Investigating the Physical Mechanisms of Quicksand Using a Custom-Designed Experimental Apparatus

Abstract

Featured Application

Abstract

1. Introduction

2. Experimental Materials and Methods

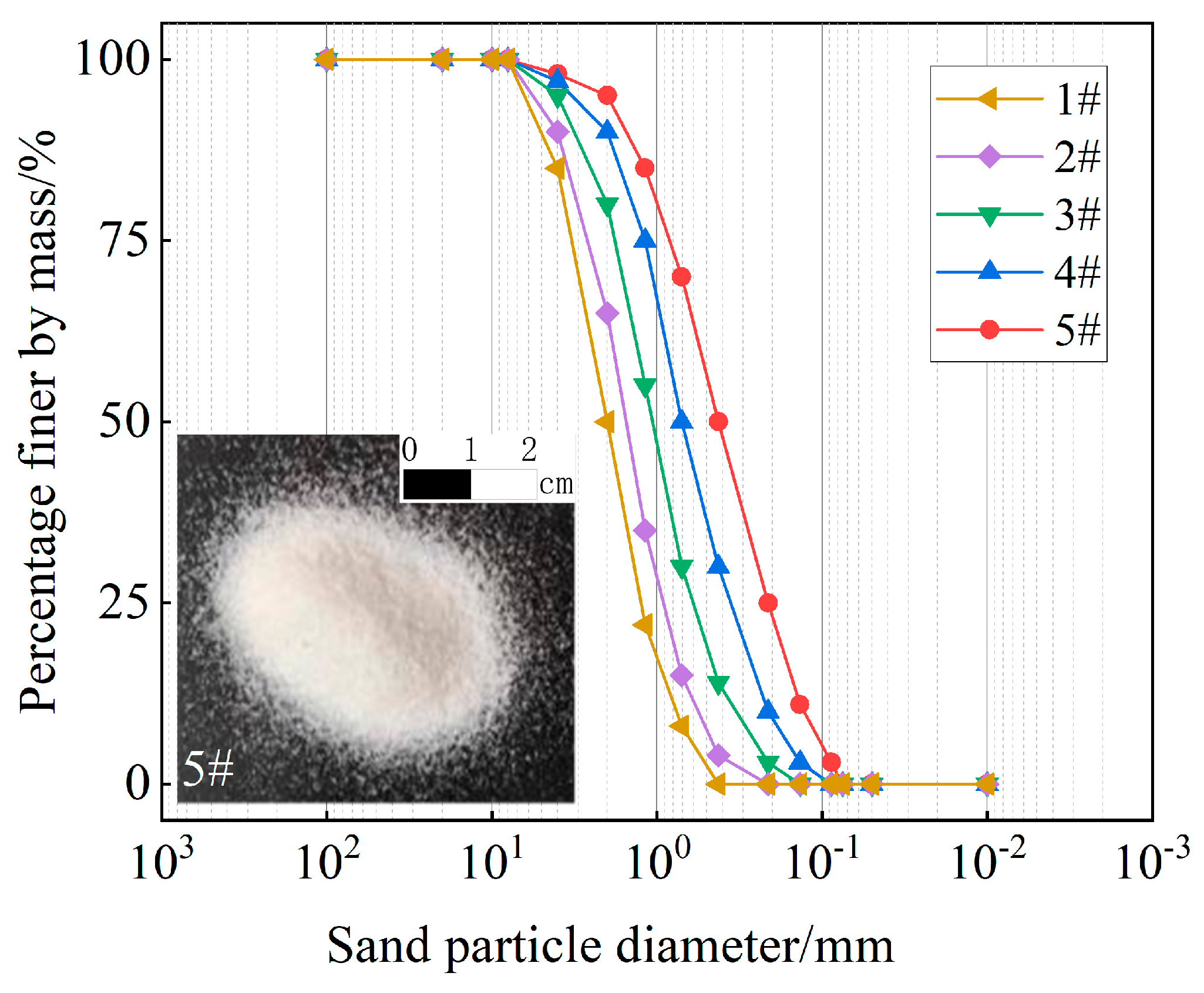

2.1. Experimental Materials

2.2. Experimental Apparatus

2.2.1. Principle of Design

2.2.2. Composition of the Testing Apparatus and the Operating Method

2.3. Experimental Steps

- (1)

- Specimen Preparation: Following the methodology of Ren et al. [17] for permeability testing of calcareous sand in island reef reclamation projects, this experiment conducted hydrodynamic seepage tests on quartz sand specimens under identical relative density conditions (Dr = 66%) to simulate natural sandy soil site conditions. The permeameter specimen chamber accommodates cylindrical specimens with a diameter of 60.000 mm and a height of 120.000 mm. A multi-layer loading protocol was implemented, ensuring uniform mass and compaction duration across all layers. Post-loading pressure measurements were acquired synchronously from all sensor tiers.

- (2)

- Specimen Saturation: The water reservoir of the supply unit was filled with distilled water, with pH effects on quartz sand permeability and quicksand behavior intentionally excluded. The water temperature was thermostatically maintained at 20.0 ± 0.5 °C to simulate typical in-situ sandy soil thermal conditions. Priming Phase: The water injection unit outlet was opened until bubble-free water discharged uniformly, then connected to the permeameter’s inlet. Controlled Saturation: Saturation permeation was conducted at a constant flow rate of 10 mL/min until uniform effluent was observed at the permeameter outlet. Process Monitoring: Multi-elevation pressure measurements (Bottom/Middle/Top) were recorded in real-time throughout saturation.

- (3)

- Flow Rate Regulation: This experimental series systematically investigates the permeability characteristics and quicksand evolution processes of quartz sand under varying particle gradation and hydrodynamic velocities. A controlled variable method was strictly implemented to gradually carry out the dynamic water permeability test under the various factor variable conditions, with a detailed experimental matrix provided in Table 2. To simulate the progressive dynamic evolution of hydraulic conditions in actual sandy soil foundation environments and systematically capture the full-process dynamics of quicksand from initiation to instability, each quartz sand specimen is subjected to five consecutive hydrodynamic seepage phases (10 min duration per phase): Low hydrodynamic pressure, initial seepage state → Enhanced hydrodynamic pressure, minor particle migration → Near-critical hydraulic gradient, quicksand precursor → High hydrodynamic pressure, localized quicksand → Extreme conditions, global quicksand initiation. Real-time pressure monitoring across vertical positions (Bottom/Middle/Top) was maintained throughout all permeation stages.

- (4)

- Seepage Monitoring: During hydrodynamic seepage testing, effluent discharged from the permeameter outlet was systematically collected and volumetrically quantified using graduated cylinders, with separate measurements recorded for each 10-min phase. This effluent volume dataset provides indirect characterization of porosity variation patterns during quicksand evolution in quartz sand specimens.

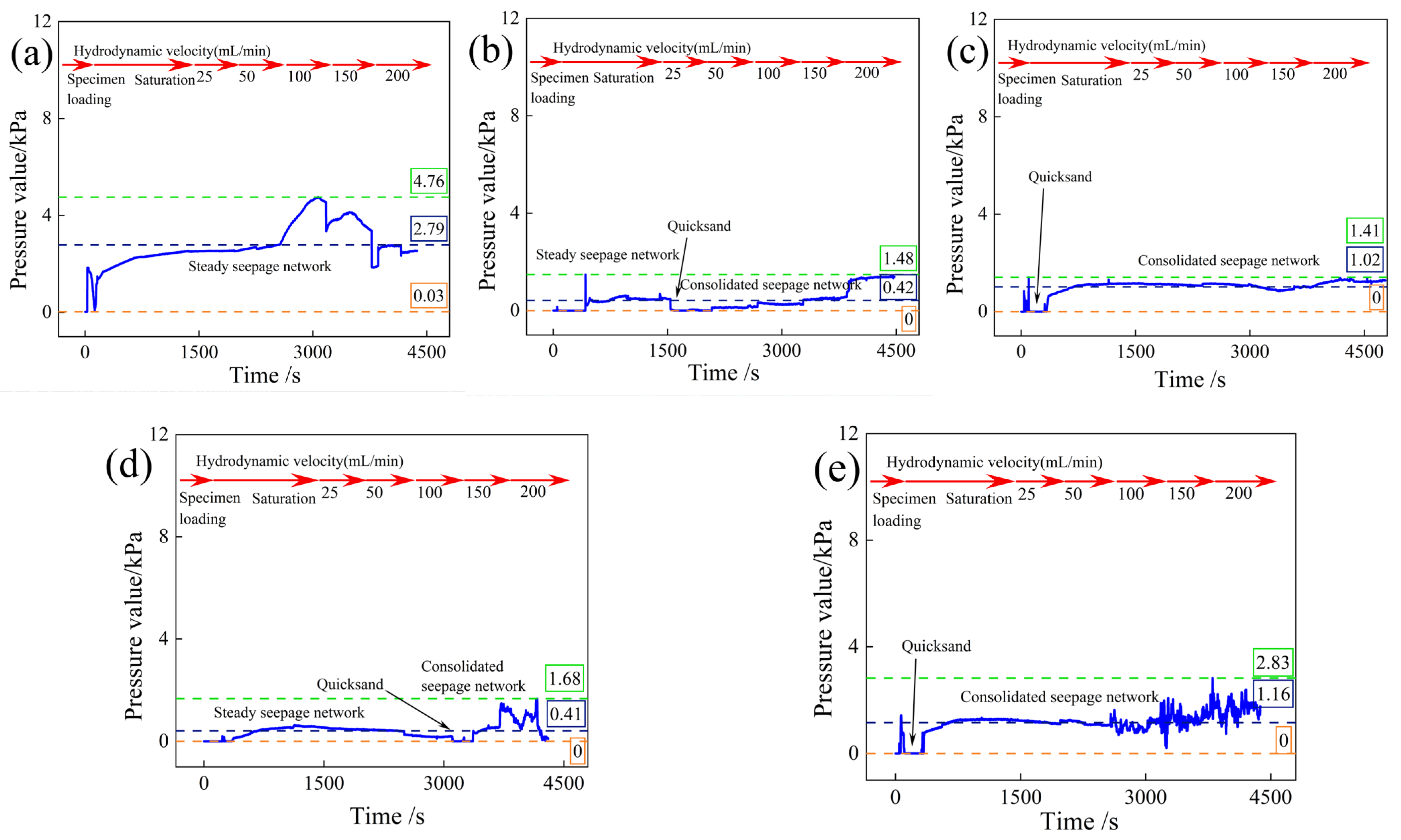

3. Result

3.1. Permeability Analysis of Quartz Quicksand

3.2. Quicksand Mechanism Analysis

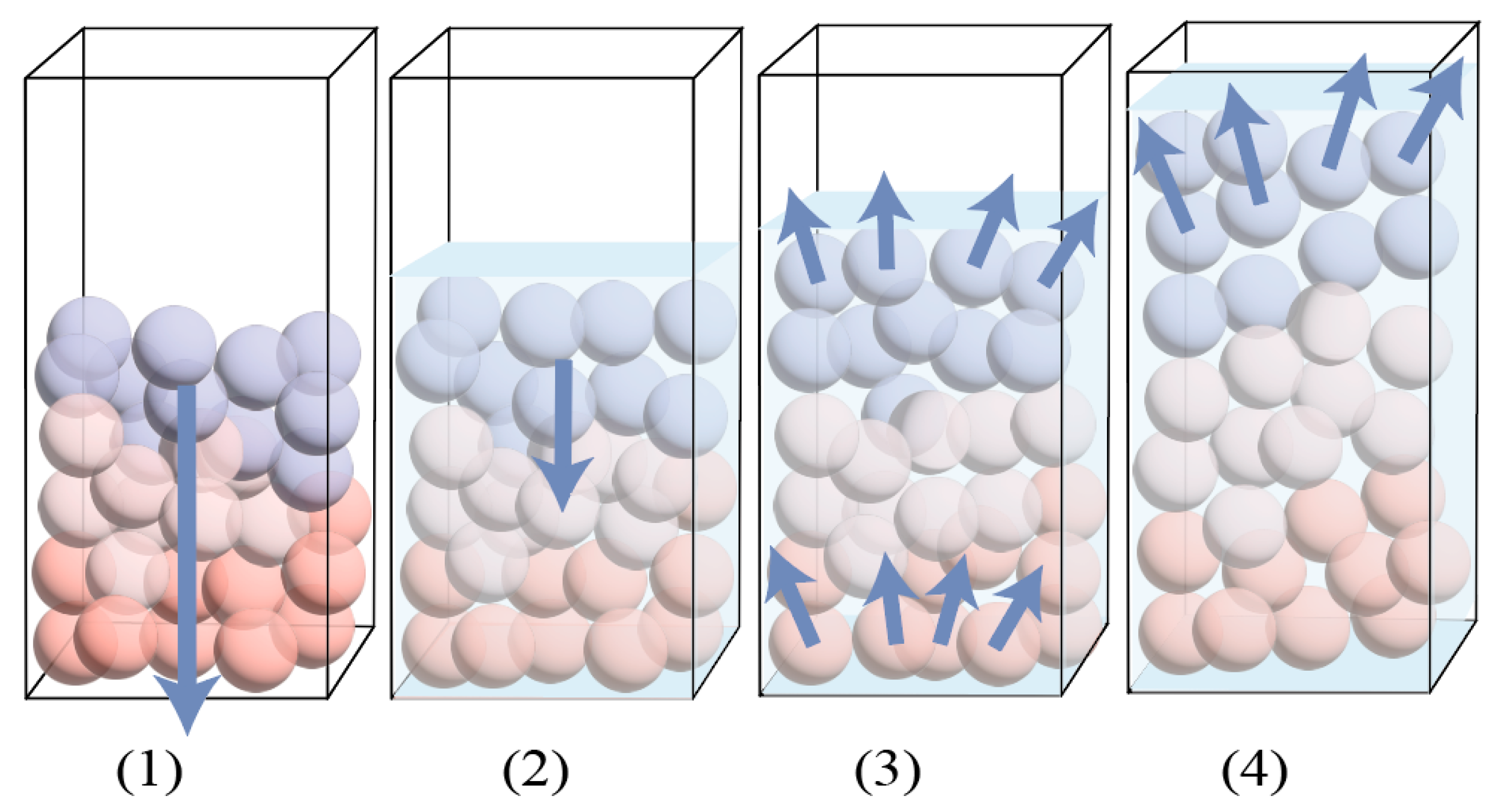

4. Discussion

- (1)

- Self-Consolidation Stage:

- (2)

- Reorganization Stage:

- (3)

- Quicksand Stage:

5. Conclusions

- (1)

- The infiltration rate of quartz sand samples was found to be minimally affected by particle gradation (d50) and strongly influenced by dynamic water velocity. A positive correlation was observed between infiltration rate and water velocity, with infiltration increasing as the velocity increased.

- (2)

- Particle gradation determined the potential for quicksand formation in the quartz sand samples, with a median particle size (d50) of 0.710 mm marking the threshold for quicksand occurrence. The dynamic water velocity controlled the timing of quicksand initiation, with an approximate quicksand thickness of 60 mm observed.

- (3)

- The evolution of quicksand occurred in three stages: “self-consolidation”, “reconstruction”, and “quicksand”. Both particle gradation and dynamic water velocity significantly impacted the “reconstruction” stage and determined whether the sample transitioned into the “quicksand” stage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meng, Q.B.; Han, L.J.; Shi, J.R.; Liu, Z.J.; Lu, T.; Li, X.Y.; Shi, G.P. Study and application of construction technology for inclined shafts penetratingdrift sand strata in coal mine. Acta Geotech. 2015, 35, 900–910. [Google Scholar]

- Wang, K.W.; Gao, G.Y.; Yue, Z.Q.; Zhang, X.L. Study on risk assessment and division of quicksand in Shanghai. J. Eng. Geol. 2013, 21, 950–958. [Google Scholar]

- Mansouri, M.; Youssoufi, M.S.E.L.; Nicot, F. Numerical simulation of the quicksand phenomenon by a 3D coupled Discrete Element—Lattice Boltzmann hydromechanical model. Int. J. Numer. Anal. Methods 2017, 41, 338–358. [Google Scholar] [CrossRef]

- John, J. Conceptualmodels for describing the liquefaction and resolidification of quicksand One-dimensional vertical behavior of a saturated, loosely packed soil column. Grundwasser 2019, 24, 145–158. [Google Scholar] [CrossRef]

- Editorial Committee of Engineering Geology Manual. Engineering Geology Handbook, 3rd ed.; China Architecture & Building Press: Beijing, China, 2007. [Google Scholar]

- Gao, G.Y.; Yao, S.F.; Cui, Y.J.; Chen, Q.S.; Zhang, X.L.; Wang, K.W. Zoning of confined aquifers inrush and quicksand in Shanghai region. NHESS 2018, 91, 1341–1363. [Google Scholar] [CrossRef]

- Liu, H.L. Soil dynamics and geotechnical seismic engineering. In Proceedings of the 9th Conference on Soil Mechanics and Geotechnical Engineering of the Chinese Society of Civil Engineering (Volume I), Beijing, China, 1 October 2003. [Google Scholar]

- Sasaki, Y.; Towhata, I.; Tokida, K.I.; Yamada, K.; Matsumoto, H.; Tamari, Y.; Saya, S. Mechanism of permanent displacement of ground caused by seismic liquefaction. Soils Found. 1992, 32, 79–96. [Google Scholar] [CrossRef] [PubMed]

- Dashti, S.; Bray, J.D. Numerical simulation of building response on liquefiable sand. J. Geotech. Geoenviron. Eng. 2012, 139, 1235–1249. [Google Scholar] [CrossRef]

- Arulanadan, K.; Sybico, J. Post-liquefaction settlement of sands. In Proceedings of the Predictive Soil Mechanics: Proceedings of the Wroth Memorial Symposium Held at St. Catherine’s College, Oxford, UK, 27–29 July 1992; pp. 94–110. [Google Scholar]

- Xenaki, V.C.; Athanasopoulos, G.A. Liquefaction resistance of sand-silt mixtures: An experimental investigation of the effect of fines. Soil Dyn. Earthq. Eng. 2003, 23, 183–194. [Google Scholar] [CrossRef]

- Li, T.; Tang, X.W. Experimental study on effect of coexistence of clay and silt on static and dynamic liquefaction of sand. Acta Geotech. 2019, 41, 169–172. [Google Scholar]

- Zhang, X.L.; Li, X.Y.; Du, X.L. Hyperbolic model for estimating liquefaction potential of sand considering the influences of fine grains. Acta Geotech. 2021, 43, 448–455. [Google Scholar]

- Wang, N. Dynamic Triaxial Experiment of the Influence of Diameter and Gradation to Coastal Sandy Liquefaction. Master’s Thesis, Ocean University of China, Qingdao, China, 2015. [Google Scholar]

- Xu, Y.F.; Lan, S.Q.; Sun, D.A.; Xia, X.H.; Yang, H.J.; Xiao, Z.Y.; Wang, J.H. New apparatus for measurement of stress effect onpermrability of unsatuarted soil. Chin. J. Rock. Mech. Eng. 2005, 1, 160–164. [Google Scholar]

- Wang, B.Z.; Wang, Q.C.; Zhang, R.L.; Xue, Y.J.; Cui, X.N. An experimental study of the permeability of undisturbed and remoldedmudstones under the loading condition. Hydrogeol. Eng. Geol. 2019, 46, 123–128. [Google Scholar]

- Gao, Z.J.; Ding, Z.Q.; Liu, J.T.; Liu, W.Y. Experimental study on the influencing factors of permeability of sand media. Hydrogeol. Eng. Geol. 2024, 51, 8–17. [Google Scholar]

- Miao, F.; Zhao, F.C.; Wu, Y.P.; Li, L.W.; Xue, Y.; Meng, J.J. A novel seepage device and ring-shear test on slip zone soils of landslide in the Three Gorges Reservoir area. Eng. Geol. 2022, 307, 06–779. [Google Scholar] [CrossRef]

- Li, B.; Ju, Y.J.; Song, B.; Zhang, K.D.; Hao, J.F. Study on the effect of fissures in expansive soils on permeability andengineering effects of canal slopes. Chin. J. Geol. Hazard Control 2024, 35, 137–144. [Google Scholar]

- Shu, L.S. Physical Geology, 3rd ed.; Geology Press: Beijing, China, 2008. [Google Scholar]

- Goktepe, A.B.; Sezer, A. Effect of particle shape on density and permeability of sands. P I Civ. Eng-Geotec 2010, 163, 307–320. [Google Scholar] [CrossRef]

- Ren, Y.B.; Wang, Y.; Yang, Q. Effects of particle size distribution and shape on permeability of calcareous sand. RSM 2018, 39, 491–497. [Google Scholar]

- Zhang, K.G.; Liu, S.Y. Soil Mechanics, 3rd ed.; China Construction Industry Press: Beijing, China, 2010. [Google Scholar]

- Khaldoun, A.; Eisre, E.; Wegdam, G.H.; Bonn, D. Liquefaction of quicksand under stress—A person trapped in salt-lake quicksand is not in any danger of being sucked under completely. Nature 2005, 437, 635. [Google Scholar] [CrossRef] [PubMed]

- Koltuk, S.; Fernandez-Steeger, T.M.; Azzam, R. Investigations on hydraulic heave in foundation pits excavated in homogeneous soils. Grundwasser 2016, 21, 203–215. [Google Scholar] [CrossRef]

- Zhang, G.M.; Zhang, K.; Wang, L.J.; Wu, Y. Mechanism of water inrush and quicksand movement induced by a borehole and measures for prevention and remediation. Bull. Eng. Geol. Environ. 2015, 74, 1395–1405. [Google Scholar] [CrossRef]

| Specimen Number | Percentage Content by Particle Size/% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0.08–0.09 | 0.09–0.14 | 0.14–0.21 | 0.21–0.43 | 0.43–0.71 | 0.71–1.18 | 1.18–2.00 | 2.00–4.00 | 4.00–8.00 | |

| 1# | 0 | 0 | 0 | 0 | 8 | 14 | 28 | 35 | 15 |

| 2# | 0 | 0 | 0 | 4 | 11 | 20 | 30 | 25 | 10 |

| 3# | 0 | 0 | 3 | 11 | 16 | 25 | 25 | 15 | 5 |

| 4# | 0 | 3 | 7 | 20 | 20 | 25 | 15 | 8 | 3 |

| 5# | 3 | 8 | 14 | 25 | 20 | 15 | 10 | 5 | 2 |

| Specimen Number | Water Injection Rate/(mL·min−1) | Water Temperature/°C | ||||

|---|---|---|---|---|---|---|

| Stage 1 | Stage 2 | Stage 3 | Stage 4 | Stage 5 | ||

| 1# | 25 | 50 | 100 | 150 | 200 | 20 |

| 2# | 25 | 50 | 100 | 150 | 200 | |

| 3# | 25 | 50 | 100 | 150 | 200 | |

| 4# | 25 | 50 | 100 | 150 | 200 | |

| 5# | 25 | 50 | 100 | 150 | 200 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Long, J.; Dong, R.; Zhang, K.; Weng, H.; Yi, Z. Investigating the Physical Mechanisms of Quicksand Using a Custom-Designed Experimental Apparatus. Appl. Sci. 2025, 15, 6415. https://doi.org/10.3390/app15126415

Long J, Dong R, Zhang K, Weng H, Yi Z. Investigating the Physical Mechanisms of Quicksand Using a Custom-Designed Experimental Apparatus. Applied Sciences. 2025; 15(12):6415. https://doi.org/10.3390/app15126415

Chicago/Turabian StyleLong, Jianhui, Rui Dong, Kaixin Zhang, Hangyu Weng, and Zhiqiang Yi. 2025. "Investigating the Physical Mechanisms of Quicksand Using a Custom-Designed Experimental Apparatus" Applied Sciences 15, no. 12: 6415. https://doi.org/10.3390/app15126415

APA StyleLong, J., Dong, R., Zhang, K., Weng, H., & Yi, Z. (2025). Investigating the Physical Mechanisms of Quicksand Using a Custom-Designed Experimental Apparatus. Applied Sciences, 15(12), 6415. https://doi.org/10.3390/app15126415