1. Introduction

The pantograph slide and the catenary wire form a typical sliding electrical contact friction pair, which provides the necessary energy for the stable operation of electric locomotives through sliding contact. Compared to the pantograph slide, the catenary wire, as a power transmission line, has higher hardness and is difficult to replace, requiring a longer service life. Therefore, the current-carrying wear between the pantograph and catenary system is mainly borne by the pantograph slide [

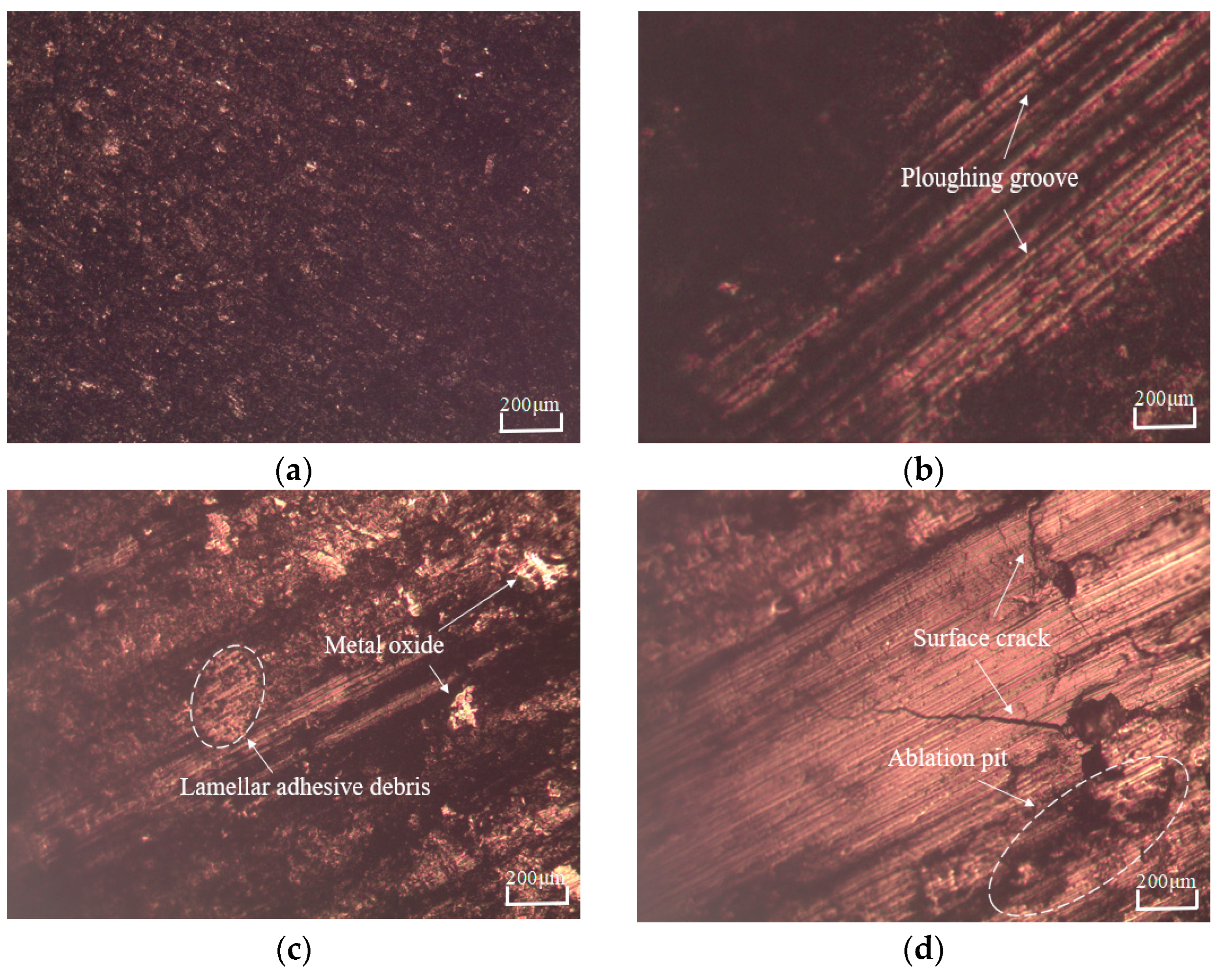

1]. Under sliding electrical contact conditions, the wear mechanism of the pantograph slide is complex, involving both mechanical and electrical wear, as well as the coupling effects between them. The interaction of these two types of wear accelerates the overall degradation [

2]. As a consumable friction pair, if the pantograph slide is worn beyond its limit without timely replacement, it will affect the safety of train operations [

3,

4]. Therefore, developing a friction and wear model for the pantograph slide is of significant theoretical and practical value in predicting the lifespan of the friction pair and guiding the friction design of the pantograph–catenary system.

In recent years, scholars both domestically and internationally have made significant contributions to the modeling of pantograph slide wear. Based on the relevant literature, there are currently two main approaches to predicting the wear of the pantograph slide and catenary wire. One approach is to calculate the correlation coefficients between various influencing factors and wear and derive a fitting formula for wear. For example, Shi Guang et al. [

5] studied the wear of the pantograph slide under different current, speed, and fluctuating load conditions and developed a regression prediction model for the wear of the pantograph slide. Hu Yan et al. [

6] investigated the effects of the catenary contact pressure, contact current, sliding speed, and operating time on the wear of pure carbon pantograph slides, using partial least squares regression to establish a wear prediction model, and analyzed the influence of each parameter on wear. Xu Wenwen et al. [

7] established a support vector regression-based model to predict the wear trends of subway pantograph slides, enabling the prediction of wear based on the operational mileage. Xie Baozhi et al. [

8] developed a wear prediction model for the pantograph slide by analyzing the variation in wear with the operational temperature under different parameters, incorporating the effect of the temperature. The second approach is to analyze the wear evolution and mechanisms under various influencing factors and derive a mathematical wear model. For example, Chen Zhonghua et al. [

9] considered both mechanical and electrical wear, as well as the coupling wear between them, and used the Archard wear model to establish a mathematical expression for the wear rate. S. Derosa et al. [

10] proposed a heuristic wear model for the pantograph slide and catenary wire, which can be used in conjunction with a numerical model of the pantograph–catenary interaction to predict wear over long periods. Some scholars have established related wear prediction models based on the wear mechanisms proposed by Lim and Ashby [

11]. For example, G. Bucca et al. [

12] proposed an adaptive wear prediction method through pantograph–catenary coupling dynamic simulations combined with experimental data. Wei Xiukun et al. [

13], based on the Lim and Ashby theory, established a wear prediction model for the pantograph slide and catenary wire by combining actual maintenance data from subway lines. However, in most of the models established through the aforementioned methods, the influence of the friction coefficient on wear is not considered. When the operating conditions change, the friction coefficient also changes, and, due to the complex evolution and mechanisms of pantograph–catenary wear, these models cannot accurately represent the wear of the pantograph–catenary system, making it difficult to predict wear precisely using any single method.

In mechanical friction systems, wear is often analyzed from the perspective of energy dissipation. Zhang Gaolong et al. [

14] found that, under dry friction, the wear rate of graphite exhibits a significant linear relationship with the frictional dissipation power of the mating surfaces. J. Abdo developed a mathematical model that relates the wear volume of materials in sliding contact to the dissipated energy, which can be used to predict the component’s service life [

15]. Additionally, studies [

16,

17,

18,

19] have shown that surface friction wear is related to its dissipated energy. By investigating the relationship between friction wear and dissipated energy, the wear mechanism and related energy dissipation can be analyzed, linking dissipated energy to the wear volume and proposing a wear calculation method based on energy dissipation theory. Although the energy dissipation method has been used to study material wear in mechanical friction systems, there is still limited research in the field of sliding electrical contact, particularly in the pantograph–catenary system. No studies have been reported on the prediction of pantograph slide wear from the perspective of energy dissipation in the pantograph–catenary system.

In the interdisciplinary research of AI-assisted predictive modeling and thermoelectric systems, remarkable progress has been achieved in recent years. Jinjiang Wang et al. [

20] proposed a physics-guided neural network (PGNN), integrating wear mechanism knowledge with data-driven learning to provide a novel paradigm for high-precision and interpretable wear prediction in pantograph–catenary systems. Wang, H et al. [

21] developed a multi-agent reinforcement learning (MARL) algorithm based on the Nash equilibrium framework, enabling heterogeneous agents to collaborate under global value function guidance for proactive pantograph control and enhanced system stability. Guangshuai Han et al. [

22] constructed a “data-driven–model prediction–experimental validation” closed-loop framework, integrating material descriptors such as matrix encoding and radial distribution analysis to achieve >90% accuracy in predicting the thermoelectric figure of merit (ZT) and accelerate the development of novel thermoelectric materials. These studies have advanced interdisciplinary applications of AI in thermoelectric systems from the perspectives of modeling, control, and material design.

This paper presents a novel method based on energy dissipation to predict the wear of the pantograph slide and explain its wear mechanism. The wear of the pantograph slide is quantitatively characterized by the current-carrying frictional energy dissipation in the pantograph–catenary system. Based on the significant linear relationship between the wear of the pantograph slide and the current-carrying frictional energy dissipation, a basic mathematical model for pantograph slide wear based on energy dissipation is established. The variation in the current-carrying frictional energy dissipation with the operational parameters is studied, providing a quantitative explanation of the interaction between electrical wear and mechanical wear from an energy perspective. This method offers a new approach and insights for the lifetime prediction of the pantograph–catenary friction pair and the study of current-carrying wear mechanisms.

2. Calculation of Current-Carrying Frictional Energy Dissipation in the Pantograph–Catenary System

For the pantograph–catenary current-carrying friction pair, the tribological behavior of the pantograph slide is influenced by the combined effects of electrical and mechanical factors. Specifically, the Joule heating effect and frictional heating effect primarily influence the wear of the pantograph slide through the work done by the current and the frictional force [

12]. During the wear process, these two effects counterbalance each other and are interrelated. Therefore, the occurrence of pantograph slide wear is inevitably accompanied by the consumption of system energy. By relating the current-carrying friction in the pantograph–catenary system to wear through energy, the wear process can be viewed as an energy dissipation process. This process consumes energy in the form of heat generation at the contact surface, electromagnetic noise, the wear of the pantograph slide surface, and the extrusion of abrasive particles, among other forms. The sum of the work done by the current and the work done by the frictional force is defined as the total dissipated energy, referred to as the pantograph–catenary current-carrying frictional energy dissipation.

2.1. Energy Generated by the Work Done by the Current

For the rough surface of the sliding electrical contact in the pantograph–catenary system, it is assumed that there are n conductive spots between the pantograph slide and the contact wire. The contact resistance of the pantograph–catenary system can be calculated using the following equation [

23]:

In the equation, denotes the actual contact area of the pantograph–catenary system; is the sum of the resistivities of the pantograph slide and the contact wire materials; represents the contact length, i.e., the width of the pantograph slide; and is the average radius of a single conductive spot.

The hardness of the materials affects the actual contact area and the shape of the conductive spots in the pantograph–catenary system. Considering the contact pressure and material hardness, the contact hardness

is defined as [

24]

In the equation, denotes the contact hardness of the pantograph slide.

By combining Equations (1) and (2), the expression for the pantograph–catenary contact resistance can be derived as

When a current flows through the contact resistance, the work done by the current can be derived from Joule’s law. The energy generated by the work done per unit contact area is given by

In the equation, denotes the energy dissipated by the Joule effect; represents the nominal contact area of the pantograph–catenary system, i.e., the rectangular area of the contact surface; and is the sliding time.

2.2. Energy Generated by the Work Done by the Frictional Force and Current-Carrying Frictional Energy Dissipation in the Pantograph–Catenary System

During the pantograph–catenary contact friction process, relative sliding motion occurs between the pantograph slide and the contact wire. The energy generated by the work done by the frictional force per unit contact area is given by

In the equation, denotes the pantograph–catenary frictional force; is the coefficient of friction; and is the sliding distance.

Therefore, the pantograph–catenary current-carrying frictional energy dissipation can be calculated as the sum of Equations (4) and (5). The expression for the current-carrying frictional energy dissipation per unit contact area is given by

4. Development of a Pantograph Slide Wear Model

4.1. Rationality Assumptions for Model Establishment

This paper proposes rationality assumptions for the pantograph–catenary current-carrying friction–wear model by integrating engineering practice and research validity, as follows.

Material Homogeneity Assumption: The pantograph slide is assumed to exhibit a uniform composition and microstructure during frictional processes, eliminating localized defects that could induce abnormal wear.

Environmental Stability Assumption: The ambient parameters (temperature: 20–25 °C; relative humidity: 40–60% RH) are assumed to remain constant throughout the experiments to exclude interference from environmental fluctuations and other undefined variables.

Scope Limitation Statement: The model does not account for critical factors such as arc discharge and thermal expansion effects, which may significantly influence the system behavior and prediction accuracy under harsh conditions (e.g., high voltage or elevated temperatures).

Wear–Energy Linear Relationship: During the steady-state wear phase, the wear volume is assumed to be linearly proportional to the dissipated energy from electrical friction, with a positive correlation [

25].

4.2. Mathematical Model of the Friction Coefficient

As shown in Equation (6), the friction coefficient directly affects the pantograph–catenary current-carrying frictional energy dissipation. To accurately calculate the pantograph slide wear under varying friction coefficients, the influence of the friction coefficient on the wear performance of the pantograph slide is considered. Based on the research findings on pantograph–catenary frictional forces [

26], a mathematical model for the pantograph–catenary frictional force, incorporating the current density, sliding speed, and contact pressure, is introduced under the same experimental conditions, as shown in Equation (8):

In the equation, denotes the pantograph–catenary frictional force; is the current density; represents the sliding speed; and is the contact pressure.

The relationship between the current density

and the current intensity

in the experiment is given by

According to Coulomb’s law, the mathematical expression for the frictional force is given by

Therefore, by combining Equations (8) to (10), the mathematical model for the pantograph slide friction coefficient is derived as

The model’s applicability is strictly constrained to the validated operational range: current intensity 100 A < I < 250 A, normal force 80 N < F < 110 N, and operation speed 60 km/h < v < 120 km/h. Experimental data indicate that the model prediction accuracy may decline or even fail when the variables exceed this range, primarily due to the nonlinear characteristics of the thermo-mechanical coupling at the contact interface and material frictional behavior, which evolve with parameter variations. It is worth emphasizing that statistical analysis shows that this defined range covers more than 90% of the train’s actual normal operating conditions, including typical scenarios such as startup acceleration, uniform cruising, and conventional braking. Thus, the model provides effective support for the analysis of pantograph–catenary sliding friction characteristics.

4.3. Pantograph Slide Wear Prediction Model

The least squares method is a flexible and widely used mathematical approach, characterized by its simplicity, fast convergence, and ease of implementation. Its fundamental principle is to minimize the sum of the squared differences between the model’s predicted values and the actual data, making it suitable for data with random errors that exhibit a linear relationship [

27].

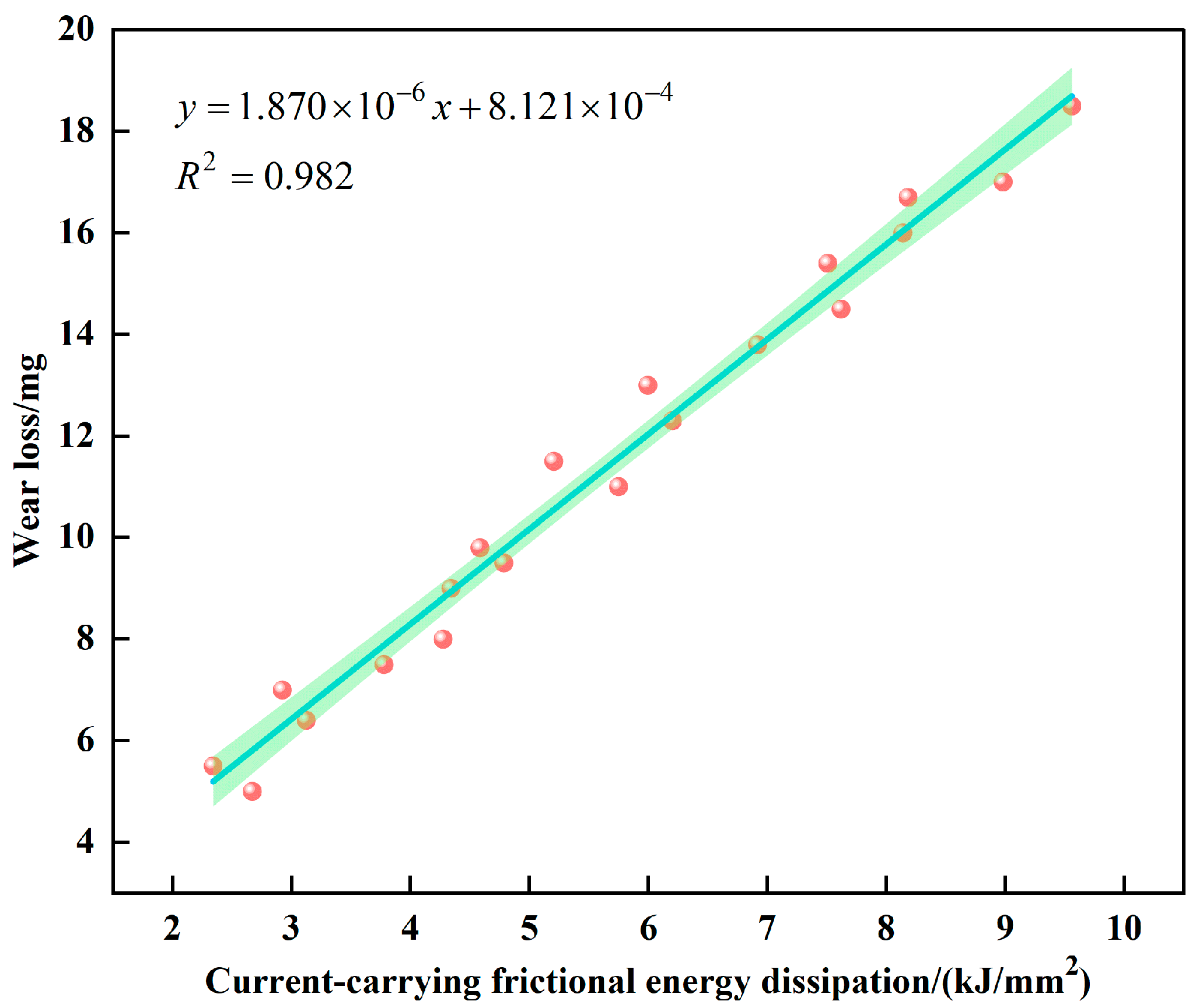

The contact currents were set to 100 A, 150 A, 200 A, and 250 A, with twenty data points collected under different pressure and speed conditions. The least squares method was used to establish a linear model between pantograph–catenary current-carrying frictional energy dissipation and pantograph slide wear. The fitting relationship between pantograph–catenary current-carrying frictional energy dissipation and pantograph slide wear is shown in

Figure 3. At a confidence level of 95%, the coefficient of determination (R

2) is 0.982. Meanwhile, the

p-value of the correlation coefficient, calculated via the

t-test, yields

p < 0.05, indicating that this correlation is highly statistically significant.

The relationship between pantograph–catenary current-carrying frictional energy dissipation

and pantograph slide wear

is expressed as

According to the above expression, a significant correlation between the wear volume and energy dissipation rate is observed (r = 0.989396, p < 0.05). However, it is critical to emphasize that this correlation only reflects a covariant relationship between the variables, as causal inference methods have not yet been used to prove that energy dissipation directly induces wear. In fact, external variables such as the electric current, the evolution of the material surface topography, the contact stress distribution, and ambient temperature fluctuations may independently affect both the wear process and energy dissipation mechanism, forming mediating effects.

In actual train operations, the contact current, contact pressure, sliding speed, and operating time are readily measurable. Based on the experimental conditions, parameters , , , and are predetermined. Therefore, by obtaining the value of the friction coefficient , the pantograph–catenary current-carrying frictional energy dissipation can be calculated, enabling the prediction of the pantograph slide wear .

Therefore, by substituting the friction coefficient from Equation (11) into Equation (6) and combining it with Equation (12), the mathematical model to predict the wear of the pantograph slide can be obtained, as shown in Equation (13):

5. Data Analysis of Pantograph Slide Wear Model

5.1. Validation of Pantograph Slide Wear Model

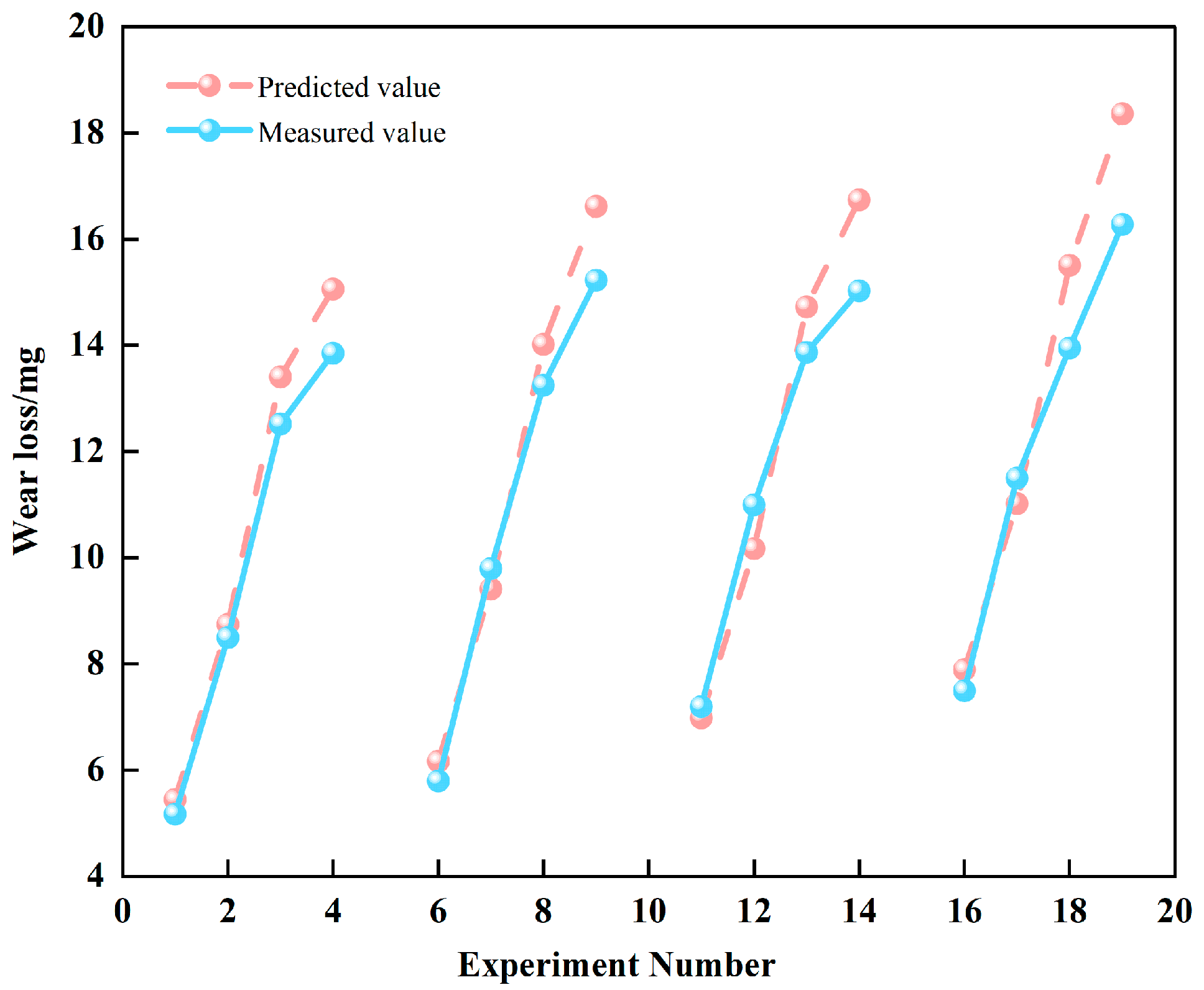

To verify the accuracy and reliability of the proposed wear model, an additional set of comparative validation experiments was conducted. The experimental conditions were set with a contact pressure of 90 N; contact currents of 100 A, 150 A, 200 A, and 250 A; and sliding speeds of 70 km/h, 90 km/h, 110 km/h, and 130 km/h. Under these varying conditions, the actual wear values of the pantograph slide were measured. Meanwhile, the corresponding predicted wear values were calculated by substituting the experimental conditions into the wear model.

The comparative validation experiments were divided into four unit groups, numbered (1, 2, 3, 4), (6, 7, 8, 9), (11, 12, 13, 14), and (16, 17, 18, 19). Within each unit group, the sliding speed was kept constant while the contact current increased sequentially. Between the different unit groups, the test points with the same position in the sequence were set to the same contact current, while the sliding speed increased progressively. The comparison between the predicted and actual wear values of the pantograph slide is shown in

Figure 4.

As shown in

Figure 4, the wear values of the pantograph slide calculated using the developed wear model closely approximate the experimentally measured values; however, there is still a certain degree of deviation between the predicted and actual wear values.

The relative errors between the predicted and actual wear values, as well as the average relative error, are presented in

Table 2.

According to the distribution of the error data, the relative errors between the model predictions and the actual values are primarily concentrated below 10%, accounting for 81.25% of the validation data. The proportion of relative errors exceeding 10% is 18.75%, with the maximum relative error being 12.776% and the average relative error only 4.611%. Therefore, the model is considered effective and can be used to predict the wear of the pantograph slide.

5.2. Sensitivity Analysis of Pantograph Slide Wear Model

To quantify the impact of key parameter fluctuations on the model output and more accurately evaluate the model’s stability under real-world operations, this study included a local sensitivity analysis on the wear model (Equation (13)). Three core parameters—the contact pressure

P, current

I, and sliding speed

v—were selected for ±10% perturbations around the baseline operating conditions (

P = 90 N,

I = 200 A,

v = 100 km/h), with variations in the predicted wear rate calculated as follows:

Here, denotes the sensitivity coefficient of parameter x (dimensionless), Δm represents the variation in the predicted wear volume (unit: mg), m is the predicted wear volume under baseline conditions, Δx is the perturbation of parameter x, and x is the baseline value of parameter x (where x takes the values of F, I, or v).

The results, derived from the calculations, are presented in

Table 3.

As shown in

Table 3, the sensitivity coefficient of the current intensity

I (0.97) exceeds that of the contact pressure

F (0.79) and sliding speed

v (0.93), indicating that the model is most sensitive to current perturbations. When the current fluctuates in practical scenarios, the model outputs may exhibit significant deviations, reflecting poor anti-interference capabilities for this parameter. Secondly, the low sensitivity of the contact pressure

F suggests strong model robustness to withstand moderate perturbations. Using average sensitivity <1 as the benchmark for anti-interference capabilities, all parameters (

I,

F,

v) meet the criterion. Overall, the model demonstrates strong anti-interference capabilities and good stability.

7. Conclusions

From the perspective of system work, this study investigates the relationship between the wear of the pantograph slide and the current-carrying frictional energy dissipation in the pantograph–catenary system. A mathematical wear model for the pantograph slide based on energy dissipation is established and validated. Within the parameter ranges considered in this study, the main conclusions are as follows.

- (1)

A method is proposed to quantitatively characterize the wear of the pantograph slide using the current-carrying frictional energy dissipation in the pantograph–catenary system. The study demonstrates a significant linear relationship between pantograph slide wear and current-carrying frictional energy dissipation.

- (2)

A mathematical wear model for the pantograph slide based on energy dissipation was developed. The predicted results from the proposed model show good agreement with the experimental measurements, with a maximum relative error of 12.776% and an average relative error of only 4.611%, demonstrating its applicability in engineering practice.

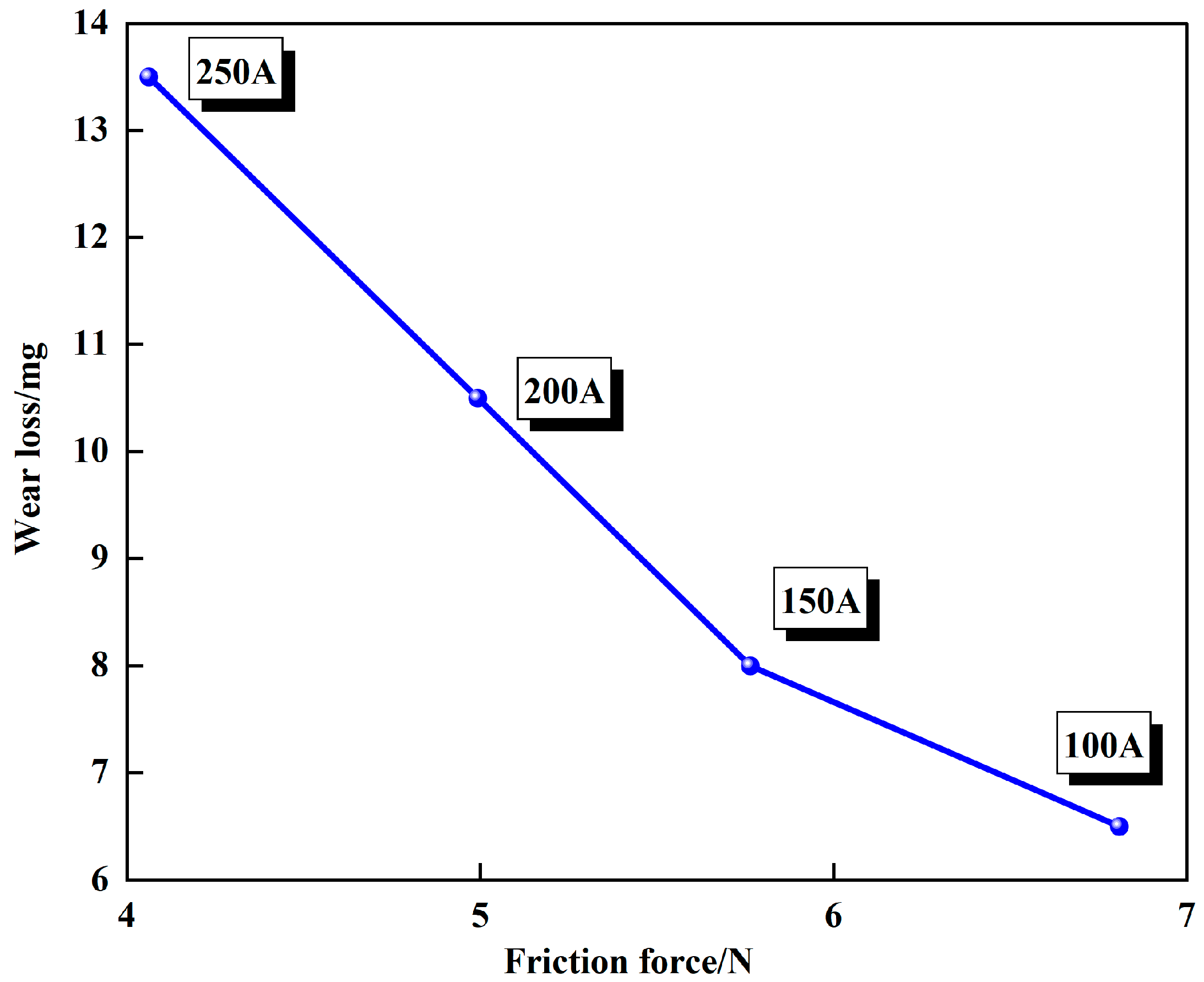

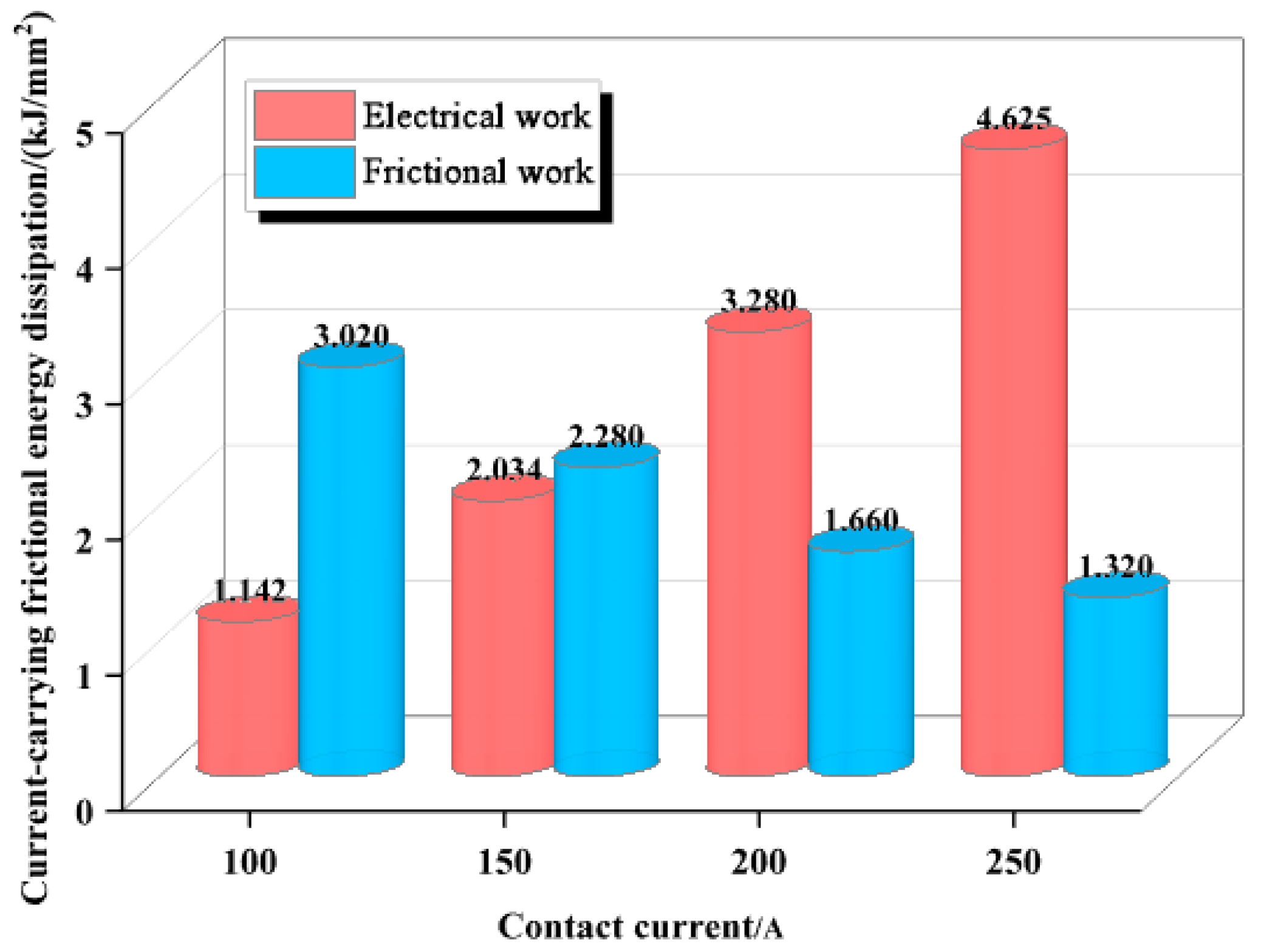

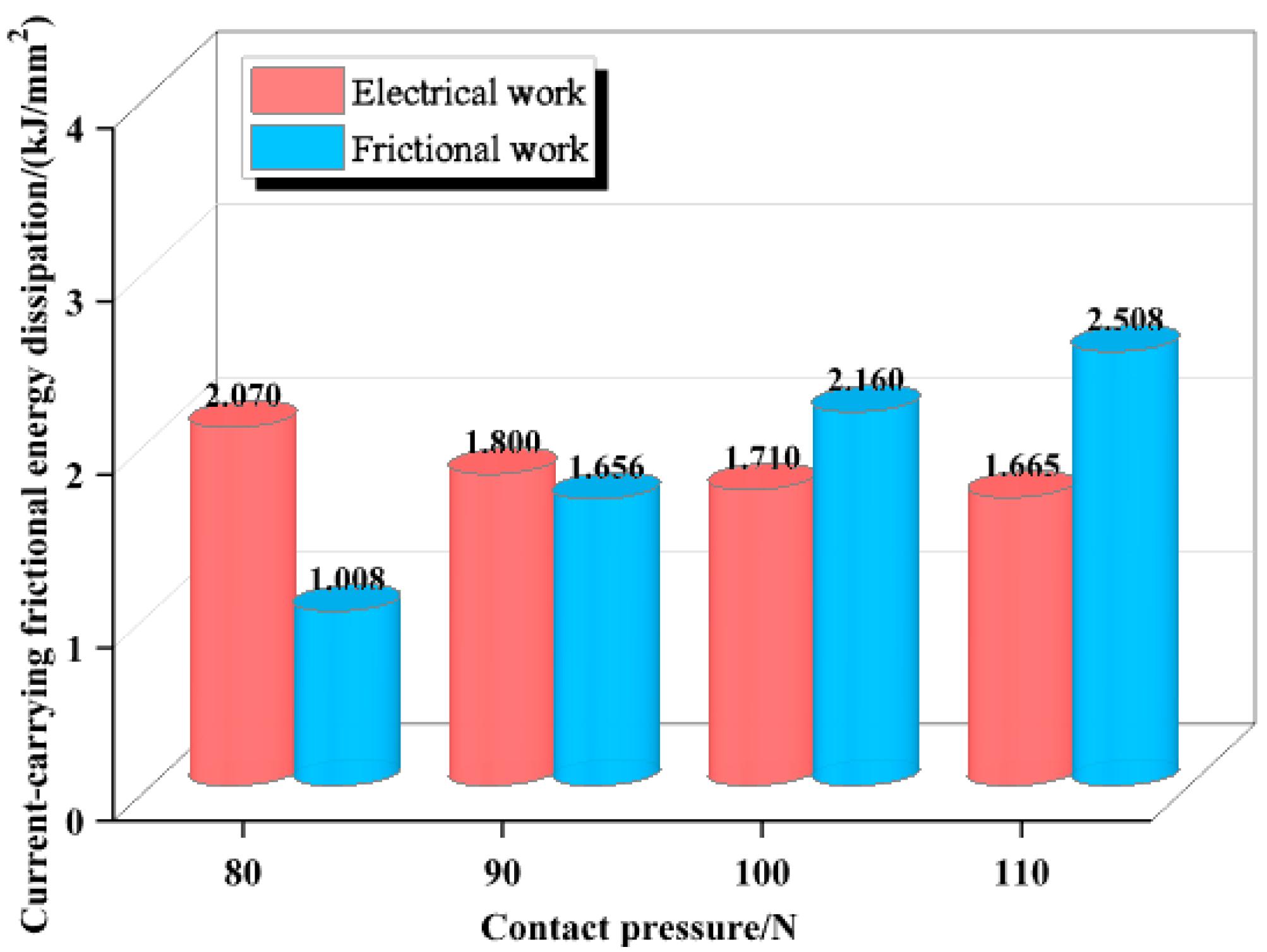

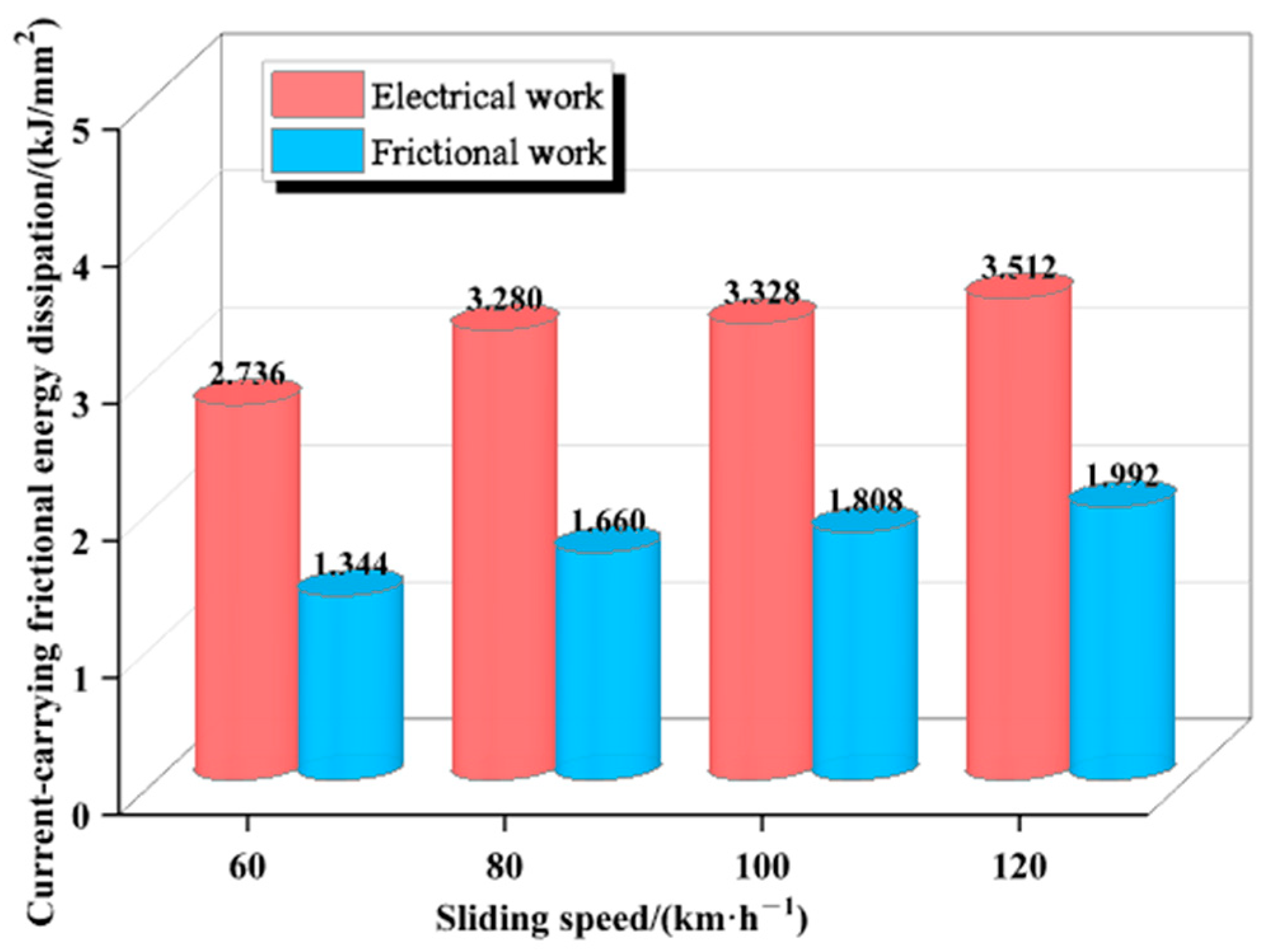

- (3)

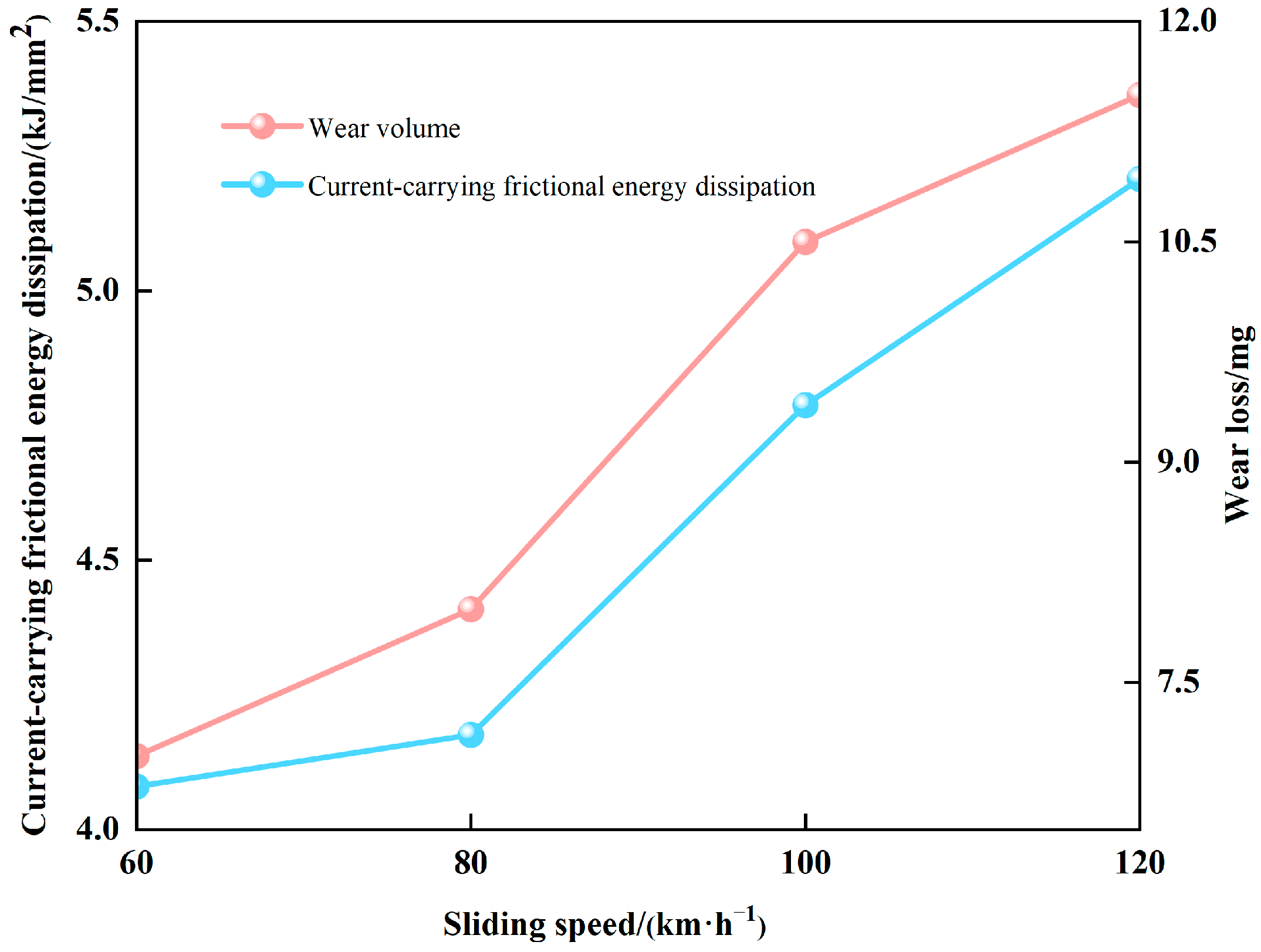

When the sliding speed and contact pressure are constant, the pantograph slide wear shows a negative correlation with the frictional force as the contact current increases; the energy generated by frictional work decreases, while the energy generated by electrical work increases. When the contact current and sliding speed are constant, an increase in contact pressure leads to an increase in the energy generated by frictional work and a decrease in the energy generated by electrical work, with the rate of decrease gradually slowing. When the contact current and contact pressure are constant, both the energy generated by frictional work and that generated by electrical work increase with rising sliding speeds.

The pantograph slide wear prediction model established in this study, as a foundational exploration, currently does not account for key uncertainty factors such as arcing energy during off-contact and environmental temperature–humidity fluctuations. Recognizing this limitation, future research will focus on the following directions to enhance the model’s prediction accuracy and applicability: (1) incorporation of uncertainty factors—based on the existing model framework, probabilistic characterization parameters for arcing energy and correction factors for environmental influences are planned to be introduced, aiming to construct a wear prediction model that more comprehensively reflects the complexity of the actual operating conditions; (2) deepening of physical model foundations—the simplifying conditions (e.g., linear assumptions) relied upon by the current model may become invalid beyond the specific operating conditions defined in this study. Thus, future work will explore modeling approaches for nonlinear effects and wear threshold behaviors to enhance the model’s physical rigor and broaden its applicability. It is important to emphasize that, despite the aforementioned limitations—including the exclusion of arcing and environmental uncertainties—the model proposed herein, as a novel research methodology, offers significant exploratory value in revealing the fundamental mechanisms of current-carrying tribo-wear in pantograph–catenary systems. This study lays the foundation for the development of more refined models in subsequent research.