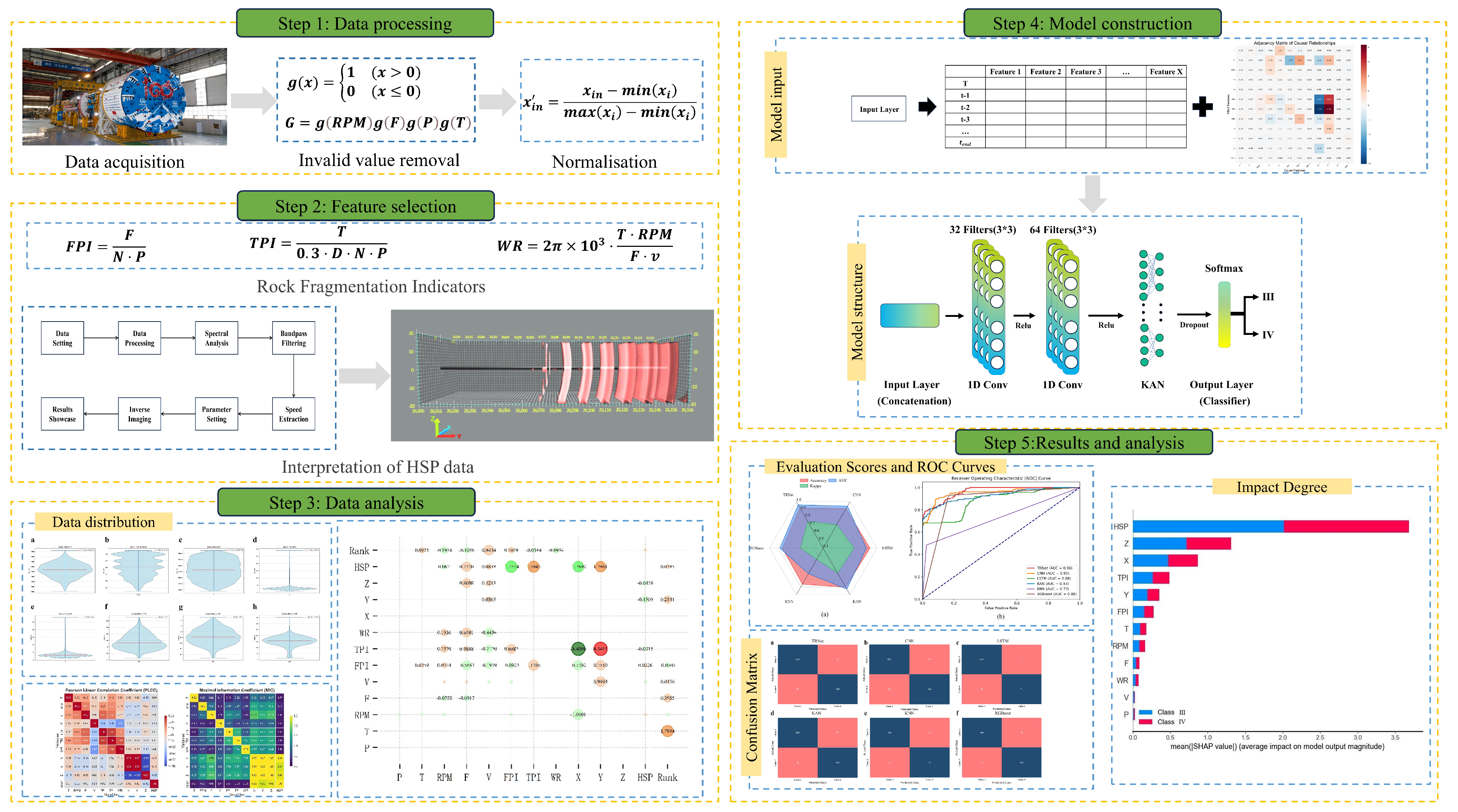

TBM Enclosure Rock Grade Prediction Method Based on Multi-Source Feature Fusion

Abstract

1. Introduction

2. Methodologies

2.1. Convolutional Neural Network (CNN)

2.2. Kolmogorov–Arnold Network (KAN)

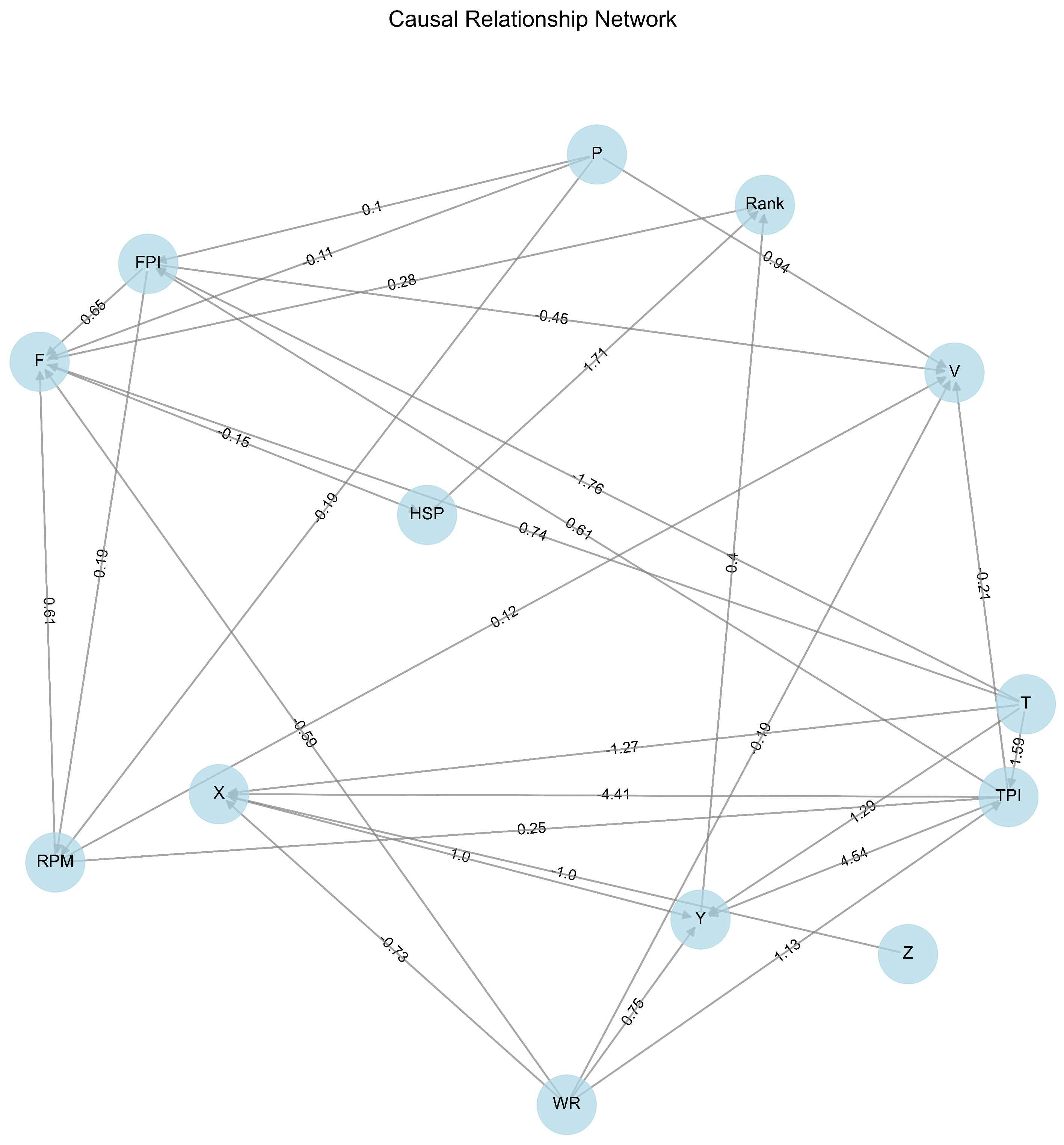

2.3. Local Causality Matrix Construction Method for Multi-Source Data Based on Direct-LiNGAM

- Step 1.

- Given an observation matrix X, centre each variable (column-wise).

- Step 2.

- For each , regress all other , and obtain residuals . Then compute the kernel-based independence measure , and derive . Select the variable that minimises this measure as the exogenous variable.

- Step 3.

- Remove from the set U and record it in the causal ordering set K.

- Step 4.

- , .

- Step 5.

- If the number of variables in U is greater than 1, return to Step 2. Otherwise, proceed to Step 6.

- Step 6.

- Append the final variable in U to the end of K; this yields the full causal order.

- Step 7.

- Estimate the final adjacency matrix B using the identified causal order.

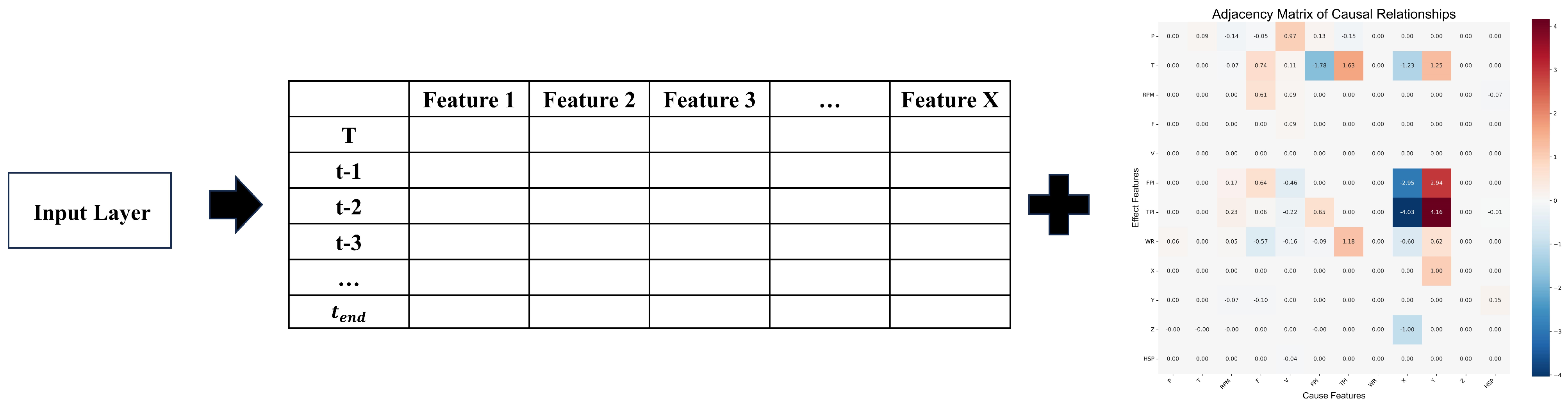

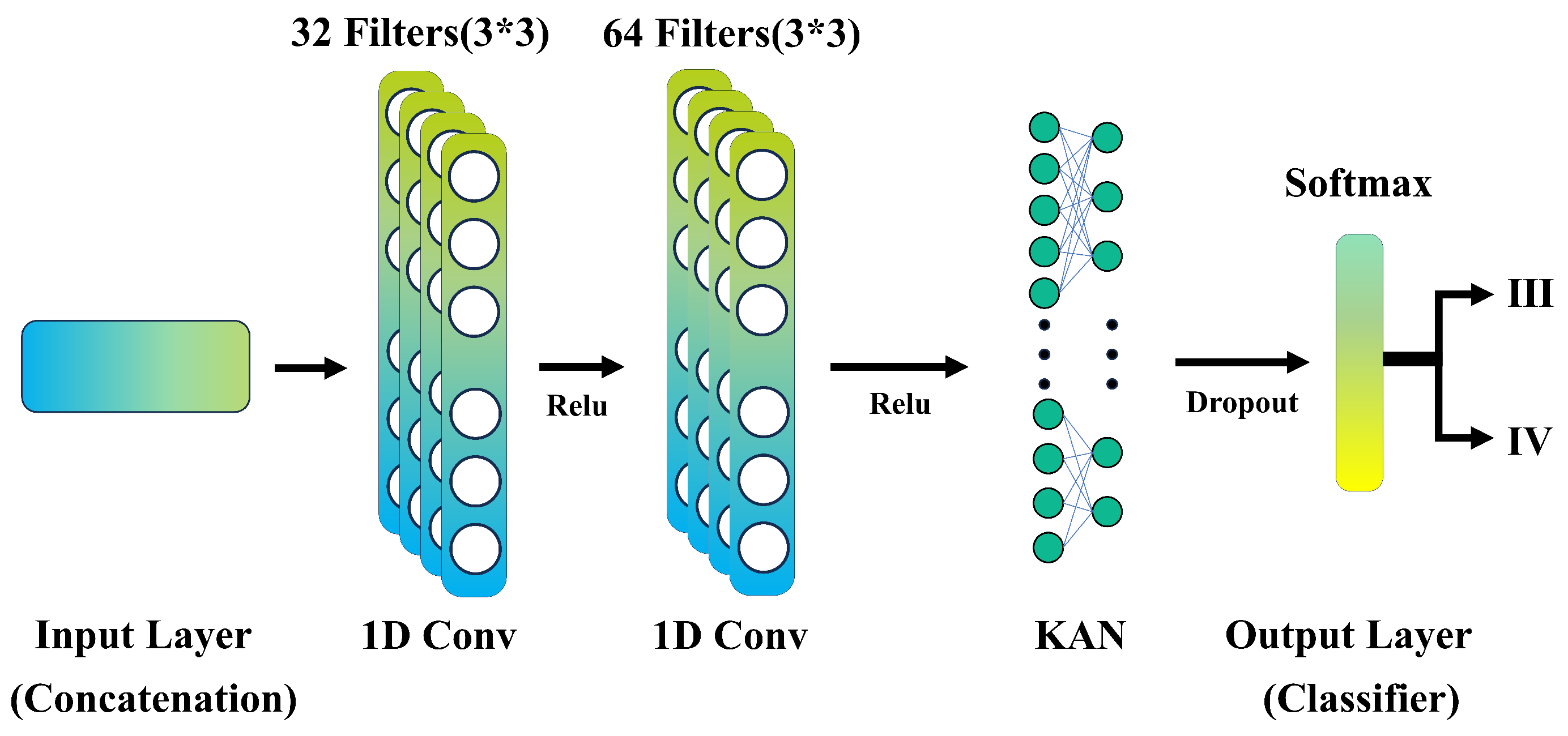

2.4. Neural Network (TRNet) for TBM Surrounding Rock Grade Prediction Based on Multi-Source Feature Fusion

2.5. Indicators for Model Evaluation

3. Case Study

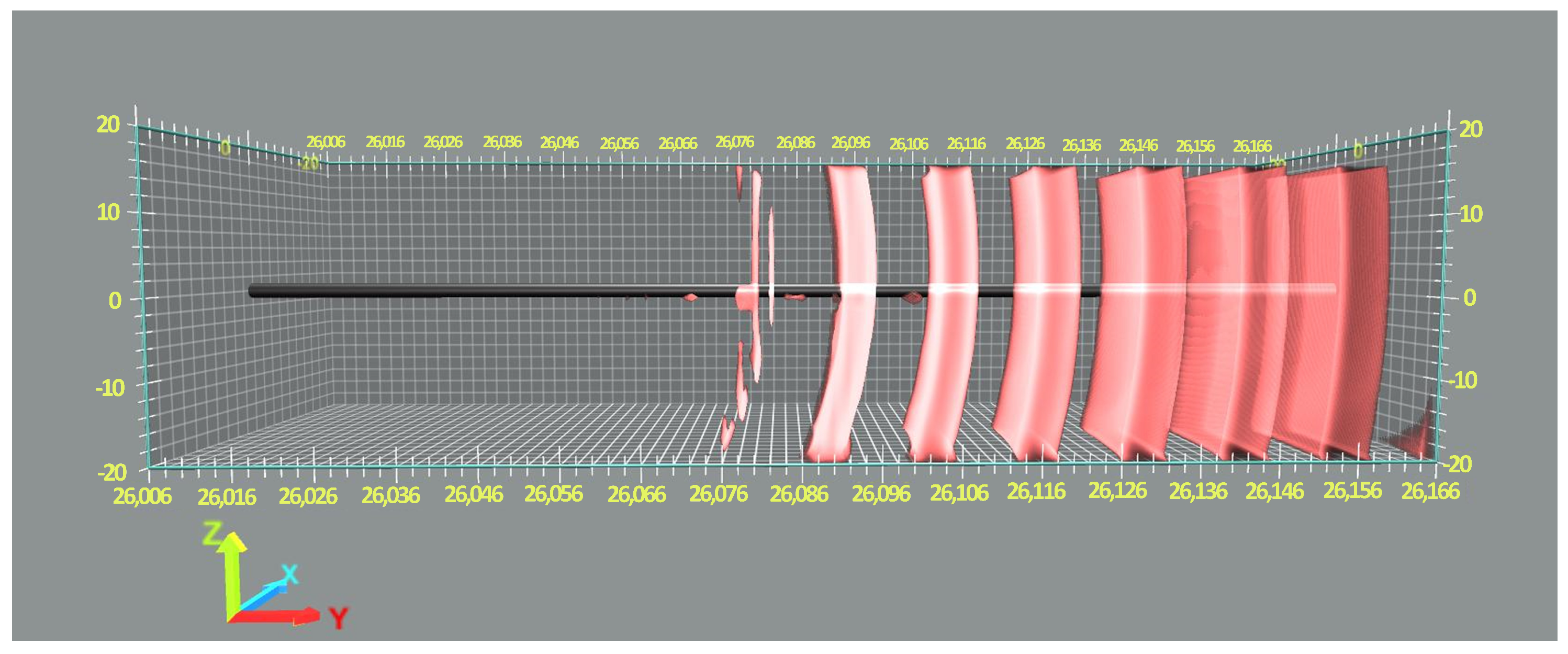

3.1. Project Overview

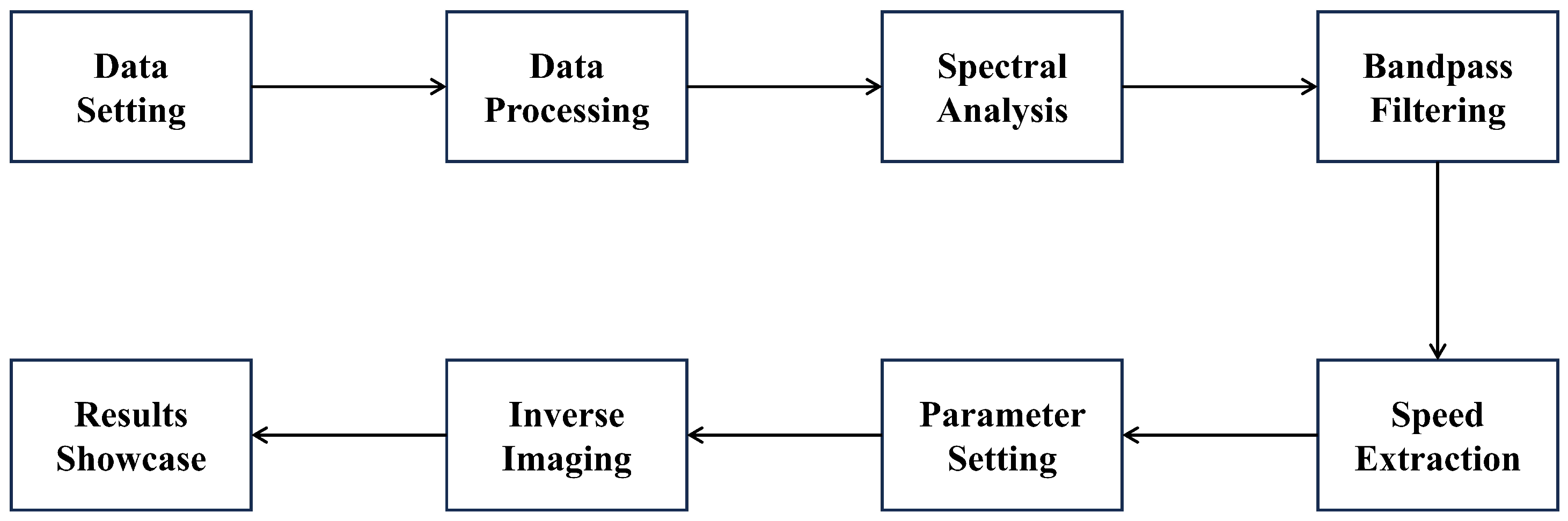

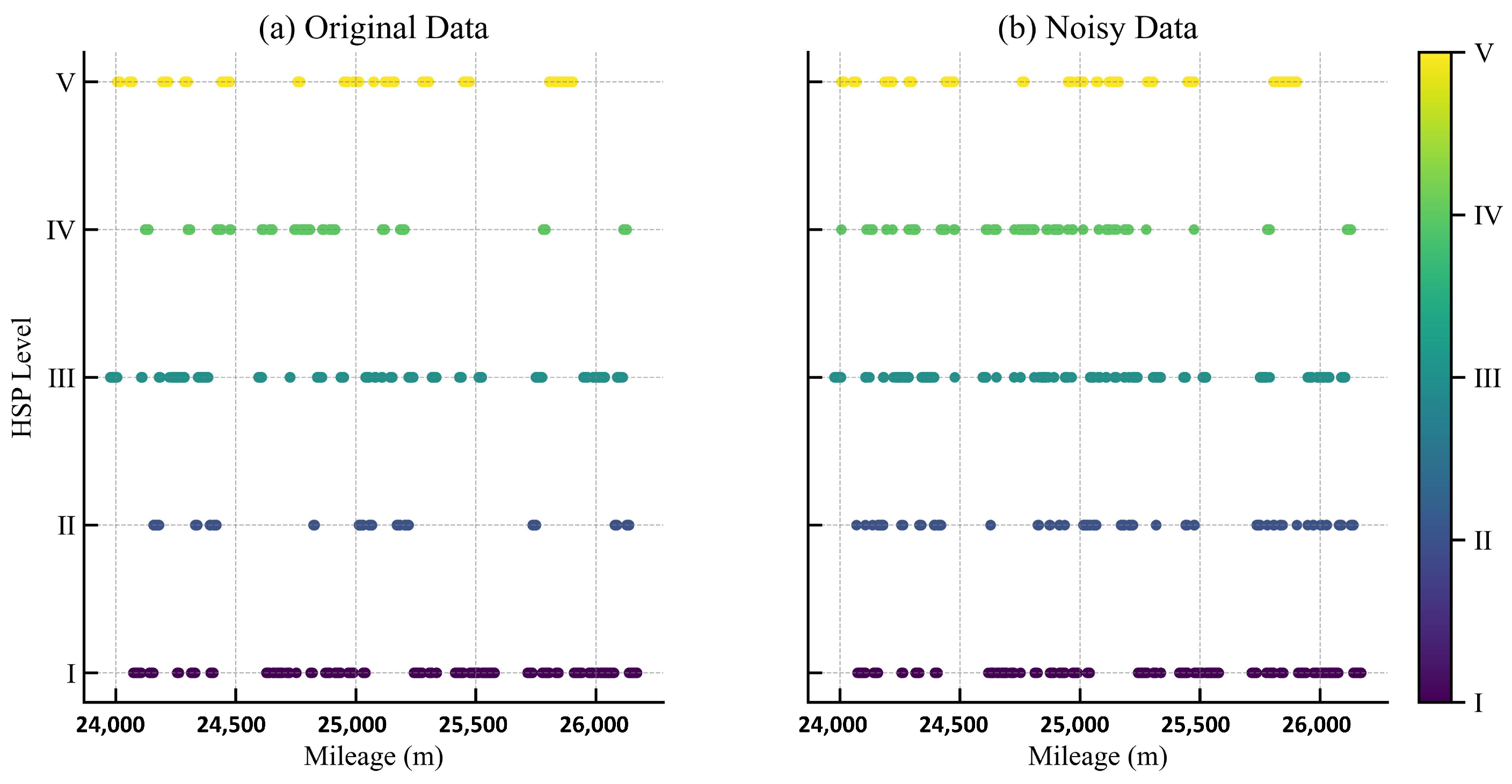

3.2. Data Preprocessing

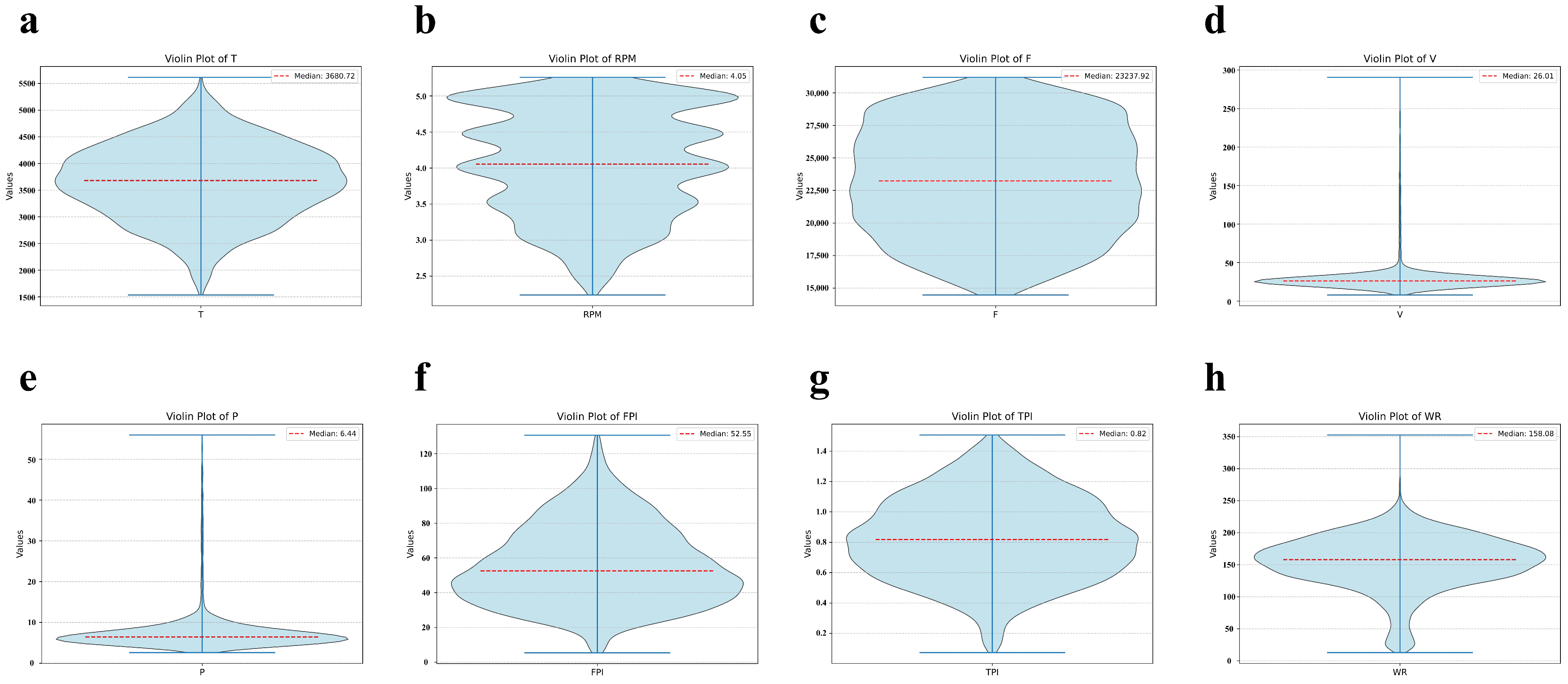

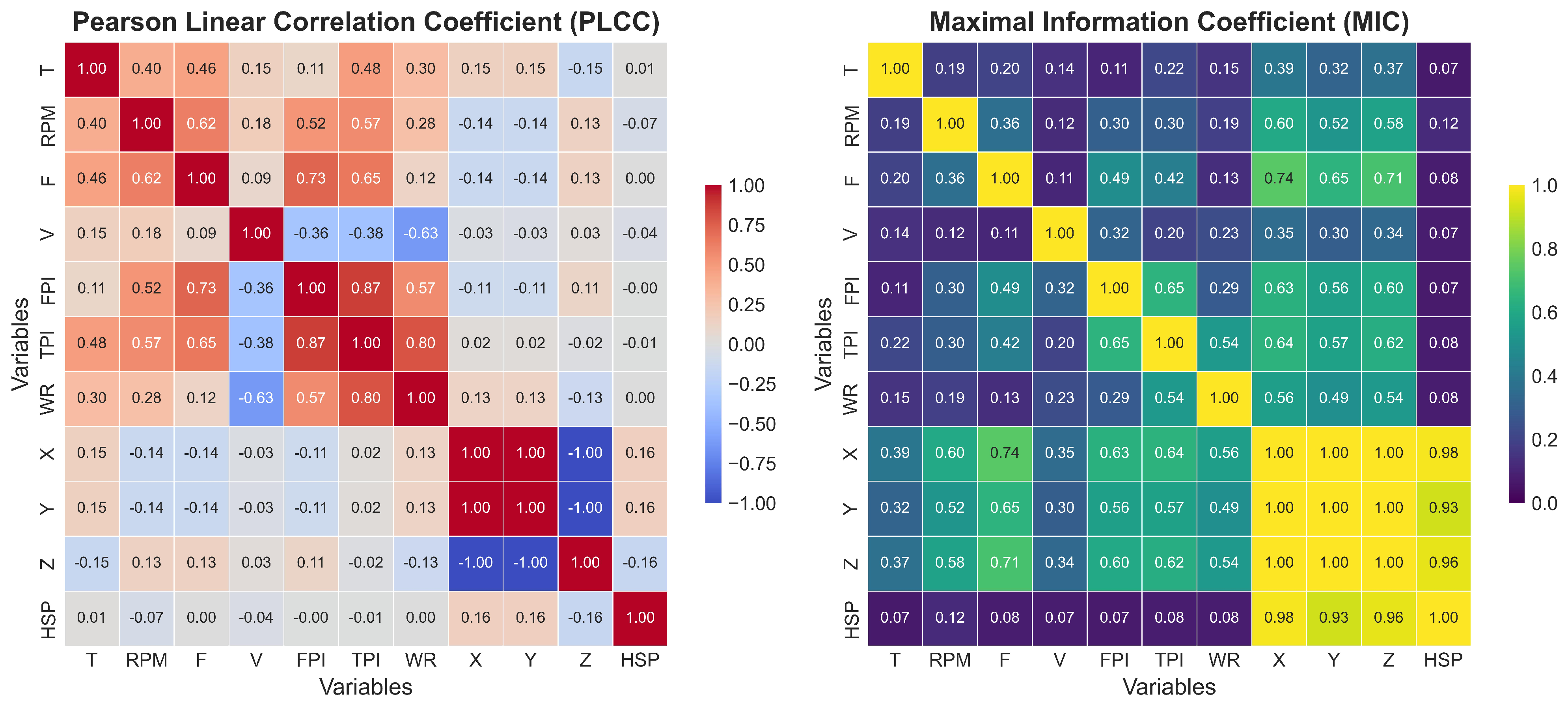

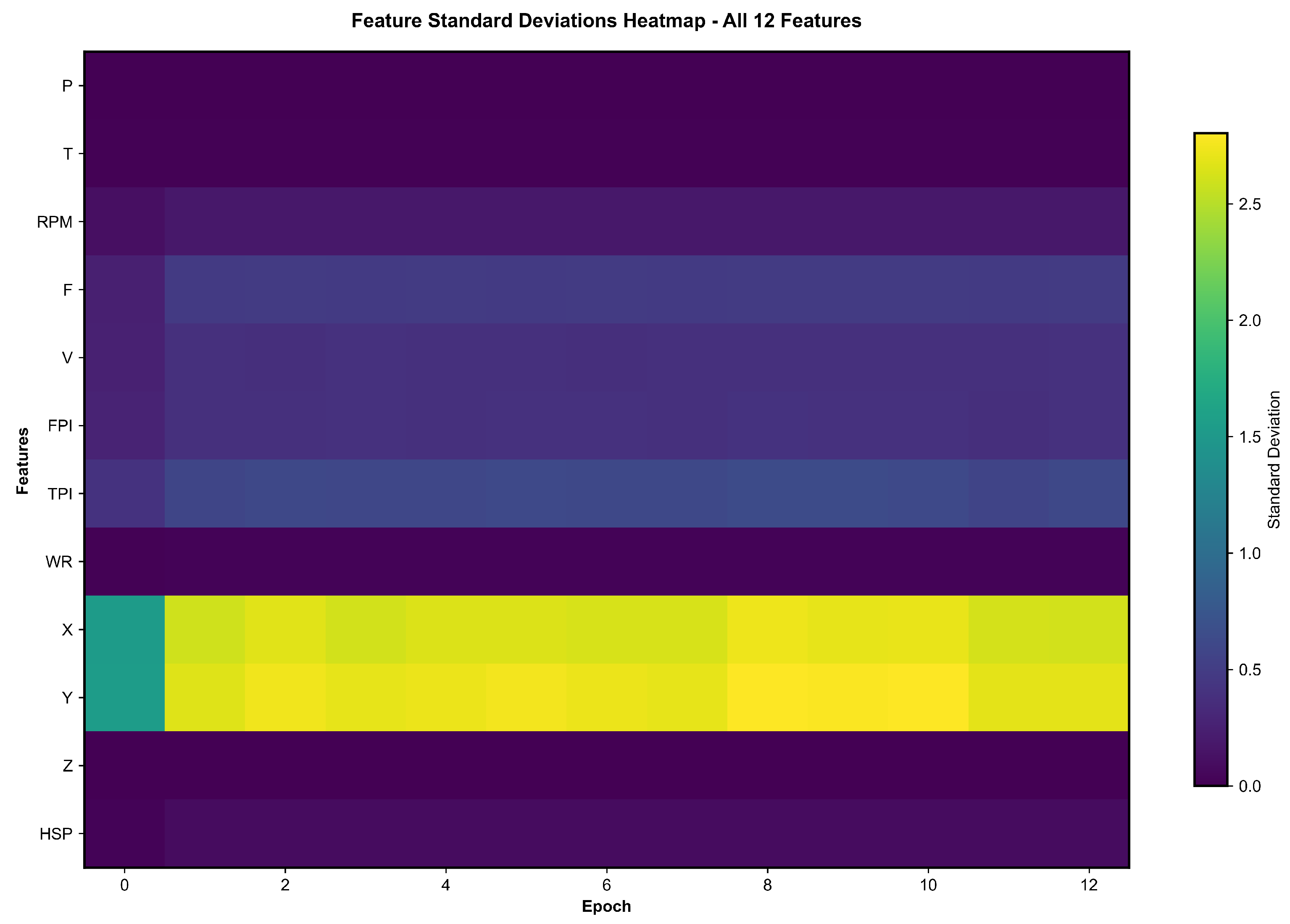

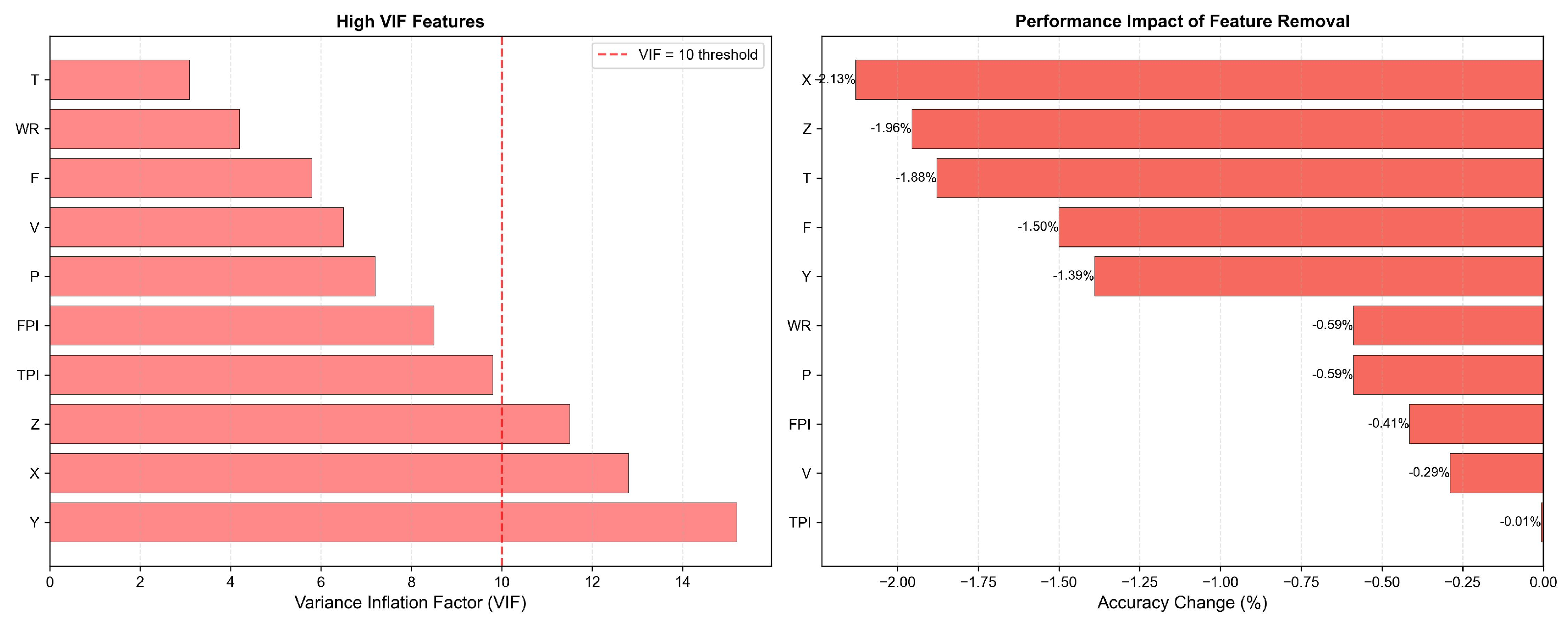

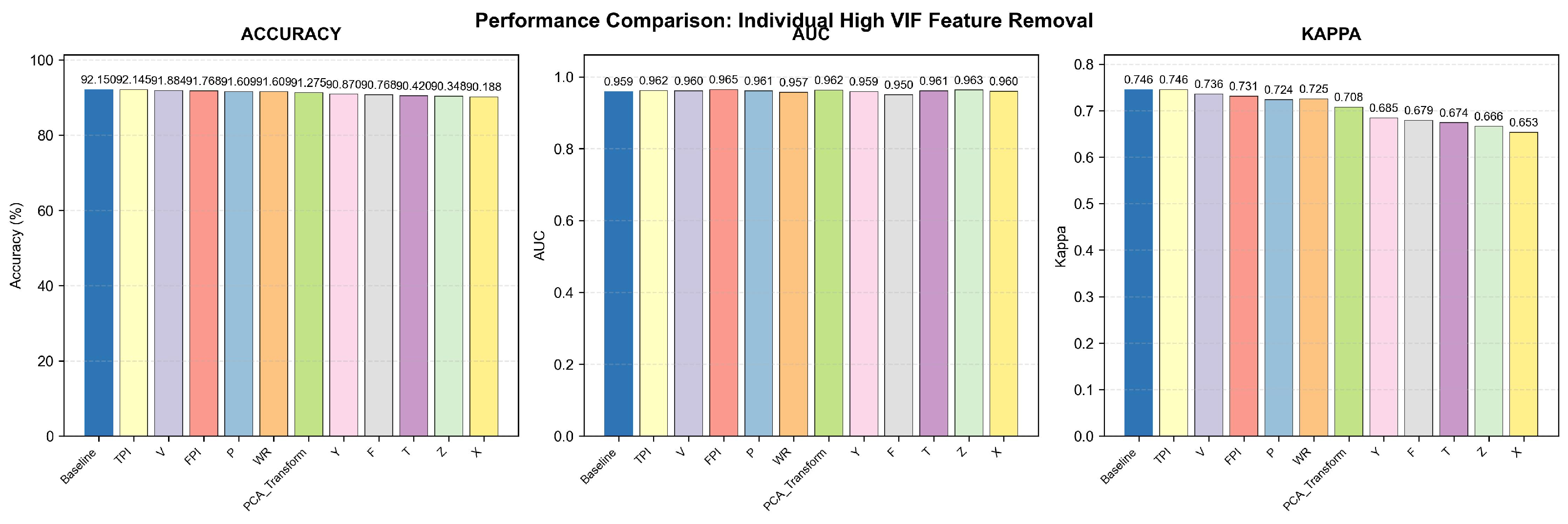

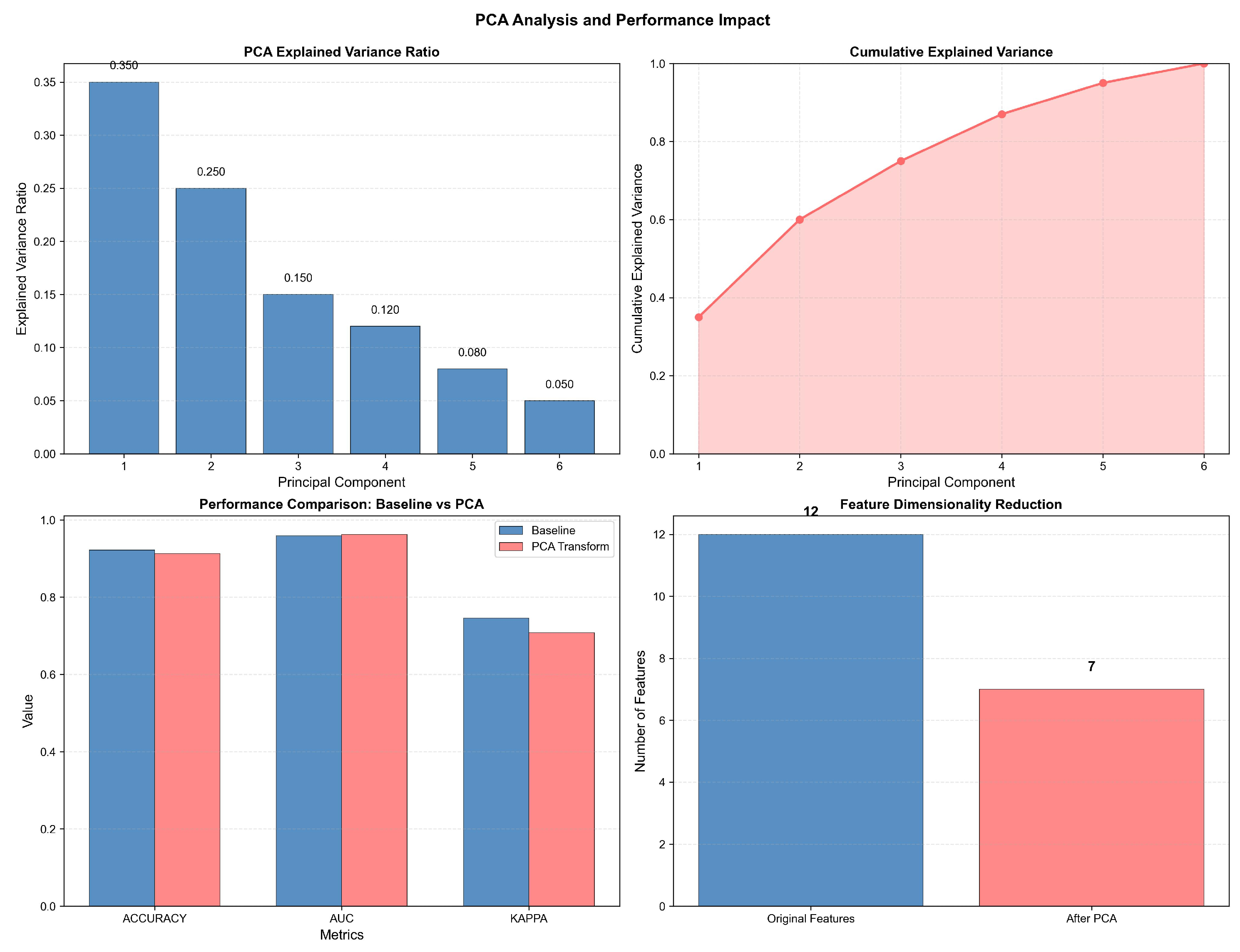

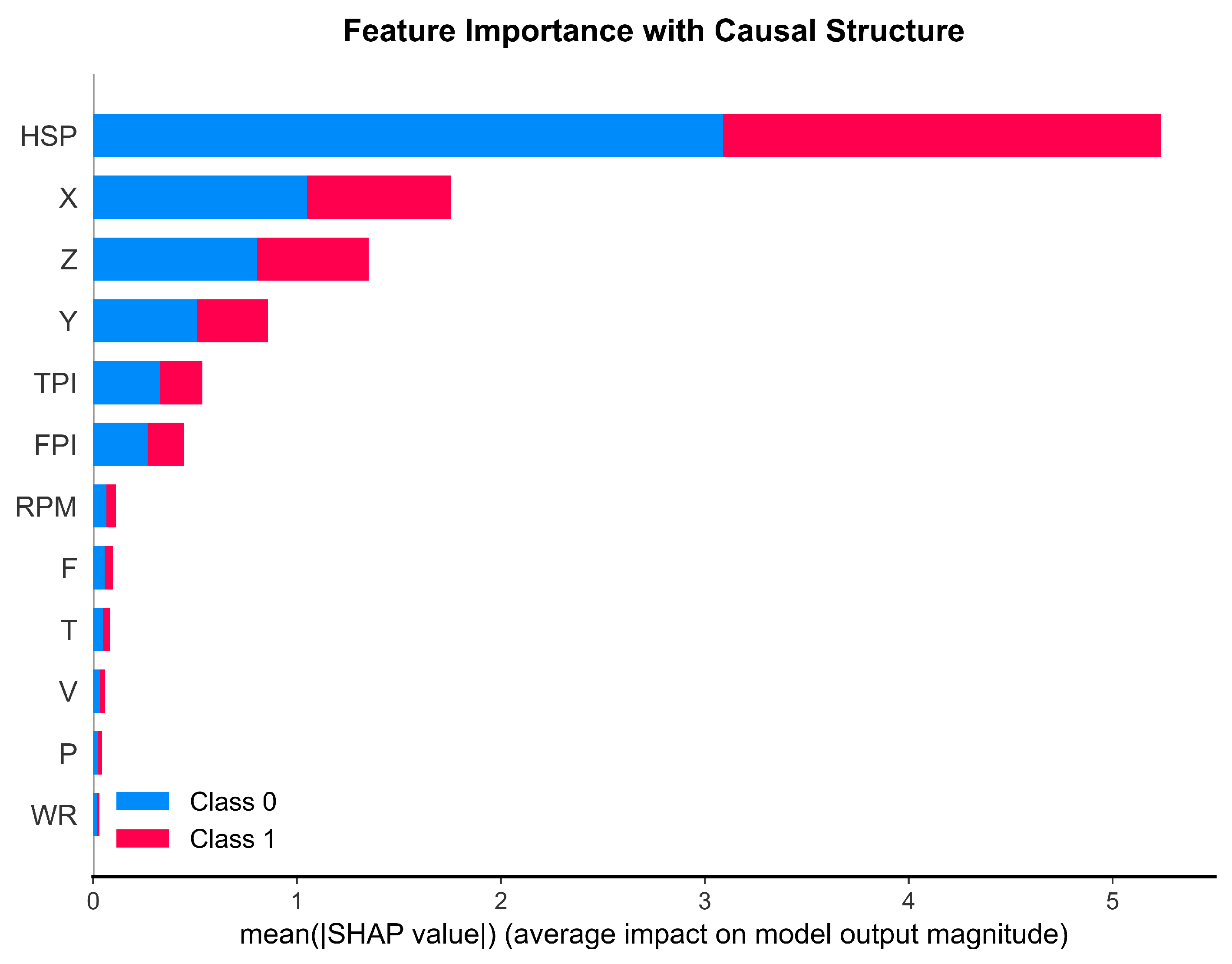

3.3. Data Analysis

4. Results and Discussion

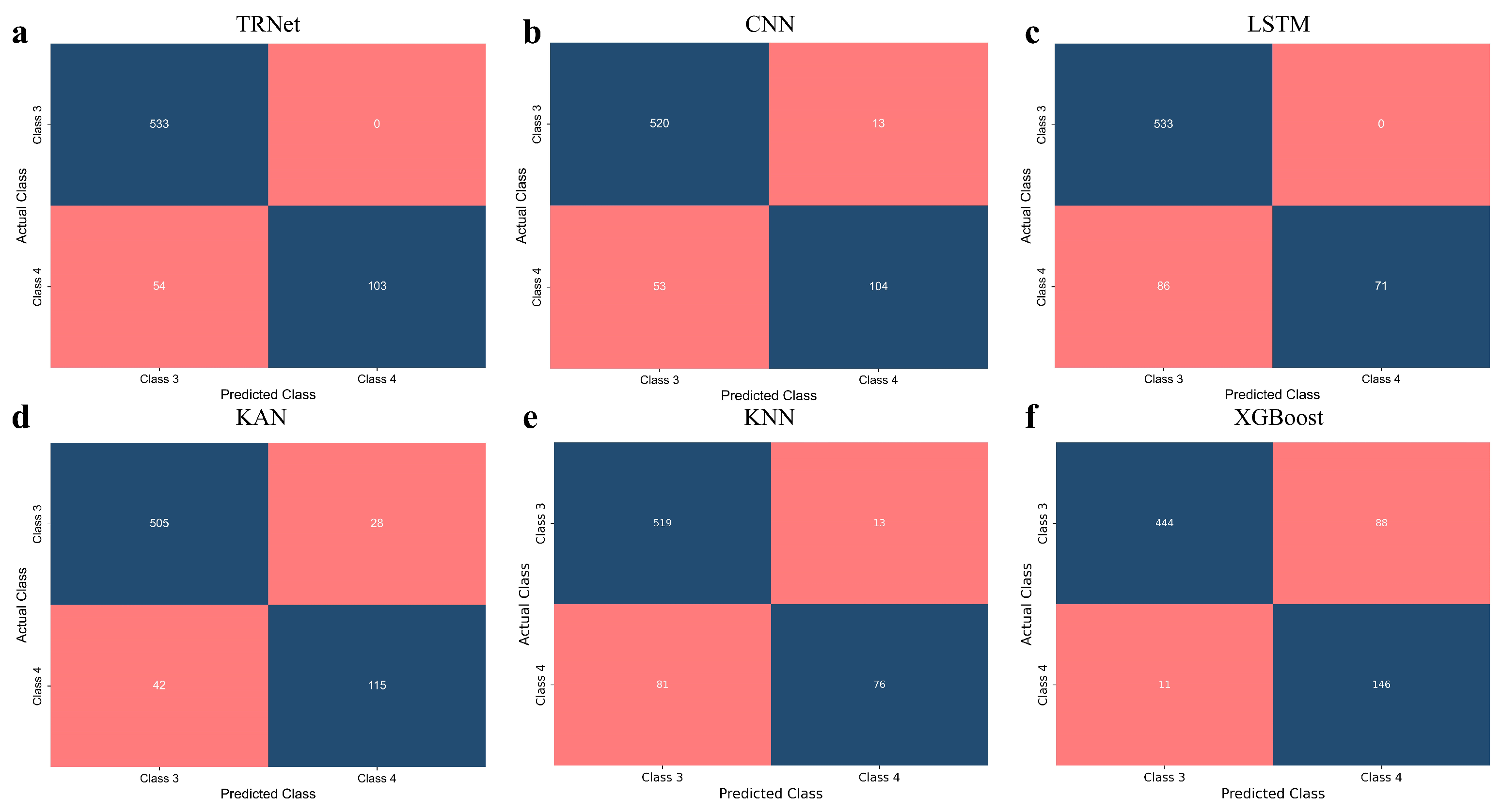

4.1. Training Process and Results

4.2. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, X.; Wu, L.J.; Wang, Y.J.; Li, J.H. Rock fragmentation indexes reflecting rock mass quality based on real-time data of TBM tunnelling. Sci. Rep. 2023, 13, 10420. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Liang, F.; Wei, K.; Zuo, C. Prediction Model for Cutterhead Rotation Speed Based on Dimensional Analysis and Elastic Net Regression. Appl. Sci. 2025, 15, 1298. [Google Scholar] [CrossRef]

- Wu, Z.; Huo, D.; Chu, Z.; Liu, X.; Weng, L.; Xu, X.; Li, Z. Advanced Identification Method for Adverse Geological Conditions in TBM Tunnels Based on Stacking Ensemble Algorithm and Bayesian Theory. Tunn. Undergr. Space Technol. 2025, 163, 106741. [Google Scholar] [CrossRef]

- Shi, K.; Shi, R.; Fu, T.; Lu, Z.; Zhang, J. A Novel Identification Approach Using RFECV–Optuna–XGBoost for Assessing Surrounding Rock Grade of Tunnel Boring Machine Based on Tunneling Parameters. Appl. Sci. 2024, 14, 2347. [Google Scholar] [CrossRef]

- Landar, S.; Velychkovych, A.; Ropyak, L.; Andrusyak, A. A Method for Applying the Use of a Smart 4 Controller for the Assessment of Drill String Bottom-Part Vibrations and Shock Loads. Vibration 2024, 7, 802–828. [Google Scholar] [CrossRef]

- Gong, Q.M.; Liu, Q.S.; Zhang, Q.B. Tunnel boring machines (TBMs) in difficult grounds. Tunn. Undergr. Space Technol. 2016, 57, 1–3. [Google Scholar] [CrossRef]

- Gong, Q.M.; Yin, L.J.; Ma, H.S.; Zhao, J. TBM tunnelling under adverse geological conditions: An overview. Tunn. Undergr. Space Technol. 2016, 57, 4–17. [Google Scholar] [CrossRef]

- Rostami, J. Performance prediction of hard rock Tunnel Boring Machines (TBMs) in difficult ground. Tunn. Undergr. Space Technol. 2016, 57, 173–182. [Google Scholar] [CrossRef]

- Zheng, Y.L.; Zhang, Q.B.; Zhao, J. Challenges and opportunities of using tunnel boring machines in mining. Tunn. Undergr. Space Technol. 2016, 57, 287–299. [Google Scholar] [CrossRef]

- Jancsecz, S.; Steiner, W. Face support for a large Mix-Shield in heterogeneous ground conditions. In Tunnelling and Underground Space Technology; Springer: Boston, MA, USA, 1994; pp. 531–550. [Google Scholar]

- Davis, E.H.; Gunn, M.J.; Mair, R.J.; Seneviratine, H.N. The Stability of Shallow Tunnels and Underground Openings in Cohesive Material. Géotechnique 1980, 30, 397–416. [Google Scholar] [CrossRef]

- Broere, W. Tunnel Face Stability and New CPT Applications. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2001. [Google Scholar]

- Jia, P.; Tang, C.A. Numerical Study on Failure Mechanism of Tunnel in Jointed Rock Mass. Tunn. Undergr. Space Technol. 2008, 23, 500–507. [Google Scholar] [CrossRef]

- Zhang, C.; Zhou, H.; Feng, X.-T. An Index for Estimating The Stability of Brittle Surrounding Rock Mass: FAI and Its Engineering Application. Rock Mech. Rock Eng. 2011, 44, 401–411. [Google Scholar] [CrossRef]

- Xia, Y.; Tian, Y.-C.; Tan, Q.; Hou, Y.-M. Side Force Formation Mechanism and Change Law of TBM Center Cutter. J. Cent. South Univ. 2016, 23, 1115–1122. [Google Scholar] [CrossRef]

- Li, J.-B.; Chen, Z.-Y.; Li, X.; Jing, L.-J.; Zhang, Y.-P.; Xiao, H.-H.; Wang, S.-J.; Yang, W.-K.; Wu, L.-J.; Li, P.-Y.; et al. Feedback on a Shared Big Dataset for Intelligent TBM Part II: Application and Forward Look. Undergr. Space 2023, 11, 26–45. [Google Scholar] [CrossRef]

- Sioutas, K.N.; Benardos, A. Boosting Model Interpretability for Transparent ML in TBM Tunneling. Appl. Sci. 2024, 14, 11394. [Google Scholar] [CrossRef]

- Liu, B.; Wang, R.; Guan, Z.; Li, J.; Xu, Z.; Guo, X.; Wang, Y. Improved support vector regression models for predicting rock mass parameters using tunnel boring machine driving data. Tunn. Undergr. Space Technol. 2019, 91, 102958. [Google Scholar] [CrossRef]

- Liu, Q.; Xinyu, W.; Huang, X.; Yin, X. Prediction model of rock mass class using classification and regression tree integrated AdaBoost algorithm based on TBM driving data. Tunn. Undergr. Space Technol. 2020, 106, 103595. [Google Scholar] [CrossRef]

- Hou, S.; Liu, Y.; Yang, Q. Real-time Prediction of Rock Mass Classification Based on TBM Operation Big Data and Stacking Technique of Ensemble Learning. J. Rock Mech. Geotech. Eng. 2022, 14, 123–143. [Google Scholar] [CrossRef]

- Cheng, X.; Tang, H.; Wu, Z.; Liang, D.; Xie, Y. BILSTM-Based Deep Neural Network for Rock-Mass Classification Prediction Using Depth-Sequence MWD Data: A Case Study of a Tunnel in Yunnan, China. Appl. Sci. 2023, 13, 6050. [Google Scholar] [CrossRef]

- Yu, H.; Tao, J.; Qin, C.; Xiao, D.; Sun, H.; Liu, C. Rock mass type prediction for tunnel boring machine using a novel semi-supervised method. Measurement 2021, 179, 109545. [Google Scholar] [CrossRef]

- Song, Y.; Feng, Y.; Wang, W.; Fan, Y.; Wu, Y.; Lv, Z. Data-driven prediction framework of surrounding rock pressure in a fully mechanized coal face with temporal-spatial correlation. Sci. Rep. 2024, 14, 28476. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.; Chen, Z.; Luo, H.; Wang, S.; Zhao, Y.; Liu, L.; Ling, D.; Jing, L. Tunnel boring machines (TBM) performance prediction: A case study using big data and deep learning. Tunn. Undergr. Space Technol. 2021, 110, 103636. [Google Scholar] [CrossRef]

- Liu, B.; Ruirui, W.; Guangzu, Z.; Guo, X.; Wang, Y.; Li, J.; Wang, S. Prediction of rock mass parameters in the TBM tunnel based on BP neural network integrated simulated annealing algorithm. Tunn. Undergr. Space Technol. 2020, 95, 103103. [Google Scholar] [CrossRef]

- Qiao, W.; Zhao, Y.; Xu, Y.; Lei, Y.; Wang, Y.; Yu, S.; Li, H. Deep learning-based pixel-level rock fragment recognition during tunnel excavation using instance segmentation model. Tunn. Undergr. Space Technol. 2021, 115, 104072. [Google Scholar] [CrossRef]

- He, Y.; Chen, Q. Construction and Application of LSTM-Based Prediction Model for Tunnel Surrounding Rock Deformation. Sustainability 2023, 15, 6877. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, L.; Fu, X. Time series prediction of tunnel boring machine (TBM) performance during excavation using causal explainable artificial intelligence (CX-AI). Autom. Constr. 2023, 147, 104730. [Google Scholar] [CrossRef]

- Tianjiao, Z. Flow Measurement of Natural Gas in Pipeline Based on 1D-Convolutional Neural Network. Int. J. Comput. Intell. Syst. 2020, 13, 1198–1206. [Google Scholar]

- Tan, D.G.; Yuan, Y.P.; Fan, P.P. CNN-GRU Based Health Assessment of Mining Electric Motor Using Adaptive Multi-Scale Attention Mechanism. Ind. Mine Autom. 2024, 50, 138–146. [Google Scholar]

- Shimizu, S.; Inazumi, T.; Sogawa, Y.; Hyvarinen, A.; Kawahara, Y.; Washio, T.; Hoyer, P.O.; Bollen, K. DirectLiNGAM: A Direct Method for Learning a Linear Non-Gaussian Structural Equation Model. J. Mach. Learn. Res. 2011, 12, 1225–1248. [Google Scholar]

- Ahola, J. The Self-Organizing Map as a Tool in Knowledge Engineering. In Pattern Recognition in Soft Computing Paradigm; World Scientific Publishing: Singapore, 2001. [Google Scholar]

- Drton, M.; Maathuis, M.H. Structure learning in graphical modeling. Annu. Rev. Stat. Appl. 2017, 4, 365–393. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, Q.; Liu, Q.; Liu, X.; Liu, B.; Wang, J.; Yin, X. A real-time prediction method for tunnel boring machine cutter-head torque using bidirectional long short-term memory networks optimized by multi-algorithm. J. Rock Mech. Geotech. Eng. 2022, 14, 798–812. [Google Scholar] [CrossRef]

- Erharter, G.H.; Marcher, T. On the pointlessness of machine learning based time delayed prediction of TBM operational data. Autom. Constr. 2021, 121, 103443. [Google Scholar] [CrossRef]

- Pang, S.; Hua, W.; Fu, W.; Liu, X.; Ni, X. Multivariable real-time prediction method of tunnel boring machine operating parameters based on spatio-temporal feature fusion. Adv. Eng. Inform. 2024, 62, 102924. [Google Scholar] [CrossRef]

- Godio, A.; Strobbia, C.; De Bacco, G. Geophysical characterisation of a rockslide in an alpine region. Eng. Geol. 2006, 83, 273–286. [Google Scholar] [CrossRef]

- Seger, C. An Investigation of Categorical Variable Encoding Techniques in Machine Learning: Binary Versus One-Hot and Feature Hashing. Ph.D. Thesis, KTH, School of Electrical Engineering and Computer Science (EECS), Stockholm, Sweden, 2018. [Google Scholar]

- Cohen, I.; Huang, Y.; Chen, J.; Benesty, J. Pearson correlation coefficient. In Noise Reduction in Speech Processing; Springer: Berlin/Heidelberg, Germany, 2009; pp. 1–4. [Google Scholar]

- Kinney, J.B.; Atwal, G.S. Equitability, mutual information, and the maximal information coefficient. Proc. Natl. Acad. Sci. USA 2014, 111, 3354–3359. [Google Scholar] [CrossRef]

- Joy, T.T.; Rana, S.; Gupta, S.; Venkatesh, S. Hyperparameter tuning for big data using Bayesian optimisation. In Proceedings of the 2016 23rd International Conference on Pattern Recognition (ICPR), Cancun, Mexico, 4–8 December 2016; pp. 2574–2579. [Google Scholar]

- Li, L.; Liu, Z.; Shen, J.; Wang, F.; Qi, W.; Jeon, S. A LightGBM-based strategy to predict tunnel rockmass class from TBM construction data for building control. Adv. Eng. Inform. 2023, 58, 102130. [Google Scholar] [CrossRef]

| Component | Parameters | Description |

|---|---|---|

| Input Layer | N/A | Concatenation of the input vector and local causal features along the feature dimension |

| 1D Conv | in_channels = input_size, out_channels = d_model/2, kernel_size = 3, padding = 1 | 1D convolutional layer for encoding, mapping from input_size to d_model/2 |

| Relu | N/A | Activation layer |

| 1D Conv | in_channels = d_model/2, out_channels = d_model, kernel_size = 3, padding = 1 | 1D convolutional layer for encoding, mapping from d_model/2 to d_model |

| Relu | N/A | Activation layer |

| KAN | [d_model, d_model/2, d_model/2, d_model/4] | RAN module with hidden layers of sizes d_model, d_model/2 and d_model/4 |

| Dropout | rate = 0.15 | Dropout layer |

| Output layer | d_model/4, num_classes | Fully connected layer |

| Surrounding Rock Rank | Length/m | Proportion/% |

|---|---|---|

| II | 4100 | |

| III | 24,070 | |

| IV | 7973 | |

| V | 1822 |

| Name | Unit | Range |

|---|---|---|

| A/D Conversion | bit | 24 |

| Channel | N/A | 8 |

| Sampling Speed | μs | 0.1– |

| Record Length | K | 1–23 |

| Dynamic Scope | v |

| Reflection Anomaly | Rank | Code |

|---|---|---|

| None | I | |

| Weak | II | |

| Obvious | III | |

| Relatively Strong | IV | |

| Strong | V |

| Parameters | Min | Median | Max | Mean | Std |

|---|---|---|---|---|---|

| P | 2.607108 | 6.44266 | 55.94638 | 7.635982 | 5.634877 |

| T | 1536.277 | 3680.723 | 5613.279 | 3656.688 | 701.2206 |

| RPM | 2.239389 | 4.054824 | 5.258368 | 4.060949 | 0.7243764 |

| F | 14,476.57 | 23,237.92 | 31,188.26 | 23,230.56 | 4178.51 |

| V | 7.954941 | 26.01329 | 290.4988 | 30.78468 | 25.78844 |

| FPI | 5.44542 | 52.55251 | 130.6987 | 56.02042 | 23.09044 |

| TPI | 0.073619 | 0.81829 | 1.506045 | 0.82678 | 0.274542 |

| WR | 12.9168 | 158.0774 | 352.7145 | 153.7523 | 41.84008 |

| Hyperparameters | Search Area | Optimal Hyperparameters |

|---|---|---|

| The dimension of hidden layer | 32, 64, 128, 512 | 64 |

| The dimension of KAN | 16, 32, 64, 128, 512 | [64, 32, 16] |

| Batch size | 16, 32, 64, 128, 256 | 32 |

| Dropout | 0.01, 0.05, 0.1, 0.2 | 0.05 |

| Patience | 5, 10, 20 | 10 |

| Serial | Accuracy | AUC | Kappa | Epoch | Train Duration/s |

|---|---|---|---|---|---|

| 1 | 0.92029 | 0.956131 | 0.741277 | 12 | 5.960255 |

| 2 | 0.92029 | 0.944145 | 0.741277 | 11 | 5.961756 |

| 3 | 0.921739 | 0.959131 | 0.746631 | 13 | 5.96497 |

| 4 | 0.921739 | 0.968798 | 0.746631 | 12 | 6.123185 |

| 5 | 0.921739 | 0.948734 | 0.746631 | 13 | 6.173523 |

| 6 | 0.921739 | 0.941898 | 0.746631 | 14 | 6.383748 |

| 7 | 0.921739 | 0.966647 | 0.746631 | 15 | 5.926478 |

| 8 | 0.921739 | 0.969336 | 0.746631 | 14 | 5.991457 |

| 9 | 0.921739 | 0.963146 | 0.746631 | 13 | 6.140293 |

| 10 | 0.921739 | 0.971977 | 0.746631 | 13 | 5.935721 |

| Method | Accuracy | AUC | Kappa | Epoch | Train Duration/s |

|---|---|---|---|---|---|

| TRNet | 0.92144275 | 0.95899427 | 0.74555987 | 12 | 6.0561 |

| CNN | 0.91159420 | 0.94224364 | 0.70426115 | 28 | 5.3334 |

| LSTM | 0.92113913 | 0.88156809 | 0.74363058 | 16 | 5.3498 |

| KAN | 0.90304347 | 0.92731085 | 0.72062828 | 12 | 5.8756 |

| KNN | 0.8636 | 0.7298 | 0.5424 | N/A | 0.01 |

| XGBoost | 0.8563 | 0.8823 | 0.6518 | N/A | 0.15 |

| Method | Accuracy | AUC | Kappa |

|---|---|---|---|

| TRNet | 0.9215 | 0.9590 | 0.7456 |

| TRNet-LiNGAM 1 | 0.9072 | 0.95753 | 0.6748 |

| TRNet-CNN 2 | 0.9174 | 0.8198 | 0.7346 |

| TRNet-KAN 3 | 0.8957 | 0.9461 | 0.6459 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.; Hu, X.; Pang, S.; Fu, W.; Chang, S.; Gao, B.; Hua, W. TBM Enclosure Rock Grade Prediction Method Based on Multi-Source Feature Fusion. Appl. Sci. 2025, 15, 6684. https://doi.org/10.3390/app15126684

Huang Y, Hu X, Pang S, Fu W, Chang S, Gao B, Hua W. TBM Enclosure Rock Grade Prediction Method Based on Multi-Source Feature Fusion. Applied Sciences. 2025; 15(12):6684. https://doi.org/10.3390/app15126684

Chicago/Turabian StyleHuang, Yong, Xiewen Hu, Shilong Pang, Wei Fu, Shuaipeng Chang, Bin Gao, and Weihua Hua. 2025. "TBM Enclosure Rock Grade Prediction Method Based on Multi-Source Feature Fusion" Applied Sciences 15, no. 12: 6684. https://doi.org/10.3390/app15126684

APA StyleHuang, Y., Hu, X., Pang, S., Fu, W., Chang, S., Gao, B., & Hua, W. (2025). TBM Enclosure Rock Grade Prediction Method Based on Multi-Source Feature Fusion. Applied Sciences, 15(12), 6684. https://doi.org/10.3390/app15126684