Analysis of Weak Links in the Mechanized Mining of Underground Metal Mines: Insights from Machine Learning and SHAP Explainability Models

Abstract

1. Introduction

2. Materials

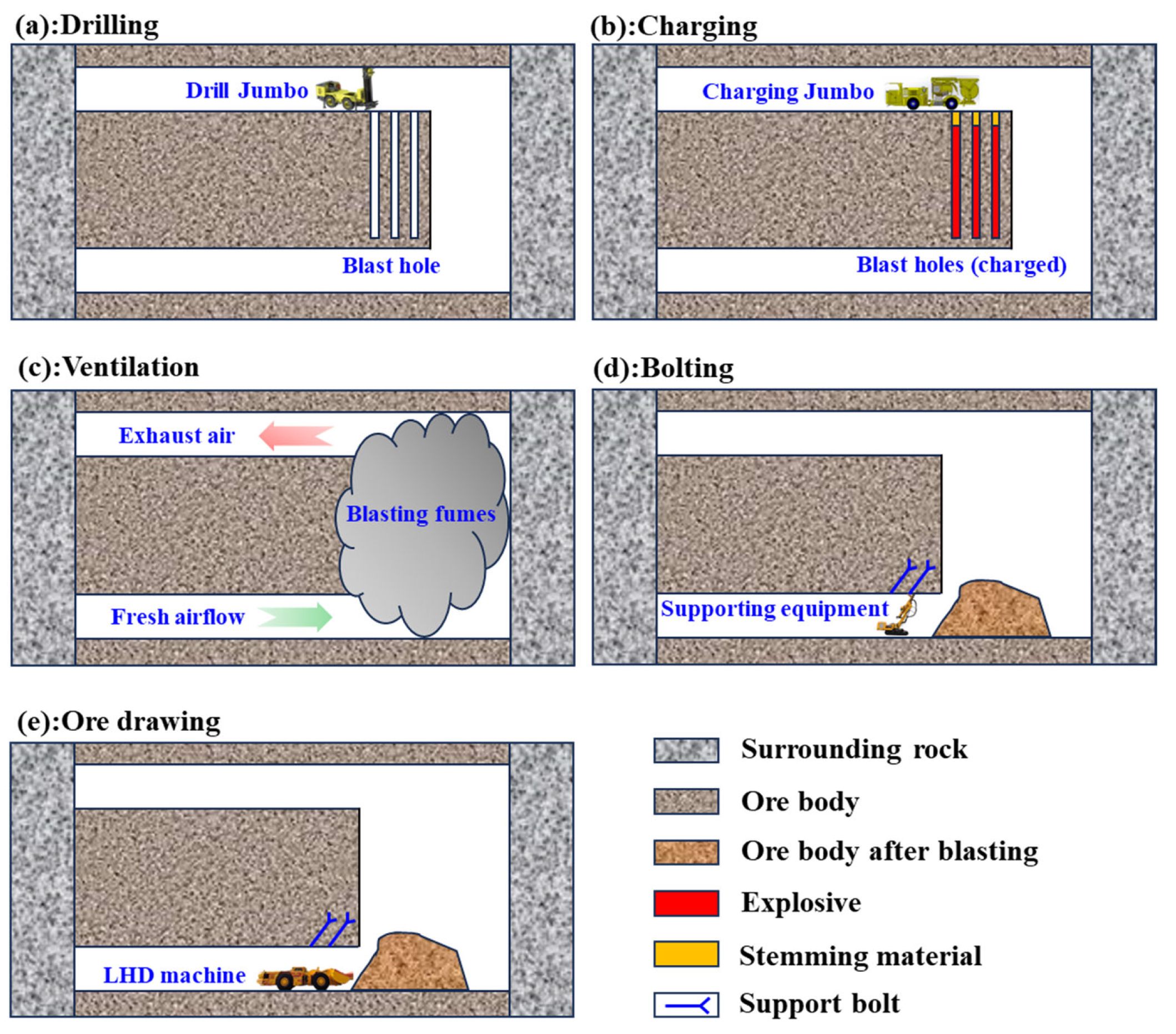

2.1. Mechanized Mining Processes

- (1)

- During the drilling stage, workers are required to operate the drilling rig to drill blast holes in accordance with the mining design. Given that the blast hole depth in medium and deep hole mining typically exceeds 15 m, the primary factor influencing mining efficiency at this stage is the drilling efficiency (DE, m/d).

- (2)

- In the charging stage, engineers utilize the charging jumbo to charge and detonate explosives within the blast holes. The charging and blasting efficiency (CBE, h/d) serves as the main influencing factor during this phase.

- (3)

- Following the blasting process, a significant amount of fumes is generated in the blasting area, necessitating ventilation for dispersion. In mines with an inefficient ventilation system, the ventilation time (VT, h/d) may exceed 12 h, thereby substantially impacting production efficiency.

- (4)

- In the support stage, due to rock mass damage caused by blasting, support operations become critical. If the surrounding rock is unstable, additional time will be allocated for support work. The support time (ST, h/d) constitutes the primary influencing factor during this stage.

- (5)

- In the ore drawing stage, loaders are employed to shovel, transport, and unload the blasted ore. The ore removal efficiency (ORE, t/d) represents the main factor affecting mining efficiency at this stage.

- (6)

- It is worth noting that in mechanized mines, the equipment maintenance time (EMT, d) of mining equipment cannot be overlooked, as it also plays a significant role in influencing production efficiency [28].

2.2. Dataset Construction

3. Methodology

3.1. Extreme Gradient Boosting (XGBoost)

3.2. Marine Predators Algorithm (MPA)

3.3. Prediction Evaluation Indicators

3.4. Sensitivity Analysis

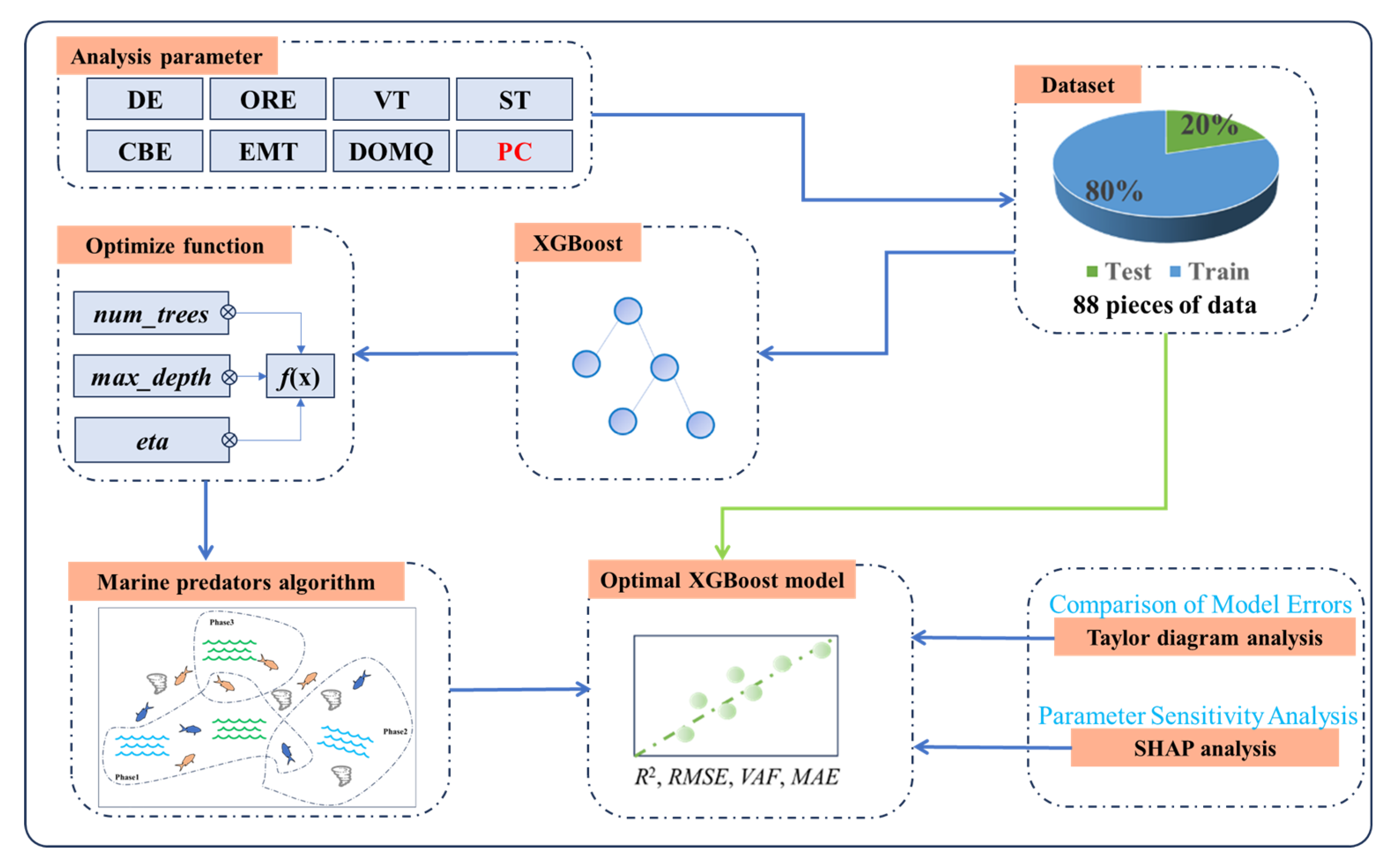

3.5. Analysis Process

- (1)

- Collect data related to mining influencing factors and construct a dataset. Subsequently, randomly divide this dataset into a training subset (comprising 80% of the dataset) and a testing subset (constituting the remaining 20%). This random partitioning ensures that the model can generalize effectively to unseen data during the training phase.

- (2)

- Define an objective function aimed at optimizing the XGBoost parameters, focusing on num_trees, max_depth, and eta. In this study, the cross-validation score calculated across multiple optimization iterations serves as the evaluation metric for the objective function.

- (3)

- Employ the MPA to iteratively optimize parameter selection for XGBoost. During each iteration, evaluate the performance of each parameter set. Once the stopping criteria are satisfied, output the optimal parameters. Through this process, the best-fitting parameters for XGBoost are determined, enabling the construction of the coupled MPA–XGBoost model. This model is then utilized to establish a regression analysis framework linking PC with other mining-related influencing factors.

- (4)

- The performance of the MPA–XGBoost model is analyzed and compared with that of other machine learning models using the Taylor diagram methodology. Simultaneously, SHAP modeling is utilized to further elucidate the relationships and significance of various mining influencing factors on PC.

4. Results

4.1. Parameter Optimization Results

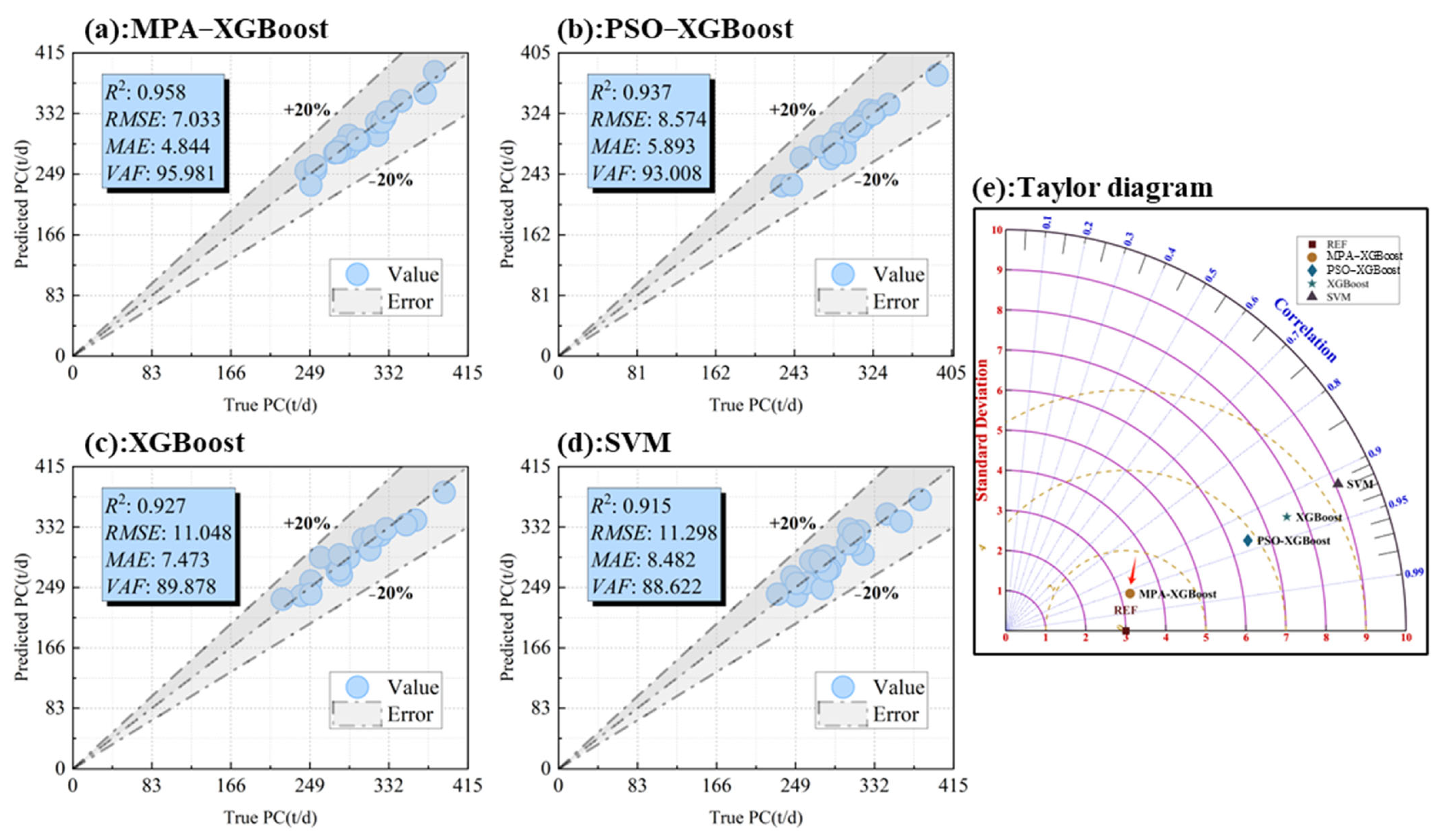

4.2. Comparison of the Accuracy of Regression Analysis Models

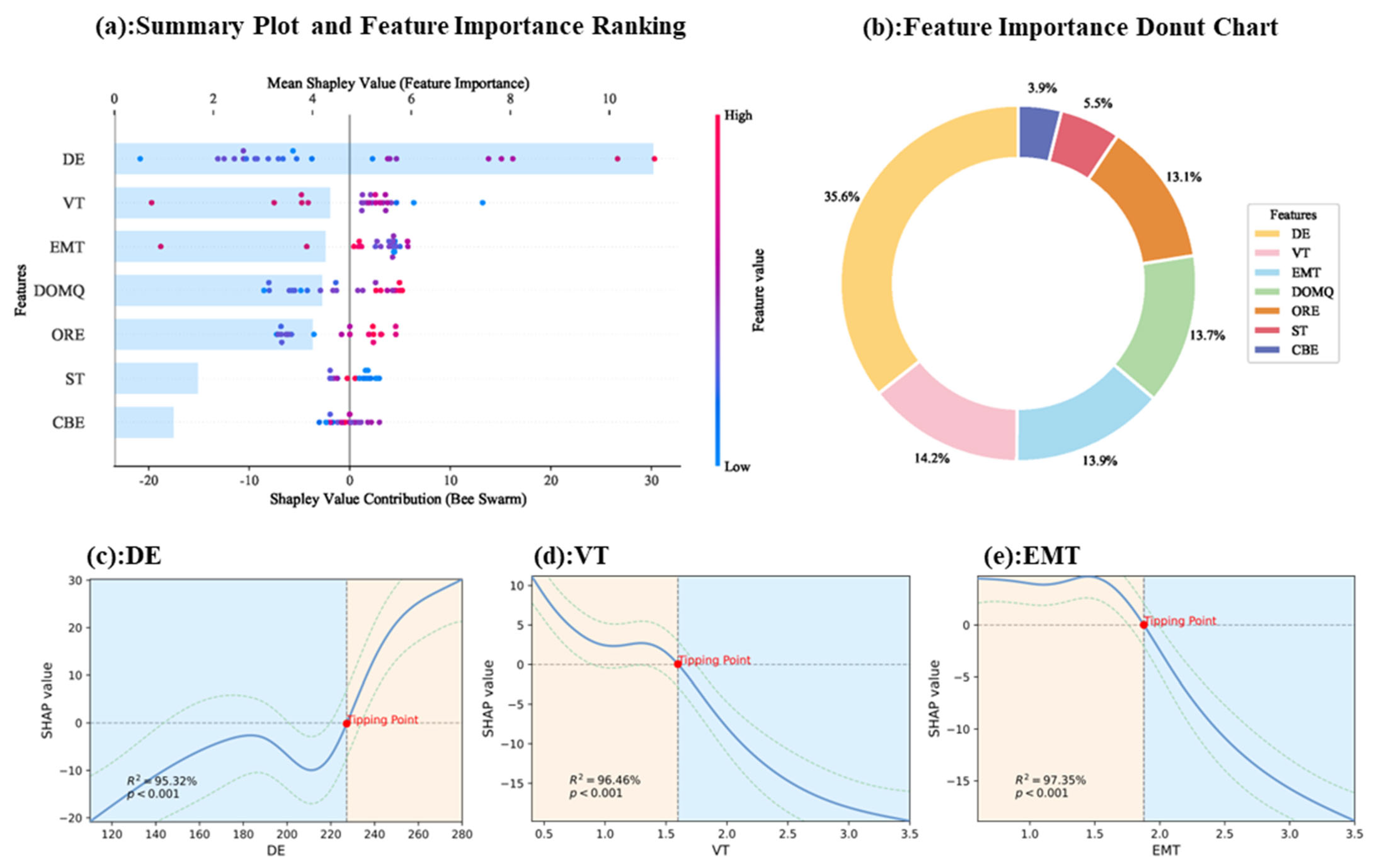

4.3. SHAP Analysis Results

5. Discussions

6. Conclusions

- (1)

- The XGBoost algorithm was employed to establish a regression relationship between multiple factors and the production capacity of the stope (PC), with parameters optimized using the MPA. The results demonstrated that the MPA achieved an optimal performance with a swarm size of 60. Under these conditions, the MPA–XGBoost coupling model exhibited an exceptional predictive performance for PC, achieving an R2 value of 0.958, VAF of 95.981%, MAE of 4.844, and RMSE of 7.033. Compared with traditional XGBoost models, PSO–XGBoost models, and common machine learning techniques such as SVM, this model showed significant advantages in regression accuracy, dataset interpretability, and capturing nonlinear relationships, providing a more precise representation of the relationship between PC and various influencing factors.

- (2)

- Using the SHAP method, the importance and contribution degree of different stope mining factors to PC were quantified. DE had the most significant overall impact on PC, contributing positively by 35.6%. VT, EMT, DOMQ, and ORE had similar contributions, accounting for 14.2%, 13.9%, 13.7%, and 13.1%, respectively. Among these, VT and EMT exerted negative impacts, while DOMQ and ORE had positive effects. ST and CBE had relatively smaller contributions, at 3.9% and 5.5%, respectively.

- (3)

- By constructing SHAP dependency plots, the influence patterns of key factors on PC were clearly illustrated. As DE increased, PC significantly improved, particularly when DE exceeded 225, where the effect became more pronounced. For VT and EMT, PC decreased gradually below a specific threshold (the tipping point) but dropped sharply above it. This indicates that increasing DE and reducing VT and EMT can significantly enhance stope PC.

- (4)

- This study effectively identified the weak links in the mechanized mining system of underground metal mines through advanced modeling, quantified the impact of various factors on mining efficiency, and provided a scientific basis for optimizing mining processes. Mining production managers can leverage these findings to improve specific production processes, such as enhancing drilling efficiency, optimizing ventilation systems, and refining equipment maintenance procedures, thereby boosting overall mine productivity and ensuring safe operations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Boloz, L.; Bialy, W. Automation and Robotization of Underground Mining in Poland. Appl. Sci. 2020, 10, 7221. [Google Scholar] [CrossRef]

- Eddies, R.; Wood, R.; Haynes, A.; Warburton, D.; Pressdee, C. Screening ground risk in underground works as part of a predictive modelling approach. Proc. Inst. Civ. Eng. Civ. Eng. 2020, 173, 49–57. [Google Scholar] [CrossRef]

- Fang, J.; Fan, C.; Wang, F.R.; Bai, D.X. Augmented Reality Platform for the Unmanned Mining Process in Underground Mines. Min. Metall. Explor. 2022, 39, 385–395. [Google Scholar] [CrossRef]

- Gao, R.G.; Zhou, K.P.; Yang, C.; Zhu, K. An Underground Mine Risk Identification Model and Safety Management Method Based on Explanation Graph-Probabilistic Multi-Plan Analysis (EG-PMPA). IEEE Access 2020, 8, 223214–223233. [Google Scholar] [CrossRef]

- Ghorbani, Y.; Nwaila, G.T.; Zhang, S.E.; Bourdeau, J.E.; Cánovas, M.; Arzua, J.; Nikadat, N. Moving towards deep underground mineral resources: Drivers, challenges and potential solutions. Resour. Policy 2023, 80, 103222. [Google Scholar] [CrossRef]

- Gligoric, Z.; Beljic, C.; Gluscevic, B.; Cvijovic, C. Underground Lead-Zinc Mine Production Planning Using Fuzzy Stochastic Inventory Policy. Arch. Min. Sci. 2015, 60, 73–92. [Google Scholar] [CrossRef]

- Hou, J.; Li, G.Q.; Chen, L.Y.; Wang, H.; Hu, N.L. Optimization of Truck-Loader Matching Based on a Simulation Method for Underground Mines. Sustainability 2023, 15, 216. [Google Scholar] [CrossRef]

- Iphar, M.; Alpay, S. A mobile application based on multi-criteria decision-making methods for underground mining method selection. Int. J. Min. Reclam. Environ. 2019, 33, 480–504. [Google Scholar] [CrossRef]

- Laptev, V.V.; Gurin, K.P. Automated Planning of Underground Mining Operations with Regard to Geological and Geotechnical Constraints. J. Min. Sci. 2023, 59, 490–496. [Google Scholar] [CrossRef]

- Lu, G.Z.; Wang, R.; Li, Q.S.; Hu, F. Three-Dimensional Dynamic Visualization Simulation of Underground Mining Engineering considering Chaos Optimization of Symmetric Varieties. Mob. Inf. Syst. 2022, 2022, 2916971. [Google Scholar] [CrossRef]

- Onifade, M.; Said, K.O.; Shivute, A.P. Safe mining operations through technological advancement. Process Saf. Environ. Prot. 2023, 175, 251–258. [Google Scholar] [CrossRef]

- Villalba Matamoros, M.E.; Kumral, M. A value adding approach to hard-rock underground mining operations: Balancing orebody orientation and mining direction through meta-heuristic optimization. J. Cent. South Univ. 2019, 26, 3126–3139. [Google Scholar] [CrossRef]

- Vogt, D. A review of rock cutting for underground mining: Past, present, and future. J. S. Afr. Inst. Min. Metall. 2016, 116, 1011–1026. [Google Scholar] [CrossRef]

- Vogt, D.; Hattingh, T. The importance of people in the process of converting a narrow tabular hard-rock mine to mechanization. J. S. Afr. Inst. Min. Metall. 2016, 116, 265–274. [Google Scholar] [CrossRef]

- Yang, C.T.; Zhang, R.P.; Liu, D.W.; Tang, Y.; Huang, R.D.; Qiu, W.C. Evaluation of Excavation Ergonomics of Drill and Blast Method Based on Game Theory G2-EW-TOPSIS Model. Appl. Sci. 2023, 13, 7205. [Google Scholar] [CrossRef]

- Wang, S.F.; Wu, Y.M.; Shi, X.L. Non-explosive mechanized and intelligent mining/heading in underground mine. Trans. Nonferrous Met. Soc. China 2024, 34, 265–282. [Google Scholar] [CrossRef]

- Nehring, M.; Topal, E.; Little, J. A new mathematical programming model for production schedule optimization in underground mining operations. J. S. Afr. Inst. Min. Metall. 2010, 110, 437–446. [Google Scholar]

- Sotoudeh, F.; Nehring, M.; Kizil, M.; Knights, P.; Mousavi, A. Production scheduling optimisation for sublevel stoping mines using mathematical programming: A review of literature and future directions. Resour. Policy 2020, 68, 101809. [Google Scholar] [CrossRef]

- Appianing, E.J.A.; Ben-Awuah, E.; Pourrahimian, Y. Life-of-mine optimization for integrated open stope development and production scheduling using a mixed-integer linear programming framework. Min. Technol. Trans. Inst. Min. Metall. 2023, 132, 106–120. [Google Scholar] [CrossRef]

- Huang, S.W.; Li, G.Q.; Ben-Awuah, E.; Afum, B.O.; Hu, N.L. A Stochastic Mixed Integer Programming Framework for Underground Mining Production Scheduling Optimization Considering Grade Uncertainty. IEEE Access 2020, 8, 24495–24505. [Google Scholar] [CrossRef]

- Liu, D.; Li, G.Q.; Hu, N.L.; Xiu, G.L.; Ma, Z.Y. Optimization of the cut-off grade for underground polymetallic mines. Gospod. Surowcami Miner. Miner. Resour. Manag. 2019, 35, 25–42. [Google Scholar] [CrossRef]

- Ali, D.; Frimpong, S. Artificial intelligence, machine learning and process automation: Existing knowledge frontier and way forward for mining sector. Artif. Intell. Rev. 2020, 53, 6025–6042. [Google Scholar] [CrossRef]

- Chimunhu, P.; Topal, E.; Ajak, A.D.; Asad, W. A review of machine learning applications for underground mine planning and scheduling. Resour. Policy 2022, 77, 102693. [Google Scholar] [CrossRef]

- Patil, S.D.; Mitra, A.; Katarikonda, K.T.; Wansink, J.D. Predictive asset availability optimization for underground trucks and loaders in the mining industry. Opsearch 2021, 58, 751–772. [Google Scholar] [CrossRef]

- Taboada, J.; Matías, J.M.; Araújo, A.; Ordóñez, C. Assessing the viability of underground slate mining by combining an expert system with a GIS. Eng. Geol. 2006, 87, 75–84. [Google Scholar] [CrossRef]

- Witulska, J.; Stefaniak, P.; Jachnik, B.; Skoczylas, A.; Sliwinski, P.; Dudzik, M. Recognition of LHD Position and Maneuvers in Underground Mining Excavations-Identification and Parametrization of Turns. Appl. Sci. 2021, 11, 6075. [Google Scholar] [CrossRef]

- Gao, F.; Li, X.; Xiong, X.; Lu, H.C.; Luo, Z.W. Refined Design and Optimization of Underground Medium and Long Hole Blasting Parameters-A Case Study of the Gaofeng Mine. Mathematics 2023, 11, 1612. [Google Scholar] [CrossRef]

- Tu, S.Y.; Jia, M.T.; Wang, L.G.; Feng, S.Z.; Huang, S. A Dynamic Scheduling Model for Underground Metal Mines under Equipment Failure Conditions. Sustainability 2023, 15, 7306. [Google Scholar] [CrossRef]

- Yu, Z.; Li, C.Q.; Zhou, J. Tunnel Boring Machine Performance Prediction Using Supervised Learning Method and Swarm Intelligence Algorithm. Mathematics 2023, 11, 4237. [Google Scholar] [CrossRef]

- Zhou, J.; Qiu, Y.G.; Zhu, S.L.; Armaghani, D.J.; Khandelwal, M.; Mohamad, E.T. Estimation of the TBM advance rate under hard rock conditions using XGBoost and Bayesian optimization. Undergr. Space 2021, 6, 506–515. [Google Scholar] [CrossRef]

- Hong, Z.X.; Tao, M.; Liu, L.L.; Zhao, M.S.; Wu, C.Q. An intelligent approach for predicting overbreak in underground blasting operation based on an optimized XGBoost model. Eng. Appl. Artif. Intell. 2023, 126, 107097. [Google Scholar] [CrossRef]

- Al-Betar, M.A.; Awadallah, M.A.; Makhadmeh, S.N.; Alyasseri, Z.A.A.; Al-Naymat, G.; Mirjalili, S. Marine Predators Algorithm: A Review. Arch. Comput. Methods Eng. 2023, 30, 3405–3435. [Google Scholar] [CrossRef] [PubMed]

- Faramarzi, A.; Heidarinejad, M.; Mirjalili, S.; Gandomi, A.H. Marine Predators Algorithm: A Nature-inspired Metaheuristic. Expert Syst. Appl. 2020, 152, 113377. [Google Scholar] [CrossRef]

- Mugemanyi, S.; Qu, Z.Y.; Rugema, F.X.; Dong, Y.C.; Wang, L.; Bananeza, C.; Nshimiyimana, A.; Mutabazi, E. Marine predators algorithm: A comprehensive review. Mach. Learn. Appl. 2023, 12, 100471. [Google Scholar] [CrossRef]

- Guo, H.; Lin, L.; Wu, J.L.; Lv, Y.C.; Tong, C.S. Optimizing Driving Parameters of the Jumbo Drill Efficiently with XGBoost-DRWIACO Framework: Applied to Increase the Feed Speed. Sensors 2024, 24, 2600. [Google Scholar] [CrossRef]

- Tao, M.; Zhao, Q.Z.; Zhao, R.; Burhan, M.M. A New Method of Rockburst Prediction for Categories with Sparse Data Using Improved XGBoost Algorithm. Nat. Resour. Res. 2025, 34, 599–618. [Google Scholar] [CrossRef]

- Xu, C.; Zhou, K.P.; Xiong, X.; Gao, F.; Lu, Y. Prediction of mining induced subsidence by sparrow search algorithm with extreme gradient boosting and TOPSIS method. Acta Geotech. 2023, 18, 4993–5009. [Google Scholar] [CrossRef]

- He, Z.G.; Armaghani, D.J.; Masoumnezhad, M.; Khandelwal, M.; Zhou, J.; Murlidhar, B.R. A Combination of Expert-Based System and Advanced Decision-Tree Algorithms to Predict Air-Overpressure Resulting from Quarry Blasting. Nat. Resour. Res. 2021, 30, 1889–1903. [Google Scholar] [CrossRef]

- Zhao, Y.F.; Chen, J.H.; Yang, S.; Chen, Y. Mining Plan Optimization of Multi-Metal Underground Mine Based on Adaptive Hybrid Mutation PSO Algorithm. Mathematics 2022, 10, 2418. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, X.X.; Yuan, H.; Wu, Z.G.; Zhou, M. A Lean Scheduling Framework for Underground Mines Based on Short Interval Control. Sustainability 2023, 15, 9195. [Google Scholar] [CrossRef]

- Sari, Y.A.; Kumral, M. Clustering-based iterative approach to stope layout optimization for sublevel stoping. J. South. Afr. Inst. Min. Metall. 2021, 121, 97–106. [Google Scholar] [CrossRef]

- Fulawka, K.; Szumny, M.; Mertuszka, P. Rock Mass Preconditioning Methods in Underground Mines and Ways of Its Evaluation-State-of-the-Art. Civ. Environ. Eng. Rep. 2024, 34, 381–402. [Google Scholar] [CrossRef]

- Hou, J.; Li, G.Q.; Wang, H.; Hu, N.L. Genetic algorithm to simultaneously optimise stope sequencing and equipment dispatching in underground short-term mine planning under time uncertainty. Int. J. Min. Reclam. Environ. 2020, 34, 307–325. [Google Scholar] [CrossRef]

- Pääkkönen, P.; Horsmanheimo, S.; Pakkala, D.; Tuomimäki, L.; Backman, J. Reference architecture design and evaluation for digitalization of underground mining. Internet Things 2024, 26, 101238. [Google Scholar] [CrossRef]

- Salinas, J.P.; Araujo, J.J.M.; Teatino, M.A.C. Uncertainty in underground mining operations: A bibliometric and systematic literature review analysis. World J. Eng. 2024. [Google Scholar] [CrossRef]

| Parameters | Parameter Description | Data Range |

|---|---|---|

| num_trees | This parameter plays a crucial role in assessing the model’s predictive performance. Generally, a higher value enhances learning and data processing capabilities, resulting in more accurate predictions. However, an excessively high value may lead to the inefficient utilization of computational resources, thereby diminishing overall efficiency. | [1, 1000] |

| max_depth | This parameter, which specifies the maximum depth of the decision tree, plays a critical role in controlling overfitting. Although larger values allow the model to capture more complex patterns and improve training performance, they also increase the risk of overfitting, thereby compromising the model’s ability to generalize to new data. | [1, +∞] |

| eta | This parameter determines the step size for each iteration and plays a pivotal role in influencing algorithm performance. Setting the value too high may degrade the algorithm’s precision, while an excessively low value will significantly prolong execution time. Both scenarios can adversely affect the algorithm’s overall effectiveness, thereby highlighting the importance of carefully adjusting this parameter to achieve an optimal balance. | [0.01, 0.1] |

| Parameters | Value |

|---|---|

| num_trees | 997 |

| max_depth | 8 |

| eta | 0.0650 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.; Zhou, K.; Li, J. Analysis of Weak Links in the Mechanized Mining of Underground Metal Mines: Insights from Machine Learning and SHAP Explainability Models. Appl. Sci. 2025, 15, 7391. https://doi.org/10.3390/app15137391

Yang C, Zhou K, Li J. Analysis of Weak Links in the Mechanized Mining of Underground Metal Mines: Insights from Machine Learning and SHAP Explainability Models. Applied Sciences. 2025; 15(13):7391. https://doi.org/10.3390/app15137391

Chicago/Turabian StyleYang, Chengye, Keping Zhou, and Jielin Li. 2025. "Analysis of Weak Links in the Mechanized Mining of Underground Metal Mines: Insights from Machine Learning and SHAP Explainability Models" Applied Sciences 15, no. 13: 7391. https://doi.org/10.3390/app15137391

APA StyleYang, C., Zhou, K., & Li, J. (2025). Analysis of Weak Links in the Mechanized Mining of Underground Metal Mines: Insights from Machine Learning and SHAP Explainability Models. Applied Sciences, 15(13), 7391. https://doi.org/10.3390/app15137391