1. Introduction

Gas Carrier Tankers (GCTs), which play a critical role in the global energy supply chain as energy demand increases, are specially designed maritime vessels. They ensure the safe and efficient transport of gas products such as Liquefied Natural Gas (LNG) and Liquefied Petroleum Gas (LPG) under low temperature or low-pressure conditions, offering significant advantages in terms of efficiency and energy density in global energy logistics. The International Maritime Organization (IMO) plays a central role in formulating and enforcing international standards for the maritime transport of LNG and LPG. Among these, the International Gas Carrier Code (IGC Code) is a critical regulatory framework that prescribes detailed safety and design criteria for ships used in the transport of liquefied gases [

1]. However, the inherently hazardous nature of these substances requires stringent operational standards and continuous risk monitoring [

2]. By their very nature, gas tanker operations present several safety and environmental hazards, including fire and explosion, structural failure, and toxic gas emissions [

3]. The complexity of these operations requires a multidisciplinary safety assessment that considers not only technological and procedural factors but also human and environmental elements [

1,

4].

Considering the pivotal function of gas carrier operations, it is imperative to employ state-of-the-art methodologies for managing associated risks. While traditional safety protocols remain important, they frequently fail to consider the complex and evolving nature of maritime operations [

5]. Consequently, there is an increasing necessity for data-driven risk evaluation techniques, including hybrid models, to assess and mitigate potential hazards more effectively [

6].

Given the increasing intricacy of operations involving gas carriers and the limitations of conventional safety measures, there is a compelling need to adopt more advanced risk management models [

1]. These models offer a more profound understanding of how diverse risks interact, thereby enabling enhanced anticipation and mitigation of emergent threats. Moreover, the integration of such techniques has been demonstrated to facilitate the identification of both immediate dangers and underlying systemic issues that have the potential to result in major accidents [

7]. A forward-thinking approach is imperative for the protection of personnel and vessels, as well as for the safeguarding of the environment. This is particularly crucial in the context of the ongoing increase in global demand for energy [

5].

It is vital to acknowledge the pressing necessity for a comprehensive risk management framework, as evidenced by several high-profile accidents involving GCTs. Notable incidents include the explosion of the M/T SYN ZANIA at PETKIM Terminal and the Kerch Strait incident involving the Maestro and Candy vessels. These incidents, frequently precipitated by technical malfunctions such as hose failures or ignition source malfunctions, underscore the vulnerability of gas tanker operations to both operational faults and systemic oversights [

8]. Moreover, the risk landscape is further exacerbated by factors such as corrosion-induced degradation, inadequate safety systems, and failure to comply with international maritime safety protocols [

4].

The consequences of such accidents are not limited to economic loss and human casualties but also encompass significant environmental impacts [

9,

10]. The uncontrolled release of liquefied gases into the atmosphere can result in significant environmental concerns, including atmospheric pollution, and pose a threat to the health of port personnel and nearby populations [

11,

12]. Furthermore, in confined and poorly ventilated areas, the flammable and toxic nature of these gases significantly increases the risk of catastrophic events, such as Boiling Liquid Expanding Vapor Explosions (BLEVE) and Unconfined Vapor Cloud Explosions (UVCE) [

1,

13,

14].

Even though a considerable number of studies have been conducted on individual risk categories in gas tanker operations, with a particular focus on explosion risk analysis, fuel leakage mechanisms, and operational safety procedures, there remains a paucity of holistic approaches that simultaneously address the interplay of these factors [

11]. In particular, the extant literature frequently fails to consider the interdependence and cumulative effects of mechanical, human, and environmental risks. This finding is of particular significance when considering the possibility of a domino effect in accident progression.

To address this gap, the present study proposes a novel hybrid risk assessment model that integrates the Fuzzy Delphi Method, Fuzzy DEMATEL, and Fault Tree Analysis (FTA). This integrated approach facilitates the identification and prioritisation of risks based on expert judgment. It also enables the mapping of causal relationships among risks and the simulation of potential accident scenarios. The objective of this study is to enhance the predictive capability of existing models and to support gas tanker operators in developing more robust and proactive safety strategies.

The subsequent sections of the paper are structured as follows:

Section 2 provides a comprehensive review of the extant literature on gas tanker safety, explosion risk, leakage control, and operational protocols. The third section delineates the methodological framework and provides a rationale for the utilisation of Fuzzy Delphi, Fuzzy DEMATEL, and FTA methodologies. The findings derived from expert input and modelling are presented in

Section 4. A discussion of the implications and limitations is offered in

Section 5. Finally,

Section 6 concludes with recommendations for improving operational safety and future research directions.

3. Methodology

The methods employed in this study were conducted within a three-stage process. In the initial phase, the Fuzzy Delphi method was employed to ascertain the criteria and factors. Subsequently, the Fuzzy DEMATEL method was employed to analyse the interaction levels between the most critical factors identified. This method was employed to elucidate the direction and intensity (effect, reaction, or neutral) of the relationship between the factors. In the final stage, the data obtained from the Fuzzy DEMATEL method were evaluated using the Fault Tree Analysis (FTA). This enabled the calculation of the probability of events and accidents, as well as the determining of the relationships between risks. Consequently, a combination of three methods was developed to ascertain the probability of accidents in gas tankers.

In this study, the fuzzy DEMATEL method was selected as the primary approach for investigating the causal relationships between factors during the development of the FTA method. DEMATEL is a valuable tool for determining the ‘AND’ and ‘OR’ gates in FTA, as it facilitates analysis of the factors that affect others and those that are affected. Consequently, a more meaningful fault tree structure can be created based on the relationships between risk factors. Citation [

34] analysed the barriers to digitalisation in businesses using a similar approach and demonstrated that the combined use of these methods yields effective results. Citation [

35] Furthermore, DEMATEL has been demonstrated to be a valuable tool in elucidating the interrelationships between failures in Failure Modes and Effect Analysis (FMEA). Furthermore, citation [

36] combined DEMATEL with FMEA and a reality scheme to enhance comprehension of cause-effect relationships. Citation [

37] proposes the utilisation of DEMATEL as a complementary tool to methods such as FTA and FMEA. In this context, the relationship network obtained using DEMATEL in our study helps to create consistent logical gates in FTA. Citation [

34] analysed the barriers to digitalisation in businesses using a similar approach and demonstrated that the combined use of these methods yields effective results.

The primary rationales for employing these methodologies in conjunction can be outlined as follows: The Fuzzy Delphi method is a systematic approach to opinion collection and criterion determination with the objective of creating an evaluation environment. The Fuzzy DEMATEL method is one of the Multi-Criteria Decision-Making (MCDM) techniques that has been extensively utilised in the literature to ascertain the direction of relationships (influence (+), reaction (−), or neutral) by identifying the interactions between factors [

38,

39]. When utilising FTA analysis in conjunction with Fuzzy DEMATEL, it is imperative to establish a linkage between the relationships inherent within cause-and-effect factors, as delineated by the Fuzzy DEMATEL, and the broader context of FTA analysis. The FTA method has emerged as an increasingly prevalent analytical approach for calculating accident and event probabilities in recent years.

A review of the extant literature reveals an absence of research in which these three methods have been integrated and used in unison. Despite the existence of prior studies grounded in binary combinations, such as Fuzzy Delphi-DEMATEL, Fuzzy DEMATEL-FTA, or FTA-FMA, a comprehensive analysis that integrates the Fuzzy Delphi, Fuzzy DEMATEL, and FTA methods has yet to be presented. In the study [

40], a combined approach using fuzzy DEMATEL and cloud model approach for risk assessment in process industries to improve system reliability. Fuzzy DEMATEL analysis was applied to determine the relationships between evaluation indices and calculate their weights. Subsequently, an alternative method was employed to calculate the risk levels of the evaluation indices and determine the comprehensive risk level. The present study contributes to the existing literature by combining Fuzzy DEMATEL and Fault Tree Analysis. The flowchart of the study is shown in

Figure 1 below.

3.1. Fuzzy Delphi Method

The Delphi method, a hallmark of traditional research practice, endeavours to reach a consensus on intricate issues by collating expert opinions through successive survey rounds [

41]. Nevertheless, it is important to note that conducting consecutive surveys to ensure the consistency of expert opinions—especially when accompanied by pressure to alter those opinions—has the potential to create negative outcomes [

42]. Zadeh’s 1965 development of fuzzy set theory provided a framework for the representation of uncertainty, facilitating the conversion of expert language into quantitative values [

43]. This theory has been incorporated into the Delphi method, which has been shown to reduce the number of interviews and research time while facilitating more effective communication of expert opinions [

44].

The initial step in the process is the creation of a fuzzy Delphi questionnaire. The fuzzy method employs various types of fuzzy numbers to convert expert opinions from linguistic terms into fuzzy numbers [

43]. The present study employed Trigonometric Fuzzy Numbers (TFN). The TBS model is represented by three real numbers: the minimum possible value (a), the maximum possible value (b), and the minimum possible value (c) [

43]. A questionnaire was developed using the linguistic variables in

Table 2 to assess the degree of influence of the criteria identified through the literature review [

45].

Step 2—Determining Average Fuzzy Evaluation Scores: The average fuzzy evaluation score for each factor is calculated using Equation (1). This calculation assumes that the estimated value for factor

j is provided by expert

i from a total of

n experts [

43,

46].

Using Equation (2), the average of the fuzzy numbers (

) associated with factor

j is calculated.

Step 3—Identifying the Most Influential Criterion: During the clarification process, the average fuzzy evaluation score (

) of each factor

j is converted into precise values. The combined fuzzy scores of the factors (

) are then finalised using Equation (3) with the simple centre of gravity method [

43,

45].

Evaluation scores (

) were used to rank the factors based on their importance. Factors with a score of 0.7 or higher were considered significant, while those with scores below this threshold were excluded from the study [

43,

45].

The acceptability of the estimation domain is analysed by calculating the difference between the average fuzzy number for the factor and each expert’s fuzzy estimate using Equation (4). The acceptability of the estimation domain is assessed by calculating the difference (

) between the average fuzzy number for factor

j (

) and each expert’s fuzzy estimate (

) using Equation (4) [

43].

The threshold value (

d) of each factor

j is calculated using Equation (5) [

43].

The threshold value (

) for each prediction field is verified using Equation (6).

The acceptability of the prediction domain is determined by the value of

. In this study, the prediction domain is accepted if

≤ 0.2 [

47].

Expert group agreement (

) is tested by calculating expert agreement for each factor with Equation (7) [

43,

45].

Here,

n represents the total number of experts,

represents the distance between the experts’ fuzzy prediction values (

) on a given factor j and the average fuzzy number (

) for all experts on that factor [

43] If this distance ≤ 0.2, the expert group consensus was assessed according to the criterion

≥ 75% or more, based on the agreement of the experts for each factor. Otherwise, factors with an expert agreement of less than 75% will be ignored [

43,

45,

47].

Expert Specifications

The objective of this study was to ascertain the reliability of the Delphi method by employing the insights of experts in the respective domains. Consequently, all individuals involved were required to possess extensive knowledge of gas tanker operations, safety, and chartering. A total of eight professionals were selected for this study, each of whom possesses significant experience in their respective fields. These experts have held roles such as operations manager, technical manager, and chartering manager in GCT shipping companies across various countries for a minimum of ten years. All selected experts participated in both rounds of the Delphi study. The following details for the experts are provided: years of experience, current departments, gas tankers’ tonnage, and number of vessels. These details can be found in

Table 3.

In the selection of experts, the primary criteria were their employment within gas tanker companies and their demonstrable experience within the sector.

3.2. Fuzzy DEMATEL Method

The DEMATEL method was first introduced by Gabus et al. in 1972 to analyse interactions between variables [

45]. As with the Delphi Method, DEMATEL relies on expert judgments and transforms evaluations from linguistic factors to fuzzy numbers using TFN. The objective of this transformation is to circumvent uncertainty and attain consensus [

47]. In 2008, Lin applied DEMATEL in a fuzzy environment [

48]. Fuzzy DEMATEL determines cause and effect criteria by analysing the relationships between criteria and sub-criteria [

47].

The DEMATEL method is predicated on the acceptance of pairwise comparisons and relationships in the decision-making process, a factor that confers upon the method an advantage over competing techniques [

49]. Fuzzy DEMATEL has been extensively utilised in a variety of fields, including risk analysis, security management, and human resources management.

The DEMATEL method was utilised in conjunction with fuzzy logic, as illustrated in

Figure 1. This method involves the transformation of raw data into a fuzzy set, followed by the application of defuzzification techniques to derive a precise result. Please see

Appendix A for detailed mathematical equations of the fuzzy DEMATEL method. In this study, the fuzzy DEMATEL method is applied by following the steps in

Figure 2.

Step-1 The Collection of Raw Data from Experts: The selected number of experts was invited to evaluate the effect of the factor

Fi on the factor

Fj on a 5-point scale [

50]. The categories are as follows: “Very highly effective” = 5, “Highly effective” = 4, “Slightly effective” = 3, “Very slightly effective” = 2, and “No effect” = 1 [

51].

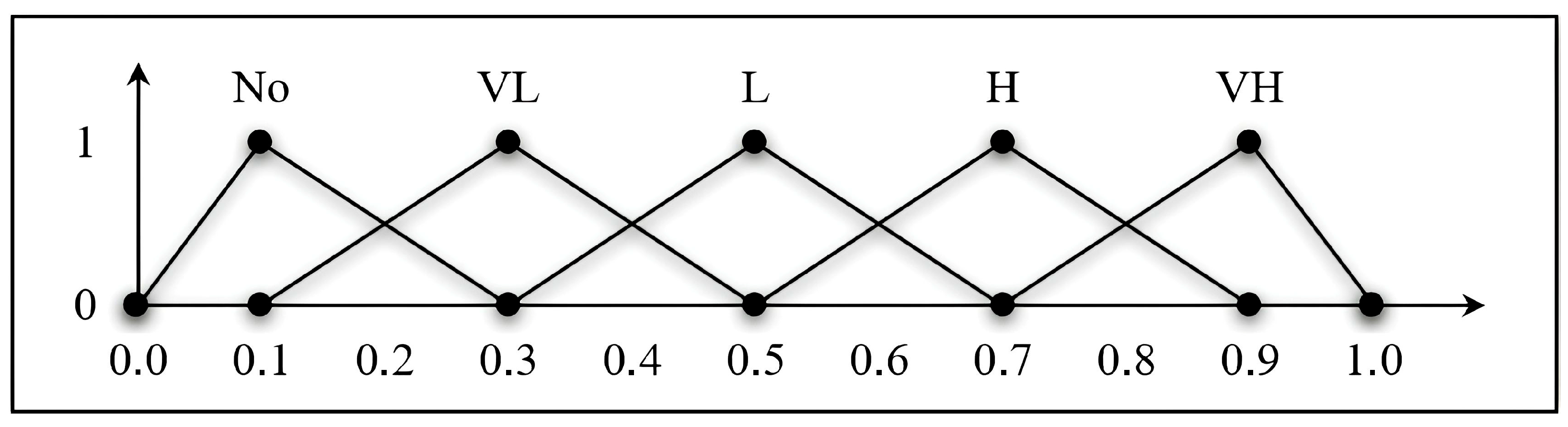

Step-2 Conversion of Linguistic Data into Fuzzy Values (Fuzzification): Different triangular values developed by [

51,

52,

53] were employed to fuzzify the linguistic data of the participants. The triangular values utilised in this study and developed by [

53] are demonstrated in

Figure 3, and the fuzzy number equivalents of the linguistic expressions are presented in

Table 4.

Step-3 The Creation of a Direct Effects Matrix (k): Individual direct influence matrix were formed by taking the influence evaluation of factor on factor for n factors from k selected experts. k is an n × n matrix that has been obtained through the process of pairwise comparisons. The purpose of this matrix is to demonstrate the effect that the criteria have on each other. Here (Equation (A1)) ij is the degree of influence of criterion i on criterion j.

Step-4 The Creation of an Average Direct Effects Matrix (): The arithmetic mean of the individual direct influence matrix was defined as the average direct influence matrix (Equation (A2)).

Step-5 Creating Normalised Direct Effects Matrix (): It was generated using Equations (A3) and (A4).

Step-6 Creating A Total Effect Matrix (): Equations (A5)–(A9) are used to obtain the total association matrix from the normalised direct effect matrix.

Step-7 Defuzzification: The process of defuzzification (Equation (A10)) is of paramount importance in the DEMATEL method, as it involves the conversion of fuzzy numbers into precise values [

52].

The CFCS (Converting Fuzzy Numbers into Crisp Scores) method, as developed by [

54], has been shown to offer a distinct advantage for distinguishing symmetric triangular fuzzy numbers over alternative methods. Research has demonstrated the efficacy of CFCS in the utilisation of Multi-Criteria Decision-Making models. Furthermore, the effectiveness of CFCS in converting fuzzy numbers into exact values has been demonstrated not only in the DEMATEL method but also in Multi-Criteria Decision Making (MCDM) and in Multi-Criteria Decision Analysis (MCDA) methods. The equations related to the method are given in (A11)–(A16).

Step-8 Determination of Criterion Weights: The sum of the rows and columns in the total stabilised relationship matrix was obtained by employing Equations (A17) and (A18).

The sum of the weights of the criteria was found by applying Equations (A19) and (A20), which express the relationship between the criteria weights and the sum of the criteria weights, which is equal to 1.

Step-9 Creation of Influence-Relationship Map: For each factor, the (R + C) and (R − C) values are calculated, and the influence-relationship map is created. An increase in the (R + C) value is indicative of the increased importance of the criterion, while a positive (R − C) value indicates that the criterion is in the influencing group, and a negative value indicates that it is in the influenced group.

To determine the interactions of the criteria, the mean of the clarified values was calculated. Criteria above the mean value were considered to influence each other directly. However, this method does not show the strength of the relationship. Therefore, a threshold value was determined by calculating the average of the influence–relationship map, and relationships below this value are disregarded [

55]. By comparing the largest value in the stabilised values matrix with the threshold value, the relationships are classified as weak, medium, and strong, thus avoiding the creation of a complex influence–relationship map.

3.3. Fault Tree Analysis (FTA)

Fault Tree Analysis (FTA) is a deductive, top-down analytical method widely used in reliability engineering and risk assessment to identify and evaluate combinations of hardware, software, human, and external factors that can lead to system failures [

56]. This systematic graphical representation facilitates the identification of critical system vulnerabilities and potential causes, enabling engineers to identify areas for improvement and implement effective mitigation strategies [

57]. FTA applications range from nuclear power plants and critical infrastructure to aerospace and automotive systems [

56]. For example, in the context of reliability-centred maintenance, FTA is used to develop models that not only predict potential failures but also guide maintenance priorities by identifying major failure propagation paths within a system [

57]. Similarly, in safety-critical sectors, FTA is regularly paired with other methodologies such as event tree analysis, Bayesian networks, or Markov chains to provide a more comprehensive view of system behaviour under failure conditions [

58]. This integration is necessary to address both qualitative and quantitative aspects of risk assessment and thus support proactive risk mitigation measures in various engineering applications [

57,

58].

Overall, the evolution of Fault Tree Analysis from its roots in classical Boolean logic to its current integrations with other probabilistic and fuzzy methods demonstrates its enduring importance as a fundamental tool in the analysis, design, and continuous improvement of complex systems [

59]. Its capacity to visually map failure structures and assess uncertainties has made FTA the cornerstone of reliability engineering and risk assessment in numerous high-risk industries. In summary, FTA remains an indispensable analytical tool in safety and risk assessment. Its evolution from a simple logical method to a sophisticated hybrid framework integrating fuzzy logic, Bayesian reasoning, dynamic analysis, and formal model checking enables it to address increasingly complex and uncertain environments within a variety of industries [

60]. Ongoing research and applications of these advanced FTA methods underline their critical role in proactively identifying and mitigating potential system failures, thereby improving overall system safety and reliability [

61].

An example diagram of an FTA is provided in

Figure 4 below.

Fault Tree Analysis (FTA) is a well-established methodology in risk and reliability assessment that facilitates the systematic identification of potential causes leading to an undesired event [

62]. In its traditional form, FTA uses logical gates (AND, OR) to hierarchically structure failure events and support qualitative and quantitative assessments of system vulnerabilities [

60]. The equations used for FTA are given as (Equations (8)–(10)) [

63].

where

pi represents the probability of failure of each basic event.

The probability of the basic event

pi is estimated based on the definition of the initial state, as shown in Equation (8).

The inclusion ratio of factor

NL in the initial event

l represents its contribution rate.

m indicates the number of primary events where the factor contributes to the initial event [

63].

Tn represents the total number of accidents examined, and

Tt is the total duration of the accident data. Once the probability of each factor is determined, the analysis proceeds by investigating how significantly the factor contributes to the top event. The significant factor is calculated based on the Fussel–Vesely Method [

64].

For instance, considering the FTA diagram in

Figure 4, the fault tree subsets are defined as

Thus, the probability of the top event can be calculated using Equation (10), where

P is the overall probability of the top event (i.e., the occurrence of a gas tanker accident with environmental consequences);

PA,

PC,

PE and

PF are the probabilities of basic events or intermediate events in the fault tree; the ‘+’ operator corresponds to the OR gate, representing scenarios where any of the involved events can cause the top event; and the ‘×’ operator corresponds to the AND gate, meaning that all connected events must occur to trigger the top event. In the specific context of the FTA developed in this study,

PA may represent the probability of gas fire,

PC the probability of a critical mechanical failure, and

PE and

PF other contributing environmental or procedural failures. The equation thus combines multiple fault paths to quantify overall system risk.

4. Findings

4.1. Fuzzy Delphi Method Findings

The study used the Fuzzy Delphi method to identify 20 risk factors based on expert opinion. The risks were ranked from highest to lowest.

Table 5 below shows the risk group and priority score for a total of 20 risks selected by the experts. These risk factors were identified through a two-round Fuzzy Delphi process involving eight experts with at least ten years of experience in gas tanker operations and management. The first set of factors was supplemented with insights from a panel of experts regarding the risks associated with existing gas tanker operations. The final selection of 20 risks reflects both the most frequently cited hazards in the literature and those most emphasised by practitioners during the Delphi process. Risk factors were categorised into six groups—Operational, Environmental, Security, Human Factors, Regulatory, and Technical—based on the primary source or nature of the risk. For example, “Technical” includes equipment-related failures such as corrosion and fire suppression malfunctions, while “Environmental” includes risks arising from weather or ecological interactions.

4.2. Interaction Analysis Between Fuzzy DEMATEL and Risks

In the second part of the study, the risks obtained in the first part using the Fuzzy Delphi method were analysed using the Fuzzy DEMATEL method. The Cause Score, Result Score, and Total Interaction Scores were determined using the Fuzzy DEMATEL method. The risks were ranked from the highest to the lowest scores obtained. In the next stage of this study, the sum of the rows (R) and the sum of the columns (C) were calculated using Equations (A17) and (A18) to produce an effective FTA diagram. The R − C and R + C values were calculated using Equations (A19) and (A20) with the R and C values.

Table 6 presents the risks according to their score rankings.

According to the data obtained in the study, R4 (Risk of fire or explosion) ranked first. This was expected as it is considered to be the highest risk factor for gas tankers. R11 (Large gas leakage due to accident) was ranked second. Gas leakage poses a serious risk due to its rapid spread throughout the ship and into the environment. In third place was R2 (Gas leakage following collision or grounding). For this risk factor, the risk is very low because the incident occurs under the ship, although cargo spillage poses a serious hazard.

Risks between R1 and R13 and those between R15 and R17 were identified as accident-causing risks because they have positive (+) values. Risks R14, R18, R19, and R20 were identified as accident-influencing risks because they have negative (−) values. The data obtained are presented in a cause-effect diagram in

Figure 5 below.

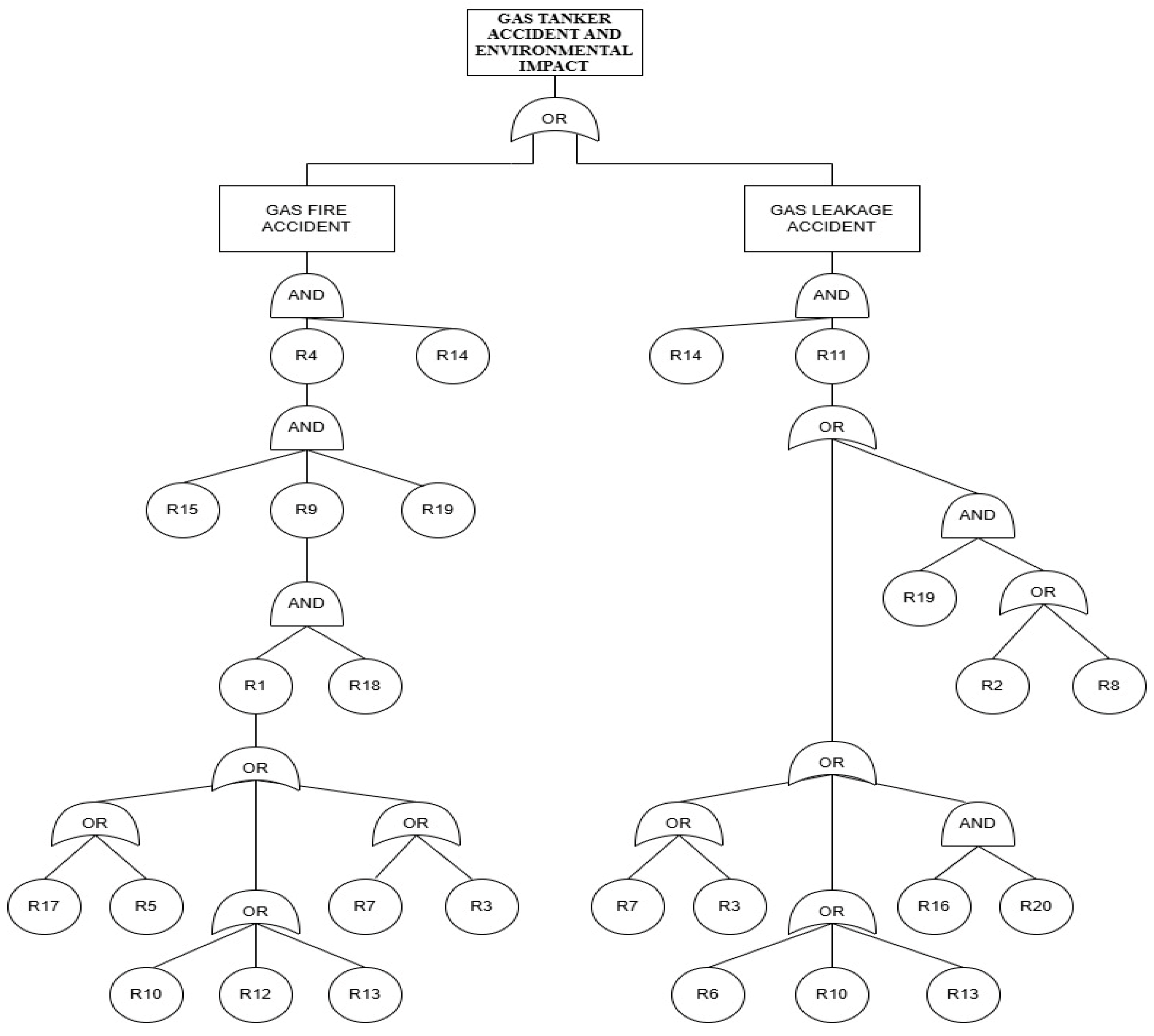

In the FTA diagram, risks with a positive (+) value are connected with an ‘OR’ gate, while risks with a negative (−) value are connected with an ‘AND’ gate, according to the cause-and-effect relationships of the risks shown in

Figure 5 above.

4.3. Interaction Analysis Between Risks Identified by the FTA

In the third phase of the study, the accident and environmental risks identified by the experts through the Fuzzy Delphi method were analysed using the Fault Tree Analysis (FTA) method. Dynamic models combining FTA with Markov chains provide a tool for analysing component priorities, event sequences, and dependencies that may affect system reliability [

65]. These methods help to bridge the gap between theoretical reliability analysis and its practical application in real-time, safety-critical environments [

61].

Expert opinion has led to the development of an FTA diagram that is suitable for use worldwide. In the FTA diagram, gas fire and gas leak accidents were identified as the main factors. In the Fuzzy DEMATEL method, the risks obtained using Equations (A17) and (A18) and calculated using Equations (A19) and (A20) are divided into cause-and-effect groups. Causal risks are linked with an ‘OR’ gate, while effect risks are linked with an ‘AND’ gate. The FTA diagram is shown in

Figure 6 below.

The risks identified include risks that may arise during the operation of gas tankers. These risks may occur both during navigation cargo handling. The risks have been classified according to expert opinion and the values in the fuzzy DEMATEL below.

To improve the clarity and traceability of the fault tree structure,

Table 7 below summarises each risk factor, its target event in the fault tree, and the logical gate used to model its relationship.

This table representation helps to consolidate the logic of the FTA diagram and makes it easier to understand which risks are directly causal and which operate through compound mechanisms

Among the risks associated with a gas fire accident, the lowest priority, R10 (Damage to marine organisms on the tanker structure), which is of the lowest priority, is caused by the accumulation of small marine organisms on the hull, and structural damage is generally difficult to detect during routine inspections. R12 (Air pollution from gas operations) reflects the risk of hazardous atmospheric conditions during the handling of gas and is a health and safety concern for both the ship’s personnel and port workers. R13 (Extreme weather conditions) poses significant risks to shipping and port operations due to the increasing frequency and intensity of adverse meteorological events. These risks—R10, R12, and R13—are linked by an ‘OR’ gate as they are the causes of risk R1 (Gas leakage during cargo handling) and represent potential risks contributing to the triggering of R1.

The risks associated with a gas leak accident, listed from the bottom up, include R6 (Increase in tank pressure under the influence of seawater temperature), which refers to pressure fluctuations in pressurised tanks caused by rising seawater temperatures, R10 (Damage to tanker structure by marine organisms), which refers to the detection and assessment of harmful effects that are generally difficult to detect due to small marine organisms causing invisible damage to the hull, and R13 (Extreme weather conditions), which refers to the increasing frequency and intensity of meteorological events that pose a critical threat to navigation and port operations. These risks—R6, R10, and R13—are linked through the ‘OR’ gate and represent potential risks that could contribute to the triggering of risk R11 (Large gas leakage due to accident).

R3 (Corrosion and leakage in tank or piping systems) and R7 (Hose or manifold damage during loading/unloading) represent potential risk factors associated with damage to storage and operational equipment. These risks are connected by an ‘OR’ gate, as either can contribute to R11 (Large gas leakage due to accident) by causing equipment failure or system malfunction during operations.

R16 (Failure of cargo tank pressure control systems) is a risk indicating the failure of pressure control mechanisms, while R20 (Impact on cargo and ship operations due to cyber-attacks) is a risk arising from the increasing reliance on automation and digitalisation in ship management systems, which may expose security vulnerabilities. R20 is a risk that affects R16 and is linked to R16 by an AND gate, representing potential risks that contribute to triggering risk R11 (Large gas leakage due to accident).

Risk R2 (Gas leakage following collision or grounding) is a risk that may occur during the voyage or manoeuvring of the ship and results from potential contributing factors. Risk R8 (Risk of collision/crash during harbour or berthing) is particularly relevant for ships manoeuvring in narrow areas in ports. These risks are linked by an ‘OR’ gate as they cause the risks R2 and R8. Risk R19 (Inadequate post-accident contingency plans) reflects this inadequacy and is linked as an influencing risk by an AND gate to risks R2 and R8, which together represent potential risks contributing to the triggering of risk R11 (Large gas leakage due to accident).

R11 (Large gas leakage due to accident) represents the risk of a significant release of gas following an accident, while R14 (Incomplete or inadequate emergency procedures) represents the risk arising from such procedures during potential emergencies. As R14 is a risk that influences R11, it is linked to R11 by an AND gate and grouped together as the final level of risks that will cause a gas leakage accident.

At the top of the diagram, gas fire/explosion and gas leakage are linked by an AND gate as two significant events, emerging as the main causes of the critical event, the gas tanker accident and its environmental impact. The gas tanker accident and its environmental impact are the most significant events because they result in serious damage to the ship, the port, and the environment, irrespective of the specific event. Regardless of the cause of the major incident, the outcome will be devastating and result in significant economic loss.

The risks identified in the FTA diagram have been calculated using Equations (8) and (9), and their distributions have been determined. The risks identified in

Table 8 below are presented on the basis of their probabilities and contribution ratios. The analysis of the risks is carried out according to the FTA on the basis of the probabilities obtained.

In the FTA analysis method, calculations were performed starting from the lowest probability ratios and progressing to the highest level to determine the most significant event based on significant events. Equation (10) was used in the calculations.

As a result of the calculations performed using the FTA method, the probability of the gas fire accident was calculated as 0.0938. The rate of gas leak accident was calculated as 0.0859. The environmental impact of the gas tanker accident was quantified as 0.02477.

4.4. Risk Model for Gas Tanker Accident Risks

By combining the fuzzy DEMATEL and FTA methods, a gas tanker risk model was developed. With the help of this risk model, ship operators will be able to monitor and evaluate possible accidents and environmental risks that may occur in gas tanker operations, incorporating the risks they have identified within their organisations.

Figure 7 shows a schematic diagram of the gas tanker risk model.

The gas tanker risk model will help to identify new potential accident risks by adding or removing various risks that may occur in gas tankers with different age distributions and deadweight. The risk model developed in this study will offer significant opportunities for integration into existing Safety Management Systems (SMS) of gas tanker operators. By systematically mapping operational, environmental, and human factor risks, companies can prioritise preventive measures in their risk assessment matrices and align them with the requirements of the International Safety Management (ISM) Code. The model can be used as the basis for dynamic risk monitoring platforms, providing real-time updates and early warnings during critical operations such as cargo handling or navigation in narrow waters. In addition, the model can be used to simulate accident scenarios derived from Fault Tree Analysis and incorporated into crew training programmes, thereby enhancing seafarers’ situational awareness and emergency preparedness. In addition, port authorities and terminal operators can use the results to design more robust port security drills that specifically address high-priority risks such as gas leaks and toxic gas emissions during cargo operations. Through these applications, the risk model will serve as both a strategic planning tool and an operational safety measure, supporting a proactive and resilient maritime safety culture.

As an open model that allows for the incorporation of new risks arising from advances in maritime technology and industry developments, this framework will serve as a critical resource for contingency plans, company-wide training programmes, and International Safety Management (ISM) systems within maritime organisations.

5. Discussion

In this study, a hybrid fuzzy modelling approach integrating Fuzzy Delphi, Fuzzy DEMATEL, and FTA methods was used to identify and prioritise critical risks associated with gas tanker operations. Fault Tree Analysis, as previously highlighted in [

65], not only identifies initiating events but also facilitates the assessment of cascading failures triggered by human–machine interactions and systemic safety weaknesses. The calculations performed using the FTA method resulted in a value of 0.0938 for the gas fire accident, as shown in

Table 8. This value is considered a very low probability, indicating that the likelihood of the accident occurring under current system conditions and with existing preventive measures is statistically very low. Although the probability of an accident is low, it is important to remember that the consequences of an accident would be severe, and even a low probability cannot be ignored. In systems using LNG/LPG, the potential impact of a gas fire could be catastrophic in terms of human safety, environmental damage, and economic loss. A gas leak accident, on the other hand, has a probability of 0.0859, according to

Table 8. It has been observed that gas leak accidents have a higher probability compared with gas fire and explosion accidents. The main reason for this is that the number of initiating events that could lead to the release of gas without immediate ignition is higher, as shown in

Figure 6. It can be seen that the risks are mainly caused by failures in the factors that trigger or prevent gas leak accidents. The ship’s crew and port personnel need to be better prepared for gas leak accidents and to more closely monitor the risks that could lead to such accidents. The environmental impact of the two gas tanker accidents was calculated as 0.02477, according to

Table 8. Considering the need to further reduce this value, especially in terms of long-term damage and duration of environmental impact, it is once again evident that all potential risks associated with LPG/LNG tankers in ports need to be monitored more carefully.

To enhance the clarity of the discussion,

Table 9 summarises the top-ranked risks from the analysis along with their corresponding implications based on model results and expert evaluation.

These insights reflect the complex interplay of operational, technical, and systemic vulnerabilities in gas tanker operations and reinforce the multidimensional risk structure outlined in this study.

Gases spread rapidly into the environment and, depending on their composition, can accumulate near surfaces due to their higher density than air. This can lead to serious hazards in ship operations due to the flammable or explosive nature of the gases. The physical and chemical properties of liquefied gases, in particular their higher molecular weight than air, resulting in limited dispersion and a tendency to accumulate near surfaces, significantly increasing the risk of explosion in the event of a leak. In addition, the environmental and operational consequences of such leaks, ranging from air pollution to ignition hazards, underscore the importance of rigorous containment, detection, and emergency response protocols. Furthermore, gas dispersion resulting from an accident poses a serious threat to port operations and the surrounding environment. The literature further supports these findings. Ref. [

66] presented a case study of an LPG explosion caused by a seal failure under high pressure, highlighting the critical nature of component integrity. Similarly, ref. [

67] emphasised that explosion dynamics are strongly influenced by environmental and structural variables such as containment and ventilation, highlighting the need to incorporate both physical and operational design features into risk reduction strategies.

An integrated framework combining event tree analysis and Computational Fluid Dynamics (CFD) has been proposed to measure LNG leakage risk and is supported by empirical case studies of valve failures [

4]. The application of predictive analytics through artificial intelligence-enabled IoT systems has also been shown to improve early warning capabilities [

70], potentially reducing the escalation of such incidents.

Risk R3 (Corrosion and leakage in tank or pipe systems), which is classified as medium risk (1.55–0.07), reflects safety vulnerabilities related to both external environmental exposure and internal system ageing. The sensitivity of these systems to weather conditions and operational stress requires frequent inspections and preventive maintenance. Similarly, risk R15 (Technical failure in fire extinguishing systems) (1.67–0.09), although not among the highest-rated risks, highlights the importance of system reliability in emergency conditions. Despite regular testing and drills, system malfunction or accidental damage during incidents can render these systems ineffective. Extensive literature confirms the complex risk profile of gas tankers. Ref. [

71] emphasises that even small leaks in LPG-carrying systems can rapidly escalate into significant emergencies if not dealt with promptly due to the thermodynamic behaviour of the mixture. Therefore, effective gas detection, leak isolation, and sensitive safety protocols are indispensable elements for the safe operation of gas tankers.

The lower priority risks R20 (Impact on cargo and ship operations due to cyber-attacks) (1.50–0.06) and R10 (Damage to tanker structure by marine organisms) (1.41–0.03) should not be overlooked. The increasing integration of cyber systems into maritime operations, including navigation, cargo tracking, and remote diagnostics, particularly with the advancement of autonomous ship technologies, has become a growing concern regarding cybersecurity vulnerabilities. Similarly, biological contamination and structural degradation caused by marine organisms, although occurring over a longer timeframe, can compromise hull integrity and affect fuel efficiency, necessitating proactive structural management and contamination prevention strategies.

Mechanical failures were shown to be strong causal factors in both fire and gas leakage scenarios. As identified in the Fuzzy DEMATEL analysis (

Table 6), risks such as R3, R7, and R16—each representing specific mechanical weaknesses—ranked among the highest contributing risks in the model. These findings confirm existing research indicating that mechanical integrity is crucial to the safe operation of LNG/LPG tankers. Preventive maintenance regimes and system redundancy should, therefore, be prioritised in safety management strategies.

Environmental factors also play an important role in the likelihood of accidents. A recent study [

72] has shown that LNG tankers operating in rough seas are subject to sloshing effects and dynamic instability, which increase cargo movement, structural loading, and the likelihood of mechanical failure. Therefore, risk-based design (RBD) approaches are essential for ships operating in such conditions to ensure structural flexibility and safe cargo containment.

Available evidence suggests that gas tanker casualties are not caused by a single factor but by a combination of hazardous conditions, ranging from the explosive potential of LNG cargoes [

22] to navigational difficulties in restricted waterways [

68] and vulnerabilities caused by adverse sea conditions [

72]. A comprehensive approach involving advanced ship design, strict navigation protocols, and robust emergency management procedures is essential for reducing the frequency and severity of such accidents. The continuous improvement of risk assessment methods [

72], the integration of lessons learned from explosion analyses in other modes of transport [

22] and the development of shallow water navigation studies [

68], as well as the monitoring and regular review of human error due to its significant role in accident causation [

1], will contribute significantly to improving the operational safety of gas tankers.

6. Conclusions

Tanker accidents are multifactorial phenomena resulting from the interaction of operational, environmental, technical, and organisational factors. A comprehensive analysis of gas tanker accidents reveals critical safety gaps ranging from structural and system design flaws to human error and extreme hydrodynamic or meteorological conditions. The results of this study confirm that gas tanker accidents cannot be attributed to a single cause but result from the complex interaction of technical, human, and managerial shortcomings. Previous studies [

4] have shown that structural defects in tank configurations and inadequate maintenance regimes significantly increase the risk of catastrophic events. This underlines the importance of early detection mechanisms and timely corrective actions to reduce the likelihood of accidents.

In this study, a hybrid approach combining Fuzzy Delphi, Fuzzy DEMATEL, and Fault Tree Analysis (FTA) methods was used to assess the accident and environmental risks associated with gas tankers. Through expert consultation, 20 key risks were identified using the Fuzzy Delphi method. These risks were then prioritised using the Fuzzy DEMATEL method, allowing a detailed assessment of their interdependencies and relative importance. FTA was then used to group and quantify these risks into two main accident categories (gas fires and gas leaks) based on their contribution.

FTA shows that even apparently low-risk elements can lead to serious incidents when combined with operational stressors or environmental challenges [

65]. These findings support the need for rigorous inspection regimes, comprehensive safety management systems, and proactive hazard identification. As highlighted by [

73], the prioritisation of inspection items in tanker inspection protocols can facilitate the early correction of hidden defects and thus prevent them from leading to accidents. The development of a corporate safety culture through routine training, increased situational awareness, and rigorous inspections are essential to reduce both the frequency and severity of LNG tanker accidents [

74].

The results of the analyses have underlined the need for comprehensive and scenario-specific emergency protocols. Robust safety protocols emphasise the need for proactive measures, including real-time monitoring and rapid post-incident response mechanisms. They also highlight the importance of regular inspections and preventive maintenance. Personnel errors related to inadequate maintenance further emphasise the need for continuous training and the implementation of stricter operational standards on board. It has also highlighted deficiencies in emergency preparedness. It requires the strict implementation of safety procedures during cargo handling, the use of corrosion-resistant materials, and expert inspections, particularly of sensitive systems such as pumps and piping. Robust emergency response plans capable of dealing with large gas leaks are also required.

The findings emphasise that operational, structural, procedural, and human factors are interrelated and collectively influence the likelihood of accidents. Corrosion-related failures, inadequate emergency procedures, and human error in cargo operations have emerged as significant factors in the escalation of accidents. In addition, the study highlights the growing importance of emerging threats such as cyber-attacks and structural damage caused by marine organisms, underlining the need for a dynamic risk management approach that evolves with technological and environmental changes. The results show that the most critical risks are fire and explosion incidents, large accidental gas leaks, and toxic gas emissions. All of these risks pose serious threats to human safety, environmental integrity, and business continuity. In particular, the risk of fire or explosion was consistently ranked as the highest priority across all methods of analysis, highlighting the catastrophic potential of flammable and explosive liquefied gases. The safety of gas tanker operations depends on regular and supervised training of personnel, strict adherence to existing safety protocols, and the availability of real-time monitoring systems that enable the master to make informed and accurate decisions. Strong and disciplined crew relations and effective risk management are essential for tankers.

6.1. Contribution to Industry and the Literature

The synthesis of fuzzy and probabilistic risk assessment techniques in this study enables a multidimensional understanding of accident causality in gas tanker operations. The results highlight the complex interaction between design flaws, operational challenges, environmental conditions, and human factors. Addressing these risks requires a holistic strategy that integrates advanced design methodologies, robust operational controls, real-time monitoring systems, and adaptive emergency management. Future studies may benefit from further use of dynamic simulation models, machine learning tools, and scenario-based validation to improve maritime safety frameworks.

This study demonstrates the applicability and effectiveness of Fuzzy Delphi, Fuzzy DEMATEL, and FTA in assessing accident and environmental risks associated with gas tanker operations. The results provide valuable insights for improving maritime safety, ensuring operational continuity, and preserving the integrity of the marine environment. By providing a comprehensive and integrated perspective on gas tanker safety, this research contributes to the development of proactive and resilient maritime risk management practices. Continued research and adaptive risk management practices are essential for improving the safety performance of gas tankers and contributing to the overall sustainability of maritime transport.

6.2. Limitations

Limitations of this study include the static nature of the selected criteria, which reflect the operational realities of existing gas tankers. These criteria may need to be reviewed in light of future technological developments and changes in the regulatory framework. In addition, as the risk assessments are based on expert opinion, the results may vary depending on the expertise of different expert panels and their level of experience. Another limitation of this study is that it is restricted to gas carriers and does not cover other types of ships.

6.3. Future Research

This study has provided a comprehensive risk assessment framework for LNG carrier operations by integrating Fuzzy Delphi, Fuzzy DEMATEL, and Fault Tree Analysis (FTA) methods. However, there remain several avenues for future research that can further enhance the robustness, adaptability, and technological relevance of maritime risk management systems. With the advent of autonomous and remotely operated vessels, future research should address how automation affects risk structures in gas carrier operations. Comparative analyses between traditional manned vessels and autonomous systems may reveal changes in risk profiles, such as reduced human error but increased exposure to cyber threats or system failures. In this way, future risks, such as fire and environmental challenges, can be analysed using the logic of this study.