Implementation of a Non-Intrusive Primal–Dual Method with 2D-3D-Coupled Models for the Analysis of a DCB Test with Cohesive Zones

Abstract

1. Introduction

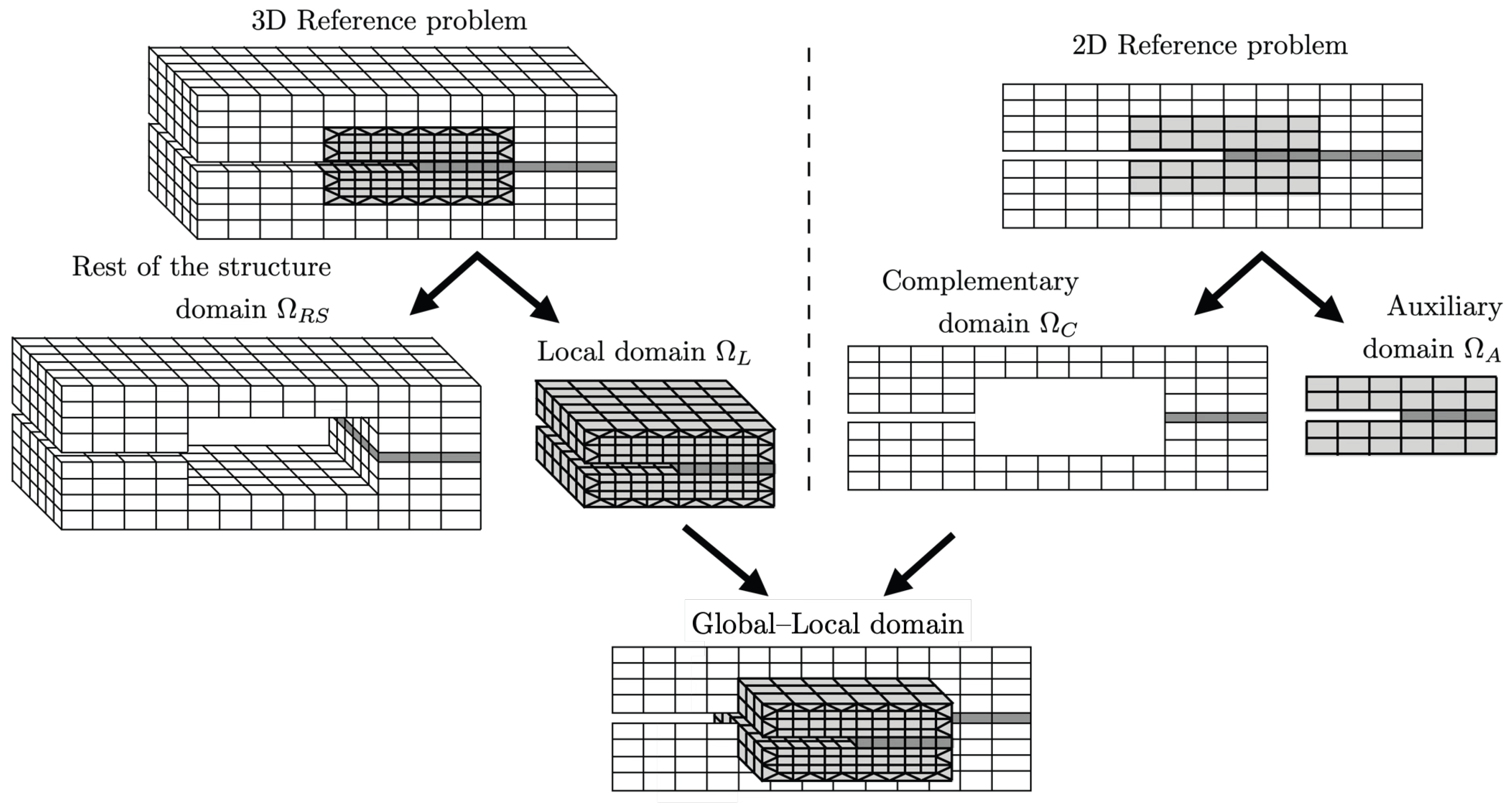

2. Global–Local Problem Formulation

2.1. Reference Problem

2.2. Implemented Non-Intrusive Method

- For the 3D model: into the local domain that represents the area where the crack growth occurs and the rest of the structure domain , so .

- For the 2D model: into the auxiliary domain that represents the area where the crack growth occurs and the rest of the structure domain , define as the complementary domain, so .

2.3. Global–Local Algorithm

| Algorithm 1 Primal–Dual Global–Local strategy |

|

3. Results of Global–Local Analysis

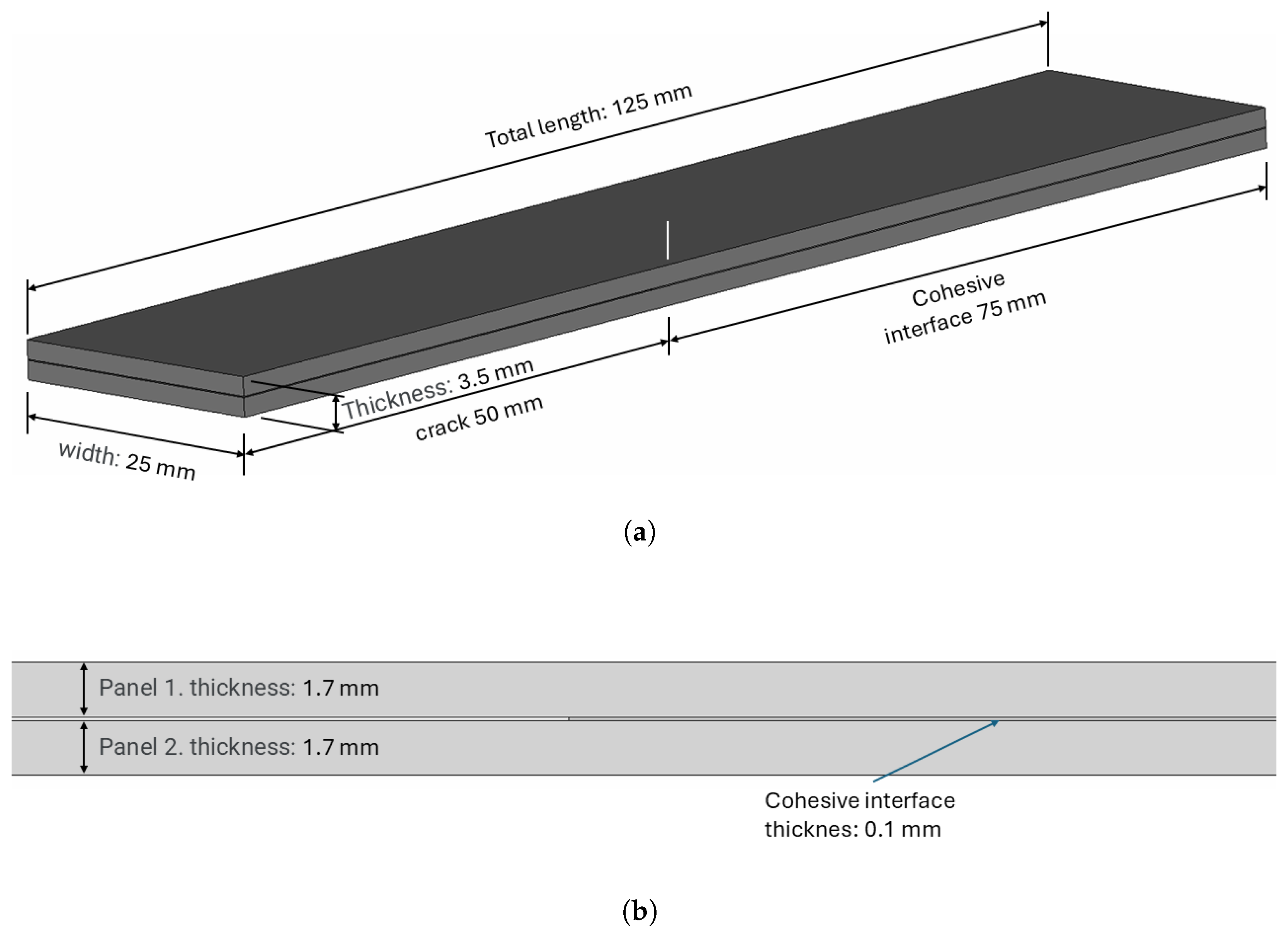

3.1. DCB Test

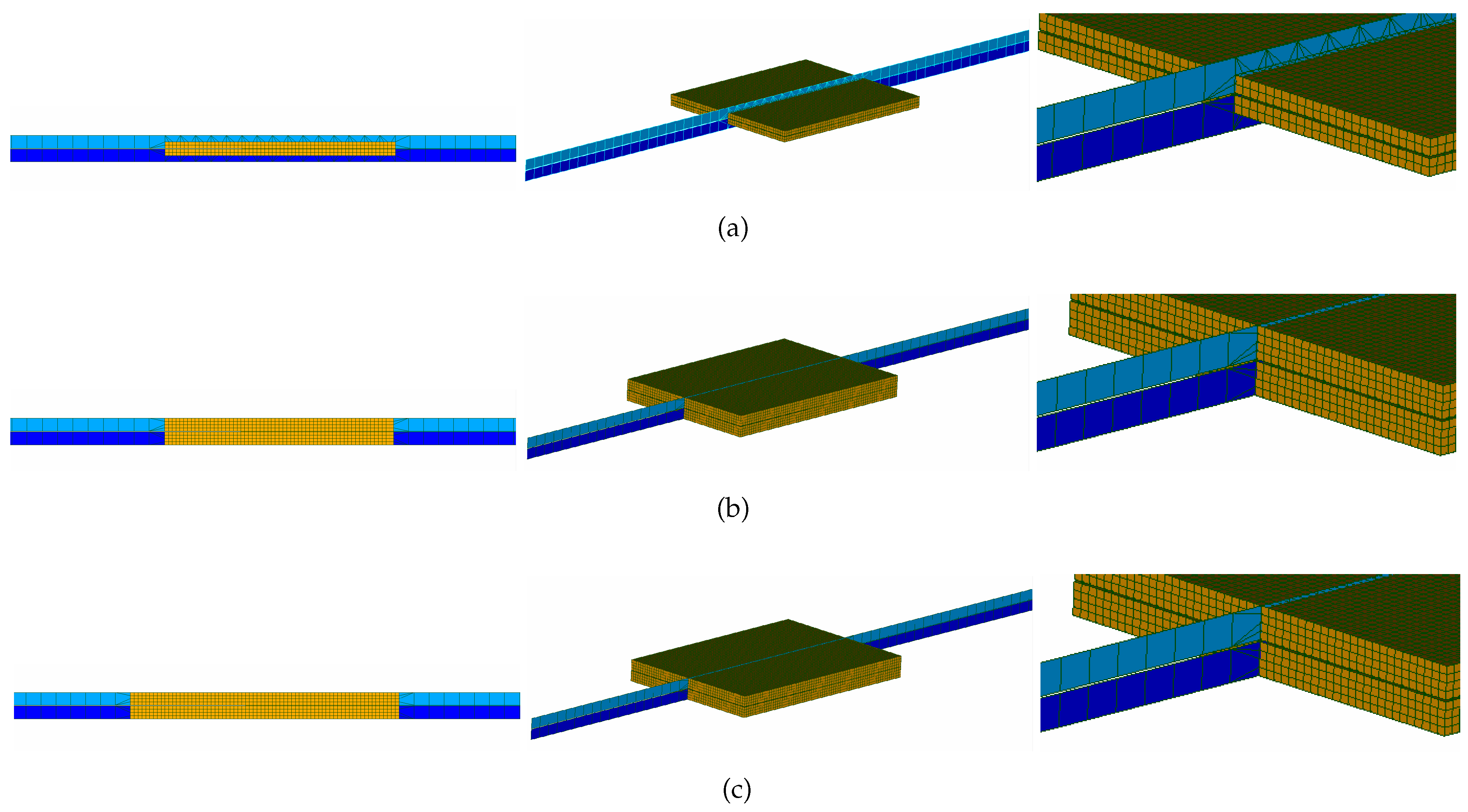

3.2. Studied Cases

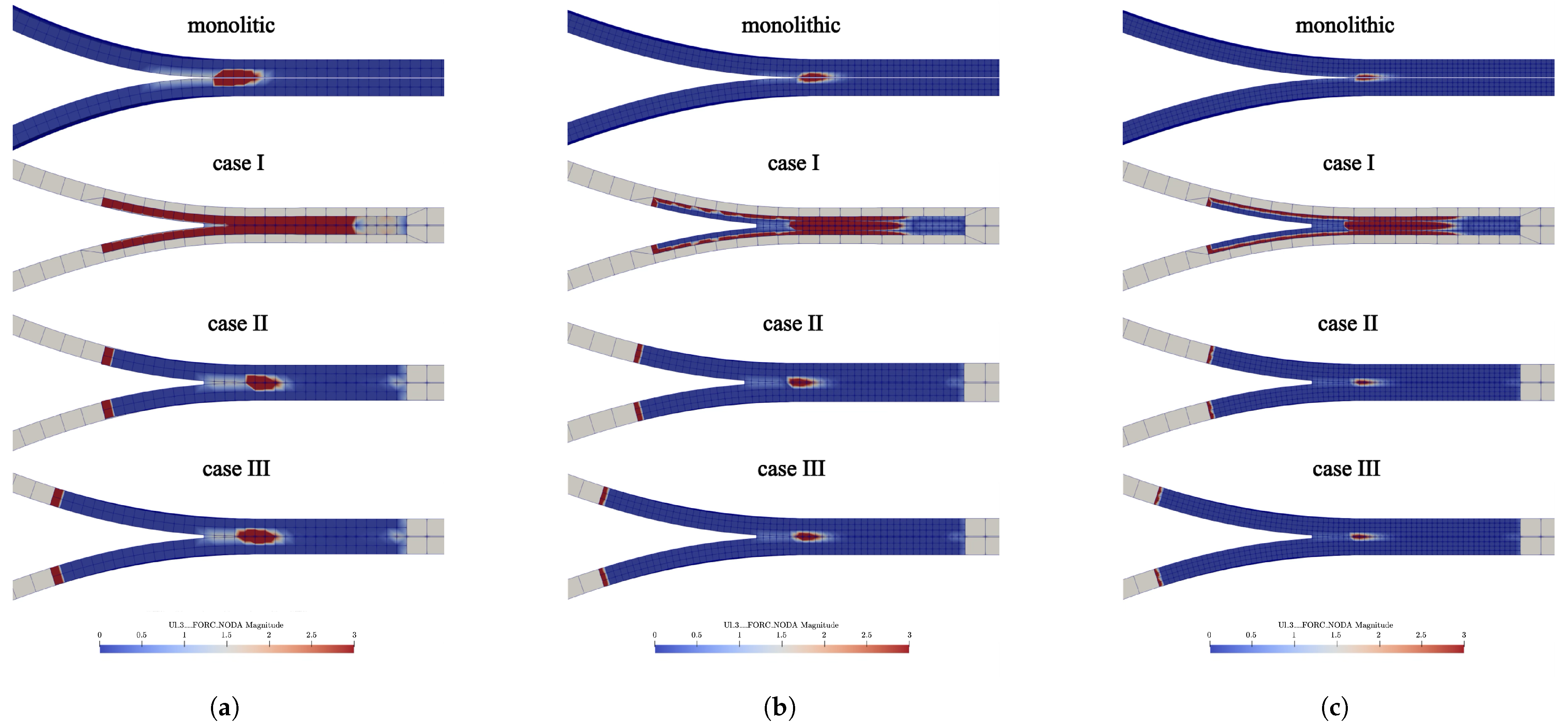

- Case I: the local problem covers 50% of the total thickness of the plate with a length of 30 mm, including 10 mm of pre-crack, Figure 3a.

- Case II: the local problem covers the entire thickness of the test, with the same length of 30 mm, including 10 mm of pre-crack, Figure 3b.

- Case III: the local problem covers the entire thickness of the test, with a length of 35 mm, including 15 mm of pre-crack, Figure 3c.

3.3. Results

3.3.1. Convergence of the Different Cases

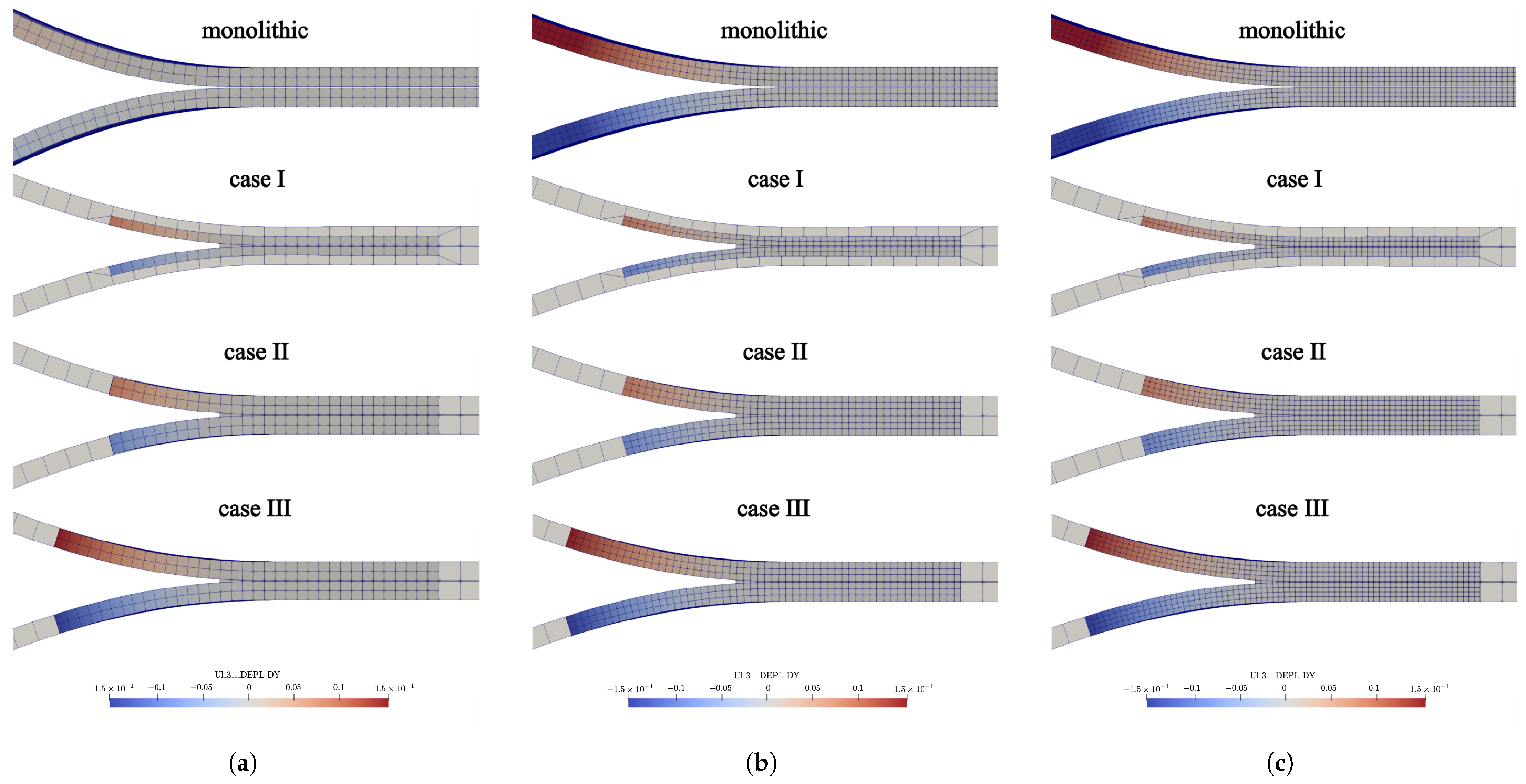

3.3.2. Deformation

3.3.3. Nodal Forces

3.3.4. Stress Distribution

3.3.5. Crack Tip Displacement

- Interpolation effects between meshes of different refinement levels, which leads to local over- or underestimation of displacement, particularly when displacement fields exhibit steep gradients or discontinuities associated with crack propagation.

- Mesh quality in the cohesive zone, particularly the aspect ratio and distortion of the elements aligned with the crack path, may significantly affect the accuracy and stability of the results. Poor mesh quality in this region can lead to artificial stiffness or premature damage localization, which in turn influences the calculated displacements and contributes to the oscillatory convergence behavior observed in the results.

- Discrete positioning of the crack front, as mesh refinement improves the accuracy of the crack front representation. This may cause the crack to interact differently with the structure and boundary conditions, resulting in slight variations in the magnitude of the maximum displacement.

3.3.6. Computation Time

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Blanco, C.; Cabrero, J.; Martin-Meizoso, A.; Gebremedhin, K. Design oriented failure model for wood accounting for different tensile and compressive behavior. Mech. Mater. 2015, 83, 103–109. [Google Scholar] [CrossRef]

- Mackenzie-Helnwein, P.; Eberhardsteiner, J.; Mang, H.A. A multi-surface plasticity model for clear wood and its application to the finite element analysis of structural details. Comput. Mech. 2003, 31, 204–218. [Google Scholar] [CrossRef]

- Sedighi-Gilani, M.; Navi, P. Micromechanical approach to wood fracture by three-dimensional mixed lattice-continuum model at fiber level. Wood Sci. Technol. 2007, 41, 619–634. [Google Scholar] [CrossRef]

- de Moura, M.; Dourado, N.; Morais, J. Crack equivalent based method applied to wood fracture characterization using the single edge notched-three point bending test. Eng. Fract. Mech. 2010, 77, 510–520. [Google Scholar] [CrossRef]

- Saavedra, E.I.; Saavedra, K.; Hinojosa, J.; Chandra, Y.; Das, R. Multi-scale modelling of rolling shear failure in cross-laminated timber structures by homogenisation and cohesive zone models. Int. J. Solids Struct. 2016, 81, 219–232. [Google Scholar]

- Dourado, N.; de Moura, M.; Morais, J.; Silva, M. Estimate of resistance curve in wood through the double cantilever beam test. Holzforschung 2010, 64, 119–126. [Google Scholar] [CrossRef]

- Dourado, N.; Morel, S.; de Moura, M.; Valentin, G.; Morais, J. Comparison of fracture properties of two wood species through cohesive crack simulations. Compos. Part A Appl. Sci. Manuf. 2008, 39, 415–427. [Google Scholar] [CrossRef]

- Hashin, Z. Finite thermoelastic fracture criterion with application to laminate cracking analysis. J. Mech. Phys. Solids 1996, 44, 1129–1145. [Google Scholar] [CrossRef]

- Nairn, J.A. Predicting layer cracks in cross-laminated timber with evaluations of strategies for suppressing them. Eur. J. Wood Wood Prod. 2019, 77, 1–15. [Google Scholar] [CrossRef]

- Moës, N.; Dolbow, J.; Belytschko, T. A finite element method for crack growth without remeshing. Int. J. Numer. Methods Eng. 1999, 46, 131–150. [Google Scholar] [CrossRef]

- Belytschko, T.; Black, T. Elastic crack growth in finite elements with minimal remeshing. Int. J. Numer. Methods Eng. 1999, 45, 601–620. [Google Scholar] [CrossRef]

- Zhou, Q.; Gong, M.; Chui, Y.H.; Mohammad, M. Measurement of rolling shear modulus and strength of cross laminated timber fabricated with black spruce. Constr. Build. Mater. 2014, 64, 379–386. [Google Scholar] [CrossRef]

- Christovasilis, I.P.; Brunetti, M.; Follesa, M.; Nocetti, M.; Vassallo, D. Evaluation of the mechanical properties of cross laminated timber with elementary beam theories. Constr. Build. Mater. 2016, 122, 202–213. [Google Scholar] [CrossRef]

- Perret, O.; Lebee, A.; Douthe, C.; Sab, K. The Bending–Gradient theory for the linear buckling of thick plates: Application to Cross Laminated Timber panels. Int. J. Solids Struct. 2016, 87, 139–152. [Google Scholar] [CrossRef]

- Pina, J.C.; Saavedra, E.; Saavedra, K. Numerical study on the elastic buckling of cross-laminated timber walls subject to compression. Constr. Build. Mater. 2019, 199, 82–91. [Google Scholar] [CrossRef]

- Park, K.; Paulino, G.H. Cohesive zone models: A critical review of traction-separation relationships across fracture surfaces. Appl. Mech. Rev. 2011, 64, 060802. [Google Scholar] [CrossRef]

- Turon, A.; Bak, B.L.V.; Lindgaard, E.; Sarrado, C.; Lund, E. Interface elements for delamination in composite laminates: Constitutive modeling. Mech. Adv. Mater. Struct. 2018, 25, 915–923. [Google Scholar]

- Qingfeng, D.; Haixiao, H.; Dongfeng, C.; Wei, C.; Shuxin, L. A new mechanism based cohesive zone model for Mode I delamination coupled with fiber bridging of composite laminates. Compos. Struct. 2024, 332, 117931. [Google Scholar]

- Wu, J.-Y.; Nguyen, V.P.; Nguyen, C.T.; Sutula, D.; Bordas, S.; Sinaie, S. Phase field modeling of fracture. Adv. Appl. Mech. 2017, 53, 1–183. [Google Scholar]

- Dolbow, J.; Sargado, J.M.; Jiang, T.; Borden, M.J. A phase-field description of dynamic cohesive fracture. Comput. Methods Appl. Mech. Eng. 2021, 387, 114118. [Google Scholar]

- Zhou, F.; Molinari, J.-F. Dynamic crack propagation with cohesive elements: A methodology to address mesh dependency. Int. J. Numer. Methods Eng. 2004, 59, 1–24. [Google Scholar] [CrossRef]

- Spring, D.W.; Leon, S.E.; Paulino, G.H. Unstructured polygonal meshes with adaptive refinement for the numerical simulation of dynamic cohesive fracture. Int. J. Fract. 2016, 189, 33–57. [Google Scholar] [CrossRef]

- Valoroso, N.; Champaney, L.; Boucard, P.-A.; Guinard, S. Identification of cohesive zone parameters using an inverse method coupled to a genetic algorithm. Int. J. Fract. 2013, 179, 129–147. [Google Scholar]

- Chen, C.T.; Gu, G.X.; Zhu, J.; Sun, W.; Fang, N.X.; Rider, W.J. Data-driven multi-scale multi-physics models to predict the effects of crack morphology on ceramic fracture. J. Mech. Phys. Solids 2020, 143, 104048. [Google Scholar]

- Reinoso, J.; Paggi, M. A consistent interface element formulation for geometrical and material nonlinearities. Comput. Mech. 2014, 54, 1569–1581. [Google Scholar] [CrossRef]

- Guidault, P.-A.; Allix, O.; Champaney, L.; Cornuault, C. A multiscale extended finite element method for crack propagation. Comput. Methods Appl. Mech. Eng. 2008, 197, 381–399. [Google Scholar] [CrossRef]

- Kerfriden, P.; Allix, O.; Gosselet, P. A three-scale domain decomposition method for the 3D analysis of debonding in laminates. Comput. Mech. 2009, 44, 343–362. [Google Scholar] [CrossRef]

- Loehnert, S.; Belytschko, T. A multiscale projection method for macro/microcrack simulations. Int. J. Numer. Methods Eng. 2007, 71, 1466–1482. [Google Scholar] [CrossRef]

- Wohlmuth, B.; Farah, P.; Hirschberger, C.B.; Borst, R.; Wriggers, P. A computational framework for interface failure analysis accounting for plasticity, damage and frictional effects. Comput. Mech. 2022, 69, 1371–1392. [Google Scholar]

- Ibrahim, A.H.; Watson, B.; Jahed, H.; Rezaee, S.; Cronin, D.S. An experimental-cohesive zone model approach to predict fatigue life of adhesive joints with varying modes of loading and joint configurations for automotive applications. J. Adhes. 2024, 69, 1–27. [Google Scholar] [CrossRef]

- Özdemir, İ.; Brekelmans, W.A.M.; Geers, M.G.D. A thermo-mechanical cohesive zone model. Comput. Mech. 2010, 46, 735–745. [Google Scholar] [CrossRef]

- Whitcomb, J.D. Iterative global/local finite element analysis. Comput. Struct. 1991, 40, 1027–1031. [Google Scholar] [CrossRef]

- Gendre, L.; Allix, O.; Gosselet, P.; Comte, F. Non-intrusive and exact global/local techniques for structural problems with local plasticity. Comput. Mech. 2009, 44, 233–245. [Google Scholar] [CrossRef]

- Fuenzalida-Henríquez, I.; Oumaziz, P.; Castillo-Ibarra, E.; Hinojosa, J. Global-Local non intrusive analysis with robin parameters: Application to plastic hardening behavior and crack propagation in 2D and 3D structures. Comput. Mech. 2022, 69, 965–978. [Google Scholar] [CrossRef]

- Jaque-Zurita, M.; Hinojosa, J.; Castillo-Ibarra, E.; Fuenzalida-Henríquez, I. Discriminant analysis based on the patch length and crack depth to determine the convergence of Global-Local Non-intrusive analysis with 1D-to-3D coupling. Symmetry 2023, 15, 2068. [Google Scholar] [CrossRef]

- Jaque-Zurita, M.; Hinojosa, J.; Fuenzalida-Henríquez, I. Global-Local non intrusive analysis with 1D to 3D coupling: Application to crack propagation and extension to commercial software. Mathematics 2023, 11, 2540. [Google Scholar] [CrossRef]

- Blackman, B.R.K.; Hadavinia, H.; Kinloch, A.J.; Williams, J.G. The use of a cohesive zone model to study the fracture of fibre composites and adhesively-bonded joints. Int. J. Fract. 2003, 119, 25–46. [Google Scholar] [CrossRef]

- Carvalho, U.T.F.; Campilho, R.D.S.G. Validation of a direct method to predict the strength of adhesively bonded joints. Sci. Technol. Mater. 2018, 30, 138–143. [Google Scholar] [CrossRef]

| Case/Model (Mesh Size) | Number of Nodes | |||

|---|---|---|---|---|

| 1 mm | 0.625 mm | 0.5 mm | ||

| Monolithic | 19,656 | 65,928 | 128,010 | |

| Case I | Global | 288 | 288 | 288 |

| Local | 3224 | 12,054 | 18,666 | |

| Case II | Global | 256 | 256 | 256 |

| Local | 4836 | 16,072 | 31,110 | |

| Case III | Global | 256 | 256 | 256 |

| Local | 5616 | 18,696 | 36,210 | |

| Aspect Ratio | Monolithic Models | Global Models | Local Models |

|---|---|---|---|

| <1.5 | - | panels | - |

| 1.5–>5 | panels | - | panels |

| 5–>10 | - | - | - |

| >10 | cohesive zone | cohesive zone | cohesive zone |

| Monolithic Model [mm] | Case | Element Size [mm] | Global/Local Model [mm] | Error |

|---|---|---|---|---|

| 4.4573 | Case I | 1 | 4.9767 | 11.65% |

| 0.625 | 4.3437 | 2.55% | ||

| 0.5 | 4.4717 | 0.32% | ||

| Case II | 1 | 4.9899 | 11.95% | |

| 0.625 | 4.3576 | 2.23% | ||

| 0.5 | 4.4852 | 0.62% | ||

| Case III | 1 | 4.9926 | 12.01% | |

| 0.625 | 4.3247 | 2.97% | ||

| 0.5 | 4.4858 | 0.64% |

| Monolithic Model [s] | Case | Element Size [mm] | Global/Local Model [s] | Time Saving |

|---|---|---|---|---|

| 2297.64 | Case I | 1 | 118 | 94.9% |

| 0.625 | 523 | 77.2% | ||

| 0.5 | 968 | 57.9% | ||

| Case II | 1 | 171 | 92.6% | |

| 0.625 | 740 | 67.8% | ||

| 0.5 | 1671 | 27.3% | ||

| Case III | 1 | 183 | 92.0% | |

| 0.625 | 947 | 58.8% | ||

| 0.5 | 2105 | 8.4% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández, R.; Hinojosa, J.; Fuenzalida-Henríquez, I.; Tuninetti, V. Implementation of a Non-Intrusive Primal–Dual Method with 2D-3D-Coupled Models for the Analysis of a DCB Test with Cohesive Zones. Appl. Sci. 2025, 15, 6924. https://doi.org/10.3390/app15126924

Hernández R, Hinojosa J, Fuenzalida-Henríquez I, Tuninetti V. Implementation of a Non-Intrusive Primal–Dual Method with 2D-3D-Coupled Models for the Analysis of a DCB Test with Cohesive Zones. Applied Sciences. 2025; 15(12):6924. https://doi.org/10.3390/app15126924

Chicago/Turabian StyleHernández, Ricardo, Jorge Hinojosa, Ignacio Fuenzalida-Henríquez, and Víctor Tuninetti. 2025. "Implementation of a Non-Intrusive Primal–Dual Method with 2D-3D-Coupled Models for the Analysis of a DCB Test with Cohesive Zones" Applied Sciences 15, no. 12: 6924. https://doi.org/10.3390/app15126924

APA StyleHernández, R., Hinojosa, J., Fuenzalida-Henríquez, I., & Tuninetti, V. (2025). Implementation of a Non-Intrusive Primal–Dual Method with 2D-3D-Coupled Models for the Analysis of a DCB Test with Cohesive Zones. Applied Sciences, 15(12), 6924. https://doi.org/10.3390/app15126924