Effect of Moisture Content and Normal Impact Velocity on the Coefficient of Restitution of ‘Memory’ Wheat Grains

Abstract

Featured Application

Abstract

1. Introduction

- To capture and analyse the force–time curves of single-kernel impacts with high-frequency piezoelectric sensing and high-speed imaging;

- To determine how kernel moisture content and impact velocity influence ;

- To provide validated data for DEM calibration and for optimising grain-handling equipment so as to minimise mechanical damage during processing.

2. Collisions and the Coefficient of Restitution ( e)

2.1. Theoretical Background

- , —masses of the bodies;

- , —initial velocity vectors;

- , —final velocity vectors.

- e = 1—perfectly elastic; no kinetic energy is lost;

- 0 < e < 1—partially elastic; some energy is dissipated, but the bodies separate;

- e = 0—perfectly inelastic; the bodies stick together, and all translational kinetic energy is lost.

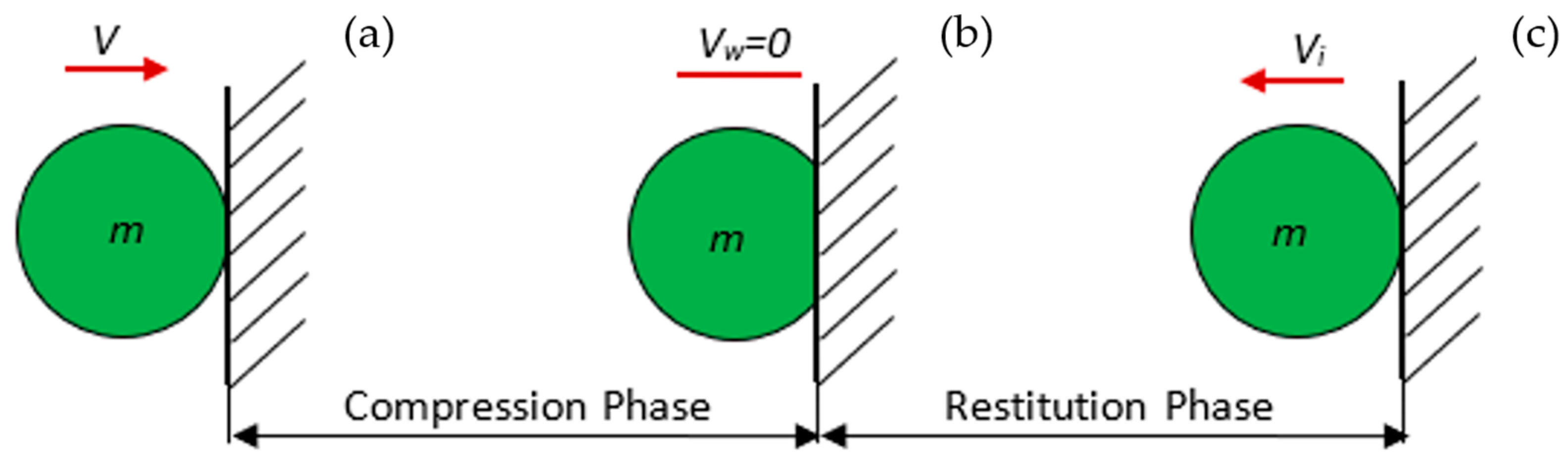

- Normal impact against an immovable plate

- e = 1—the particle rebounds with unchanged speed;

- e = 0—the particle comes to rest on the plate;

- 0 < e < 1—the particle rebounds with reduced speed.

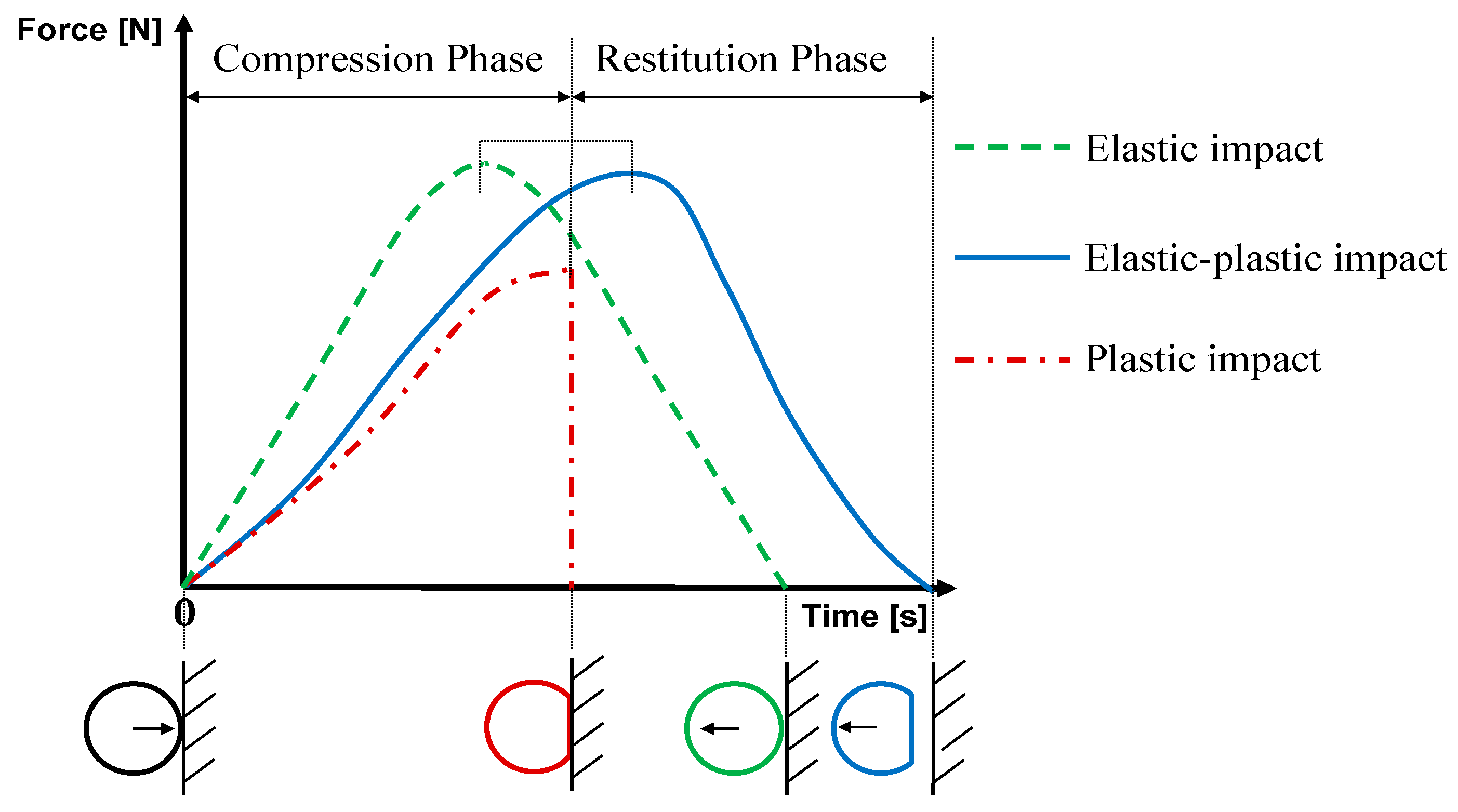

- Elasticity versus plasticity of wheat kernels

- Lower CoR;

- Longer contact times, because energy absorption prolongs the unloading phase.

2.2. Methods for Determining the Coefficient of Restitution (CoR, e)

- (a)

- Velocity-based method;

- (b)

- Height-based (drop-test) method;

- (c)

- Impulse-based (force-impulse) method.

2.2.1. Velocity-Based Method

2.2.2. Height-Based (Drop-Test) Method

- —coefficient of restitution (CoR);

- , —velocities just before and after impact;

- —drop height (release height);

- —rebound height.

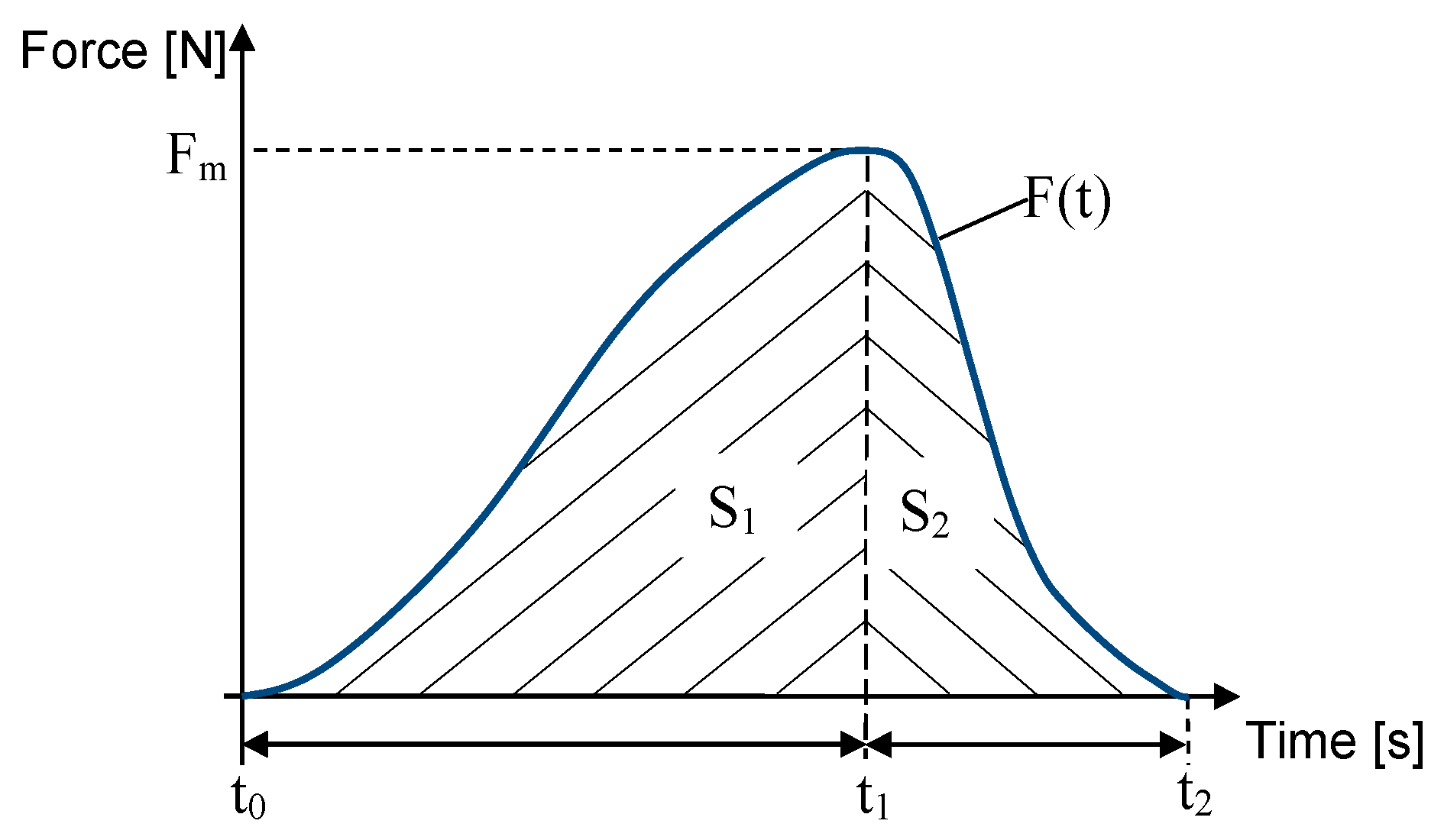

2.2.3. Impulse-Based Method

- e = 1—perfectly elastic: no kinetic-energy loss, full rebound;

- e = 0—perfectly inelastic: the bodies stick together, and all kinetic energy is dissipated;

- 0 < e < 1—partially elastic: some energy is lost during impact.

3. Experimental Study on the Coefficient of Restitution of Wheat Grains

3.1. Factors Influencing Determination of the Coefficient of Restitution

- Impact velocity, which directly affects , can be controlled in two common ways: (i) a calibrated spring launcher [29] or (ii) varying the drop height, a method widely used with wheat grains [23,28]. The latter approach produces velocities of 1–5 m s−1 with good repeatability while preserving the grain’s initial state.

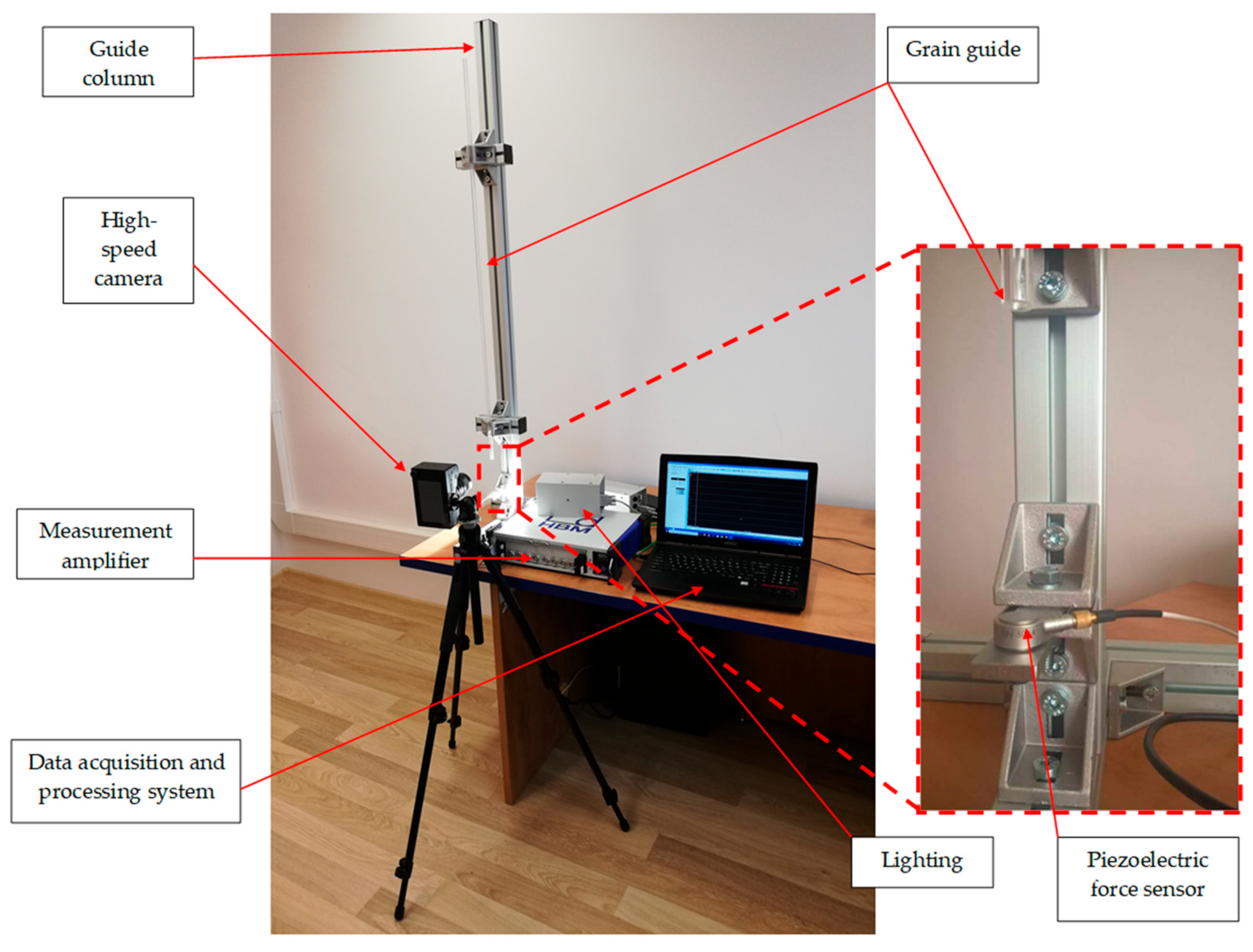

3.2. Experimental Test Stand

- Aluminium support frame;

- Transparent grain guide that ensured precise positioning and release;

- Piezoelectric force sensor (sensitivity 112.41 mV N−1; range 44.48 N);

- High-speed camera with dedicated lighting for tracking grain motion and velocity;

- HBM measurement amplifier sampling at 1 MHz;

- Computer with acquisition and analysis software.

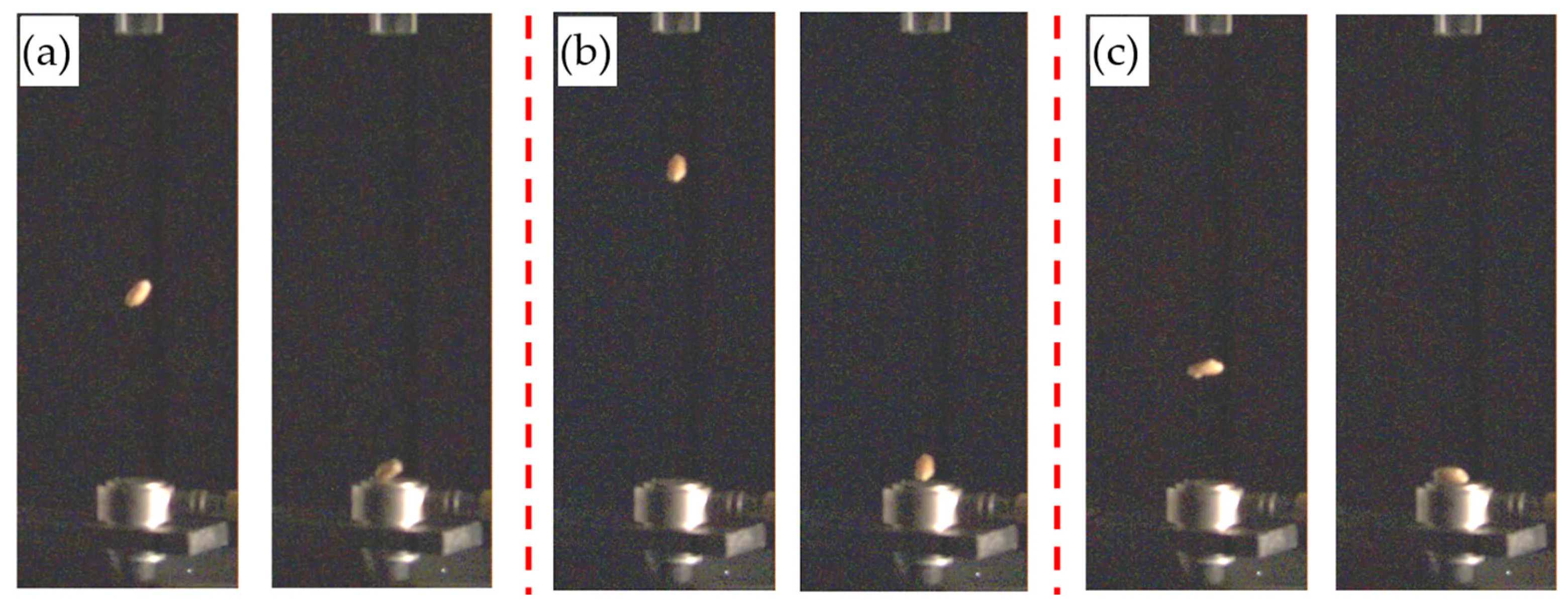

3.3. Pre-Collision Velocity Measurement

- Free-fall through a guide tube: Each grain was dropped through a vertical polycarbonate tube (internal diameter 5 mm). Preliminary tests confirmed that this diameter suppressed lateral movement and matched the geometry of ‘Memory’ grains.

- Visual inspection: Every drop was filmed with a high-speed camera (8816 fps). Trajectories were reviewed frame-by-frame, and grains showing visible rotation or instability were discarded.

- Reduction of random effects: a large sample was tested, providing statistical stabilisation of the results.

- Method validation by repeatability tests: From each moisture level, 20 grains were re-measured. The resulting values differed by no more than ±0.02, confirming high repeatability. All calibration and uncertainty estimates followed ISO GUM guidelines.

3.4. Measurement Accuracy Determination

3.5. Characteristics of Research Samples

- Grain mass: determined with an analytical balance (RADWAG PS 1000/Y; accuracy ±0.001 g); 200 randomly selected grains were weighed individually on a controlled surface.

- Moisture content: measured with a moisture analyser (RADWAG MA 200.3Y WH.B) and the routine reference method for cereals (PN-EN ISO 712:2009), which dries a prepared analytical sample at 130 °C.

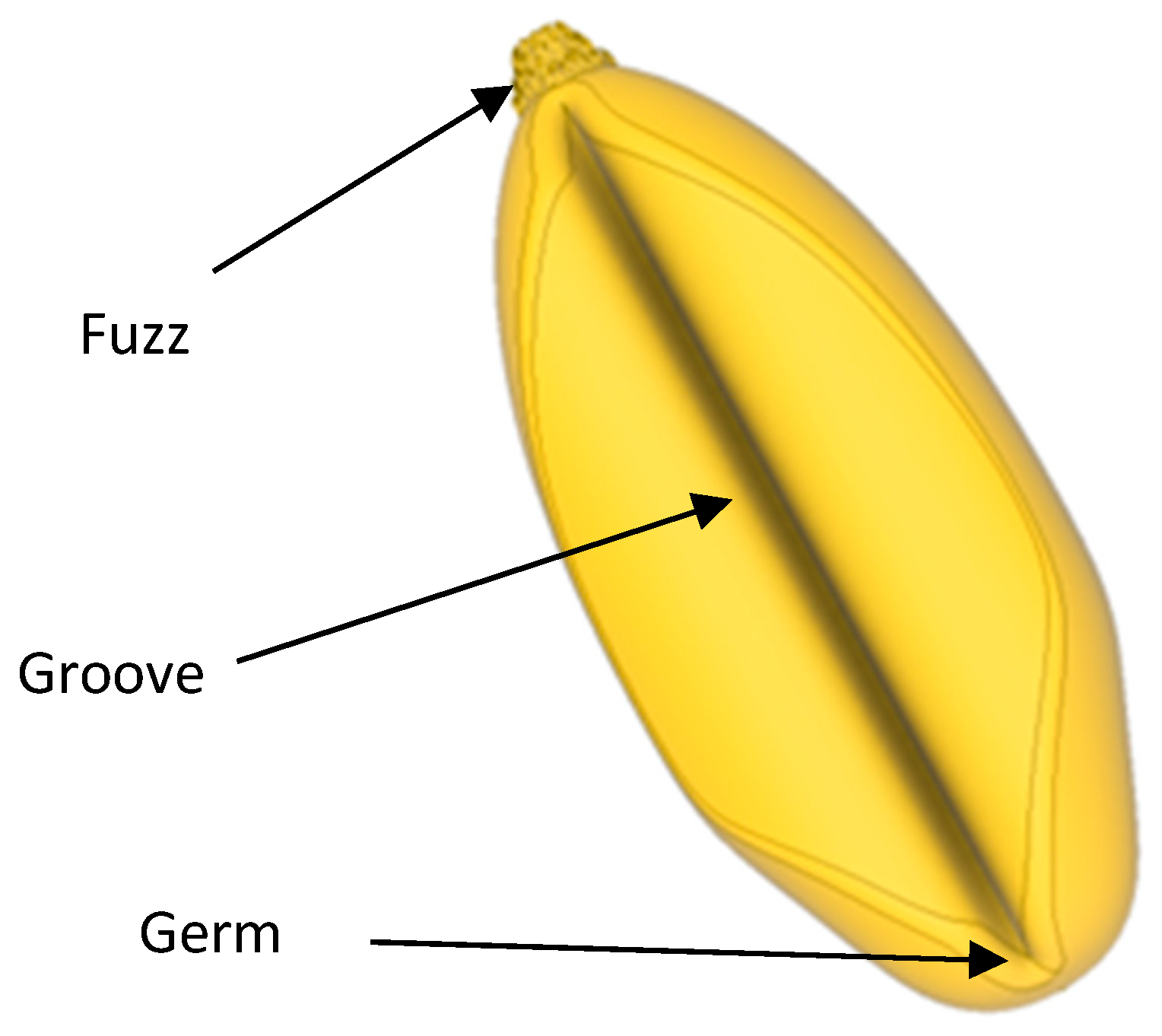

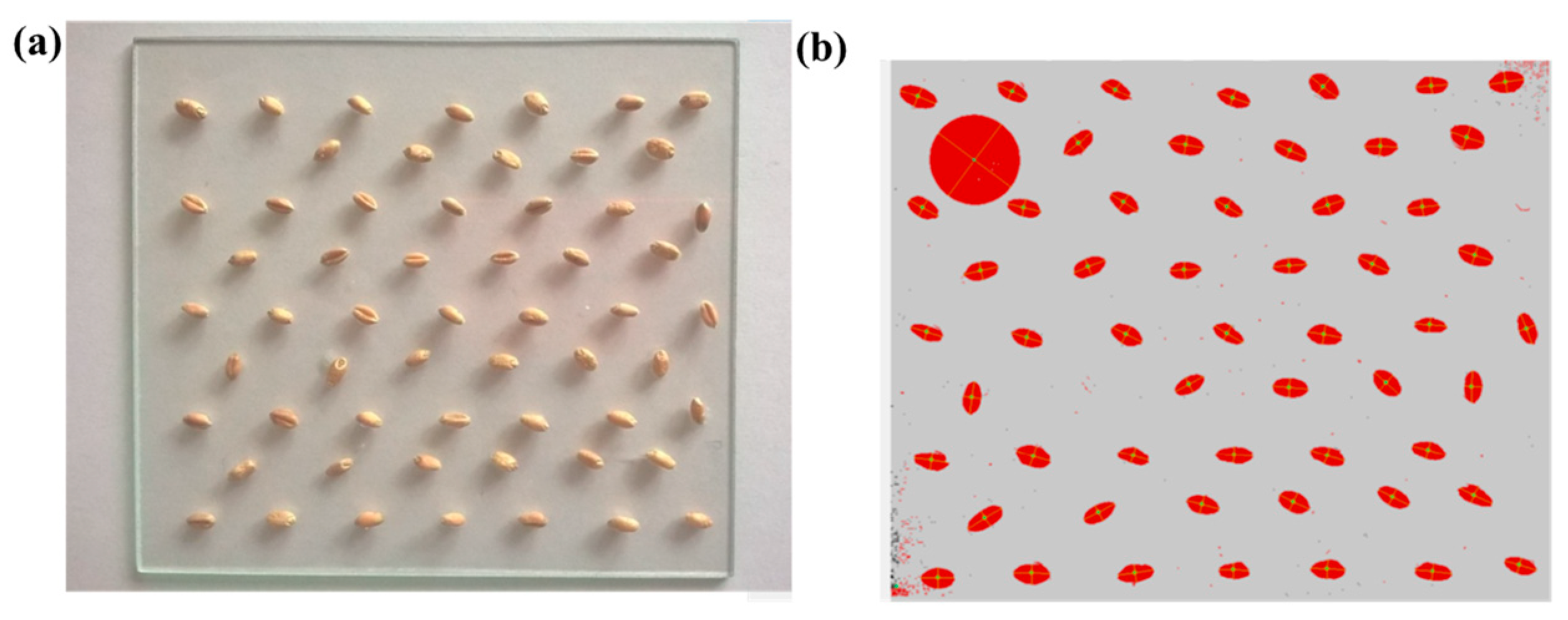

- Principal dimensions: obtained by a photogrammetric method. High-contrast images were captured on a custom light table that provided back-lighting of the samples, then processed with GABAR software 1.0 developed at the Department of Working Machines, Poznań University of Technology (Figure 8a). Mean values and standard deviations of grain length, width and thickness were recorded.

- Average grain mass: 0.045 ± 0.008 g;

- Baseline moisture content: 7%;

- Grain length: 6.41 ± 0.50 mm;

- Grain width: 3.04 ± 0.38 mm.

- —mass of the missing water,

- M—mass of the grain,

- —initial moisture level,

- —target moisture level.

3.6. Research Plan

4. Results

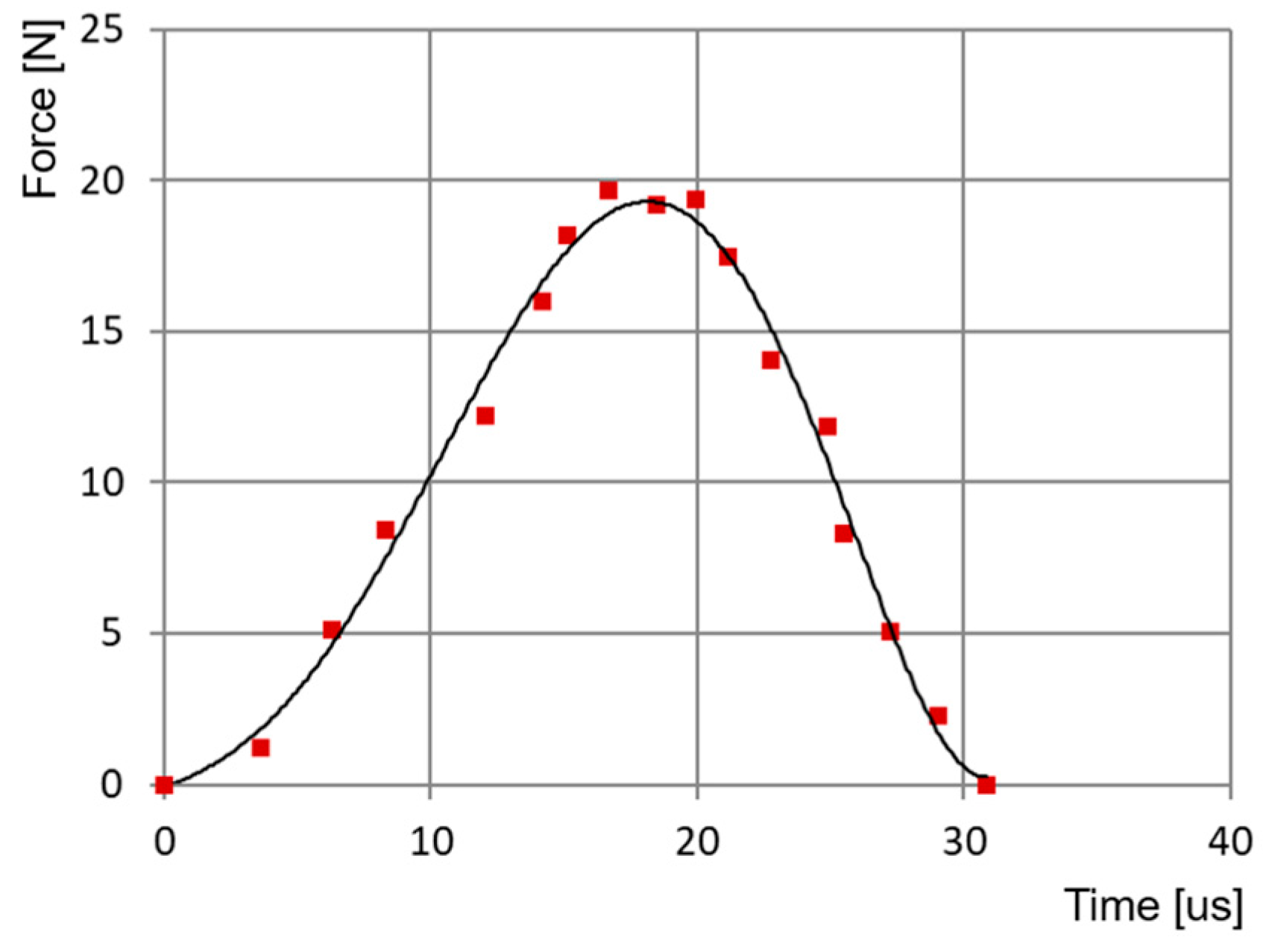

4.1. Identification of Contact Force in Collision of Wheat Grains with a Flat Metal Surface

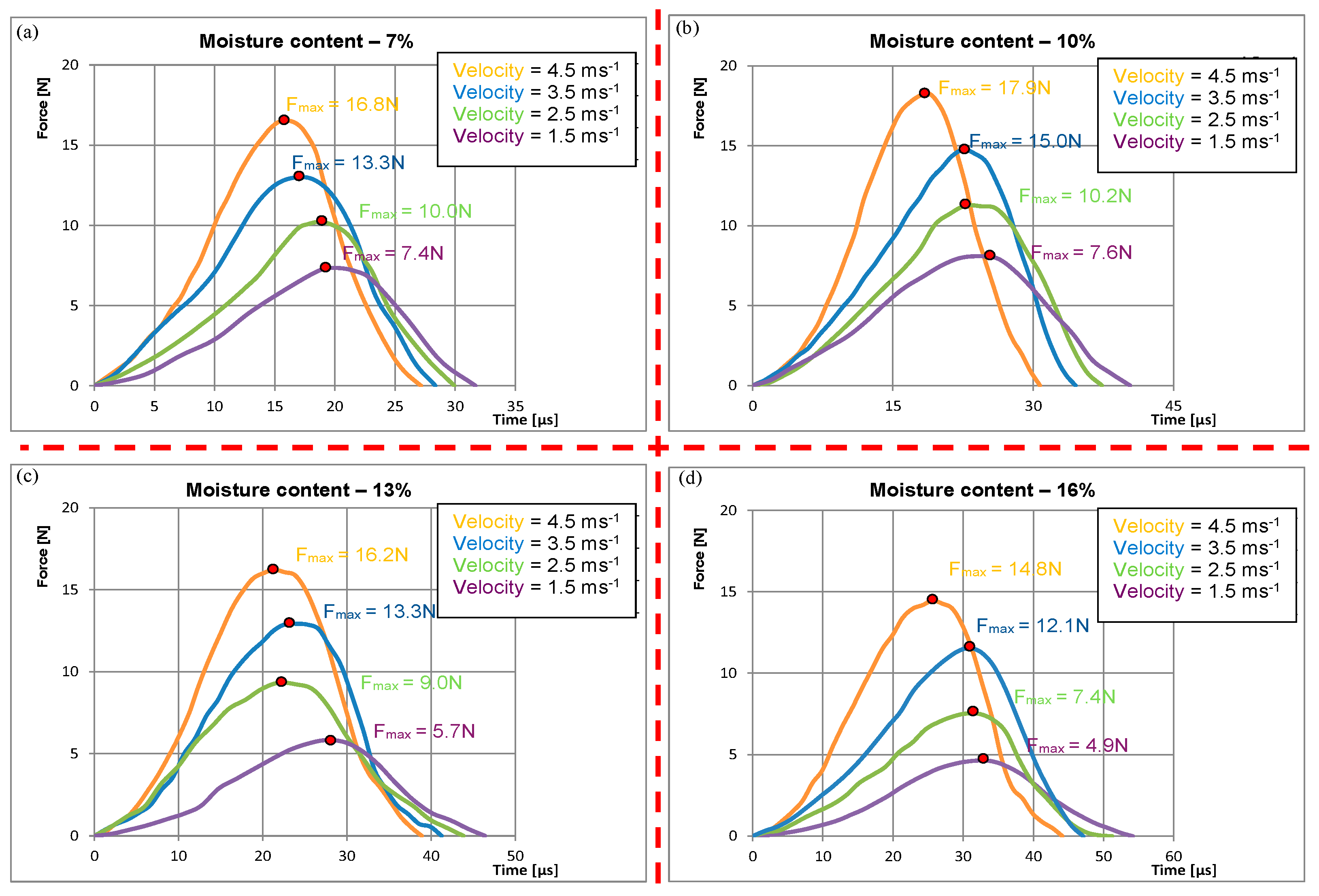

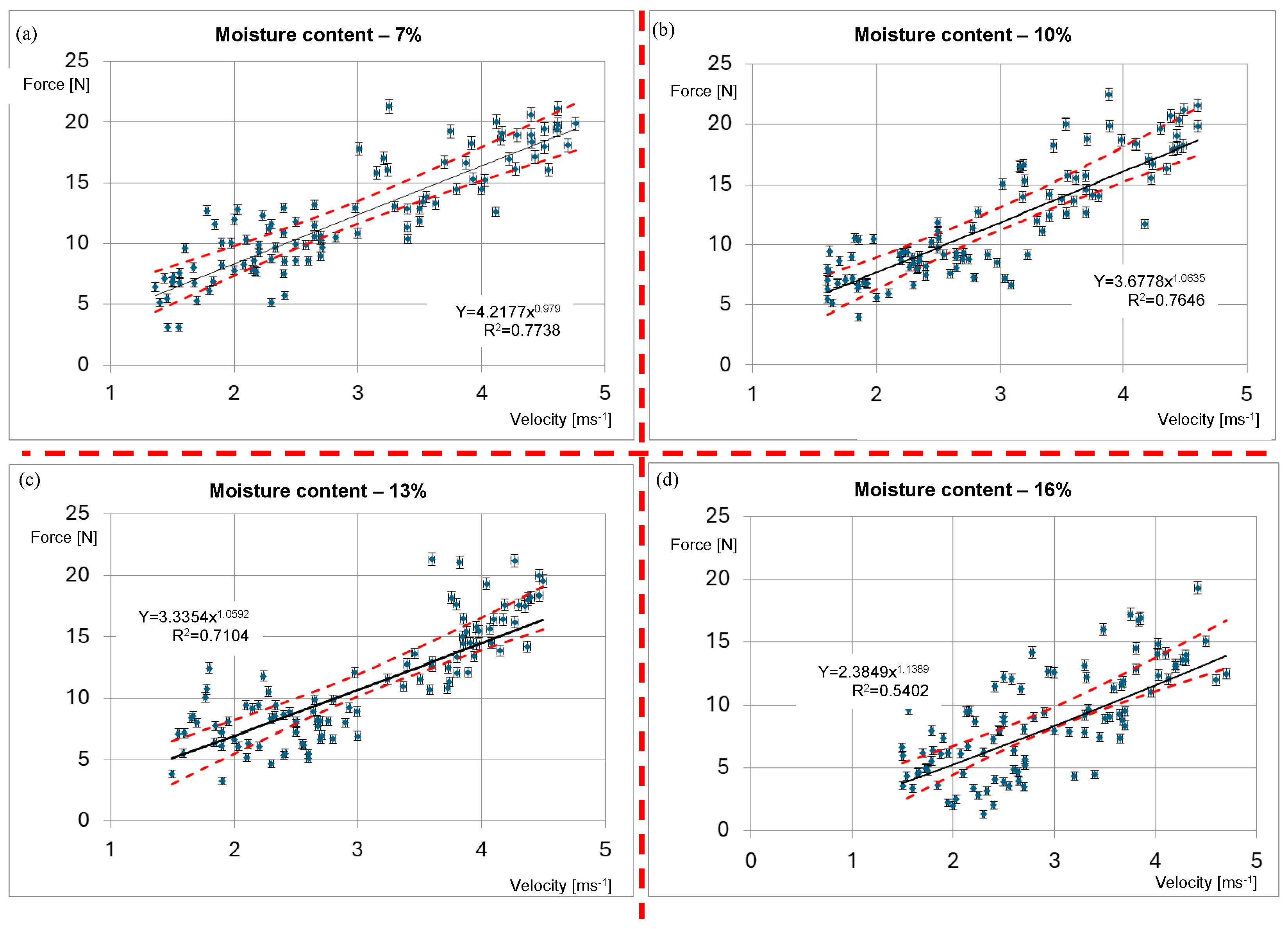

4.2. Identification of the Relationship Between Maximum Contact Force and Collision Time at Different Moisture Levels

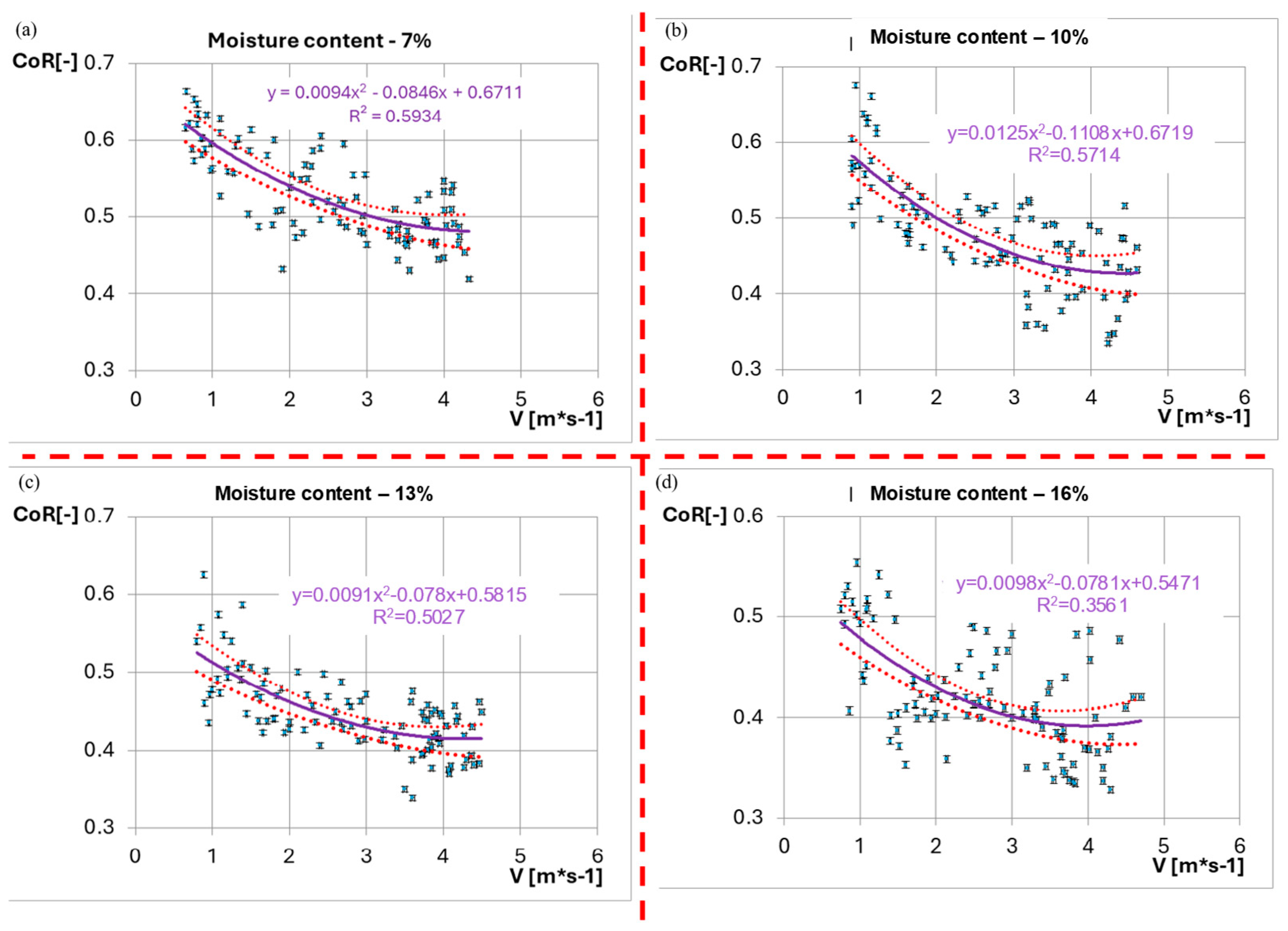

5. Evaluation of Coefficient of Restitution (CoR)

5.1. Data Processing

5.2. Results and Interpretation

5.3. Practical Significance of the Results

- Moisture content: A strong correlation exists between CoR and grain moisture, as illustrated in Figure 14; for the ‘Memory’ wheat variety, structural damage is markedly lower when moisture remains below 10%. Higher moisture significantly increases plastic deformation and internal damping, thereby lowering the CoR and prolonging contact time during impact.

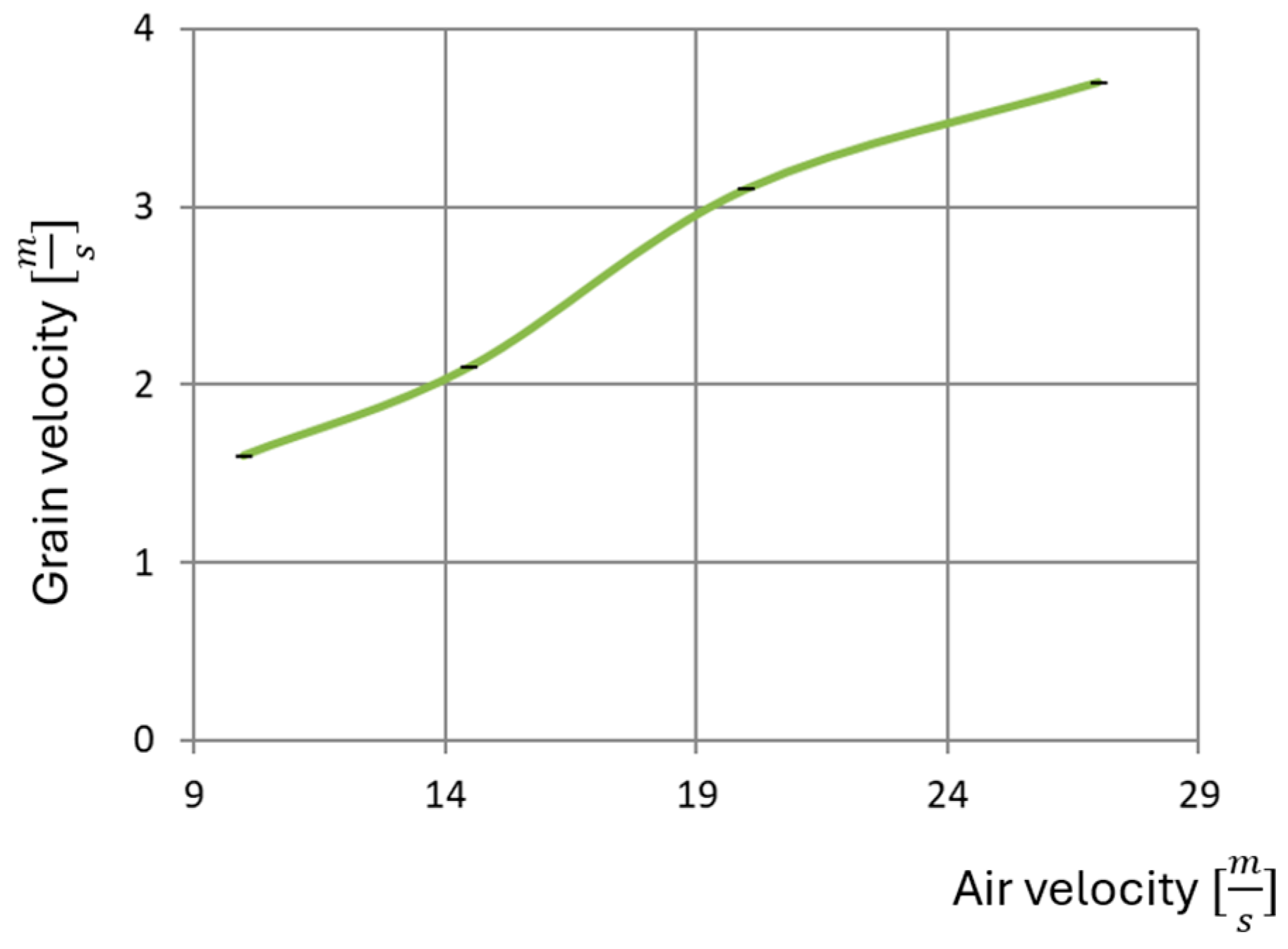

- Impact velocity: Grain-surface impact velocity is another critical factor, particularly when selecting transport speeds in pneumatic conveying systems such as seed drills. In this study, CoR decreased from 0.6 to 0.4–0.5 as velocity rose from 1.0 to 5.0 m·s−1 (Figure 8). High-moisture kernels impacted at higher velocities are therefore especially vulnerable to internal mechanical damage.

- Equipment design: Impact dynamics also inform equipment design. Machine contact surfaces (e.g., metal plates, guides or rotary components) should absorb part of the impact energy or distribute forces evenly. Using slightly elastic materials and non-perpendicular geometries can help to minimise grain damage under operating conditions.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Curtis, B.C. Wheat in the World. In Bread Wheat Improvement and Production; Curtis, B.C., Rajaram, S., Macpherson, H.G., Eds.; Plant Production and Protection Series 30; FAO: Roma, Italy, 2002; pp. 1–18. ISBN 92-5-104809-6. [Google Scholar]

- Iwańska, M.; Paderewski, J.; Stępień, M.; Rodrigues, P.C. Adaptation of Winter Wheat Cultivars to Different Environments: A Case Study in Poland. Agronomy 2020, 10, 632. [Google Scholar] [CrossRef]

- Chen, Z.; Wassgren, C.; Ambrose, R. Measured damage resistance of corn and wheat kernels to compression, friction, and repeated impacts. Powder Technol. 2020, 380, 638–648. [Google Scholar] [CrossRef]

- Stronge, W. Impact Mechanics, 2nd ed.; Cambridge University Press: Cambridge, UK, 2018; ISBN 9781139050227. [Google Scholar] [CrossRef]

- Glenn, G.M.; Younce, F.L.; Pitts, M.J. Fundamental physical properties characterizing the hardness of wheat endosperm. J. Cereal Sci. 1991, 13, 179–194. [Google Scholar] [CrossRef]

- Mousaviraad, M.; Tekeste, M. Effect of grain moisture content on physical, mechanical, and bulk dynamic behaviour of maize. Biosyst. Eng. 2020, 195, 186–197. [Google Scholar] [CrossRef]

- Marcinkiewicz, J. Modelowanie sił Kontaktowych w Układzie ZIARNO roślinne–Powierzchnia Zespołu Roboczego w Aspekcie Zjawisk o Przebiegu Dynamicznym. Doctoral Dissertation, Politechnika Poznańska, Poznań, Poland, 2023. [Google Scholar]

- Fan, Y.; Wang, H.; Zhou, T.; Zou, L.; Jiang, Z.; Hu, M. Prediction of Coefficient of Restitution for Impact Elastoplastic Spheres Considering Finite Plate Thickness. Chin. J. Mech. Eng. 2024, 37, 91. [Google Scholar] [CrossRef]

- Haug, E.J.; Wu, S.C.; Yang, S.M. Dynamics of mechanical systems with coulomb friction, stiction, impact and constraint addition deletion—I theory. Mech. Mach. Theory 1986, 21, 401–406. [Google Scholar] [CrossRef]

- Hu, G.; Hu, Z.; Jian, B.; Liu, L.; Wan, H. On the determination of the damping coefficient of non-linear spring-dashpot system to model Hertz contact for simulation by discrete element method. J. Comput. 2011, 6, 984–988. [Google Scholar] [CrossRef]

- Ivanov, A.P. Dynamics of Systems with Mechanical Collisions; Mezhdunarodnaya Programma Obrazovaniya: Moscow, Russia, 1997. (In Russian) [Google Scholar]

- Panovko, Y.G. Introduction to the Theory of Mechanical Impact; Nauka: Moscow, Russia, 1977. (In Russian) [Google Scholar]

- Wriggers, P. Computational Contact Mechanics, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2006; ISBN -13: 978-0-471-49680-9. [Google Scholar] [CrossRef]

- Flickinger, D.M.; Bowling, A. Simultaneous oblique impacts and contacts in multibody systems with friction. Multibody Syst. Dyn. 2010, 23, 249–261. [Google Scholar] [CrossRef]

- Rodriguez, A.; Bowling, A. Solution to indeterminate multipoint impact with frictional contact using constraints. Multibody Syst. Dyn. 2012, 28, 313–330. [Google Scholar] [CrossRef]

- Goldsmith, W. Impact: The Theory and Physical Behaviour of Colliding Solids; Edward Arnold Ltd.: London, UK, 1960. [Google Scholar]

- Li, Y.; Qiu, X.; Zhang, X. Different definitions and corresponding applicabilities of the coefficient of restitution. Mech. Eng. 2015, 37, 773–777. [Google Scholar] [CrossRef]

- Gao, Z.; Lu, C.; Li, H.; He, J.; Wang, Q.; Huang, S.; Li, Y.; Zhan, H. Measurement Method of Collision Restitution Coefficient between Corn Seed and Soil Based on the Collision Dynamics Theory of Mass Point and Fixed Surface. Agriculture 2022, 12, 1611. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, M. Measurement and analysis of restitution coefficient between maize seed and soil based on high-speed photography. Int. J. Agric. Biol. Eng. 2017, 10, 113–118. [Google Scholar]

- Liu, Y.; Zong, W.Y.; Ma, L.N. Determination of 3D collision recovery coefficient of oil sunflower seeds by high-speed photography. Trans. Chin. Soc. Agric. Eng. 2020, 36, 44–53. [Google Scholar]

- Sandeep, C.S.; Senetakis, K.; Cheung, D.; Choi, C.E.; Wang, Y.; Coop, M.R.; Ng, C.W.W. Experimental study on the coefficient of restitution of grain against block interfaces for natural and engineered materials. Can. Geotech. J. 2021, 58, 35–48. [Google Scholar] [CrossRef]

- Szwed, G.; Pecen, J. Wyniki badań współczynnika restytucji niektórych nasion roślin uprawnych. Inżynieria Rol. 2006, 4, 289–295. [Google Scholar]

- Wang, C.; Li, Y.; Ma, L.; Ma, Z. Experimental study on measurement of restitution coefficient of wheat seeds in collision models. Trans. Chin. Soc. Agric. Eng. 2012, 28, 274–279. [Google Scholar] [CrossRef]

- Horabik, J.; Beczek, M.; Molenda, M. Determination of the restitution coefficient of seeds and coefficients of visco-elastic Hertz contact models for DEM simulations. Biosyst. Eng. 2017, 161, 106–119. [Google Scholar] [CrossRef]

- Mi, G.; Liu, Y.; Wang, T.; Dong, J.; Zhang, S.; Li, Q.; Chen, K.; Huang, Y. Measurement of Physical Properties of Sorghum Seeds and Calibration of Discrete Element Modeling Parameters. Agriculture 2022, 12, 681. [Google Scholar] [CrossRef]

- Yu, K.; Elghannay, H.A.; Tafti, D. An impulse based model for spherical particle collisions with sliding and rolling. Powder Technol. 2017, 319, 102–116. [Google Scholar] [CrossRef]

- Wang, L.; Yang, H.; Wang, Z.; Wang, Q.; Lu, C.; Wang, C.; He, J. Calibration of DEM Polyhedron Model for Wheat Seed Based on Angle of Repose Test and Semi-Resolved CFD-DEM Coupling Simulation. Agriculture 2025, 15, 506. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, W.; Wang, F.; Liu, Y.; Zhao, B.; Fang, X. Experimental Analysis and Verification of the Influence on the Elastic Recovery Coefficient of Wheat. Appl. Sci. 2023, 13, 5481. [Google Scholar] [CrossRef]

- Wang, J.; Xu, C.; Xu, Y.; Wang, Z.; Qi, X.; Wang, J.; Zhou, W.; Tang, H.; Wang, Q. Influencing Factors Analysis and Simulation Calibration of Restitution Coefficient of Rice Grain. Appl. Sci. 2021, 11, 5884. [Google Scholar] [CrossRef]

- Wang, L.; Zheng, Z.; Yu, Y.; Liu, T.; Zhang, Z. Determination of the energetic coefficient of restitution of maize grain based on laboratory experiments and DEM simulations. Powder Technol. 2020, 362, 645–658. [Google Scholar] [CrossRef]

- Wang, L.; Wu, B.; Wu, Z.; Li, R.; Feng, X. Experimental determination of the coefficient of restitution of particle-particle collision for frozen maize grains. Powder Technol. 2018, 338, 263–273. [Google Scholar] [CrossRef]

- Qiu, Y.-K.; An, J.-H.; Yi, M.-L.; Luo, J.-R.; Wang, L.-Z.; Tu, J.; Zhou, Z.-M.; Huang, C. Effect of grain size on mechanical property, friction and wear property and corrosion property of CoCrNi medium-entropy alloy. Zhongguo Youse Jinshu Xuebao/Chin. J. Nonferrous Met. 2023, 33, 1890–1901. [Google Scholar]

- Jiang, J.; Sun, W.; Luo, N. Atomic insights into effects of temperature and grain diameter on the micro-deformation mechanism, mechanical properties and sluggish diffusion of nanocrystalline high-entropy alloys. Mater. Today Commun. 2022, 33, 104224. [Google Scholar] [CrossRef]

- Figueroa, J.D.C.; Hernández, Z.J.E.; Véles, M.J.J.; Duarte, P.R.; Martínez-Flores, H.E.; Ponce-García, N. Evaluation of degree of elasticity and other mechanical properties of wheat kernels. Cereal Chem. 2011, 88, 12–18. [Google Scholar] [CrossRef]

- Ahmed, M.; Hassan, F.U. Cumulative effect of temperature and solar radiation on wheat yield. Not. Bot. Horti Agrobot. Cluj-Napoca 2011, 39, 146–152. [Google Scholar] [CrossRef]

- Lai, H.W.; Chow, M.W.K.; Ma, C.K.; Yan, A.Y.K. Calibration of the Frame Rate of High-Speed Digital Video Recorders by Stationary Counting Method. NCSLI Meas. 2018, 12, 38–44. [Google Scholar] [CrossRef]

- Yu, C.K.; Hsieh, P.R.; Yuter, S.E.; Cheng, L.W.; Tsai, C.L.; Lin, C.Y.; Chen, Y. Measuring droplet fall speed with a high-speed camera: Indoor accuracy and potential outdoor applications. Atmos. Meas. Tech. 2016, 9, 1755–1766. [Google Scholar] [CrossRef]

- Sun, J.; Si, H.; Li, X.; Guo, Y. Measurement test and analysis on the restitution coefficient of the coarse cereals grain. J. Chin. Agric. Mech. 2020, 41, 88–93. [Google Scholar] [CrossRef]

- Wojtkowski, M.; Pecen, J.; Horabik, J.; Molenda, M. Rapeseed Impact Against a Flat Surface: Physical Testing and DEM Simulation with Two Contact Models. Powder Technol. 2010, 204, 196–206. [Google Scholar] [CrossRef]

- Guide to the Expression of Uncertainty in Measurement (GUM). ISO/IEC/OIML/BIPM, last ed. BIPM JCGM 100 2008. Available online: https://www.bipm.org/documents/20126/2071204/JCGM_100_2008_E.pdf (accessed on 30 December 2024).

- Janiczek, R. Metody Oceny Niepewności Pomiarów; Pracownia Komputerowa Jacka Skalmierskiego: Katowice, Poland; Gliwice, Poland, 2008. [Google Scholar]

- Tahereh, N.; Heydari, M.M.; Meda, V. Combination of germination and innovative microwave-assisted infrared drying of lentils: Effect of physicochemical properties of different varieties on water uptake, germination, and drying kinetics. Appl. Food Res. 2022, 2, 100040. [Google Scholar] [CrossRef]

- Alizadeh, E.; Bertrand, F.; Chaouki, J. Development of a granular normal contact force model based on a non- Newtonian liquid filled dashpot. Powder Technol. 2013, 237, 202–212. [Google Scholar] [CrossRef]

- Oomah, B.D.; Ward, S.; Balasubramanian, P. Dehulling and selected physical characteristics of Canadian dry bean (Phaseolus vulgaris L.) cultivars. Food Res. Int. 2010, 43, 1410–1415. [Google Scholar] [CrossRef]

- Segler, G. Pneumatic Grain Conveying; National Institute of Agricultural Engineering: Silsoe, UK, 1951. [Google Scholar]

- Gierz, Ł.; Kęska, W.; Gierz, S. Badania laboratoryjne czasu transportu ziarna pszenicy w przewodzie nasiennym siewnika. J. Res. Appl. Agric. Eng. 2012, 57, 37–40. [Google Scholar]

- Gierz, Ł.; Kęska, W. Badania symulacyjne i laboratoryjne czasu transportu ziarna rzepaku w przewodzie nasiennym siewnika. J. Res. Appl. Agric. Eng. 2012, 57, 73–78. [Google Scholar]

- Li, X.F.; Liu, F.; Zhao, M.Q. Determination of contact parameters between maize seeds and seeders. J. Agric. Mech. Res. 2018, 40, 149–153. [Google Scholar]

- Kong, F.T.; Shi, L.; Zhang, Y.T. Determination and analysis of recovery coefficient in seed cotton collision model. China Agric. Sci. Technol. Rev. 2019, 21, 92–99. [Google Scholar]

- Zhang, Y.; Liu, F.; Zhao, M.Q. Experimental study on Physical and mechanical characteristics of Mung bean. J. Agric. Mech. Res. 2017, 39, 119–124. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marcinkiewicz, J.; Ślaski, G.W.; Spadło, M. Effect of Moisture Content and Normal Impact Velocity on the Coefficient of Restitution of ‘Memory’ Wheat Grains. Appl. Sci. 2025, 15, 6055. https://doi.org/10.3390/app15116055

Marcinkiewicz J, Ślaski GW, Spadło M. Effect of Moisture Content and Normal Impact Velocity on the Coefficient of Restitution of ‘Memory’ Wheat Grains. Applied Sciences. 2025; 15(11):6055. https://doi.org/10.3390/app15116055

Chicago/Turabian StyleMarcinkiewicz, Jacek, Grzegorz Waldemar Ślaski, and Mikołaj Spadło. 2025. "Effect of Moisture Content and Normal Impact Velocity on the Coefficient of Restitution of ‘Memory’ Wheat Grains" Applied Sciences 15, no. 11: 6055. https://doi.org/10.3390/app15116055

APA StyleMarcinkiewicz, J., Ślaski, G. W., & Spadło, M. (2025). Effect of Moisture Content and Normal Impact Velocity on the Coefficient of Restitution of ‘Memory’ Wheat Grains. Applied Sciences, 15(11), 6055. https://doi.org/10.3390/app15116055