A Comparison of Cement and Guar Gum Stabilisation of Oxford Clay Under Controlled Wetting and Drying Cycles

Abstract

1. Introduction

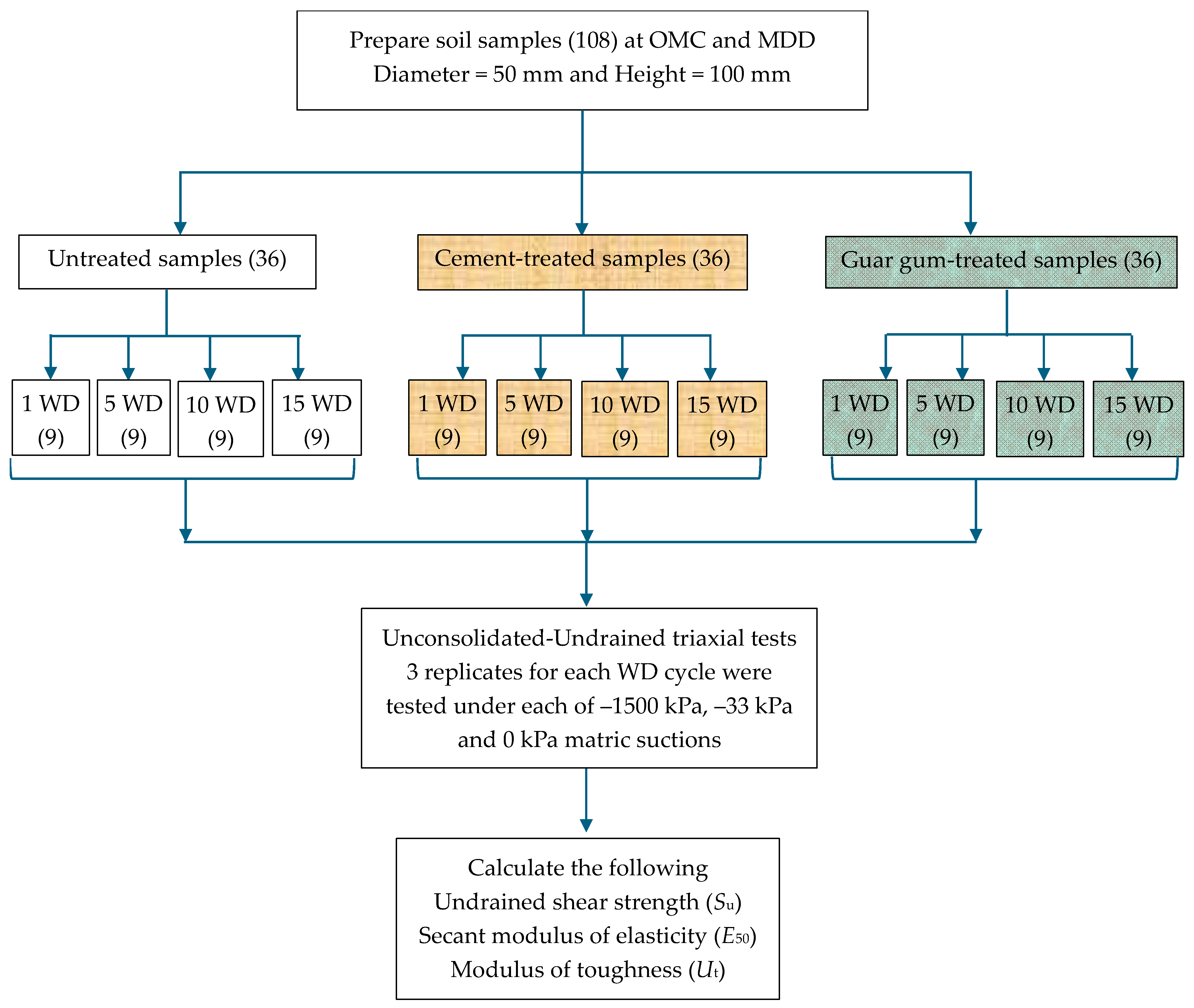

2. Materials and Methods

2.1. Materials

2.2. Preparation of Soil Samples

2.3. Measurement of Volumetric Strain

2.4. Unconsolidated–Undrained Triaxial Testing and Analysis

- −1500 kPa matric suction: This represents a dry-season or post-compaction condition in which matric suction contributes to higher strength.

- −33 kPa matric suction: Samples were first fully saturated and then allowed to dry partially. This condition simulates field capacity, such as a few days after the rainfall.

- Full saturation: Achieved through prolonged soaking to eliminate matric suction, this represents the worst-case scenario, such as heavy rainfall or flooding, when strength is lowest due to the absence of suction.

2.5. X-Ray CT Scanning and Visualisation

3. Results

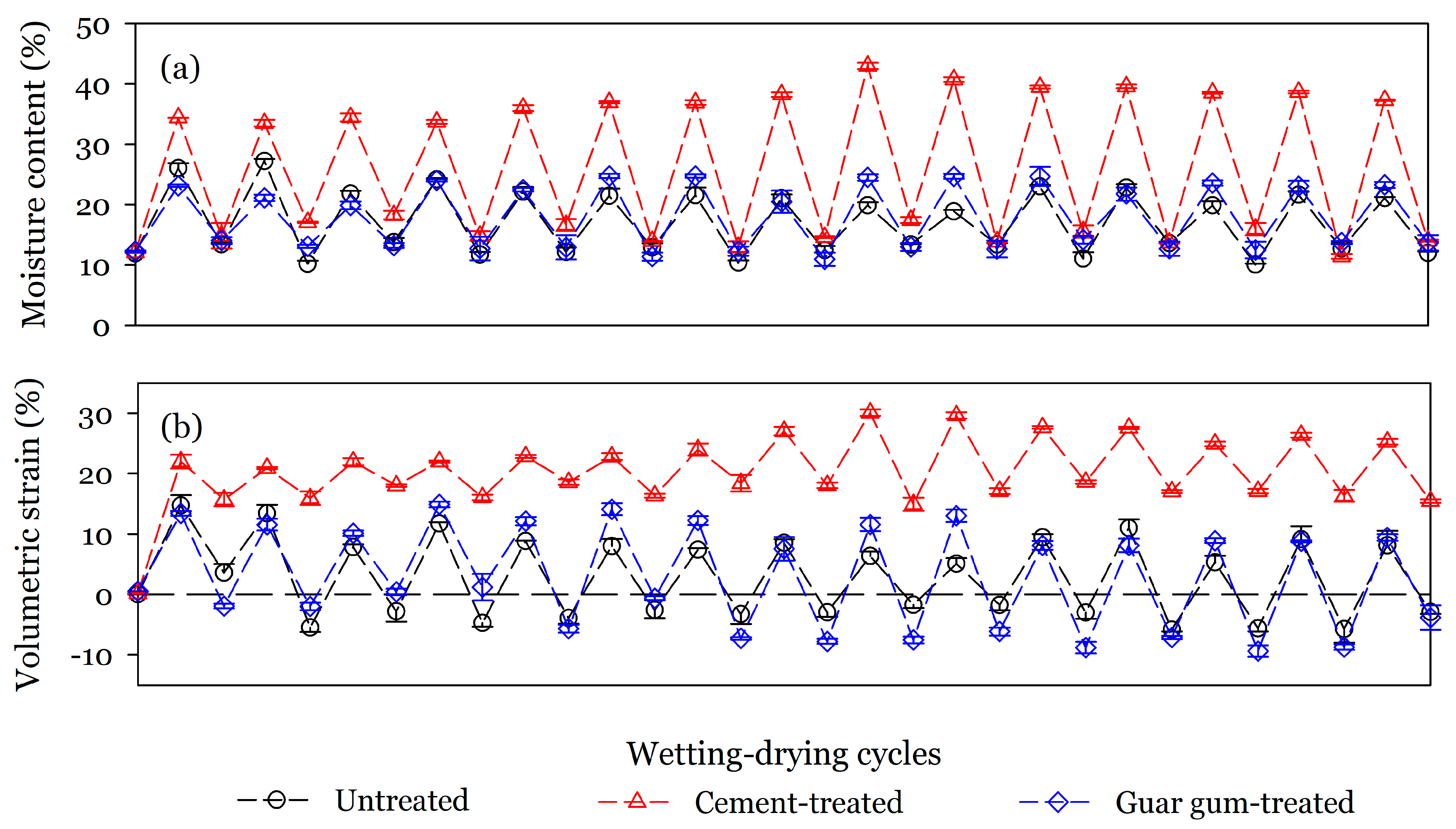

3.1. Moisture Dynamics and Volumetric Behaviour Under WD Cycles

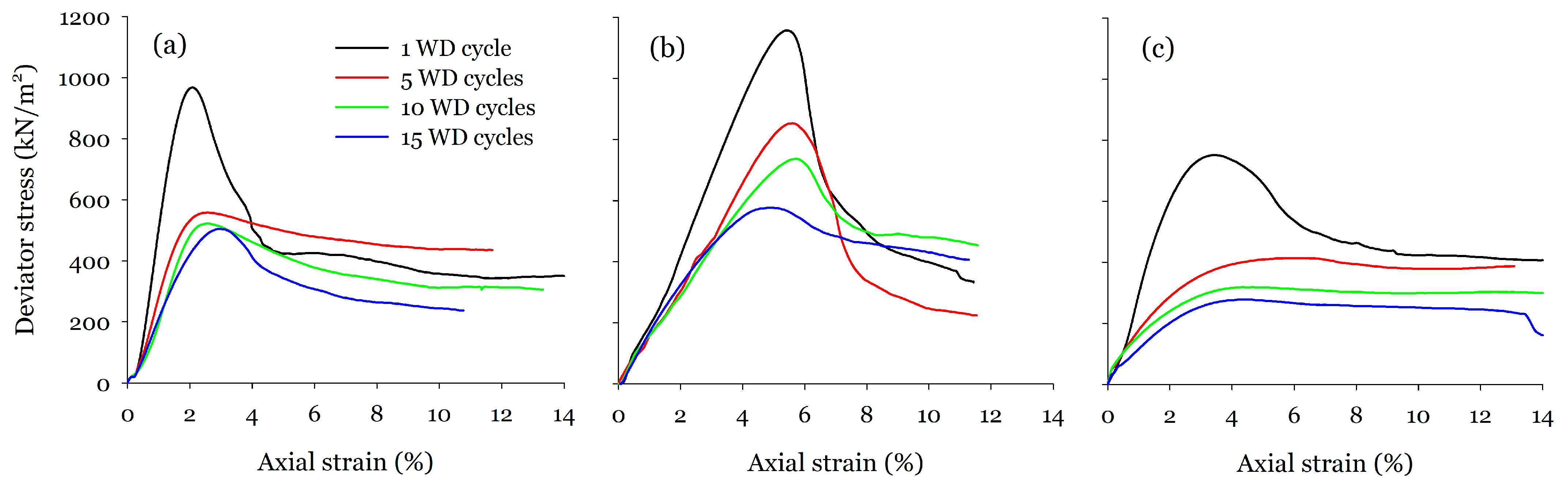

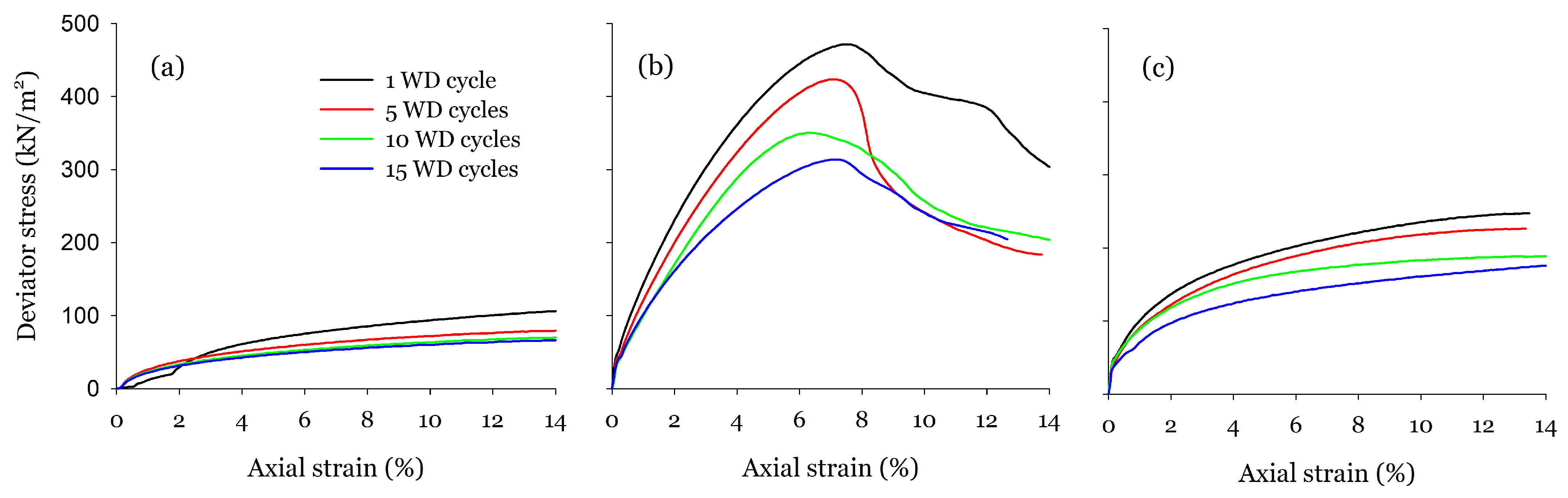

3.2. Stress–Strain Behaviour at −1500 kPa Matric Suction

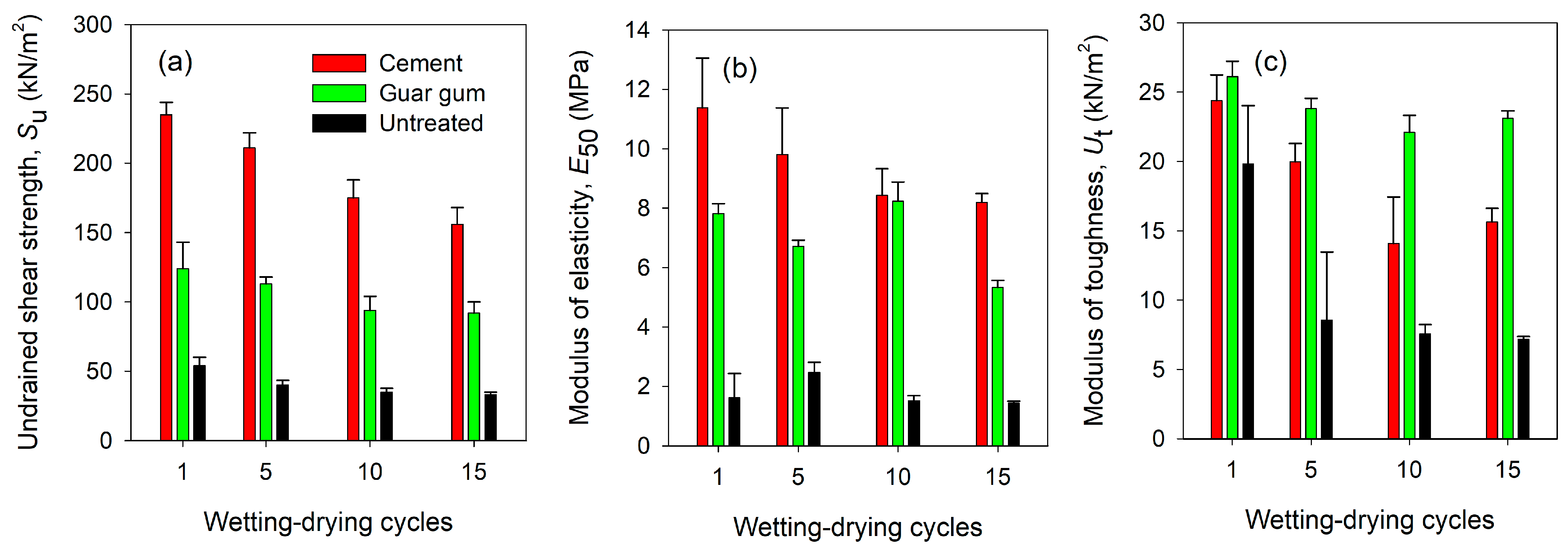

3.3. Stress–Strain Behaviour at −33 kPa Matric Suction

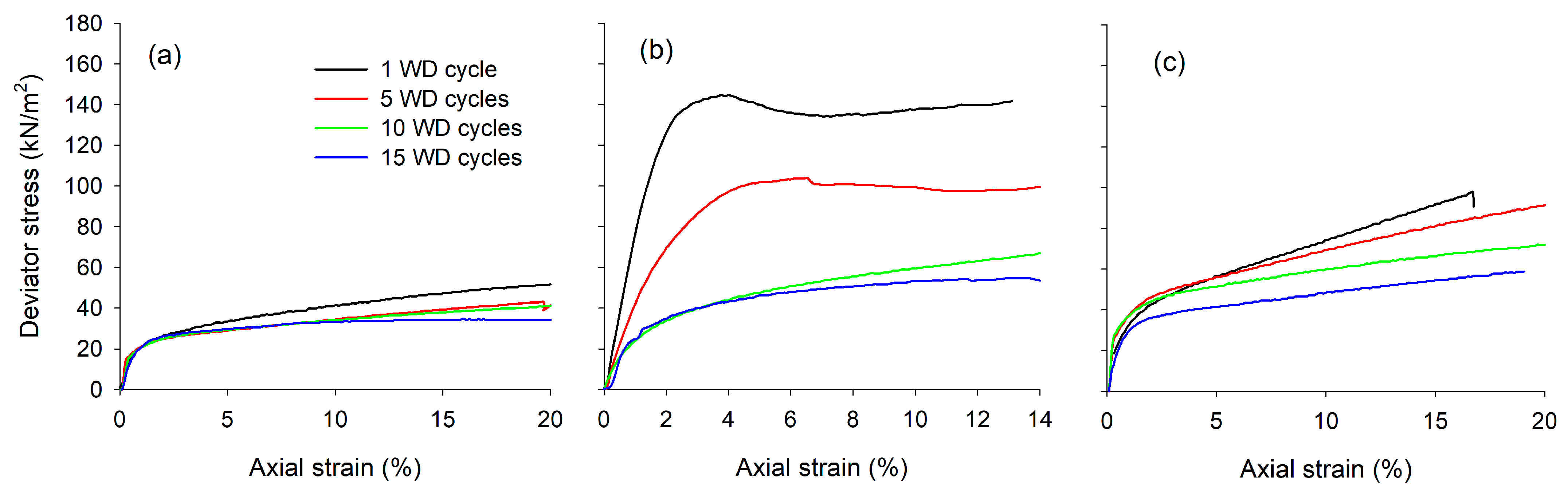

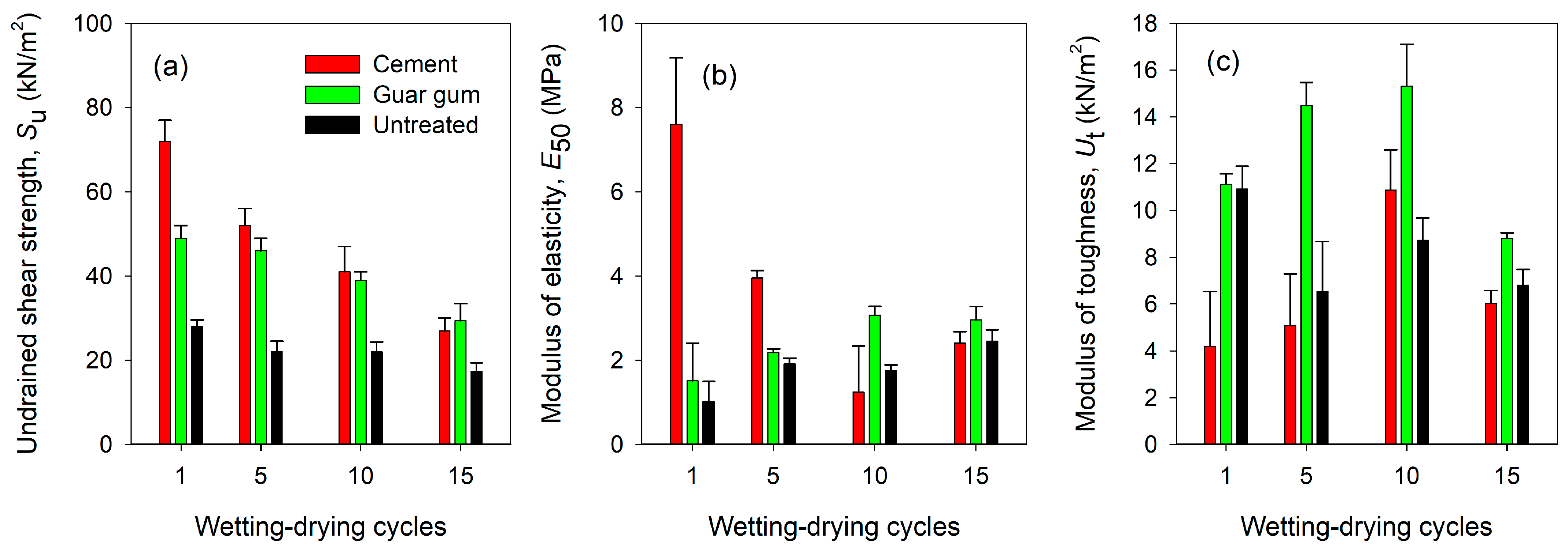

3.4. Stress–Strain Behaviour at Saturation

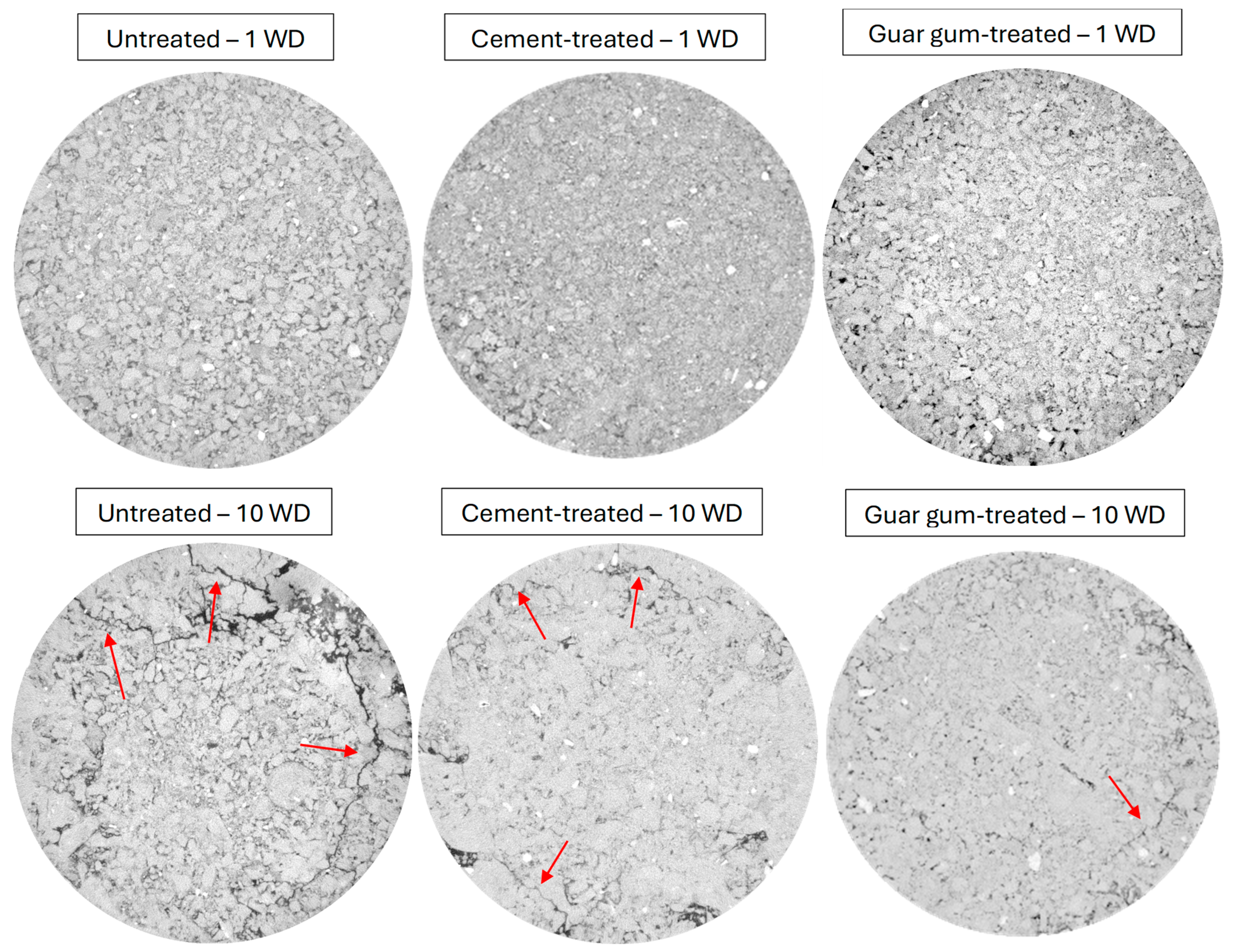

3.5. X-Ray CT Visualisation

3.6. Cost–Carbon Emission Comparison Analysis

4. Discussion

4.1. Volumetric Response and Moisture Dynamics

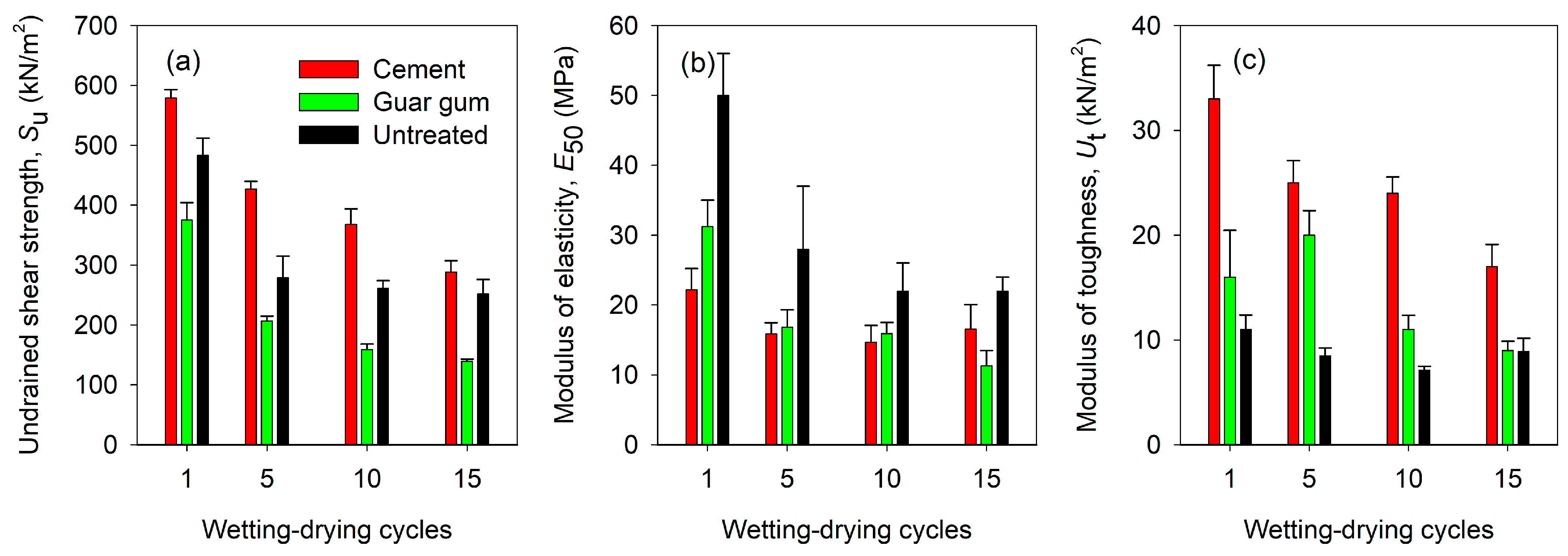

4.2. Mechanical Performance Under WD Cycles

4.3. Sustainability Assessment

4.4. Biodegradation Risks and Matrix Influence in Guar Gum-Stabilised Soils

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Treatment | Matric Suction (kPa) | WD Cycles (No.) | Moisture Content (%) | Undrained Shear Strength, Su (kPa) | Secant Modulus of Elasticity, E50 (MPa) | Modulus of Toughness, Ut (kPa) |

|---|---|---|---|---|---|---|

| Untreated | −1500 | 1 | 12 ± 0.5 | 483 ± 29 | 50.2 ± 6.1 | 11 ± 1.4 |

| 5 | 12 ± 0.43 | 279 ±36 | 28.4 ± 9.3 | 8.5 ± 0.8 | ||

| 10 | 13 ± 0.68 | 261 ± 13 | 22.3 ± 4.2 | 7.1 ± 0.4 | ||

| 15 | 12 ± 0.29 | 252 ± 24 | 22.1 ± 1.8 | 8.9 ± 1.3 | ||

| −33 | 1 | 19 ± 0.79 | 54 ± 3 | 1.6 ± 0.8 | 19.8 ± 4.2 | |

| 5 | 17 ± 0.83 | 40 ± 4 | 2.5 ± 0.3 | 8.6 ± 4.9 | ||

| 10 | 17 ± 0.48 | 35 ± 3 | 1.5 ± 0.2 | 7.6 ± 0.7 | ||

| 15 | 16 ± 0.39 | 33 ± 2 | 1.4 ± 0.1 | 7.2 ± 0.2 | ||

| 0 | 1 | 26 ± 2.43 | 28 ± 2 | 1.0 ± 0.4 | 10.9 ± 0.9 | |

| 5 | 22 ± 1.21 | 22 ± 3 | 1.9 ± 0.1 | 6.6 ± 2.1 | ||

| 10 | 21 ± 0.95 | 22 ± 2 | 1.8 ± 0.2 | 8.7 ± 0.9 | ||

| 15 | 21 ± 1.01 | 17 ± 2 | 2.5 ± 0.3 | 6.8 ± 0.7 | ||

| Cement-treated | −1500 | 1 | 14 ± 0.98 | 579 ± 14 | 22.3 ± 3.4 | 33.3 ± 3.2 |

| 5 | 15 ± 1.18 | 427 ± 13 | 16.7 ± 2.3 | 25.9 ± 2.1 | ||

| 10 | 12 ± 0.28 | 368 ± 16 | 15.2 ± 1.9 | 24.2 ± 1.6 | ||

| 15 | 14 ± 1.38 | 288 ± 19 | 17.1 ± 3.6 | 17.3 ± 2.1 | ||

| −33 | 1 | 24 ± 0.95 | 235 ± 9 | 11.4 ± 1.7 | 24.4 ± 1.9 | |

| 5 | 24 ± 0.81 | 211 ± 11 | 9.8 ± 1.6 | 19.9 ± 1.3 | ||

| 10 | 22 ±0.78 | 175 ± 13 | 8.4 ± 0.9 | 14.1 ± 3.3 | ||

| 15 | 24 ± 0.69 | 156 ± 12 | 8.2 ± 0.3 | 15.6 ± 0.9 | ||

| 0 | 1 | 32 ± 1.31 | 72 ± 5 | 7.6 ± 1.6 | 4.2 ± 2.3 | |

| 5 | 34 ± 1.34 | 52 ± 4 | 4.0 ± 0.2 | 5.1 ± 0.2 | ||

| 10 | 34 ± 1.52 | 41 ± 6 | 1.2 ± 1.1 | 10.9 ± 1.7 | ||

| 15 | 33 ± 1.23 | 27 ± 3 | 2.4 ± 0.3 | 6.0 ± 0.6 | ||

| Guar gum-treated | −1500 | 1 | 12 ± 0.36 | 375 ± 29 | 31.2 ± 3.8 | 16.3 ± 4.5 |

| 5 | 13 ± 0.44 | 207 ± 8 | 17.9 ± 3.4 | 20.1 ± 2.3 | ||

| 10 | 11 ±0.23 | 159 ± 5 | 15.5 ± 2.1 | 11.4 ± 1.3 | ||

| 15 | 12 ± 0.09 | 139 ± 4 | 11.7 ± 2.2 | 9.4 ± 0.9 | ||

| −33 | 1 | 17 ± 0.56 | 124 ± 19 | 7.8 ± 0.3 | 26.1 ± 1.1 | |

| 5 | 16 ± 0.89 | 113 ± 5 | 6.7 ± 0.2 | 23.8 ± 0.7 | ||

| 10 | 16 ± 0.49 | 94 ± 10 | 8.2 ± 0.2 | 22.1 ± 1.2 | ||

| 15 | 17 ± 0.94 | 92 ± 8 | 5.3 ± 0.2 | 23.1 ± 0.5 | ||

| 0 | 1 | 24 ± 1.89 | 49 ± 3 | 1.5 ± 0.9 | 11.1 ± 0.5 | |

| 5 | 22 ± 0.67 | 46 ± 3 | 2.2 ± 0.1 | 14.5 ± 0.9 | ||

| 10 | 22 ± 0.38 | 39 ± 2 | 3.1 ± 0.2 | 15.3 ± 1.8 | ||

| 15 | 22 ± 0.39 | 29 ± 4 | 2.6 ± 0.3 | 8.8 ± 0.2 |

References

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2021: The Physical Science Basis; Cambridge University Press: Cambridge, UK, 2021. [Google Scholar]

- Shah, S.S.A.; Turrakheil, K.S.; Naveed, M. Impact of wetting and drying cycles on the hydromechanical properties of soil and implications on slope stability. Atmosphere 2024, 15, 1368. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Leung, A.K.; Woon, K.H. Effects of soil density on grass-induced suction distributions in compacted soil subjected to rainfall. Can. Geotech. J. 2014, 51, 311–321. [Google Scholar] [CrossRef]

- Goh, S.G.; Rahardjo, H.; Leong, E.C. Shear strength of unsaturated soils under multiple drying–wetting cycles. J. Geotech. Geoenviron. Eng. 2014, 140. [Google Scholar] [CrossRef]

- Tripathy, S.; Subba Rao, K.S.; Fredlund, D.G. Water content–void ratio swell–shrink paths of compacted expansive soils. Can. Geotech. J. 2002, 39, 938–959. [Google Scholar] [CrossRef]

- Yesiller, N.; Miller, C.J.; Inci, G.; Yaldo, K. Desiccation and cracking behavior of three compacted landfill liner soils. Eng. Geol. 2000, 57, 105–121. [Google Scholar] [CrossRef]

- Turrakheil, K.S.; Shah, S.S.A.; Naveed, M. Evolution of soil pore structure and shear strength deterioration of compacted soil under controlled wetting and drying cycles. Atmosphere 2024, 15, 843. [Google Scholar] [CrossRef]

- Narsilio, G.A.; Santamarina, J.C.; Altschaeffl, A.G. Effects of wetting-drying cycles and desiccation cracks on mechanical behaviour of an unsaturated soil. Catena 2020, 194, 104721. [Google Scholar] [CrossRef]

- Albrecht, B.A.; Benson, C.H. Effect of desiccation on compacted natural clays. J. Geotech. Geoenviron. Eng. 2001, 127, 67–75. [Google Scholar] [CrossRef]

- Cui, Y.J.; Tang, A.M.; Mantho, A.T.; De Laure, E. Monitoring field soil suction using miniature tensiometers. Geotech. Test. J. 2008, 31, 95–100. [Google Scholar] [CrossRef]

- Simona, S.; Barnichon, J.D.; Cui, Y.J.; Tang, A.M.; Delage, P. Microstructure and anisotropic swelling behaviour of compacted bentonite/sand mixture. J. Rock Mech. Geotech. Eng. 2014, 6, 126–132. [Google Scholar] [CrossRef]

- Mitchell, J.K.; Soga, K. Fundamentals of Soil Behaviour, 3rd ed.; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Chen, R.; Ng, C.W.W. Impact of wetting–drying cycles on hydro-mechanical behavior of an unsaturated compacted clay. Appl. Clay Sci. 2013, 86, 38–46. [Google Scholar] [CrossRef]

- Nabil, M.; Mustapha, A.; Rios, S. Impact of wetting–drying cycles on the mechanical properties of lime-stabilized soils. Int. J. Pavement Res. Technol. 2020, 13, 83–92. [Google Scholar] [CrossRef]

- Wassermann, A.; Abdallah, A.; Cuisinier, O. Impact of wetting and drying cycles on the mechanical behaviour of a cement-treated soil. Transp. Geotech. 2022, 36, 100804. [Google Scholar] [CrossRef]

- Consoli, N.C.; Prietto, P.D.M.; Ulbrich, L.A. Influence of fiber and cement addition on behavior of sandy soil. J. Geotech. Geoenviron. Eng. 1998, 124, 1211–1214. [Google Scholar] [CrossRef]

- Hopkins, T.C.; Hunsucker, D.Q.; Beckham, T. Long-term performance of flexible pavements located on cement-treated soils. Transp. Res. Rec. 1994, 1440, 20–28. [Google Scholar]

- Lv, S.; Xia, C.; Liu, H.; You, L.; Qu, F.; Zhong, W.; Yang, Y.; Washko, S. Strength and fatigue performance for cement-treated aggregate base materials. Int. J. Pavement Eng. 2019, 22, 690–699. [Google Scholar] [CrossRef]

- Roberts, J.D. Performance of Cement-Modified Soils: A Follow-Up Report; Federal Highway Administration: Washington, DC, USA, 1986. [Google Scholar]

- Niu, W.; Guo, B.; Li, K.; Ren, Z.; Zheng, Y.; Liu, J.; Lin, H.; Men, X. Cementitious material-based stabilization of soft soils by stabilizer. Constr. Build. Mater. 2024, 425, 136046. [Google Scholar] [CrossRef]

- Dai, D.; Peng, J.; Wei, R.; Li, L.; Lin, H. Improvement in dynamic behaviors of cement-stabilized soil by super-absorbent-polymer under cyclic loading. Soil Dyn. Earthq. Eng. 2022, 163, 107554. [Google Scholar] [CrossRef]

- Azimi, M.; Soltani, A.; Mirzababaei, M.; Jaksa, M.B.; Ashwath, N. Biopolymer stabilization of clayey soil. J. Rock Mech. Geotech. Eng. 2024, 16, 2801–2812. [Google Scholar] [CrossRef]

- Bagriacik, B.; Ok, B.; Kahiyah, M.T.M.A. An experimental study on improvement of cohesive soil with eco-friendly guar gum. Soils Rocks 2021, 44, e2021060020. [Google Scholar] [CrossRef]

- Banne, S.P.; Kulkarni, S.; Baldovino, J.A. Effect of guar gum content on the mechanical properties of laterite soil for subgrade soil application. Polymers 2024, 16, 2202. [Google Scholar] [CrossRef]

- Keshav, N.; Prabhu, A.; Kattimani, A.; Dharwad, A.; Kallatti, C.; Mahalank, S. Enhancing the properties of expansive soil using biopolymers—Xanthan gum and guar gum. In Proceedings of the Indian Geotechnical Conference 2019, Surat, India, 19–21 December 2019; Springer: Singapore, 2021; Volume 138, pp. 121–131. [Google Scholar] [CrossRef]

- Sujatha, E.R.; Saisree, S. Geotechnical behaviour of guar gum-treated soil. Soils Found. 2019, 59, 2155–2166. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Olgun, C.G.; Baghini, M.S. Fundamentals of soil stabilization. Int. J. Geo-Eng. 2017, 8, 26. [Google Scholar] [CrossRef]

- Chang, I.; Lee, M.; Tran, A.T.P.; Lee, S.; Kwon, Y.-M.; Im, J.; Cho, G.-C. Review on biopolymer-based soil treatment (BPST) technology in geotechnical engineering practices. Transp. Geotech. 2020, 24, 100385. [Google Scholar] [CrossRef]

- BS 1377-1:2016; Methods of Test for Soils for Civil Engineering Purposes—Part 1: General Requirements and Sample Preparation. British Standards Institution (BSI): London, UK, 2016.

- BS 1377-7:1990; Methods of Test for Soils for Civil Engineering Purposes—Part 7: Shear Strength Tests (Total Stress). British Standards Institution (BSI): London, UK, 1990.

- Rasband, W. ImageJ, version 1.54h; U.S. National Institutes of Health: Bethesda, MD, USA, 2023. [Google Scholar]

- Subramani, A.K.; Ramani, S.E.; Selvasembian, R. Understanding the microstructure, mineralogical and adsorption characteristics of guar gum blended soil as a liner material. Environ. Monit. Assess. 2021, 193, 855. [Google Scholar] [CrossRef]

- IndexBox. Cement Price in the United Kingdom. 2022. Available online: https://www.indexbox.io/search/cement-price-in-the-united-kingdom/ (accessed on 12 June 2025).

- Agriwatch. Guar Gum Export Price Analysis. May 2024. Available online: https://www.agriwatch.com/market-report/guar-gum (accessed on 12 June 2025).

- International Energy Agency (IEA). Cement Production and CO2 Emissions: Global Trends and Outlooks; IEA: Paris, France, 2021; Available online: https://www.iea.org/reports/cement (accessed on 12 June 2025).

- Kumar, M.A.; Moghal, A.A.B.; Vydehi, K.V.; Almajed, A. Embodied energy in the production of guar and xanthan biopolymers and their cross-linking effect in enhancing the geotechnical properties of cohesive soil. Buildings 2023, 13, 2304. [Google Scholar] [CrossRef]

- Cojean, R. Review of: Al-Rawas, A.A.; Goosen, M.F.A. (Eds.): Expansive Soils: Recent Advances in Characterization and Treatment. Bull. Eng. Geol. Environ. 2007, 66, 505. [Google Scholar] [CrossRef]

- Acharya, R.; Pedarla, A.; Bheemasetti, T.V.; Puppala, A. Assessment of guar gum biopolymer treatment toward mitigation of desiccation cracking on slopes built with expansive soils. Transp. Res. Rec. 2019, 2657, 78–88. [Google Scholar] [CrossRef]

- Rasul, J.M.; Ghataora, G.S.; Burrow, M.P.N. The effect of wetting and drying on the performance of stabilized subgrade soils. Transp. Geotech. 2018, 14, 1–7. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Rachan, R.; Chindaprasirt, P. Analysis of strength development in cement-stabilized silty clay from microstructural considerations. Constr. Build. Mater. 2010, 24, 2011–2021. [Google Scholar] [CrossRef]

- Cuisinier, O.; Masrouri, F.; Mehenni, A. Alteration of the hydromechanical performances of a stabilized compacted soil exposed to successive wetting–drying cycles. J. Mater. Civ. Eng. 2020, 32, 04020052. [Google Scholar] [CrossRef]

- Estabragh, A.R.; Pereshkafti, M.R.S.; Parsaei, B.; Javadi, A.A. Stabilised expansive soil behaviour during wetting and drying. Int. J. Pavement Eng. 2013, 14, 418–427. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Menzies, B.K. Advanced Unsaturated Soil Mechanics and Engineering; Taylor & Francis: London, UK, 2007. [Google Scholar]

- Hamza, M.; Nie, Z.; Aziz, M.; Ijaz, N.; Fang, C.; Ghani, M.U.; Ijaz, Z.; Noshin, S.; Salman, M. Geotechnical properties of problematic expansive subgrade stabilized with guar gum biopolymer. Clean Technol. Environ. Policy 2023, 25, 1699–1719. [Google Scholar] [CrossRef]

- Shah, S.N.; Ali, S.A.; Khan, A. Impact of wetting–drying cycles on the mechanical behavior of expansive soils. Int. J. Geotech. Eng. 2024, 18, 123–134. [Google Scholar]

- EN 1997-1; Eurocode 7—Geotechnical Design—Part 1: General Rules. CEN: Brussels, Belgium, 2004.

- Liu, Y.; Ni, J.; Gu, J.; Liu, S.; Huang, Y.; Sadeghi, H. Influence of biopolymer–vegetation interaction on soil hydro-mechanical properties under climate change: A review. Sci. Total Environ. 2024, 954, 176535. [Google Scholar] [CrossRef]

- Reddy, K.R.; Janga, J.K.; Kumar, G. Sustainability and resilience: A new paradigm in geotechnical and geoenvironmental engineering. Indian Geotech. J. 2024. [Google Scholar] [CrossRef]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Abu Dabous, S.; Zeiada, W.; Zayed, T.; Al-Ruzouq, R. Sustainability-informed multi-criteria decision support framework for ranking and prioritization of pavement sections. J. Clean. Prod. 2020, 244, 118755. [Google Scholar] [CrossRef]

- Raj, N.; Selvakumar, S.; Soundara, B.; Kulanthaivel, P. Sustainable utilization of biopolymers as green adhesive in soil improvement: A review. Environ. Sci. Pollut. Res. 2023, 30, 118117–118132. [Google Scholar] [CrossRef]

- Fatehi, H.; Ong, D.E.L.; Yu, J.; Chang, I. Biopolymers as green binders for soil improvement in geotechnical applications: A review. Geosciences 2021, 11, 291. [Google Scholar] [CrossRef]

- Awasthi, S.K.; Kumar, M.; Kumar, V.; Sarsaiya, S.; Anerao, P.; Ghosh, P.; Singh, L.; Liu, H.; Zhang, Z.; Awasthi, M.K. Comprehensive review on recent advancements in biodegradation and sustainable management of biopolymers. Environ. Pollut. 2022, 307, 119600. [Google Scholar] [CrossRef] [PubMed]

- Kögel-Knabner, I.; Amelung, W.; Cao, Z.; Fiedler, S.; Frenzel, P.; Jahn, R.; Kalbitz, K.; Kölbl, A.; Schloter, M. Biogeochemistry of paddy soils. Geoderma 2010, 157, 1–14. [Google Scholar] [CrossRef]

| Material | Target Density of Soil (kg/m3) | Dosage (%) | Quantity Required for 1 m3 of Soil (kg) | Cost per Ton (GBP) | Total Cost for 1 m3 Soil (GBP) | CO2 Emissions per Ton (ton) | Total CO2 Emissions for 1 m3 Soil (kg) |

|---|---|---|---|---|---|---|---|

| Cement | 1.6 | 6 | 96 | 150 | 15 | 0.9 | 86.4 |

| Guar gum | 1 | 16 | 1500 | 24 | 0.1 | 1.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turrakheil, K.S.; Shah, S.S.A.; Naveed, M. A Comparison of Cement and Guar Gum Stabilisation of Oxford Clay Under Controlled Wetting and Drying Cycles. Appl. Sci. 2025, 15, 6913. https://doi.org/10.3390/app15126913

Turrakheil KS, Shah SSA, Naveed M. A Comparison of Cement and Guar Gum Stabilisation of Oxford Clay Under Controlled Wetting and Drying Cycles. Applied Sciences. 2025; 15(12):6913. https://doi.org/10.3390/app15126913

Chicago/Turabian StyleTurrakheil, Kanishka Sauis, Syed Samran Ali Shah, and Muhammad Naveed. 2025. "A Comparison of Cement and Guar Gum Stabilisation of Oxford Clay Under Controlled Wetting and Drying Cycles" Applied Sciences 15, no. 12: 6913. https://doi.org/10.3390/app15126913

APA StyleTurrakheil, K. S., Shah, S. S. A., & Naveed, M. (2025). A Comparison of Cement and Guar Gum Stabilisation of Oxford Clay Under Controlled Wetting and Drying Cycles. Applied Sciences, 15(12), 6913. https://doi.org/10.3390/app15126913