1. Introduction

In recent years, the global energy sector has continued to grow rapidly. According to the statistics of the International Renewable Energy Agency (IRENA), as of the end of 2023, the total global installed capacity of renewable energy has reached 337 million kilowatts, accounting for 30% of the total global installed power generation capacity, with a compound annual growth rate of 9.3% over the past 10 years. It is expected that the total installed capacity of the world will exceed 1.1 billion kilowatts by 2030 [

1]. However, the large-scale grid integration of new energy sources has also brought a series of technical challenges to the power system: its volatility and intermittency have led to frequent grid frequency and voltage stability problems, the increasingly severe phenomenon of low-voltage or high-voltage off-grid, and the coupling of power electronic equipment with synchronous systems has triggered broadband oscillation problems [

2,

3,

4,

5,

6]. These problems have triggered major grid accidents several times around the world. For example, a localized grid collapse triggered by a large-scale wind power off-grid in Northwest China in 2019 resulted in a power outage of several hours [

7], and wind and photovoltaic (PV) power crises were exacerbated by a large-scale off-grid due to insufficient low-voltage ride-through capability during a winter storm in Texas, USA, in 2021 [

8]. To address these technical challenges, accurate simulation analysis is necessary, and valid conclusions from simulation analysis rely on accurate modeling of new energy sources. For example, inaccurate LVRT modeling can affect the validation of relay protection algorithms, potentially leading to the misoperation of actual protection devices and triggering chain failures [

9,

10,

11]. Therefore, to address the accurate modeling problems of the new energy “black box” controller fault ride-through control, this paper conducts related research, aiming to improve the accuracy and applicability of the new energy model, thereby providing theoretical support for the safe and stable operation of the new power system.

For a long time, scholars around the world have conducted numerous studies on wind power, photovoltaics, and energy storage power generation system models, gaining a deeper understanding of their related model structures and operational principles. For example, Hu et al. [

12] and Tang et al. [

13] ignored the current control process and modeled the amplitude-phase dynamics of the DFIG wind power system under DC voltage and rotor speed time scales, respectively. Jin et al. [

14] established the equivalent impedance model of the DFIG wind power system and grid based on the impedance analysis method, which is used to analyze the interaction between the wind power grid-connected system and the grid. El-Shimy et al. [

15] proposed a reduced-order model of a PV power system for small-signal stability assessment and estimated the maximum penetration level of the PV system. This study emphasized the importance of simplified models in power system stability analysis. Ning et al. [

16] developed a Norton equivalent model for PV power systems and analyzed the effects of grid-connected capacity and grid strength on system resonance. Yonezawa et al. [

17] developed a detailed and averaged model of a large-scale PV power system for electromagnetic transient simulation under grid faults. The model can accurately reflect the dynamic behavior of the PV system, but it has high computational complexity. Zhang et al. [

18] proposes a composite demand-side simplified model structure containing loads, distributed PV generation, and energy storage systems and proposes a model parameter identification method based on environmental signals and fault data. The model structure is capable of recognizing the dynamic characteristics of PV generation and energy storage systems at the high-voltage bus by simplifying these systems. Fan et al. [

19] proposes a simplification algorithm based on equivalent circuit modeling for large-scale battery packs, which can significantly improve simulation speed while maintaining accuracy, considering inconsistencies. However, most of the above studies have simplified or abstracted the models for different problems modeled in a particular scenario, which facilitates the analysis of the problem but, at the same time, reduces the accuracy of the model. In addition, existing studies also lack in-depth research on the modeling methods of new energy systems that take into account different fault control characteristics. In reality, when different types of short-circuit faults occur in the power grid, the new energy units tend to exhibit different control characteristics, i.e., the control objectives, control structures, control parameters, and control instructions of the unit control system will change with the fault changes to make the units exhibit different dynamic response characteristics [

20,

21].

In terms of model control parameter calibration, the transient control structure and parameters of the inverter, as the core component of the new energy power generation system, determine the transient response characteristics of the new energy during fault. However, the control structure and the parameters of the inverter in the new energy unit are usually complex to obtain directly due to changes in the operating environment and the black box nature of the actual controller. Therefore, it is necessary to estimate the unknown links in the model by combining the system identification method. System identification encompasses two key aspects: system structure identification and system parameter identification. For the system model structure, this paper selects a general model that can satisfy various calculation functions, such as tidal current calculation, transient stability simulation calculation, short-circuit calculation, and small disturbance stability calculation, among others. This model also features a variety of different decoupling control strategies. The parameter identification of the system is primarily divided into traditional identification methods and artificial intelligence identification methods [

22]. Among them, the traditional identification method obtains the control parameters of the model through dynamic fitting methods, including the least squares method, theoretical analysis method, and frequency domain analysis method, among others. Kong et al. [

23] proposes a two-stage parameter identification method for a direct-drive wind turbine converter dual closed-loop control system. A power step command is used to identify the control parameters based on the current response, employing the damped least squares method. Takahashi et al. [

24] proposes a recursive least squares sensorless identification method for online identification of permanent magnet synchronous generator parameters, which can effectively detect feature changes during aging and degradation. Zhang et al. [

25] proposed a new decoupled weighted recursive least squares (DWRLS) method, which improves the modeling accuracy by estimating fast and slow dynamic parameters separately. Xia et al. [

26] improves the parameter discrimination accuracy of state-of-charge (SOC) estimation models for battery management systems based on the forgetting factor recursive least squares method.

The traditional identification methods are generally only applicable to the identification of linear systems, and they are difficult to apply to the identification of nonlinear systems. To address this issue, artificial intelligence (AI)-based identification methods have been proposed in the literature. These AI methods are intelligent techniques to identify model parameters by simulating human intelligence, automatic reasoning, learning, and searching, with strong problem-solving ability, and are not subject to the constraints of nonlinear links. Thus, they are more suitable for new energy systems that have high dimensionality of variables, strong coupling, and highly nonlinearized characteristics. Standard artificial intelligence algorithms include, for example, genetic algorithms, particle swarm optimization, differential evolution, and the JAYA algorithm, among others. Wu et al. [

27] proposed a PMSM parameter identification method based on an improved cuckoo search algorithm. Yang-Wu et al. [

28] proposed a genetic algorithm (GA)-based method for PMSG model parameter identification. Gao et al. [

29] proposed an improved pollination algorithm for identifying the parameters of PMSM. Leng et al. [

30] introduced a PSO algorithm based on chaotic mapping and Gaussian perturbation for parameter identification of PMSG motors. However, these optimization methods suffer from slow convergence, easy premature convergence, and low identification accuracy [

31,

32]. To address these problems, Yang et al. [

33] proposed a Grey Wolf Optimizer (GWO) algorithm with an information-sharing search strategy to solve the parameter identification problem of doubly fed converters. In [

34], a chaotic adaptive search GWO algorithm is proposed to recognize the parameters of PMSM. Liu et al. [

35] proposed a parameter estimation method for the PMSM drive system based on an improved particle swarm algorithm to solve the parameter estimation model of the PMSM drive system. Wu et al. [

36] indicates that the traditional photovoltaic cell model parameter identification method has several shortcomings, including low accuracy, slow convergence speed, and a high risk of falling into local optima. Therefore, this study proposes a photovoltaic cell model parameter identification method that improves upon the elephant swarm optimization algorithm. Han et al. [

37] proposed a parameter identification method based on an atomic search algorithm; the experimental results demonstrate that the algorithm exhibits high accuracy and a fast convergence speed, achieving better results in PV cell model parameter identification. Yang et al. [

38] In order to accurately identify the circuit model parameters, an improved optimization algorithm based on particle swarm optimization is used, which combines the optimization strategies and hybrid algorithms proposed in recent years to make up for the fact that the traditional particle swarm algorithm tends to get stuck in the local optimal solution. The efficiency of the multidimensional search is reduced.

In summary, although the new energy transient model parameter identification has achieved some research results, there are still the following difficulties:

(1) The new energy unit “black box” controller fault traversal characteristics are complex, linear and nonlinear coupling is strong, parameter identification is difficult, identification results are poorly adapted, and accuracy is low.

(2) The dynamic response of new energy units under symmetrical and asymmetrical fault types, different operating conditions, and various high and low voltage ride-throughs exhibits significant differences and shows strong sequential consistency. Its control strategy and parameters are diverse and intensive, with low identification efficiency.

(3) The fault ride-through control mechanism of the new energy unit “black box” controller is unknown, and equivalent modeling is difficult;

To solve these problems, the main contributions of this paper can be summarized as follows:

(1) A new energy unit “black box” controller fault traversal parameter identification method based on the genetic Newton algorithm is proposed, which can accurately identify the actual doubly fed wind turbine control strategy and parameters under symmetrical/asymmetrical fault types, different operating conditions, and different high and low voltage traversals.

(2) A segmentation method for the fault-crossing process based on statistical modal characteristics is proposed to divide the data interval of the fault stage accurately, and a general structured model framework for fault-crossing segmentation control of doubly fed wind turbines is constructed.

(3) A genetic Newtonian hybrid fault traversal parameter optimization algorithm is proposed, which combines global search and local optimization to improve accuracy and robustness significantly.

(4) Based on the proposed method and theory, a set of generalized black box new energy unit parameter identification software is developed by combining Matlab App Designer Version: 9.11.0.1769968 (R2021b) and PSD-BPA version 3.1. The proposed method and the developed software are validated using semi-physical hardware-in-the-loop test data from the RTLAB-based doubly fed unit. The results demonstrate that the proposed method is more accurate and robust, achieving a 2.89% reduction in error compared to the traditional method, which is of significant value for engineering applications. Meanwhile, the developed parameter identification software platform automates the entire process of data preprocessing, parameter optimization, and simulation verification, improving modeling efficiency by 40% and addressing the issue of convenience in engineering applications.

The structure of this paper is as follows:

Part I: Based on the new energy scale statistics of the International Renewable Energy Agency (IRENA), we point out the key grid integration technical challenges facing the global new energy development and emphasize that high-precision new energy modeling is the theoretical cornerstone of the security and stability analysis of new power systems. By systematically combing the research progress of wind power, photovoltaic and energy storage modeling, and combining it with the comparative analysis of the optimization performance of various identification algorithms, the current technological bottlenecks and methodological limitations are further clarified, thus laying an important theoretical foundation and research basis for the innovative solutions proposed in this study.

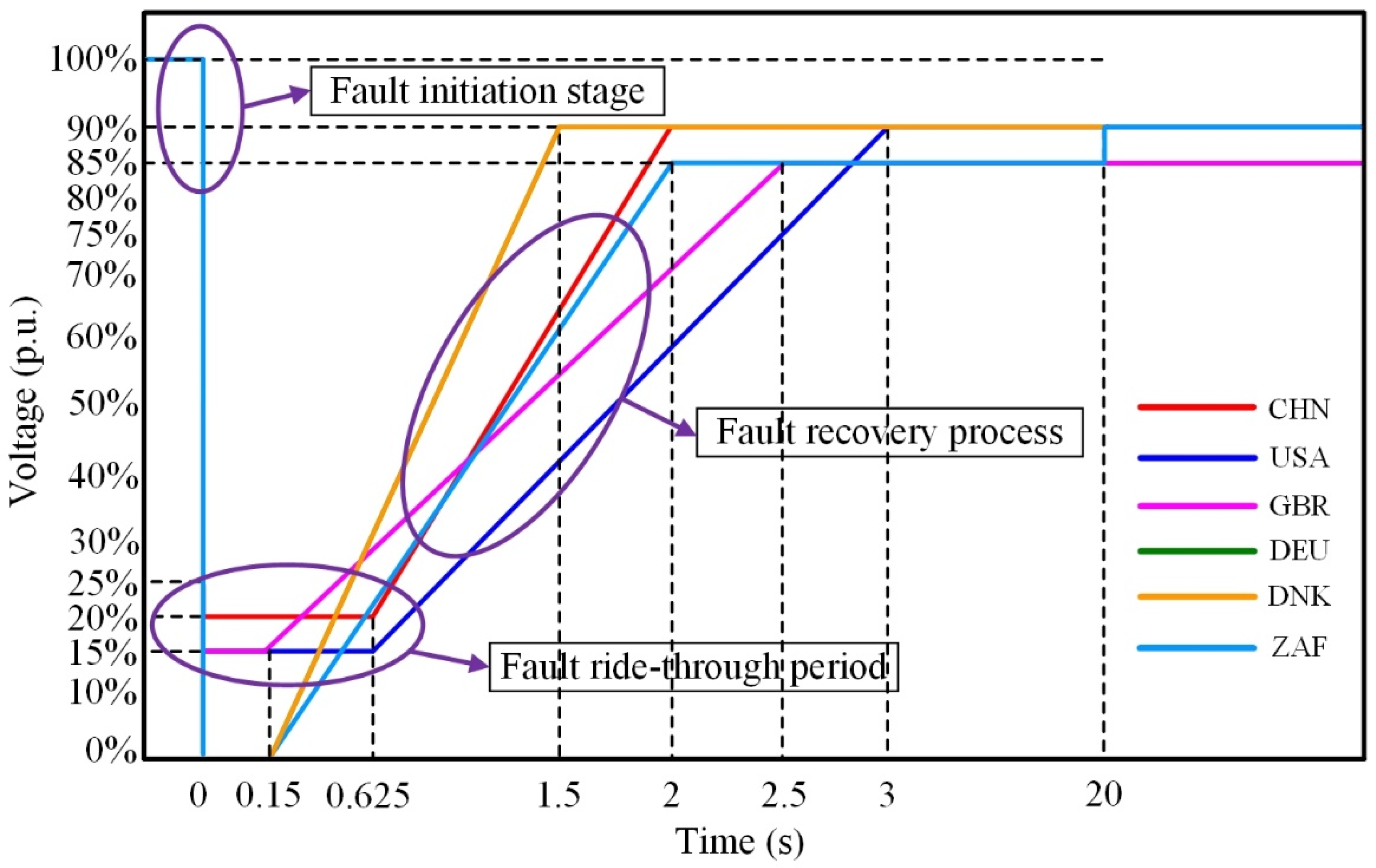

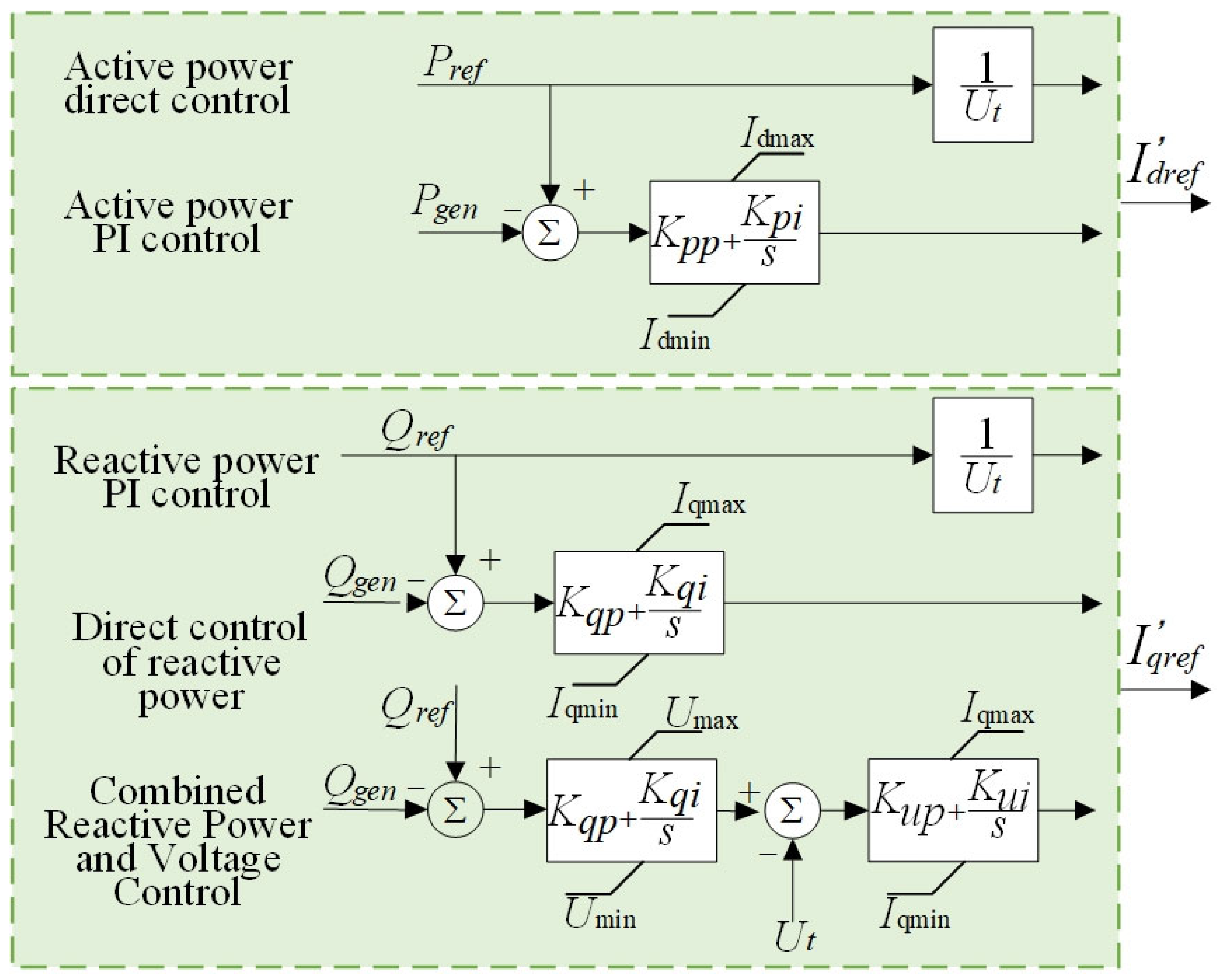

Part II: The common fault ride-through segmented control characteristics of new energy units are analyzed according to the high and low ride-through standards of new energy units in various countries, based on which a general structured model of three-segment control of wind turbine fault ride-through is established, and the core control parameters of the control strategies in each phase are analyzed.

Part III: The RTLAB hardware in-loop test simulation platform is utilized to conduct in-loop testing of the actual doubly fed wind turbine black box controller and to obtain the output response data of the controller under various operating states. Aiming at the measured data, a method of data segmentation preprocessing using the statistical modal feature segmentation method and a method for fast and accurate identification of structured models using the genetic Newtonian algorithm are proposed.

Part IV: According to the control identification method and various optimization algorithms proposed in this paper, a universal parameter identification software simulation platform is developed by combining Matlab App Designer and PSD-BPA.

Part V: The actual black box controller of a doubly fed wind turbine model that has been put into operation is selected for the RTLAB semi-physical hardware-in-the-loop test, and combined with the output response data, the parameter identification software platform, and the general structured electromechanical transient model of the doubly fed wind turbine, the parameter identification for the fault ride-through control of this doubly fed turbine’s black box controller is completed, and the simulation results of the different identification algorithms are compared in a variety of operating conditions. Which proves the validity and accuracy of the proposed parameter identification method and the developed software. The results demonstrate that the method proposed in this paper is more accurate and robust with higher engineering application value.

3. Parameter Identification of Black Box New Energy Units

3.1. A Black Box New Energy Unit Fault Ride-Through Control Parameter Identification Method Based on Measured Data

In order to identify the parameters of the new energy structured model more efficiently and accurately, this paper adopts the proposed black box new energy unit structured model fault ride-through identification method based on measured data, and the specific flow is shown in

Figure 10:

(1) Build a new energy controller semi-physical hardware-in-the-loop test simulation platform based on RTLAB and test the measured response data of the new energy actual controller under a variety of working conditions on this platform.

(2) Clean and preprocess the collected measured recorded waveform data of new energy under normal and fault conditions, including removing outliers, filling in missing values, and normalizing data amplitude. Then, valuable features are extracted from the preprocessed data to help the computer quickly and accurately identify the normal operation state and fault ride-through three-segment operation states of the data. After that, the measured operating condition data are divided into four sets: low penetration symmetric fault set, low penetration asymmetric fault set, high penetration symmetric fault set, and high penetration asymmetric fault set, based on the fault type. A corresponding fault classification model is then established for each set. Finally, each type of fault data set is divided into a training set and a test set according to the data usage.

(3) The measured response data set of a single fault type is selected. The statistical modal feature segmentation method is utilized to segment the fault ride-through into three segments (fault ride-through period, fault recovery starting point, and fault recovery process) of the training set and test set condition data under the jurisdiction of the training set to obtain the segmented data of the training set and the segmented data of the test set.

(4) Aggregate the fault ride-through three-segment data of the training set conditions, and use the genetic Newton algorithm cycle to optimize the key control parameters of the multi-strategy control model of the fault ride-through three-segment control, calculate the size of the adaptive value of each individual in the population according to the objective function (Equation (1)) after each iteration and rank them, select the optimal parent individual according to the principle of the smaller, the better the adaptive degree, and carry out the cross-mutations to generate a new generation of populations. The cycle repeats until the adaptation degree of iterative individuals meets the threshold requirement or reaches the maximum number of iterations and then jumps out of the genetic optimization, after which, according to the suitable solution region searched by the genetic algorithm, the limited-memory Broyden–Fletcher–Goldfarb–Shanno (L-BFGS) algorithm is used to carry out the refinement of parameter optimization. By comparing the size of the final adaptation value of each control strategy under the same control stage, the optimal combination of control strategies and their control parameters are quickly outputted, and finally, the structured simulation model of the electromechanical transient state of the black box new energy unit is constructed by synthesizing the basic information of the actual capital collection and the optimal identification results.

where

yreal and

ysim are measured data values and model fitting outputs, respectively.

(5) Select the test set segmentation data with the same fault type for the verification of identification results, extract the power size, fault type, fault start and end time, and other fault characteristic parameters of the test set of measured conditions, and import the fault characteristic parameters of the test set of conditions into the structured simulation model of the new energy unit of the black box in a cycle for simulation to ensure that the measured model and the structured model in the fault ride-through condition simulation have the same depth and duration of the voltage dips. After the simulation is completed, all the simulation data of the structured model under the fault type are exported, and the deviation between the simulation and the measured data is calculated according to the Chinese national standard GB/T44650-2024 [

47]. If the deviation of all the conditions meets the standard requirements, the optimal identification results can be considered as the equivalent control of the black box new energy unit under this fault type; if there are test conditions whose deviation does not meet the requirements, it is necessary to carry out the test again after re-identification or modification of the original identification results until the error results of all the test sets of conditions meet the standard requirements.

(6) After completing the identification and examination of the optimal control of the structured model of the black box new energy unit under four types of faults according to the above method, a structured simulation model that can fully characterize the fault ride-through characteristics of the actual black box unit is finally obtained. The resulting structured model of the new energy unit is simulated for both high and low-fault ride-through scenarios, and the corresponding reactive power support coefficients and active recovery coefficients are calculated and compared with the values stipulated in the national standard to evaluate the fault ride-through performance of the structured model of the black box unit.

3.2. Semi-Physical Hardware-in-the-Loop Test of RTLAB-Based Black Box New Energy Unit Controller

The black box new energy unit RTLAB hardware-in-the-loop simulation test is a method that utilizes the real-time digital simulator RTLAB and the actual controller of the new energy unit to construct a closed-loop test environment and conduct a series of fault ride-through tests. This method is the most common in the testing of large-capacity power electronic devices, which not only can reflect the dynamic response characteristics of the device comprehensively, adequately, accurately, and efficiently but also has a lower cost, a higher automation rate, and a higher safety factor compared with the purely physical test method.

The semi-physical hardware-in-the-loop test platform of the black box new energy unit controller based on RTLAB is shown in

Figure 11. The RTLAB simulation platform and the black box controller interact with each other through the bi-directional DB37 line for the control signals and electrical quantities. The host computer controls and monitors the operating commands and signals of the RTLAB simulation platform and the controller through a bi-directional high-speed fiber optic or network cable. Before carrying out the test, it is necessary to build the primary circuit model and user signal observation interface of the corresponding new energy unit in the real-time digital simulation software RT-LAB installed in the host computer. Considering the high switching frequency of the new energy inverter, it is generally chosen to be built in a small-step environment. After the virtual model is constructed, the generated C code is downloaded to the RTLAB simulation platform using the compilation and download function of the software.

During the test operation, the RTLAB simulation platform and the black box controller carry out real-time bidirectional signal communication through the GTAO\GTDI analog-to-digital converter board and I/O interface. After receiving the voltage and current feedback signals from the RTLAB virtual model, the actual controller calculates the corresponding PWM control signals according to its operation state and, at the same time, transmits the PWM control signals to the RTLAB simulation platform, which then uses the PWM signals to complete the control of the virtual model inverter, thus finally forming a closed-loop simulation of the whole grid-connected system. RTLAB simulation platform: The RTLAB platform then uses the PWM signals to complete the control of the virtual model inverter, thus finally forming a closed-loop simulation of the entire unit grid-connected system.

In the whole closed-loop simulation process, the grid-connection commands of the RTLAB virtual model, fault settings, parameter changes of the unit, as well as the changes of the actual controller control parameters and power regulation parameters are all accomplished through the RTLAB user interface control module of the host computer. In contrast, all the operation data of the simulation system and the operation status signals of the controllers are uniformly received and observed through the RTLAB user interface data receiving and observing module.

As shown in

Figure 12a,b, in order to verify the effectiveness of the proposed structured model fault ride-through control identification method, this paper takes a wind power black box unit as an example. The semi-physical test system for grid-connected doubly fed wind turbines is built within the RTLAB real-time simulation platform. The output response of the new energy black box controller is tested in-loop in a variety of working conditions according to the Chinese national standard GB/T44650-2024 parameter test protocol document. The output response of the controller is tested in the loop. The measured response data of the controller is also obtained by using recorded waveforms, in which the recorded variables include the instantaneous values of the three-phase voltages and currents at the measurement point, the fundamental positive sequence component U

sim of the output voltage, the active power P

sim, the reactive power Q

sim, the active current I

dsim, and the reactive current I

qsim.

3.3. Processing of Measured Data and Selection of Optimization Algorithms

3.3.1. Data Segmentation Preprocessing Based on Statistical Modal Features

When carrying out the identification of active and reactive three-segment control models for each fault type, the selection of a precise segmentation of the training set data and a reliable optimization algorithm will determine the accuracy of the identification results. Therefore, this paper firstly analyzes the statistical characteristics of the measured data and proposes a segmentation method based on the statistical modal characteristics, which utilizes the centralized trend characteristics of voltage, active, and reactive data during fault ride-through and recovery to segment the data and divides the whole data segment into six parts shown in

Figure 13. The specific segmentation steps are shown below:

(1) Based on the received controller fault ride-through voltage thresholds and voltage data, initially determine the starting point Sin for entering the fault ride-through state and the termination point Sout for exiting the fault ride-through state for the working condition in which it is located.

(2) Extract the statistical modal eigenvalues of voltage, active power, and reactive power during the fault ride-through phase, i.e., the steady-state values during the fault ride-through period, using the initial starting and ending data point locations.

(3) Setting the deviation threshold and combining with Equation (2), first determine the data start and end points of voltage, active power, and reactive power during the fault ride-through period, and then take a large for the data start point of each variable to obtain the start point S1 of the fault ride-through period, and take a small for the data endpoint of each variable to obtain the endpoint S2 of the fault ride-through period.

where

S1

var and

S2

var are the start and end point positions during fault ride-through for each variable;

datavar is the fault ride-through data for each variable;

modevar is the steady-state value during fault ride-through for each variable; and

DEV is the deviation threshold.

(4) Similarly, the data of each variable starts from the endpoint S2 of the fault ride-through period, firstly extracts the normal steady-state value of each variable, and then combines with Equation (2) to obtain the starting point position of each variable to enter into the normal steady-state operation after the fault, i.e., the position of the endpoint of each variable’s fault recovery process, and then takes the larger one to obtain the data’s endpoint S4 of the fault recovery process.

(5) For the fault recovery starting point phase, the starting point is the endpoint S2 of the fault ride-through period, and the endpoint S3 generally defaults to be the 10% to 20% position of the period from the endpoint S2 of the fault ride-through period to the endpoint S4 of the fault recovery process;

3.3.2. Genetic Proposed Newton Hybrid Optimization Algorithm

After completing the segmentation and categorization of all working condition data in the training set, combined with the proposed structured three-segment control model for active and reactive fault ride-through, the active and reactive multi-control strategy models contained in each stage are identified with their respective parameters. The control strategy with the smallest identification error is selected as the optimal control strategy for testing at that stage.

Due to the existence of both linear and nonlinear models in the control model to be identified and the large size and complexity of the measured sample set data of the model, if only a linear optimization algorithm is used, it is impossible to optimize the nonlinear model effectively. If only a nonlinear algorithm is used, it is easy for the optimization process to fall into a local optimum and fail to find the global optimal solution, which affects the quality of the optimization results and the accuracy of the model. To overcome the aforementioned problems, this paper employs a hybrid optimization approach combining a genetic algorithm with L-BFGS for parameter identification.

Genetic algorithm (GA) is a computational model simulating Darwinian natural selection, featuring strong global search capability that enables rapid approximation of optimal solutions in early stages. However, its local search ability tends to weaken in later stages. On the other hand, the limited-memory Broyden–Fletcher–Goldfarb–Shanno (L-BFGS) algorithm, as a quasi-Newton method, demonstrates excellent local convergence properties but is sensitive to initial values. Recognizing these complementary characteristics, this study develops a novel hybrid approach that organically combines both algorithms into a genetic quasi-Newton method [

48]. The hybrid approach leverages the complementary strengths of both algorithms: the genetic algorithm’s strong global search capability and rapid initial exploration, combined with the Newton method’s (L-BFGS) fast local convergence. This integration addresses key limitations of each method—the genetic algorithm’s weakening local search ability in later stages and the Newton method’s sensitivity to initial values. The implementation involves two key components: (1) the genetic algorithm performs initial global exploration to identify promising solution regions, and (2) automatic switching to L-BFGS when population diversity falls below a threshold or fitness improvement stagnates. This synergistic combination effectively solves problems of slow optimization while preserving each algorithm’s strengths. The specific implementation method is as follows:

(1) Initialize the parameters related to the genetic Newtonian algorithm, including the population size M, the maximum number of iterations Gmax, and the fitness threshold. Randomly generate the initial population P = {k1,k2,…, kM}, and the population individual ki is a parameter vector, where the jth parameter takes the value range of [kmin_j,kmax_j].

(2) Calculate the fitness

f(

ki) of each individual in the initial population using the objective function and rank them according to their size, and the fitness calculation formula is as follows:

where

ε is the anti-zero division positive number.

(3) Perform a selection crossover mutation operation according to the principle that the larger the fitness value, the better; use roulette to select the two parent individuals with higher fitness for a single-point crossover operation, and carry out a mutation operation on the generated offspring individuals to increase the diversity of the population to avoid the population from falling into the local optimal solution.

(4) Calculate the fitness value of the new individual; if it meets the fitness threshold or the maximum number of iterations, then exit the genetic optimization; if it does not meet, use the elite retention strategy to update the population again and recycle steps (2) and (3) until the fitness of the new individual or the number of iterations meets the requirements.

(5) The approximate solution obtained by the genetic algorithm serves as the initial solution for the proposed Newton method, which is then locally optimized to refine the solution’s accuracy. Calculate the gradient of the objective function

J(

kbest) of the current approximate solution

kbest and update the approximation matrix of the Hessian (i.e., the approximation of the second-order derivatives), where the initial Hessian matrix

H1 is usually a unitary matrix, and the gradient is calculated with the following formula for updating the Hessian matrix:

where

Sk is the change in the current parameter update;

yk is the change in the gradient.

(6) The current parameters are re-updated based on the computed approximate solution

kbest gradient, combined with the Hessian’s approximation matrix, updated by the following equation:

where

is the inverse of the Hessian matrix.

knew is the new approximate solution obtained by updating.

(7) Cyclically call steps (5) and (6) until the objective function value J(k) of the latest approximate solution converges to a sufficiently small threshold ϵ or the number of iterations reaches the upper limit, terminate the iteration of the proposed Newton method, and output the optimal solution.

3.4. Comparison Error Calculation

The calculation of transient steady-state deviation in the three segments of the fault ride-through control is shown in the Chinese national standard GB/T44650-2024, whose main purpose is to test the accuracy of the model by calculating the deviation between the simulation data of the structured model and the measured data. After completing the segmentation of simulation data and measured data for the test condition, the deviations of the electrical quantities in the normal steady state before fault occurrence, the transient steady state during fault ride-through, and the transient steady state after fault recovery are calculated, and the electrical quantities for which the deviations are to be calculated include the output voltage U, the active power P, the reactive power Q, the active current Id, and the reactive current Iq. The types of deviations to be calculated include the average deviation in the transient interval of each period, the average deviation and maximum deviation in the steady-state interval, and the weighted average total deviation of the whole process. The formulas for calculating the average deviation, maximum deviation, and weighted average total deviation are as follows:

The average deviation FME of the steady state and transient intervals for each time period:

where

XS is the hardware-in-the-loop simulation data standardized value in the test interval;

XM is the model simulation data standardized value in the test interval; and

N is the number of data in the test interval.

The average absolute deviation FMAE of the steady state and transient intervals for each time period:

Maximum deviation from the steady-state interval FMXE:

Full process weighted average absolute deviation FG:

where

FMAE1 is the average deviation from the normal steady state before the fault;

FMAE2 is the average deviation from the transient steady state during fault ride-through; and

FMAE3 is the average deviation from the transient steady state for fault recovery.

The deviation calculation results between the simulation data and measured data of the new energy structured model for the test condition shall meet the following conditions: (1) The deviation of each voltage on the high-voltage side of the step-up transformer of the power generation unit of the new energy structured model for all the test conditions shall be no greater than the maximum permissible value of the voltage deviation in

Table 2; (2) The average deviation of the current, the reactive current, the active power, and the reactive power in the steady state and the transient intervals for all the test conditions, the maximum deviation in the steady-state interval, and the weighted average total deviation should not be greater than the maximum permissible deviation in

Table 2: (3) For the model simulation test under the two-phase asymmetrical fault condition, the maximum permissible deviation of the positive sequence component of the fundamental wave is 1.5 times the value in

Table 4.

Table 4 contains the national standard provisions for the detection of the maximum permissible deviation value of the electrical quantity.

In the table, FME_SS is the average deviation allowance for steady-state intervals; FME_TS is the average deviation allowance for transient intervals; FMXE_SS is the maximum deviation allowance for steady-state intervals; and FG is the weighted average absolute deviation allowance for all intervals.

4. Development of a New Energy-Structured Model Fault Ride-Through Identification Software Platform Based on Matlab and BPA

MATLAB App Designer, developed by Math Works, is an integrated development environment designed for rapidly building interactive applications that combine a graphical user interface (GUI) with object-oriented programming. Its key advantage is an intuitive and easy-to-use interface that allows researchers to create and deploy applications quickly with simple drag-and-drop operations. Leveraging MATLAB’s powerful computational and optimization libraries, App Designer excels in parameter identification, optimization, and data manipulation, enabling real-time parameter tuning and visualization of results. However, when dealing with complex power system simulation, especially new energy-structured modeling, the built-in functions of MATLAB App Designer may not be able to meet the demand for high-precision simulation and system dynamic behaviors, especially in the accurate simulation of new energy devices such as wind power and photovoltaic power plants after they are connected to the power grid. Therefore, it is often necessary to use it in combination with a dedicated simulation tool to ensure modeling accuracy.

PSD-BPA (Power System Dynamics-Bonneville Power Administration) is a comprehensive power system simulation tool developed by the China Electric Power Research Institute (CEPRI), widely used in tasks such as tidal current calculation and transient stability analysis, and excels particularly in modeling and dynamic simulation of wind power and photovoltaic systems. Although BPA has advantages in the stability analysis of new energy systems connected to the grid, its lack of flexible custom programming and algorithm design functions limits the realization of personalized analysis needs. In addition, the operation of BPA is more specialized, and ordinary users face a higher threshold of using it.

Based on this, this study combines the advantages of MATLAB App Designer and PSD-BPA to develop efficient parameter identification software for new energy-structured models. With the graphical interface provided by App Designer, researchers can easily adjust the parameters, view the identification results in real-time, and dynamically present the effects of parameter changes on the simulation results, which greatly simplifies the operation process. At the same time, with the powerful algorithm library of MATLAB, the software can efficiently identify and optimize the parameters and improve the identification accuracy and speed. Through the simulation function of PSD-BPA, it can accurately simulate the dynamic characteristics of the new energy equipment after connecting to the power grid and verify the accuracy and reliability of the parameters. This integrated solution makes up for the shortcomings of the MATLAB App Designer in simulation function and, at the same time, enhances the flexibility of the PSD-BPA in personalized identification and real-time optimization, which provides strong support for the control identification, parameter optimization, and engineering applications of new energy systems.

The main components of the parameter identification simulation software based on the joint development of MATLAB and PSD-BPA proposed in this paper include the data import and processing module, control parameter identification module, PSD-BPA program simulation inspection module, error calculation, and model evaluation module. The MATLAB main program consists of data processing, a parameter identification algorithm, and a BPA calling program. The specific working principle of the joint parameter identification software and the physical diagram of the software are shown in

Figure 14 and

Figure 15.

The main functions of each functional module of the software are as follows:

① Data Import and Processing Module: It is used to import measured data, classify them based on fault type and usage after step transformation, and segment all kinds of data according to the three segments of the fault ride-through and extract the characteristic parameters of faults in each working condition.

② Control Parameter Identification Module: Select the relevant optimization algorithm, set the initialization parameters, combine the optimization algorithm and the measured segmentation data to carry out a variety of control model parameter identifications, and determine the optimal control combination according to the results of the identification error of each model.

③ PSD-BPA Program Simulation and Inspection Module: Based on the optimal control combination obtained from the identification, the basic income information, and the characteristic parameters of working conditions and faults, construct the DAT power trend calculation model and SWI power stability calculation model corresponding to the electromechanical transient structural model of the new energy unit, and then call the power trend calculation program PFNT.EXE to calculate the DAT power trend model in parallel and obtain the result of the power trend. Then, combined with the power current result data and the power stability calculation program SWNT.EXE, the power SWI stability model is calculated in parallel to obtain the SWX simulation data files of the BPA unit structured model under various working conditions. The code of the BPA software calculation program is shown in

Figure 16.

④ Error Calculation and Model Evaluation Module: It is used to calculate the error between the measured data and the .SWX simulation data under the same working condition, judge the advantages and disadvantages of the identification results according to the error results, evaluate the fault ride-through performance of the new energy structured model obtained from the final identification, and derive the corresponding control model and evaluation report.