The Plasticization of Alkali-Activated Cement System Na2O-CaO-Al2O3-SiO2-H2O: Problems and Decisions

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Testing Methods

2.1. Raw Materials

- ground granulated blast-furnace slag (further, GBFS) (oxides, % by mass: CaO—47.30; SiO2—39.00; Al2O3—5.90; Fe2O3—0.30; MgO—5.82; SO3—1.50; LOI—0.18), specific surface area (S) = 450 m2/kg (by Blaine), modulus of basicity Mb = 1.2, glassy phase content—75.0%;

- Portland cement clinker (clinker) (oxides, % by mass: CaO—64.93; SiO2—22.60; Al2O3—5.29; Fe2O3—3.93; MgO—0.84; SO3—0.50; K2O + Na2O—0.70; LOI—0.90), specific surface area (S) = 450 m2/kg (by Blaine), modulus of basicity Mb = 2.4.

- calcined soda-ash of technical grade (Na2CO3) (further, soda-ash) per CAS 497-19-8, pH (1.0% aqueous solution, 25 °C) = 11.4;

- sodium metasilicate pentahydrate Na2SiO3∙5H2O (sodium metasilicate) per CAS 497-19-8, pH (1.0% aqueous solution, 25 °C) = 12.7.

- aluminum powder according to CAS No. 7429-90-5 (content, %: active aluminum—85.00–93.00, Fe—0.50, Si—0.40, Cu—0.05, Mn—0.05, moisture—0.20, fatty admixtures—3.80), water covering ≥ 7000 cm2/g;

- sodium nitrate (NaNO3) according to CAS No. 7631-99-4.

2.2. Testing Methods

2.2.1. Tests on Mortars and Concrete in the Fresh State

2.2.2. Tests on Mortars and Concrete in the Hardened State

3. Fundamentals

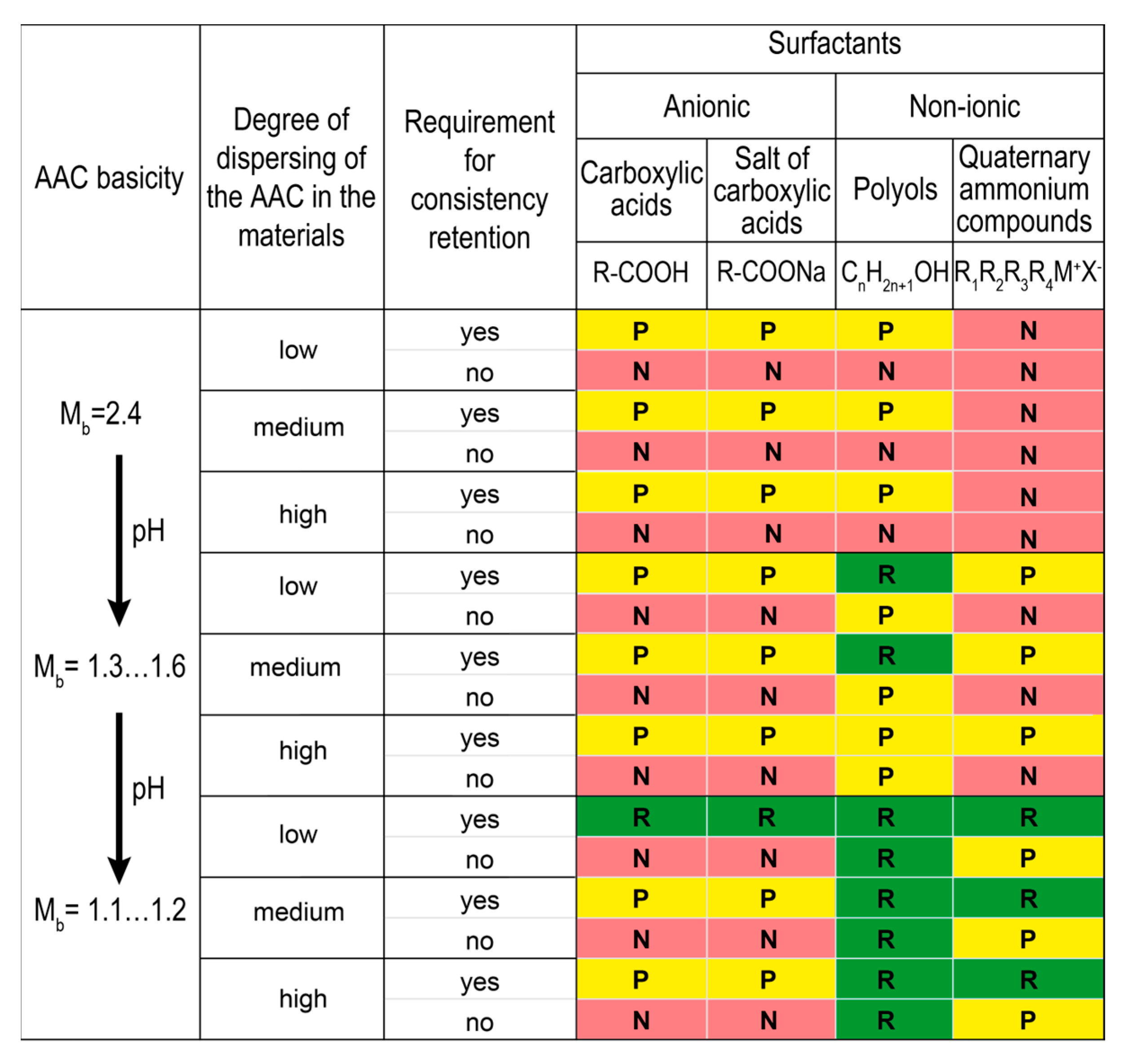

3.1. The Influence of the AAC Basicity

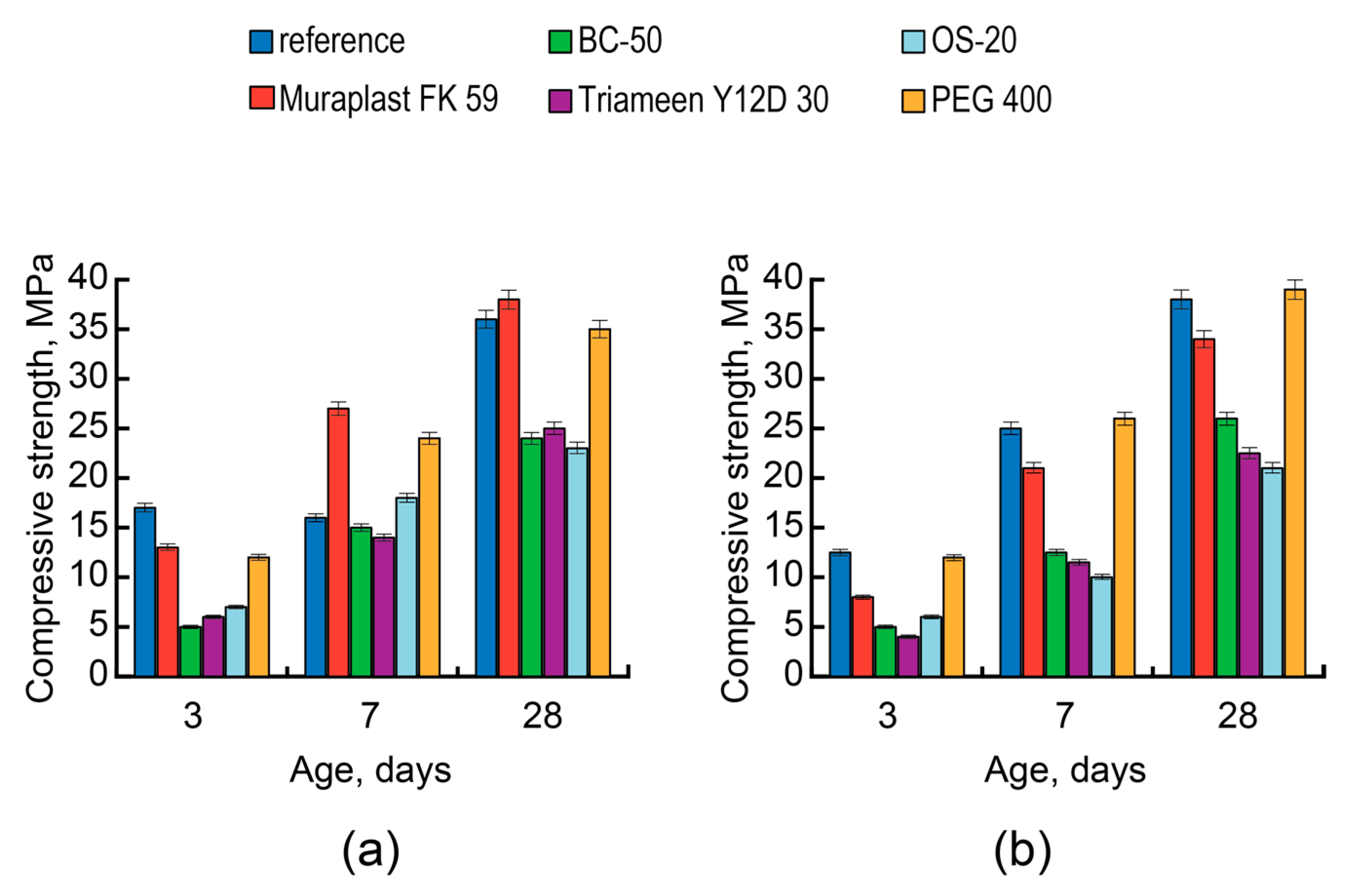

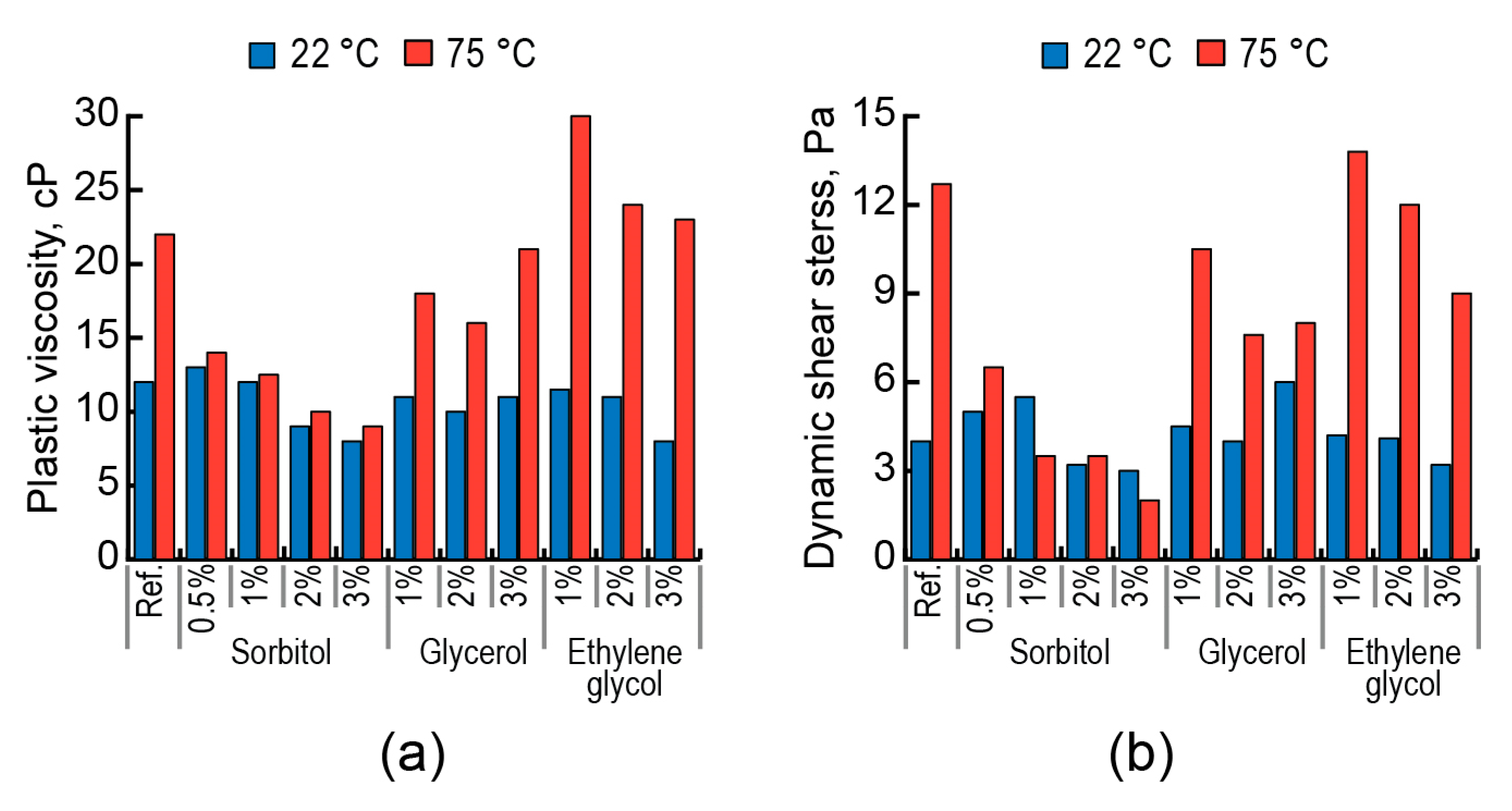

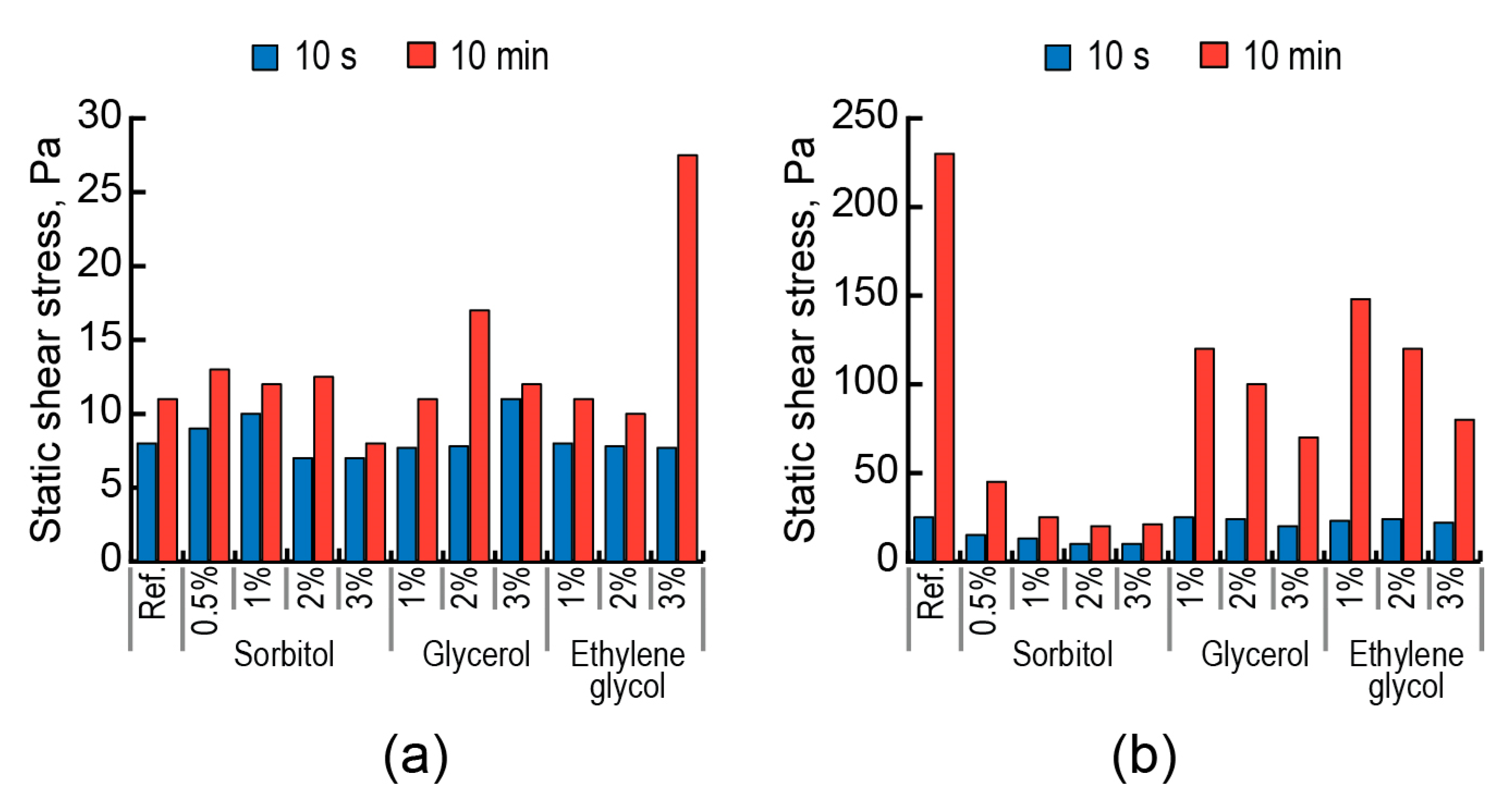

3.1.1. Factor #1: Molecular Structure of a Surfactant

3.1.2. Factor #2: Charge of Polar Groups of a Surfactant

3.1.3. Factor #3: Molecular Weight of a Surfactant

3.2. The Influence of the Anion of the Alkaline Component

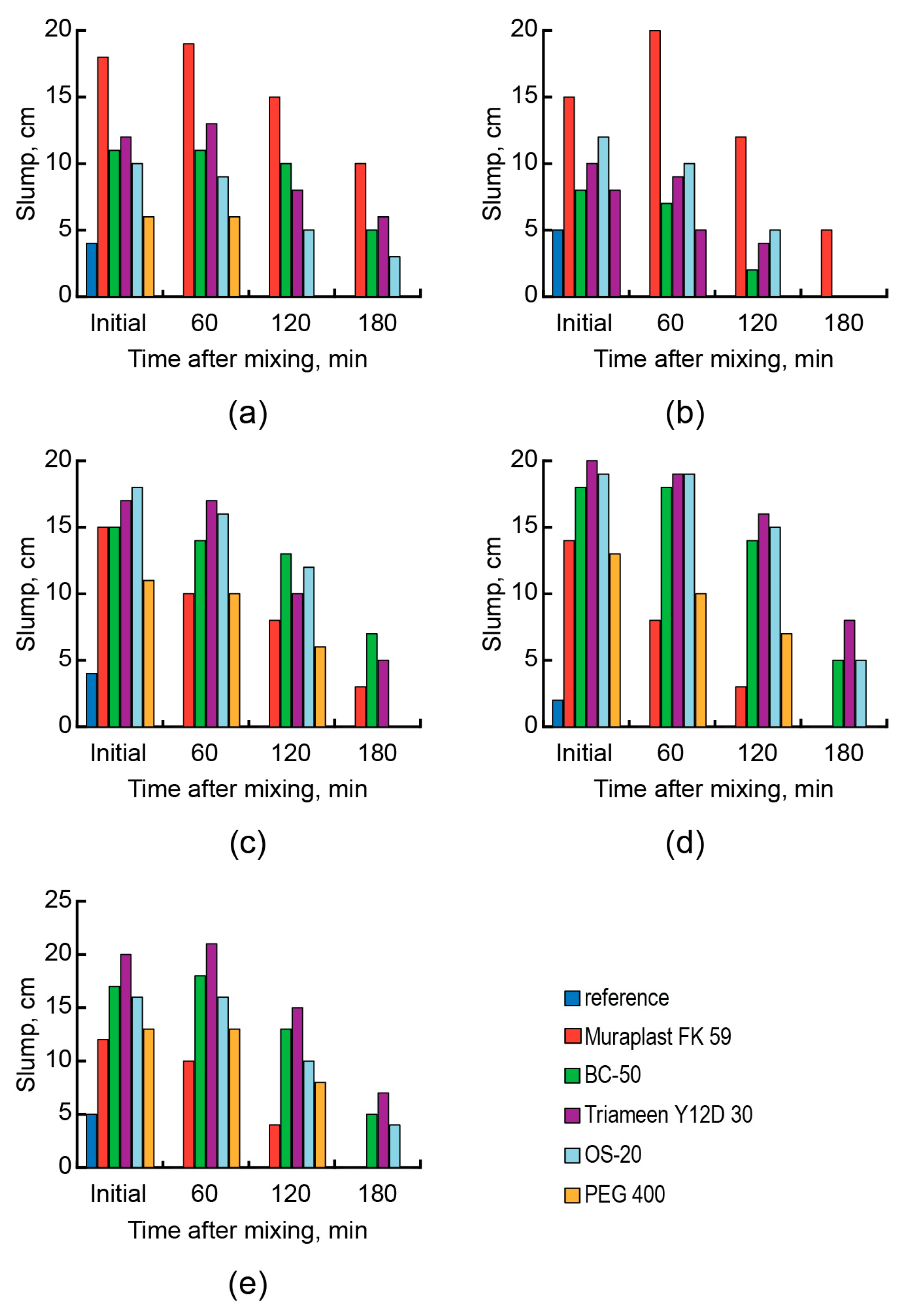

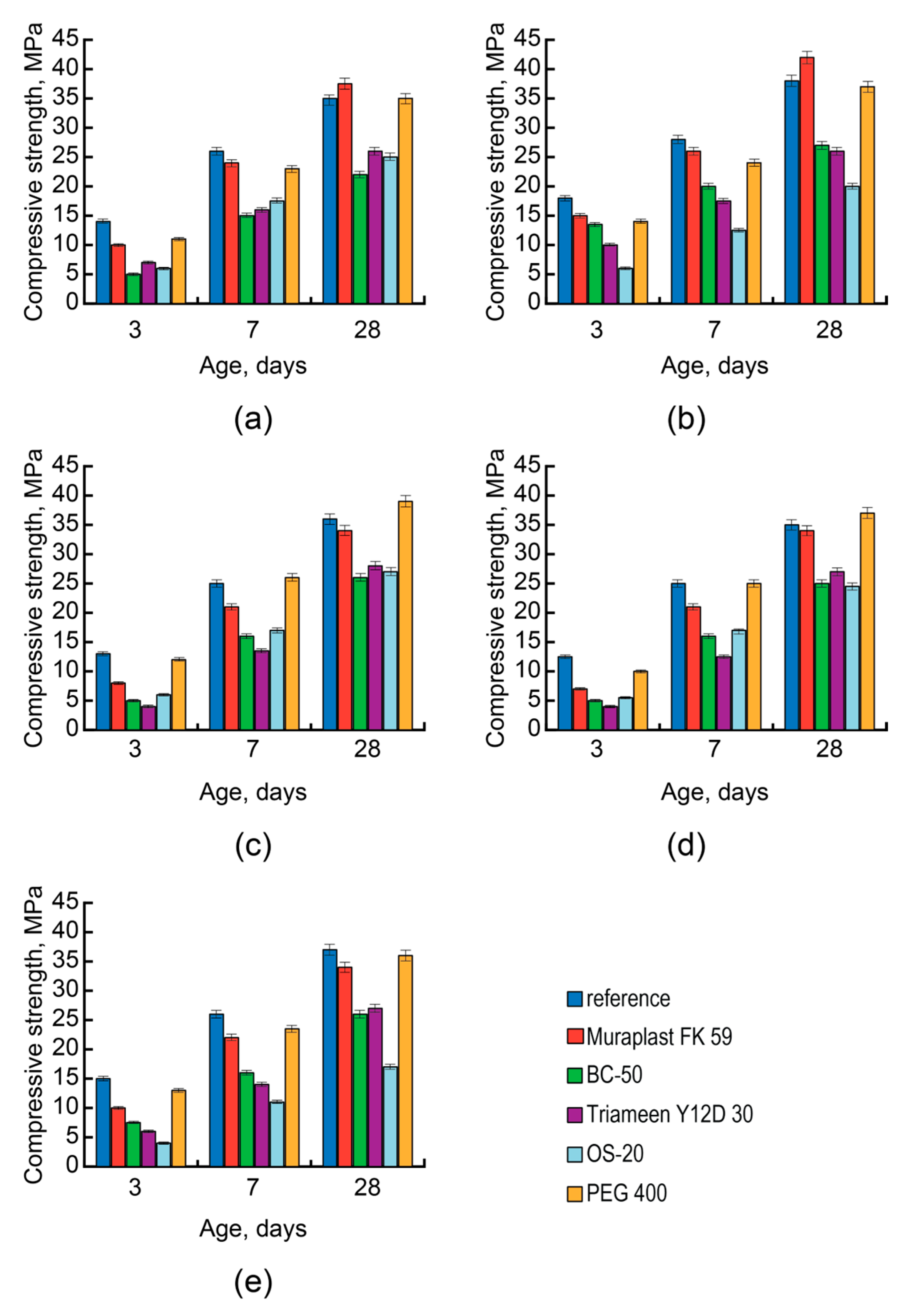

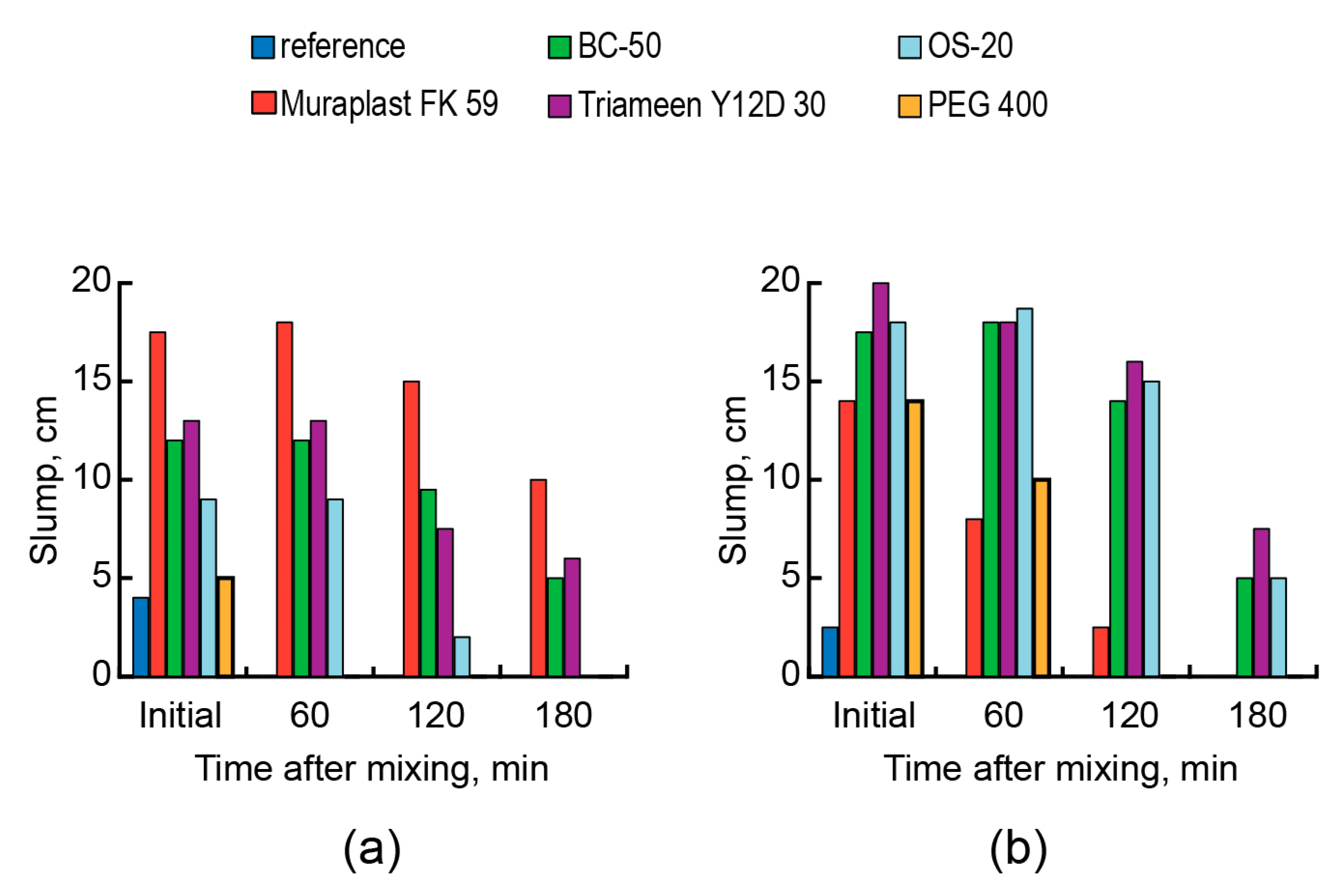

3.2.1. Factors #1 and #2: Molecular Structure and Charge of Polar Groups of a Surfactant

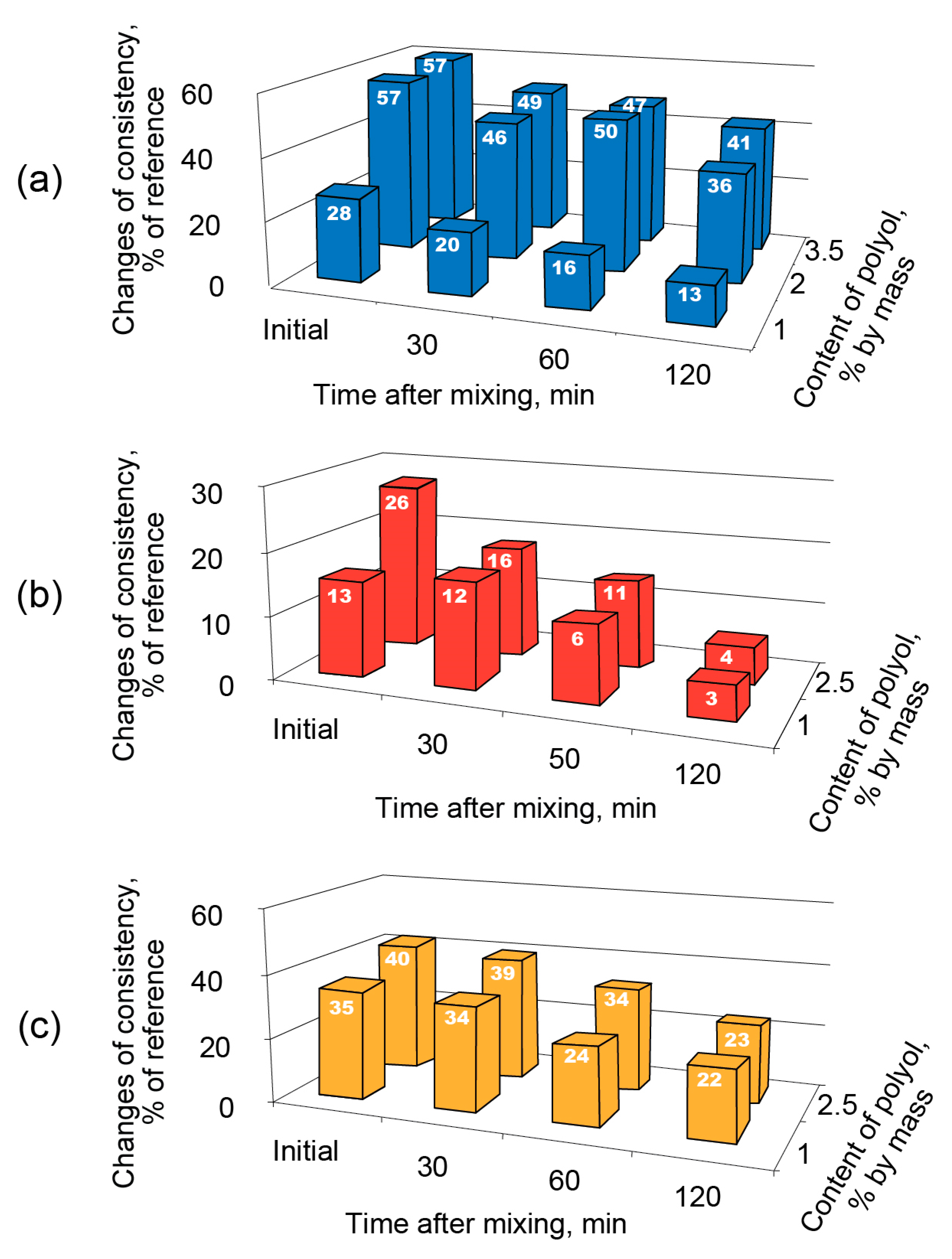

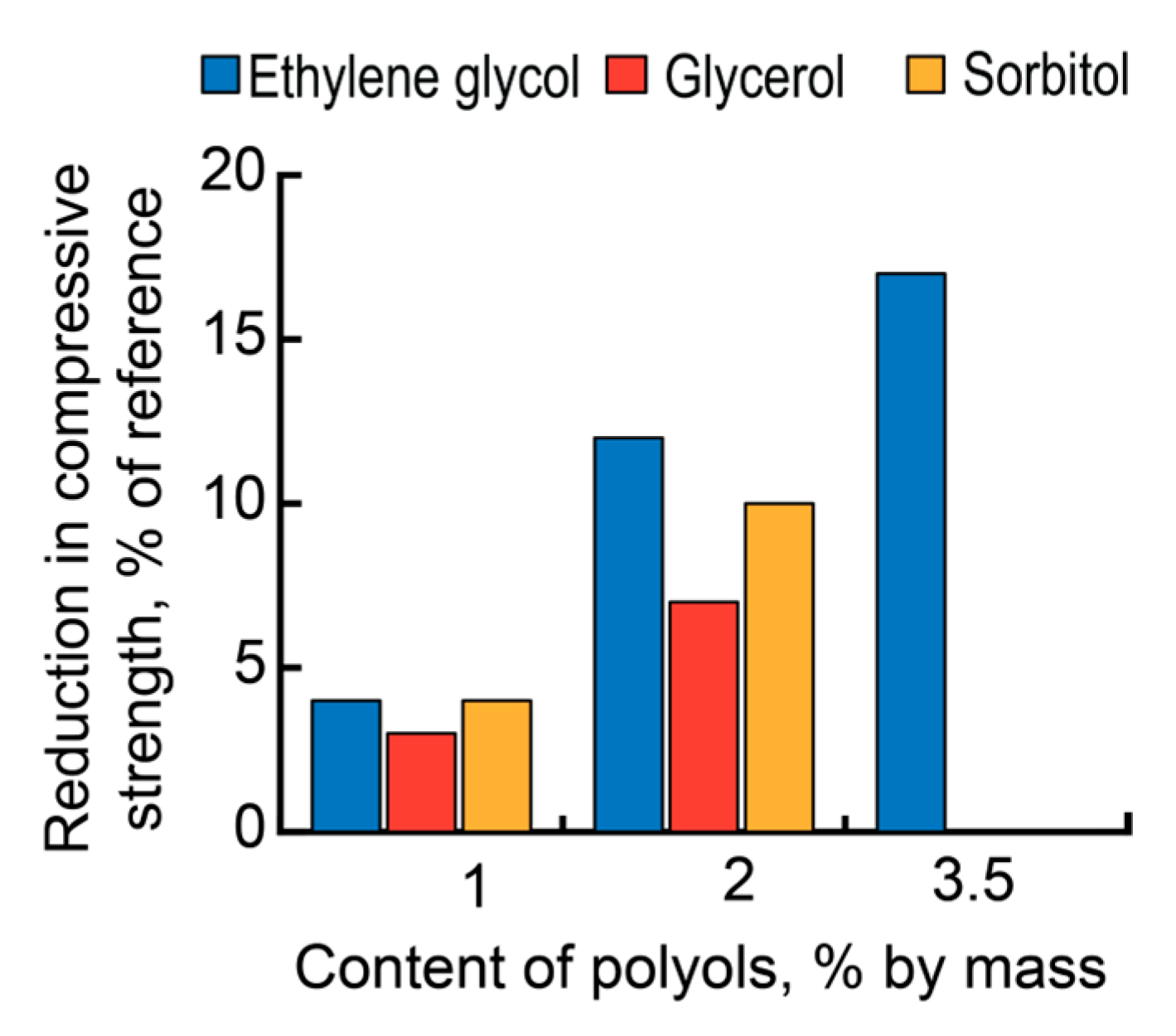

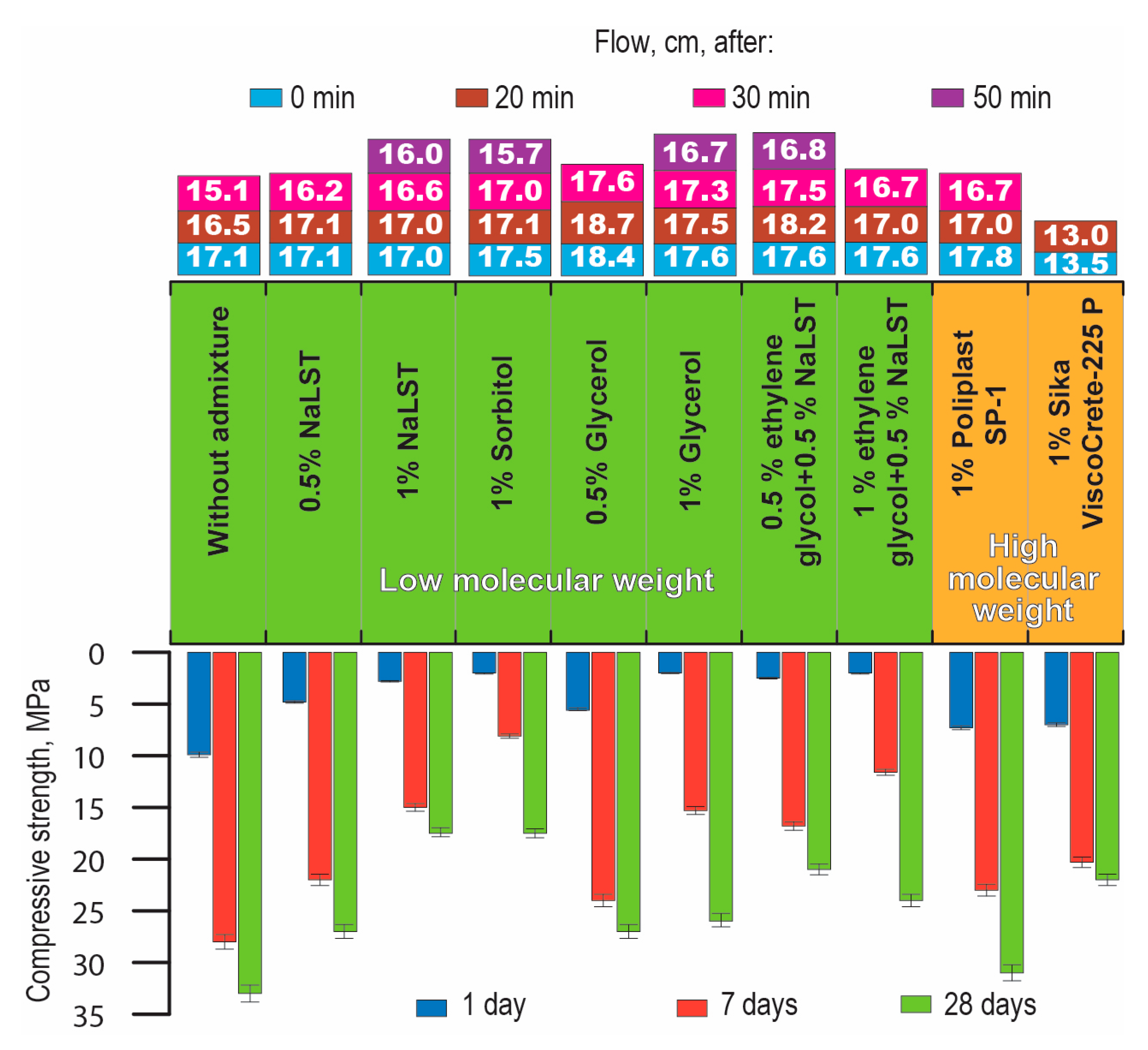

3.2.2. Factor #3: Molecular Weight of a Surfactant

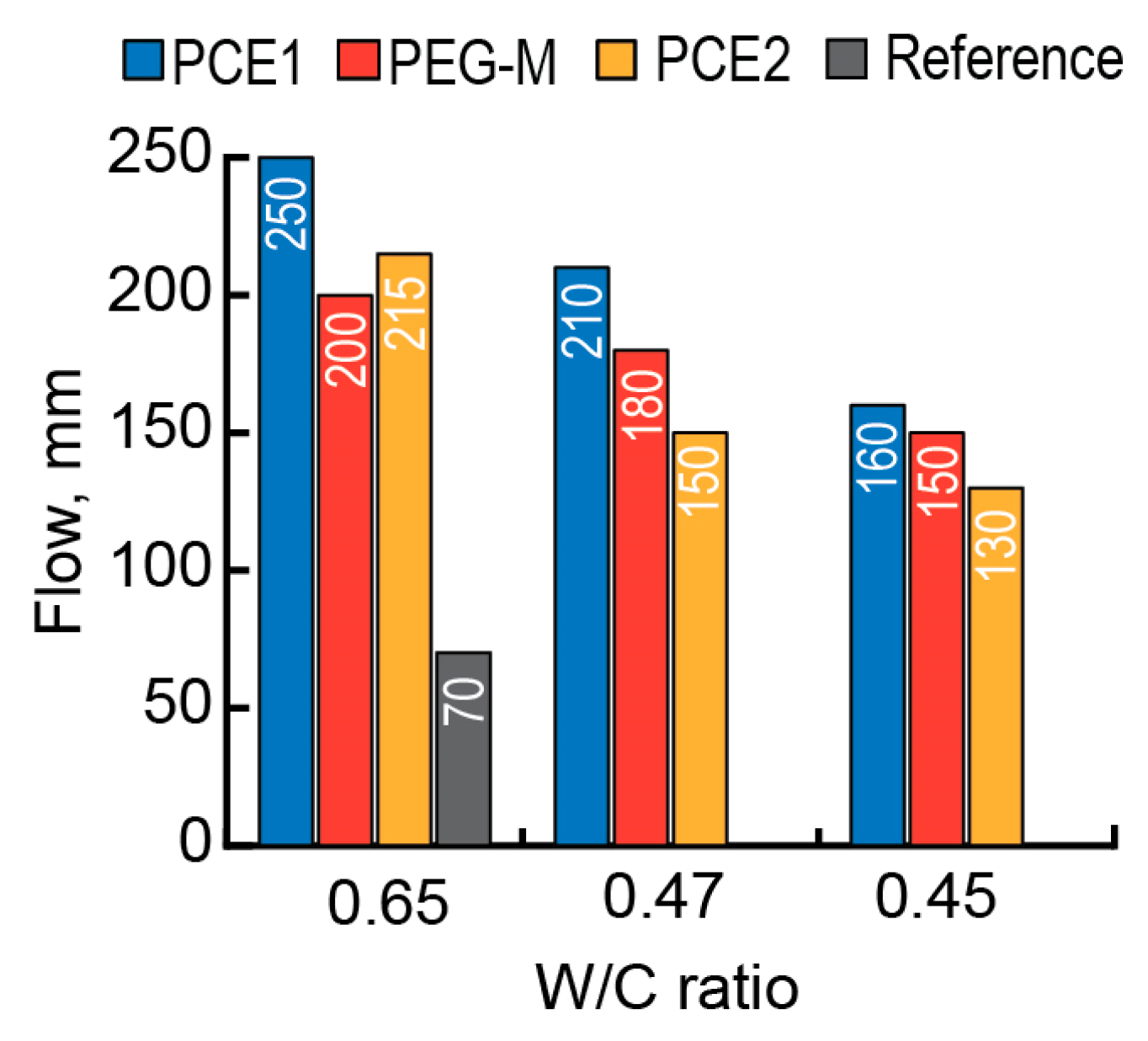

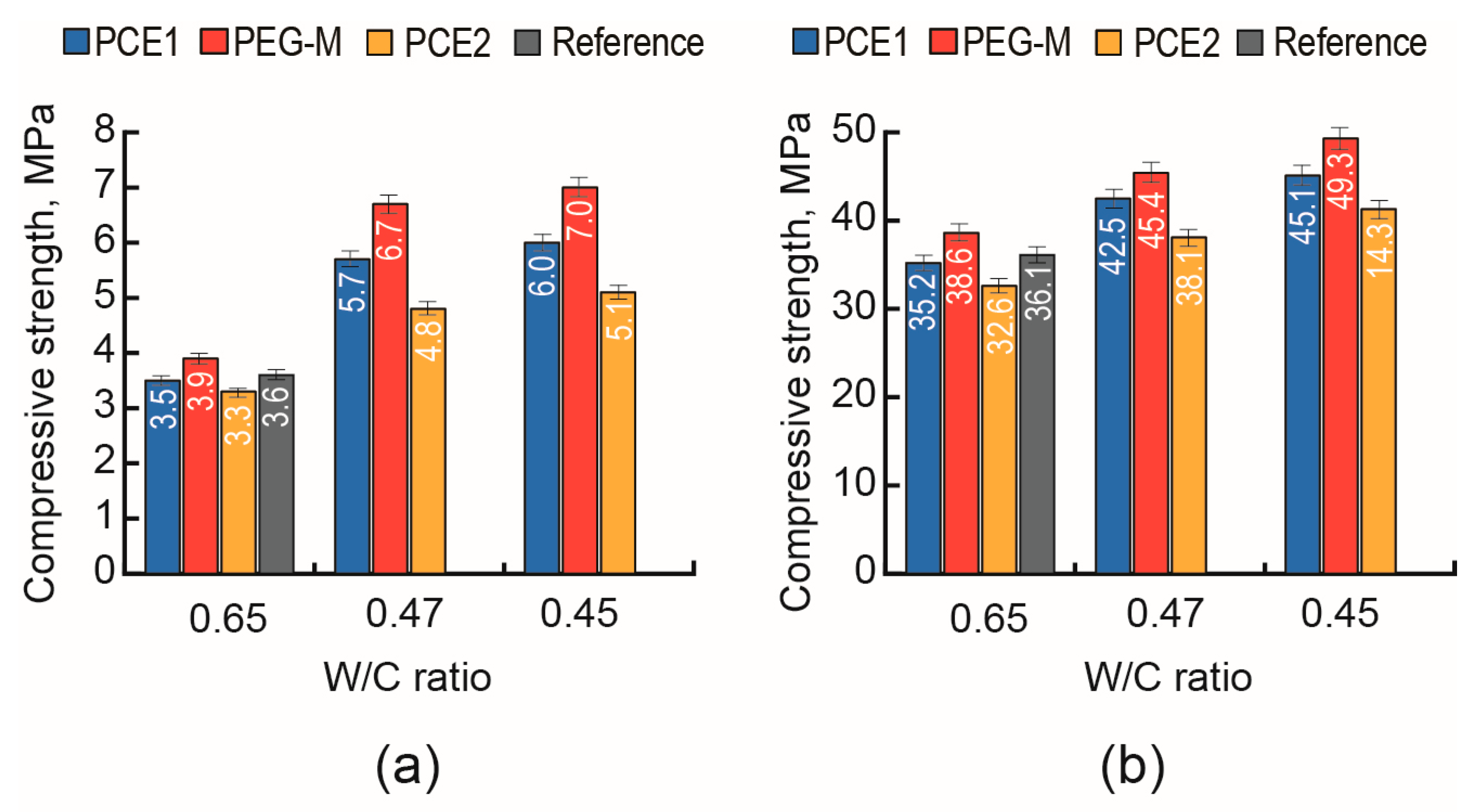

3.3. The Influence of the Degree of Dispersing of the AAC in the Materials

3.3.1. Factors #1 and #2: Molecular Structure and Charge of Polar Groups of a Surfactant

3.3.2. Factor #3: Molecular Weight of a Surfactant

4. Discussion

5. Technology and Case Studies

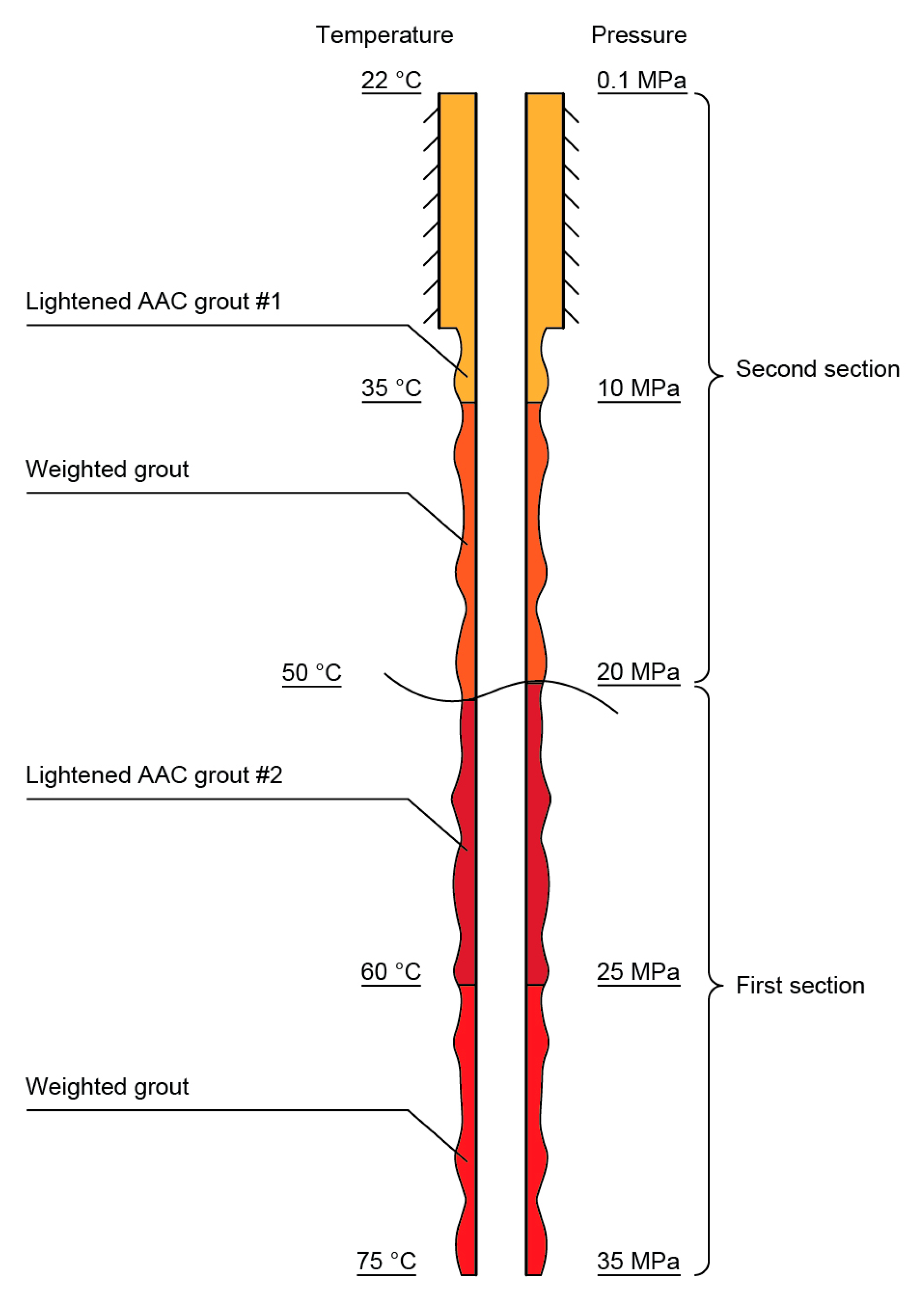

5.1. Lightened AAC Grouts

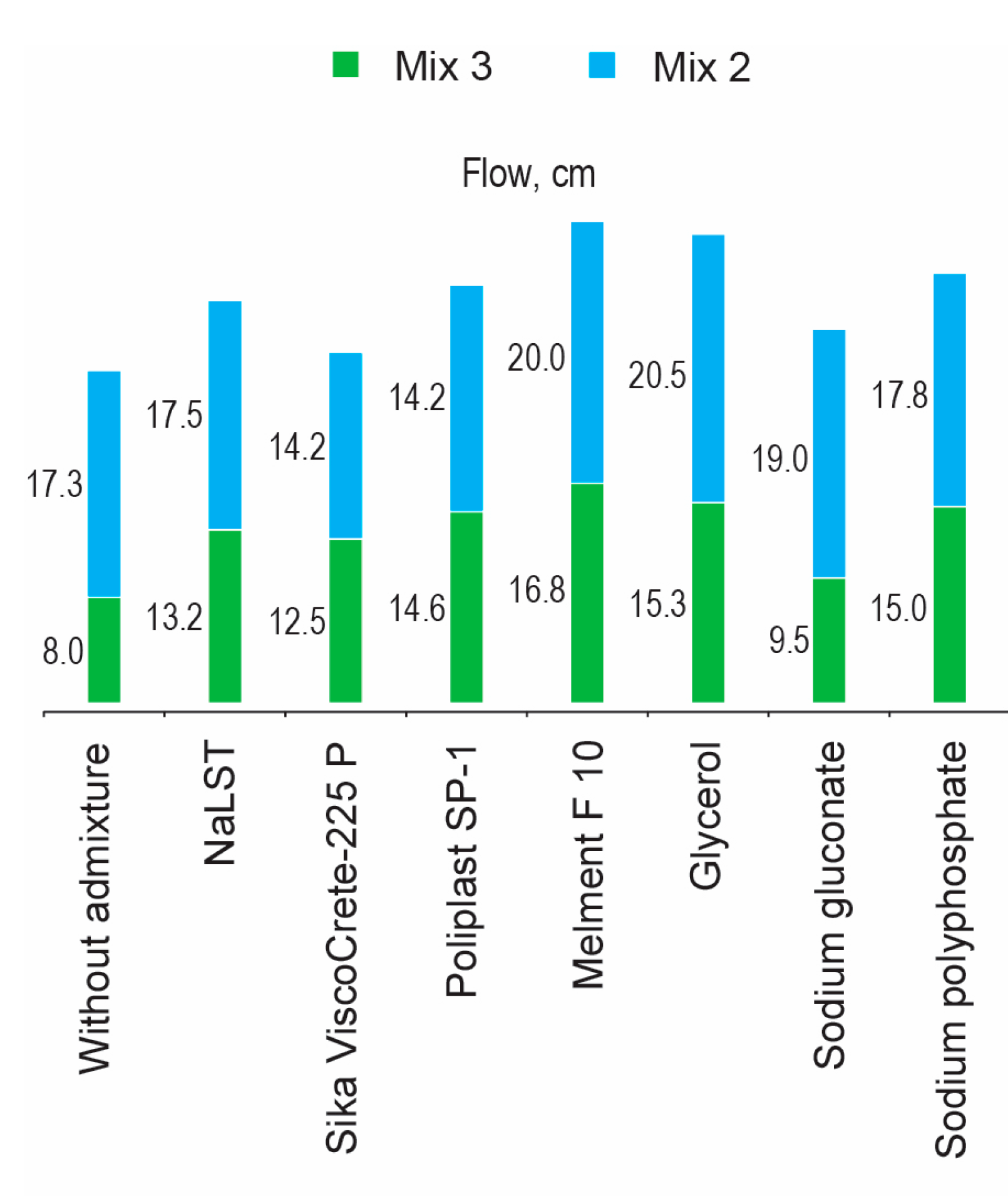

5.2. Building AAC Mortars

- to escape intermixing of AAC components;

- to store the components in separate tanks.

5.2.1. Dry Mixes for Anchoring Application

5.2.2. Dry Mixes for Floor Application

5.3. Heavyweight AAC Concretes

5.3.1. Concrete for Pavement Application

5.3.2. Concrete for Monolithic-Framed Construction

6. Conclusions

- A conclusion was made that with the decrease of the alkali-activated cement basicity from Mb = 2.4 to Mb ≤ 1.3, the content of the alkaline component should be increased. As a result, the action effect of admixtures with ester bonds (PCE) in the molecular structure due to alkaline hydrolysis decreased. The substitution of anionic for cationic or nonionic surfactants increased the action effect, with its dependence from the surfactant molecular weight decreasing. The use of polyhydrosiloxane in conjunction with NaLST was effective for obtaining the desirable effect from plasticization, regardless of the alkali-activated cement basicity, especially with regard to the surface activity of nonionic surfactants.

- The substitution of carbonates for silicates in the alkaline component required substituting PCE for polyols or polyethers, taken alone or in conjunction with NaLST. The effectiveness of plasticization increased with the decrease of the surfactant molecular weight. With the increase of the content of the alkaline component as a result of the decrease of the alkali-activated cement basicity, the importance of the anion of the alkaline component decreased, and anionic surfactants were to be substituted for nonionic surfactants.

- With the increase of the degree of dispersing of the alkali-activated cement suspensions in the transition from heavyweight concretes to building mortars and further to lightened grouts, polyester-based plasticizers were to be substituted for polyols, that is, the role of the molecular weight decreased. This could be attributed to the higher contents of the liquid phase, which added a plasticizing effect.

- The developed and proposed principles which take into account the technology-related features of AAC materials like lightened grouts, building mortars, and heavyweight concretes were explored in a pilot-scale production. The lightened grouts were obtained using polyols, building mortars, and heavyweight concretes—polyethers and carboxylic acid salts in conjunction with NaLST.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-Efficient Cements: Potential Economically Viable Solutions for a Low-CO2 Cement-Based Materials Industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Naqi, A.; Jang, J. Recent Progress in Green Cement Technology Utilizing Low-Carbon Emission Fuels and Raw Materials: A Review. Sustainability 2019, 11, 537. [Google Scholar] [CrossRef]

- Raghav, M.; Park, T.; Yang, H.-M.; Lee, S.-Y.; Karthick, S.; Lee, H.-S. Review of the Effects of Supplementary Cementitious Materials and Chemical Additives on the Physical, Mechanical and Durability Properties of Hydraulic Concrete. Materials 2021, 14, 7270. [Google Scholar] [CrossRef] [PubMed]

- Provis, J.L.; Winnefeld, F. Outcomes of the Round Robin Tests of RILEM TC 247-DTA on the Durability of Alkali-Activated Concrete. MATEC Web Conf. 2018, 199, 02024. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, L.; Li, J.; De Belie, N.; Shi, X.; Van Den Heede, P.; Zhang, C.; Liu, Z.; Talakokula, V.; Jin, Z.; et al. Report of RILEM TC 281-CCC: Effect of Loading on the Carbonation Performance of Concrete with Supplementary Cementitious Materials—An Interlaboratory Comparison of Different Test Methods and Related Observations. Mater. Struct. 2023, 56, 110. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Garcia-Lodeiro, I.; Maltseva, O.; Palomo, A. Sustainable Cements: Hybrid Alkaline Cements Overview. In Proceedings of the 75th RILEM Annual Week 2021; Escalante-Garcia, J.I., Castro Borges, P., Duran-Herrera, A., Eds.; RILEM Bookseries; Springer International Publishing: Cham, Switzerland, 2023; Volume 40, pp. 626–639. ISBN 978-3-031-21734-0. [Google Scholar]

- Von Greve-Dierfeld, S.; Lothenbach, B.; Vollpracht, A.; Wu, B.; Huet, B.; Andrade, C.; Medina, C.; Thiel, C.; Gruyaert, E.; Vanoutrive, H.; et al. Understanding the Carbonation of Concrete with Supplementary Cementitious Materials: A Critical Review by RILEM TC 281-CCC. Mater. Struct. 2020, 53, 136. [Google Scholar] [CrossRef]

- THE 17 GOALS. Available online: https://sdgs.un.org/goals (accessed on 8 September 2023).

- A European Green Deal. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 15 June 2025).

- Krivenko, P. Why Alkaline Activation—60 Years of the Theory and Practice of Alkali-Activated Materials. J. Ceram. Sci. Technol. 2017, 8, 323–334. [Google Scholar] [CrossRef]

- Fyfe, W.S.; Turner, F.J.; Verhoogen, J. Metamorphic Reactions and Metamorphic Facies Geological Society of America Memoirs; Geological Society of America: Ithaca, NY, USA, 1958. [Google Scholar]

- Palomo, A.; Maltseva, O.; Garcia-Lodeiro, I.; Fernández-Jiménez, A. Portland Versus Alkaline Cement: Continuity or Clean Break: “A Key Decision for Global Sustainability. Front. Chem. 2021, 9, 705475. [Google Scholar] [CrossRef]

- Krivenko, P.; Rudenko, I.; Konstantynovskyi, O.; Vaičiukynienė, D. Feasibility of Incorporating SO42−-Ions in Zeolite-like Matrices Based on Alkaline Aluminosilicate Binders. Constr. Build. Mater. 2023, 391, 131878. [Google Scholar] [CrossRef]

- Kryvenko, P.; Rudenko, I.; Konstantynovskyi, O.; Gelevera, O. Design, Characterization, and Incorporation of the Alkaline Aluminosilicate Binder in Temperature-Insulating Composites. Materials 2024, 17, 664. [Google Scholar] [CrossRef]

- Krivenko, P.; Puertas, F.; Gots, V.; Helevera, O.; Rogozina, N. Influence of Whitening Additives on the Properties of Decorative Slag-Alkali Cements and Mortars. Mater. Constr. 2023, 73, e311. [Google Scholar] [CrossRef]

- Guvalov, A.; Abbasova, S. Influence of Rheological Active Additives on the Properties of Self-Compacting Concrete. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2021, 36, 381–386. [Google Scholar] [CrossRef]

- Jiao, D.; Shi, C.; Yuan, Q.; An, X.; Liu, Y.; Li, H. Effect of Constituents on Rheological Properties of Fresh Concrete-A Review. Cem. Concr. Compos. 2017, 83, 146–159. [Google Scholar] [CrossRef]

- Bispo, R.A.; Vicente, G.O.; Silva Júnior, G.P.D.; Benjamim, D.U.; Alcântara, M.A.D.M. Investigation of Rheological Behavior of Self-Compacting and High Performance Composite Concretes. Mater. Res. 2021, 24, e20210264. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Skaf, M.; Santamaría, A.; Hernández-Bagaces, J.J.; Ortega-López, V. Temporal Flowability Evolution of Slag-Based Self-Compacting Concrete with Recycled Concrete Aggregate. J. Clean. Prod. 2021, 299, 126890. [Google Scholar] [CrossRef]

- Qin, Y.; Qu, C.; Ma, C.; Zhou, L. One-Part Alkali-Activated Materials: State of the Art and Perspectives. Polymers 2022, 14, 5046. [Google Scholar] [CrossRef] [PubMed]

- Elzeadani, M.; Bompa, D.V.; Elghazouli, A.Y. One Part Alkali Activated Materials: A State-of-the-Art Review. J. Build. Eng. 2022, 57, 104871. [Google Scholar] [CrossRef]

- Lei, L.; Hirata, T.; Plank, J. 40 Years of PCE Superplasticizers—History, Current State-of-the-Art and an Outlook. Cem. Concr. Res. 2022, 157, 106826. [Google Scholar] [CrossRef]

- Runova, R.F.; Kochevyh, M.O.; Rudenko, I.I. On the Slump Loss Problem of Superplasticized Concrete Mixes. In Proceedings of the Admixtures—Enhancing Concrete Performance, Scotland, UK, 6 July 2005; pp. 149–156. [Google Scholar]

- Puertas, F.; Varga, C.; Alonso, M.M. Rheology of Alkali-Activated Slag Pastes. Effect of the Nature and Concentration of the Activating Solution. Cem. Concr. Compos. 2014, 53, 279–288. [Google Scholar] [CrossRef]

- Puertas, F.; Alonso, M.M.; Gismera, S.; Lanzón, M.; Blanco-Varela, M.T. Rheology of Cementitious Materials: Alkali-Activated Materials or Geopolymers. MATEC Web Conf. 2018, 149, 01002. [Google Scholar] [CrossRef]

- DSTU B V.2.7-171:2008 (EN 934-2:2001, NEQ); Building Materials. Admixtures for Concretes and Building Mortars. General Specifications. National Standard of Ukraine: Kyiv, Ukraine, 2008.

- Palacios, M.; Puertas, F. Estabilidad de Aditivos Superplastificantes y Reductores de La Retracción En Medios Fuertemente Básicos. Mater. Constr. 2004, 54, 65–86. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.G.; Cheng, Y.-B. Effect of Admixtures on Properties of Alkali-Activated Slag Concrete. Cem. Concr. Res. 2000, 30, 1367–1374. [Google Scholar] [CrossRef]

- Palacios, M.; Puertas, F. Effect of Superplasticizer and Shrinkage-Reducing Admixtures on Alkali-Activated Slag Pastes and Mortars. Cem. Concr. Res. 2005, 35, 1358–1367. [Google Scholar] [CrossRef]

- Bessaies-Bey, H.; Khayat, K.H.; Palacios, M.; Schmidt, W.; Roussel, N. Viscosity Modifying Agents: Key Components of Advanced Cement-Based Materials with Adapted Rheology. Cem. Concr. Res. 2022, 152, 106646. [Google Scholar] [CrossRef]

- Palacios, M.; Houst, Y.F.; Bowen, P.; Puertas, F. Adsorption of Superplasticizer Admixtures on Alkali-Activated Slag Pastes. Cem. Concr. Res. 2009, 39, 670–677. [Google Scholar] [CrossRef]

- Plank, J.; Schroefl, C.; Gruber, M.; Lesti, M.; Sieber, R. Effectiveness of Polycarboxylate Superplasticizers in Ultra-High Strength Concrete: The Importance of PCE Compatibility with Silica Fume. J. Adv. Concr. Technol. 2009, 7, 5–12. [Google Scholar] [CrossRef]

- Flatt, R.J.; Houst, Y.F.; Bowen, P.; Hofmann, H.; Widmer, J.; Sulser, U.; Maeder, U.; Bürge, T.A. Interaction of Superplasticizers with Model Powders in Highly Alkaline Médium. In Superplasticizers and Other Chemical Admixtures in Concrete; American Concrete Institute: Detroit, MI, USA, 1997; pp. 743–762. [Google Scholar]

- Yamada, K.; Ogawa, S.; Hanehara, S. Controlling of the Adsorption and Dispersing Force of Polycarboxylate-Type Superplasticizer by Sulfate Ion Concentration in Aqueous Phase. Cem. Concr. Res. 2001, 31, 375–383. [Google Scholar] [CrossRef]

- Plank, J.; Winter, C. Competitive Adsorption between Superplasticizer and Retarder Molecules on Mineral Binder Surface. Cem. Concr. Res. 2008, 38, 599–605. [Google Scholar] [CrossRef]

- Krivenko, P.V.; Runova, R.F.; Rudenko, I.I. Plasticized Concrete and Mortar Based on Cements System Na2O–CaO–Al2O3–SiO2–H2O: Monography; Lira-K: Kyiv, Ukraine, 2022. [Google Scholar]

- Rashad, A.M. A Comprehensive Overview about the Influence of Different Additives on the Properties of Alkali-Activated Slag—A Guide for Civil Engineer. Constr. Build. Mater. 2013, 47, 29–55. [Google Scholar] [CrossRef]

- Conte, T.; Plank, J. Influence of Polycarboxylate Ether on the Rheological Behavior of Alkali Activated Slag Paste; F. A. Finger Institut für Baustoffkunde Bauhaus-Universität Weimar: Weimar, Germany, 2018; Volume 1, pp. 803–811. [Google Scholar]

- Marchon, D.; Sulser, U.; Eberhardt, A.; Flatt, R.J. Molecular Design of Comb-Shaped Polycarboxylate Dispersants for Environmentally Friendly Concrete. Soft Matter 2013, 9, 10719. [Google Scholar] [CrossRef]

- Kashani, A.; Provis, J.L.; Xu, J.; Kilcullen, A.R.; Qiao, G.G.; Van Deventer, J.S.J. Effect of Molecular Architecture of Polycarboxylate Ethers on Plasticizing Performance in Alkali-Activated Slag Paste. J. Mater. Sci. 2014, 49, 2761–2772. [Google Scholar] [CrossRef]

- Flatt, R.J.; Bowen, P. Electrostatic Repulsion between Particles in Cement Suspensions: Domain of Validity of Linearized Poisson–Boltzmann Equation for Nonideal Electrolytes. Cem. Concr. Res. 2003, 33, 781–791. [Google Scholar] [CrossRef]

- Rosen, M.J.; Kunjappu, J.T. Surfactants and Interfacial Phenomena: Monography; Willey: New York, NY, USA, 2012. [Google Scholar]

- Williams, J.M. High Internal Phase Water-in-Oil Emulsions: Influence of Surfactants and Cosurfactants on Emulsion Stability and Foam Quality. Langmuir 1991, 7, 1370–1377. [Google Scholar] [CrossRef]

- Holmberg, K.; Lindman, B.; Kronberg, B. Surface Chemistry of Surfactants and Polymers; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Tian, Y.; Yuan, Q.; Yang, C.; Yang, K.; Yu, L.; Zhang, M.; Zhu, X. Insights into the Efficiency Loss of Naphthalene Superplasticizer in Alkali-Activated Slag Pastes. J. Build. Eng. 2023, 68, 106176. [Google Scholar] [CrossRef]

- Palacios, M.; Puertas, F. Effect of Shrinkage-Reducing Admixtures on the Properties of Alkali-Activated Slag Mortars and Pastes. Cem. Concr. Res. 2007, 37, 691–702. [Google Scholar] [CrossRef]

- Partschefeld, S.; Tutal, A.; Halmanseder, T.; Schneider, J.; Osburg, A. Investigations on Stability of Polycarboxylate Superplasticizers in Alkaline Activators for Geopolymer Binders. Materials 2023, 16, 5369. [Google Scholar] [CrossRef] [PubMed]

- Alrefaei, Y.; Wang, Y.-S.; Dai, J.-G. The Effectiveness of Different Superplasticizers in Ambient Cured One-Part Alkali Activated Pastes. Cem. Concr. Compos. 2019, 97, 166–174. [Google Scholar] [CrossRef]

- Chang, J.J. A Study on the Setting Characteristics of Sodium Silicate-Activated Slag Pastes. Cem. Concr. Res. 2003, 33, 1005–1011. [Google Scholar] [CrossRef]

- Keser, H.E.; Ramyar, K.; Gultekin, A. Effect of Water-reducing Admixtures Water Content on Rheology, Workability, and Mechanical Properties of Fly Ash-based Geopolymer and Slag-based Alkali-activated Mixtures. Struct. Concr. 2023, suco.202300113. [Google Scholar] [CrossRef]

- Jolicoeur, C.; Simard, M.A.; Sharman, J.; Zamojska, R.; Dupuis, M.; Spiratos, E.; Doglas, E. Chemical Activation of Blast-Furnace Slag: An Overview and Systematic Experimental Investigations; Energy, Mines and Resources: Ottawa, ON, Canada, 1992. [Google Scholar]

- Collepardi, M.; Grossi, G.; Pellizon Birelli, M.; Ventura, G. Influence of D-Sorbitol on the Properties of Binders to Immobilize Acid Nuclear Wastes. In Proceedings of the SP-239: 8th CanMET/ACI International Conference on Superplasticizers and Other Chemical Admixtures in Concrete, Sorrento, Italy, 29 October–1 November 2006; American Concrete Institute: Detroit, MI, USA, 2006. [Google Scholar]

- Tong, S.; Yuqi, Z.; Qiang, W. Recent Advances in Chemical Admixtures for Improving the Workability of Alkali-Activated Slag-Based Material Systems. Constr. Build. Mater. 2021, 272, 121647. [Google Scholar] [CrossRef]

- Luukkonen, T.; Abdollahnejad, Z.; Ohenoja, K.; Kinnunen, P.; Illikainen, M. Suitability of Commercial Superplasticizers for One-Part Alkali-Activated Blast-Furnace Slag Mortar. J. Sustain. Cem.-Based Mater. 2019, 8, 244–257. [Google Scholar] [CrossRef]

- Kalina, L.; Bílek, V.; Hrubý, P.; Iliushchenko, V.; Kalina, M.; Smilek, J. On the Action Mechanism of Lignosulfonate Plasticizer in Alkali-Activated Slag-Based System. Cem. Concr. Res. 2022, 157, 106822. [Google Scholar] [CrossRef]

- Kalina, L.; Hajdúchová, M.; Langová, M.; Enev, V. Possibilities of Using Plasticizers in Alkali-Activated Systems. Mater. Sci. Forum 2016, 851, 57–62. [Google Scholar] [CrossRef]

- Mikhailova, O.; Rovnanik, P. Effect of Polyethylene Glycol on the Rheological Properties and Heat of Hydration of Alkali Activated Slag Pastes. IOP Conf. Ser. Mater. Sci. Eng. 2018, 385, 012037. [Google Scholar] [CrossRef]

- Runova, R.; Gots, V.; Rudenko, I.; Konstantynovskyi, O.; Lastivka, O. The Efficiency of Plasticizing Surfactants in Alkali-Activated Cement Mortars and Concretes. MATEC Web Conf. 2018, 230, 03016. [Google Scholar] [CrossRef]

- Krivenko, P.; Rudenko, I.; Konstantynovskyi, O. Comparison of Influence of Surfactants on Thermokinetic Characteristics of Alkali-Activated Slag Cement. East.-Eur. J. Enterp. Technol. 2021, 6, 39–48. [Google Scholar] [CrossRef]

- Usherov-Marshak, A.; Sopov, V.; Kabus, A. Calorimetry in Chemistry and Technology of Cement and Concrete. In Proceedings of the Thermal Analysis and Calorimetry, Chisinau, Moldova, 28–31 August 2017; p. 353. [Google Scholar]

- Performance of an Advanced Polycarboxylate-Based Powder Superplasticizer. In Proceedings of the SP-217: Seventh CANMET/ACI International Conference on Superplasticizers and Other Chemical Admixtures in Concrete, Berlin, Germany, 20–23 October 2003; American Concrete Institute: Detroit, MI, USA, 2003.

- Development of Slump-Loss Controlling Agent with Minimal Setting Retardation. In Proceedings of the SP-217: Seventh CANMET/ACI International Conference on Superplasticizers and Other Chemical Admixtures in Concrete, Berlin, Germany, 20–23 October 2003; American Concrete Institute: Detroit, MI, USA, 2003.

- Alonso, A.A. Comportamiento y Compatibilidad de Cementos y Aditivos Superplastificantes Basados En Policarboxilatos. Efectos de La Naturaleza de Los Cementos y Estructura de Los Aditivos. Ph.D. Thesis, Univesrsidad Autonoma de Madrid, Madrid, Spain, 2011. [Google Scholar]

- Burgos-Montes, O.; Palacios, M.; Rivilla, P.; Puertas, F. Compatibility between Superplasticizer Admixtures and Cements with Mineral Additions. Constr. Build. Mater. 2012, 31, 300–309. [Google Scholar] [CrossRef]

- Conte, T.; Plank, J. Impact of Molecular Structure and Composition of Polycarboxylate Comb Polymers on the Flow Properties of Alkali-Activated Slag. Cem. Concr. Res. 2019, 116, 95–101. [Google Scholar] [CrossRef]

- Lei, L.; Chan, H.-K. Investigation into the Molecular Design and Plasticizing Effectiveness of HPEG-Based Polycarboxylate Superplasticizers in Alkali-Activated Slag. Cem. Concr. Res. 2020, 136, 106150. [Google Scholar] [CrossRef]

- Su, T.; Wang, Q.; Lu, J. Effect of NaOH content on the fluidizing effect of PCEs with different structures in NaOH-activated slag. Cem. Concr. Res. 2023, 166, 107112. [Google Scholar] [CrossRef]

- Chen, J.; Plank, J. Which factors impact the effectiveness of PCEs in alkali-activated slag cements? Cem. Concr. Res. 2025, 190, 107807. [Google Scholar] [CrossRef]

- Zhang, Y.; Chan, H.-K.; Han, Z.; Lei, L. Why do conventional MAA-MPEG PCEs not work in alkali-activated slag systems? Cem. Concr. Res. 2024, 184, 107599. [Google Scholar] [CrossRef]

- Lei, L.; Zhang, Y. Preparation of isoprenol ether-based polycarboxylate superplasticizers with exceptional dispersing power in alkali-activated slag: Comparison with ordinary Portland cement. Compos. Part B Eng. 2021, 223, 109077. [Google Scholar] [CrossRef]

- Ezzat, M.; Latsrisaeng, P.; Lesage, K.; Yardimci, M.Y.; Hoogenboom, R.; De Schutter, G. Novel Concrete Superplasticizers with Sterically Hindered Amines as Stabilizing Pendant Side Chains. Eur. Polym. J. 2023, 196, 112301. [Google Scholar] [CrossRef]

- Ezzat, M.; Xu, X.; El Cheikh, K.; Lesage, K.; Hoogenboom, R.; De Schutter, G. Structure-Property Relationships for Polycarboxylate Ether Superplasticizers by Means of RAFT Polymerization. J. Colloid Interface Sci. 2019, 553, 788–797. [Google Scholar] [CrossRef] [PubMed]

- Wallevik, O.H.; Wallevik, J.E. Rheology as a Tool in Concrete Science: The Use of Rheographs and Workability Boxes. Cem. Concr. Res. 2011, 41, 1279–1288. [Google Scholar] [CrossRef]

- Wallevik, J.E. Rheological Properties of Cement Paste: Thixotropic Behavior and Structural Breakdown. Cem. Concr. Res. 2009, 39, 14–29. [Google Scholar] [CrossRef]

- Alonso, M.M.; Gismera, S.; Blanco, M.T.; Lanzón, M.; Puertas, F. Alkali-Activated Mortars: Workability and Rheological Behaviour. Constr. Build. Mater. 2017, 145, 576–587. [Google Scholar] [CrossRef]

- Lastivka, O.V. Modified Concrete Based on Alkaline Slag Portland Cement for In-Situ Construction. Ph.D. Thesis, Kyiv National University of Construction and Architecture, Kyiv, Ukraine, 2015. [Google Scholar]

- Mamatkulov, A.M. Lightweight Slag Alkaline Tamping Mortats. Ph.D. Thesis, Kyiv National University of Construction and Architecture, Kyiv, Ukraine, 2000. [Google Scholar]

- Skoryk, V.V. Backfill Mortars Based on Alkaline Cement for Variable Cure Conditions in the Well. Ph.D. Thesis, Kyiv National University of Construction and Architecture, Kyiv, Ukraine, 2018. [Google Scholar]

- DSTU B V.2.7-232:2010; Sand for Construction Work. Testing Methods. National Standard of Ukraine: Kyiv, Ukraine, 2010.

- EN 12350-2:2019; Testing Fresh Concrete—Part 2: Slump Test. European Committee for Standardization: Brussels, Belgium, 2019.

- DSTU B V.2.7-126:2011; Modified Dry Building Mixtures. General Specifications. National Standard of Ukraine: Kyiv, Ukraine, 2011.

- DSTU B V.2.7-86-99; Oil-Well Cements. Test Methods. National Standard of Ukraine: Kyiv, Ukraine, 2000.

- ISO 10426-2:2003; Petroleum and Natural Gas Industries—Cements and Materials for Well Cementing. Part 2: Testing of Well Cements. International Organization for Standardization: Geneva, Switzerland, 2003.

- EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. European Committee for Standardization: Brussels, Belgium, 2019.

- DSTU B V.2.7-49-96; Concretes. Rapid Methods for Determination of Frost Resistance by Repeated Alternated Freezing and Thawing. National Standard of Ukraine: Kyiv, Ukraine, 1996.

- DSTU B V.2.7-47; Concretes. Methods for Determination of Frost Resistance. General Requirements. National standard of Ukraine: Kyiv, Ukraine, 1996.

- EN 196-1:2005; Methods of Testing Cement—Part 1: Determination of Strength. European Committee for Standardization: Brussels, Belgium, 2005.

- EN 1542:1999; Products and Systems for the Protection and Repair of Concrete Structures—Test Methods—Measurement of Bond Strength by Pull-Off. European Committee for Standardization: Brussels, Belgium, 1999.

- EN 1881:2006; Products and Systems for the Protection and Repair of Concrete Structures—Test Methods—Testing of Anchoring Products by the Pull-Out Method. European Committee for Standardization: Brussels, Belgium, 2006.

- Volynska, I.V. Eco-Concrete on the Basis of Slag-Cement on the Use of Mica-Based by-Products of the Mining Industry. Ph.D. Thesis, Kyiv National University of Construction and Architecture, Kyiv, Ukraine, 2018. [Google Scholar]

- Terlyha, V.; Sobol, K. Tamping Mortars with Stabilizing and Plasticizing Admixtures. SSP J. Civ. Eng. 2012, 7, 87–94. [Google Scholar] [CrossRef]

- Tao, C.; Kutchko, B.G.; Rosenbaum, E.; Massoudi, M. A Review of Rheological Modeling of Cement Slurry in Oil Well Applications. Energies 2020, 13, 570. [Google Scholar] [CrossRef]

- Munjal, P.; Hau, K.K.; Prabhakar, A.; Arthur, C.C.H. Oil Well Cement for High Temperature-A Review. IOP Conf. Ser. Mater. Sci. Eng. 2019, 652, 012055. [Google Scholar] [CrossRef]

- Ma, C.; Tan, Y.; Li, E.; Dai, Y.; Yang, M. High-Performance Grouting Mortar Based on Mineral Admixtures. Adv. Mater. Sci. Eng. 2015, 2015, 425456. [Google Scholar] [CrossRef]

- Wang, Y.; Ren, A.; Wang, Y.; He, J.; Chen, Z. Investigations on Corrosion and Mechanical Properties of a 20 Year Old Ground Anchor Exhumed at a Power Station Site. Can. Geotech. J. 2016, 53, 589–602. [Google Scholar] [CrossRef]

- Kryvenko, P.V.; Gots, V.I.; Petropavlovskyi, O.; Rudenko, I.; Konstantynovskyi, O.P. Complex Shrinkage-Reducing Additives for Alkali Activated Slag Cement Fine Concrete. Solid State Phenom. 2021, 321, 165–170. [Google Scholar] [CrossRef]

- Krivenko, P.V.; Petropavlovskyi, O.M.; Rudenko, I.I.; Konstantynovskyi, O.P.; Kovalchuk, A.V. Complex Multifunctional Additive for Anchoring Grout Based on Alkali-Activated Portland Cement. IOP Conf. Ser. Mater. Sci. Eng. 2020, 907, 012055. [Google Scholar] [CrossRef]

- Hoła, J.; Sadowski, Ł.; Hoła, A. The Effect of Failure to Comply with Technological and Technical Requirements on the Condition of Newly Built Cement Mortar Floors. Proc. Inst. Mech. Eng. Part J. Mater. Des. Appl. 2018, 233, 268–275. [Google Scholar] [CrossRef]

- Troyan, V.V. Dry Mixes and Mortars on Their Basis for the Device of Floors of Industrial Buildings. Ph.D. Thesis, Kyiv National University of Construction and Architecture, Kyiv, Ukraine, 2007. [Google Scholar]

- Nosovskyi, Y.L. Mortars Based on Composite Binder for Flow Floors. Ph.D. Thesis, Kyiv National University of Construction and Architecture, Kyiv, Ukraine, 2004. [Google Scholar]

- Wasim, M.; Ngo, T.D.; Law, D. A State-of-the-Art Review on the Durability of Geopolymer Concrete for Sustainable Structures and Infrastructure. Constr. Build. Mater. 2021, 291, 123381. [Google Scholar] [CrossRef]

- Krivenko, P.; Rudenko, I.; Konstantynovskyi, O. Effect of Technological Factors on Freeze-Thaw Resistance of Alkali-Activated Slag Cement Concrete in NaCl Solution. AIP Conf. Proc. 2023, 2684, 040011. [Google Scholar]

- Krivenko, P.; Rudenko, I.; Konstantynovskyi, O.; Boiko, O. Prevention of Steel Reinforcement Corrosion in Alkali-Activated Slag Cement Concrete Mixed with Seawater. E3S Web Conf. 2021, 280, 07004. [Google Scholar] [CrossRef]

- Krivenko, P.; Rudenko, I.; Konstantynovskyi, O.; Vaičiukynienė, D. Mitigation of Corrosion Initiated by Cl− and SO42−-Ions in Blast Furnace Cement Concrete Mixed with Sea Water. Materials 2022, 15, 3003. [Google Scholar] [CrossRef]

| Mix | Modulus of AAC Basicity, Mb | Components, % by Mass | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| AAC | Milled Sand fr. < 0.16 | Sand fr. 0.16/0.63 | Sand fr. 0.63/1.25 | Granite Screening (fr. 1.25/2.5) | Water | ||||||

| GBFS | Clinker | Soda-Ash | Sodium Metasili Cate | Calcium Sulphate Hemihydrate | |||||||

| Mix 1 | 2.4 | 0.0 | 28.5 | 0.0 | 0.7 (0.2) | 2.6 | 11.9 | 9.5 | 14.3 | 11.9 | 20.6 |

| Mix 2 | 1.2 | 24.5 | 1.6 | 0.0 | 2.0 (0.6) | 0.0 | 16.3 | 40.8 | 0.0 | 0.0 | 14.8 |

| Mix 3 | 24.7 | 1.6 | 1.0 (0.6) | 0.0 | 0.0 | 16.4 | 41.2 | 0.0 | 0.0 | 15.1 | |

| Mix 4 | 20.0 | 1.1 | 1.0 (0.6) | 2.0 (0.6) | 0.0 | 20.0 | 41.0 | 0.0 | 0.0 | 14.6 | |

| Mix | Modulus of AAC Basicity, Mb | Components, % by Mass | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| AAC | Silica Sand | Granite Gravel fr. 5/10 | Granite Gravel fr. 10/20 | Water | ||||||

| GBFS | Clinker | Soda-Ash | Sodium Metasilicate | Calcium Sulphate Hemihydrate | ||||||

| Mix 5 | 1.6 | 6.7 | 6.7 | 0.0 | 0.4 (0.1) | 0.9 | 30.2 | 13.8 | 34.0 | 7.3 |

| Mix 6 | 6.7 | 6.7 | 0.3 (0.12) | 0.0 | 0.9 | 30.1 | 13.8 | 33.9 | 7.6 | |

| Mix 7 | 1.3 | 12.4 | 1.7 | 0.6 (0.35) | 0.0 | 0.0 | 30.2 | 13.9 | 34.0 | 7.2 |

| Mix 8 | 1.2 | 13.8 | 0.0 | 0.0 | 0.8 (0.2) | 0.0 | 30.4 | 13.9 | 34.2 | 6.8 |

| Mix 9 | 13.9 | 0.0 | 0.7 (0.4) | 0.0 | 0.0 | 30.3 | 13.9 | 34.0 | 7.1 | |

| Mix 10 | 13.6 | 0.0 | 0.6 (0.35) | 0.4 (0.1) | 0.0 | 30.3 | 14.0 | 34.1 | 6.9 | |

| Admixture | Charges of Polar Groups | Chemical Nature | Content, % by Mass of AAC |

|---|---|---|---|

| “JK-04PP” (PCE1) (JIANKAI, Beijing, China) | anionic | PCE | 0.5 |

| “Vinavil fluxe” (PCE2) (Mapei, Milan, Italy) | 0.5 | ||

| “Muraplast FK 59” (MC-Bauchemie, Bottrop, Germany) | 1.0 | ||

| “Sika ViscoCrete-225 P” (Sika, Stuttgart, Germany) | 0.5–1.0 | ||

| “Poliplast SP-1” (XTC, Odessa, Ukraine) | based on sulphonated naphthalene formaldehyde condensates | 0.5–1.0 | |

| “Melment F 10” (BASF, Ludwigshafen, Germany) | based on sulphonated melamine formaldehyde condensates | 0.5 | |

| “Melflux PP100F” (PEG-M) (BASF, Ludwigshafen, Germany) | based on modified polyethylene glycol (copolymer of polyethylene glycol and acrylic acid) | 0.5 | |

| “Mapetard SD 2000” (Mapei) | based on sodium gluconate | 0.5 | |

| Ethylene glycol (CAS 107-21-1) | 2-atomic polyol | 0.5–2.5 | |

| Glycerol (CAS 56-81-5) | 3-atomic polyol | 0.5–2.5 | |

| Sorbitol (CAS 50-70-4) | 6-atomic polyol | 0.5–3.5 | |

| Sodium hexametaphosphate (CAS 10124-56-8) | sodium polyphosphate | 0.3–1.0 | |

| “BC-50” (further, BC-50) (CAS 139-07-1) | cationic | dodecyl dimethyl benzyl ammonium chloride, salt of quaternary ammonium compound | 1.0 |

| “Triameen Y12D 30” (CAS 2372-82-9) | dodecyl dipropylene triamine | 1.0 | |

| “OS-20” (CAS 68439-49-6) | nonionic | oxyethylated fatty alcohol | 1.0 |

| “PEG 400” (CAS 25322-68-3) | polyethylene glycols | 1.0 |

| Grout | Components, % by Mass | ||||||

|---|---|---|---|---|---|---|---|

| GBFS | Clinker | Bentonite | Soda-Ash | Sodium Metasilicate | Sodium Nitrate | Sorbitol | |

| #1 | 80.94 | 4.65 | 7.44 | 2.79 | 1.86 | 1.86 | 0.46 |

| #2 | 73.05 | 8.91 | 7.13 | 6.24 | 2.67 | 1.78 | 0.22 |

| Constituents, % by Mass | ||||||

|---|---|---|---|---|---|---|

| AAC | Silica Sand | Granite Gravel (fr. 2/5) | Granite Gravel (fr. 5/10) | Granite Gravel (fr. 10/20) | Type of Surfactant | Water |

| AAC with Mb = 1.6 | ||||||

| 250 | 730 | - | 370 | 870 | polyester | 180 |

| 250 | 495 | 120 | 280 | 985 | 163 | |

| 500 | 520 | - | 350 | 850 | 170 | |

| 500 | 430 | 104 | 240 | 860 | 165 | |

| AAC with Mb = 1.3 | ||||||

| 250 | 730 | - | 370 | 870 | polyether | 175 |

| 250 | 495 | 120 | 280 | 985 | 160 | |

| 500 | 520 | - | 350 | 850 | 170 | |

| 500 | 430 | 104 | 240 | 860 | 170 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kryvenko, P.; Rudenko, I.; Konstantynovskyi, O. The Plasticization of Alkali-Activated Cement System Na2O-CaO-Al2O3-SiO2-H2O: Problems and Decisions. Appl. Sci. 2025, 15, 6928. https://doi.org/10.3390/app15126928

Kryvenko P, Rudenko I, Konstantynovskyi O. The Plasticization of Alkali-Activated Cement System Na2O-CaO-Al2O3-SiO2-H2O: Problems and Decisions. Applied Sciences. 2025; 15(12):6928. https://doi.org/10.3390/app15126928

Chicago/Turabian StyleKryvenko, Pavlo, Igor Rudenko, and Oleksandr Konstantynovskyi. 2025. "The Plasticization of Alkali-Activated Cement System Na2O-CaO-Al2O3-SiO2-H2O: Problems and Decisions" Applied Sciences 15, no. 12: 6928. https://doi.org/10.3390/app15126928

APA StyleKryvenko, P., Rudenko, I., & Konstantynovskyi, O. (2025). The Plasticization of Alkali-Activated Cement System Na2O-CaO-Al2O3-SiO2-H2O: Problems and Decisions. Applied Sciences, 15(12), 6928. https://doi.org/10.3390/app15126928