3.2. Simulation Results and Discussions

The first paragraph of this section describes the main parameters that will change in each simulation case.

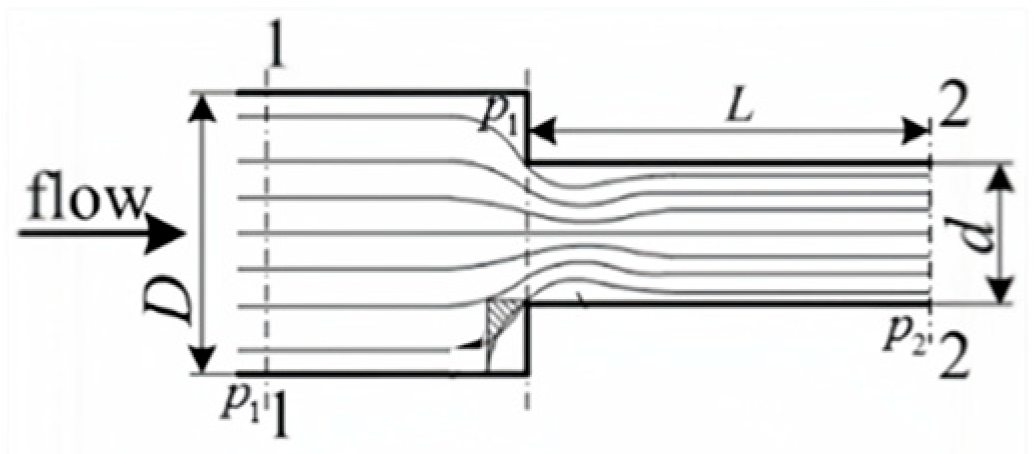

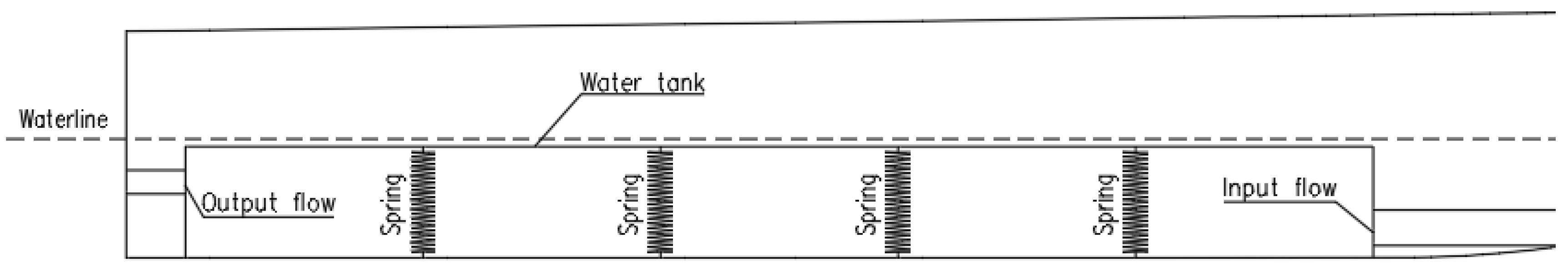

Table 2 presents each case’s wave parameters used for simulation. The main focus of this study is the calculation of the wave force acting on the boat (Equation (27)), which is derived from the formation of the intersected area—overlap between the wave and the boat’s motion profile. The wave frequency (expressed in Hz) is the number of waves passing a fixed point in a given time. We conducted simulations for different wave frequencies from 0.4 Hz to 0.2 Hz. For Case 1 and Case 2, 0.4 Hz and 0.3 Hz, respectively, and for Cases 3 and 4 being the same, 0.2 Hz. The wave height is set to be the same in all four cases at 1.25 m, meeting the conditions outlined in

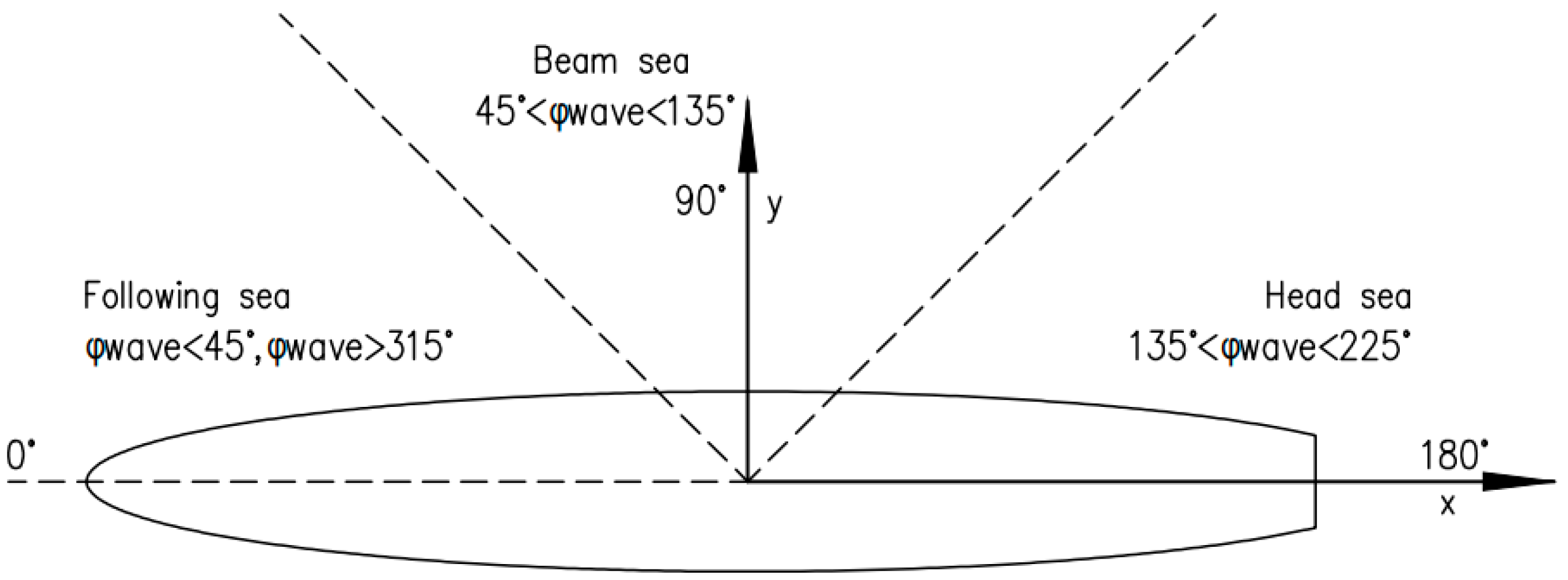

Section 2.2 with the wave slope being less than 0.1412, and compatible with the frequencies mentioned above. The wave angle is set to 180 degrees in all four cases, representing the boat moving against the wave flow. The conditions are arbitrarily selected to evaluate the wave actuator’s performance. The tank coefficients are reiterated here for a more detailed description. Both the damping and spring coefficients are set to 20 in Cases 1, 2, and 3, while in Case 4, the damping coefficient is 25, and the spring coefficient is 40. They are tuned through trial and error. The boat’s initial velocity (Equation (11)) is 4.12 m/s for Case 4 and 2.06 m/s for the remaining three cases.

This paragraph introduces the types of simulation parameters and explains the reasons for their selection. In this study, the boat’s weight is fixed. Therefore, in Cases 1 and 4, the most influencing parameter affecting the force on the boat is the wave frequency (from 0.4 to 0.2 Hz), assuming that more wave crests will generate greater force on the wave actuator. The next influencing parameter is the boat’s initial velocity (2.06–4.12 m/s); the faster the boat, the more wave crests it encounters. Also, other important ones are the tank’s damping coefficient (from 20 to 25) and spring coefficient (from 20 to 40). These are the four parameters affecting the performance of the wave actuator. Considering the above, the following four simulation cases were conducted.

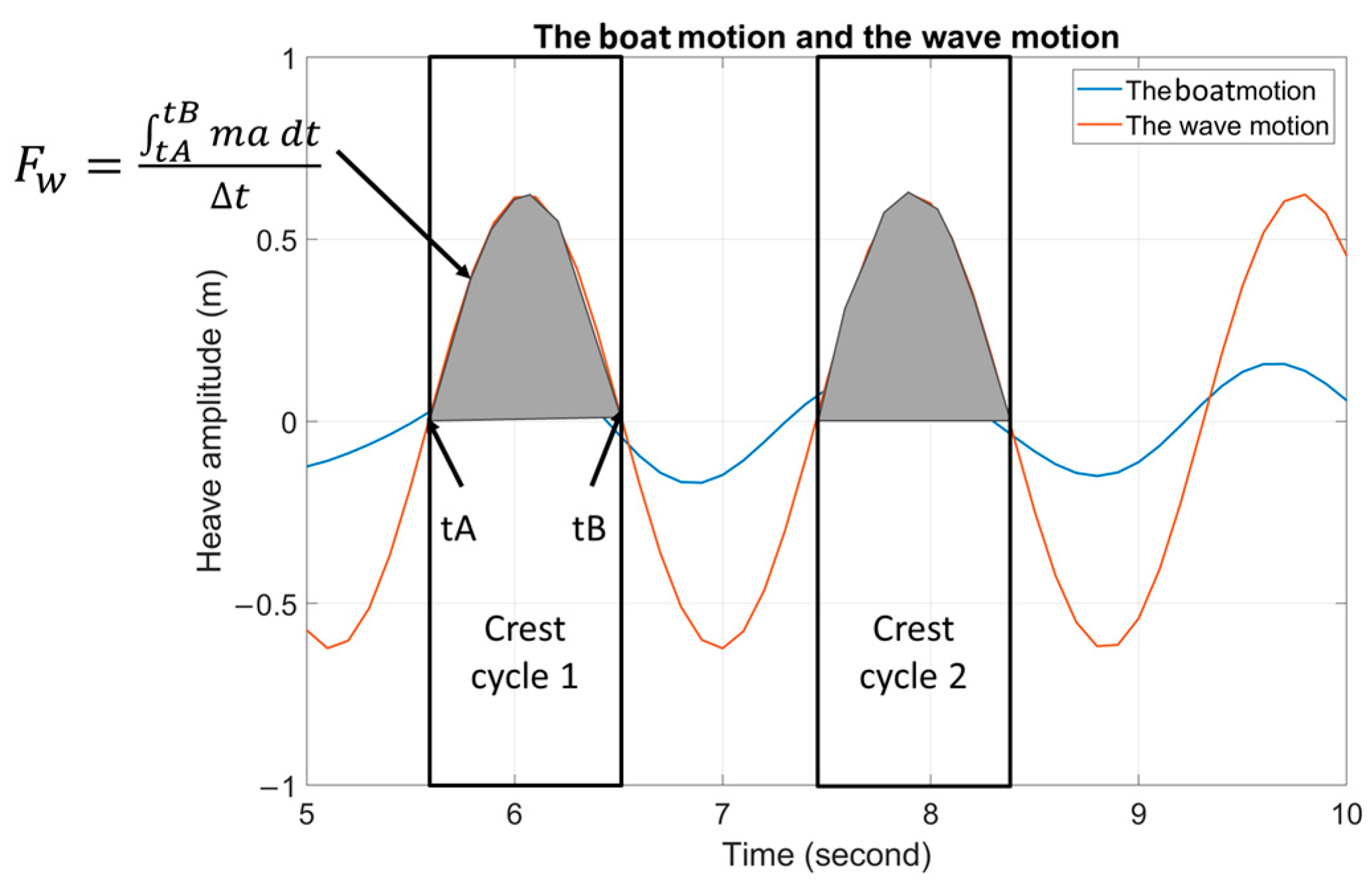

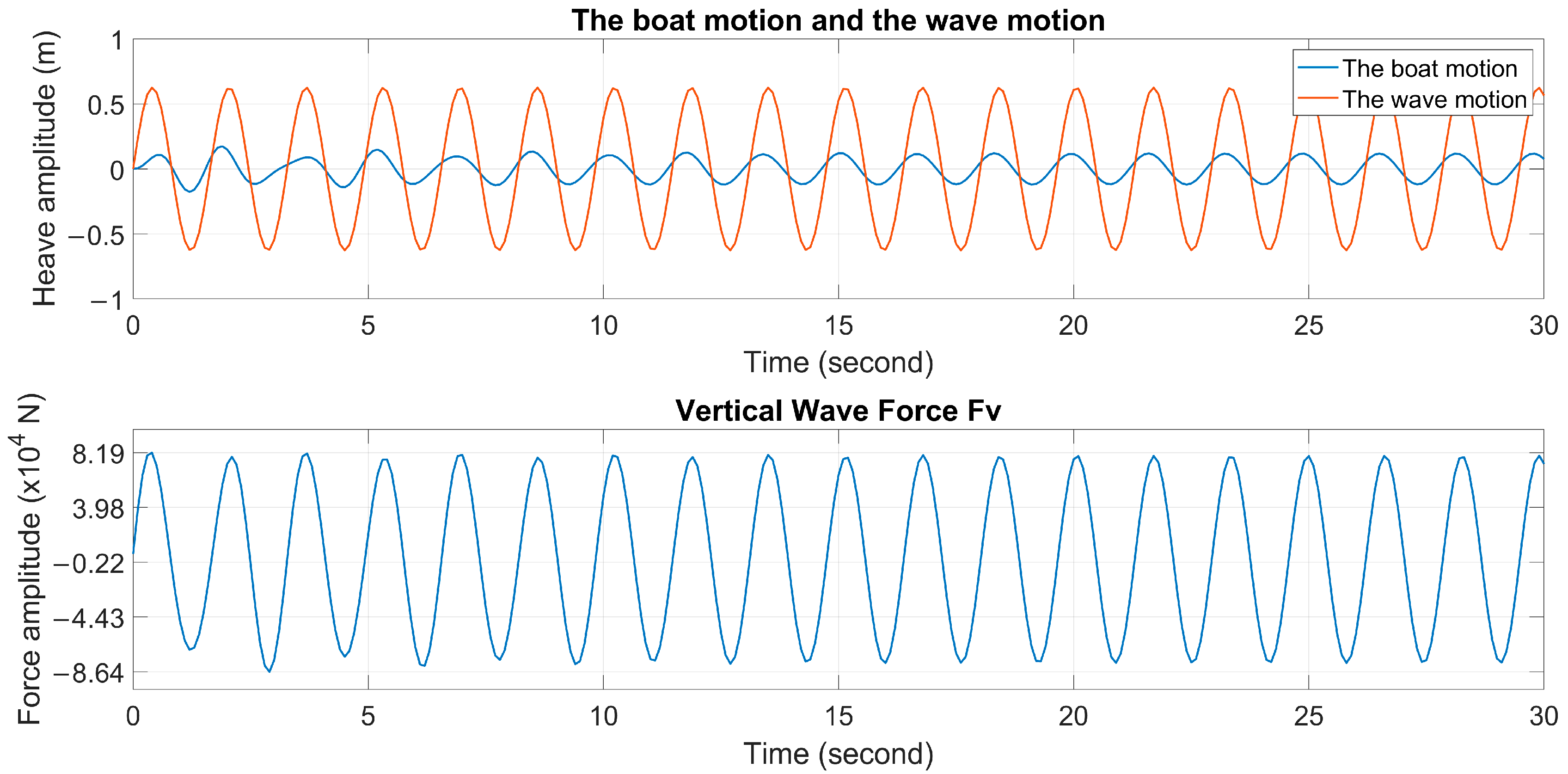

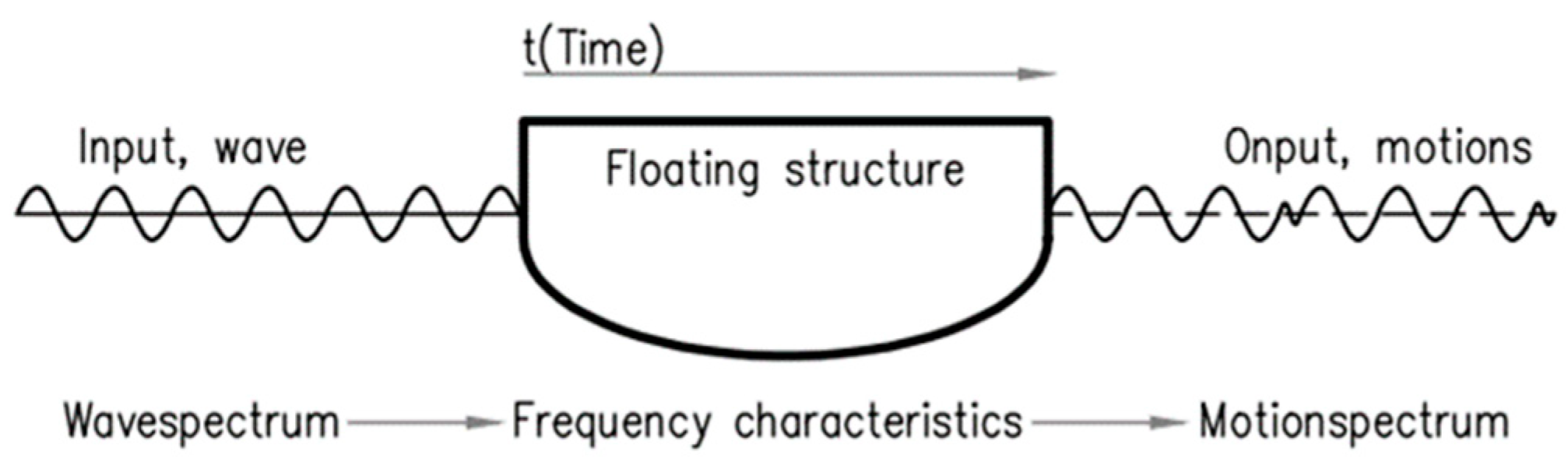

Before presenting the simulation results, here is a list of the information that will appear. In the graphs for all four cases, the orange line represents wave amplitude, and the blue line represents boat motion in the upper frame. Also, in all the vertical wave force figures, the lower frame shows the force amplitude, and the blue line represents the force over time acting on the wave actuator. These graphs assess the performance and behavior of the wave actuator under various wave conditions affecting the boat. The simulation results in all the tables in the four cases present the key information. The simulation parameters are reiterated, with the differences between the cases highlighted. The number of cycles refers to the upper half of the cycle shown in the amplitude graph. The calculated results for (Equation (31)), (Equation (30)), and (Equation (29)) are presented corresponding to each cycle. At the bottom of the table, the , which represents the average speed achieved over 30 s of simulation. Here, denotes the total number of wave cycles considered in the simulation, and is the average velocity during the i-th wave cycle. The table also presents the corresponding efficiency values as defined in Equation (32). A time-domain simulation is conducted to evaluate the wave actuator’s performance under regular waves, while considering velocity and displacement constraints. The MATLAB code is employed to examine the interaction between the simulated boat motion and wave motion, as well as to analyze the wave force exerted on the boat over time.

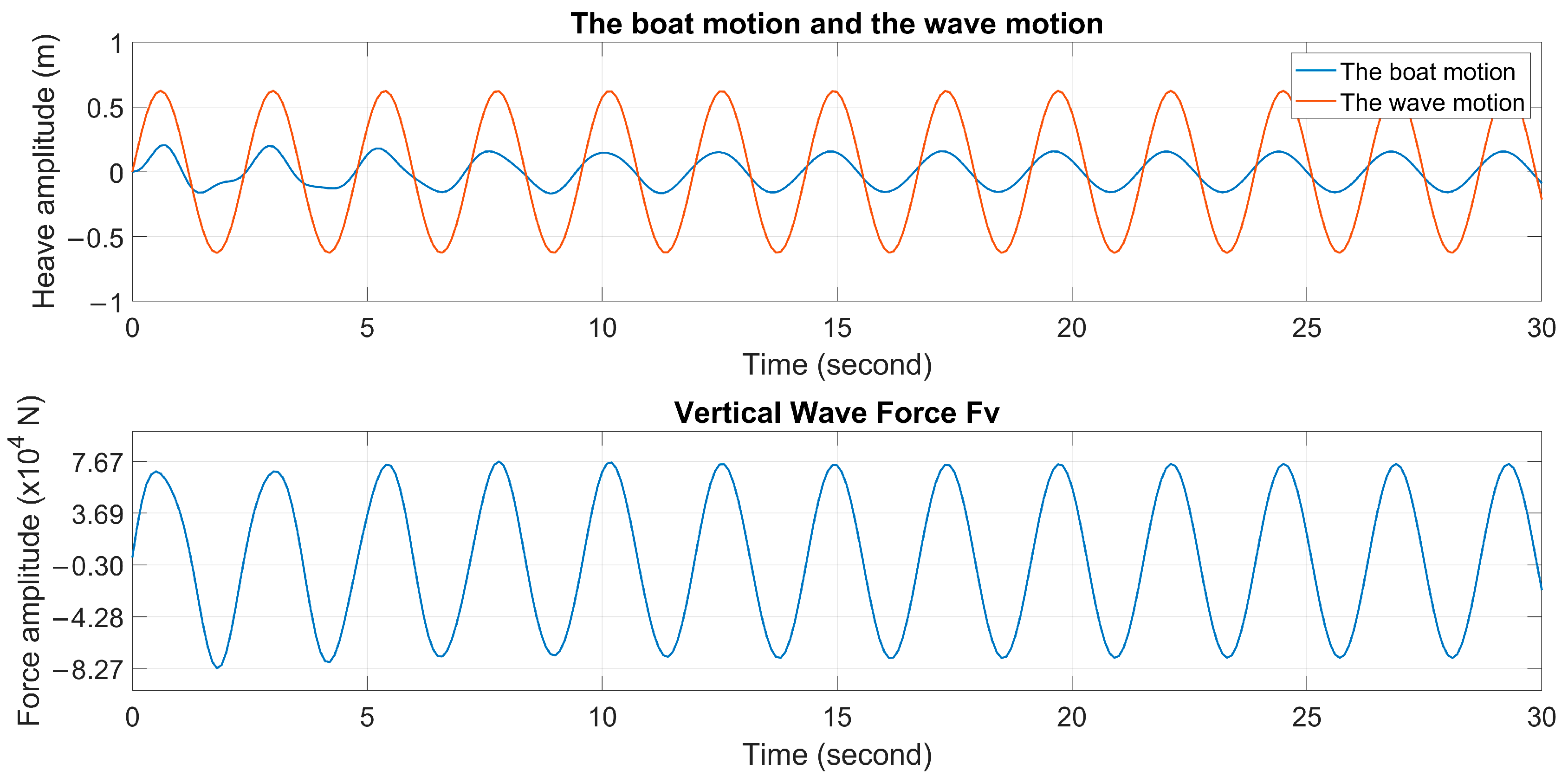

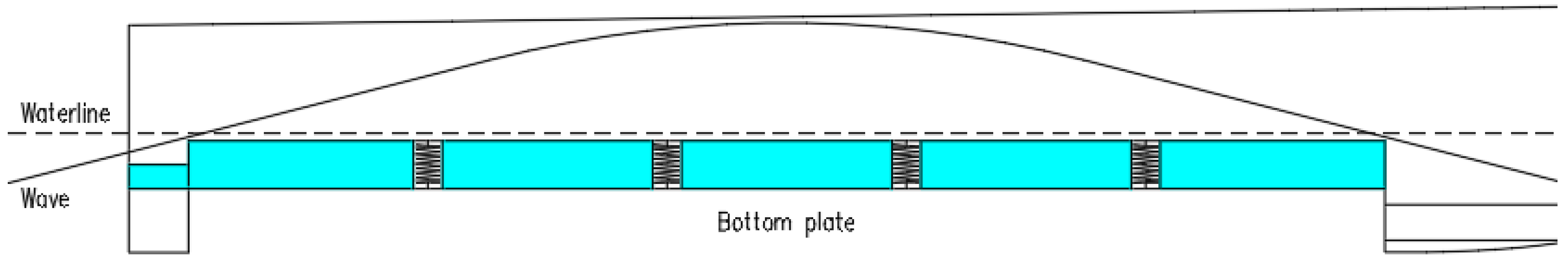

In Case 1, the boat had a damping coefficient of 20, a spring coefficient of 20, an initial speed of 2.06 m/s, and a wave angle of 180°. The simulation included displacement and velocity limits, suggesting that increasing wave amplitudes or draft size could improve wave energy conversion efficiency as depicted in

Figure 11 and

Table 3. A higher draft makes the boat more resistant to undulation, and changes to the boat’s initial velocity limit had little impact.

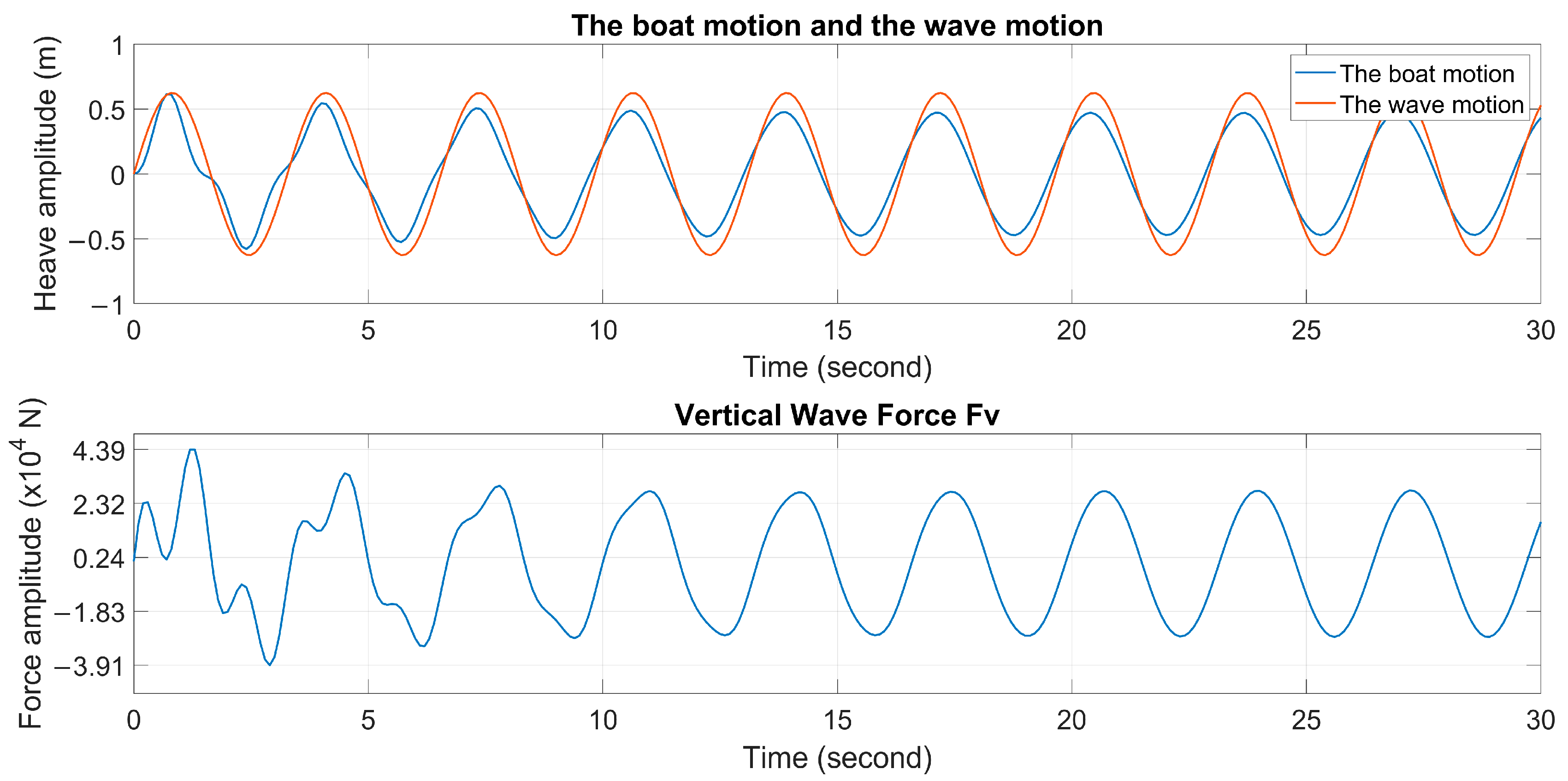

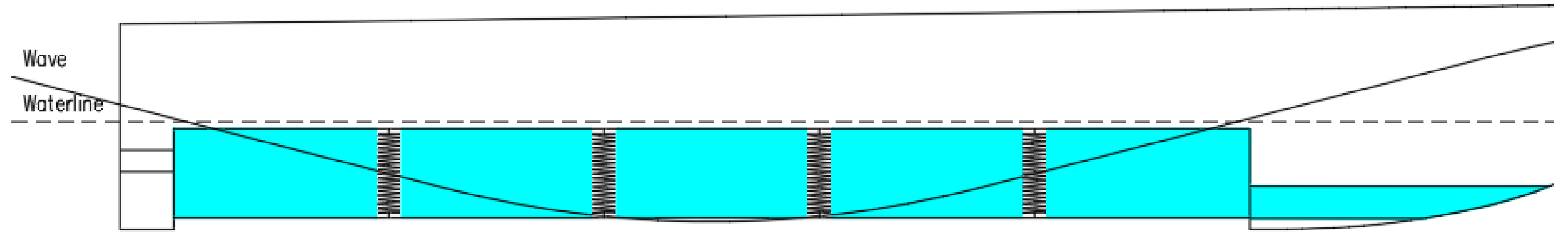

In Case 2, from

Figure 12 and

Table 4, it can be observed that the frequency for calculating the total force on the boat is adjusted, and similar to Case 3 (

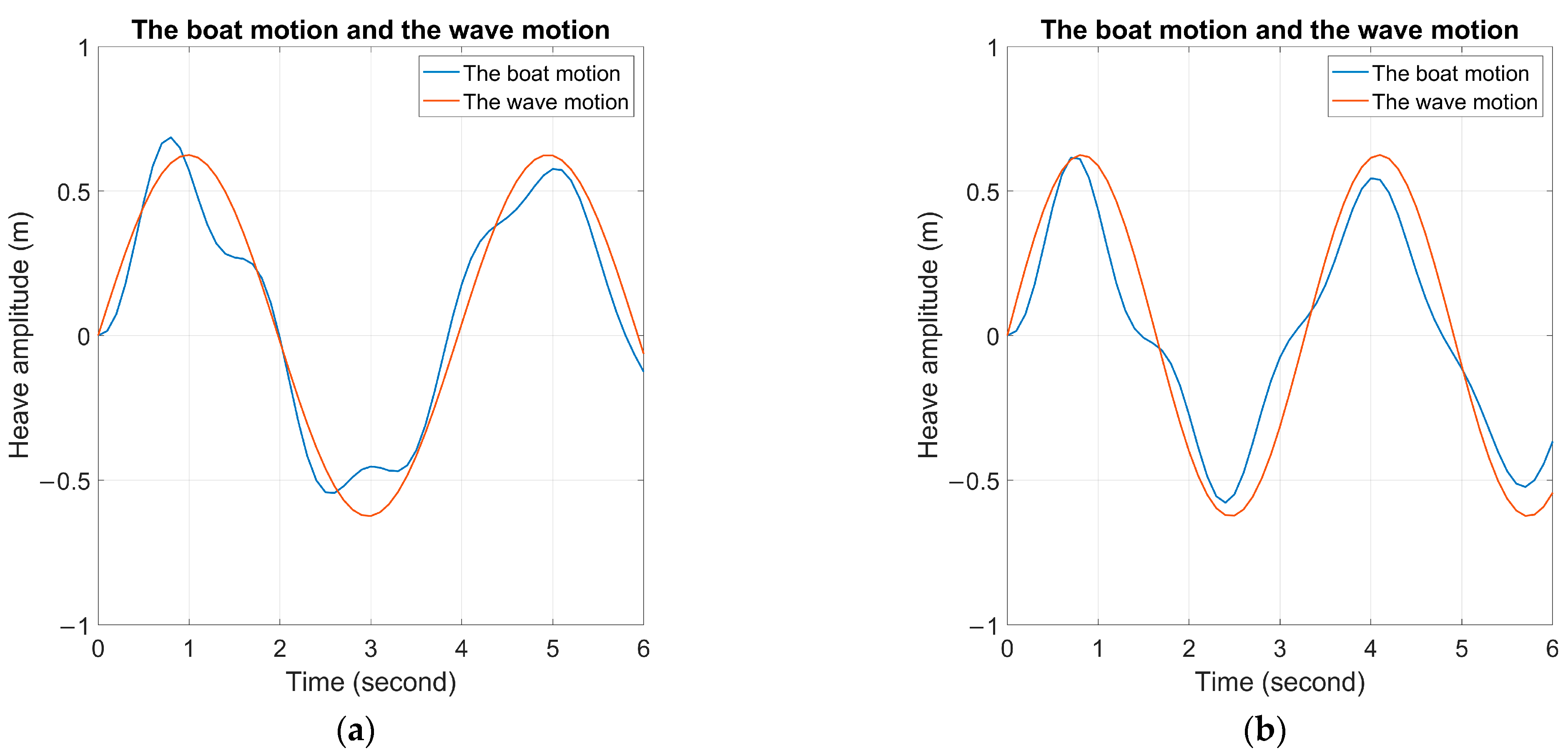

Table 5), reducing wave frequency decreased wave energy conversion. The simulation results for Case 4 did not fully meet expectations, as shown in

Table 6. The simulation results for Case 4 did not fully meet expectations, as shown in

Table 6.

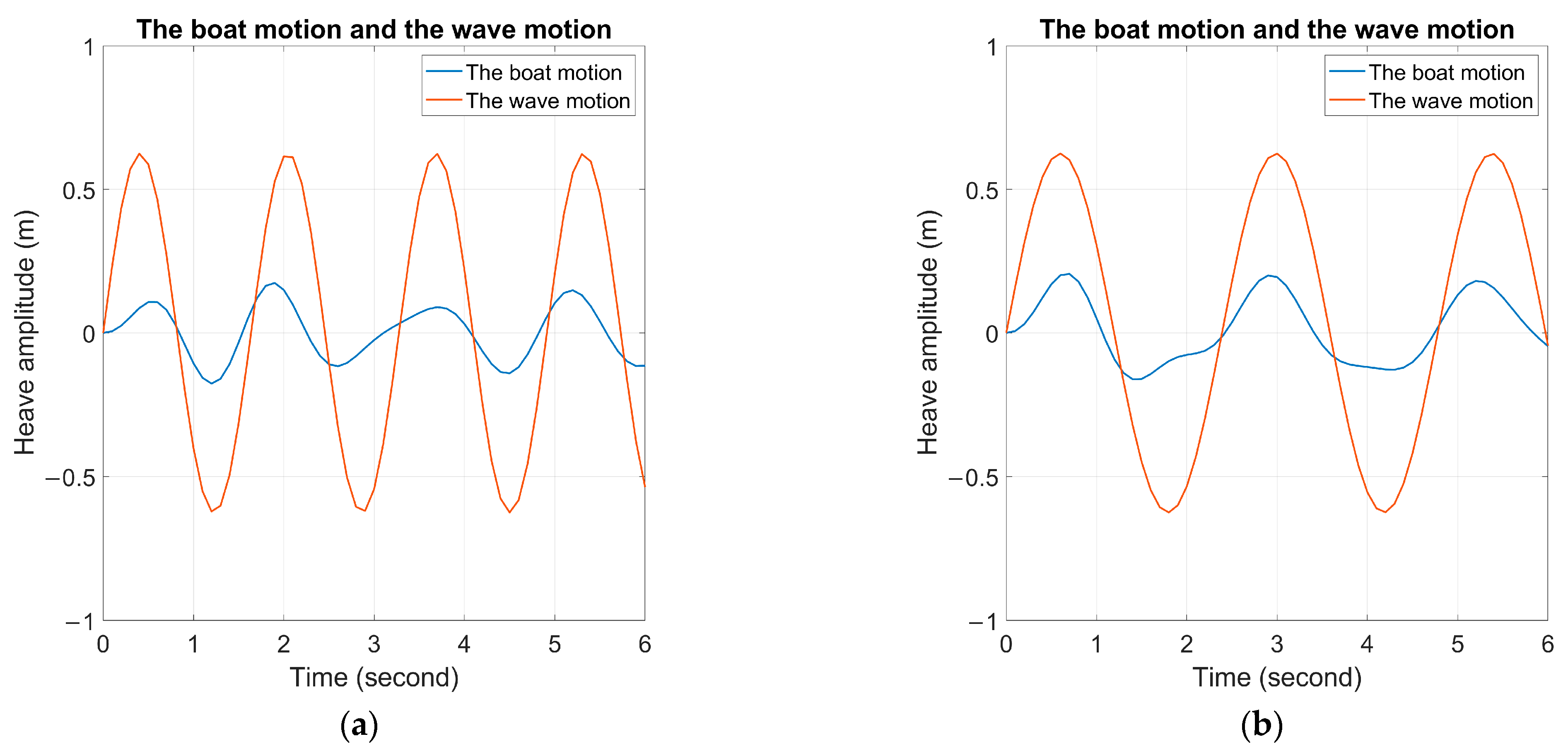

All waves have different speeds according to their wavelength. The wavelength (

) is calculated using:

, where

and

is the wave period in seconds. Wavelength is inversely proportional to the frequency of the wave: waves with higher frequencies have shorter wavelengths, while waves with lower frequencies have longer wavelengths. Compared to Case 1, the wavelength in Cases 3 and 4 is much longer due to the reduced wave frequency. This is clearly illustrated in

Figure 13 and

Figure 14. The variation in boat motion and wave motion is not large, unlike Case 1.

In all cases, the oscillations of the waves and the boat both stabilized after about 5 s. As shown in

Table 7 for comparison, Case 1 had a

of 4.312 m/s and

of 63.3% with wave angle of 180°. Case 2 had the highest

of 6.098 m/s and

of 67.9% with a frequency of 0.3 Hz, indicating good wave energy exploitation. Longer wave periods are expected to produce better results. However, in Case 3,

and

decreased significantly (4.768 m/s and 38.8%). Case 4 had a slight increase in

and

(5.233 m/s and 49.5%) due to changes in initial velocity and tank coefficients, but Case 2 was more efficient. Wave analysis and boat behavior are influenced by wave frequency and phase.

Figure 11.

Amplitude graph for Case 1.

Figure 11.

Amplitude graph for Case 1.

Table 3.

Results of simulation for Case 1.

Table 3.

Results of simulation for Case 1.

| bt = 20.0; ct = 20.0; V = 4.0; Frequency = 0.4 Hz |

|---|

| | Cycle: 1 | Cycle: 2 | Cycle: 3 | Cycle: 4 | Cycle: 5 | Cycle: 6 |

| (W) | 9621.81 | 17,842.5 | 24,538.2 | 33,914.2 | 39,691 | 48,778.2 |

| (W) | 83,259 | 87281 | 83,610.3 | 87,881.9 | 84,215.3 | 86,393.9 |

| (m/s) | 4.282 | 4.329 | 4.3 | 4.323 | 4.308 | 4.323 |

| | Cycle: 7 | Cycle: 8 | Cycle: 9 | Cycle: 10 | Cycle: 11 | Cycle: 12–15 |

| (W) | 54,813.3 | 64,200.2 | 69,229.9 | 76,613.4 | 81,309.9 | 85,393.9 |

| (W) | 84,992.1 | 87,717.9 | 86,426.4 | 88,394.4 | 90,070.8 | 94,692 |

| (m/s) | 4.311 | 4.313 | 4.312 | 4.316 | 4.315 | 4.316 |

| : 4.312 m/s | : 63.3% |

Figure 12.

Amplitude graph for Case 2.

Figure 12.

Amplitude graph for Case 2.

Table 4.

Results of simulation for Case 2.

Table 4.

Results of simulation for Case 2.

| bt = 20.0; ct = 20.0; V = 4.0; Frequency = 0.3 Hz |

|---|

| | Cycle: 1 | Cycle: 2 | Cycle: 3 | Cycle: 4 | Cycle: 5 |

| (W) | 22,925.9 | 33,895.2 | 44,202.3 | 53,611.8 | 62,404 |

| (W) | 79,094.3 | 81,552.3 | 81,651.2 | 80,870.6 | 80,703 |

| (m/s) | 6.127 | 6.042 | 6.06 | 6.1 | 6.12 |

| | Cycle: 6 | Cycle: 7 | Cycle: 8 | Cycle: 9 | Cycle: 10–11 |

| (W) | 71,576.6 | 78,523.3 | 80,348.3 | 80,355.8 | 80,335.9 |

| (W) | 82,948.6 | 86,387.9 | 94,915.6 | 105,155 | 115,362 |

| (m/s) | 6.115 | 6.107 | 6.102 | 6.102 | 6.103 |

| : 6.098 m/s | : 67.9% |

Figure 13.

Amplitude graph for Case 3.

Figure 13.

Amplitude graph for Case 3.

Table 5.

Results of simulation for Case 3.

Table 5.

Results of simulation for Case 3.

| bt = 20.0; ct = 20.0; V = 4.0; Frequency = 0.2 Hz |

|---|

| | Cycle: 1 | Cycle: 2 | Cycle: 3 |

| (W) | 2923.52 | 4407.67 | 5248.25 |

| (W) | 16,700.1 | 16,544.7 | 14,413.7 |

| (m/s) | 4.787 | 4.7 | 4.822 |

| | Cycle: 4 | Cycle: 5 | Cycle: 6 |

| (W) | 7055.82 | 8132.06 | 9455.58 |

| (W) | 15,930.3 | 15,679.1 | 16,583 |

| (m/s) | 4.76 | 4.771 | 4.768 |

| : 4.768 m/s | : 38.8% |

Figure 14.

Amplitude graph for Case 4.

Figure 14.

Amplitude graph for Case 4.

Table 6.

Results of simulation for Case 4.

Table 6.

Results of simulation for Case 4.

| bt = 25.0; ct = 40.0; V = 8.0; Frequency = 0.2 Hz |

|---|

| | Cycle: 1 | Cycle: 2 | Cycle: 3 | Cycle: 4 |

| (W) | 4542.35 | 7497.1 | 10,408.998 | 13,265.786 |

| (W) | 27,125.891 | 27,643.309 | 28,221.379 | 28,631.233 |

| (m/s) | 5.428 | 5.33 | 5.259 | 5.212 |

| | Cycle: 5 | Cycle: 6 | Cycle: 7 | Cycle: 8 |

| (W) | 16,118.897 | 18,764.279 | 21,223.052 | 23,432.669 |

| (W) | 29,268.216 | 29,821.467 | 30,550.743 | 31,532.541 |

| (m/s) | 5.183 | 5.163 | 5.144 | 5.141 |

| : 5.233 m/s | : 49.5% |

The wave energy conversion potential is highest in Case 2. Referring to

Figure 5, the larger intersected area between the boat and wave motion implies more energy. In Case 1, the crests are too closely spaced due to high wave frequency, while Cases 3 and 4, the wavelengths are extended due to low wave frequency. Case 2 emerges as the optimal choice. In Case 2, the difference between the crest of the boat motion and the crest of the wave is the greatest, resulting in the highest pressure on the wave actuator out of the four cases.

Table 7.

Simulation results.

Table 7.

Simulation results.

| | (m/s) | (%) |

|---|

| Case 1 | 4.312 | 63.3 |

| Case 2 | 6.098 | 67.9 |

| Case 3 | 4.768 | 38.8 |

| Case 4 | 5.233 | 49.5 |

Figure 15 and

Figure 16 present the intersected area during the first 6 s of simulation for all four cases. Wave frequency is reduced from 0.4 to 0.2 Hz in all simulations. Tank coefficients and initial velocity are changed only in Case 4 to demonstrate the feasibility of increasing the input. As shown in

Figure 15, the wave period has increased, allowing the system more time to convert wave energy. In Case 1, absorbed wave energy during one-cycle transition phase is smaller than in Case 2 (

in Case 1 = 9621.806 W and

in Case 2 = 22925.896 W). During the bullish wave phase, the area between the orange and blue lines is larger in Case 2 than Case 1.

To evaluate the prediction and simulation, we compare Cases 2 and 3, aiming to exploit the waves better with longer periods. Case 3 has a much larger wave period than Case 2, resulting in a smaller area between the orange and blue lines during the rising phase, as the boat moves with waves close to each other. The absorbed wave energy in Case 3 is converted in a shorter period ( in Case 2 = 22925.896 W and in Case 3 = 2923.522 W). In 30 s of simulation, Case 2 has more cycles, resulting in a higher due to the wave crest applying more force on the tank bottom.

The absorbed wave energy at the transition phase of one cycle in Case 3 is smaller than in Case 4 ( in Case 3 = 2923.522 W and in Case 4 = 4542.350 W). The increase in the tank coefficient has little effect on the final cruise speed result. However, doubling the boat’s initial speed from 2.06 m/s to 4.12 m/s, the cruising speed only increased from 4.8 m/s to 5.2 m/s, so this design parameter is not energy efficient.