate. However, at WG content higher than 22.5%, a decrease in the compressive strength was noted. In turn, the studies presented in [42] have demonstrated that using WG as a partial replacement for the fine aggregate significantly improves the thermo-insulating ability and fire-proof performance of the geopolymer mortar based on FA.

Using WG as a coarse aggregate was described in [43]. The 28-day compressive and tensile strength of the geopolymer concrete based on FA was investigated. The coarse aggregate was substituted with the waste glass by 10% to 40%. A downfall of the compressive strength was observed as the share of the recycled waste glass increased in the coarse aggregate. The research presented in [44] shows that WG can effectively replace up to 50% of the coarse aggregate without a significant change in the strength.

The investigations aimed to obtain geopolymer based only on waste binders, with mechanical performance similar to that of ordinary cement mortar. The fly ash obtained from a Polish power plant was used as the main alkali-activated binder. Broken glass from a refuse site in Szczecin was employed to improve the geopolymer’s mechanical properties. The tests showed the possibility of using waste glass to improve the geopolymer mortar’s mechanical performance, particularly its compressive strength. Substituting 10% of FA with WG brought about more than a fourfold increase in the compressive strength and more than a twofold increase in the flexural strength. The compressive strength of all specimens containing WG was above 35 MPa and was similar to the strength of the mortars containing class 32.5 cement [45].

2. Materials and Methods

2.1. Materials

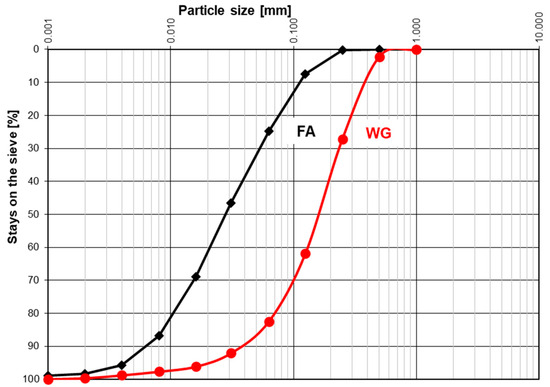

Geopolymers were produced based on waste materials: fly ash and waste white glass. The fly ash was taken from electrofilters in the Dolna Odra power plant (Gryfino, Poland). The fly ash chemical composition is presented in Table 1, and its grain size distribution is presented in Figure 1. The broken white laboratory glass, stored at the University (WPUT, Szczecin, Poland), was used as WG. The waste glass was ground in the jaw crusher (EKO-LAB, Cracow, Poland, LAB-08-240) and sieved on a sieve with a mesh of 1 mm. The WG grain size distribution is presented in Figure 1.

Table 1.

Chemical composition of fly ash (FA).

Figure 1.

Particle size distribution of fly ash (FA) and waste glass (WG).

The following substances were also used for geopolymer manufacturing:

- -

- Sodium hydroxide (water solution of sodium hydroxide, NaOH) with molar modulus 10 (Warchem S.A., Warsaw, Poland).

- -

- Sodium metasilicate pentahydrate (Na2SiO3·5H2O) with a molar mass of 212.4 g/mol (Warchem S.A., Warsaw, Poland).

A standard cement mortar has been prepared to compare the geopolymer’s thermal and mechanical properties according to the European Standard EN-196-1 [29]. Three specimens (40 × 40 × 160 mm) of the reference cement mortar (RCM) were prepared using 450 g of Portland cement (CEM IV/B(V) 32.5 N, Górażdże Cement S.A., Chorula, Poland), 1350 g of sand (standard quartz sand up to 2 mm [46]), and 225 g of water.

2.2. Preparation of Geopolymer Specimens

The initial mixtures were produced by mixing the fly ash (FA) with waste glass (WG). The FA was replaced by the WG with 10%, 20%, and 30% by mass. The mixture of 10-molar NaOH aqueous solutions with sodium silicate, in a ratio of 1:2.5, was prepared separately. The solution was added to the mixtures of FA and WG. The liquid–solid ratio was fixed at 1:2.5. To synthesise geopolymer samples, the mixed solids and liquids underwent mechanical stirring for 1 h. The obtained homogeneous slurry of FA and GP was transferred into silicone forms of 40 × 40 × 40 mm3 (in order to test the thermal properties and compressive strength). The beams 40 × 40 × 160 mm3 were prepared to determine the flexural strength. The forms with geopolymer were stored in an oven at 60 °C for 48 h to complete the polycondensation reaction. After curing, the samples were demoulded and stored in air-dry conditions (20 °C and RH < 50%).

The samples containing 100% FA and no WG were labelled G0WG. The sample marked as G10WG contained 10% WG and 90% FA; the sample G20WG contained 20% WG and 80% FA; and the sample G30WG contained 30% WG and 70% FA (by mass).

2.3. Test Methods

The geopolymers’ chemical composition and surface microstructure were analysed using a scanning electron microscope (Hitachi Co., Ltd., Tokyo, Japan, TM3000) with an EDS analyser (Bruker Co., Billerica, MA, USA, Bruker Quantax EDS). The specimens with a surface area of about 2 cm2 and thickness of up to 3 mm were prepared by cutting from the central part of the cubic specimens. The specimens were sprayed with the gold and palladium alloy in the vacuum chamber to increase the surface electrical conductivity. SEM photographs with a magnification of 100× to 800× were obtained for analysing the geopolymers’ microstructure.

The density of the geopolymers and reference cement mortar was calculated using the geometric method to determine the mass-to-volume ratio. The specimens’ masses were measured with a precise scale PS6000.X2 (RADWAG, Radom, Poland).

The thermal parameters were determined by a non-stationary method. The method is based on the heat flux analysis at the unsteady flow. The apparatus uses the superficial or pin probes with a specific thermal conductivity range. The superficial probe (Applied Precision, Bratislava, Slovakia, Isomet 2114) was used in the experiment. The cubic specimens 40 × 40 × 40 mm3 in dry state were used for tests after 28 days of curing. The specimens were stored in the laboratory in dry conditions until their mass stabilised. The thermal conductivity λ, volumetric specific heat cv, and thermal diffusivity a were registered.

The compressive and flexural strength were determined on the dry geopolymers and RCM after 28 days of curing. Tests were carried out using the strength machine (Toni Technik GmbH, Berlin, Germany) at a maximum load of 100 kN. The compressive strength was measured on the cubic specimens 40 × 40 × 40 mm3 with an accuracy of 0.1 MPa. The specimens were placed centrally on the strength machine’s plate so that the rubbed surface was on the side. The load was uniformly raised at the rate of 2400 ± 200 N/s during the whole test, until the specimen was destroyed. The flexural strength was measured on the beams 40 × 40 × 160 mm3 using the strength machine (Toni Technik GmbH, Berlin, Germany) and the mortar testing attachment. A three-point loading method was employed. The strength machine (Toni Technik GmbH, Berlin, Germany) was equipped with a bending mechanism consisting of two steel supporting rollers with a diameter of 10 ± 0.5 mm and an axial distance of 100 ± 0.5 mm, and a third roller (loading) placed centrally between the supporting rollers. The test consists of placing the beam 40 × 40 × 160 mm3 perpendicularly to the rollers, so that the central roller is above the beam’s centre, i.e., at a length of 8 cm from its beginning. The load is transferred by the loading roller to the side surface of the beam at a rate of 50 ± 10 N/s until the beam breaks. The flexural strength Rt is calculated from the formula:

where Rt—flexural strength [MPa];

- Ft—breaking load at the beam’s centre [N];

- b—side length of the beam’s section [mm];

- l—distance between the supports [mm].

Tests were conducted according to the European Standard [46].

3. Results and Discussion

3.1. Geopolymers Performance

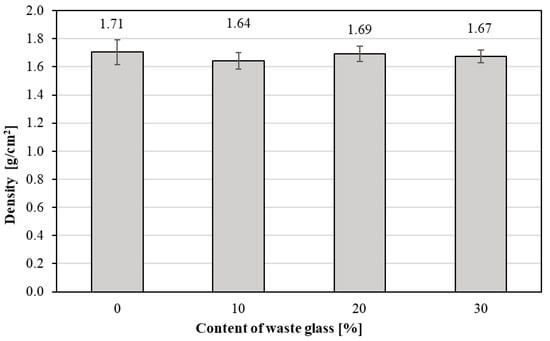

The densities of the geopolymer specimens determined by the geometrical method after 28 days of curing are presented in Figure 2. The density of the geopolymer containing WG was slightly lower than that without WG addition. The highest density was determined for the G20WG composite, which contained 20% of the waste glass. Increasing the WG content in the geopolymer hinders its compaction and increases porosity, consequently lowering the density. The waste glass creates a pozzolanic reaction, producing additional C-S-H and increasing viscosity [47]. Diminishing the waste glass particles and consequently increasing their specific surface area causes the growth of pozzolanic reactivity [48].

Figure 2.

The density of geopolymers depending on the percentage of the waste glass addition.

3.2. Microstructure Analysis

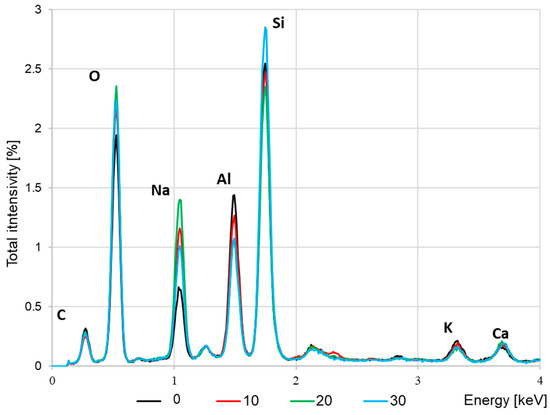

Figure 3 presents the results of geopolymers’ chemical composition tests performed by EDS analysis. The structures of the tested geopolymers can be categorised as poly(sialate-siloxo) and poly(sialate-disiloxo) based on the Si to Al ratio [49]. The increase in the Si to Al ratio contributes to the creation of a three-dimensional polymer matrix called poly(sialate-siloxo) and poly(sialate-disiloxo) [49]. The EDS analysis shows that the Si to Al ratio was 1.77, 1.95, 2.35, and 2.64 when WG content was 0%, 10%, 20%, and 30%, respectively. According to Chindaprasirt et al. [50], the Si to Al ratio suitable for mechanical properties development should be within the range of 3.5 to 4.0. The molar ratio SiO2/Al2O3 reported in [46] was between 2.5 and 5.0. According to [51], the molar ratio SiO2/Al2O3 most favourable for the strength development in the tested geopolymers was between 3.4 and 3.8. In the present investigation, the determined Si to Al ratios were significantly lower than those obtained by the cited authors. However, as stated in [49,50,51], the optimum mechanical performance for WG content below 30% has been achieved.

Figure 3.

EDS analysis of geopolymers containing various amounts of waste glass.

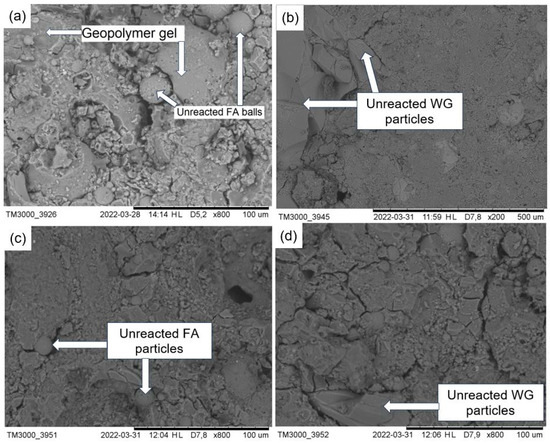

An SEM analysis of the hardened geopolymer pastes was conducted to study the microstructures of the geopolymers containing various amounts of WG. The micrographs of geopolymer specimens containing various amounts of WG are presented in Figure 4. There are many spherical particles—also known as unreacted FA balls (Figure 4a). Unreacted WG particles with smooth surfaces and non-regular, sharp edges are present in all specimens containing WG (Figure 4b–d). The number of unreacted FA particles diminishes with growing WG content, resulting from more reactive SiO2 presence.

Figure 4.

SEM micrographs of geopolymer paste specimens containing various amounts of WG: (a) 0% WG; (b) 10% WG; (c) 20% WG; (d) 30% WG.

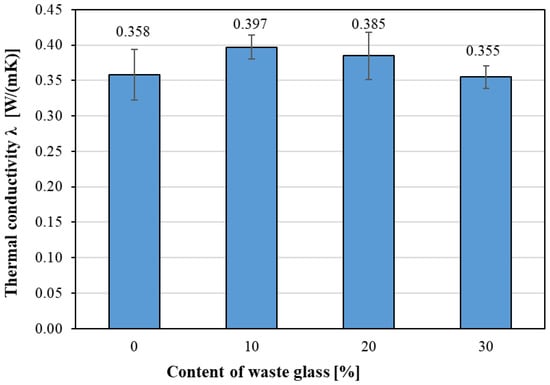

3.3. Thermal Conductivity

Figure 5 presents the average values of the thermal conductivity λ of the tested geopolymers. The determined λ values were close to each other. A slight increase in thermal conductivity with increasing WG content was observed, but only for 10% and 20% WG content. For 30% WG content, the λ value was slightly lower than that for the geopolymer without WG. While bulk density measurements show minimal variation, the microstructural changes induced by waste glass addition may affect the pore size distribution and connectivity, influencing thermal properties independently of bulk density. The thermal conductivity of the reference cement mortar RCM was λ = 1.77 ± 0.02 W/m⋅K (Table 2). All tested geopolymers have demonstrated a λ value that is lower by more than 80%; they show good insulation properties. However, the optimal WG content for thermal insulation appears to be 0% or 30%, rather than the intermediate concentrations. Table 2 presents the test results of the thermal properties and density of the cement mortar RMC after 28 days of curing.

Figure 5.

The average values of thermal conductivity of the tested geopolymers.

Table 2.

Density and thermal parameters of cement mortar RMC.

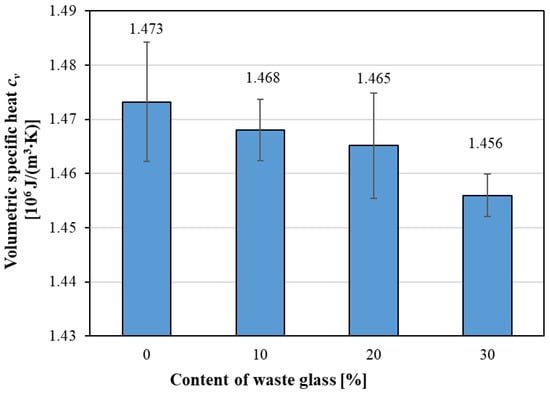

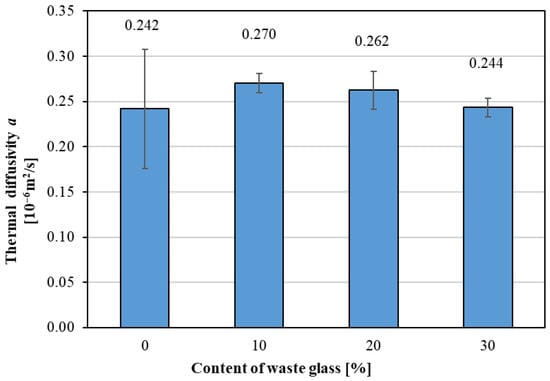

Figure 6 presents the average values of volumetric specific heat cv. The differences in cv values for the particular specimens were only slight. However, compared to the reference mortar RCM, for which the cv value is 1.75 ± 0.04 MJ/m3·K (Table 2), the good insulating ability of all tested geopolymers has been confirmed. The good insulating ability was also confirmed by testing the thermal diffusivity a, presented in Figure 7. The character of changes with varying quantities of WG is similar to that of cv. The RMC mortar’s average value was 1.02 ± 0.02 × 10−6 m2/s (Table 2).

Figure 6.

The average values of volumetric specific heat of the tested geopolymers.

Figure 7.

The average values of thermal diffusivity of the tested geopolymers.

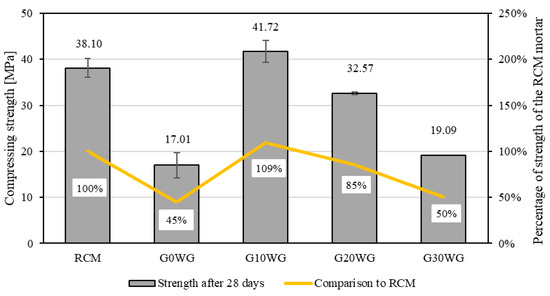

3.4. Mechanical Performance of Geopolymers

The compressive strength determination results for geopolymers after 28 days of curing are presented in Figure 8. The result for the reference mortar RCM is also provided for comparative purposes. The highest compressive strength was demonstrated by G10WG specimens, containing 10% of the waste broken glass. The G10WG geopolymer’s strength was 9% higher than the RCM. The compressive strength of G20WG geopolymer with 20% WG content was 32.57 MPa, which is 85% of the value for the RCM. However, the obtained strength is still above the minimum standard value for the cements of the strength class 32.5 (fc, min = 32.5 MPa) according to the European Standard EN 197-1 [45]. The compressive strength of GW0WG and GW30WG was 45% and 50% of the value for the RCM, respectively.

Figure 8.

Compressive strength of geopolymers and reference mortar RCM after 28 days of curing.

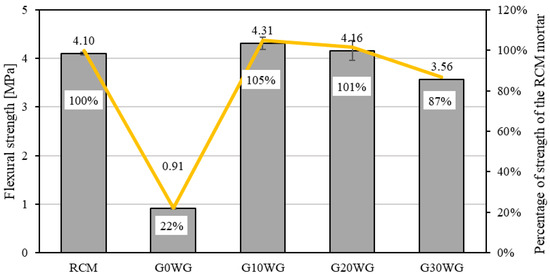

Figure 9 presents the results of geopolymers’ flexural strength testing compared to the reference mortar RCM.

Figure 9.

Flexural strength of geopolymers and reference mortar RCM after 28 days of curing.

The highest flexural strength was demonstrated by geopolymers containing 10% and 20% waste glass (G10WG and G20WG). Their strength was 105% and 101% RCM, respectively. The G30WG geopolymer, containing 30% WG, had 87% of the RCM’s flexural strength, which is still a good result. The broken glass waste improved the flexural strength of the geopolymers because of the grain’s shape and sharp and non-regular edges.

4. Conclusions

The impact of using waste broken glass as a partial substitute for fly ashes on the geopolymer’s physical characteristics was investigated in the presented study. The aim was to analyse its usefulness for geopolymers production. The following conclusions can be formulated based on the tests performed.

- The addition of waste glass can improve the mechanical performance of the geopolymer. It is possible to achieve maximum compressive strength if the waste glass content is no higher than 20%.

- It is possible to produce geopolymer containing waste glass as a partial replacement for fly ash with compressive strength similar to the cement mortar containing class 32.5 Portland cement.

- The addition of waste glass significantly improves the flexural strength of the geopolymers, which is a consequence of the physical properties of the glass and the non-regular shape of its grains.

- The higher content of the reactive silicon oxide and aluminium oxide produced as a result of adding glass waste intensifies polycondensation, improving the mechanical performance.

- All tested geopolymers have demonstrated good insulating ability compared to the cement mortar. The results of thermal conductivity tests on the geopolymers indicate that adding 10% glass waste leads to a slight increase in λ (from 0.358 to 0.397 W/mK), which can be attributed to the higher thermal conductivity of glass particles compared to the geopolymer matrix. At higher waste glass content (20% and 30%), λ values decrease, probably due to changes in the microstructure of geopolymers associated with the distribution of pores in the composite.

- Utilising the waste glass is economical and environmentally friendly as it leads to diminished energy consumption, lower grinding and sorting costs, and reduced use of natural raw materials.

Author Contributions

Conceptualization, K.C.; methodology, K.C., J.S. and E.H.; formal analysis, K.C., E.H. and J.S.; investigation, K.C. and J.S.; supervision, E.H.; writing—original draft preparation E.H. and J.S.; writing—review and editing, E.H., J.S. and K.C. All authors have read and agreed to the published version of the manuscript.

Funding

Financially supported by Minister of Science under the “Regional Initiative of Excellence” (RID) programme.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All additional data are available after personal communication with the authors.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Andrew, R.M. Global CO2 emissions from cement production, 1928–2018. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef]

- Freire, A.l.; José, H.J.; Moreira, R.F.P.M. Potential applications for geopolymers in carbon capture and storage. Int. J. Greenh. Gas Control 2022, 118, 103687. [Google Scholar] [CrossRef]

- Khandelwal, M.; Ranjith, P.G.; Pan, Z.; Sanjayan, J.G. Effect of strain rate on strength properties of low-calcium fly-ash-based geopolymer mortar under dry condition. Arab. J. Geosci. 2013, 6, 2383–2389. [Google Scholar] [CrossRef]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; Hamdan, S.; Deventer, J.S.J.V. Microstructural changes in alkali activated fly ash/slag geopolymers with sulfate exposure. Mater. Struct. 2013, 46, 361–373. [Google Scholar] [CrossRef]

- Lee, N.K.; Koh, K.T.; An, G.H.; Ryu, G.S. Influence of binder composition on the gel structure in alkali activated fly ash/slag pastes exposed to elevated temperatures. Ceram. Int. 2017, 43, 2471–2480. [Google Scholar] [CrossRef]

- Ryu, G.S.; Lee, Y.B.; Koh, K.T.; Chung, Y.S. The mechanical properties of fly ash-based geopolymer concrete with alkaline activators. Construct. Build. Mater. 2013, 47, 409–418. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Effect of GGBFS on setting, workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Construct. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef]

- Provis, J.L. Geopolymers and other alkali activated materials: Why, how, and what? Mater. Struct. 2014, 47, 11–25. [Google Scholar] [CrossRef]

- Brough, A.R.; Atkinson, A. Sodium silicate-based, alkali-activated slag mortars: Part I. Strength, hydration and microstructure. Cement Concr. Res. 2002, 32, 865–879. [Google Scholar] [CrossRef]

- Li, C.; Sun, H.; Li, L. A review: The comparison between alkali-activated slag (Si + Ca) and metakaolin (Si + Al) cements. Cem. Concr. Res. 2010, 40, 1341–1349. [Google Scholar] [CrossRef]

- Rashad, A.M. Properties of alkali-activated fly ash concrete blended with slag. Iran. J. Mater. Sci. Eng. 2013, 10, 57–64. [Google Scholar]

- Aydın, S. A ternary optimisation of mineral additives of alkali activated cement mortars. Construct. Build. Mater. 2013, 43, 131–138. [Google Scholar] [CrossRef]

- Bernal, S.A.; Provis, J.L.; Fernandez-Jimenez, A.; Krivenko, P.V.; Kavalerova, E.; Palacios, M.; Shi, C. Binder chemistry—High-calcium alkali-activated materials. In Alkali Activated Materials: State-of-the-Art Report, RILEM TC 224-AAM; Provis, J.L., Deventer, J.S.J.V., Eds.; Springer: Dordrecht, The Netherlands, 2014; pp. 59–91. [Google Scholar]

- U.S.E.P. Advancing Sustainable Materials Management: 2013 Fact Sheet. 2015. Available online: https://www.epa.gov/sites/default/files/2015-09/documents/2013_advncng_smm_fs.pdf (accessed on 1 May 2025).

- Eurostat Statistics Explained. Recycling—Secondary Material Price Indicator. [Online]. Available online: http://ec.europa.eu/eurostat/statistics-explained/index.php/Recycling_%E2%80%93_secondary_material_price_indicator (accessed on 12 January 2024).

- Qin, B.; Lin, M.; Xu, Z.; Ruan, J. Preparing ultra-thin glass from waste glass containing impurities of household waste by the combined technology of in-situ deposition and vacuum pyrolysis. Resour. Conserv. Recycl. 2022, 185, 106451. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency (EPA). National Overview: Facts and Figures on Materials. Wastes and Recycling. 2021. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/national-overview-facts-and-figures-materials (accessed on 1 May 2025).

- Larsen, A.W.; Merrild, H.; Christensen, T.H. Recycling of glass: Accounting of greenhouse gases and global warming contributions. Waste Manag. Res. 2009, 27, 754–762. [Google Scholar] [CrossRef]

- Yao, Z.; Qin, B.; Huang, Z.; Ruan, J.; Xu, Z. Green combined resource recycling system for the recycling of waste glass. ACS Sustain. Chem. Eng. 2021, 9, 7361–7368. [Google Scholar] [CrossRef]

- Sooš, L.; Matúš, M.; Pokusovă, M.; Čăcko, V.; Băbics, J. The recycling of waste laminated glass through decomposition technologies. Recycling 2021, 6, 26. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Siddique, R.; Mendis, P.; Zhuge, Y.; Wong, H.S.; Lokuge, W.; Aravinthan, T.; Schubel, P. Recycling of landfill wastes (tyres, plastics and glass) in construction—A review on global waste generation, performance, application and future opportunities. In Resources, Conservation and Recycling; Elsevier B.V.: Amsterdam, The Netherlands, 2021; Volume 173. [Google Scholar] [CrossRef]

- Delbari, S.A.; Hof, L.A. Glass waste circular economy—Advancing to high-value glass sheets recovery using industry 4.0 and 5.0 technologies. J. Clean. Prod. 2024, 462, 142629. [Google Scholar] [CrossRef]

- Huang, Y.; Chen, Z.; Liu, Y.; Lu, J.-X.; Bian, Z.; Yio, M.; Cheeseman, C.; Wang, F.; Sun Poon, C. Recycling of waste glass and incinerated sewage sludge ash in glass- ceramics. Waste Manag. 2024, 174, 229–239. [Google Scholar] [CrossRef] [PubMed]

- Ogundairo, T.O.; Adegoke, D.D.; Akinwumi, I.I.; Olofinnade, O.M. Sustainable use of recycled waste glass as an alternative material for building construction—A review. IOP Conf. Ser. Mater. Sci. Eng. 2019, 640, 012073. [Google Scholar] [CrossRef]

- Yuan, X.; Wang, J.; Song, Q.; Xu, Z. Integrated assessment of economic benefits and environmental impact in waste glass closed-loop recycling for promoting glass circularity. J. Clean. Prod. 2024, 444, 141155. [Google Scholar] [CrossRef]

- Svenson, M.N.; Thirion, L.M.; Youngman, R.E.; Mauro, J.C.; Rzoska, S.J.; Bockowski, M.; Smedskjaer, M.M. Pressure-induced changes in interdiffusivity and compressive stress in chemically strengthened glass. ACS Appl. Mater. 2014, 6, 10436–10444. [Google Scholar] [CrossRef]

- Berneschi, S.; Righini, G.C.; Pelli, S. Towards a glass new world: The role of ion- exchange in modern technology. Appl. Sci. 2021, 11, 4610. [Google Scholar] [CrossRef]

- Deng, Z.; Yang, Z.; Pan, X. Synergetic effects of recycled crumb rubber and glass cullet on the engineering properties of geopolymer mortar. Cement Concr. Comp. 2023, 137, 104907. [Google Scholar] [CrossRef]

- Saccani, A.; Manzi, S.; Lancellotti, I.; Barbieri, L. Manufacturing and durability of alkali activated mortars containing different types of glass waste as aggregates valorisation. Construct. Build. Mater. 2020, 237, 117733. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Abd Ellatief, M.; Heneigel, A.M.; Abd Elrahman, M. Characteristics of eco-friendly ultra-high-performance geopolymer concrete incorporating waste materials. Ceram. Int. 2022, 48, 19662–19674. [Google Scholar] [CrossRef]

- Khan, M.N.N.; Sarker, P.K. Effect of waste glass fine aggregate on the strength, durability and high temperature resistance of alkali-activated fly ash and GGBFS blended mortar. Construct. Build. Mater. 2020, 263, 120177. [Google Scholar] [CrossRef]

- Hou, S.; Duan, Z.; Singh, Z.; Ma, A. Improvement on the properties of waste glass mortar with nanomaterials. Construct. Build. Mater. 2020, 254, 118973. [Google Scholar] [CrossRef]

- Lu, J.X.; Poon, C.S. Use of waste glass in alkali activated cement mortar. Construct. Build. Mater. 2018, 160, 399–407. [Google Scholar] [CrossRef]

- Taher, S.M.S.; Saadullah, S.T.; Haido, J.H.; Tayeh, B.A. Behavior of geopolymer concrete deep beams containing waste aggregate of glass and limestone as a partial replacement of natural sand. Case Stud. Constr. Mater. 2021, 15, e00744. [Google Scholar] [CrossRef]

- Xiao, R.; Polaczyk, P.; Zhang, M.; Jiang, X.; Zhang, Y.; Huang, B.; Hu, W. Evaluation of glass powder-based geopolymer stabilized road bases containing recycled waste glass aggregate. Transport. Res. Rec. 2020, 2674, 22–32. [Google Scholar] [CrossRef]

- Mejía de Gutiérrez, M.; Villaquirán-Caicedo, M.A.; Guzmán-Aponte, L.A. Alkali- activated metakaolin mortars using glass waste as fine aggregate: Mechanical and photocatalytic properties. Construct. Build. Mater. 2020, 235, 117510. [Google Scholar] [CrossRef]

- Lu, J.X.; Shen, P.; Zheng, H.; Zhan, B.; Ali, H.A.; He, P.; Poon, S.C. Synergetic recycling of waste glass and recycled aggregates in cement mortars: Physical, durability and microstructure performance. Cement Concr. Compos. 2020, 113, 103632. [Google Scholar] [CrossRef]

- Varma, D.N.; Singh, S.P. A Review on Waste Glass-based Geopolymer Composites as a Sustainable Binder. Silicon 2023, 15, 7685–7703. [Google Scholar] [CrossRef]

- Gao, X.; Yao, X.; Xie, R.; Li, X.; Cheng, J.; Yang, T. Performance of fly ash-based geopolymer mortars with waste cathode ray tubes glass fine aggregate: A comparative study with cement mortars. Construct. Build. Mater. 2022, 344, 128243. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Ngo, T.; Kashani, A. GlassWaste versus Sand as Aggregates: The Characteristics of the Evolving Geopolymer Binders. J. Clean. Prod. 2018, 193, 593–603. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Heniegal, A.M.; Abdellatief, M.; Tayeh, B.A.; Elrahman, M.A. Properties of Ultra-High Performance Geopolymer Concrete Incorporating Recycled Waste Glass. Case Stud. Constr. Mater. 2022, 17, e01393. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Lao-un, J.; Zaetang, Y.; Wongkvanklom, A.; Phoo-ngernkham, T.; Wongsa, A.; Sata, V. Thermal Insulating and Fire Resistance Performances of Geopolymer Mortar Containing Auto GlassWaste as Fine Aggregate. J. Build. Eng. 2022, 60, 105178. [Google Scholar] [CrossRef]

- Kuri, J.C.; Hosan, A.; Uddin, F.; Shaikh, A.; Biswas, W.K. The Effect of Recycled Waste Glass as a Coarse Aggregate on the Properties of Portland Cement Concrete and Geopolymer Concrete. Buildings 2023, 13, 586. [Google Scholar] [CrossRef]

- Srivastava, V.; Gautam, S.P.; Agarwal, V.C.; Mehta, P.K. GlassWastes as Coarse Aggregate in Concrete. J. Environ. Nanotechnol. 2014, 3, 2319–5541. [Google Scholar]

- BS EN 197-1:2011. Cement—Part 1: Composition, Specifications and Conformity. Available online: https://www.en-standard.eu/bs-en-197-1-2011-cement-composition-specifications-and-conformity-criteria-for-common-cements/ (accessed on 8 May 2025).

- BS EN 196-1:2016; Methods of Testing Cement. Determination of Strength. British Standards Institution (BSI): London, UK. [CrossRef]

- Gołek, Ł.; Szudek, W.; Łój, G. Utilization of ground waste glass cullet in the industrial production of precast concrete elements. Cem. Lime Concr. 2021, 26, 118–133. [Google Scholar] [CrossRef]

- Ziejewska, C.; Grela, A.; Hebda, M. Influence of Waste Glass Particle Size on the Physico-Mechanical Properties and Porosity of Foamed Geopolymer Composites Based on Coal Fly Ash. Materials 2023, 16, 2044. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Xiao, R.; Ma, Y.; Zhang, M.; Bai, Y.; Huang, B. Influence of waste glass powder on the physico-mechanical properties and microstructures of fly ash-based geopolymer paste after exposure to high temperatures. Construct. Build. Mater. 2020, 262, 120579. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rattanasak, U.; Vongvoradit, P.; Jenjirapanya, S. Thermal treatment and utilization of Al-rich waste in high calcium fly ash geopolymeric materials. Int. J. Miner. Metal. Mater. 2012, 19, 872–878. [Google Scholar] [CrossRef]

- De Silva, P.; Sagoe-Crenstil, K.; Sirivivatnanon, V. Kinetics of geopolymerization: Role of Al2O3 and SiO2. Cem. Concr. Res. 2007, 37, 512–518. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).