Abstract

Municipal solid waste management (MSWM) on islands involves several challenges relating to politics, society, the environment, and technology. This paper addresses the potential for producing biogas and biomethane from food waste on Tenerife, including waste from households, with the aim of reducing landfill and primary fossil energy consumption. The study also introduces the European and Regional policy framework and requirements. Effective microorganisms have been studied as proposals to stabilise the food waste from households, avoiding odours and decomposition during storage. The trials show positive results in terms of the preservation of organic matter until the food waste is transported to the biogas plant. In addition, a new concept for a small biogas plant made of textile materials, which are suited to the municipalities of Tenerife, is presented to provide an easy-to-build solution, with ranges of up to 75 kW in electrical power. With a theoretical potential of 299,012 tons of food waste being available per year (based on 2022), preliminary laboratory experiments with real samples of the island showed a theoretical potential of 28.97 × 106 Nm3 for biogas and 264,612 tons for digestate, which can be used as fertilisers, with potential savings of 18.15 × 106 L of gasoline and 42.66 × 103 equivalent CO2 tons.

1. Introduction

There have been many political initiatives, at both national and regional levels, to take measures that encompass concrete follow-up actions to reinforce and support the objectives of the sustainable development agenda, such as the approval of the “Canary Agenda for Sustainable Development 2030” in 2021 [1,2], in accordance with the 17 goals of the “2030 Agenda for Sustainable Development” of the United Nations [1,3]. These political initiatives also fit with the efforts of the European Parliament and European Council to prevent, reuse, recycle, and eliminate the waste generated in European countries, establishing objectives up to 2035 [4,5].

Islands often face acute pressure on their resource management and energy systems due to their geographical location, limited land area, and economic reliance on sensitive sectors such as tourism. The Canary Islands, recognised by the EU as an outermost region, exemplify this predicament [6]. Their extreme dependency on imported fossil fuels for energy, coupled with the intense demands of a thriving tourism industry, creates a complex environmental landscape concerning waste generation and management. This paper presents the anaerobic digestion of food waste as a solution to relieve waste management on the island by reducing the amount of biodegradable material sent to landfills, while also promoting the production of renewable energy.

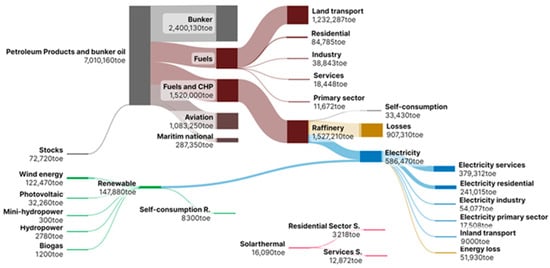

Figure 1 shows how the energy inputs and outputs in the Canary archipelago are graphically distributed; 96.34% of the primary energy is based on fossil fuels and 3.66% is derived from renewable energies. Tenerife consumes 41.3% of the petroleum products imported, mainly from Africa, and, to a lesser extent, from Mexico. Furthermore, by area of usage, most of the ‘last use’ energy demand corresponds to the transportation sector, which consumes 79.8% of this demand; land transport accounts for 35.4% and air transport accounts for 31%. Overall, 19.8% of the country’s energy is transformed into electricity for the rest of the islands’ activities. This is followed by the areas of public administration, commerce, and services (14%), and the residential sector (12% of the consumption) [2]. Because of the high dependency on oil derivatives, the energy sector is also the main driver of greenhouse gas (GHG) emissions in the Canary Islands, representing more than 85% of total emissions, which is equivalent to about six out of every seven tons of GHG [2,7].

Figure 1.

Energy balance in Canary Islands in tons of oil equivalent (toe) in 2022. Sankey diagram is adapted based on Canary Islands energy yearbook 2022 and from the Canary Government [7,8,9].

1.1. European, National and Local Legal Frameworks on Municipal Solid Waste Management for the Case of Tenerife

The “Waste Framework Directive”, also known as “Directive 2008/98/EC” of the European Parliament and the Council of 19 November 2008 on waste, was adopted with the intention of converting the European Union into a ‘recycling society’ and aiding in the fight against climate change. The ‘waste management hierarchy’ concept was introduced by this new regulation as a crucial tool to break the link between trash generation and economic growth, preventing waste, preparing materials for reuse and recycling, supporting the development of alternative forms of recovery (such as energy recovery), and aiding in trash disposal. The last actualisation of the Waste Framework Directive 2018/851 (of 30 May 2018) established concrete reutilisation and recycling goals of 55% by 2025 and 65% by 2035 [10,11]. The National Law 22/2011 of July 28, concerning waste and contaminated soils, updated Law 7/2022 of April 8 on the circular economy [12,13]. These laws updated Spanish legislation on this matter and developed frameworks for waste management strategies at national, regional, and local levels, as well as setting minimum objectives for the “Autonomous Communities”, according to the European Framework Directive 2008/98/EC and Directive 2018/851 [13]. “Autonomies” prepare their respective plans for waste prevention and the local entities are then enabled to carry out the waste management programmes, either separately or jointly [5,12]. Royal Decree 160/2021, of December 30, which approved the updated Integral Waste Plan of the Canary Islands 2021–2027 (Plan Integral de Residuos de Canarias, hereinafter, PIRCAN) [5], unifies both waste management and prevention. It was conceived as a planning document to prevent the production of waste and, where appropriate, resolve the problems arising from its management, in accordance with the relevant laws in force at the time of its formulation [5]. With this background, there are territorial management strategies like the “Special Territorial Waste Management Plan for the Island of Tenerife” (“Plan Territorial Especial de Ordenación de Residuos de la isla de Tenerife” or PTEOR, approved in July 2011) [14] with concrete measures regarding financing, waste management, the determination of appropriate sites for treatment and storage facilities, social awareness, and municipal and citizen participation [15]. It is important to note that the PTEOR should be updated according to the last PIRCAN revision and the revisions of state laws [16].

The PTEOR from 2011 included general information about the composition of the collected municipal waste (CER 200301) from 2001, with 497,949 tons per year and an organic fraction of 30.9%, which is equivalent to 157,650 tons per year [15]. The municipal solid waste has three categories: residues similar to household waste; residues from industrial, institutional and commercial activities (RICIA), which also includes selectively collected residues from kitchens, restaurants, and food markets; and residues from construction and demolition [15].

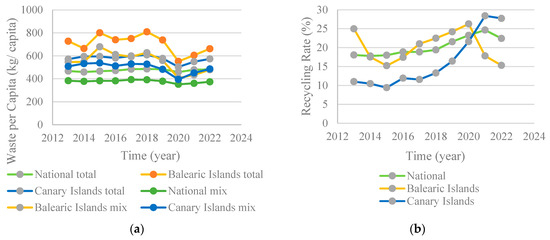

In 2022, the average national recycling rate of municipal solid waste was 22.4%, which was still far from the European recycling average rate of 58% [17,18]. In 2022, 513 kg of municipal waste per capita was generated in the EU and 48% of this was recycled (material recycling and composting) [17]. Figure 2a,b show the recycling rate for solid municipal waste at a national and autonomic level in two of the most important tourist regions in the country: the Balearic Islands and the Canary Islands. In terms of the non-separated municipal waste, which is mainly from households, both regions exceed the national rate. Figure 2b shows how the recycling rate of these residues increased over time but recycling capacity remained the same, with 27.72% of municipal solid waste recycled in the Canary Islands in 2022. This recycling rate increased, particularly since 2017, to over 16% and was 5.3% higher than the national average, demonstrating the regional political will to implement recycling concepts and technologies.

Figure 2.

(a) Municipal solid waste per capita in Spain and both archipelagos; (b) recycling rates of municipal solid waste in Spain and in the Balearic and Canary Islands [18,19].

1.2. Canary Islands, Tenerife and Its Biodegradable Solid Municipal Waste, Including Kitchen, Restaurant and Food Waste Potential

Food waste can be transformed into more valuable products through thermal, chemical, or biochemical conversion. However, it is common practice put it in a landfill and generate conventional energy [20]. In comparison to landfill techniques with electricity production and incineration with steam recovery and cogeneration, anaerobic digestion with cogeneration has been identified to be the most effective waste management practice [21].

In 2021, 131 kg of food waste was produced per inhabitant in the EU. This food waste originated in households (53.5%), the manufacturing of food products and beverages (21.4%), restaurants and food services (9.2%), primary production (8.4%), and retail and other food distribution (6.9%), representing approximately 25% of the municipal solid waste in 2022 [22,23].

On islands, where the land resources are limited, waste volume varies seasonably strongly and the waste production per capita exceeds continental averages [24]. Municipal solid waste management is a substantial issue that requires a comprehensive political, environmental, socio-economic, and technological approach [24,25]. Furthermore, poor logistics often result in illegal dumping and uncontrolled combustion, posing a risk to health and the environment due to emissions from the illegal combustion of wastes [26,27]. On the Canary Islands, the main source of economic growth is the tourism sector and so the waste rate per capita is particularly influenced by this industry, which has a significant effect on waste generation [28]. The production and evolution of municipal waste is not the same in different island areas and also differs compared to the rest of Spain, as there are tourist areas with higher economic service activities (e.g., Santiago del Teide, Puerto de la Cruz, Arona, Guía de Isora, or Adeje) [29]. The tourism industry has gained significant weight in the region’s economy, directly contributing to increased waste generation during recent decades [5]. The intense tourist occupancy throughout the year (about 13 million visitors each year) increases the consumption of energy and water per capita, as well as the need for infrastructure, public facilities, and services [2]. Consequently, the municipal waste rates per capita produced in these tourist areas are some of the highest in the country, together with the Balearic Islands [18], with values up to 1070.65 kg per capita in Arona, 705.10 kg per capita in Puerto de la Cruz, and 662.86 kg per capita in Adeje [16]. Furthermore, the Canary Islands have a high population density of approximately 300 inhabitants per km2, which is significantly higher than the national average of 93 inhabitants per km2. Most of the population is concentrated around the main urban areas, particularly on islands of Gran Canaria and Tenerife [2].

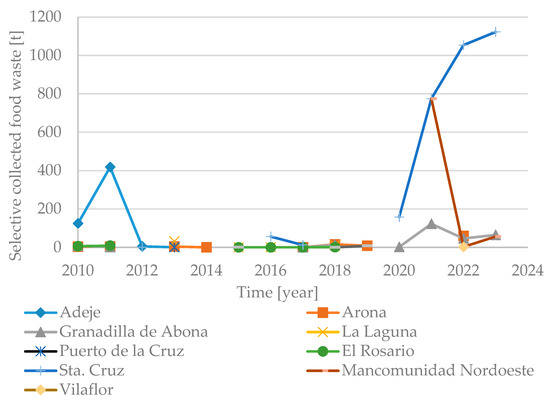

According to the latest European Waste Framework Directive 2018/851, European countries have to introduce the selective collection of biowaste and (by 31 December 2023 at the latest) implement the selective collection of municipal biowaste [10]. This date was anticipated to be December 2021 for cities with more than 5000 inhabitants, in the draft law on waste and contaminated soils of 28 May 2021. Since October 2021, there has been an actuation plan developed for the capital city, Santa Cruz de Tenerife, to encourage it to adopt the necessary measures and implement the selective collection of bioresidues, not just for big producers but also for households [11]. The first activities in Santa Cruz, regarding big producers (such as hotels, restaurants, bars, cafes, food markets, schools, hospitals, and nursing homes), yielded 792.3 t of selectively collected organic food waste from August 2020 to October 2021, with less than 2% containing foreign material [11]. Figure 3 shows the evolution of the collected waste from kitchens and restaurants registered from El Cabildo, CER Code 200108, until 2023. Santa Cruz showed the largest increase since the improvements in selective food waste collection. Other regions on the island also showed activities related to selectively collecting food waste (e.g., Granadilla de Abona, Adeje, Arona or Vilaflor). Mancomunidad de Tenerife started a pilot project in 2022 to introduce a brown selective container for bioresidues [30].

Figure 3.

The food waste from kitchens and restaurants [29]. The graphs are discontinuous in some time periods because the records contain unregistered data in some years.

1.3. Stabilisation of Biodegradable Solid Waste and Its Collection

The collection of food waste poses challenges because of the start of degradation processes that lead to unpleasant odours and energy losses if the waste is not stabilised. To stabilise the stored biowaste fraction until it is collected and used for biogas production, without major energy losses, we propose biological pretreatment for small producers, based on effective microorganisms, and suggest an automated concept for bigger producers and restaurants.

1.3.1. Small Producers Like Households

Pretreatment based on effective microorganisms has been proposed and studied. This biological pretreatment, introduced by Higa [31], is based on a mixture of bacteria, including predominant acid lactic bacteria, yeasts, photosynthetic bacteria, actinomycetes and other taxonomic groups [31,32,33]. The biochemical effect of lactic acid fermentation, which is considered environmentally friendly, has been an established and tested approach for food preservation for centuries [34,35]. The ensiling of forage crops, whereby lactic acid bacteria produce lactic acid and other beneficial organic acids through spontaneous fermentation under anaerobic conditions—achieving pH levels that inhibit the growth of pathogens—is a worldwide well-known preservation method [36]. Consequently, recent studies demonstrate that effective microorganisms reduce the need for plant protection products while improving crop, soil, and plant growth [37,38] and reducing odour nuisance [36].

1.3.2. Restaurants and Kitchens

Hotels and big restaurants generally use the exchange collection method due to lower volumes, as it is less cost-intensive and does not require a large investment. The food waste is stored in a sealed vessel and is collected by a logistics company once a day [39].

On the other hand, there are other options with automated storage modules which include integrated homogenisation and the crushing of the food waste. This system offers many advantages such as improved hygiene, less cleaning, easier handling, longer collection cycles (weekly or biweekly periods), fewer logistical requirements and lower consequent costs, and no need for refrigeration (in case there is no daily collection). The storage of the module is connected to a load sensor, which indicates when the food waste has to be collected by the logistics company. The mechanical shredding of food waste takes place with the addition of water. After the food waste is ground down, it is driven into an airtight tank with a load sensor, which produces a signal when the fill level reaches 80% [40].

2. Materials and Methods

2.1. Effective Microorganisms

The stock solution contains microorganisms in an inactive state and is used to produce ‘effective microorganisms’ (EM). To activate the microorganisms, 3% of the mixture is combined with 3% sugar cane molasses and diluted with 94% water. This mixture is then left to ferment for 10–14 days at a constant temperature level of between 30 and 38 °C. Overall, 1 L of original solution corresponds to 30 L of activated EM, from the company Chiemgau, Germany.

In order to investigate the effects of a silage with EM, ensiling tests were carried out at room temperature with activated EM and a control group without additives at different ensiling durations (6/12/20 days). For this proposal, food waste was collected from the University of Landshut canteen kitchen every other day for one week. Each sample was collected in airtight 10 L containers. The samples were homogenised after collection and then stored in an airtight manner in a refrigerator until the experiment was performed.

Experimental Description

Effective microorganism experiments were carried out with food waste from the canteen of the University of Applied Sciences at Landshut. The food residues were homogenised and pasteurised to ensure hygienic conditions in the laboratory, mechanically crushed to a particle size of 12 mm, and heated at 70 °C for one hour, according to the legal requirements [41]. Normally, the pasteurisation of food waste takes places at the biogas plant, before or after biogas fermentation.

After homogenisation and pasteurisation, food waste was ensiled in an airtight manner in layers in different sample buckets: one bucket with 603.9 g of food waste and 15.92 g effective microorganisms and a second bucket with 604 g of food waste substrate but without effective microorganisms. Samples were taken and chemically analysed after 6, 12, and 20 days.

To evaluate the stabilisation of the food waste before and after the ensiling, the following parameters were analysed three times to ensure reproducibility during the experiment, at the beginning, and then after 6, 12 and 20 days: the dry matter (DM) [%], the volatile solids (VSs) [%], the chemical oxygen demand (COD), the ammonium content (NH4+), the organic acids content (oA), and the pH value. The resulting analysed chemical parameters are shown with a Confidence Interval = 95%.

2.2. Biogas Yield from Food Waste from Complejo Ambiental de Tenerife

On 4 October 2022, a food waste sample was taken from El Complejo Ambiental de Tenerife, the solid waste treatment centre in Tenerife, a place where waste generated on the island can be treated and managed in the most efficient way possible. Biogas experiments were conducted with this substrate, following the recommendations of the VDI 4623 [42]. The reproducibility of the experiments was ensured with three repetitions of the trial. The materials mainly came from Santa Cruz and consisted of biowaste from kitchens and restaurants, with a high content of fruit peelings from oranges and bananas; the samples were approximately 10% oranges and 15% bananas. The experiments were conducted in the laboratory under mesophilic conditions at 38 °C under the effect of a laboratory shaker in small 100 mL chromatography vials with gas-tight septa. The produced gas was calculated through the measurement of the overpressure with a Type G1111 vacuum barometer of the company Greisinger, Remscheid, Germany, and the overpressure was set at 600 hPa to avoid biological inhibition.

2.3. Methods

Dry matter, volatile solids, temperature, pH, soluble chemical oxygen demand (s COD), the ammonium NH4+-N, and equivalent organic acids concentrations were analysed at the beginning and at the end of the silage and biogas trials. The silage was also chemically analysed after 6, 12, and 20 days. After centrifugation at 8000 rpm for 10 min using a Hettich EBA 200 centrifuge, Tuttlingen, Germany, we performed the chemical analyses using a Hach DR3900 spectrophotometer and Hach LCK cuvette tests, Düsseldorf, Germany, 514 and 014 for COD, we conducted LCK Test 303 for the ammonium, and we used LCK 365 for the determination of the total organic acids. DM and VS levels were determined according to the DIN EN 15935 [43].

The biogas experiments were conducted in 1 L gas-tight Xylem MF/1000 systems (Washington, DC, USA). Biogas production was monitored using WTW OxyTop®-IDS pressure sensors (Washington, DC, USA), with a pressure measurement range of 500–1500 hPa, connected to a Xylem Multi 3620 data logger (Washington, DC, USA). The logger recorded pressure variations within the range with an accuracy of ±1%. To avoid biological inhibition, the digesters were depressurised at 350 hPa.

3. Results

3.1. Stabilisation Results with Effective Microorganisms

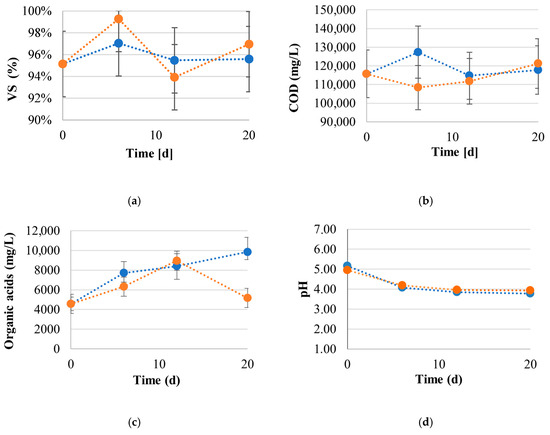

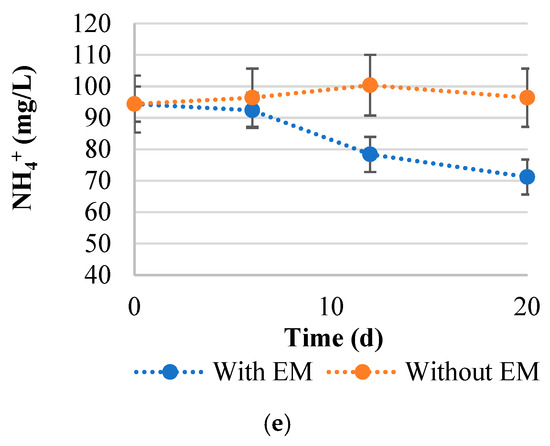

Figure 4 shows the development of the various chemical parameters over the course of the ensiling period. The VS level (a) remains constant with EM additive. This indicates the successful preservation of the organic matter through the formation of organic acids. In contrast, the DM in the silage without additives shows an increase towards the end, which indicates that the material is drying out. The VS level remains largely the same in both experiments. In the silage with EM, the COD (b) values show an initial increase, which indicates an increment in the solubilised organic load, followed by a decrease. The decrease indicates the stabilisation of the organic decomposition by the EM after an increment at the beginning produced organic acids. After five days, no further carbon compounds are dissolved in solution. The silage without additives shows a gradual increase in COD, after a slight decrease during the same 5 days, indicating an increase in organic load and, possibly, less effective stabilisation. The increase indicates te further degradation of carbon compounds from the biomass matrix. However, this could be beneficial for the biogas yield. Ensiling with EM results in a continuous increase in the concentration of organic acids (c), suggesting increasing acid production (an indicator of successful ensiling). In contrast, the fluctuations in silages without additives indicate less constant acid production, which represents a lower efficiency of ensiling. Both ensilages show a steady decrease in pH value (d), although no significant difference can be seen. This indicates that acid formation is essentially complete after about 12 days. The ammonium concentrations (e) in the silage treated with an EM decrease over the course of the ensiling period. This may indicate that either less protein degradation is taking place or that ammonium is not being produced during this ensiling phase. However, it could also mean that ammonium is absorbed and utilised by microbial activity. In contrast, the ammonium levels in the silage without EM remain consistently high and show less fluctuation, indicating a constant release of ammonium, presumably due to the breakdown of proteins.

Figure 4.

Stabilisation of pasteurised food waste experiments with; (a) VSs (%); (b) COD in mg/L; (c) organic acids in mg/L; (d) pH; (e) NH4+ in mg/L.

The results indicate that the application of EM seems to have a positive effect on the stabilisation of the food waste silage, especially regarding the preservation of VSs and of organic acid production, which inhibit putrefactive microorganisms and resulting odour nuisance, as no odour nuisance was detected at the end of the experiments with EM. The continued production of acids, the stabilisation of organic matter, and the improvement in visual appearance and odour compared to the control group without additional treatment highlight the effectiveness of EM treatment.

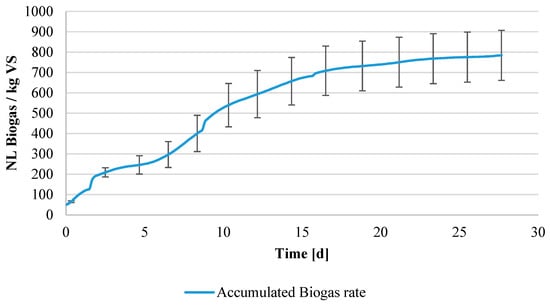

3.2. Results of Biogas Yield with Food Waste from Complejo Ambiental de Tenerife

To estimate the biogas potential on the island, experiments were carried out with real samples obtained from selectively collected food waste from municipal solid waste.

The principal characterisation parameters of the biogas experiment are presented in Table 1.

Table 1.

Inoculum and food waste composition.

The anaerobic batch ran for 28 days with three repetitions and achieved biogas yields up to 784 NL/kg VSs +/− 15% SD (Confidence Interval = 95%). The values used for food waste mixtures, reaching biogas yields of 752 NL/kgVS [44] with 55% methane, are given in the literature on the subject. Figure 5 shows the development of the experiment over the time span. The biogas yield obtained and also the chemical analysis results, which displayed an initial soluble chemical oxygen demand of nearly 132,000 mg/L, are values that constitute intermediate results compared to those pure food waste values [45,46], but high levels in comparison to other organic fractions of municipal waste [46,47].

Figure 5.

Biogas yields from the separated collected food waste, which is centrally stored, fulfilled and partially composted in el Complejo Ambiental de Tenerife.

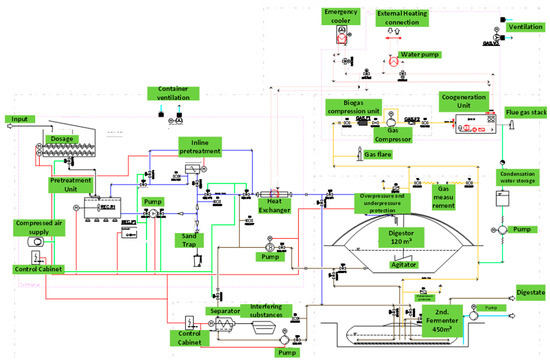

4. Small Biogas Plant Concept

Anaerobic digestion is a stablished process used for the management of food waste [48]. There are different established concepts for the anaerobic digestion of food waste, including batch and continuous reactors, submerged and solid-state systems, and biogas plants with single- or multi-stage fermenters [48,49]. Building new biogas plants for the fermentation of food waste is expensive and there are some issues that have limited this [49]. These include the use of foreign materials, which can lead to undesired sedimentation and an inefficient process, as well as process instability due to possible acidification [48]. As a solution for the decentralised production of biogas from food waste on the island of Tenerife, this paper also presents a new biogas plant concept, affordable for small producers, which can be fed with the selective and stabilised collected food waste at the municipal landfill or directly in the small towns. This concept is based on digesters made of high-quality textile materials, such as high-density polyethylene (HDPE) films. These films are impermeable to liquids, durable, and certified by the German Institute for Building Technology (DIBt). They have a typical lifespan of 25 years and are used in landfills [50,51]. Such films are also used in agriculture to prevent liquids from escaping, and are called plastic-sealing membranes. If the membrane is damaged, the leak detection system, which is installed in accordance with the general method approved by G-Quadrat Geosynthetics, will detect this and allow the damage to be repaired [51]. These plants are simple to build in a short space of time and in an economical way, as the construction is not based on concrete but on textile materials and a light metal construction that supports the textile materials that make up the reactor [52]. The biogas reactor is partly located underground; it acts as insulation and improves the sustainability of the plant, protecting against UV radiation [51]. This small biogas plant ranges in electrical power output from 25 to 50 kWel and meets all the legal and technical requirements to ensure a reliable and long-lasting plant operation [53,54,55]. All interfering substrates, such as stones or other foreign materials, are removed at the feeding line of the biogas process during the homogenisation process. These can damage the textile material or leave sediment in the system. To avoid any gas release, it is essential to ensure continuous compliance with the safety rules for biogas facilities with membrane seals and the resulting requirements [55]. Leakages should be detected quickly and reliably, and spilled water-polluting substances should be retained and disposed of accordingly [53,54]. The biogas obtained will be used to produce electricity and heat, reducing the use of fossil fuels on the island. According to the biogas yields obtained from food waste, shown in Figure 5, after 15 days, with approximately 674 NL/kg VSs and postfermentation with enough hydraulic retention time to obtain the remaining biogas yields of at least 55 days, the application presented can be operated directly in urban districts, accommodating approximately 20,000 tons of food waste per year [52]. This would be the equivalent to the potential food waste from the household waste collected in La Laguna in 2020, with an estimated potential of approximately 18,500 tons, or in Santa Cruz de Tenerife, with a potential of 36,850 tons in 2020 [17,23,56]. Indeed, 18,500 tons of food waste is equivalent to approximately 1.8 × 106 Nm3 biogas and to a biomethane potential of 10.88 GWh Hs per year.

Figure 6 shows the prototype for the small biogas plant made of textile materials and its components. The initial substrate, with approx. 12% DM, will be mixed with recirculated reactor content, with a typical DM of 6%, in the homogenisation tank. After homogenisation, the feeding line drives the mixed substrate into the main biogas reactor, which is heated by an external heat exchanger placed in the main feeding line. Therefore, the biogas reactor content will be recirculated in order to maintain the operating conditions at 37 °C. After an adequate hydraulic retention time, the digestate will be driven into secondary storage, which also functions as a secondary biogas reactor. This secondary reactor will be not heated, but will work at ambient temperatures. The digestate will, therefore, be stored and used as fertiliser on demand, being taken from the secondary reactor, which acts as a closed storage tank. The biogas plant is equipped with a cogeneration unit to produce heat and electricity simultaneously. The heat will be mainly used for self-heating and any surplus production will be fed into the external heating supply network. A stirrer is supplied to the main biogas reactor, but not to the secondary fermenter. To prevent sedimentation and floating layers, the digestate passes through a separator before entering the secondary fermenter. The plant concept also includes other components, such as an emergency cooler for the cogeneration unit and a torch in case the biogas cannot be used in the cogeneration unit. A ventilation unit connected to a methane sensor is also installed in the facilities where the heat exchanger, the pumps, the mixing, and pretreatment unit are built. This biogas plant was constructed in accordance with the hazardous areas’ protection normative and is equipped with all the necessary ATEX-certified components.

Figure 6.

Prototype small biogas plant made of textile materials.

It is important to note that this prototype was mainly built for agricultural substrates. In accordance with Regulation (EC) No. 1069/2009 of the European Parliament and Council of October 21 and Royal Decree 1528/2012 of November 8, if animal byproducts or derived products are used as raw materials for biogas plants, it will be necessary to equip the biogas plant with a pasteurisation unit [12,41]. Therefore, the biogas plant in Figure 6 should be equipped with a supplementary pasteurisation unit to meet the legal requirements, in case food waste from kitchens and restaurants with rests from animal byproducts or derived products is used as the biogas substrate.

5. Discussion

This research aims to make use of food waste on the island of Tenerife to produce biogas through anaerobic digestion. The reutilisation of biodegradable waste, in the form biogas, requires an improvement in the current selective waste collection system on the island. This would be a step towards avoiding landfilling and replacing some of the primary energy supply, 96.34% of which is currently produced from fossil fuels.

The selective collection of waste from kitchens and restaurants in the metropolitan area of Santa Cruz, Tenerife, started in 2021 and reached 1053 tons in 2022 [29], reflecting the political efforts to improve the recycling rate of metropolitan areas on the island. The percentage of collected biodegradable waste on the island is still very low (approximately 1700 tons of food waste from 1,196,050 tons of collected solid municipal waste in 2022) [57].

With a theoretical potential of 299,012 tons of potential food waste (2021), from municipal solid waste, based on the European average of 25% being food waste [22,23,58]; this gives a biogas potential of 28.97 × 106 Nm3, equivalent to 18.15 × 106 L gasoline. This would also mean savings of 42.66 × 103 equivalent CO2 tons. After the fermentation process, the remaining organic fraction can also be used as fertiliser. This amounted to 264,612 tons. Municipal initiatives began the collection of the biodegradable fraction from municipal households, with pilot projects implementing the brown waste container some years ago; a biological pretreatment to stabilise the food waste was also investigated. The biodegradable residues were ensiled with effective microorganisms and a positive effect on the biological waste stabilisation was observed. The DM and the VSs were conserved and the solubilised COD did not show any significant variation after the entire ensiling period. Organic acids were produced and the pH decreased in the EM-treated substrate that shows an inhibitory effect on pathogens and prevent odours; NH4+ did not show any relevant effects.

A new developed small biogas plant has been proposed that is made of textile materials. Decentralised small biogas plant systems are increasing in importance as savings in logistics and transportation significantly influence operational costs. Based on this prototype, this system can produce up to a total power capacity of 75 kWel and process a maximum amount of food waste of approx. 80,000 tons per year. In the future, this concept should be applied to achieve a self-sufficient and decentralised energy supply. In summary, small-scale decentralised plants offer several advantages like localised treatment; lower transportation costs; simplified construction with easier and more cost-effective construction techniques displaying less demand for materials and easier engineering processes; efficient operation with simplified operations and maintenance; and versatile output for various applications such as vehicle fuel in the form of CNG or direct energy supply.

6. Conclusions

There is unexploited renewable energy in Tenerife. This is based on the anaerobic fermentation of food waste and its conversion into biogas. Tenerife shows significant potential in recycling matters. At present, logistics improve every year and brown containers for biodegradable materials have been implemented in some urban centres. At the moment, biodegradable materials are composted or landfilled. This comprises potential energy in the form of biogas, which remains untapped. Biogas production would mean the substitution of fossil fuels, a reduction in less municipal waste to be landfilled and, also an improvement in the greenhouse gas balance on the island.

The anaerobic digestion of sewage with food waste as a co-substrate could also be an object of investigation, as this could improve the economic efficiency of existing anaerobic digestion treatment plants by incorporating food waste.

Author Contributions

V.H.-S. contributed to the study’s writing, conception, methodology, investigation and validation. M.E.B. contributed to the study’s methodology, investigation, validation, reviewing and editing. J.H. contributed to the study’s reviewing, methodology, investigation, and project administration. D.C. contributed to the study’s conceptualisation and formal analysis. S.S. contributed to the study’s conceptualisation and formal analysis. T.F. contributed to the conceptualisation and visualisation. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Bavarian Ministry of Economic Affairs, Regional Development and Energy, Project “Small biogas plants made of textile materials BGA-Textil-BE/19/02”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Acknowledgments

We specially thank the Complejo Ambiental de Tenerife for their support, the whole of the Department of Chemical Engineering and Pharmaceutical Technology at La Laguna University, the Faculty of Mechanical Engineering of the University of Applied Sciences in Landshut and the Bavarian Ministry for Economic Affairs, Research and Development.

Conflicts of Interest

Author Tobias Finsterwalder was employed by the company Finsterwalder Umwelttechnik GmbH & Co. KG. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Gobierno de Canarias. Instituto Canario de Estadística. Indicadores Para Los Objetivos de Desarrollo Sostenible. Available online: https://www3.gobiernodecanarias.org/aplicaciones/appsistac/ods/ (accessed on 6 January 2025).

- Gobierno de Canarias. IDAE. Ministerio para la Transición Demográfica y el Reto Demográfico. Estrategia de Energía En Las Islas Canarias. Situación inicial. 2022. Available online: https://www.idae.es/oficina-tecnica-de-energia-limpia-y-proyectos-inteligentes-en-las-islas/energia-sostenible-en-las-islas-pniec-prtr/transicion-energetica-en-las-islas-canarias/situacion-actual (accessed on 16 June 2025).

- Gobierno de Canarias. Agenda Canaria de Desarollo Sostenible 2030: Estrategia Conjunta Para El Impulso de Los ODS. 2021. Available online: https://www.gobiernodecanarias.org/cmsweb/export/sites/agendacanaria2030/galerias/documentos/agendacanaria2030.pdf (accessed on 18 June 2025).

- European Parliament. Directiva 2008/98/CE Del Parlamento Europeo y Del Consejo de 19 de Noviembre de 2008 Los Residuos y Por La Que Se Derogan Determinadas Directivas. In Diario Oficial de la Unión Europea; European Parliament: Strasbourg, France, 2008. [Google Scholar]

- Gobierno de Canarias. Conserjería de Transición Ecológica, L. contra el C.C. y P.Territorial. Boletín Oficial de Canarias BOC-2022/9. Jueves 13 de Enero de 2022-148. Available online: https://www.gobiernodecanarias.org/boc/2022/009/002.html (accessed on 2 December 2024).

- Gobierno de Canarias. Conserjería de Hacienda y Relaciones con la Unión Europea. Canarias: Región Ultraperiférica. Available online: https://www.gobiernodecanarias.org/asuntoseuropeos/rup/canarias_en_las_rup/index.html (accessed on 19 April 2025).

- Gobierno de Canarias. Conserjería de Transición Ecológica y Energía. Observatorio de la Energía de canarias Anuario Energético de Canarias 2022. Available online: https://datosdelanzarote.lztic.com/media/item/docs/AnuarioEnergeticoCanarias_2022.pdf (accessed on 16 June 2025).

- Gobierno de Canarias. Conserjería de Transición Ecológica y Energía. Observatorio de la Energía de Canarias. Observatorio de La Energía de Canarias-Diagrama de Sankey. Available online: https://www3.gobiernodecanarias.org/ceic/energia/oecan/diagrama-de-sankey (accessed on 6 January 2025).

- SankeyArt GmbH Professional Sankey Diagram Maker. Available online: https://www.sankeyart.com/ (accessed on 13 December 2024).

- The European Parliament and The Council of the European Union. Diario Oficial de La Unión Europea. Directiva (UE) 2018/851 Del Parlamento Europeo y Del Consejo, de 30 de Mayo de 2018, Por La Que Se Modifica La Directiva 2008/98/CE Sobre Los Residuos (Texto Pertinente a Efectos Del EEE). Available online: https://eur-lex.europa.eu/legal-content/ES/TXT/?uri=CELEX%3A32018L0851 (accessed on 2 December 2024).

- Ayuntamiento de Santa Cruz de Tenerife. Valoriza. PLAN DE DESPLIEGUE DEL SERVICIO DE RECOGIDA DEL RESIDUO ORGÁNICO DOMICILIARIO Octubre 2021. Available online: https://santacruzlimpia.es/wp-content/uploads/2022/02/Plan-de-despliegue-del-servicio-de-recogida-del-residuo-organico-domiciliario.pdf (accessed on 13 March 2025).

- Gobierno de España. Ministerio de la Presidencia, J. y R. con las Cortes. Boletín Oficial Del Estado BOE-A-2011-13046, Ley 22/2011, de 28 de Julio, de Residuos y Suelos Contaminados. de 28 de Julio, de Residuos y Suelos Contaminados. Available online: https://www.boe.es/buscar/act.php?id=BOE-A-2011-13046 (accessed on 2 December 2024).

- Gobierno de España. Ministerio de la Presidencia, J. y R. con las Cortes. Boletín Oficial Del Estado BOE-A-2022-5809, Ley 7/2022, de 8 de Abril, de Residuos y Suelos Contaminados Para Una Economía Circular. Available online: https://www.boe.es/buscar/act.php?id=BOE-A-2022-5809 (accessed on 2 July 2024).

- Gobierno de Canarias. Conserjería de Política Territorial y Medio Ambiente. Plan Integral de Resíduos de Canarias (2.000–2.006). Memoria General. 2001. Available online: https://datosdelanzarote.lztic.com/media/item/docs/Plan-integral-de-residuos-de-Canarias-2000-06-(Memoria)-2013061014230231memo.pdf (accessed on 16 June 2025).

- Cabildo de Tenerife. Comisión de Evaluación Ambiental de Tenerife. Plan Territorial Especial de Ordenación de Residuos de Tenerife. Área de Medio Natural, Sostenibilidad, Seguridad y Emergencia. 2009. Available online: https://www.tenerife.es/w/residuos-de-la-isla-de-tenerife?redirect=%2Fplanes-territoriales (accessed on 16 June 2025).

- Audiencia de Cuentas de Canarias Informe de Fiscalización Sobre La Gestión de Resíduos Sólidos Urbanos Por Los Ayuntamientos de Población Superior a 20.000 Habitantes, Ejercicio. 2023. Available online: https://acuentascanarias.org/informes/2023/1703245731__ID262021.pdf (accessed on 16 June 2025).

- Eurostat. Statistic Explained. Environment and Energy. Waste Management Indicators. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_management_indicators (accessed on 1 April 2025).

- Instituto Nacional de Estadística Meta 11.6. De Aquí a 2030, Reducir El Impacto Ambiental Negativo per Cápita de Las Ciudades, Incluso Prestando Especial Atención a La Calidad Del Aire y La Gestión de Los Desechos Municipales y de Otro Tipo. Cantidad per Cápita de Residuos Recogidos Por Comunidades Autónomas, Periodo y Clase de Residuos. Available online: https://www.ine.es/jaxiT3/Datos.htm?tpx=47115#_tabs-grafico (accessed on 6 May 2025).

- Instituto Nacional de Estadística INEbase/Agricultura y Medio Ambiente/Residuos y Protección Ambiental /Estadística Sobre Recogida y Tratamiento de Residuos/Resultados. Available online: https://www.ine.es/dyngs/INEbase/es/operacion.htm?c=Estadistica_C&cid=1254736176844&menu=resultados&idp=1254735976612 (accessed on 10 January 2025).

- Sindhu, R.; Gnansounou, E.; Rebello, S.; Binod, P.; Varjani, S.; Thakur, I.S.; Nair, R.B.; Pandey, A. Conversion of Food and Kitchen Waste to Value-Added Products. J. Environ. Manage 2019, 241, 619–630. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Su, H.; Baeyens, J.; Tan, T. Reviewing the Anaerobic Digestion of Food Waste for Biogas Production. Renew. Sustain. Energy Rev. 2014, 38, 383–392. [Google Scholar] [CrossRef]

- Eurostat. Statistics Explained. Environment and Energy. Municipal Waste Generated, 2004 and 2022. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Municipal_waste_statistics (accessed on 25 February 2025).

- Eurostat. Statistics Explained. Environment and Energy. Food Waste and Food Waste Prevention-Estimates. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Food_waste_and_food_waste_prevention_-_estimates#Amounts_of_food_waste_at_EU_level (accessed on 25 April 2025).

- Singh, S.J.; Elgie, A.; Noll, D.; Eckelman, M.J. The Challenge of Solid Waste on Small Islands: Proposing a Socio-Metabolic Research (SMR) Framework. Curr. Opin. Environ. Sustain. 2023, 62, 101274. [Google Scholar] [CrossRef]

- Iyamu, H.O.; Anda, M.; Ho, G. A Review of Municipal Solid Waste Management in the BRIC and High-Income Countries: A Thematic Framework for Low-Income Countries. Habitat Int. 2020, 95, 102097. [Google Scholar] [CrossRef]

- Santamarta, J.C.; Miklin, L.; Gomes-Nadal, C.O.; Rodríguez-Alcántara, J.S.; Rodríguez-Martín, J.; Cruz-Pérez, N. Waste Management and Territorial Impact in the Canary Islands. Land 2023, 12, 212. [Google Scholar] [CrossRef]

- Quesada-Ruiz, L.C.; Rodriguez-Galiano, V.; Jordá-Borrell, R. Characterization and Mapping of Illegal Landfill Potential Occurrence in the Canary Islands. Waste Manag. 2019, 85, 506–518. [Google Scholar] [CrossRef] [PubMed]

- Gobierno de Canarias. Estrategia Canaria de Economía Circular 2021–2030. Documento Completo. Propuesta Realizada Por La Consejería de Economía, Conocimiento y Empleo Mediante Encargo al Instituto Tecnológico de Canarias S.A. 2021. Available online: https://economiacircularcanarias.com/wp-content/uploads/2021/07/Estrategia-Canaria-Economia-Circular.pdf (accessed on 16 June 2025).

- Cabildo de Tenerife. Servicio Técnico de Desarollo Sostenible. Conjuntos de Datos. Gestión de Resíduos de Tenerife. Available online: https://datos.tenerife.es/es/datos/conjuntos-de-datos/gestion-de-residuos-de-tenerife?return=aHR0cHM6Ly9kYXRvcy50ZW5lcmlmZS5lcy9lcy9kYXRvcy9jb25qdW50b3MtZGUtZGF0b3M= (accessed on 6 May 2025).

- Gobierno de Canarias. Conserjería de Transición Ecológica. Oficinas Verdes de Canarias. La Mancomunidad Del Nordeste de Tenerife Inicia Un Proyecto Para Instalar Contenedores de Biorresiduos. Available online: https://www.oficinasverdes.es/noticias/la-mancomunidad-del-nordeste-de-tenerife-inicia-un-proyecto-para-la-instalacion-de-contenedores-de-biorresiduos/ (accessed on 6 May 2025).

- Higa, T.; Parr, J.F. Beneficial and Effective Microorganisms for a Sustainable Agriculture and Environment; International Nature Farming Research Center: Atami, Japan, 1994. [Google Scholar]

- Bayerische Landesanstalt für Weinbau und Gartenbau. Rascher, Birgit. Effektive Mikroorganismen Versuchsergebnisse Aus Bamberg 2011. Available online: https://www.lwg.bayern.de/mam/cms06/gartenakademie/dateien/em_rascher.pdf (accessed on 16 June 2025).

- Dobrzyński, J.; Kulkova, I.; Wierzchowski, P.S.; Wróbel, B. Response of Physicochemical and Microbiological Properties to the Application of Effective Microorganisms in the Water of the Turawa Reservoir. Water 2022, 14, 12. [Google Scholar] [CrossRef]

- Aguirre-Garcia, Y.L.; Nery-Flores, S.D.; Campos-Muzquiz, L.G.; Flores-Gallegos, A.C.; Palomo-Ligas, L.; Ascacio-Valdés, J.A.; Sepúlveda-Torres, L.; Rodríguez-Herrera, R. Lactic Acid Fermentation in the Food Industry and Bio-Preservation of Food. Fermentation 2024, 10, 168. [Google Scholar] [CrossRef]

- Zapaśnik, A.; Sokołowska, B.; Bryła, M. Role of Lactic Acid Bacteria in Food Preservation and Safety. Foods 2022, 11, 1283. [Google Scholar] [CrossRef] [PubMed]

- Okoye, C.O.; Wang, Y.; Gao, L.; Wu, Y.; Li, X.; Sun, J.; Jiang, J. The Performance of Lactic Acid Bacteria in Silage Production: A Review of Modern Biotechnology for Silage Improvement. Microbiol. Res. 2023, 266, 127212. [Google Scholar] [CrossRef] [PubMed]

- Pszczółkowski, P.; Sawicka, B.; Barbaś, P.; Skiba, D.; Krochmal-Marczak, B. The Use of Effective Microorganisms as a Sustainable Alternative to Improve the Quality of Potatoes in Food Processing. Appl. Sci. 2023, 13, 7062. [Google Scholar] [CrossRef]

- Hidalgo, D.; Corona, F.; Martín-Marroquín, J.M. Manure Biostabilization by Effective Microorganisms as a Way to Improve Its Agronomic Value. Biomass Convers. Biorefin. 2022, 12, 4649–4664. [Google Scholar] [CrossRef]

- Hotel Bahia del Duque, C.A.T. Spain. Personal Notice environmental manager 2022. 2022. Available online: https://thetaishotels.com/es/emas/ (accessed on 18 June 2025).

- MEIKO Maschinenbau GmbH & Co. KG Speisereste-Anlagen Zur Speiseresteentsorgung-MEIKO. Available online: https://www.meiko.com/de-ch/produkte/speisereste-anlagen# (accessed on 6 January 2025).

- European Union. EUR-Lex Regulation (EC) No 1069/2009 of the European Parliament and of the Council of 21 October 2009 Laying down Health Rules as Regards Animal by-Products and Derived Products Not Intended for Human Consumption and Repealing Regulation (EC) No 1774/2002 (Animal by-Products Regulation). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32009R1069 (accessed on 15 December 2024).

- Verein Deutscher Ingenieure e.V. VDI 4630 Fermentation of Organic Materials - Characterization of the Substrate, Sampling, Collection of Material Data, Fermentation Tests 2016. Available online: https://www.vdi.de/en/home/vdi-standards/details/vdi-4630-fermentation-of-organic-materials-characterization-of-the-substrate-sampling-collection-of-material-data-fermentation-tests (accessed on 16 June 2025).

- Deutsches Institut für Normung e.V. (DIN). DIN EN 15935:2021-10, Boden, Abfall, behandelter Bioabfall und Schlamm_- Bestimmung des Glühverlusts; Deutsche Fassung EN_15935:2021. 2021. Available online: https://www.dinmedia.de/en/standard/din-en-15935/337130022 (accessed on 16 June 2025).

- Donatelli, J.A.; Chang, S. Biological Methane Potentials of Food Waste of Different Components: Methane Yields, Production Kinetics, and Element Balance. Bioresour. Technol. 2024, 413, 131435. [Google Scholar] [CrossRef] [PubMed]

- Lisboa, M.S.; Lansing, S. Characterizing Food Waste Substrates for Co-Digestion through Biochemical Methane Potential (BMP) Experiments. Waste Manag. 2013, 33, 2664–2669. [Google Scholar] [CrossRef] [PubMed]

- Bayerische Landesanstalt für Landwirtschaft Biogasausbeuten Verschiedener Substrate-Programm Berechnung-LfL. Available online: https://www.lfl.bayern.de/iba/energie/049711/?sel_list=49%2Cb&anker0=substratanker#substratanker (accessed on 20 December 2024).

- Niemiec, M.; Sikora, J.; Szeląg-Sikora, A.; Gródek-Szostak, Z.; Komorowska, M. Assessment of the Possibilities for the Use of Selected Waste in Terms of Biogas Yield and Further Use of Its Digestate in Agriculture. Materials 2022, 15, 988. [Google Scholar] [CrossRef] [PubMed]

- Mirmohamadsadeghi, S.; Karimi, K.; Tabatabaei, M.; Aghbashlo, M. Biogas Production from Food Wastes: A Review on Recent Developments and Future Perspectives. Bioresour. Technol. Rep. 2019, 7, 100202. [Google Scholar] [CrossRef]

- Pramanik, S.K.; Suja, F.B.; Zain, S.M.; Pramanik, B.K. The Anaerobic Digestion Process of Biogas Production from Food Waste: Prospects and Constraints. Bioresour. Technol. Rep. 2019, 8, 100310. [Google Scholar] [CrossRef]

- Mechanische Verfahrenstechnik-Partikeltechnologie 1; Springer-Lehrbuch; Springer: Berlin/Heidelberg, Germany, 2009; ISBN 978-3-540-32551-2.

- Hofmann, J. Vortrag Abschlußbericht Zum FuE-Projekt Kleine Biogasanlage Textilen Materialien. 2022. Available online: https://www.haw-landshut.de/fileadmin/Hochschule_Landshut_NEU/Ungeschuetzt/FSP_Energie/LA_Energiegespraeche/Biogasvortrag_20220620.pdf (accessed on 16 June 2025).

- Hidalgo-Sánchez, V.; Hofmann, J.; Borges, M.E.; Behmel, U.; Hehenberger-Risse, D.; Finsterwalder, T.; Pritscher, C.; Blattenberger, J.; Wainz, T.; Dillis, M. Operation of a Pilot-Scale Biogas Plant Made of Textile Materials and Application of Its Results to a Full-Sized Demonstration Plant. Sustainability 2024, 16, 3177. [Google Scholar] [CrossRef]

- Bundesministerium der Justiz. Bundesamt für Justiz. AwSV-Verordnung Über Anlagen Zum Umgang Mit Wassergefährdenden Stoffen 1, 2. Available online: https://www.gesetze-im-internet.de/awsv/BJNR090500017.html (accessed on 31 December 2024).

- Bundesministerium der Justiz. Bundesamt für Justiz. WHG-Nichtamtliches Inhaltsverzeichnis. Available online: https://www.gesetze-im-internet.de/whg_2009/ (accessed on 31 March 2025).

- Bundesministerium der Justiz. Bundesamt für Justiz. BImSchG-Gesetz Zum Schutz Vor Schädlichen Umwelteinwirkungen Durch Luftverunreinigungen, Geräusche, Erschütterungen Und Ähnliche Vorgänge. Available online: https://www.gesetze-im-internet.de/bimschg/BJNR007210974.html (accessed on 31 March 2025).

- Cabildo de Tenerife. Datos Abiertos. Conjuntos de datos Cantidad de Residuos Domésticos Recibidos En El Complejo Ambiental de Tenerife. Available online: https://datos.tenerife.es/es/datos/conjuntos-de-datos/cantidad-residuos-domesticos-recibidos-complejo-ambiental-tenerife?return=aHR0cHM6Ly9kYXRvcy50ZW5lcmlmZS5lcy9lcy9kYXRvcy9jb25qdW50b3MtZGUtZGF0b3M= (accessed on 6 May 2025).

- Gobierno de Canarias. Servicio de Cambio Climático e Información Ambiental Consejería de Transición Ecológica, L.C. el C.C. y P.T. Informe de Coyuntura Canario 2014–2020. Introducción e Informe 0. 2021. Available online: https://www.gobiernodecanarias.org/medioambiente/materias/informacion-ambiental/derechos-ciudadanos/simac/informes-coyuntura-ambiental/informe-coyuntura-ambiental-2014-2020/ (accessed on 16 June 2025).

- European Union. Eurostat. Demography of Europe–2024 Edition. Available online: https://ec.europa.eu/eurostat/web/interactive-publications/demography-2024 (accessed on 15 March 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).